Patents

Literature

79results about How to "Accurate drilling position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

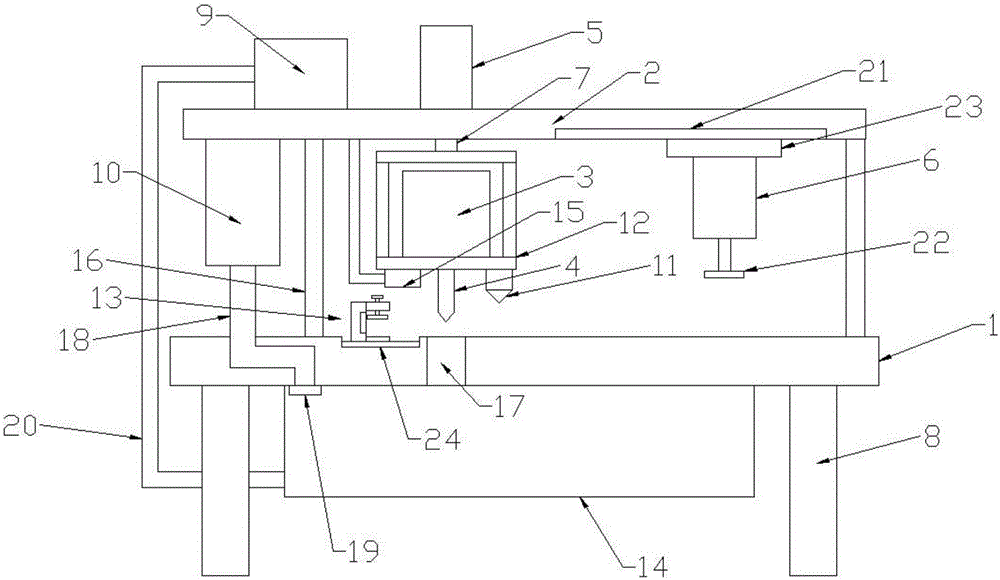

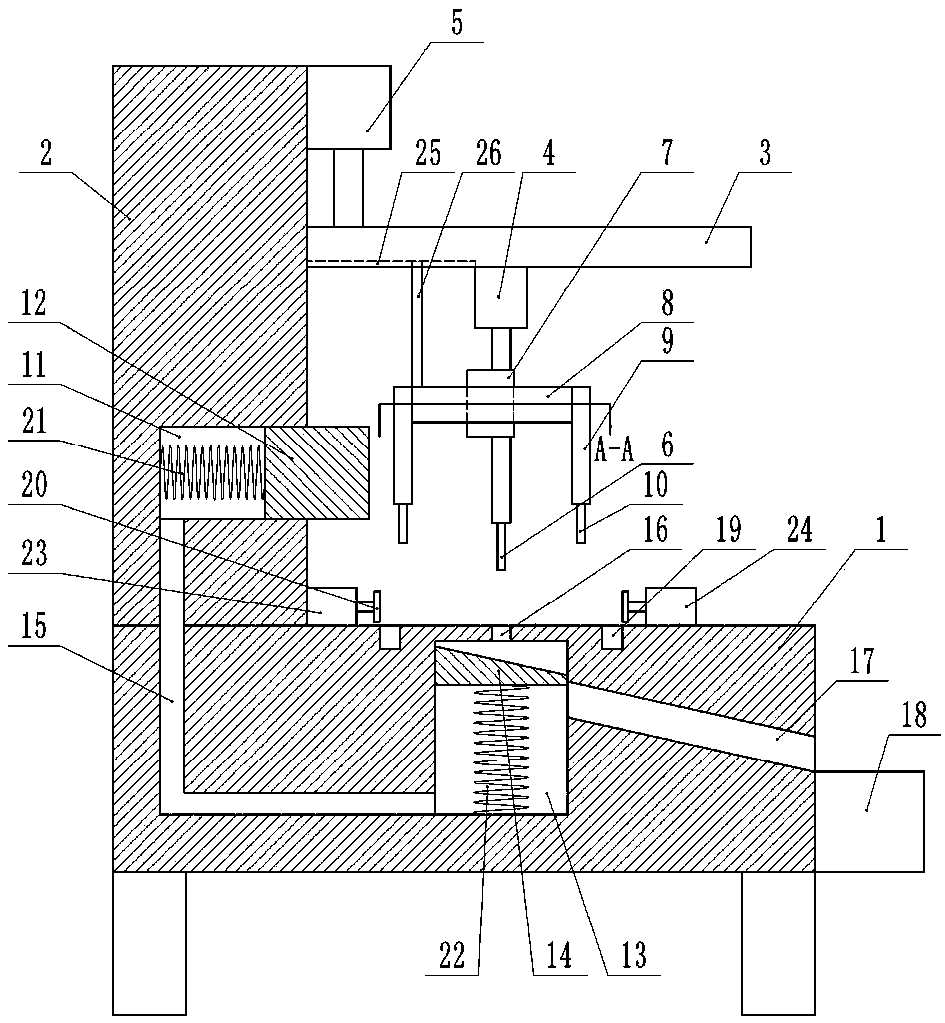

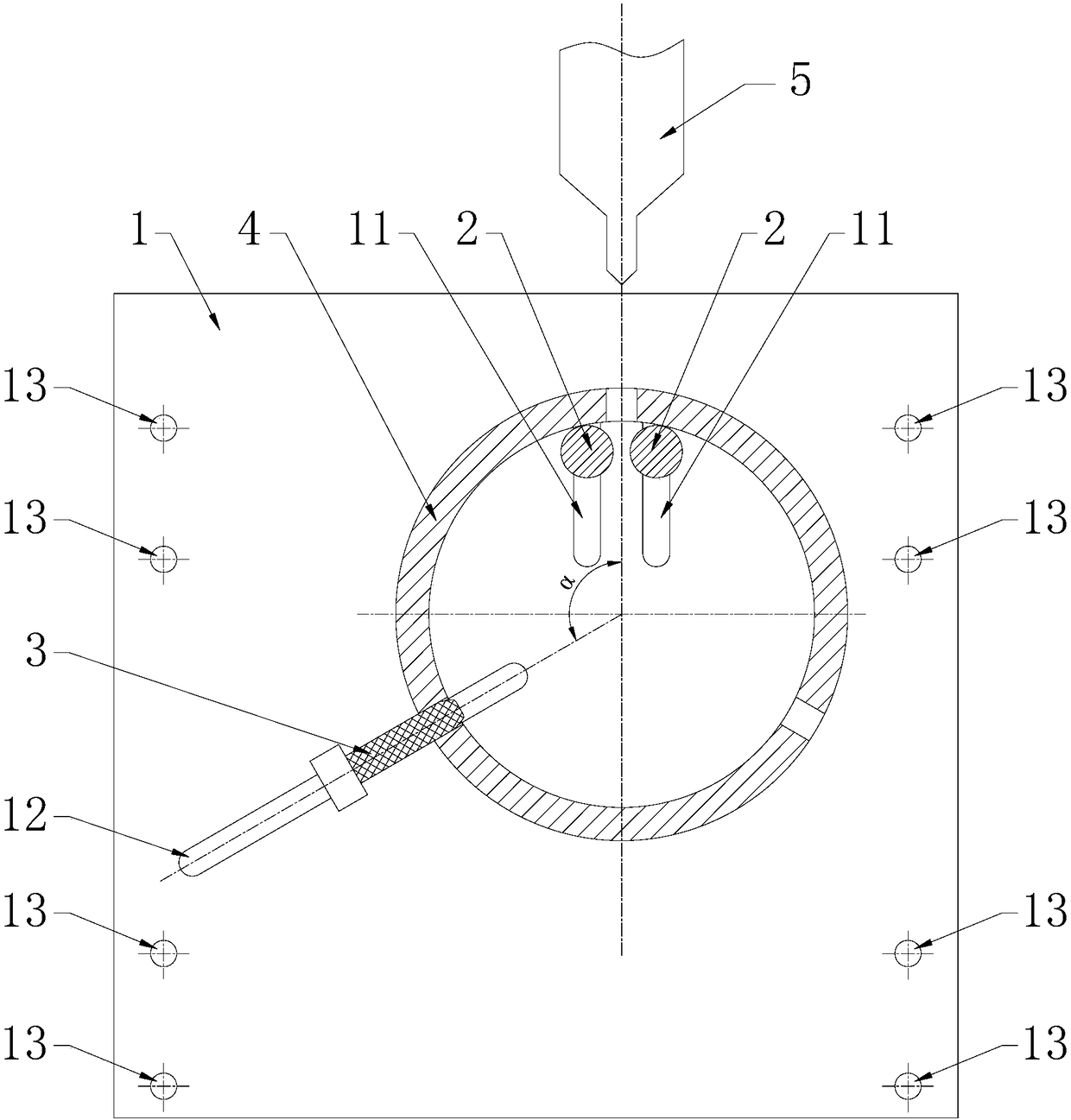

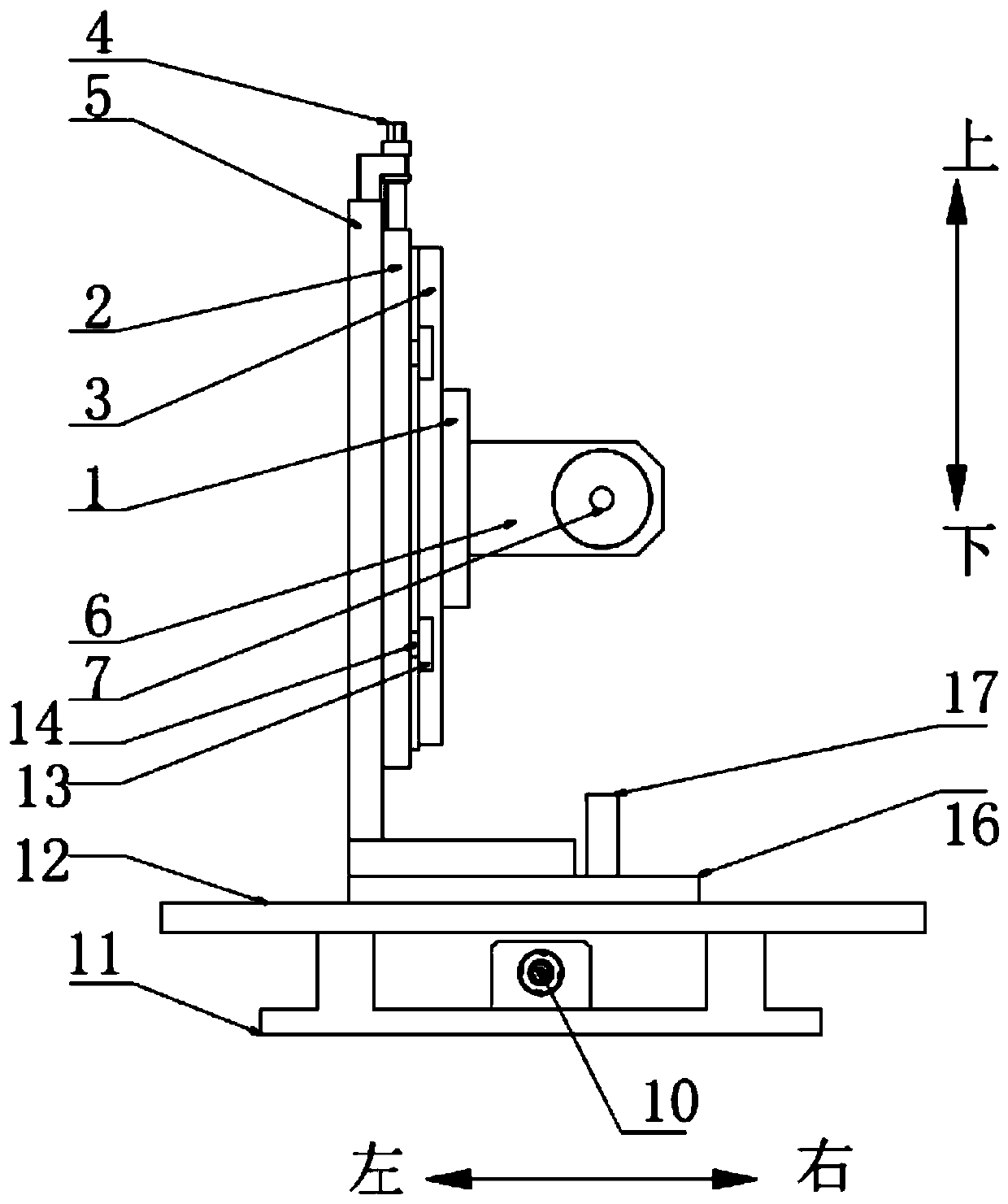

Steel plate drilling device

ActiveCN106346044AEasy to fixReduce generationPositioning apparatusBoring/drilling componentsHydraulic cylinderUniversal joint

The invention discloses a steel plate drilling device. The steel plate drilling device comprises a frame, a motor, a drilling head and support legs, wherein the motor is mounted on a motor frame; the drilling head is fixedly mounted on an output shaft of the motor; a laser lamp is mounted on the lower side of the motor frame via a universal joint; one end of an air extractor is communicated with an air extracting pipe; the air extracting pipe is communicated with the inside of a water tank; a sliding groove is formed in the upper surface of the frame, and is slidably connected with a fixing device; the fixing device comprises a vertical plate, an upper transverse plate, a lower transverse plate, a movable plate, a bolt and a magnet block; a horizontal sliding rail is fixed on the lower side of the right end of a top plate, and is slidably connected with a sliding block; a second hydraulic cylinder is fixedly arranged on the sliding block; a horizontal pressing plate is fixedly mounted at the lower end of the second hydraulic cylinder. According to the steel plate drilling device, the fixing device is used for fixing up-and-down vibration of a steel plate; the pressing plate is capable of limiting left-and-right sliding motion of the steel plate; the steel plate can be firmly fixed; great errors caused by vibration of equipment can be avoided; the occurrence of defective products can be reduced; the laser lamp is used for positioning the steel plate and enabling a drilling position to be more accurate.

Owner:日照德信机械制造有限公司

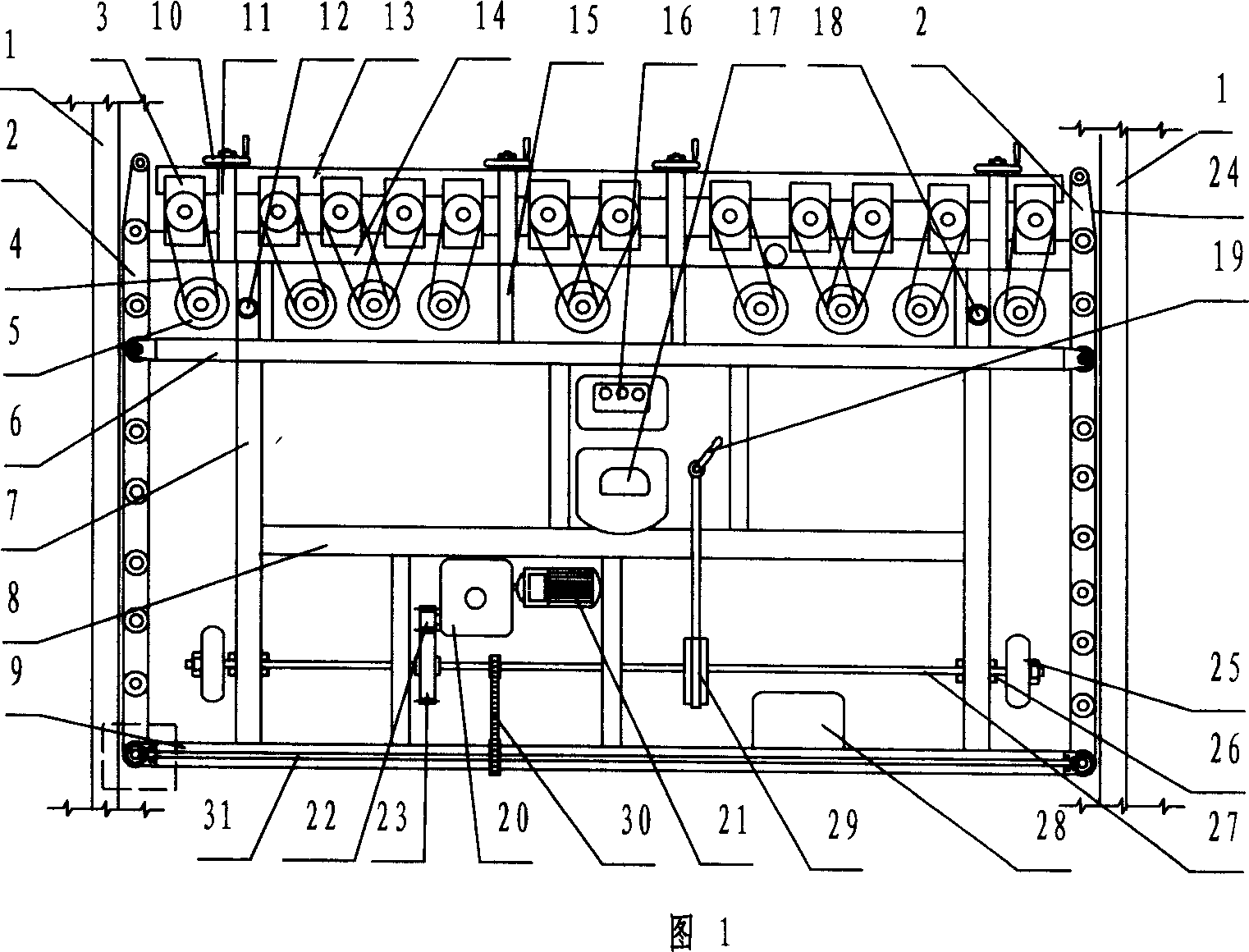

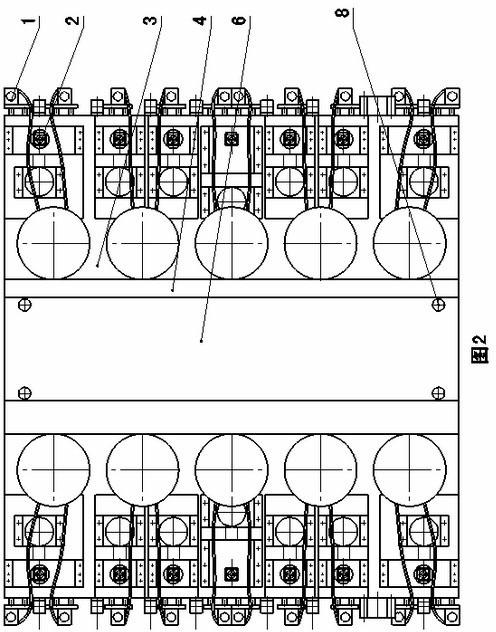

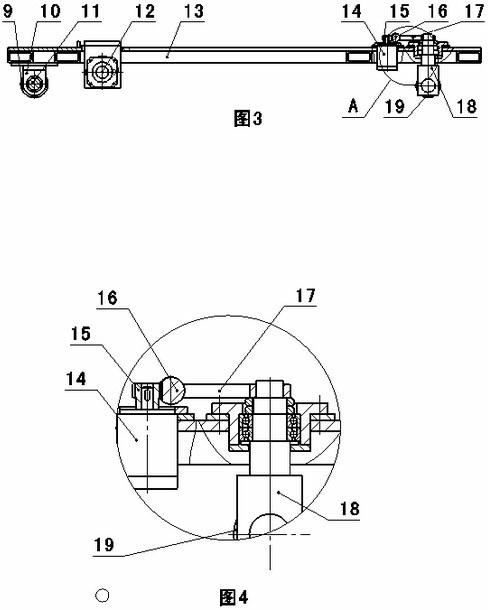

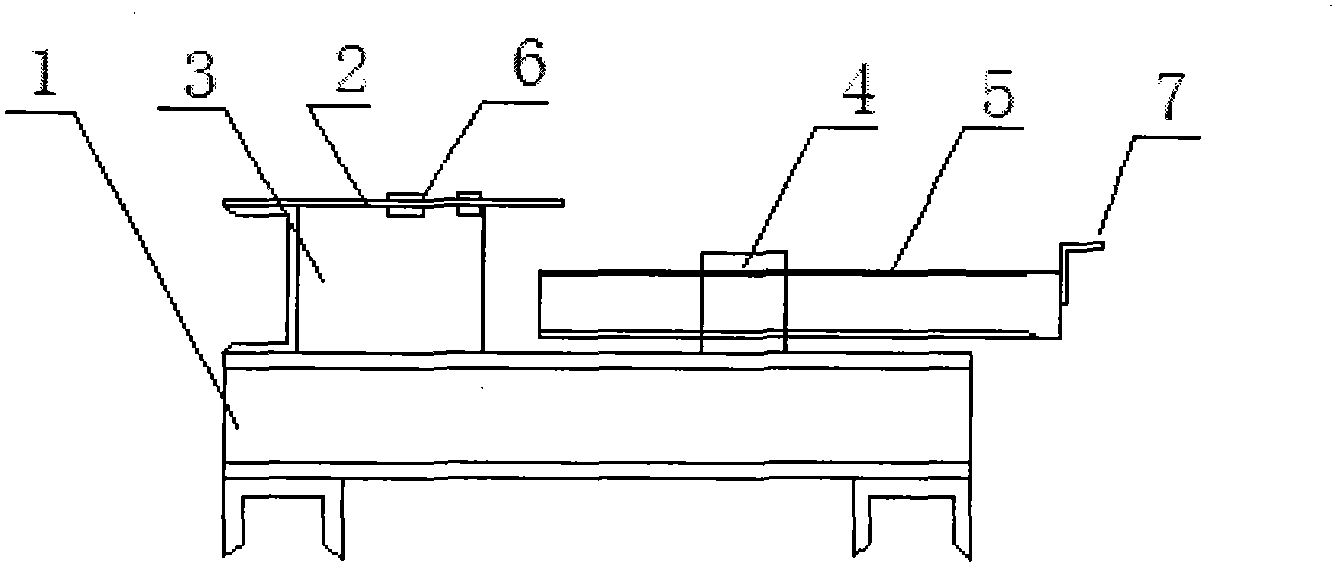

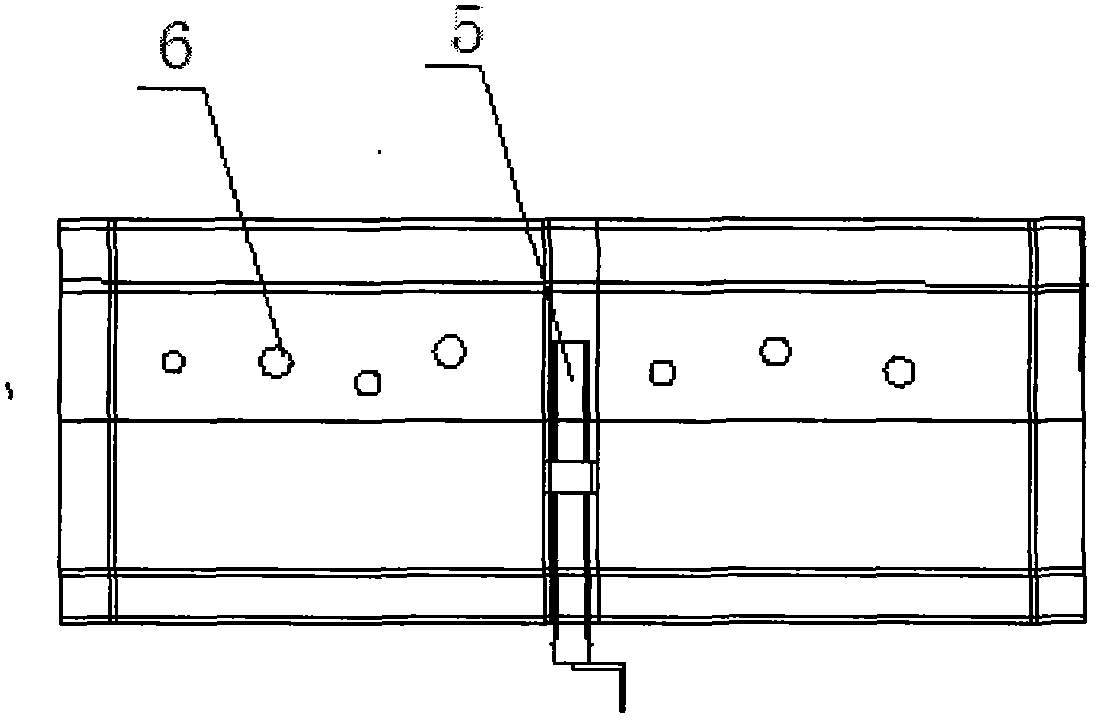

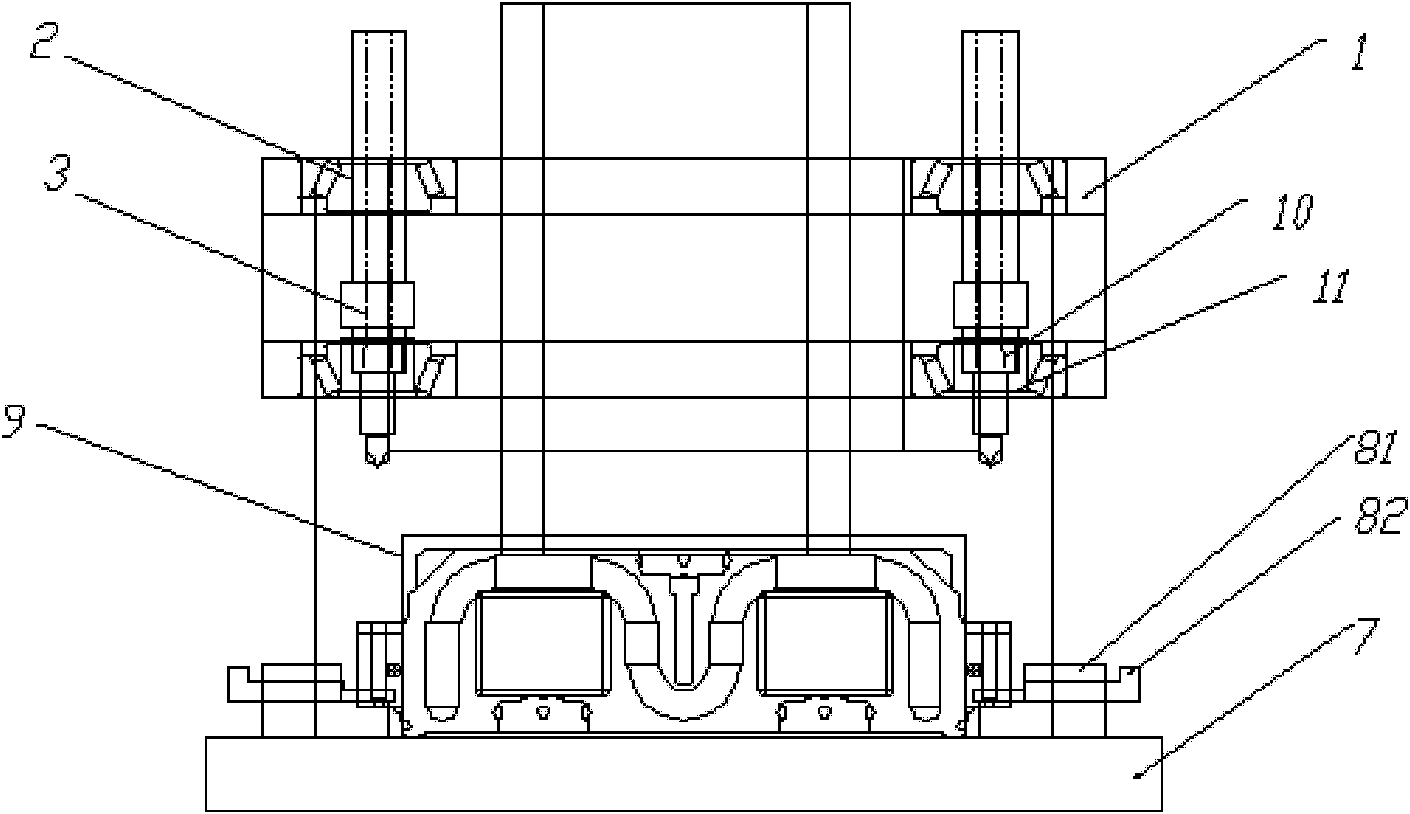

Combined driller for machining container bottom plate

InactiveCN1931486ASimple structureEasy to operateLarge fixed membersBoring/drilling componentsEngineeringMechanical engineering

The combined drilling machine for machining container bottom plate includes a combined driller an elevator. The combined driller includes a driller frame, a walking mechanism comprising four wheels, drilling sets and belt guiding mechanism. The combined drilling machine may be set inside container to drill over 10 holes simultaneously on the bottom plate, with the hole interval and number being adjusted. After finishing the drilling job inside one container, the combined driller may withdraw to the elevator for entering the next container. The present invention has simple operation, high production efficiency, low labor strength and high drilling quality.

