Tackifier, drilling fluid containing tackifier, and stock solution of drilling fluid

A technology of viscosifier and emulsifier, which is applied in the field of drilling fluid and its reserve fluid, and viscosifier, which can solve the problems of large amount of drilling fluid and limited total capacity of offshore drilling platforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, the preparation of tackifier

[0022] a. Add deionized water, 3g sodium dodecylbenzenesulfonate, and 1.0g polyvinyl alcohol (model 1799) to the cleaned four-necked flask in turn;

[0023] b. Weigh 35g of methyl acrylate and 0.4g of N,N-methylenebisacrylamide in a clean beaker, and mix them evenly in the beaker;

[0024] c, take by weighing 0.15g potassium persulfate, dissolve with a little deionized water, set aside;

[0025] d. Pour 1 / 3 of the mixture of methyl acrylate and N,N-methylenebisacrylamide and 1 / 3 of the potassium persulfate solution into a four-necked flask, and connect the four-necked flask to the stirrer device, Stir for 1 hour under the conditions of nitrogen flow, rotation speed of 600r / min, and room temperature, and then heat up to a temperature of 70°C. While continuing to pass nitrogen gas, add the remaining methyl acrylate and potassium persulfate dropwise to the four-necked flask respectively. Dropping time was controlled at 2 hours...

Embodiment 2

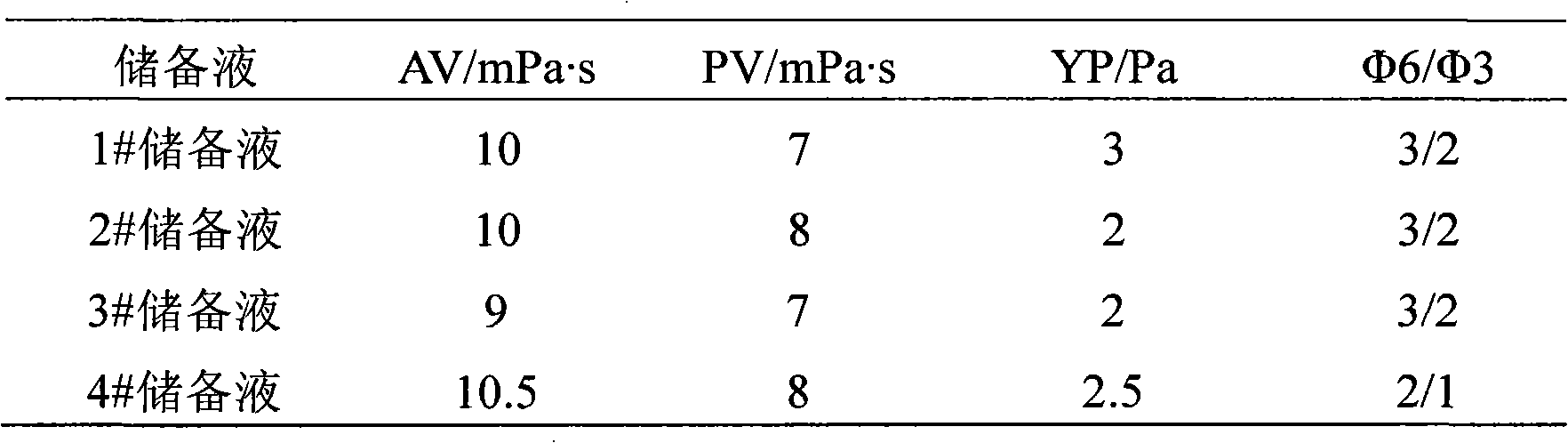

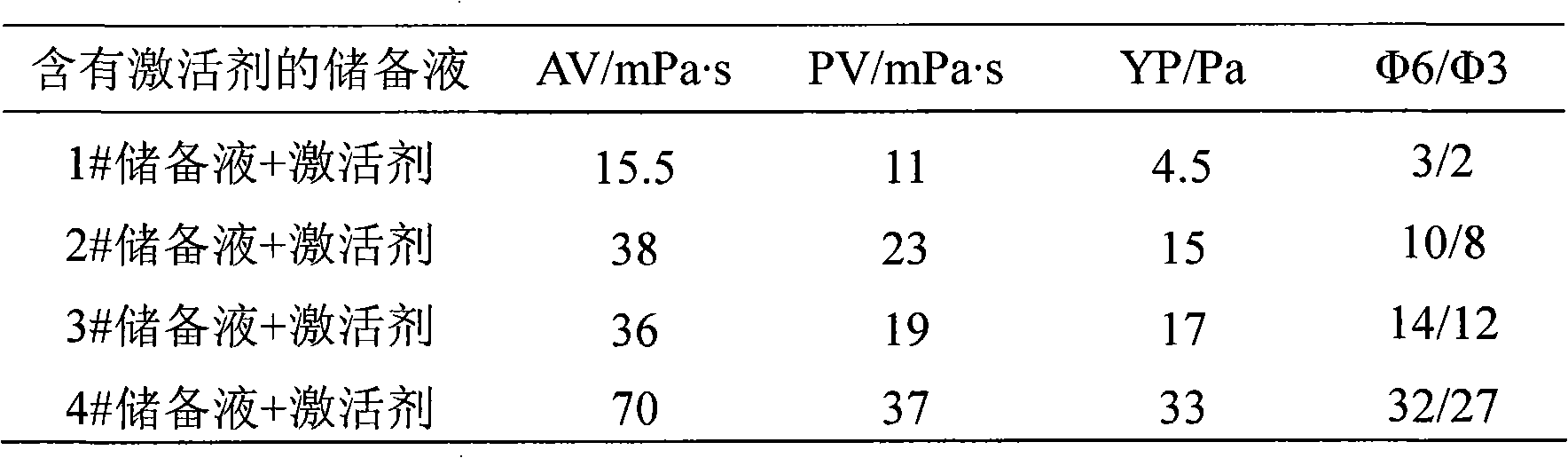

[0026] Embodiment 2, the preparation and performance test thereof of the stock fluid that contains the drilling fluid of embodiment 1

[0027] (1) under stirring condition, add 5g sodium bentonite, 0.4g polyanionic cellulose, 0.3g xanthan gum, 2.5g thickening agent prepared in Example 1 and 0.2g passivator lemon successively in 90g South China Sea seawater acid to obtain 1# stock solution.

