Method for producing tooth implantation surgical guide stent

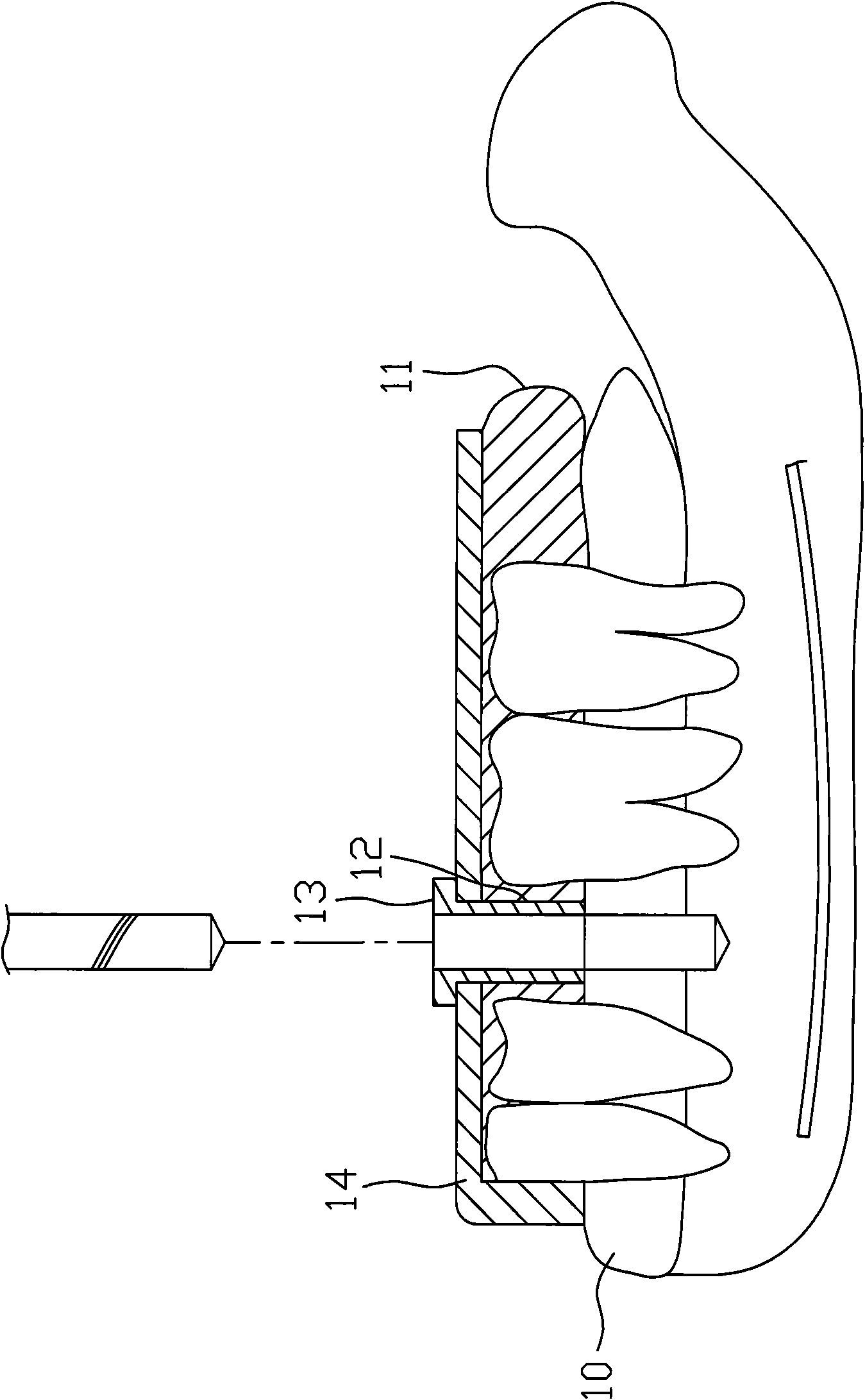

A technology for surgical guidance and manufacturing methods, which is applied in the fields of dental implants, dental restorations, and dentistry, and can solve problems such as high manufacturing costs, poor manufacturing efficiency, and low accuracy of the guide plate 11, and achieve time-saving and labor-saving manufacturing cost, reduce production cost, and reduce the effect of repeated correction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with embodiment the present invention is described in detail:

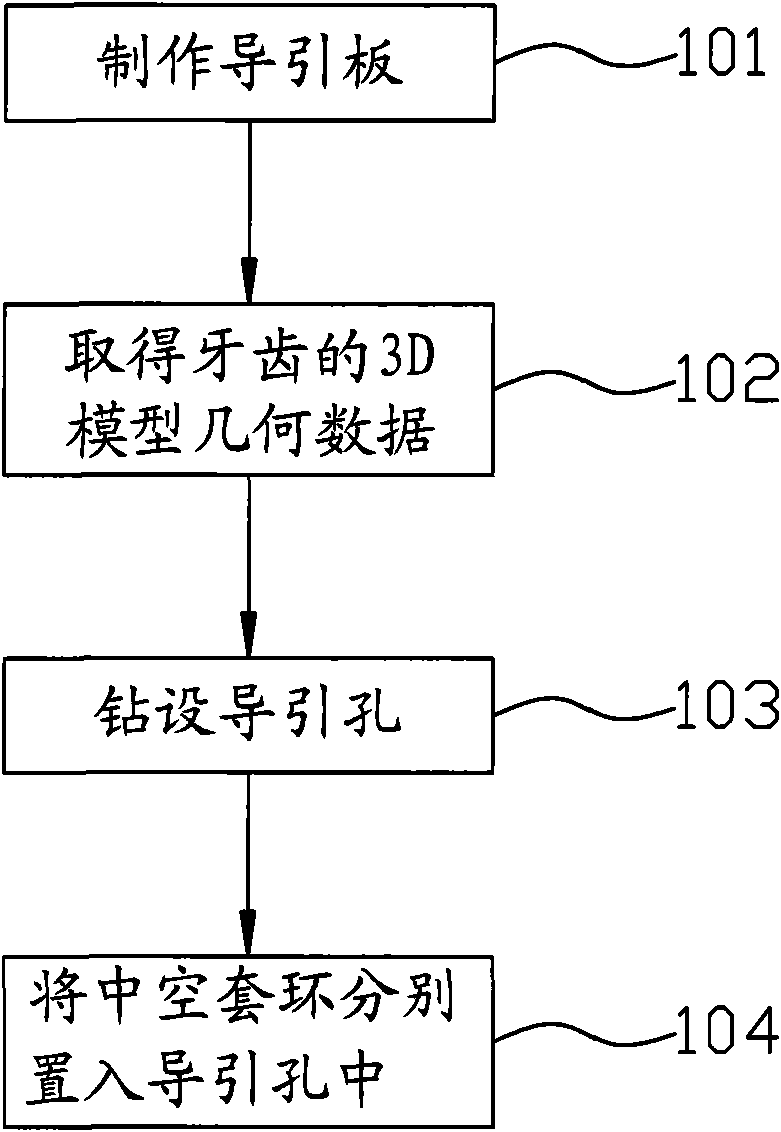

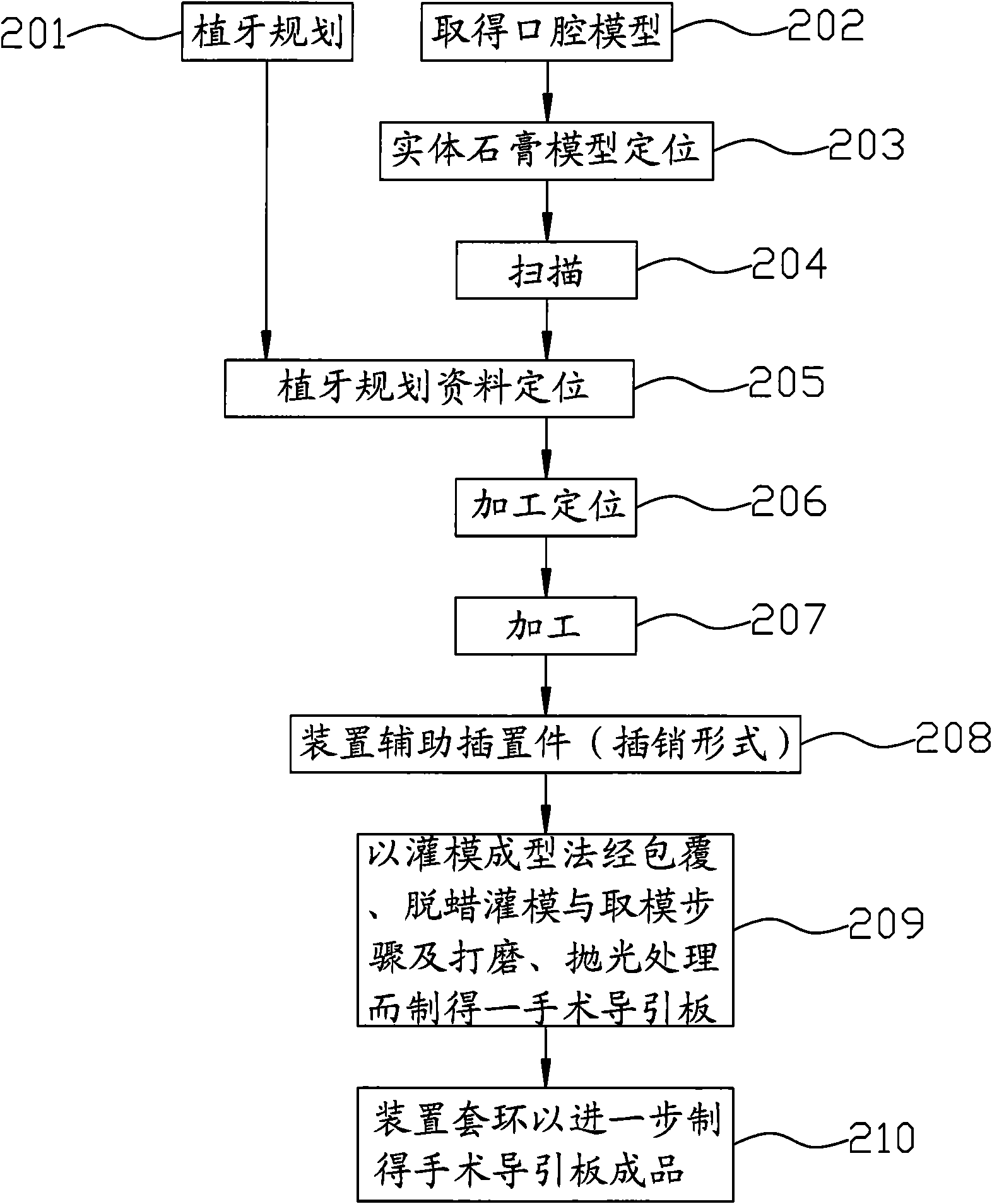

[0042] refer to image 3 A first preferred embodiment of the manufacturing method of the dental implant surgery guide plate of the present invention comprises the following steps:

[0043] Step 201 is implant planning, using the dentist to perform implant planning on the 3D stereoscopic model obtained after the patient's oral cavity tomography, and obtain and build a digital model with implant planning data, such as Figure 17 As shown, it is a schematic diagram of the digital model image with the dental implant planning data.

[0044] Step 202 is to obtain the oral cavity model, copy the shape of the patient's oral cavity, and make such Figure 7 A solid plaster model is shown2.

[0045] refer to Figure 8 , step 203 is the positioning of the solid plaster model, and the solid plaster model 2 obtained in step 202 is fixed to a solid processing jig 3 by a fixing method selected from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com