Owner:宗恒立

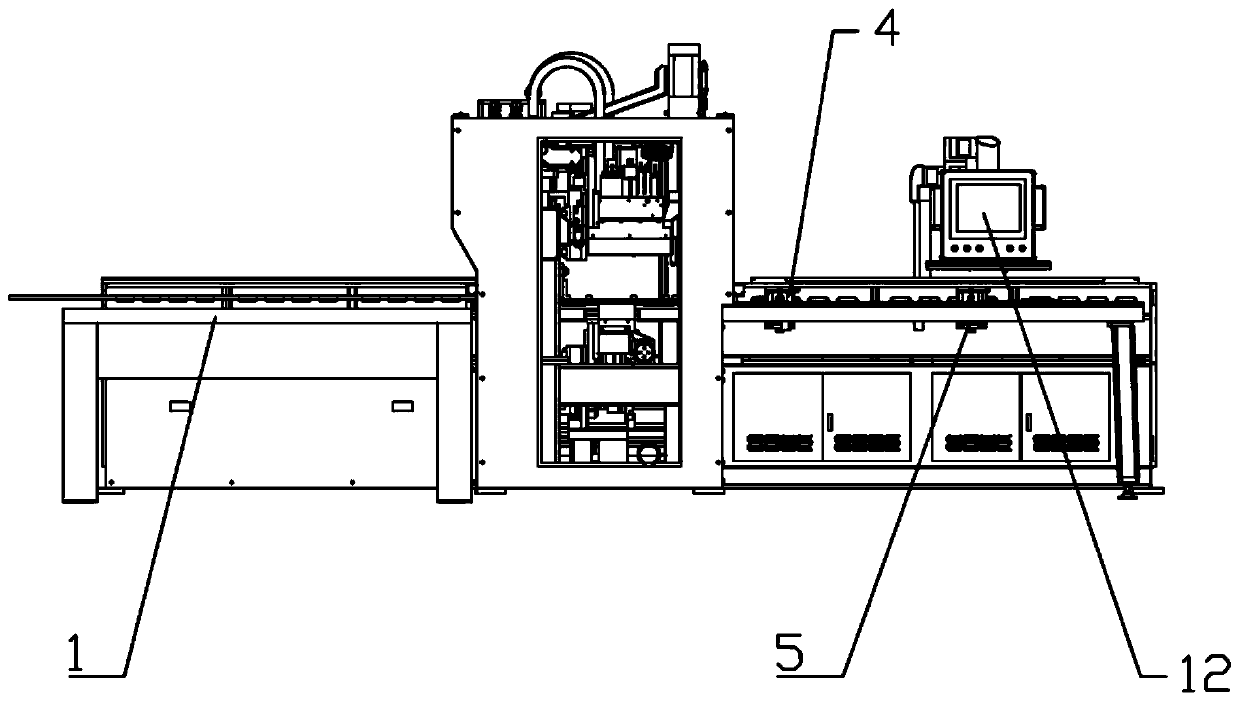

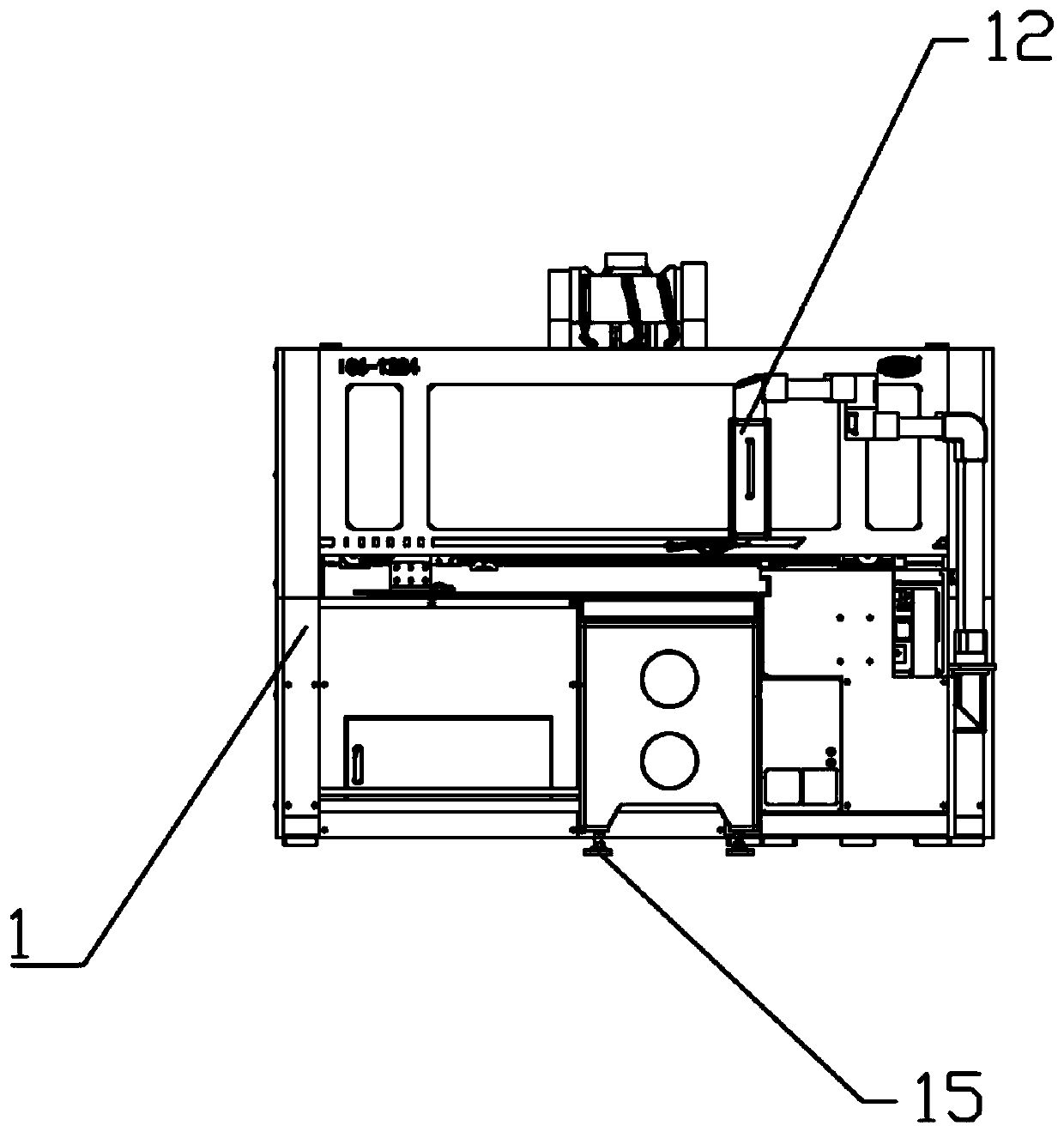

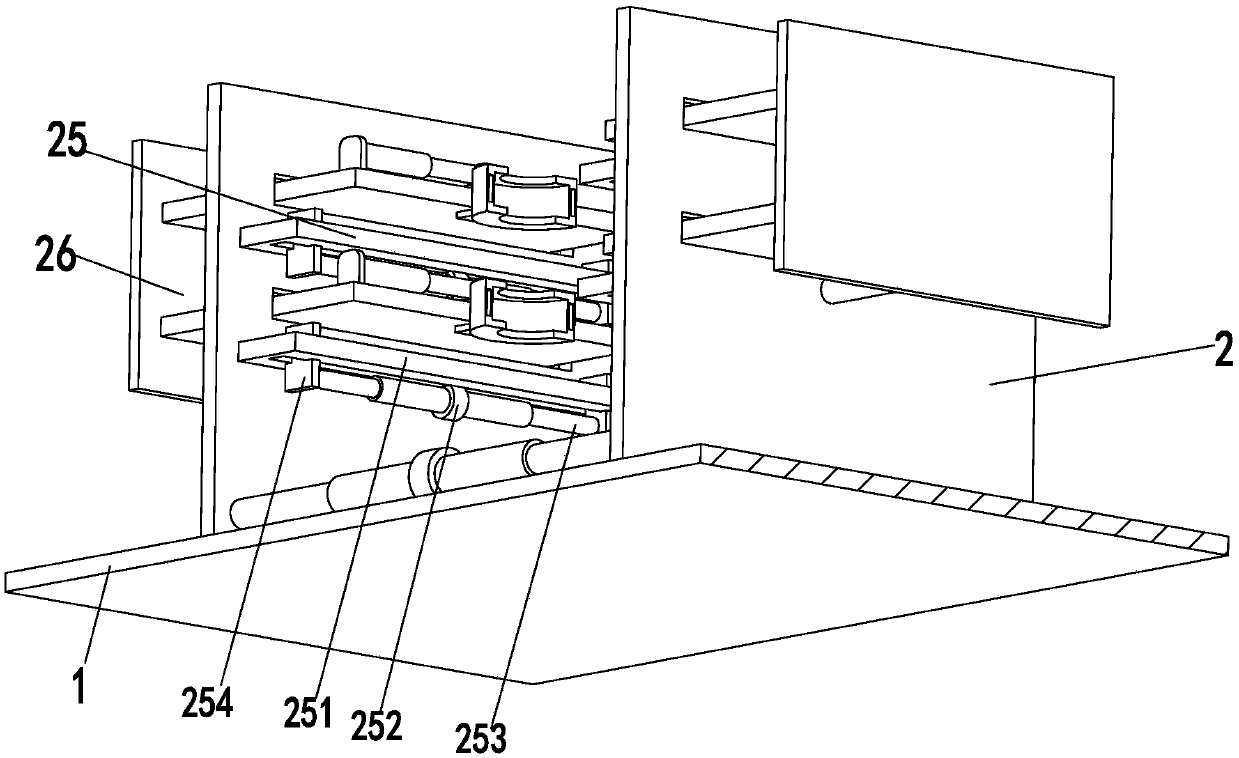

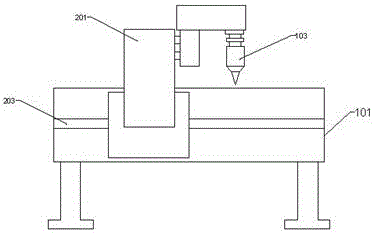

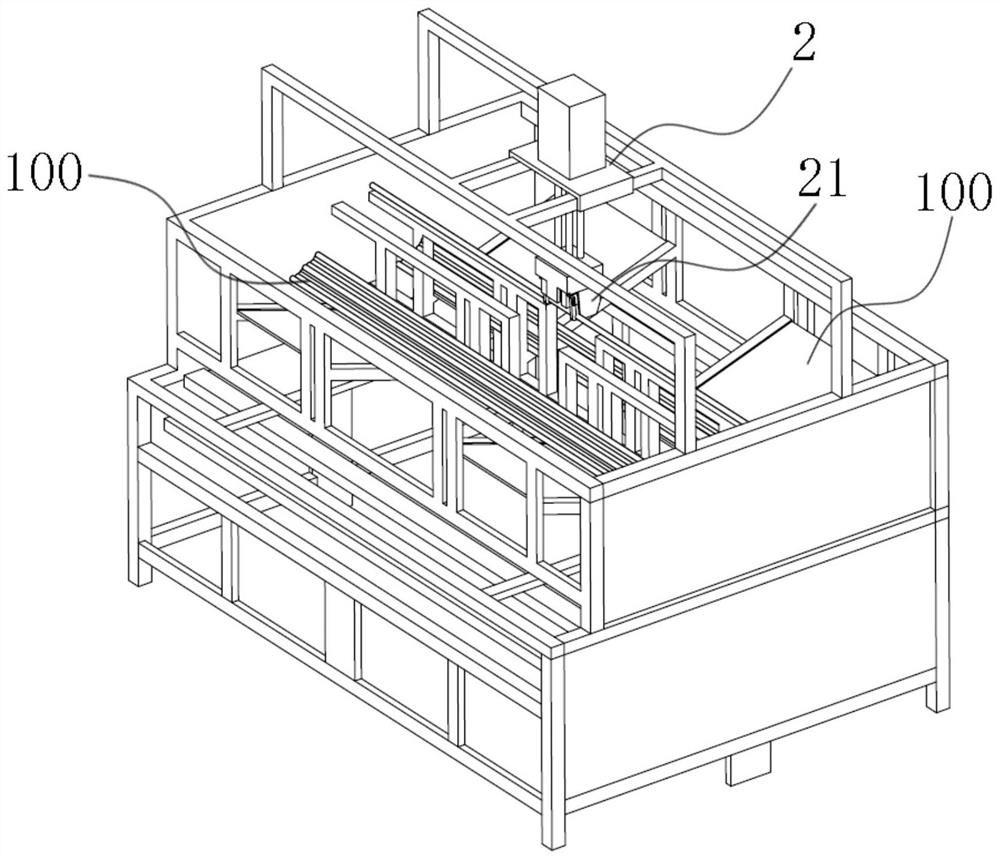

Full-automatic high-efficiency six-sided drill

PendingCN109719805AGuaranteed punching effectImprove drilling efficiencyStationary drilling machinesMulti-purpose machinesElectric machineryDrive motor

The invention relates to a full-automatic high-efficiency six-sided drill. The full-automatic high-efficiency six-sided drill comprises a lathe bed, wherein a feeding assembly, an executing assembly and a control assembly are arranged on the lathe bed; the feeding assembly is used for conveying a plate to the position of the executing assembly; the executing assembly is used for drilling the plate; the control assembly is used for controlling the feeding assembly and the executing assembly to perform corresponding actions; the plate is driven to move on a box body through mutual cooperation ofa driving motor, a clamp and a synchronous belt; and the plate is moved to a designated processing position under the control of a computer. Through matching of a lifting assembly and a reinforcing assembly, the drilling position of a drill bit is more accurate, and the drilling effect of the plate is ensured; through the cooperation of a translation assembly and a slotting drill bit, slotting processing is carried out on the plate, and six driving shafts and one auxiliary shaft are mutually matched, so that the drilling processing efficiency of the plate is improved, the processing effect ofthe plate is ensured; and the full-automatic high-efficiency six-sided drill has the advantages of high automation degree, safety and high efficiency.

Owner:山东佳梆数控科技集团有限公司

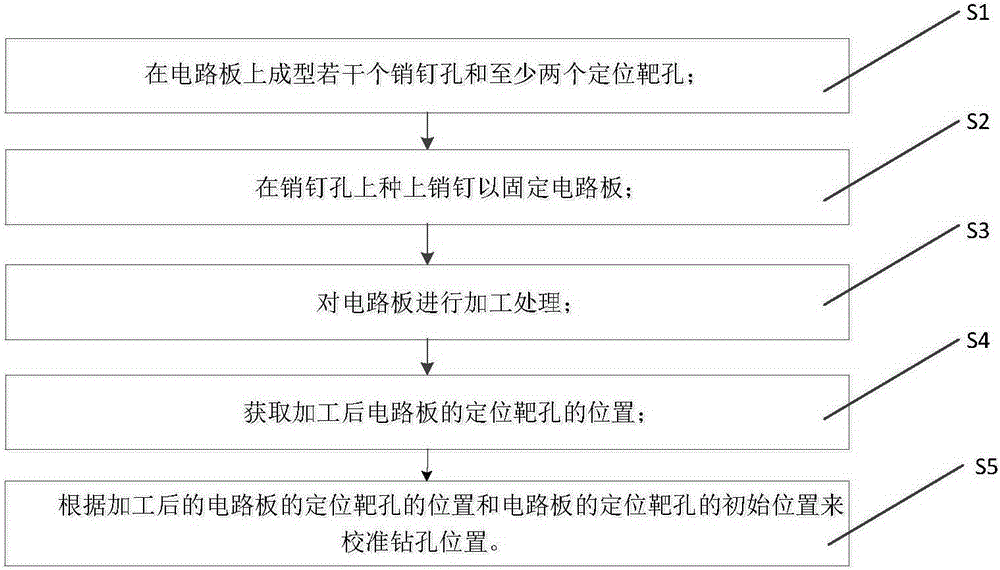

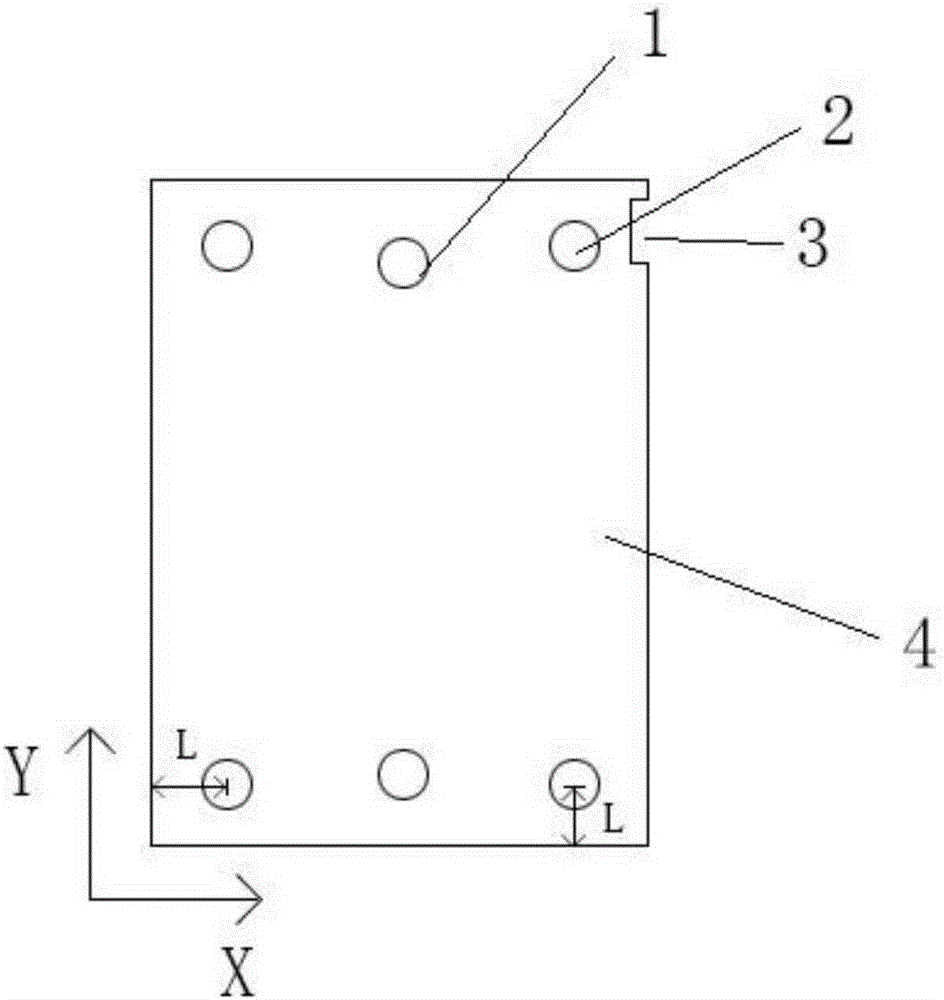

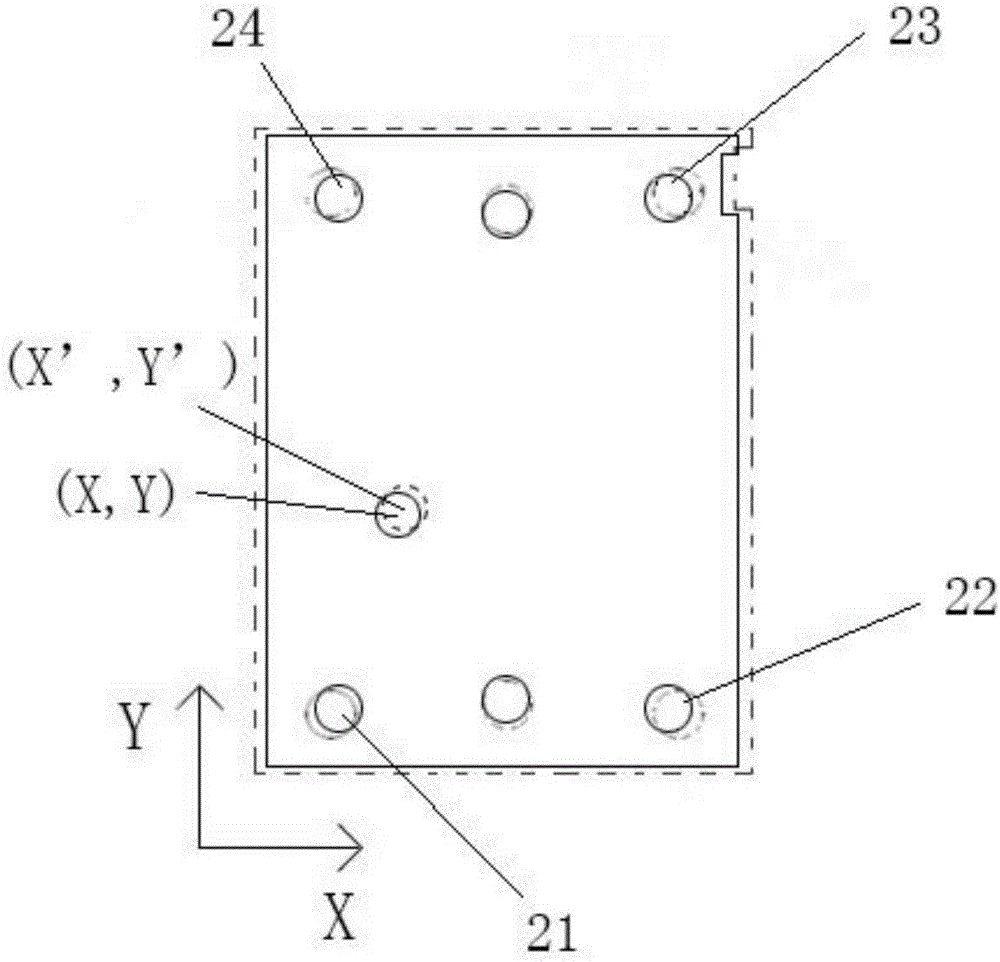

Method for calibrating drill hole of circuit board

ActiveCN105216054AAchieve precise positioningImprove utilizationMetal working apparatusEngineeringDrilling machines

The invention provides a method for calibrating a drill hole of a circuit board, belonging to the technical field of circuit board production. The method comprises the following steps: molding pin holes in the circuit board, and fixing the circuit board through pins; obtaining the position data of a positioning target hole, positioned in the same board surface with a pre-drilled hole, after the circuit board is deformed; according to the position data of the positioning target hole after the circuit board is deformed and the position data of the positioning target hole before the circuit board is deformed, calibrating the position of the drill hole. The accurate positioning for the position of the drill hole is realized. A device for fixing the pins does not need to be finely adjusted, the adjustment time is shortened, therefore the working ratio of a drilling machine is increased, and the production efficiency is improved.

