General drilling mould for hub of drum-type rotating sieve

A technology of rotating filter screen and wheel hub, applied in the direction of drilling dies for workpieces, etc., can solve the problems of decreased positioning accuracy, bulky structure, and many tires, etc., and achieves shortened processing time, accurate drilling positions, and accurate equalization angles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

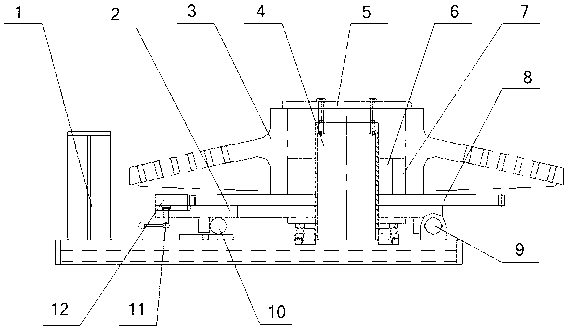

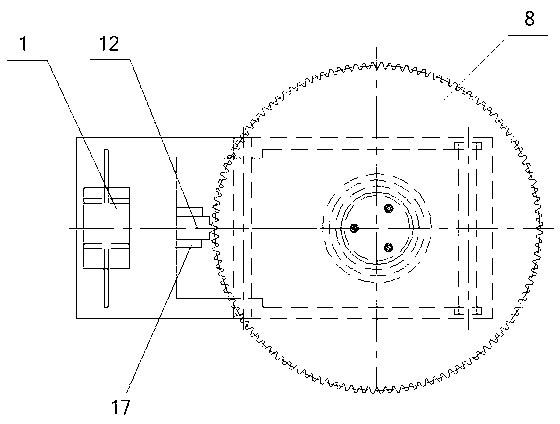

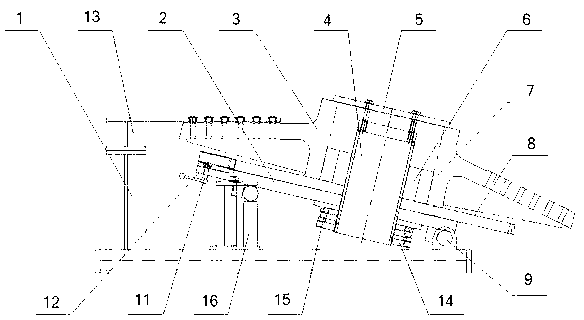

[0015] Concrete structure of the present invention is as follows: see Figure 1-3 , one end of the main body 2 is hinged on the base 1 through the hinge shaft 9, and a balance piece 10 is provided under the other end of the main body 2 to keep it horizontal; a rotatable mandrel 4 is installed on the main body 2, and the indexing gear 8 is located and fixed on the mandrel 4, assemble the thrust bearing 15 and the nut 14 at the lower end of the mandrel 4, and adjust the nut 14 at the lower end of the mandrel 4 to make the indexing gear 8 have a gap with the upper part of the main body 2, so that the indexing gear 8 Rotate labor-saving; the upper end of the mandrel 4 is connected with the pressure plate 5 by bolts; the other end of the main body 2 is fixedly connected with the tooth-shaped positioning block seat 17, and a chute is arranged on the tooth-shaped positioning block seat 17, and the tooth-shaped positioning is slidably connected in the chute. Block 12, the tooth-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com