[0028] In 1# stock solution, the mass-number ratio of water, sodium bentonite, polyanion cellulose, xanthan gum, thickener and passivator is 90:5:0.4:0.3:2.5:0.2.

[0029] (2) under stirring condition, add 4g sodium bentonite, 0.5g polyanion cellulose, 0.4g xanthan gum, 5g embodiment 1 preparation viscosifier and 0.3g passivator citric acid successively in 85g South China Sea seawater , to obtain 2# stock solution.

[0030] In 2# stock solution, the mass-number ratio of water, sodium bentonite, polyanion cellulose, xanthan gum, thickener and passivator is 85:4:0.5:0.4:5:0.3.

[0031] (3...

Embodiment 3

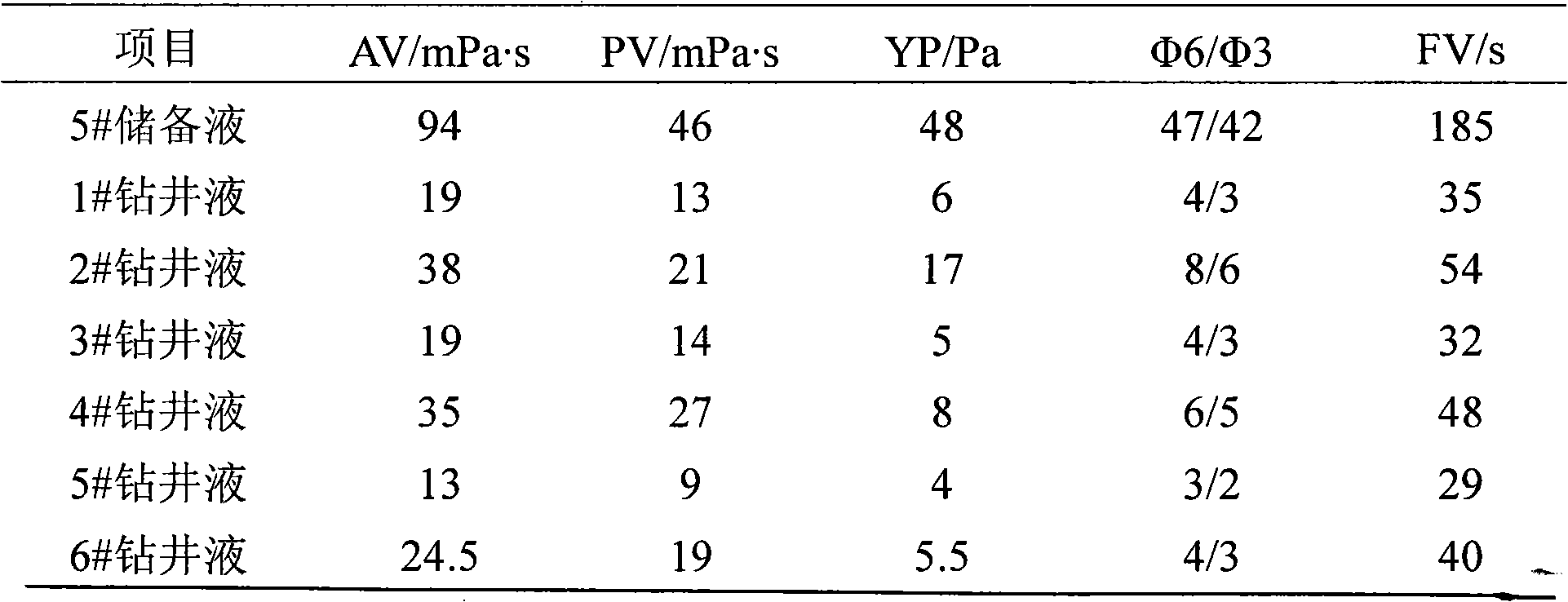

[0042] Embodiment 3, the preparation and performance test thereof of the drilling fluid that contains reserve fluid

[0043] Under stirring condition, add 10g sodium bentonite, 1g polyanionic cellulose, 0.75g xanthan gum, 15g embodiment 1 viscosifier and 0.75g passivator successively in 250ml South China Sea seawater, barite increases the weight to 1.92g / cm 3 . Obtain 5# stock solution.

[0044] In 5# stock solution, the ratio of mass and number of water, sodium bentonite, polyanionic cellulose, xanthan gum, thickener and passivator prepared in Example 1 is 90:4:0.4:0.3:6:0.3 .

[0045]The activators in the 2#, 4# and 6# drilling fluids prepared below are sodium hydroxide.

[0046] (1) Mix 200ml of 5# stock solution with 168ml of South China Sea seawater without activator to obtain 1# drilling fluid with a density of 1.50g / cm 3 .

[0047] (2) 200ml of 5# stock solution and 168ml of seawater containing activator (wherein, the mass percentage of activator is 0.2%) are mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com