Owner:NEW FOUNDER HLDG DEV LLC +1

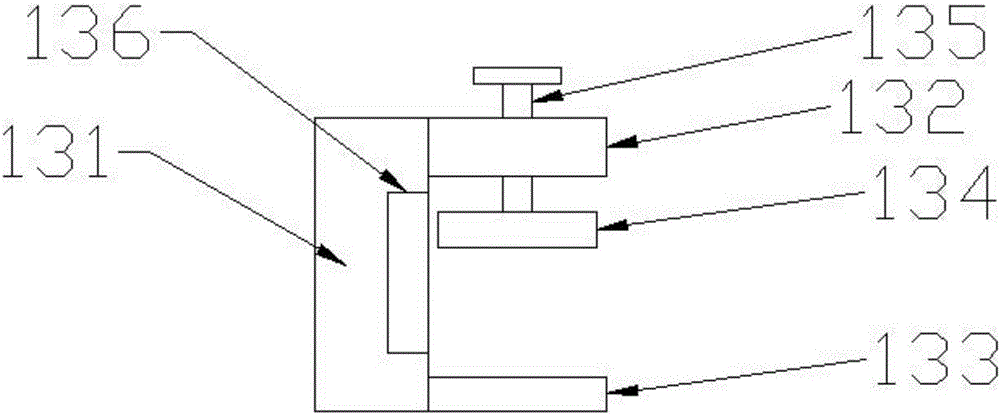

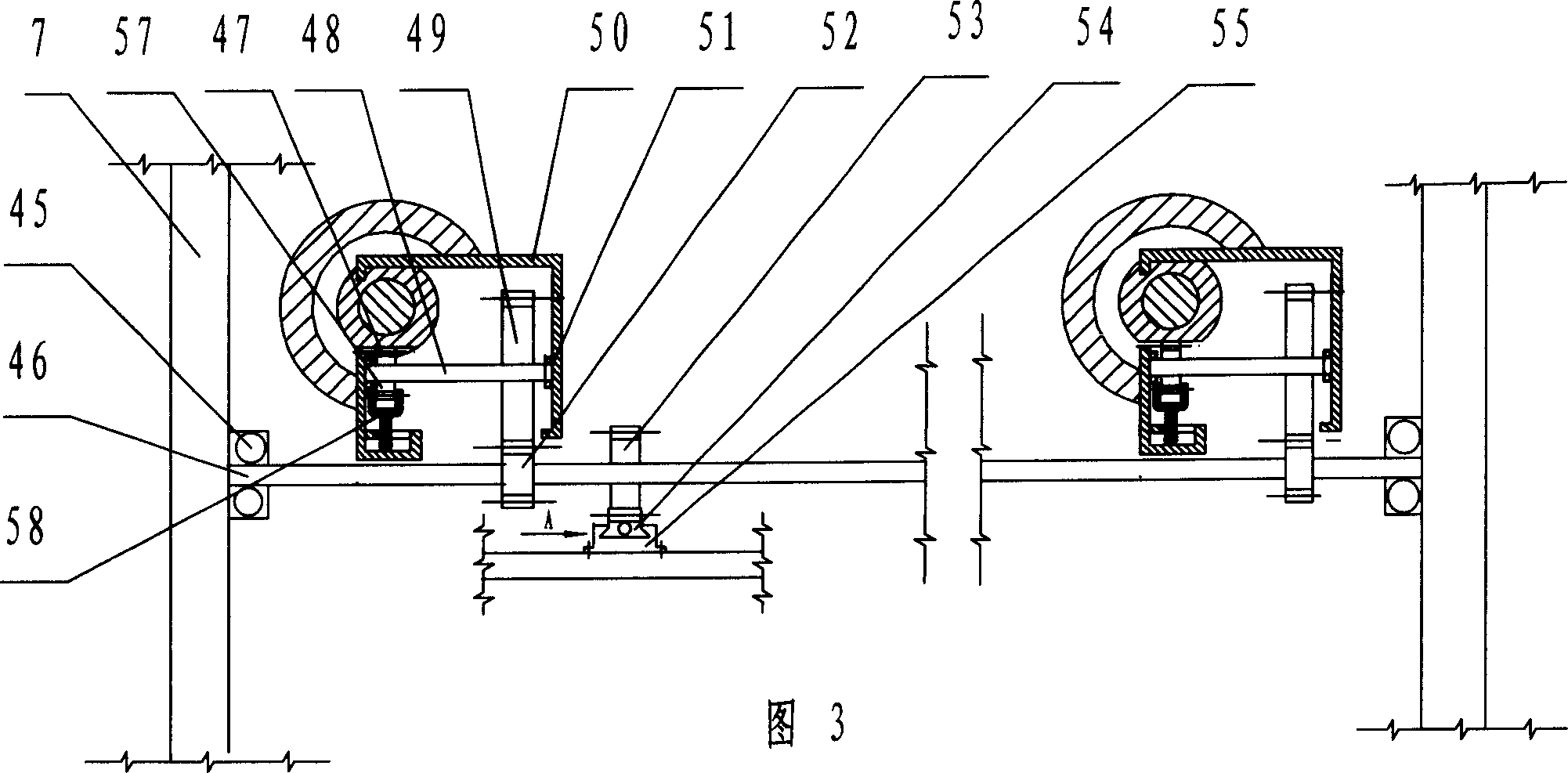

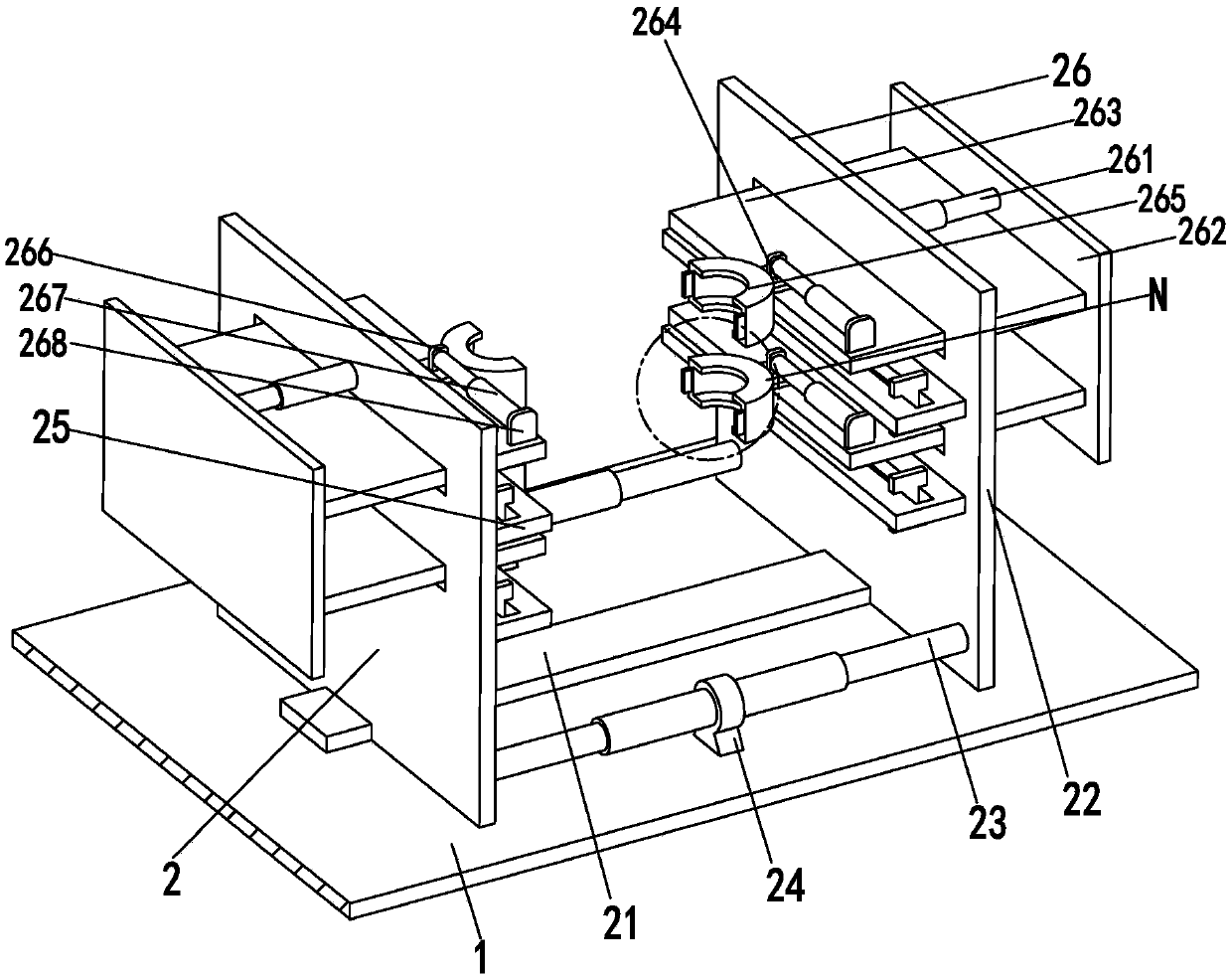

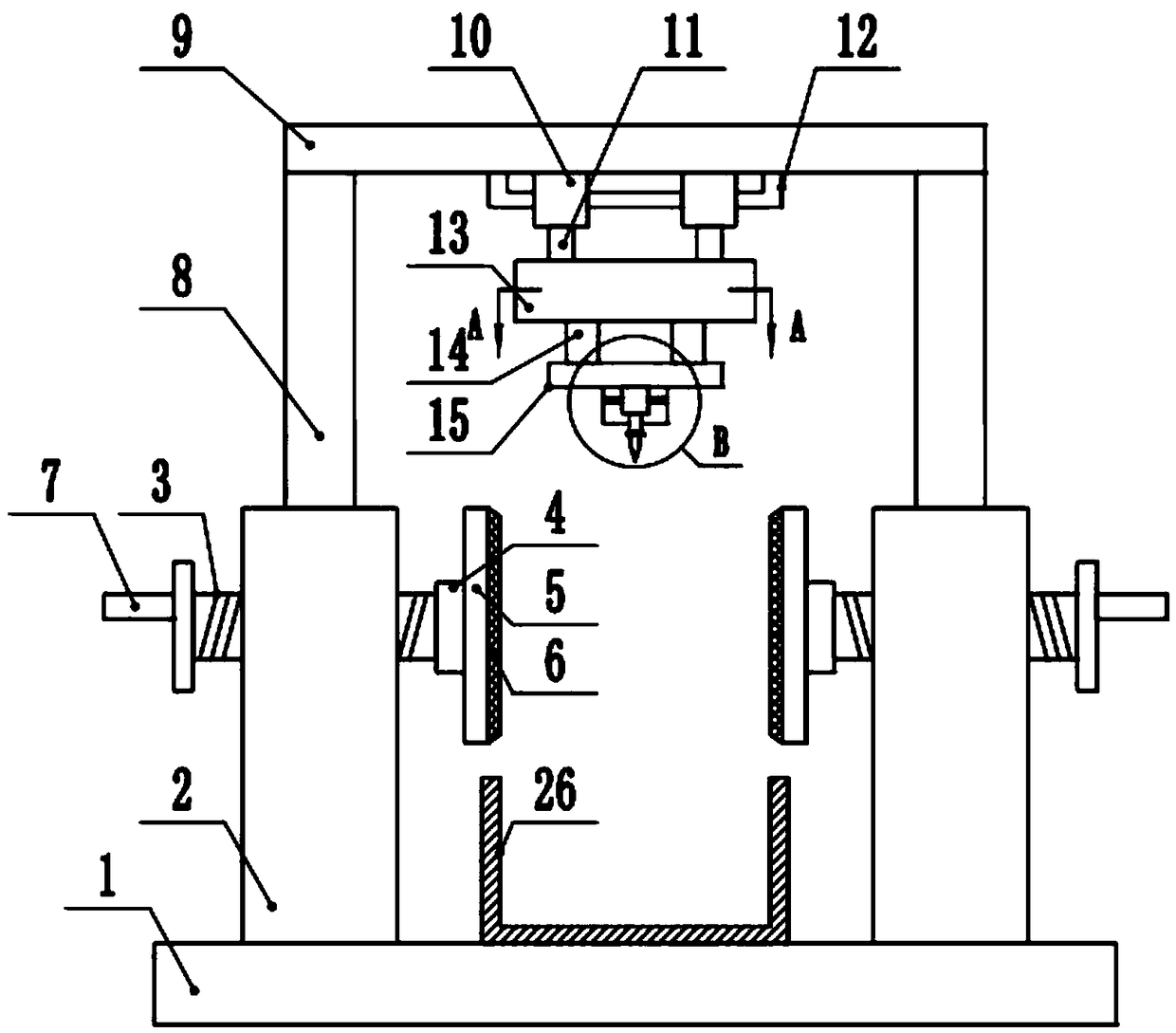

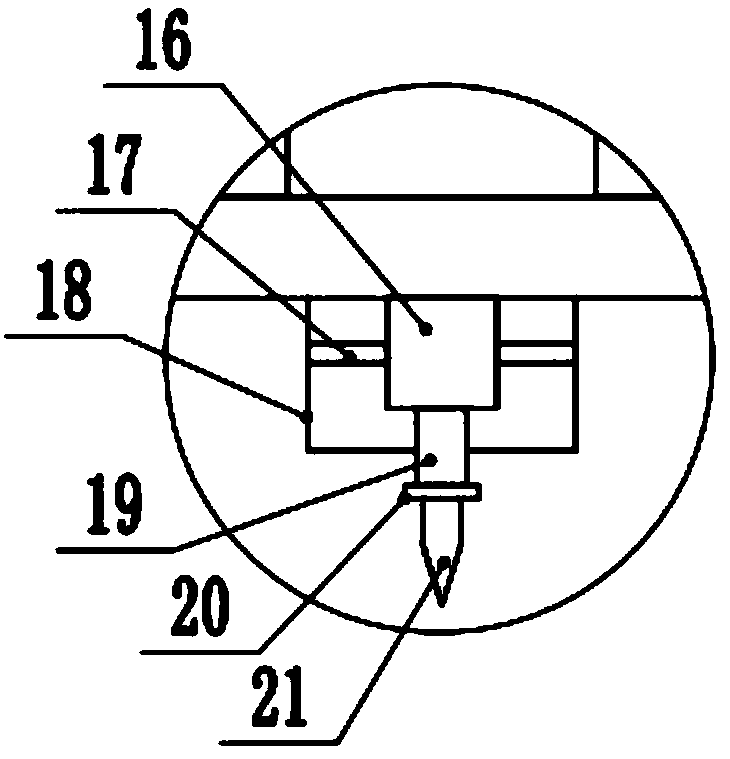

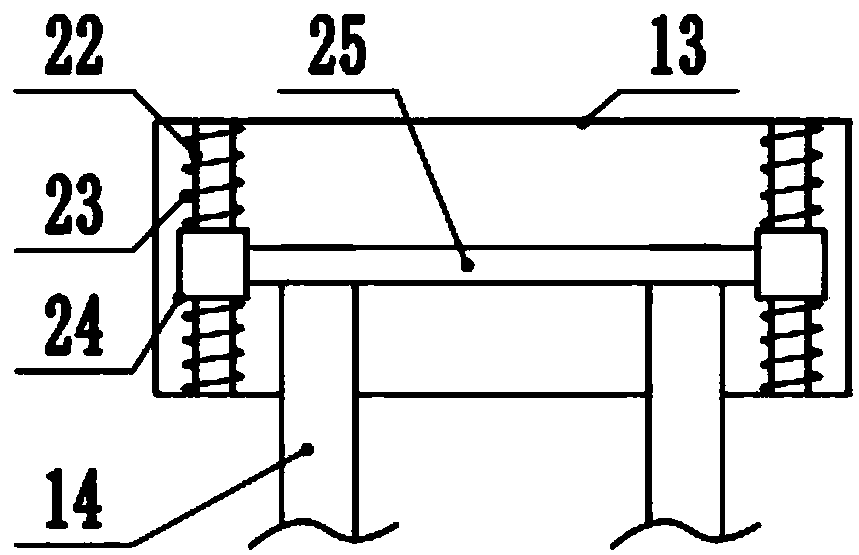

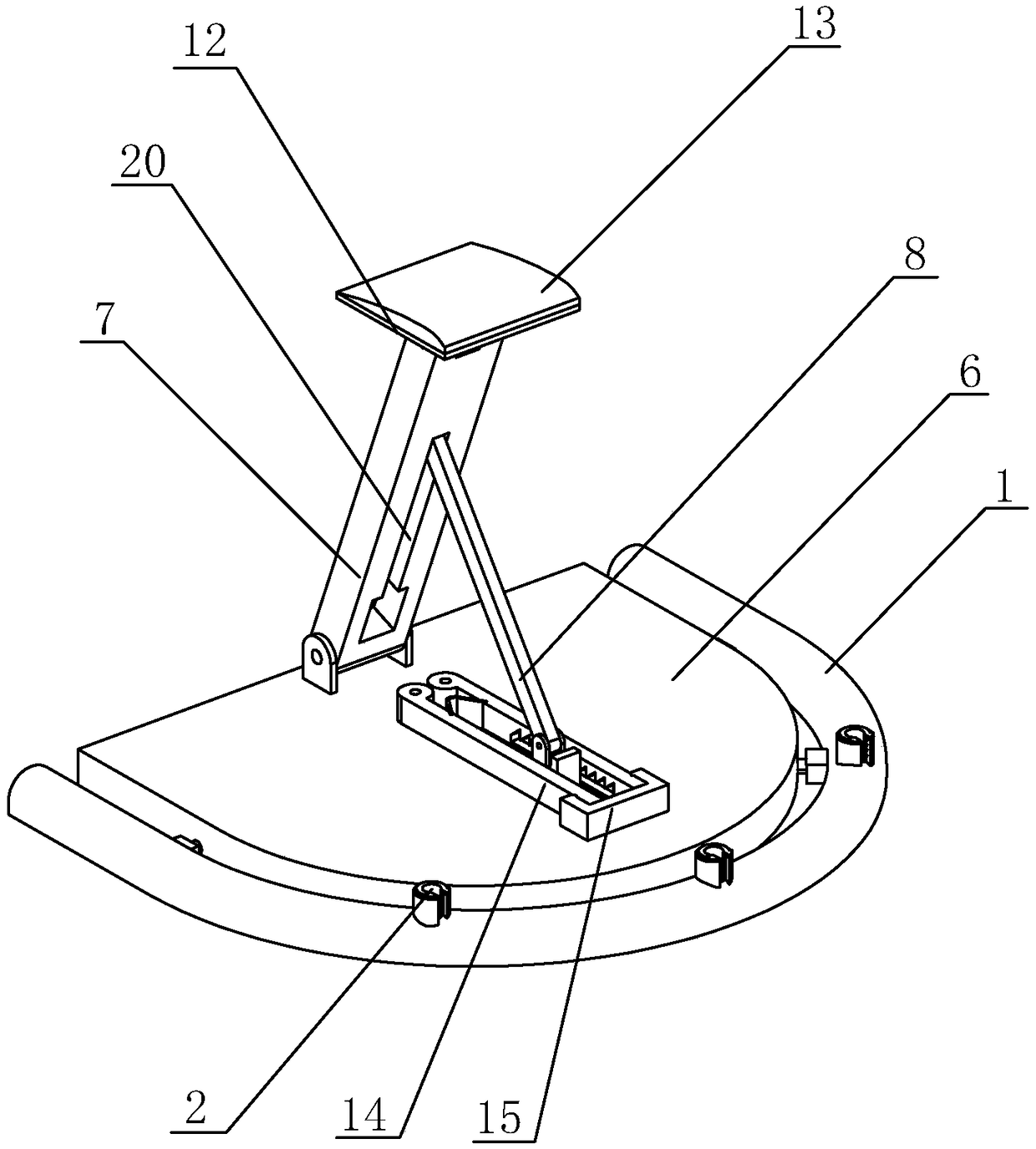

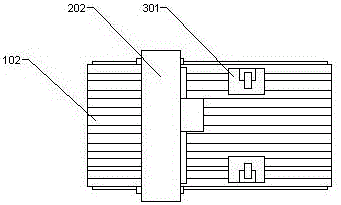

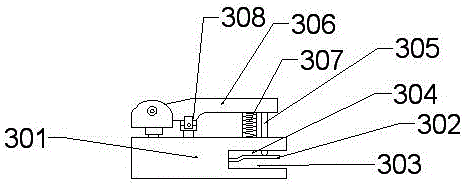

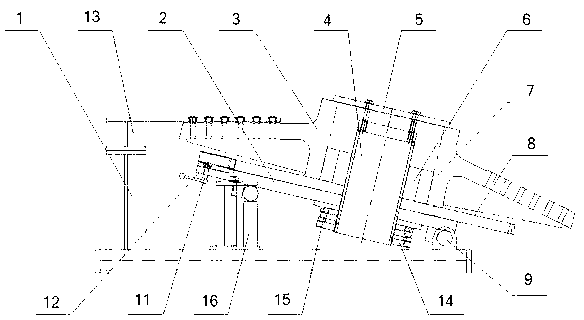

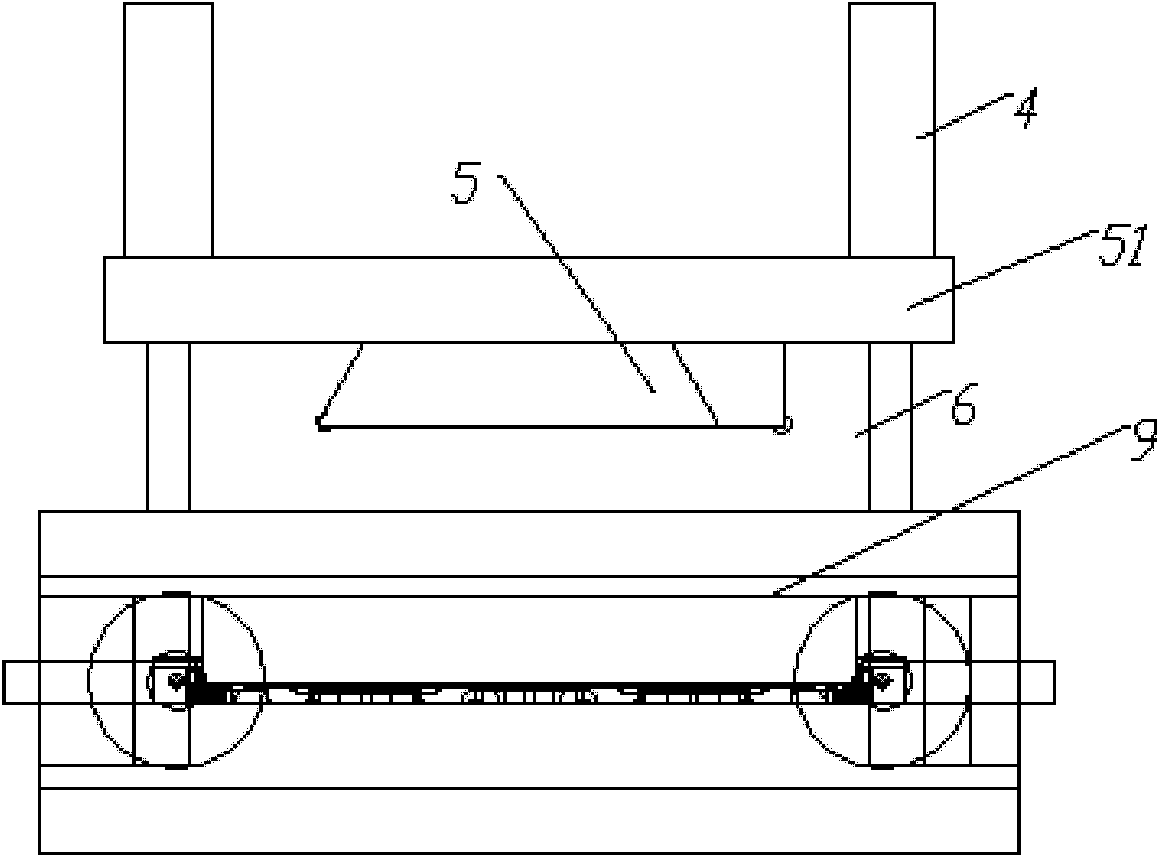

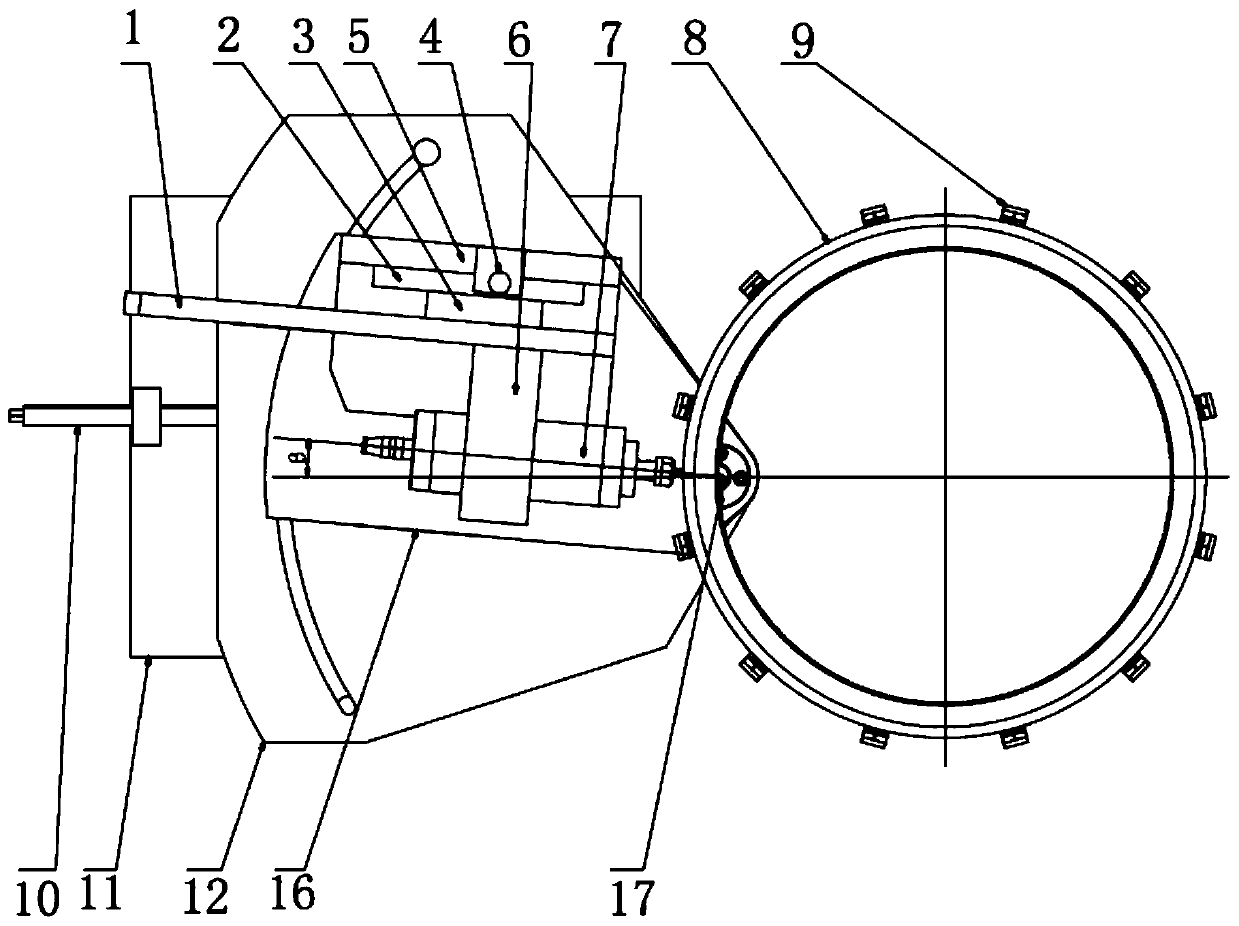

Hole-drilling and screw-locking device for container floor boards

ActiveCN102490214AReduce labor intensityReduce manufacturing costStationary drilling machinesIntermittent motionEconomic benefits

A hole-drilling and screw-locking device for container floor boards resolves the problems that installation of container floor boards depends on manual operation of workers and production efficiency is poor. The hole-drilling and screw-locking device for container floor boards is provided with a traveling device which comprises a vehicle body, a driving part and a steering part. A horizontal moving device is installed on the upper portion of the vehicle body, a position changing device is arranged at the upper portion of the horizontal moving device, a hole-drilling device and a screw-locking device are installed on the position changing device, and the horizontal moving device, the position changing device, the hole-drilling device, the screw-locking device and the vehicle body are jointly in intermittent motion to achieve the hole-drilling and screw-locking functions. The hole-drilling and screw-locking device for container floor boards has the advantages of adopting mechanical devices to replace manual operation of workers, being capable of achieving hole drilling and screw locking of a row of screws in one-time operation, lowering labor intensity of operators, improving production efficiency, lowering production cost of containers and increasing economic benefits of enterprises. Due to the fact that mechanical devices are used for hole drilling and screw locking, hole-drilling positions are accurate, screw-locking force is uniform, and accordingly, assembling quality of container floor boards is improved.

Owner:东方国际集装箱(锦州)有限公司 +1

Drilling device for wood boards

PendingCN108544580AImprove processing efficiencyGuaranteed stabilityStationary drilling machinesBark-zones/chip/dust/waste removalDrill bitEngineering

The invention belongs to the technical field of wood board processing devices, and particularly discloses a drilling device for wood boards. The drilling device comprises a worktable and an auxiliaryrod, the worktable is provided with a vertical column, the column is provided with a cylinder, a beam is connected to a piston rod of the cylinder, the beam is provided with a motor, and an output shaft of the motor is provided with a drill bit. The auxiliary rod is connected to the output shaft of the motor, the auxiliary rod is provided with a support frame, vertical rods are arranged on the support frame, and brushes are connected to the vertical rods. A first sliding hole is formed in the vertical column, an ejecting block is arranged in the first sliding hole, and the worktable is provided with a through hole, a second sliding hole, a slider, a second spring, a material guiding hole and a clamping portion. The drilling device is mainly used for drilling the wood boards, and the problem that waste chip is usually left in a hole to affect subsequent splicing of the wood boards after drilling of the wood boards is completed is solved.

