Large-cutting-depth turning and milling composite rotary blade used under heavy-load condition

A technology of indexing inserts and inserts, which is applied in the direction of cutting inserts, milling cutting inserts, milling cutters, etc., can solve the problems of tool-chip bonding, uneven tool force, short tool life, etc., and improve the use of Long life, smooth chip removal and smooth cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

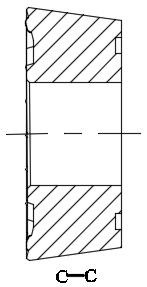

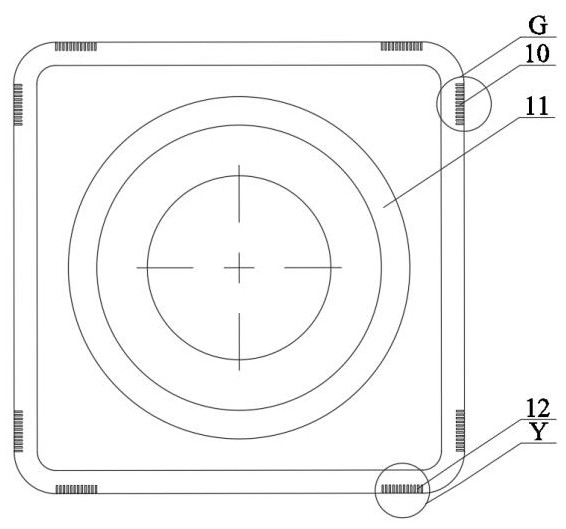

[0023] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a large depth of cut turn-milling composite indexable insert under heavy load conditions, the shape of the insert is a square truss shape. The cutting edge of the blade is a negative chamfer cutting edge (4), and a circular arc edge (6) transition is provided between every two adjacent negative chamfer cutting edges (4); the square raised platform (7) on the upper surface of the blade is connected with the blade The rake face (3) forms an arched chipbreaker (2); there is a trapezoidal protrusion (9) at the intersection of the insert rake face (3); the insert rake face (3) is provided with a drop-shaped protrusion ( 1). A fastening screw hole (8) is provided at the geometric center of the square raised platform on the upper surface of the blade, and a circular cooling groove (11) is provided on the bottom surface of the blade.

specific Embodiment approach 2

[0024] Specific implementation mode two: combination figure 1 , figure 2 , image 3 As shown, the rake face (3) of the insert in this embodiment is provided with a drop-shaped protrusion (1), and the rake face (3) and the side of the square raised platform (7) form an arched chip breaker (2) . The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

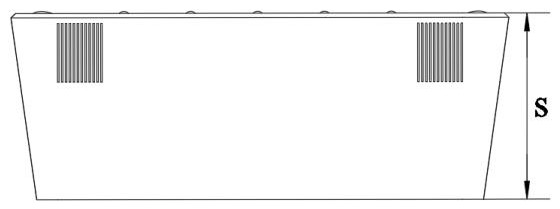

[0025] Specific implementation mode three: combination figure 2 , image 3 As shown, the blade thickness S=4.76mm in this embodiment. The undisclosed technical features in this embodiment are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com