Large width hydraulic folding intelligent paddy field stubble machine

A foldable and hydraulic technology, applied in the fields of farming equipment, chassis of agricultural equipment, agricultural machinery and equipment, etc., can solve the problems of inconvenient road transportation and field transfer, large width, etc., and achieve easy field transfer, large working width and flexibility. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

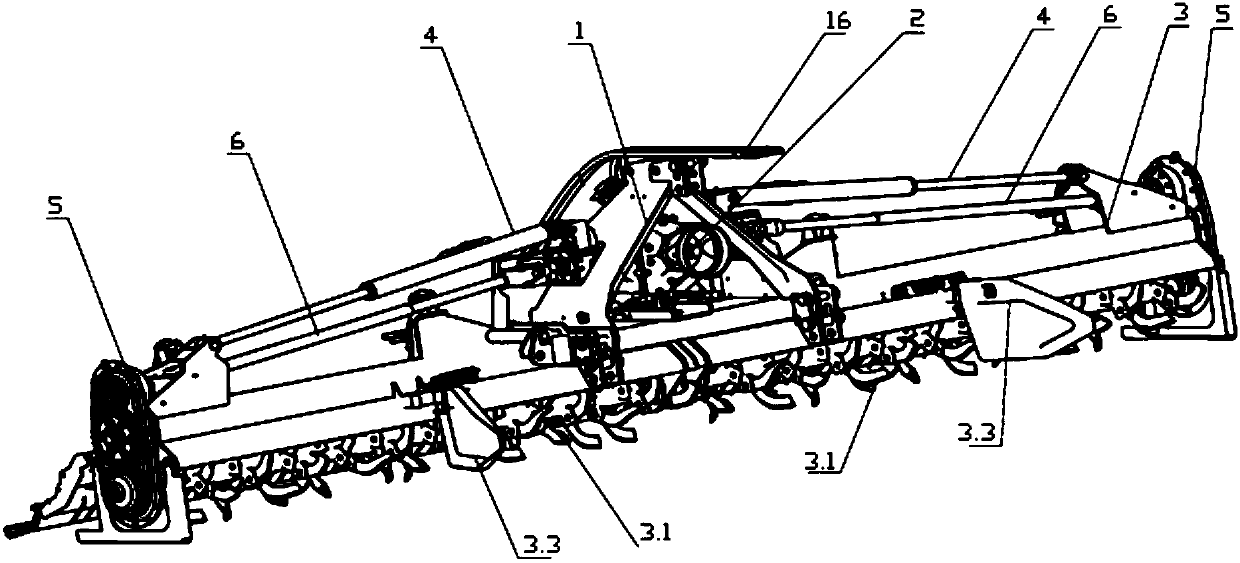

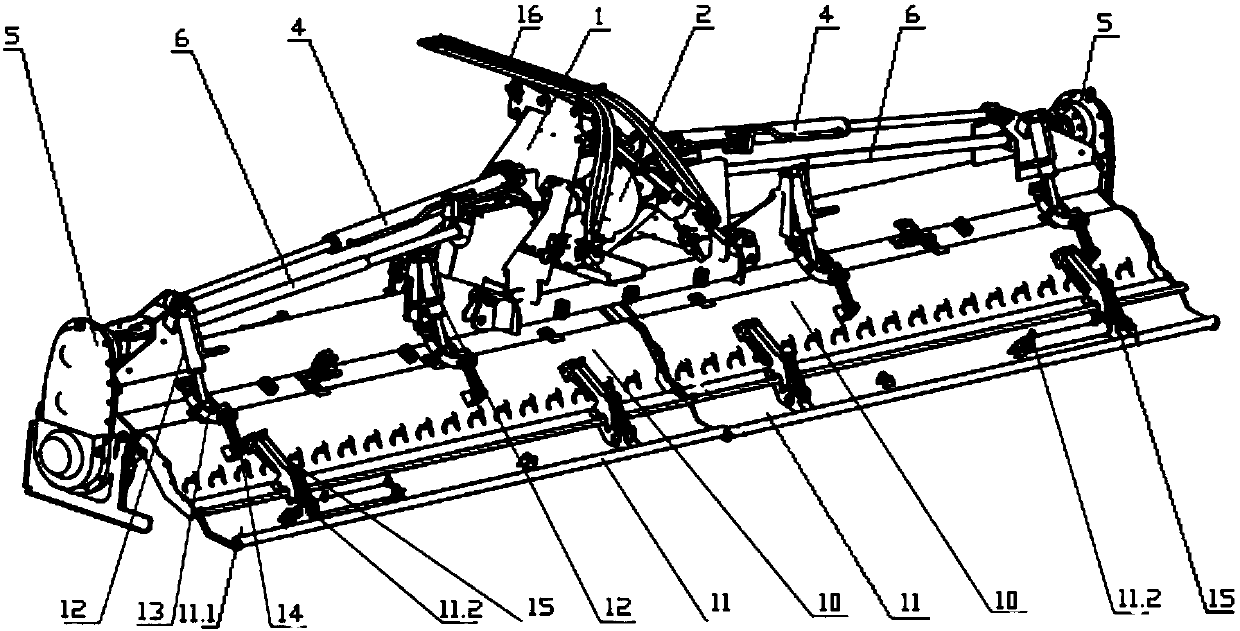

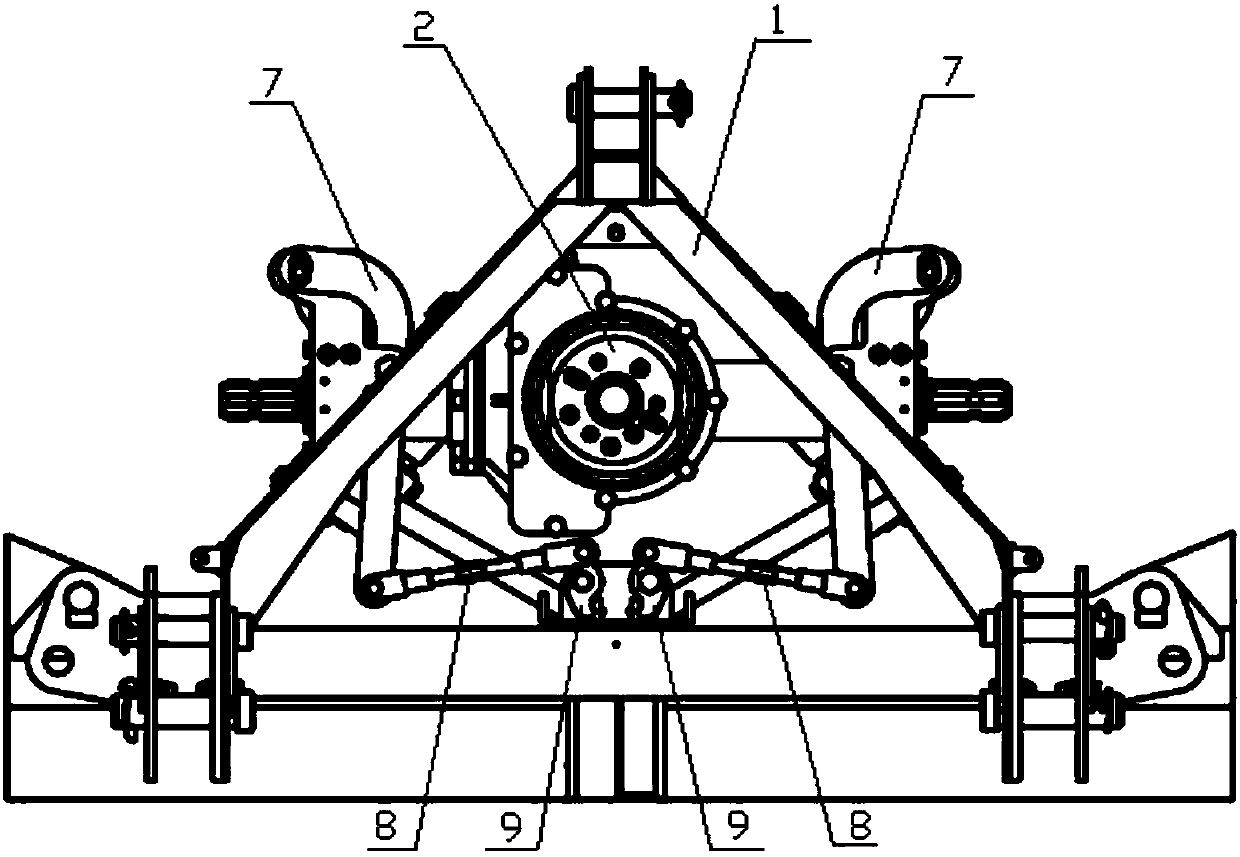

[0027] Embodiment 1: as figure 1 , figure 2 , Figure 7The shown large-scale wide hydraulic folding intelligent paddy field stubble machine includes a three-point suspension frame 1 and an intermediate gear box 2. The intermediate gear box 2 is arranged in the middle of the suspension frame 1, and the left and right sides of the suspension frame 1 are provided with relevant suspension frames. 1. A left-right symmetrical rack unit that can be flipped up and folded. The rack unit includes a frame 3, a transmission mechanism at the outer end of the frame 3, and a folding control mechanism for controlling the flipping and folding of the frame 3 on the upper part of the frame 3. The frame 3 is close to The inboard end of suspension frame 1 is movably connected with suspension frame 1 with pin shaft, and the folding control mechanism is opening and closing oil cylinder 4, and the movable end of opening and closing oil cylinder 4 is movably connected with frame 3 top outsides with ...

Embodiment 2

[0035] Embodiment 2: as figure 1 , figure 2 , Figure 7The shown large-scale wide hydraulic folding intelligent paddy field stubble machine includes a three-point suspension frame 1 and an intermediate gear box 2. The intermediate gear box 2 is arranged in the middle of the suspension frame 1, and the left and right sides of the suspension frame 1 are provided with relevant suspension frames. 1. A left-right symmetrical rack unit that can be flipped up and folded. The rack unit includes a frame 3, a transmission mechanism at the outer end of the frame 3, and a folding control mechanism for controlling the flipping and folding of the frame 3 on the upper part of the frame 3. The frame 3 is close to The inboard end of suspension frame 1 is movably connected with suspension frame 1 with pin shaft, and the folding control mechanism is opening and closing oil cylinder 4, and the movable end of opening and closing oil cylinder 4 is movably connected with frame 3 top outsides with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com