Environmental friendly drill of acid sodium pyrophosphate and preparing method thereof

A technology of sodium acid pyrophosphate and sodium pyrophosphate, which is applied in the field of drilling operations in oil and gas fields, can solve problems such as insufficient decentralization, and achieve good economic and social benefits, high-efficiency sand-carrying ability, and excellent wellbore stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In order to solve the problem in the prior art that the upper formation conduit and surface casing in the TARAPOA block of Ecuador are not properly lowered, this embodiment provides an acid sodium pyrophosphate environment-friendly drilling fluid, which is composed of the following raw materials in mass percentage: Sodium pyrophosphate 2-5%, viscosity enhancer 0.2-1.5%, fluid loss reducer 0.5-2.0%, weighting agent 5-15%, and the balance is water.

[0019] The acid sodium pyrophosphate environment-friendly drilling fluid is prepared under normal temperature and pressure. The preparation process: add the formula amount of sodium pyrophosphate, fluid loss reducer, viscosity increasing agent and weighting agent in the formula amount of water in sequence, and fully stir and mix. Evenly prepared as drilling fluid.

[0020] Principle of the present invention:

[0021] Sodium acid pyrophosphate is used as the main component. Compared with conventional viscosity reducers such a...

Embodiment 2

[0023] On the basis of Example 1, this example provides an acid sodium pyrophosphate environment-friendly drilling fluid, which is composed of the following raw materials in mass percentage: sodium pyrophosphate 5%, viscosity increasing agent 0.8%, fluid loss reducer 0.5% %, weighting agent 5%, water 88.7%.

[0024] Preparation method: add sodium pyrophosphate, fluid loss reducer, viscosity raising agent and weighting agent in the prescribed amount of water in sequence, stir well and mix uniformly to prepare drilling fluid.

[0025] The sodium pyrophosphate (main agent) in this example is food-grade sodium pyrophosphate, the fluid loss control agent is starch, the viscosity increasing agent is high-viscosity polyanionic cellulose, and the weighting agent is barite.

Embodiment 3

[0027] On the basis of Example 1, this example provides an acid sodium pyrophosphate environment-friendly drilling fluid, which is composed of the following raw materials in mass percentage: sodium pyrophosphate 2%, viscosity increasing agent 1.3%, fluid loss reducer 0.5% %, weighting agent 5%, and the balance is water.

[0028] Preparation method: add sodium pyrophosphate, fluid loss reducer, viscosity raising agent and weighting agent in the prescribed amount of water in sequence, stir well and mix uniformly to prepare drilling fluid.

[0029] The sodium pyrophosphate (main agent) in this example is food-grade sodium pyrophosphate, the fluid loss reducer is low-viscosity polyanionic cellulose, and the viscosity-raising agent is made of 0.3% xanthan gum (relative molecular mass is 2×10 6 ~2×10 7 ) and 1% bentonite, and the weighting agent is 325 mesh limestone.

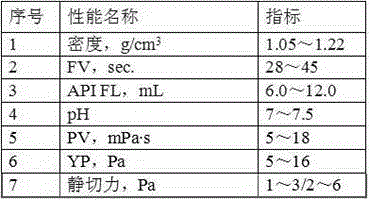

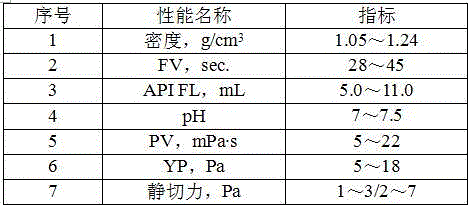

[0030] 1. Test performance experiment

[0031] According to the testing standard of drilling fluid recommended ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com