Owner:重庆草衣木食文化传播有限公司

Dental implantation guide plate, drill bit and application method thereof

Owner:SHANGHAI JADE DIGITAL DENTAL LAB CO LTD

Automatic wood board machining robot

ActiveCN108673648AExpand the scope of useReduce lossesDrilling machinesBark-zones/chip/dust/waste removalWaste materialPulp and paper industry

The invention discloses an automatic wood board machining robot. The automatic wood board machining robot comprises a bottom plate, a supporting device, a perforating device and a waste material box,the perforating device is arranged on the bottom plate, the supporting device is arranged at the lower end of the perforating device, the waste material box is arranged at the lower end of the supporting device, moreover, both the supporting device and the waste material box are installed on the bottom plate, the supporting device comprises a linear guide rail, a supporting frame, a position adjusting air cylinder, a mounting seat, a fixing mechanism and a guide mechanism, and the perforating device comprises a linear slide rail, an electric sliding block, a telescopic mounting frame, a drilling mechanism and a cleaning mechanism. According to the automatic wood board machining robot, the problems that in an existing wood board drilling process, the labor cost is high, potential safety hazards exist, the working stability is poor, saw dust splashes around, and the drilling position is prone to deviation can be solved, an automatic drilling function on a wood board can be achieved, andthe advantages of being low in labor cost, good in safety, good in stability, free of splashing of the saw dust, accurate in drilling position and the like are achieved.

Owner:WENZHOU QIFANG NEW ENERGY CO LTD

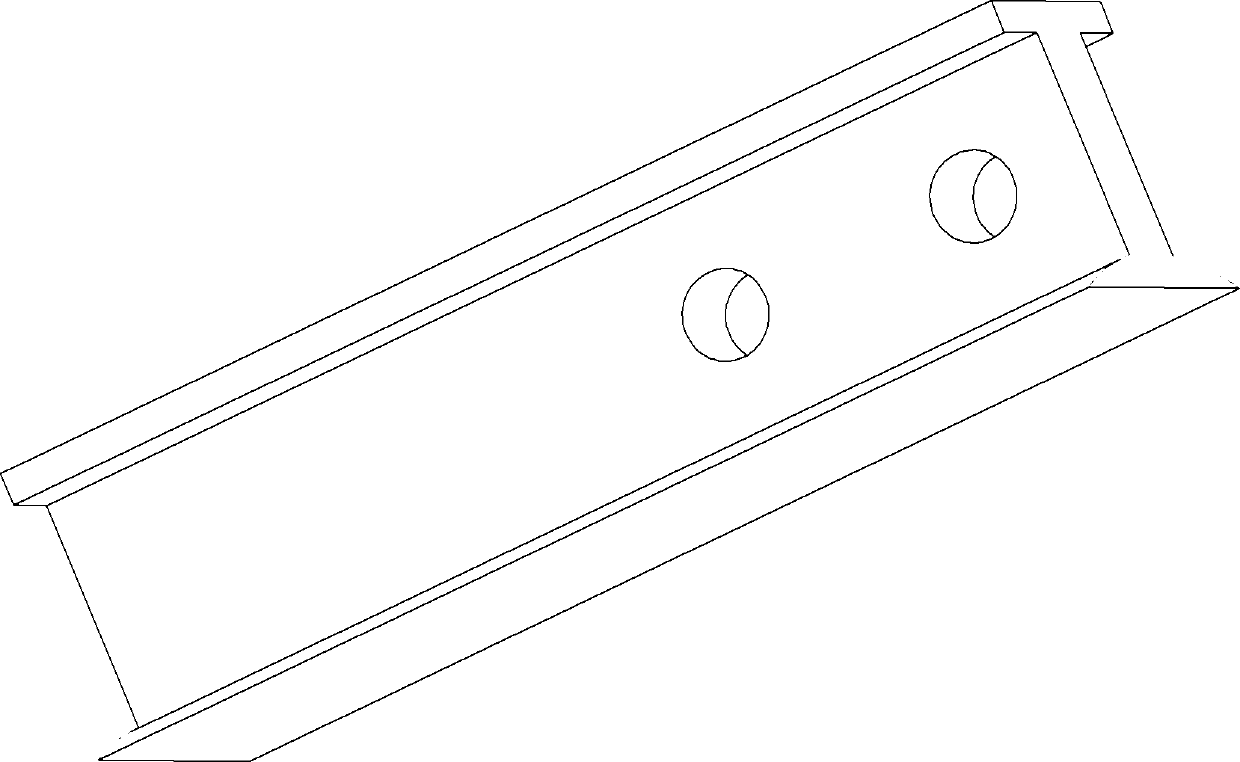

Positioning fixture for steel rail drilling

InactiveCN102605688AImprove processing efficiencySimple drilling procedureRailway track constructionMechanical engineeringDrilling machines

The invention discloses a positioning fixture for steel rail drilling, which comprises a bottom plate for holding a steel rail. A clamping mechanism for clamping the steel rail from two sides is disposed on the upper surface of the bottom plate and comprises two opposing clamping blocks disposed on two sides and a driving mechanism. The driving mechanism is used for increasing or decreasing the distance between the two clamping blocks to loose or clamp the steel rail. A fixed positioning block for positioning the steel rail in drilling is disposed at the front end of the bottom plate. A flat plate parallel to the bottom plate is disposed at the upper end of every clamping block. The flat plate is provided with a bit positioning hole which axially and perpendicularly penetrates through a center line of the bottom of the steel rail which is clamped. After the fixture is fixed on a drilling machine and the steel rail is clamped, the bit can be aligned with the positioning hole for drilling, and punching the steel rail, removing a positioning device and moving the steel rail to the drilling machine to drill the steel rail in the prior art is not required. The drilling process using the fixture is simple, and the efficiency of machining the steel rails is improved greatly.

Owner:永煤集团股份有限公司新桥煤矿

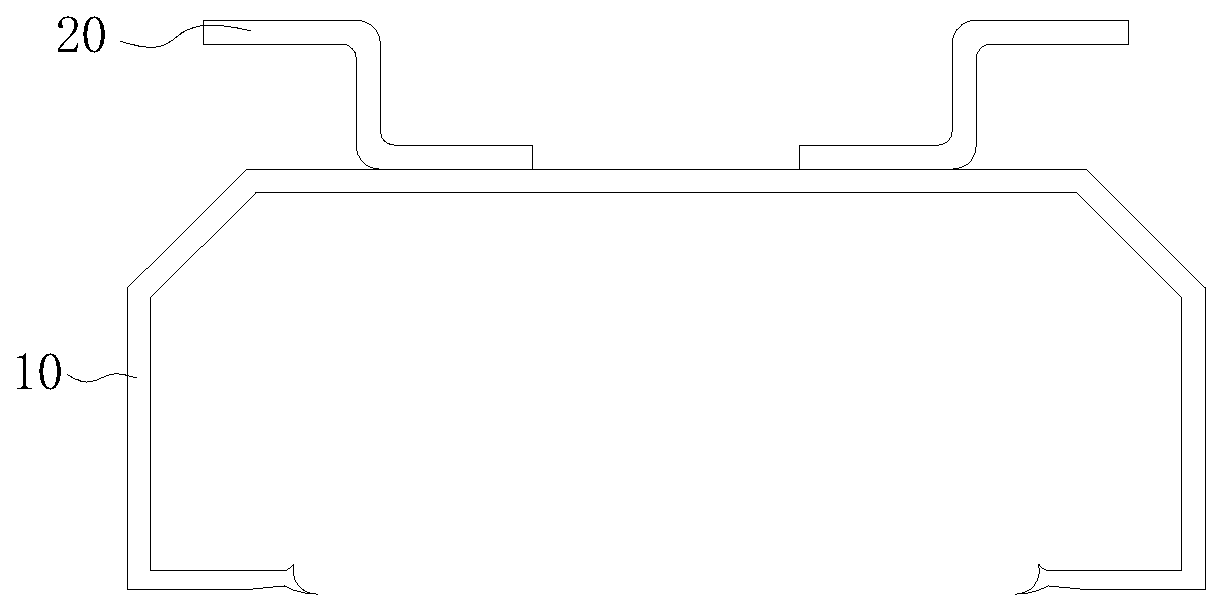

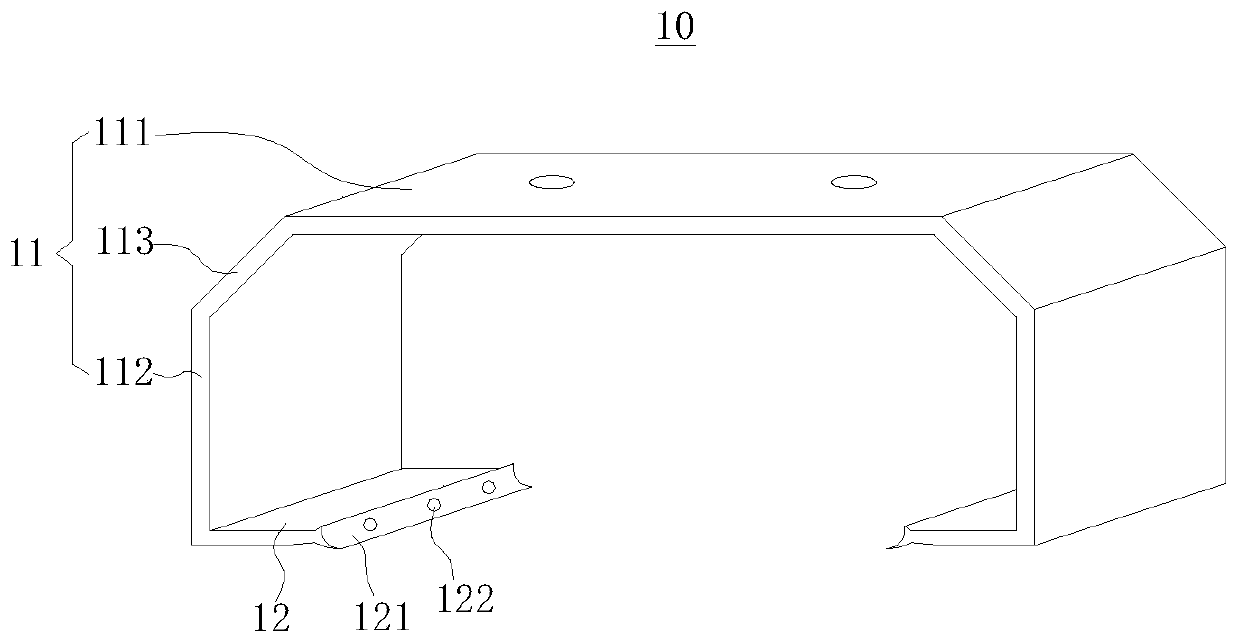

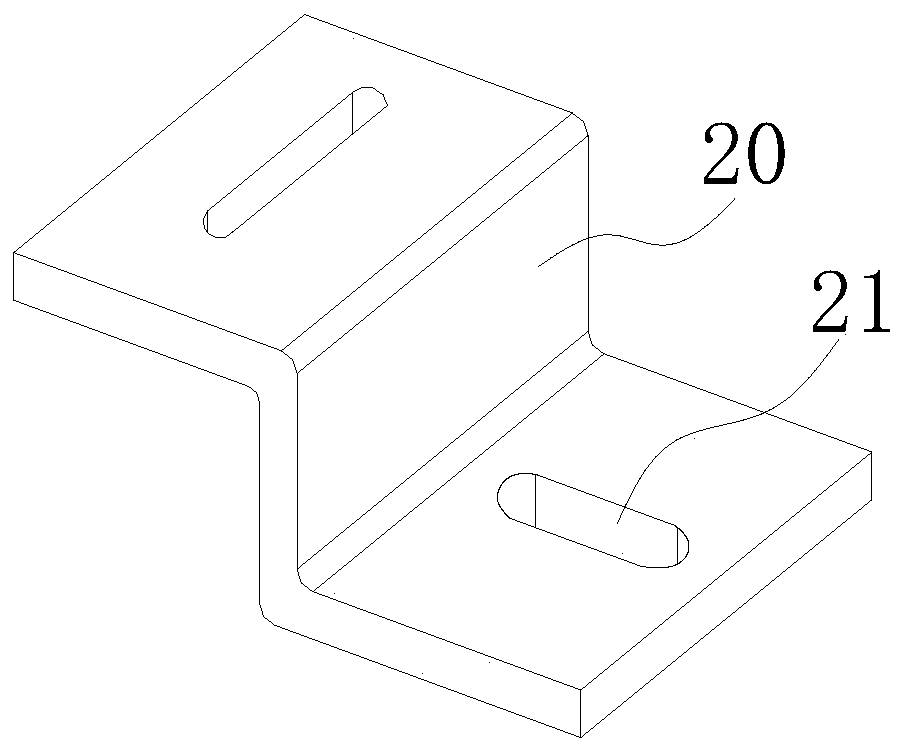

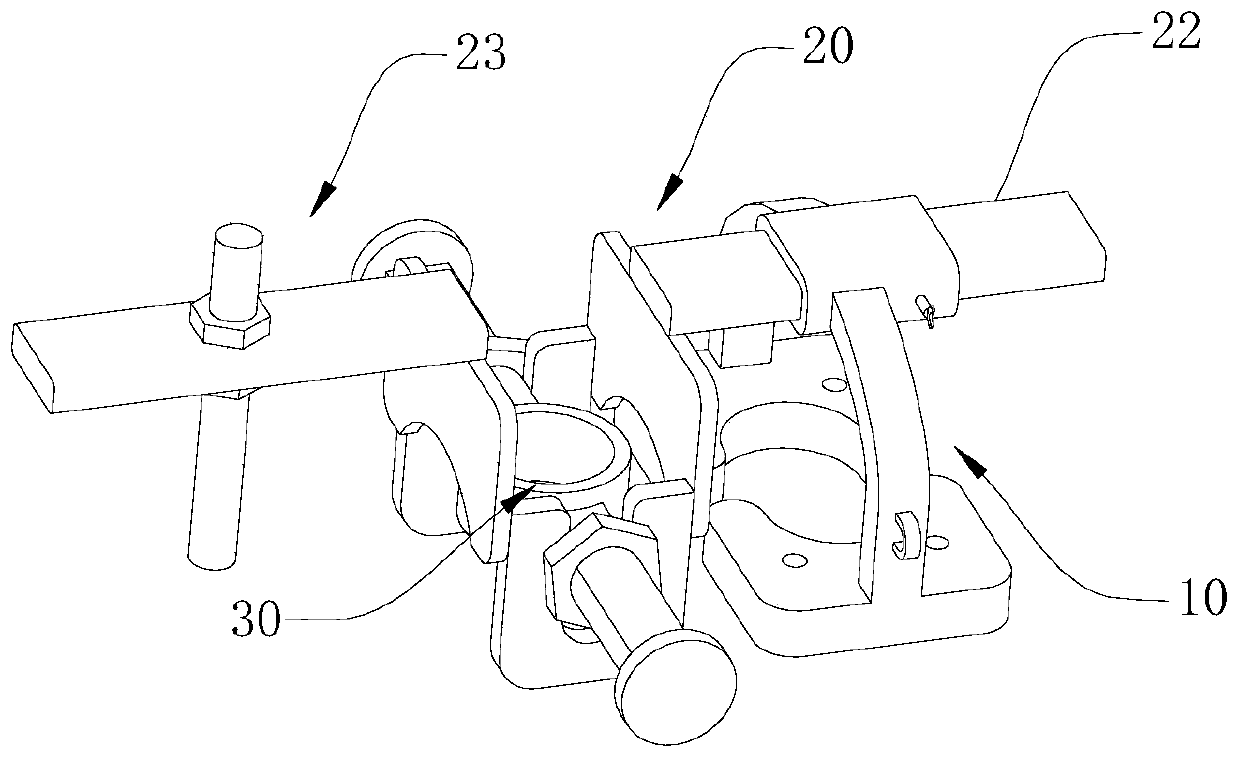

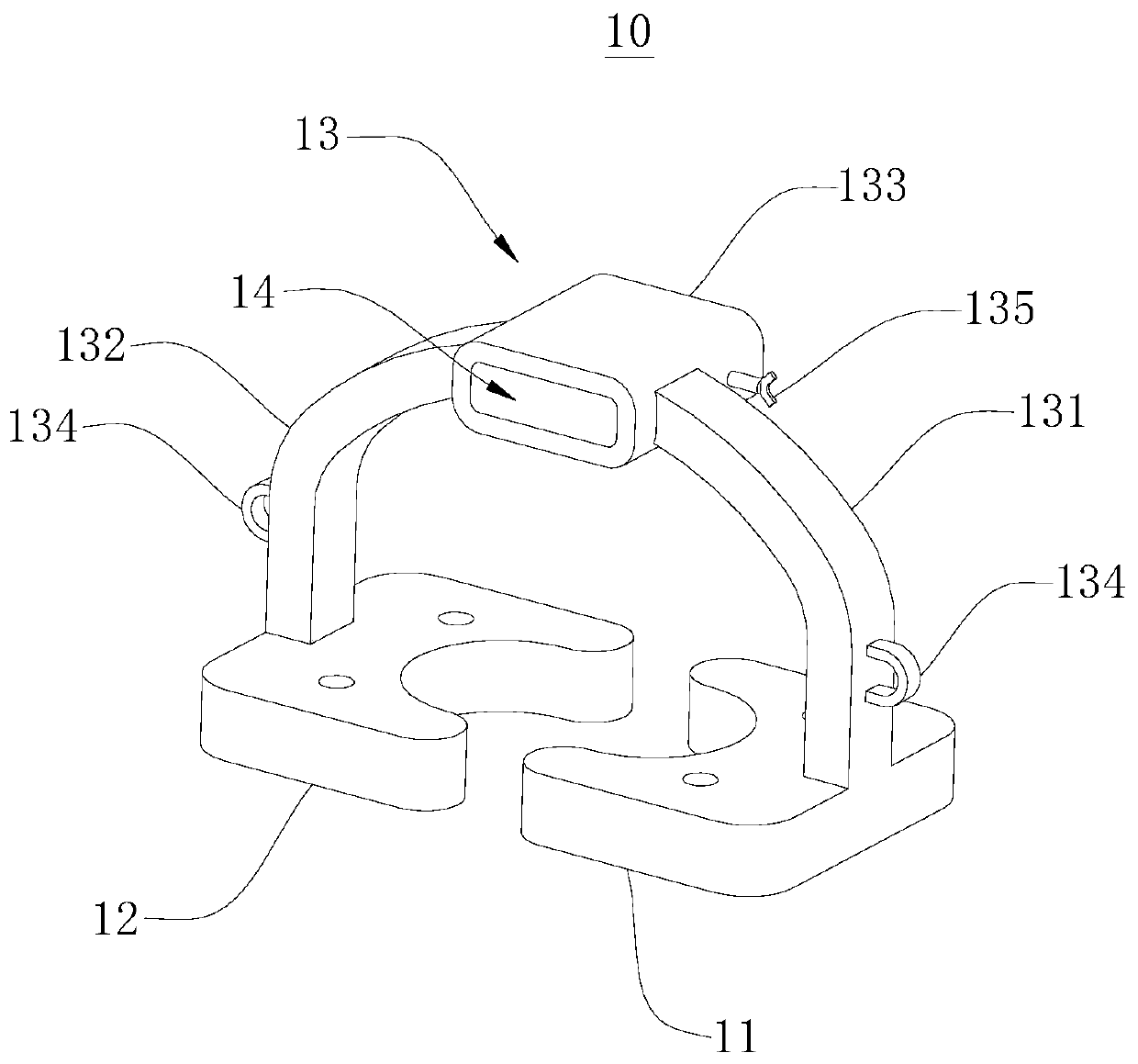

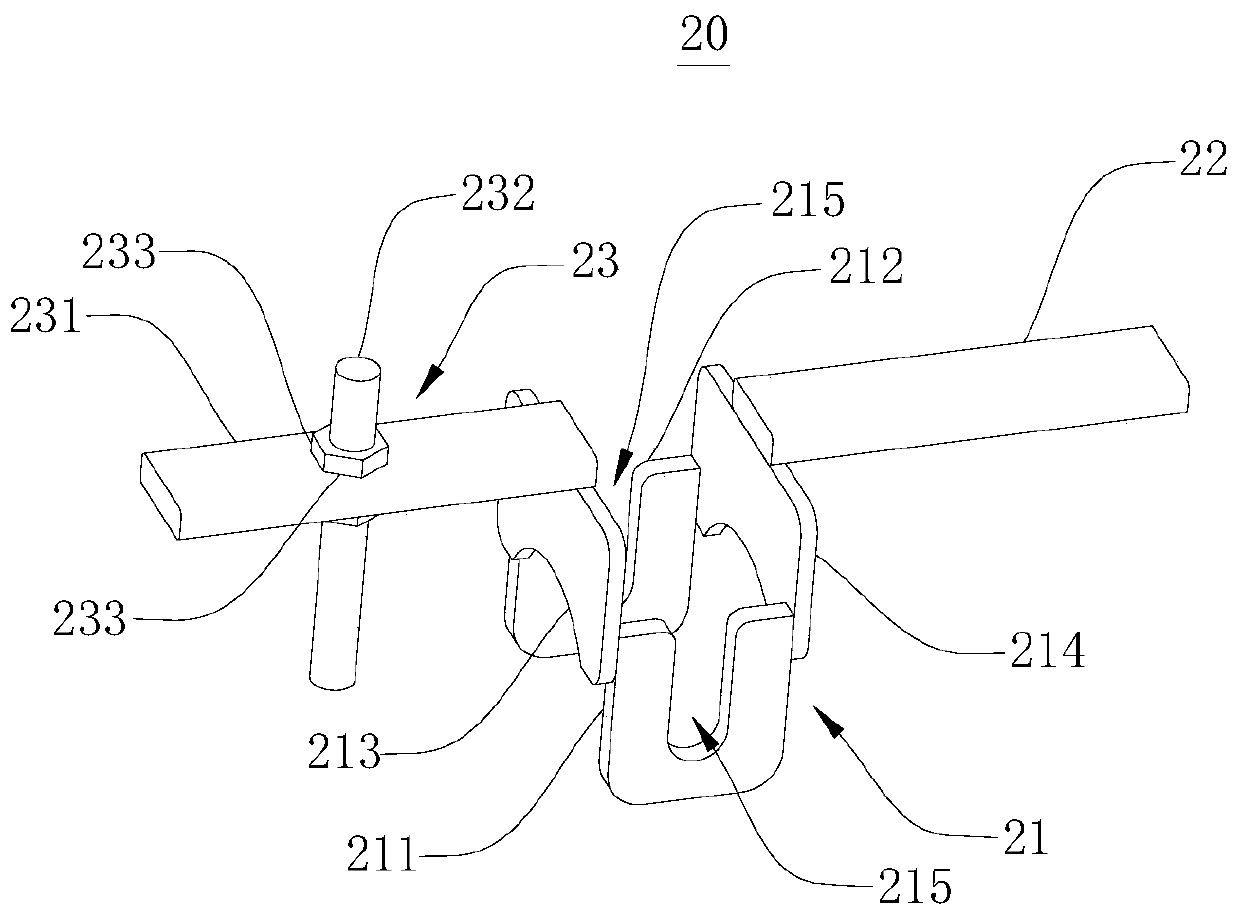

Tunnel inspection robot walking track supporting hanging frame and mounting method thereof

The invention discloses a tunnel inspection robot walking track supporting hanging frame and a mounting method, and belongs to the technical field of tunnel inspection. The supporting hanging frame comprises a main frame body, wherein the main frame body comprises a U-shaped frame and fixing parts, the number of the fixing parts is two, the fixing parts are symmetrically arranged at the ends, faraway from the bottom of the U-shaped frame, of the two vertical sides of the U-shaped frame, one ends of the fixing parts face the inner side of the U-shaped frame, arc-shaped grooves are formed in the ends, facing the inner side of the U-shaped frame, of the fixing parts, and a plurality of threaded holes are formed in the bottoms of the arc-shaped grooves. The supporting hanging frame has the advantages that the structure is simple, the manufacturing cost is low, use is convenient, mounting is convenient and fast, fixation is firm, and the stability is good. The mounting method is convenientto operate, high in mounting efficiency, and high in mounting precision and stability as well.

Owner:YUNNAN POWER GRID CO LTD KUNMING POWER SUPPLY BUREAU

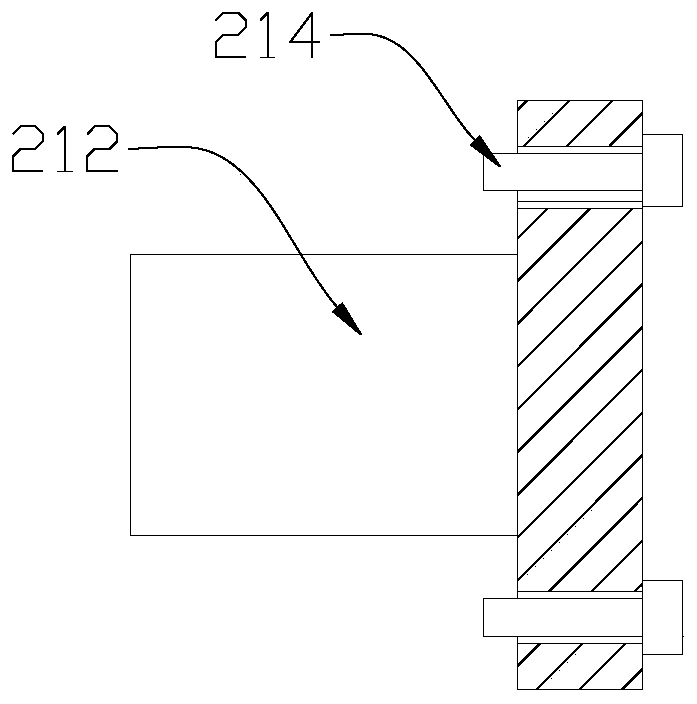

Drilling positioning mold based on clamping piece of transformer

The invention discloses a drilling positioning mold based on a clamping piece of a transformer. The drilling positioning mold comprises a base, a drill bushing template, a positioning baffle board, a bolt fixing seat and an abutting bolt, wherein the drill bushing template, the positioning baffle board and the bolt fixing seat are arranged on the base, a plurality of positioning drill bushing holes are arranged on the drill bushing template, the abutting bolt is arranged on the bolt fixing seat, and a handle is arranged at the rear end of the abutting bolt. By means of the drilling positioning mold, users need not draw lines on each steel channel for positioning, so that time and labor are saved, positions for drilling holes are accurate, the steel channel is simple to clamp, only one person is required for rapidly completing the hole drilling progress, and production efficiencies are greatly improved.

Owner:山东沂蒙电力设备有限公司

Steel pipe machining device based on PLC control

InactiveCN110711876AAvoid shakingAccurate locationPositioning apparatusMetal working apparatusSteel tubeProcessing accuracy

The invention discloses a steel pipe machining device based on PLC control. The steel pipe machining device comprises a supporting seat, a fixing part arranged on the supporting seat, a screw rod connected with the fixing part, two limiting parts sequentially distributed in the length direction of the screw rod, multiple supporting parts sequentially distributed in the circumferential direction ofthe screw rod, a drill bit and a power part used for driving the drill bit to drill a steel pipe. Each limiting part comprises a threaded block in threaded connection with the screw rod, and a rotating block rotationally connected with the threaded block. Each supporting part comprises two connecting parts and an ejection plate, wherein the two ends of the ejection plate are in pivot connection with the rotating blocks in the two limiting parts through the two connecting parts. The steel pipe machining device can be used for conducting drilling machining on the steel pipe effectively, the precision is high, and the effect is good.

Owner:COLLEGE OF APPLIED SCI JIANGXI UNIV OF SCI & TECH

Drilling device for auto part processing

InactiveCN108637299AEasy to drillImprove efficiencyFeeding apparatusPositioning apparatusEngineeringThreaded rod

The invention discloses a drilling device for auto part processing. The drilling device comprises a base, wherein the left and right sides of the upper surface of the base are fixedly connected with brackets, the middle of the upper portion of each bracket is internally in threaded connected with a threaded rod, the number of the threaded rods is two, one point of the inner side of each threaded rod is slidably connected with a shaft sleeve, the surface of the other side of the corresponding shaft sleeve is fixedly connected with a stationary fixture, the surface of the other side of the corresponding stationary fixture is fixedly provided with a rubber pad, one end of the outer side of each threaded rod is fixedly provided with a handle, the upper end of each bracket is fixedly connectedwith a fixing rod, the upper ends of the fixing rods are fixedly provided with a connecting rod, and the left and right sides of the lower surface of the connecting rod are provided with telescopic motors. The drilling device for the auto part processing has the advantages that the drilling position of a part can be adjusted by adjusting the distance between the two stationary fixtures, so that the drilling position can be more accurate, a drill can move vertically through the control of the telescopic motors, so that the drilling of the drill is more convenient, the efficiency is higher, andthe practicability is high.

Owner:合肥岑遥新材料科技有限公司

Oral stationary planting guide plate

The invention discloses an oral stationary planting guide plate, and relates to the technical field of oral planting. The oral stationary planting guide plate comprises a substrate, a plurality of installation holes are formed in the substrate, a positioning ring is embedded coaxially in the installation hole, a ring gap is formed in one side, far from the inner concave surface of the substrate, of the positioning ring, a plate gap corresponding to the ring gap in the same direction is formed in the side wall of the substrate, a fixing plate is connected onto one side of the inner concave surface of the substrate in an inserting way, an intraoral fulcrum bar is hinged to one side of the fixing plate, and a regulating fulcrum bar is hinged to the intraoral fulcrum bar. The substrate sleevesthe alveolar ridge, the intraoral fulcrum bar is abutted against the inner side of the oral cavity by pushing the regulating fulcrum bar, then the oral cavity of a patient is gradually expanded, andthe adjustability is high; due to the ring gap and the plate gap, a drill bit also conveniently enters the positioning ring transversely, the patient can also keep the mouth open for a long period oftime while the head part of the patient rotates, and the controllability is high. The fixing plate and the substrate are separately arranged, the substrate is specially made according to the alveolarridge of the patient, the fixing plate and the parts are universal with the substrate, and the universality is high.

Owner:上海臻威医疗器械有限公司

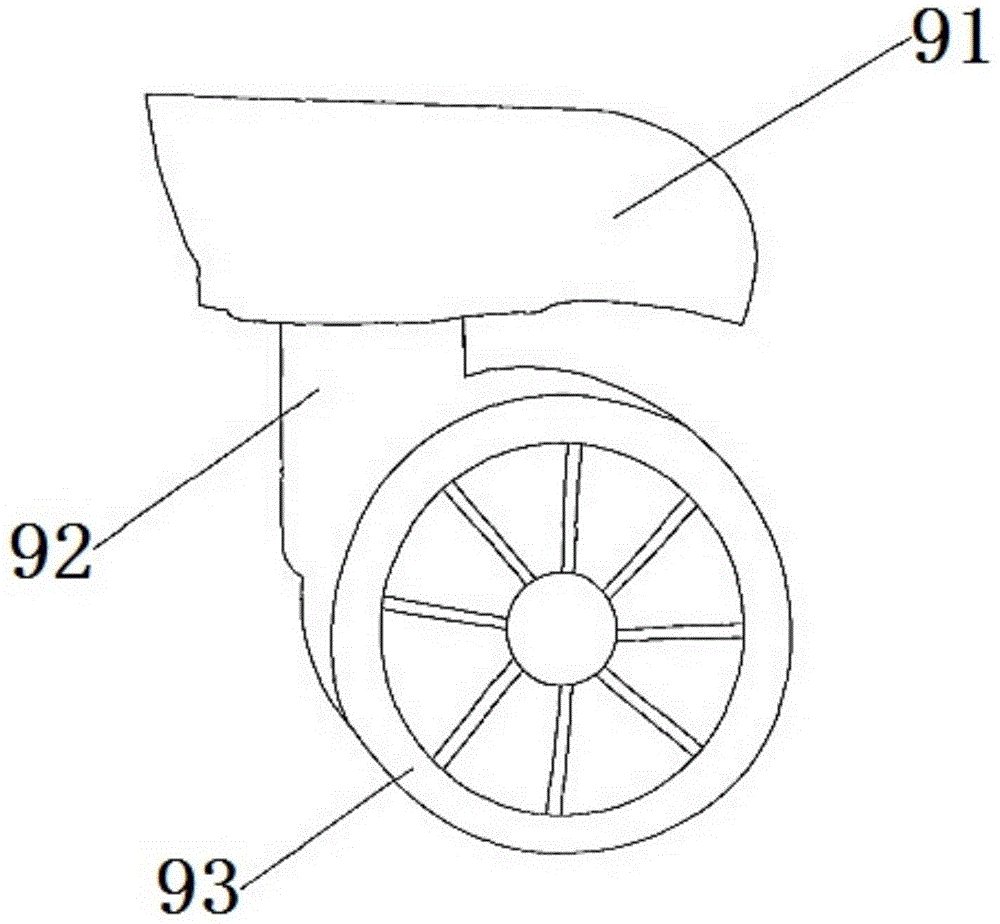

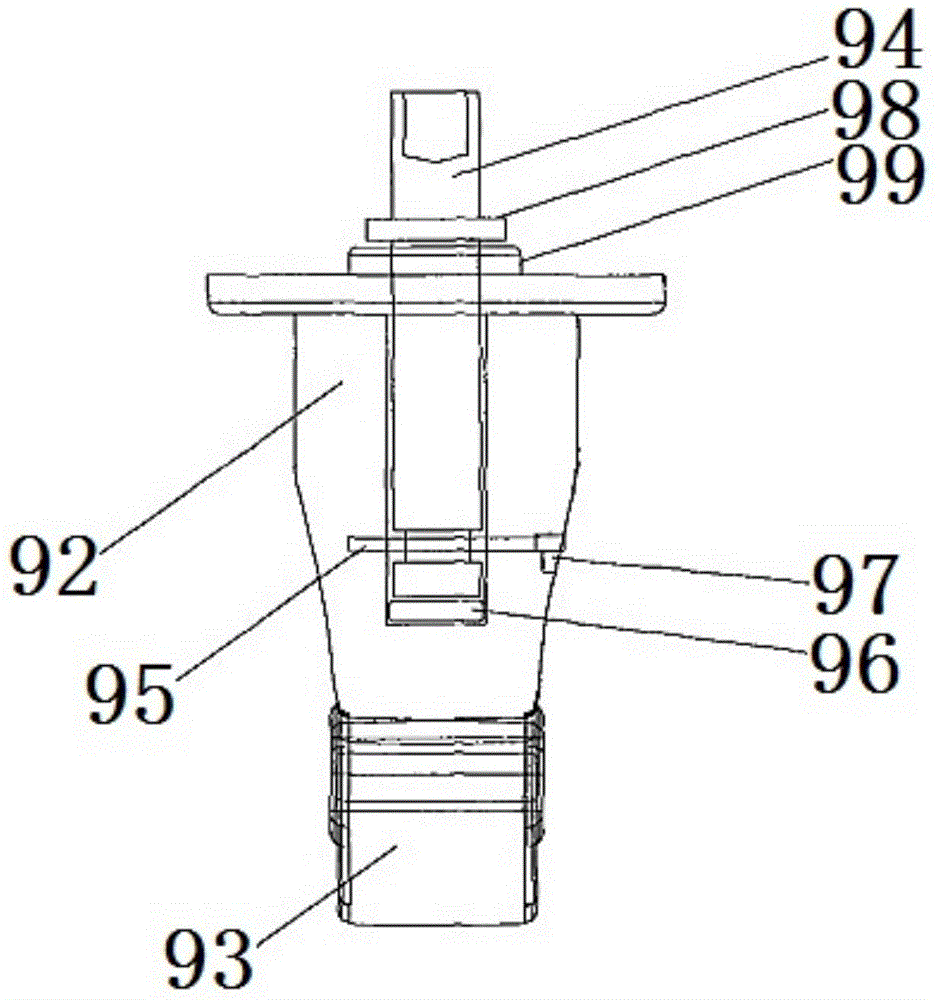

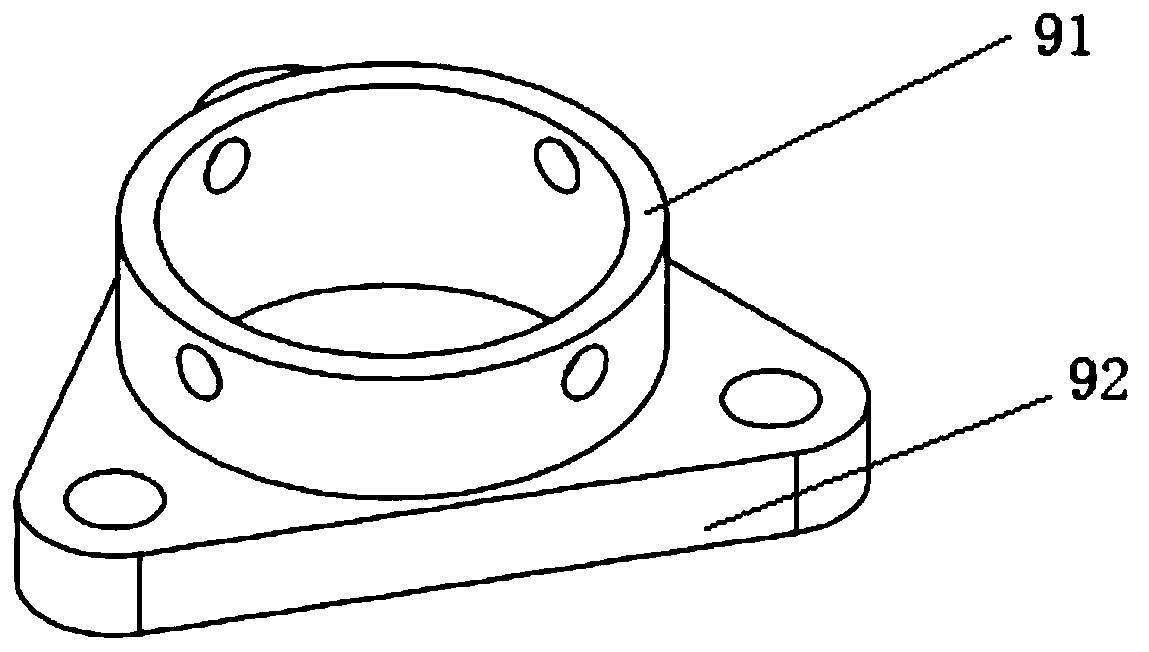

Bearing drilling device

InactiveCN104959656AHigh positioning accuracyImprove drilling efficiencyBearing componentsDrill jigsDrillRivet

A bearing drilling device comprises a base. The base is provided with a core shaft. A hub bearing is fixed to the core shaft. A drill template is arranged on the upper end face of the hub bearing. The drill template is fixed through a nut. A drill template handle is arranged on one side of the drill template. A base handle is arranged on one side of the base. Universal wheels are arranged at the bottom of the base and include wheel shells, supports and wheel bodies and further include rivets and lock pieces. Inserting holes are formed in the bottom faces of the wheel shells. The supports are provided with inserting grooves. The bottom ends of the rivets penetrate through the inserting holes and stretch into the inserting grooves. Friction plates are arranged between the bottoms of the inserting grooves and the bottom ends of the corresponding rivets. First through holes are formed in the parts, located in the inserting grooves, of the rivets. Fixing grooves and second through holes are formed in the left side walls and the right side walls of the inserting grooves respectively. Grooves are formed in the outer side walls of the supports and communicated with the second through holes. The second through holes are communicated with the first through holes. The first through holes are communicated with the fixing grooves. The right ends of the lock pieces are clamped in the grooves. The left ends of the lock pieces penetrate through the second through holes and the first through holes in sequence and are located in the fixing grooves.

Owner:ANHUI QIANSHAN BEARING MFG

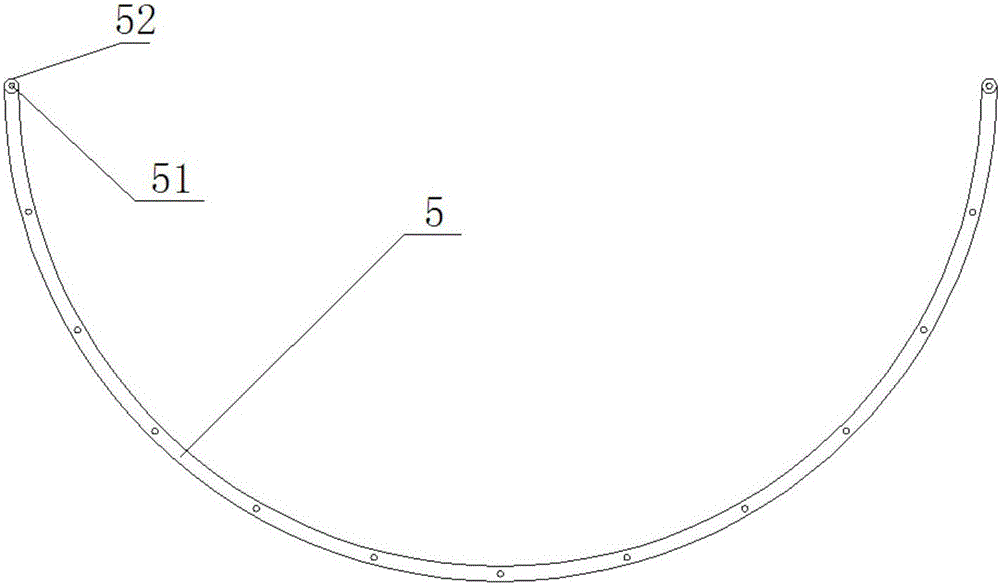

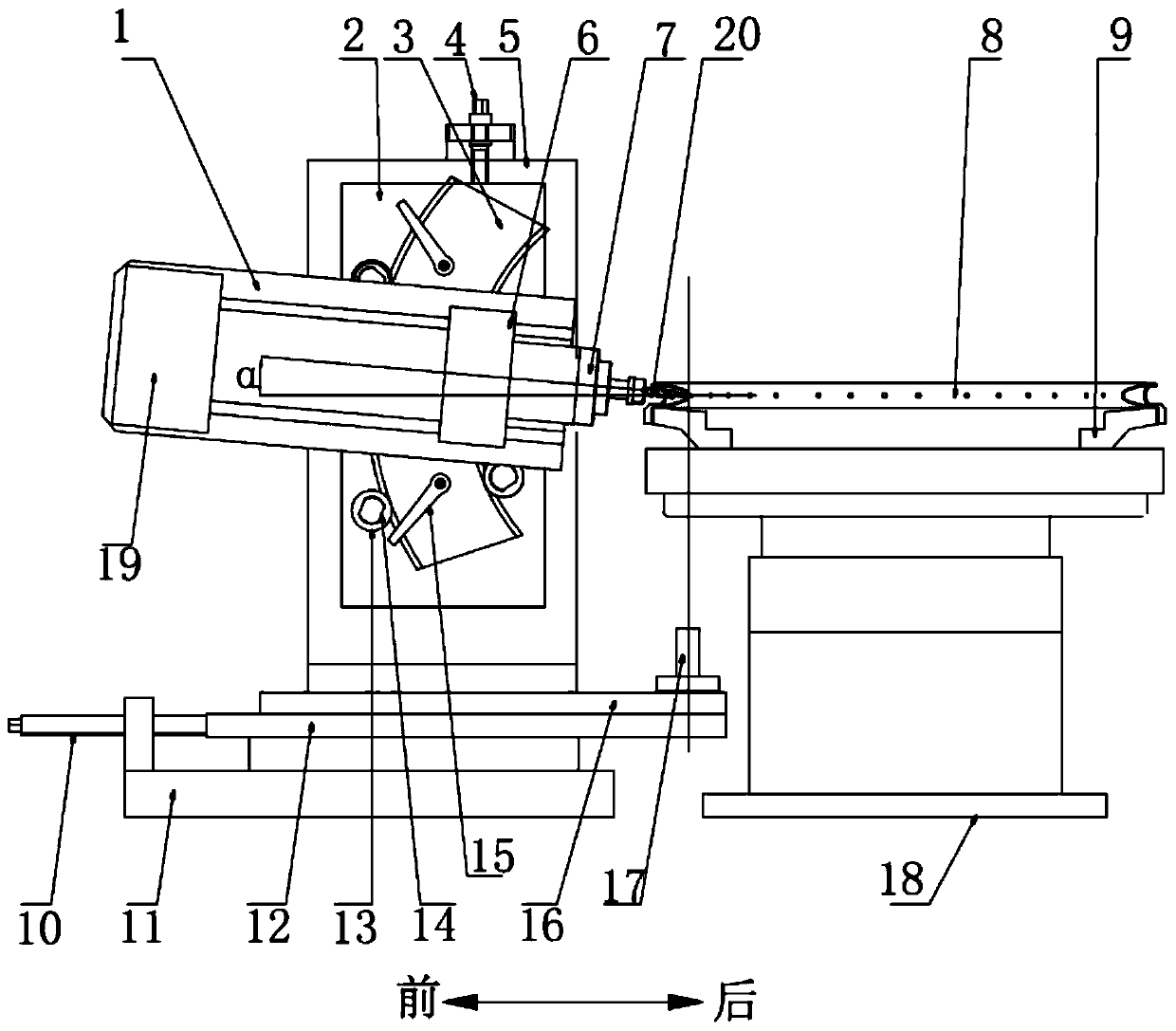

Machining method for semicircular batten

The invention provides a machine method for a semicircular batten. The machining method includes the following steps that a blank is fixed to a floor-type lathe through a clamp A, and after a circle of batten is formed through turning, the batten is cut off according to sizes; connecting holes are drilled in the two ends of the batten correspondingly, and butt-joint steps and butt-joint arcs are formed through milling; and circular holes distributed in the semicircular batten are drilled. According to the method, through holes are formed in the blank in advance, then the blank is fixed to the clamp A which is fixed to the floor-type lathe through screws, and the evenly-distributed screws can effectively prevent the blank from deforming in the turning process; a numerical control milling machine is used for precisely machining the connecting holes, the butt-joint arcs and the butt-joint steps, and then a drilling clamp B is used for ensuring accurate drilling positions, so that technical requirements of a drawing are met.

Owner:GUIZHOU ZUNYI CHI YU PRECISION MACHINERY MFG

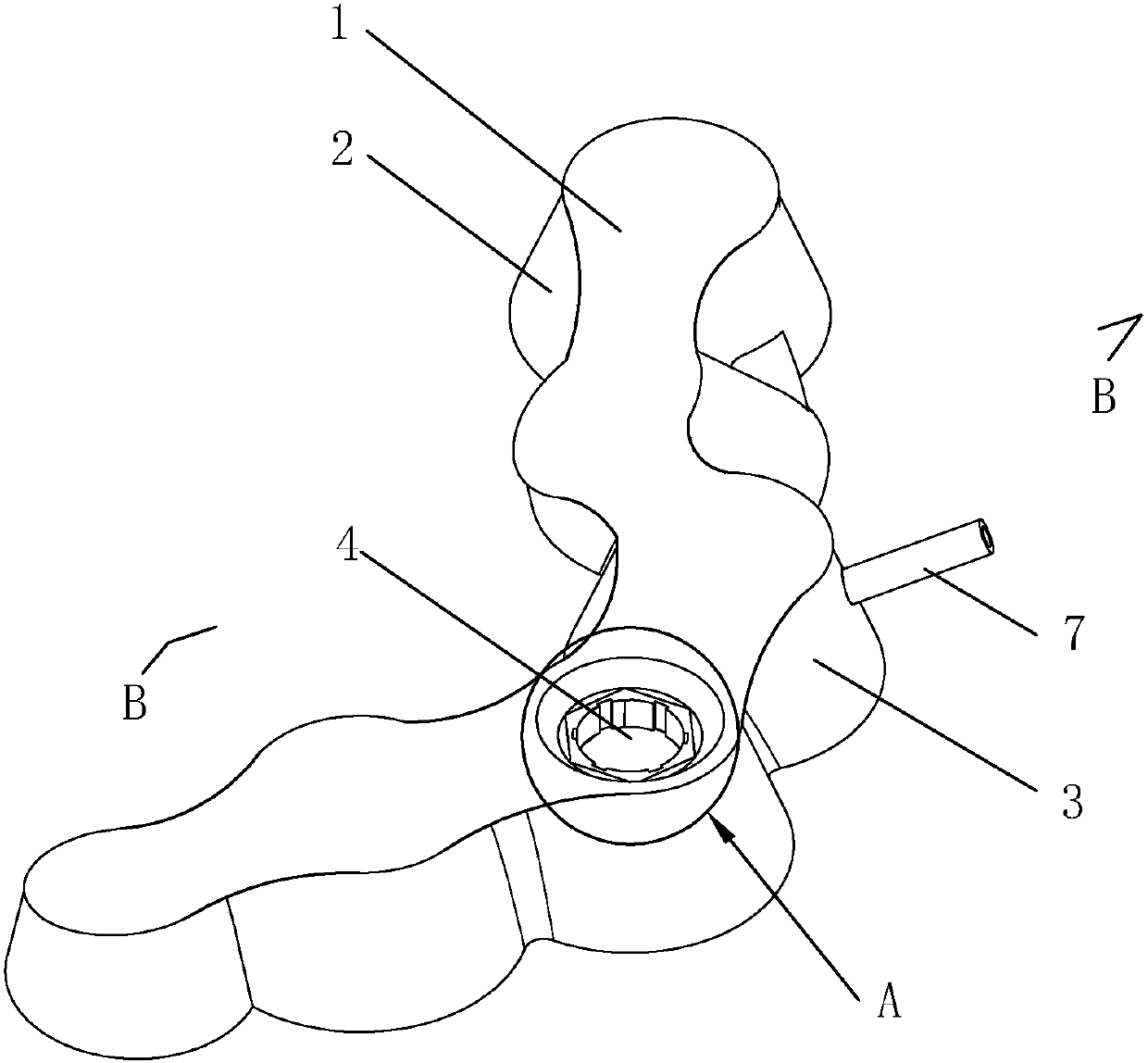

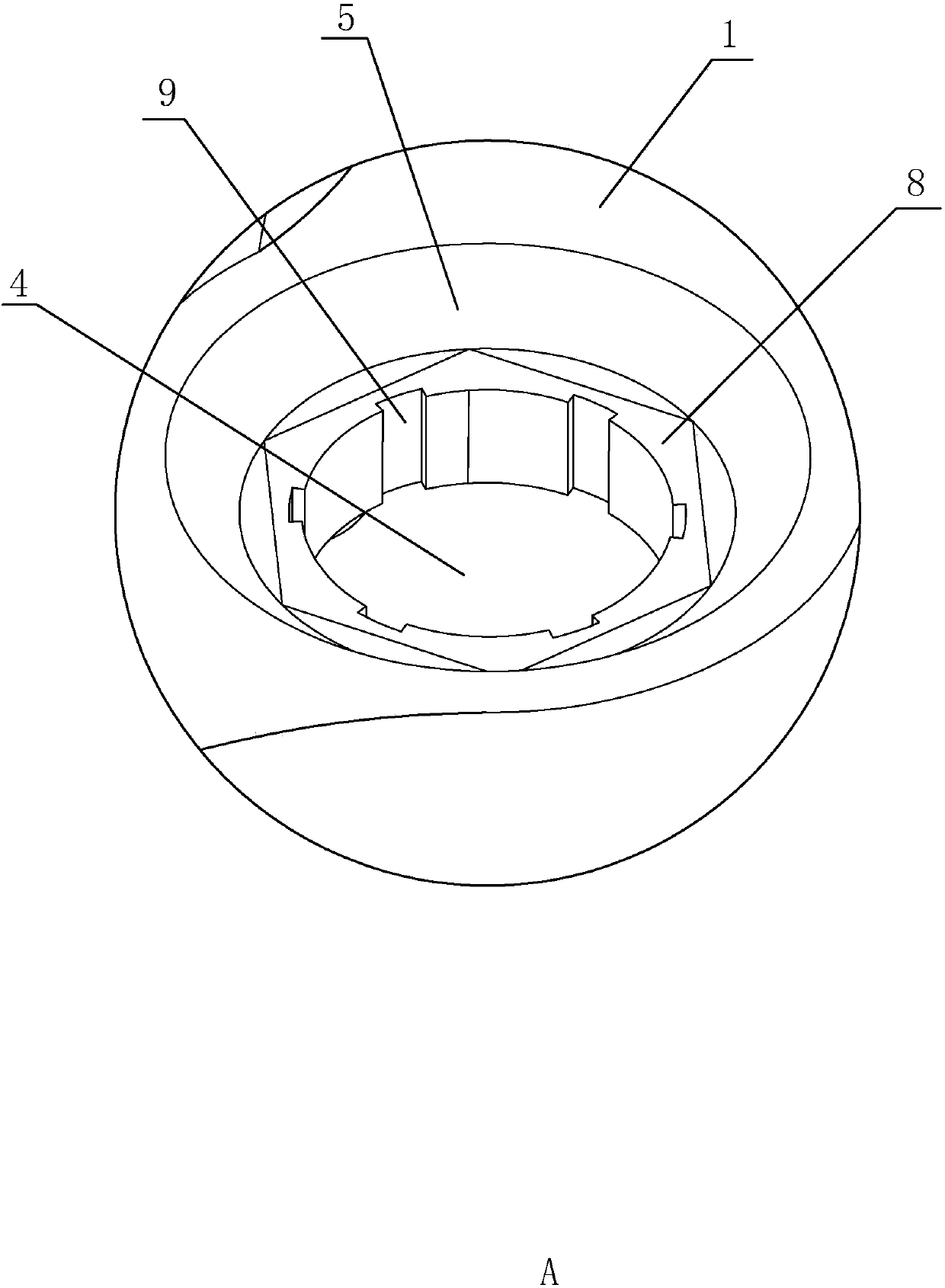

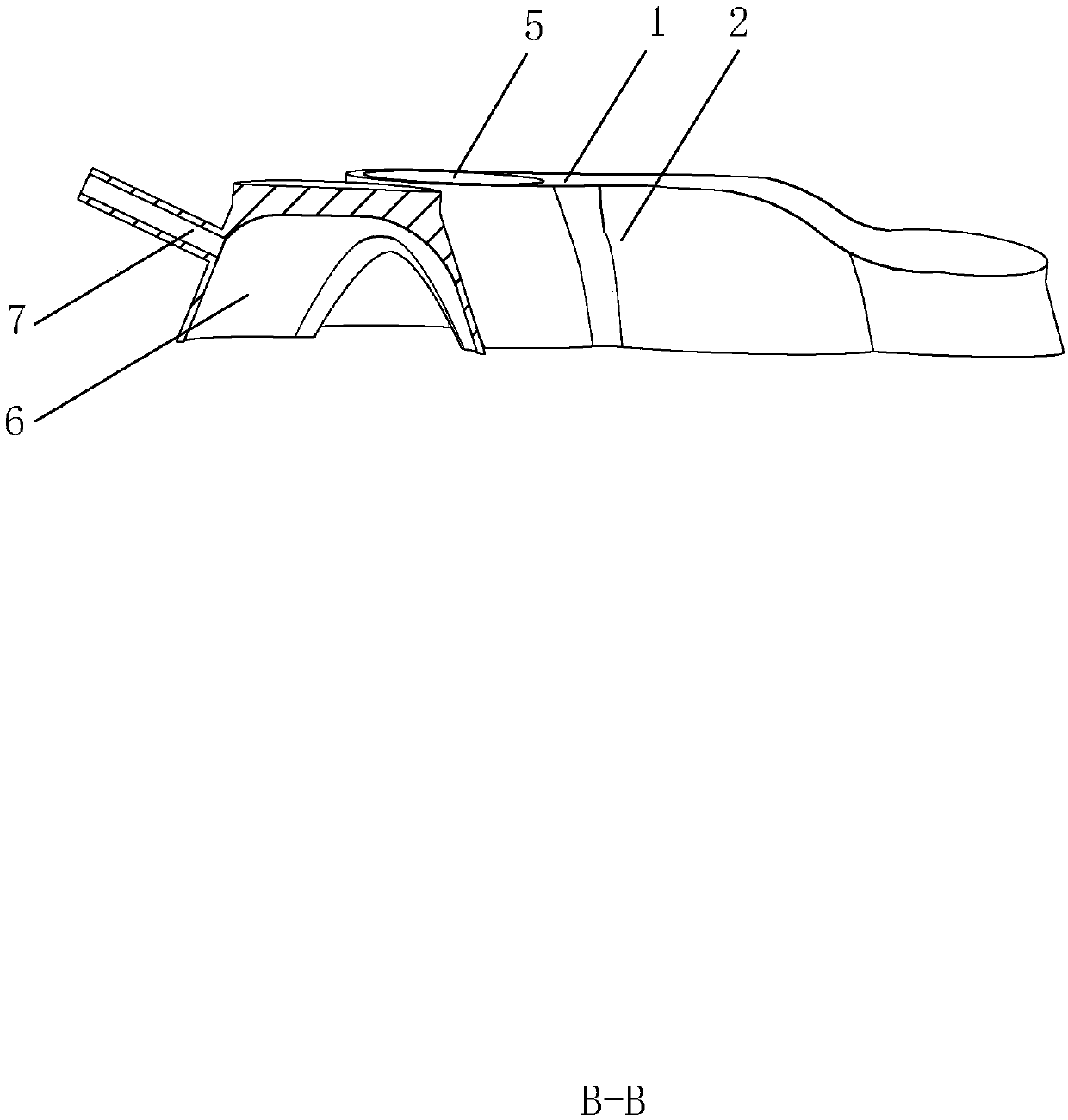

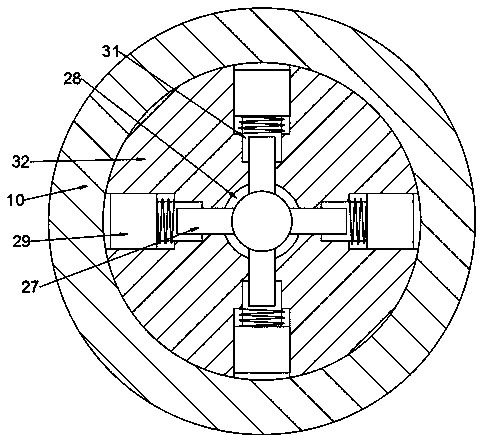

A quick-release slip drilling template

The invention relates to a drilling jig for drilling on a quick-release slip. The drilling jig comprises a clamp body, a lower lining tile, a gland, an upper lining tile, a lining column, a drilling jig plate and a drill bushing, wherein grooves are arranged on the clamp body and the gland, bosses are correspondingly arranged on the lower lining tile and the upper lining tile in the circumferential direction, the lower lining tile and the upper lining tile are closely fitted and embedded in the grooves of the clamp body and the gland respectively, one end of the gland is connected with one side of the clamp body through a hinge pin, a U-shaped port is arranged at the other end of the gland, a flat head bolt and a compression nut are used for connection, the lining column is tightly clamped between the lower lining tile and the upper lining tile, screw holes and pin holes are arranged on the side surfaces of the upper lining tile and the lower lining tile, a countersunk hole and a pin hole are correspondingly arranged on the drilling jig plate and fixed with the upper lining tile and the lower lining tile respectively through a screw and a positioning pin, and a drill bushing is fixedly mounted on the drilling jig plate. The drilling jig is reasonable in structure, simple for manufacturing and convenient for mounting and clamping, and can realize drilling of circular holes on the clamp body and the inner edge of the gland; furthermore, the positions of the drilled holes are accurate, and the drilling jig is suitable for the quick-release slips and can be applied to quick changeovers.

Owner:TIANRUN IND TECH CO LTD

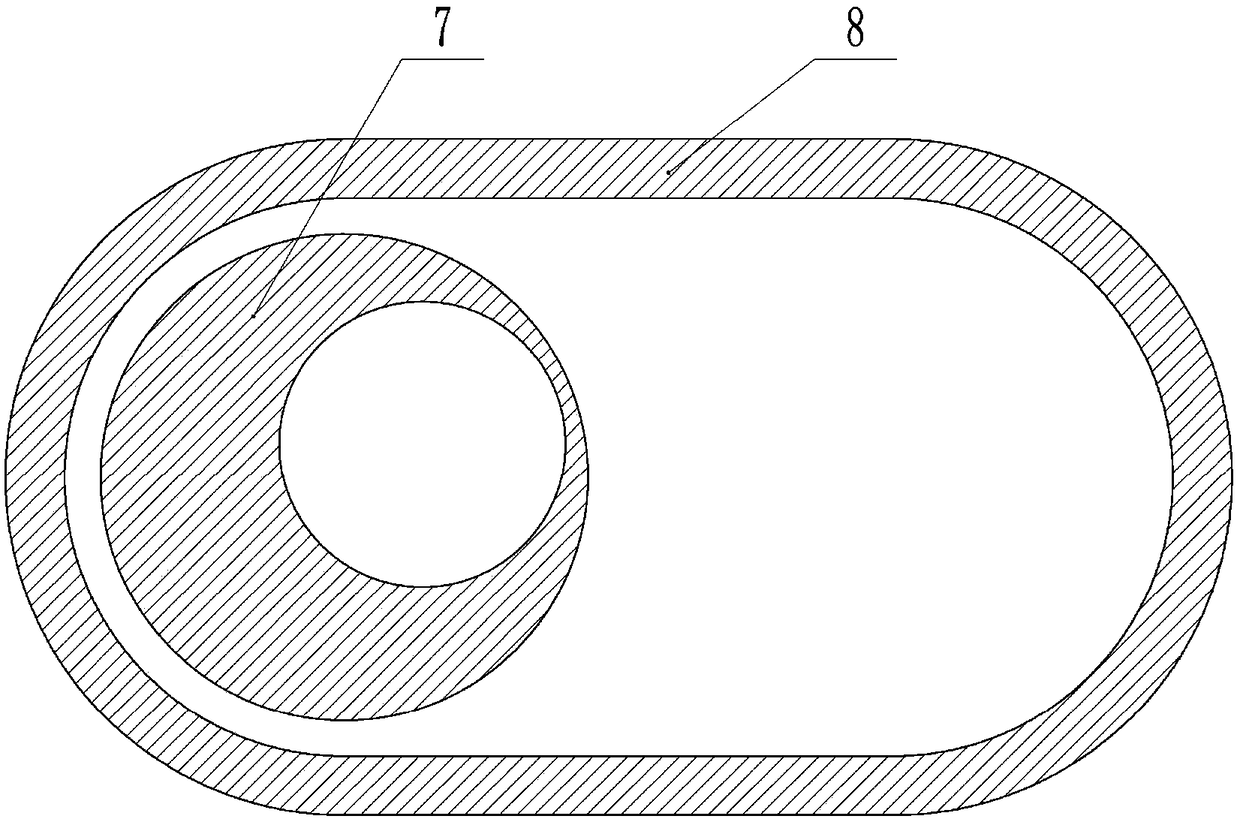

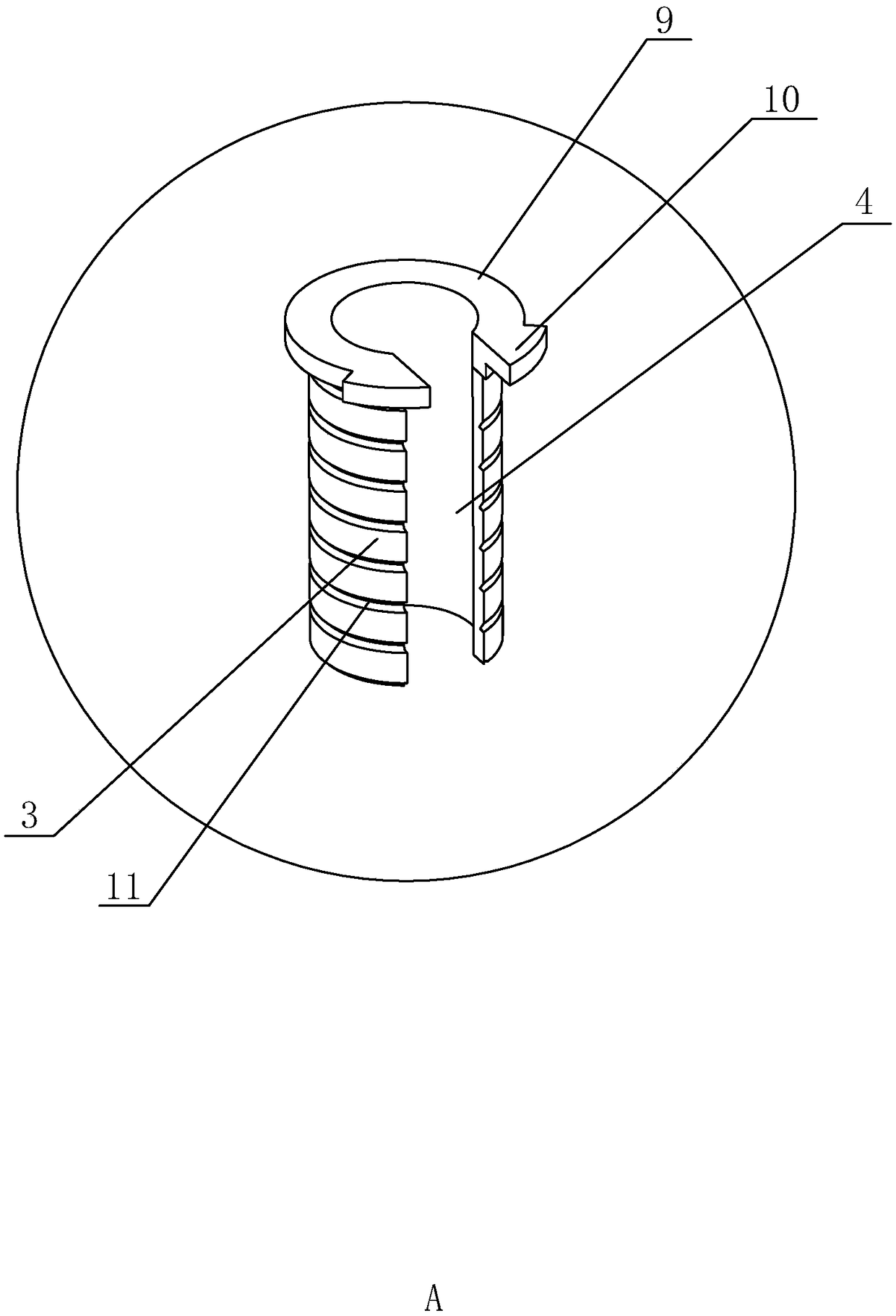

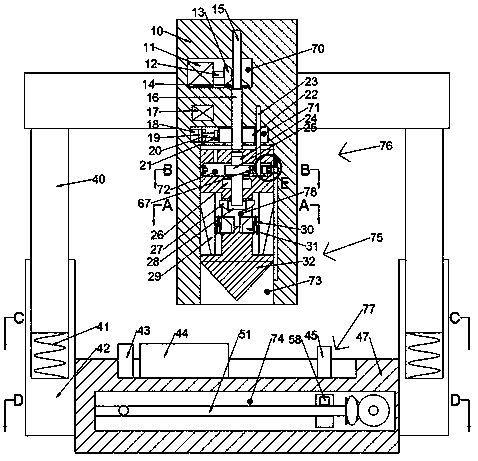

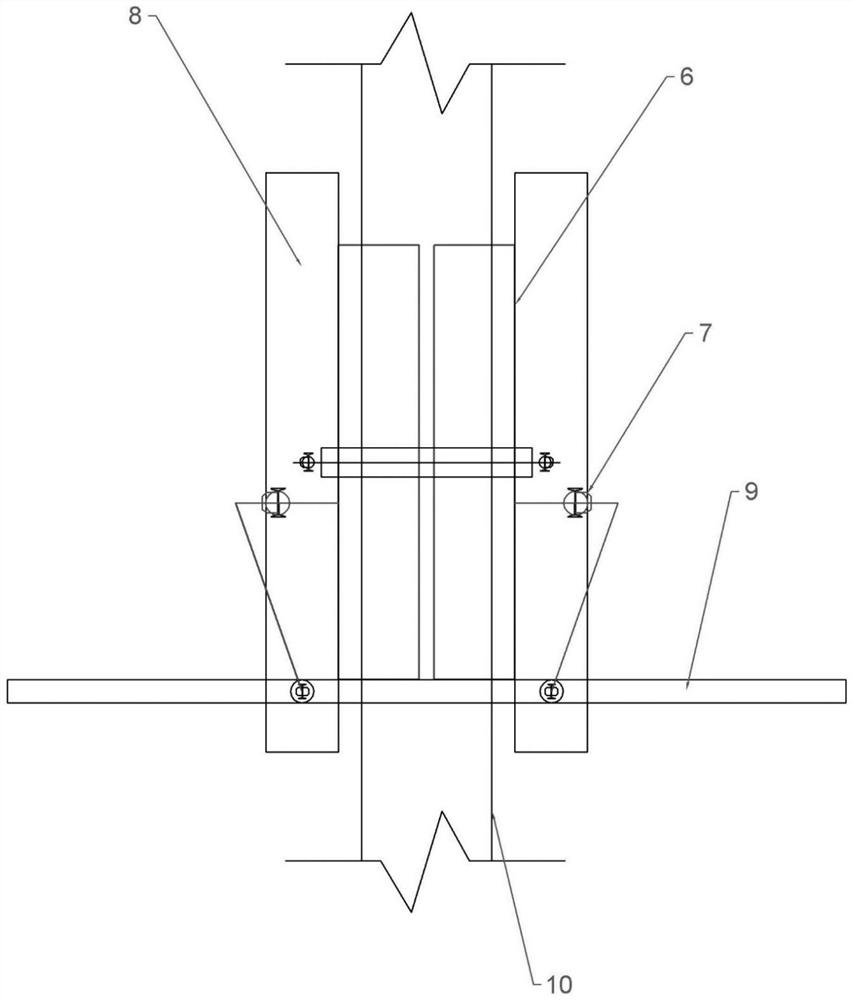

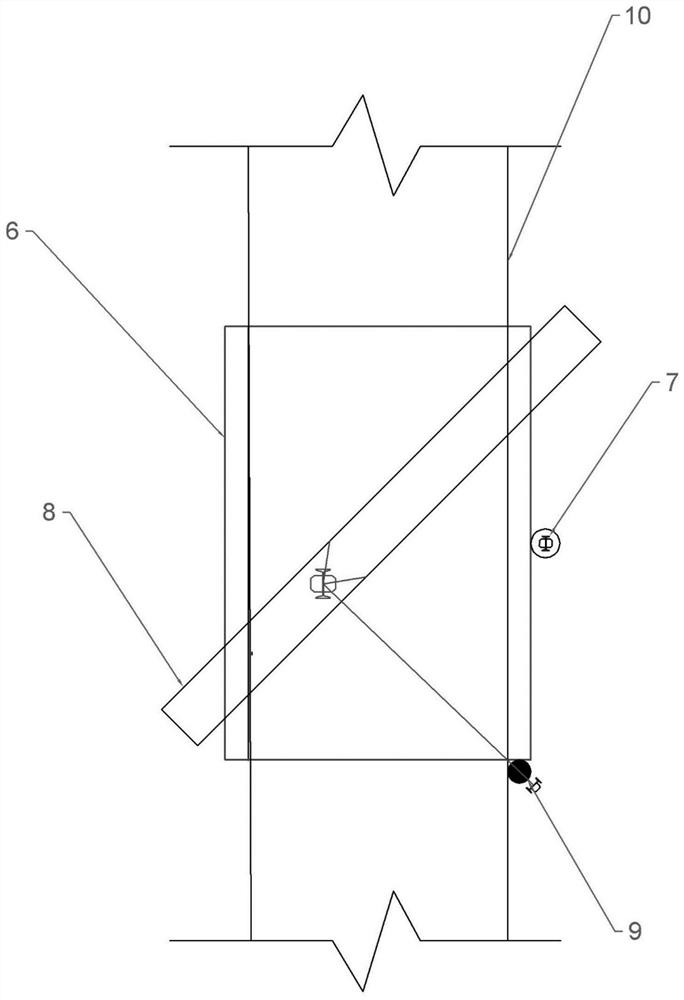

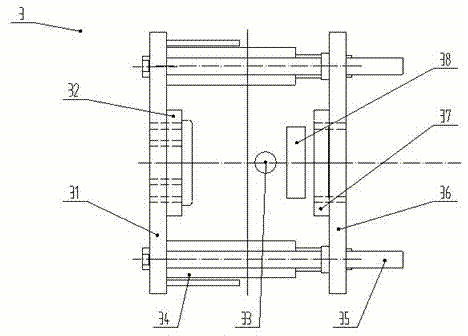

Outer ring machining method of precise angular contact ball bearing and drilling device thereof

InactiveCN108127346AControl variationSmall amount of deformationShaftsBearing componentsBall bearingEngineering

The invention discloses an outer ring machining method of a precise angular contact ball bearing. The outer ring machining method sequentially comprises the following steps of coarsely grinding the end face; coarsely grinding the outer diameter; grinding the outer diameter and the inner diameter;coarselygrinding an outer groove; coarselygrinding a counterbore; additionally conducting tempering; finally grinding the end face;finely grinding the end face; finely grinding the outer diameter; finally grinding the counterbore; finally grinding the outer diameter;finally grinding agroove; conductingultrafine grinding on the groove. The working procedure of finally grinding the counterbore is set after the outer diameter is finely grinded and before the outer diameter is finally grinded, measuring the height of a lock point is converted into measuring the diameter of the counterbore, the change amount of the working procedure is effectively controlled, the deformation amount of the working procedure is reduced, the deformation generating during final grinding of the counterbore can be amended, the flanging phenomenon generated in the junction of the groove during final grinding of the counterbore can be restored, the precision during final grinding of the groove is guaranteed, three working procedures are reduced simultaneously, the work efficiency is improved, a bearing sleeve drilling device is adopted for drilling, the structure is simple, few parts are utilized, the price is low, the drilling and machining position is accurate, a bearing sleeve cannot be deformed, and the drilling quality of the bearing sleeve is improved.

Owner:XINCHANG JIANGBEI BEARING

Glass drilling machine performing firm positioning and clamping

InactiveCN105835239ASimple processHigh degree of automationWorking accessoriesStone-like material working toolsMachine toolMachining

The invention relates to a glass drilling machine performing firm positioning and clamping, and belongs to the technical field of glass machining. The glass drilling machine comprises a machine tool body, a conveying belt arranged on the machine tool body and used for supporting and conveying glass to be drilled, and a drilling machine used for drilling the glass. The glass drilling machine further comprises a displacement unit used for bearing and driving the drilling machine to adjust the drilling position and fixing units used for fixing the glass. Compared with the prior art, the glass drilling device has the beneficial effects that the drilling procedure is effectively simplified, especially, the manual glass moving procedure is reduced, and the mechanical stand column and drilling machine moving speed is much higher than the manual glass moving speed.

Owner:宿州市天艺玻璃股份有限公司

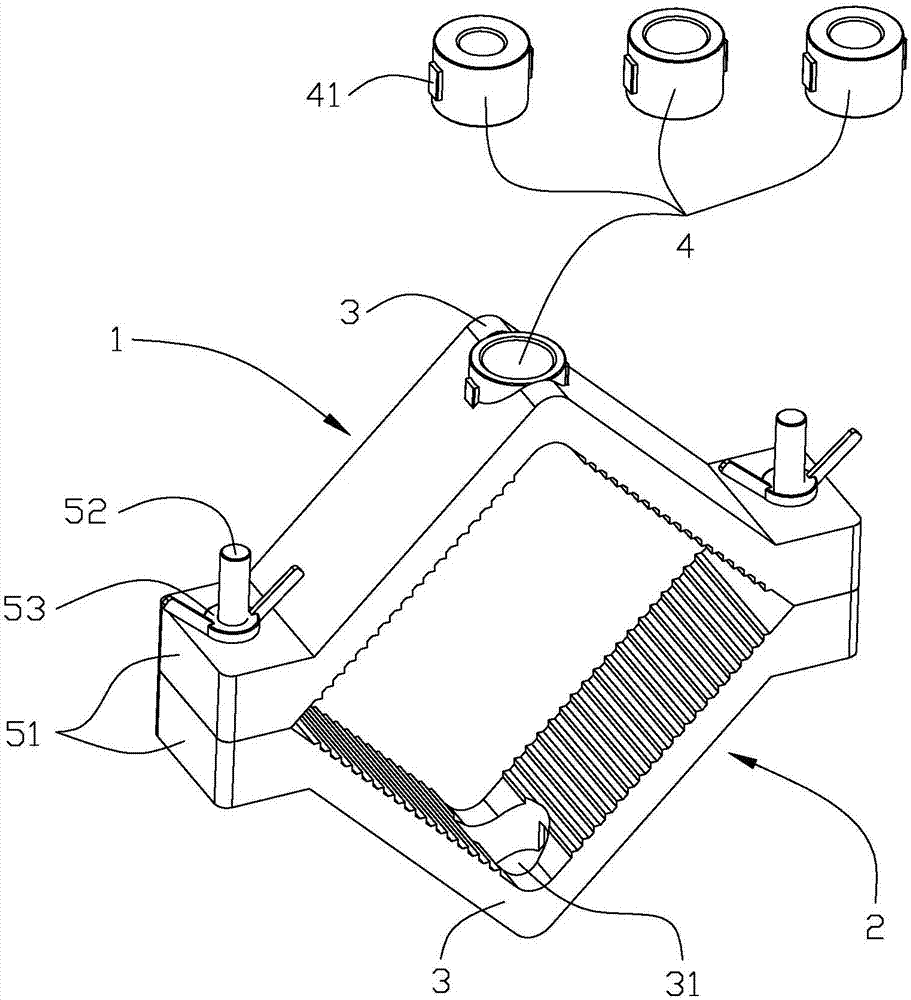

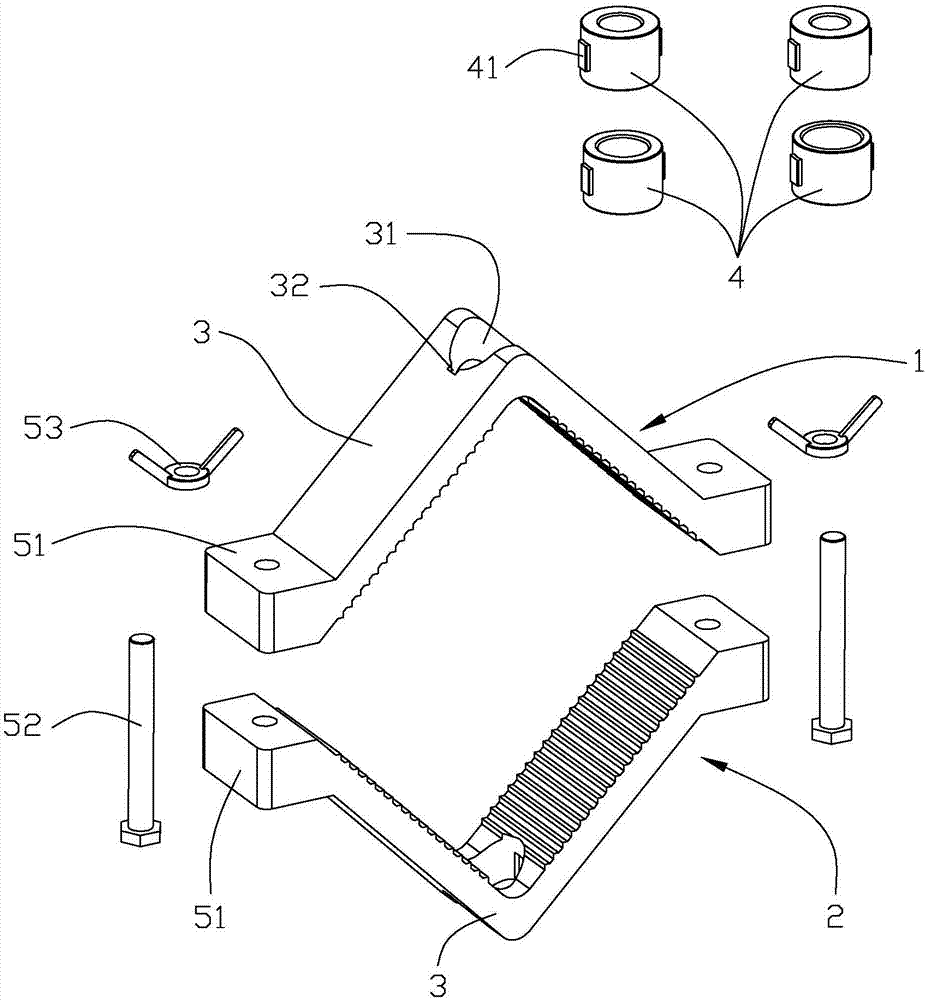

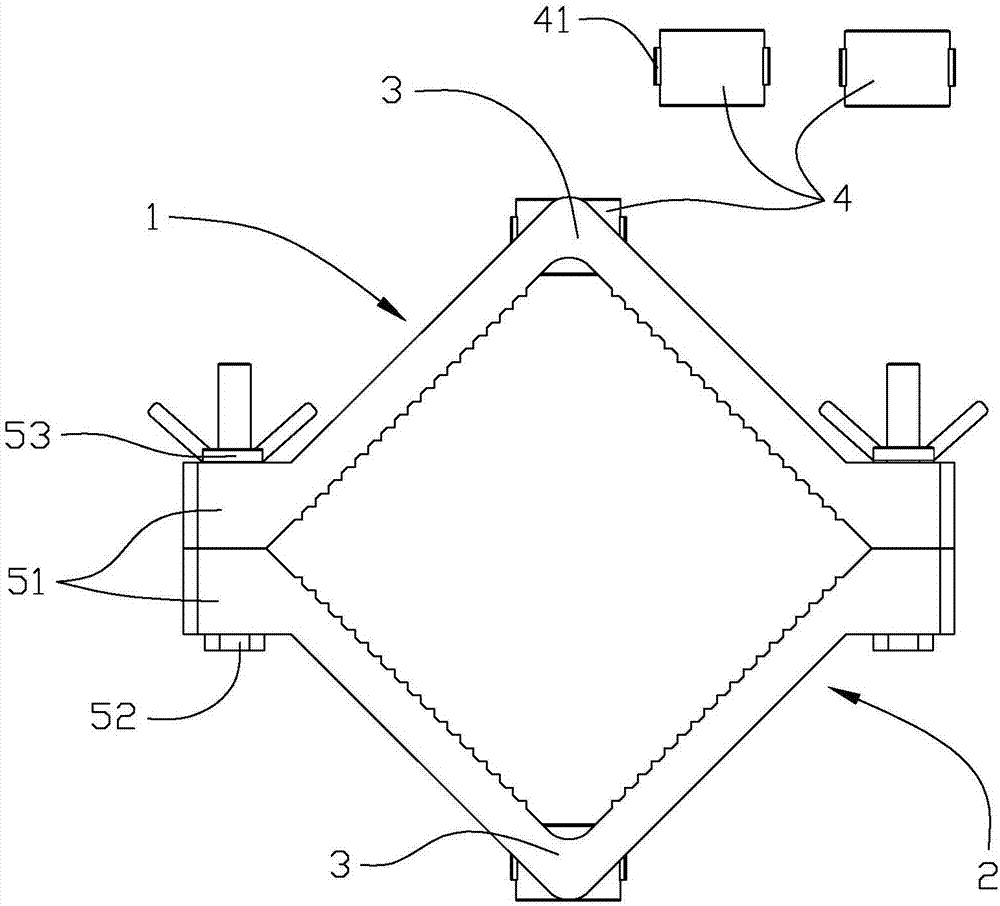

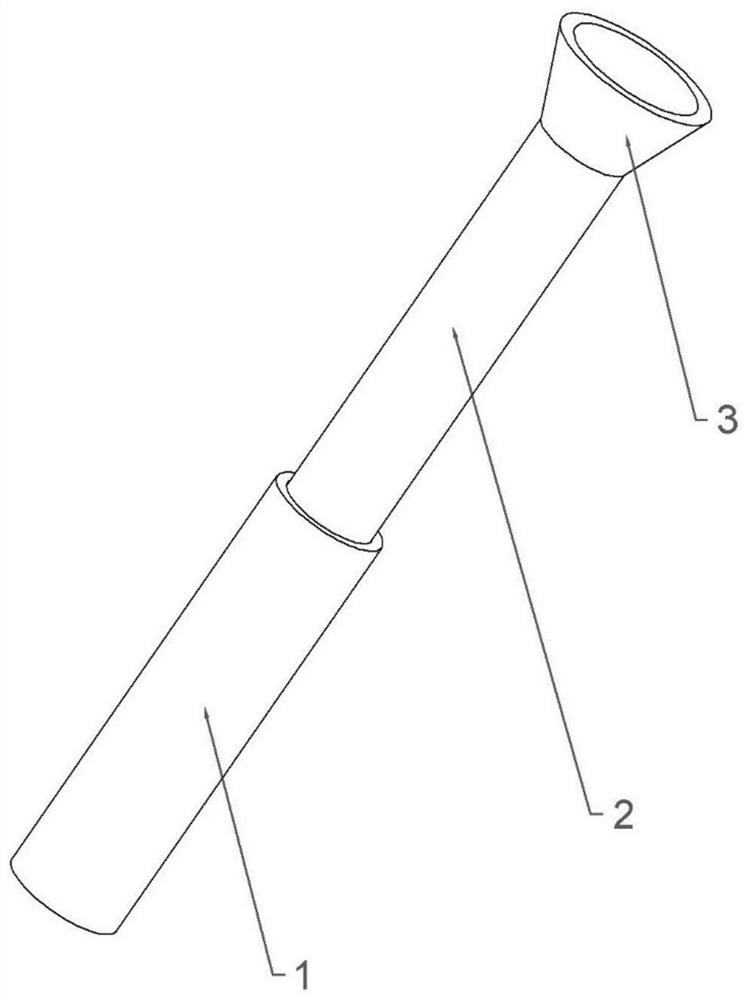

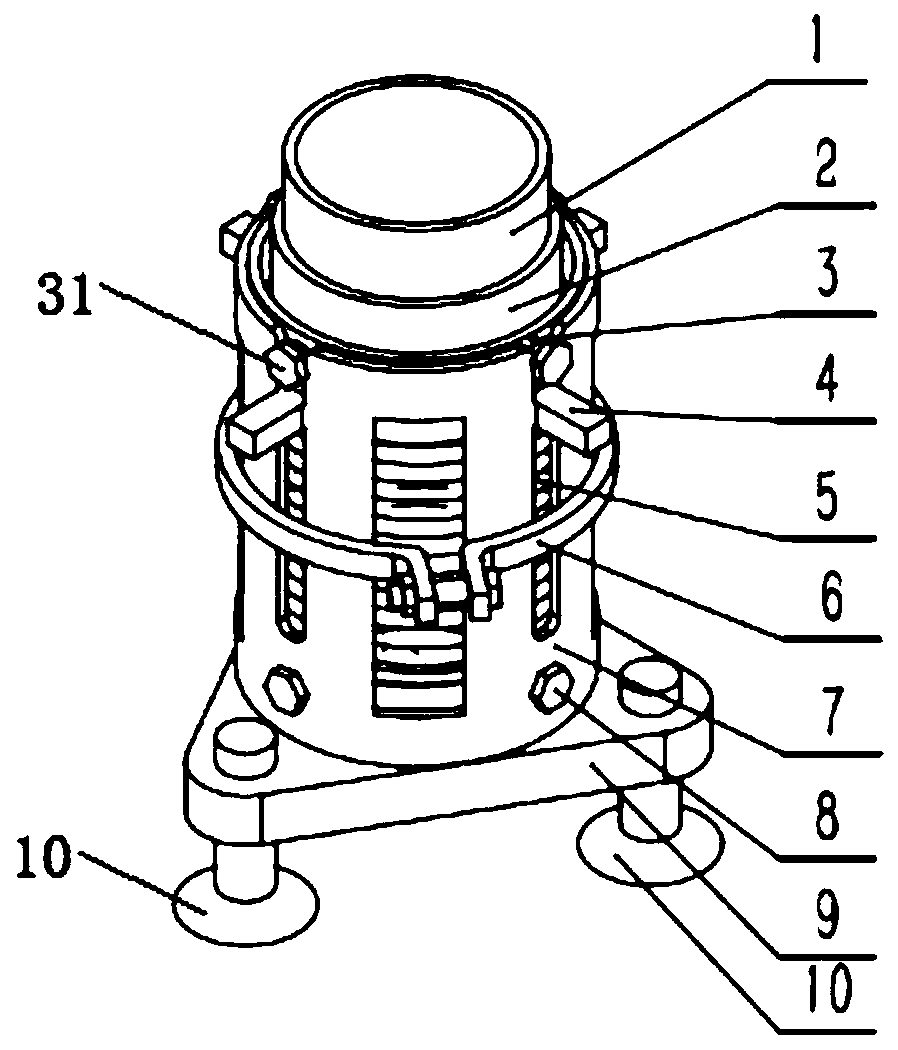

Round pipe drilling assisting device

PendingCN107984259AAccurate drilling positionPrevent deviationDrilling/boring measurement devicesPositioning apparatusDrill bitLocking mechanism

The invention discloses a round pipe drilling assisting device capable of achieving effective clamping, low in cost, capable of performing positioning conveniently and high in reliability. The round pipe drilling assisting device comprises an upper locking component and a lower locking component; the middles of the upper locking component and the lower locking component are provided with clampingplates which are bent to be right-angled; the two clamping plates are arranged oppositely to form a square hole for clamping a round pipe; the inner side faces of the clamping plates are provided withantiskid lines; locking mechanisms are arranged at the left ends and the right ends of the upper locking component and the lower locking component so that the upper locking component and the lower locking component can tightly clamp the round pipe; the clamping plate of the upper locking component is provided with a drilling fixing groove which is in the right angle center parting line of the clamping plate; and a plurality of drilling guide sleeves are detachably connected in the drilling fixing groove and provided with inner holes allowing a drill bit to penetrate through, and the inner holes are of different sizes. By means of the round pipe drilling assisting device, the defect that the drill bit is prone to slipping on the round pipe and cannot be well positioned when a worker drillsthe round pipe currently is eliminated, no waste is generated, and the production cost is reduced.

Owner:FOSHAN UNIVERSITY

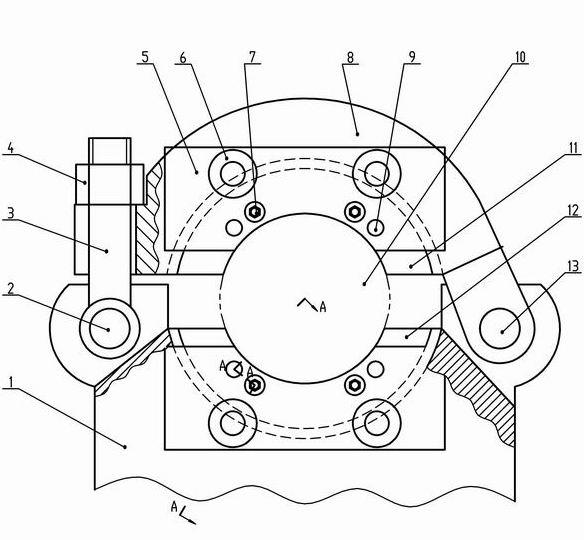

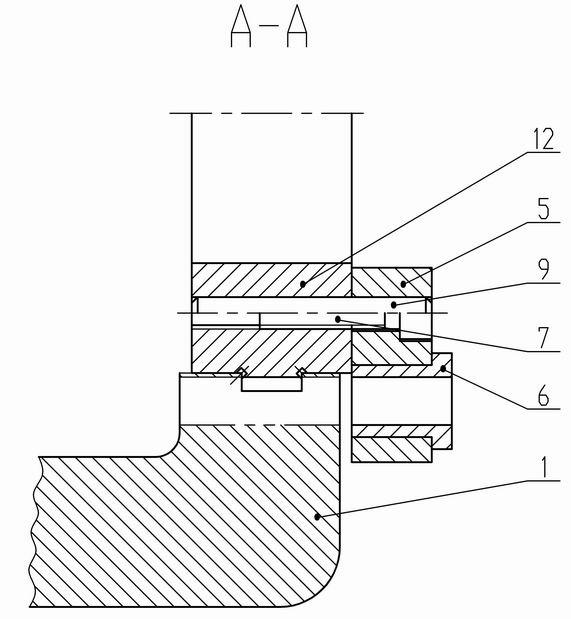

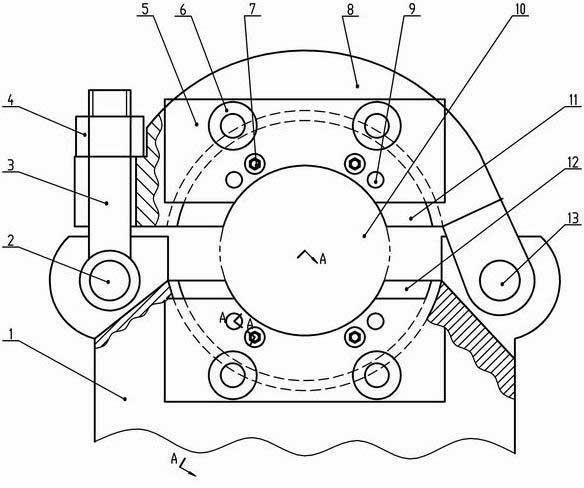

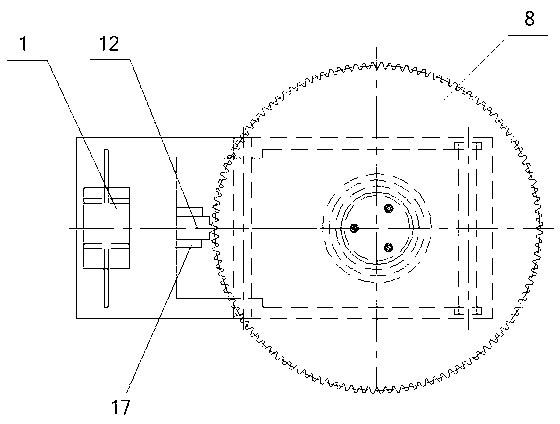

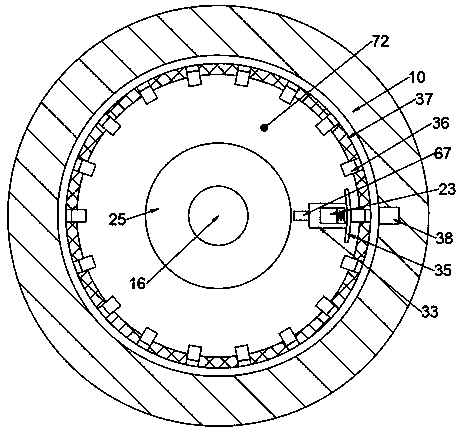

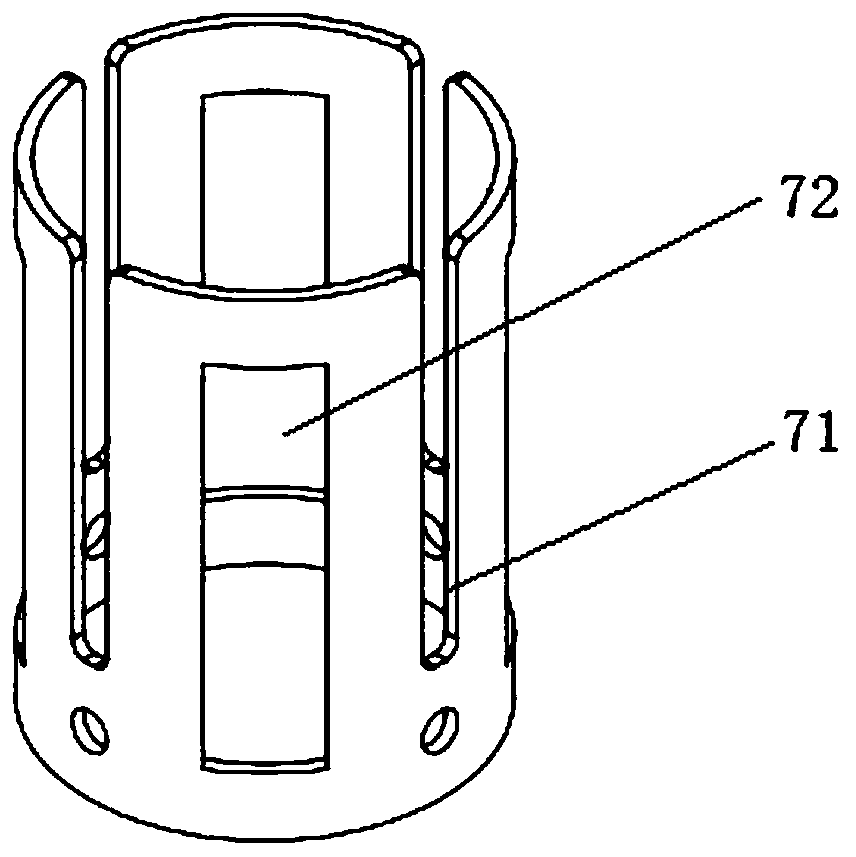

General drilling mould for hub of drum-type rotating sieve

A general drilling mould for a hub of a drum-type rotating sieve comprises a base, an index gear and a mandrel. The general drilling mould is characterized in that one end of a body is hinged on the base, the rotatable mandrel is mounted on the body, the index gear is positioned above the body and fixed on the mandrel, a thrust bearing and a nut are assembled at the lower end of the mandrel, the upper end of the mandrel is connected with a press plate through a bolt, the other end of the body is connected with a toothed positioning block in a sliding mode, a stirring groove is formed in the tooth-shaped positioning block, the stirring pin is arranged on a rotating piece connected with a handle, and the stirring piece is inserted into the stirring groove of the tooth-shaped positioning block. A positioning sleeve is mounted on the mandrel in a sleeved manner. Sizing blocks in different sizes are provided and are disposed on the base to fix turning angles of the body. Special drilling templates of different types are provided and are connected at one end of the base through bolts. The general drilling mould is adaptive to processing needs on hubs with different bore diameters of drum-type rotating sieves, the turning angles can be adjusted and can be equally divided into multiple angles, equally-divided angles are accurate, drilling positions are accurate, the general drilling mould is simple and convenient to process and operate and labor-saving, processing time is greatly shortened, and processing efficiency is obviously improved.

Owner:CHINA ENERGY ENG GRP SHENYANG ELECTRIC POWER MACHINERY GENERAL FACTORY CO LTD

Assembly for assisting tooth implantation in posterior tooth area

The invention discloses an assembly for assisting tooth implantation in a posterior tooth area, and belongs to the technical field of medical articles. The assembly for assisting tooth implantation inthe posterior region comprises a fixing assembly, a position-limiting assembly and a sleeve assembly, wherein the fixing assembly comprises a first clamping block and a second clamping block which are arranged oppositely, the top of the first clamping block is connected with the top of the second clamping block through an arch-shaped connecting assembly, the top of the connecting assembly is provided with a sliding hole, the position-limiting assembly comprises a clamping assembly, and a sliding block and a supporting assembly which are respectively arranged on two sides of the top of the clamping assembly, the sliding block penetrates the sliding hole and is in sliding fit with the sliding hole, the sliding block is fixedly connected with the connecting assembly, and the sleeve assemblyis connected with the clamping assembly. In the assembly for assisting tooth implantation in the posterior region, a relative position relationship between the position-limiting component and the fixing assembly is adjusted by sliding, thereby a position of the sleeve assembly is adjusted, and then a drilling position on the gum is adjusted, so that the entire assembly can meet a distance betweenteeth of different patients, and can be used repeatedly.

Owner:西南医科大学附属口腔医院

Drilling equipment with hole expanding function

ActiveCN111376054AEasy to drillEasy to reamOther manufacturing equipments/toolsLarge fixed membersEngineeringMachine

The invention discloses drilling equipment with a hole expanding function. The drilling equipment comprises a machine body, a clamping cavity is formed in the machine body, supporting bases are fixedly arranged on the left side and the right side of the clamping cavity correspondingly, supporting columns are slidably connected in the supporting bases, supporting springs are connected between the supporting columns and the supporting bases, a main body is fixedly arranged between the supporting columns, and a clamping device for clamping a workpiece is arranged in the machine body. According tothe drilling equipment, the accuracy of drilling in position and vertical direction can be guaranteed, hole expanding machining can be carried out during drilling, tool replacement is avoided, and the machining speed and the machining efficiency are improved.

Owner:徐州鸿祥机械制造有限公司

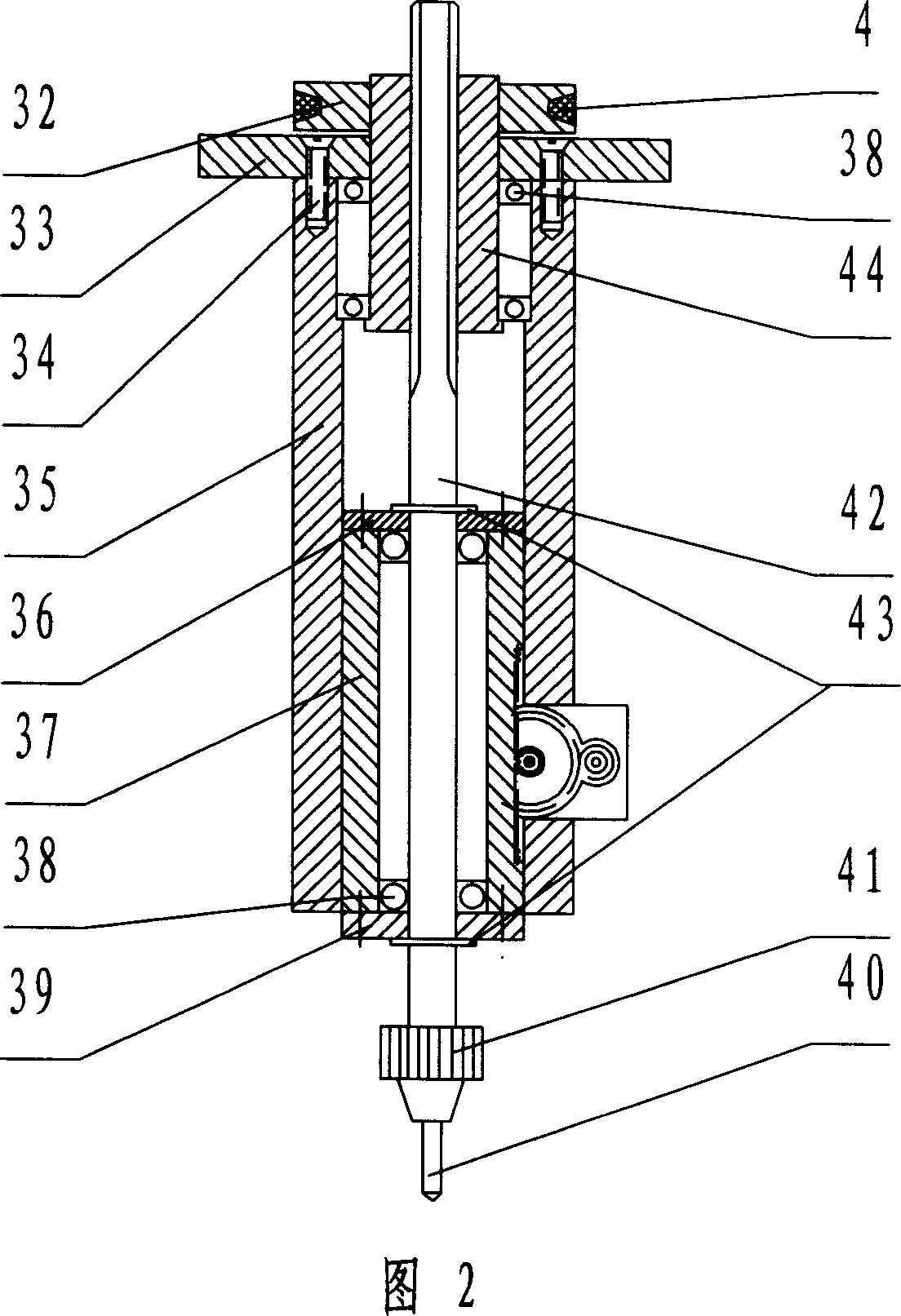

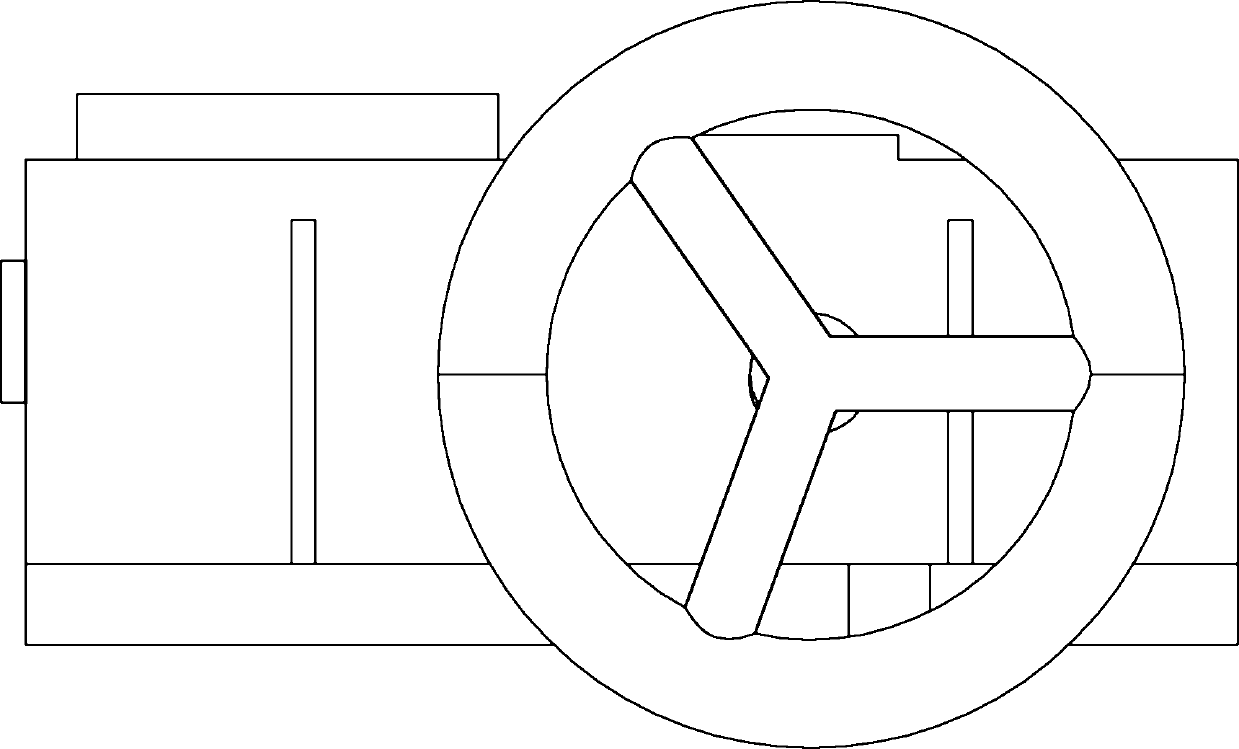

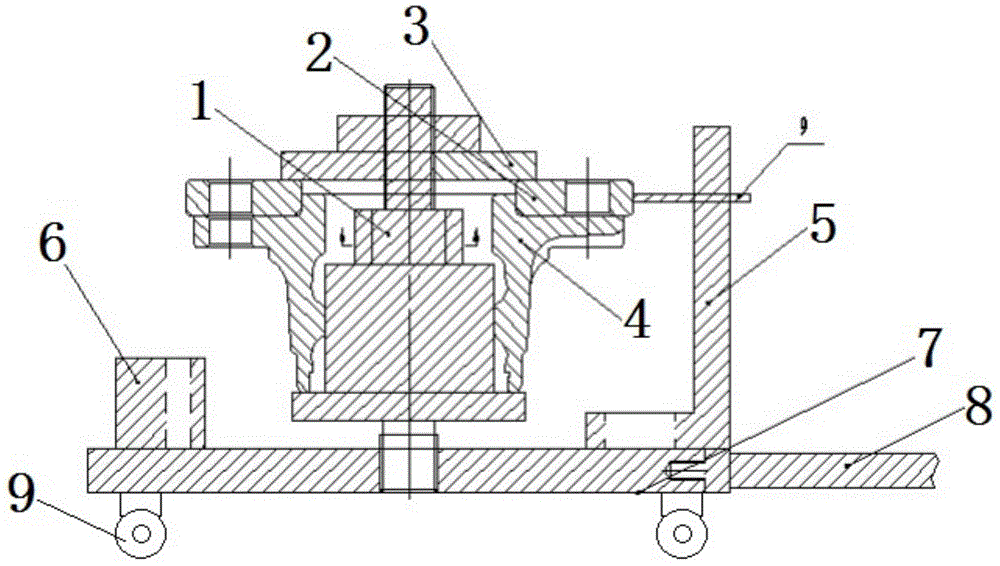

Drilling rig

ActiveCN102847984ANo deflectionGuaranteed accuracyPositioning apparatusBoring/drilling componentsEngineeringMechanical engineering

The invention discloses a drilling rig which comprises a bearing fixing plate, tapered roller bearings, an extension rod, a support plate, a slide rail, a slider, a bottom plate and a product holder. The product holder for fixing a product on the bottom plate is arranged on the bottom plate. The support plate is also disposed on the bottom plate. A slide rail fixing plate is disposed on the support plate. The longitudinal slide rail is arranged on the slide rail fixing plate. A slide way on the slider is exactly sleeved outside the slide rail and is capable of sliding along the slide rail. The bearing fixing plate is fixed on the slider. At least one pair of tapered roller bearings coaxially arranged in longitudinal symmetry is arranged on the bearing fixing plate. The upper end of the extension rod which can be fixedly connected with a drill bit is fixedly inserted into the corresponding tapered roller bearing. The drilling rig avoids deflection of the drill bit in longitudinal feeding and guarantees accurate drilling position. The tapered roller bearings in pairs fit with the extension rod to guarantee no deflection of the drill bit in drilling, and accordingly diameter accuracy and roundness of drilled holes are guaranteed.

Owner:KUSN GUANGHE ELECTRONICS TECH

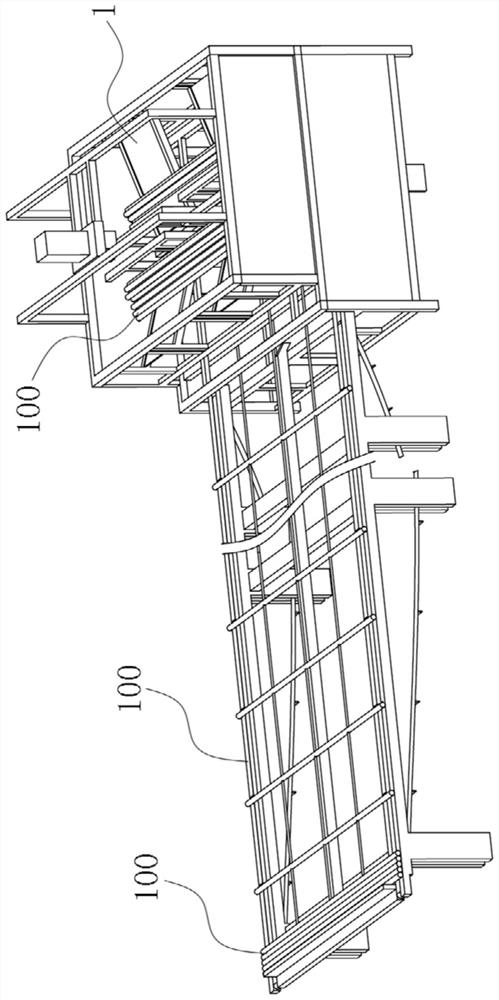

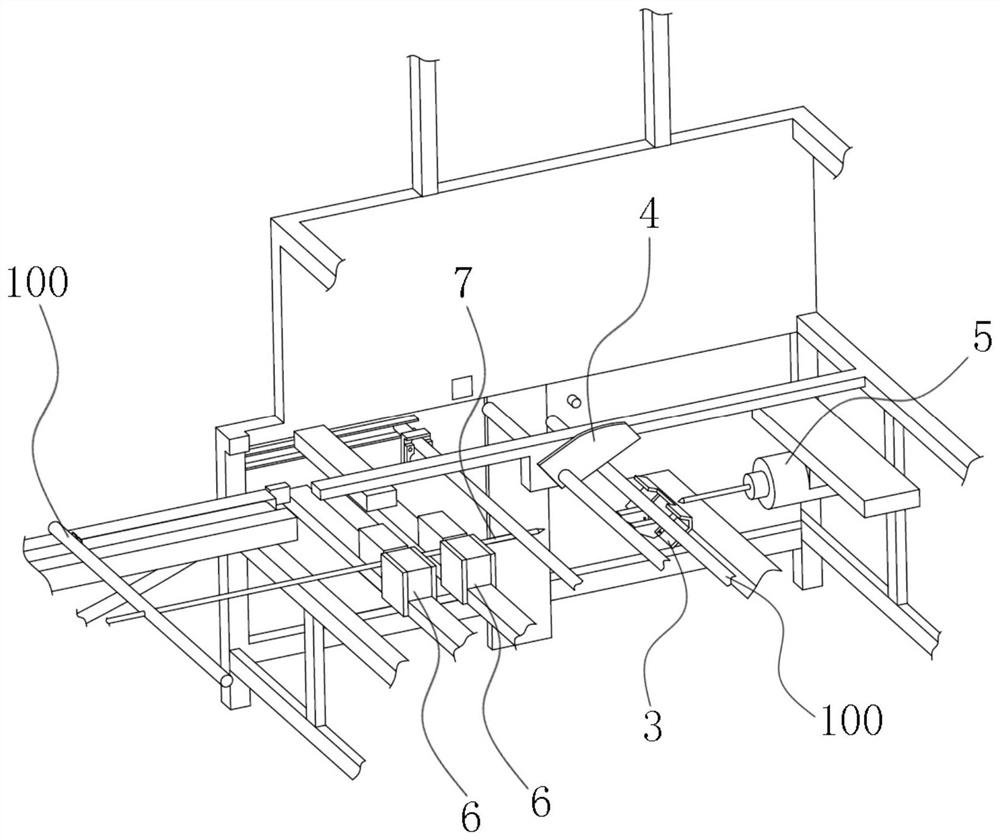

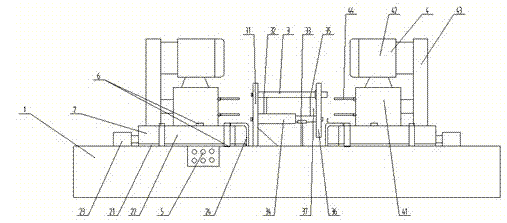

Palings or fence production line capable of achieving full-automatic threading

PendingCN112277112AHigh degree of automationRealize assembly line productionCane mechanical workingAssembly linePalisade

The invention discloses a palings or fence production line capable of achieving full-automatic threading. The whole process from feeding to forming is completed through cooperative cooperation of a storage table, a grabbing mechanism, a material stirring mechanism, a first clamp mechanism, a material pressing mechanism, a drilling mechanism, a second clamp mechanism, a needle clamping mechanism and a conveying table. The palings or fence production line has the advantages that the automation degree is high, and full-automatic weaving assembly line production of fences is achieved through a series of operations such as automatic feeding, alignment, straightening, drilling and threading; the drilling position is accurate, the manufactured fences are equal in height, the straightness is high,the procedure is simple and convenient, the procedure of cutting and dividing again in the future is omitted, labor is reduced, and the benefits of enterprises are increased; and the weaving speed isincreased, the fence weaving efficiency is improved, the fence weaving speed can be increased to 10 times or above of the manual weaving speed or the semi-mechanical weaving speed, and the productioncost is only half of the manual weaving cost or the semi-mechanical weaving cost.

Owner:肖境钟

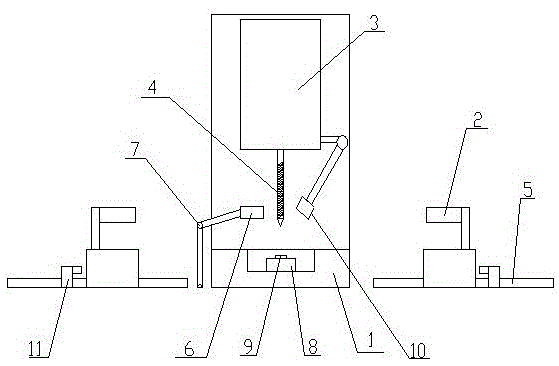

Drilling device for automobile rear suspending plate

InactiveCN105458773AAccurate drilling positionImprove drilling accuracyDrilling/boring measurement devicesPositioning apparatusCushionEngineering

The invention provides a drilling device for an automobile rear suspending plate. The drilling device comprises a placing table, wherein clamping devices are arranged at the two sides of the placing table; a drilling machine is arranged above the placing table; a drill bit is arranged on the drilling machine for drilling a product on the placing table; the lower ends of the clamping devices are provided with slide rails; the clamping devices move left and right by virtue of the slide rails; a drilling position determining device is arranged on the placing table; and the drilling position determining device is used for regulating the position by virtue of a bending rod. According to the drilling device, the product is clamped by virtue of the clamping devices at the two sides of the placing table for being positioned, and the product is drilled by virtue of the drilling machine, so that the drilling position is guaranteed to be precise; the positions of the clamping devices are regulated by virtue of the slide rails to adapt to different drilling positions, so that the drilling precision is improved; a regulating cushion block is arranged for regulating the height of the product on the placing table; and a contact sensor is arranged for protecting the regulating cushion block and the placing table, so that the service life of the equipment is prolonged.

Owner:WUHU POWER TECH

Tunnel feet-lock anchor rod accurate positioning and construction method

PendingCN112267903AEnsure drilling qualityShorten the timeAnchoring boltsMesh reinforcementArchitectural engineering

The invention relates to the technical field of building construction, and discloses a tunnel feet-lock anchor rod accurate positioning and construction method. A feet-lock anchor pipe drilling positioning device is used to guide the drilling direction of a drill rod of a drilling machine, and the construction method comprises the following steps that S1, a tunnel face is blasted and excavated; S2, lofting and stationing are conducted, the position of a steel frame is measured and lofted by a measuring group according to the designed mileage and section; S3, the steel frame is installed; the machined and formed small-section steel frame is installed from one side of an arch wall to the other side of the arch wall, the next steel frame is sequentially installed, and reinforcing meshes are synchronously installed; S4, a feet-lock anchor pipe is drilled, the feet-lock anchor pipe positioning device is installed, and the feet-lock anchor pipe is drilled by using the drilling machine; S5, the feet-lock anchor pipe is installed, namely the feet-lock anchor pipe is processed and formed in advance according to design requirements, after hole cleaning, the feet-lock anchor pipe is jacked into the hole by adopting the drilling machine, and a feet-lock anchor pipe connecting rib is welded; and S6, grouting is conducted on the feet-lock anchor pipe. By the adoption of the method, the requirements for drilling and installing of the tunnel feet-lock anchor pipe can be met.

Owner:THE 8TH GRP OF CHINA RAILWAY 1ST ENG CO LTD +1

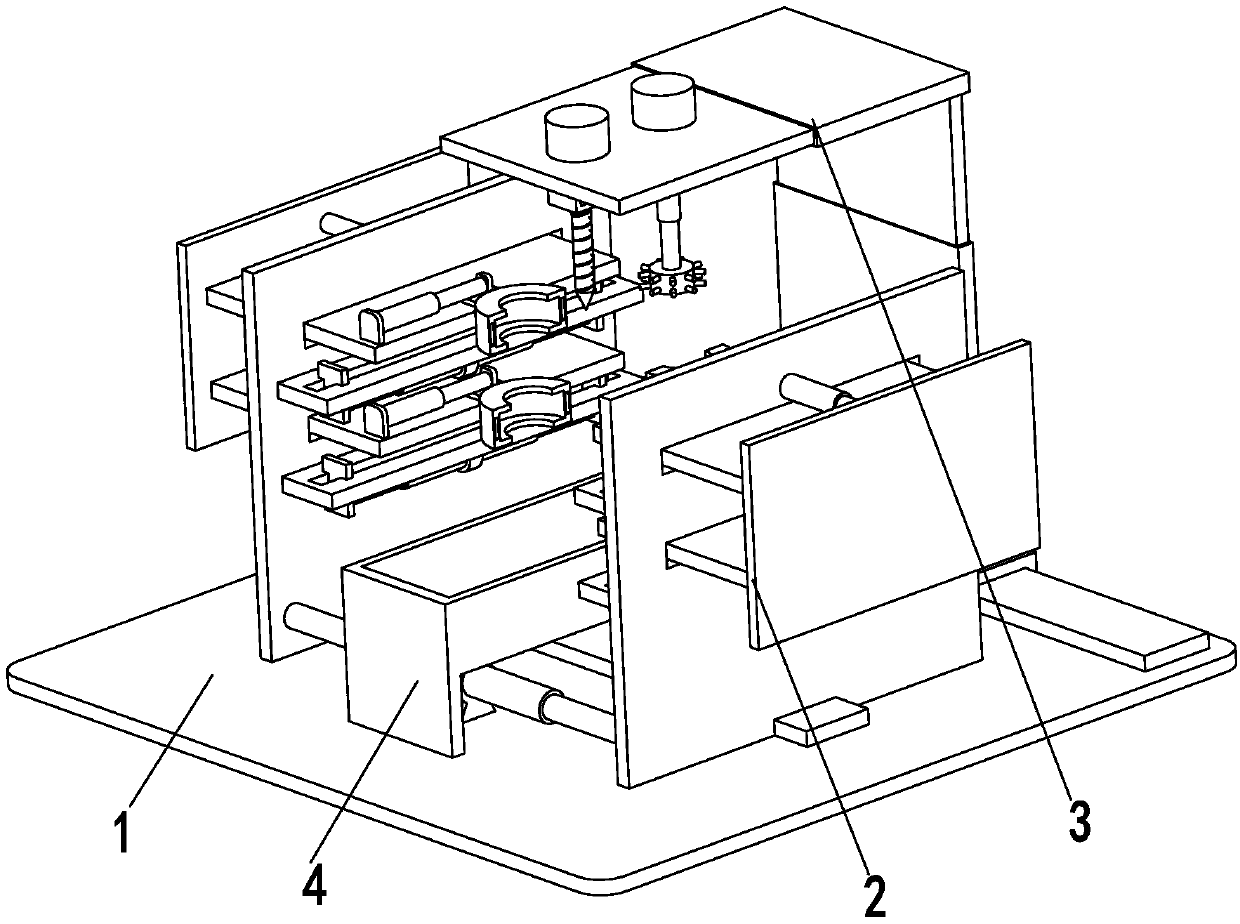

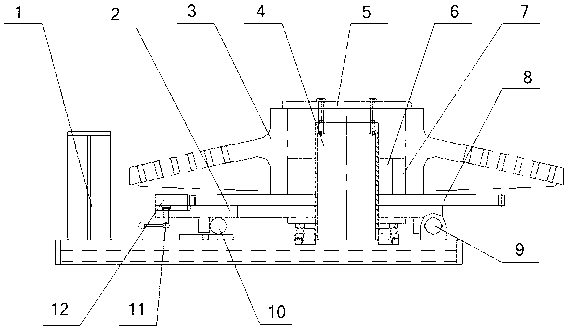

Drilling equipment

InactiveCN103240439AImprove reliabilityLow skill level requiredPositioning apparatusDrill jigsEngineeringMulti axis

The invention discloses drilling equipment which comprises a framework, feeding devices, a clamping device, drilling devices, control buttons and sensing devices. The clamping device is arranged on the framework, the feeding devices are symmetrically arranged on two sides of the clamping device, the control buttons are arranged in the front of the framework, the drilling devices are arranged on the feeding devices and are provided with multi-axis devices, and a plurality of drill bits are connected with the multi-axis devices. When a cylinder is machined, a workpiece is clamped manually in advance, the control buttons are pressed, the workpiece is quickly and fixedly clamped by the clamping device, the feeding devices move to preset stations, the sensing devices work, and the multiple drill bits simultaneously drill holes on the workpiece. The drilling equipment has the advantages that the drilled holes are positioned accurately, the machining efficiency is high, a service method is simple, and the requirement on the technical level of workers is low; and a cylinder driving mode is adopted for the feeding devices and the clamping device and is high in reliability, driving force is high, and the product machining quality is guaranteed.

Owner:QUZHOU UNIV +1

Drilling device for rim with spokes

PendingCN110625160AEasy to processEasy to adjustFeeding apparatusLarge fixed membersEngineeringMachining

The invention discloses a drilling device for a rim with spokes. The drilling device comprises a supporting seat, a rack, a feed driving mechanism and a swing locking component, and the supporting seat is configured as a support component for installing a rim; the rack is located on one side of the supporting seat, and provided with a feed support plate which is provided with a drill bit; the feeddriving mechanism is used for driving the drill bit to feed or retract along a guide component; the feed support plate is provided with a first arc fitting part, and the rack is provided with a second arc fitting part which is in clamping fit with the first arc fitting part, so that the feed support plate can be swung relative to an arc path limited by the first arc fitting part and the second arc fitting part; the circle center corresponding to the arc path is located on the rim installed on the supporting seat; and the swing locking component is used for locking or unlocking the feed support plate. The drilling device has the advantages of convenient machining, accurate drilling position and convenient regulation.

Owner:SHENZHEN NEW CANGHAI MACHINERY

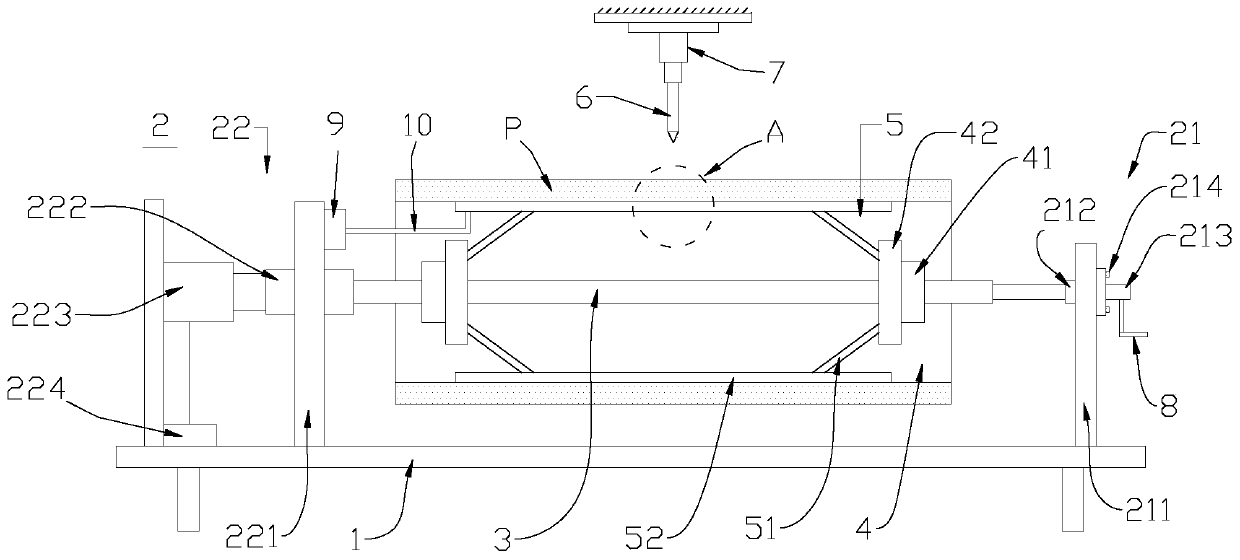

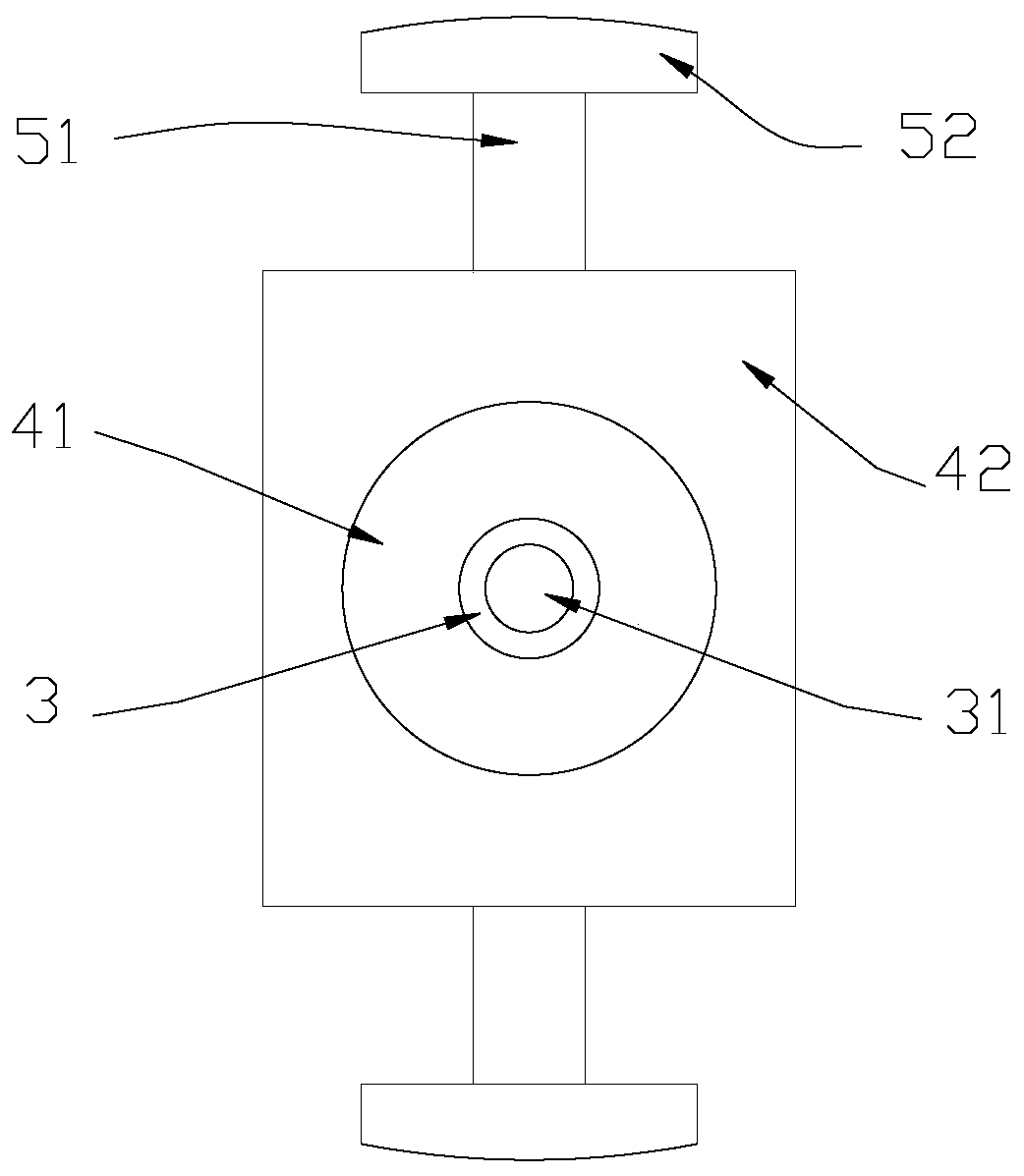

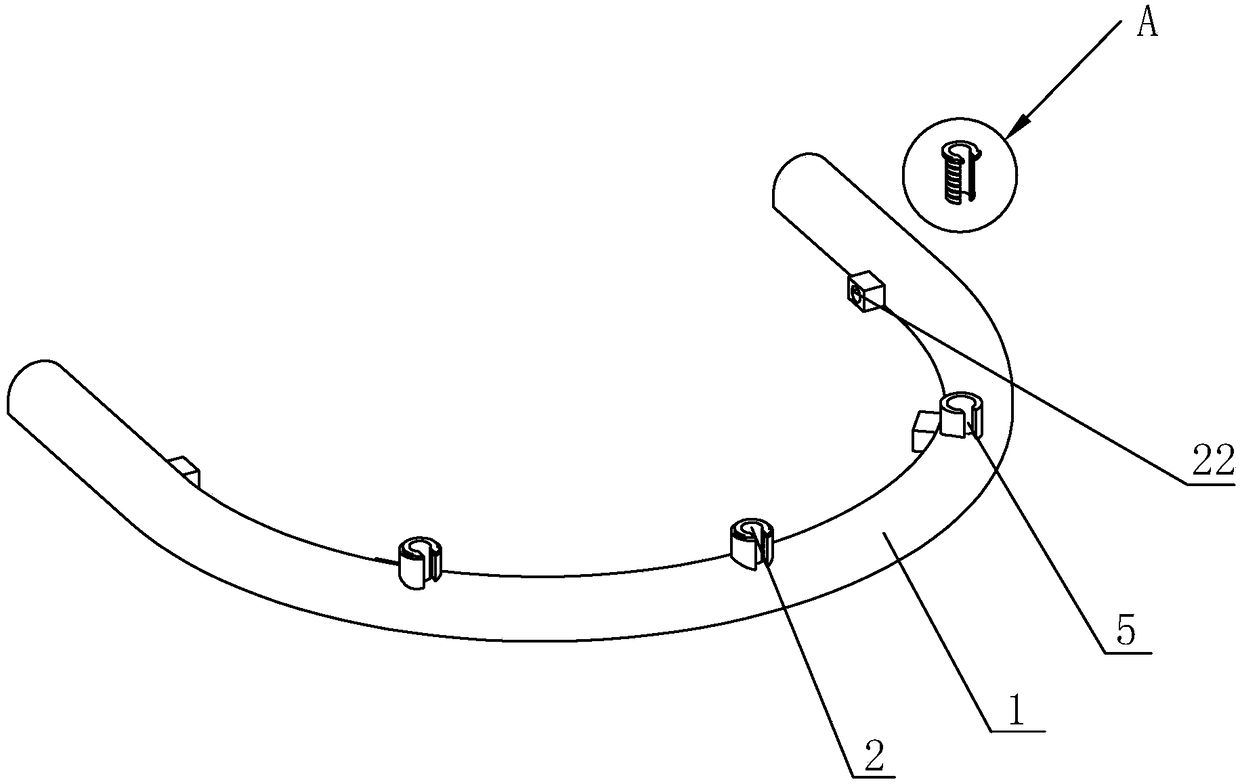

Portable drilling method residual stress testing auxiliary drilling device

PendingCN110238426ASolve the errorAddress controllabilityMeasurement/indication equipmentsWork benchesEngineeringDrill bit

The invention relates to a portable drilling method residual stress testing auxiliary drilling device, and belongs to the technical field of testing platforms. The device comprises a base, a platform shell, an inner limiting ring, an outer limiting ring, a limiting block, a moving block and a drill bit sleeve, wherein the platform shell is fixedly connected to the base, a track used for allowing the inner limiting ring to move up and down and an observation hole are formed in the platform shell, a spring is arranged at the portion, between the inner limiting ring and the base, in the platform shell, an extending part of the inner limiting ring is arranged in a rail formed in the platform shell and moves up and down along the track, the outer limiting ring is arranged on the periphery of the platform shell in a sleeving mode and is used for limiting movement displacement of the inner limiting ring, the limiting block is arranged above the inner limiting ring and is in contact fixation with the moving block through limiting screws which is arranged on the limiting block, the sleeve is arranged in the moving block, and the end of the sleeve is matched with a drill bit. According to the device, the drilling position of a to-be-drilled part can be centring adjusted, an electric hand drill can be directly installed to carry out precisely drilling, the drilling depth can be adjusted according to needs, the efficiency is high, and the stability is good.

Owner:SHENYANG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com