Patents

Literature

48results about How to "Increase working width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

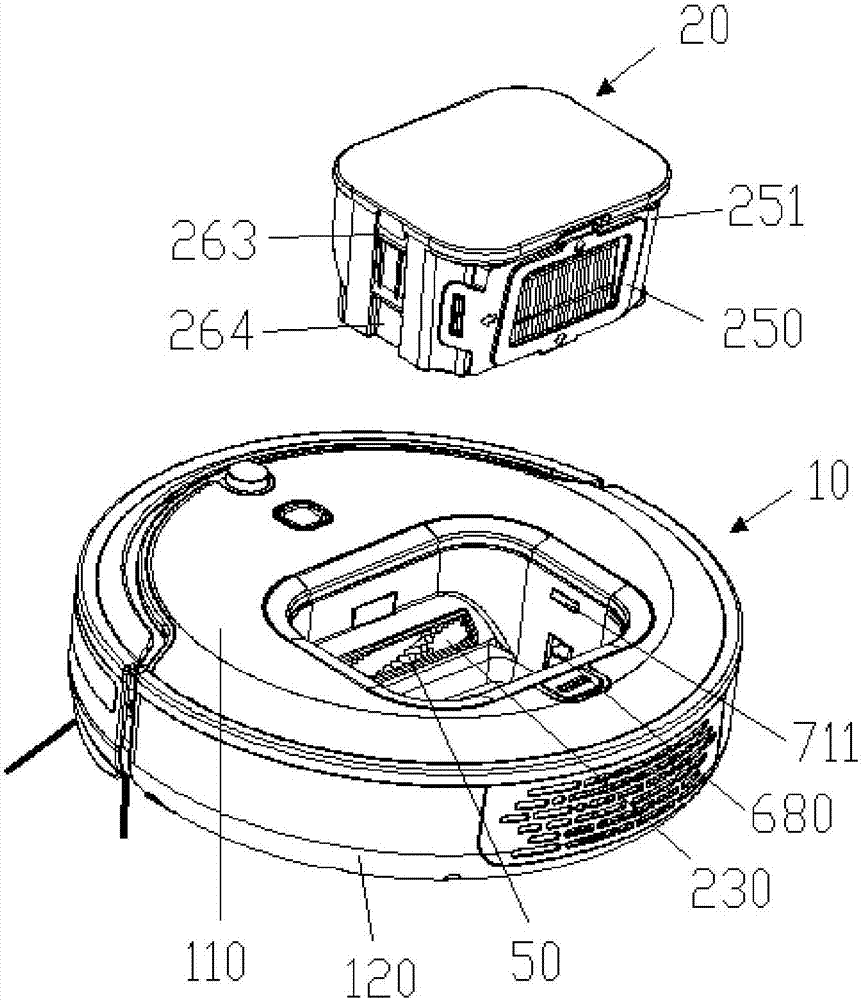

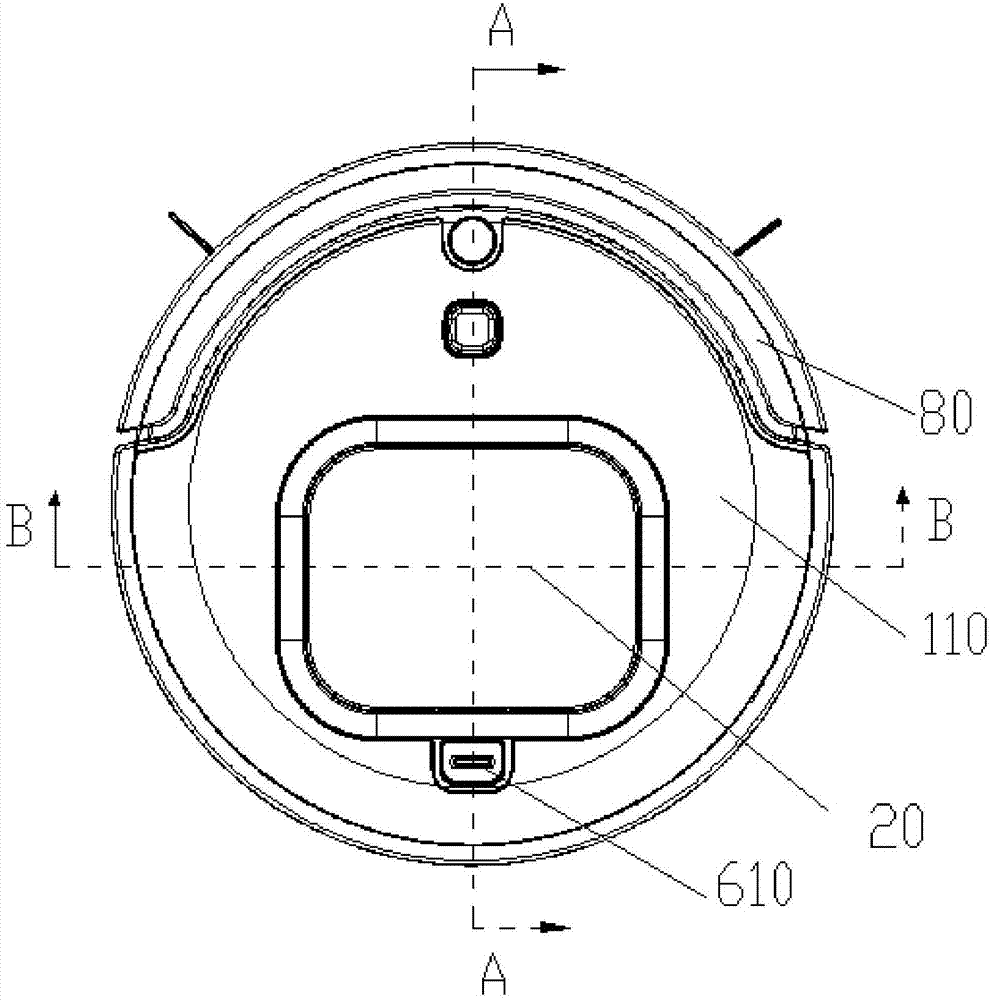

Mobile robot

PendingCN107307798AIncrease the lengthIncrease working widthCarpet cleanersFloor cleanersControl theoryMobile robot

Owner:SHENZHEN SILVER STAR INTELLIGENT TECH CO LTD

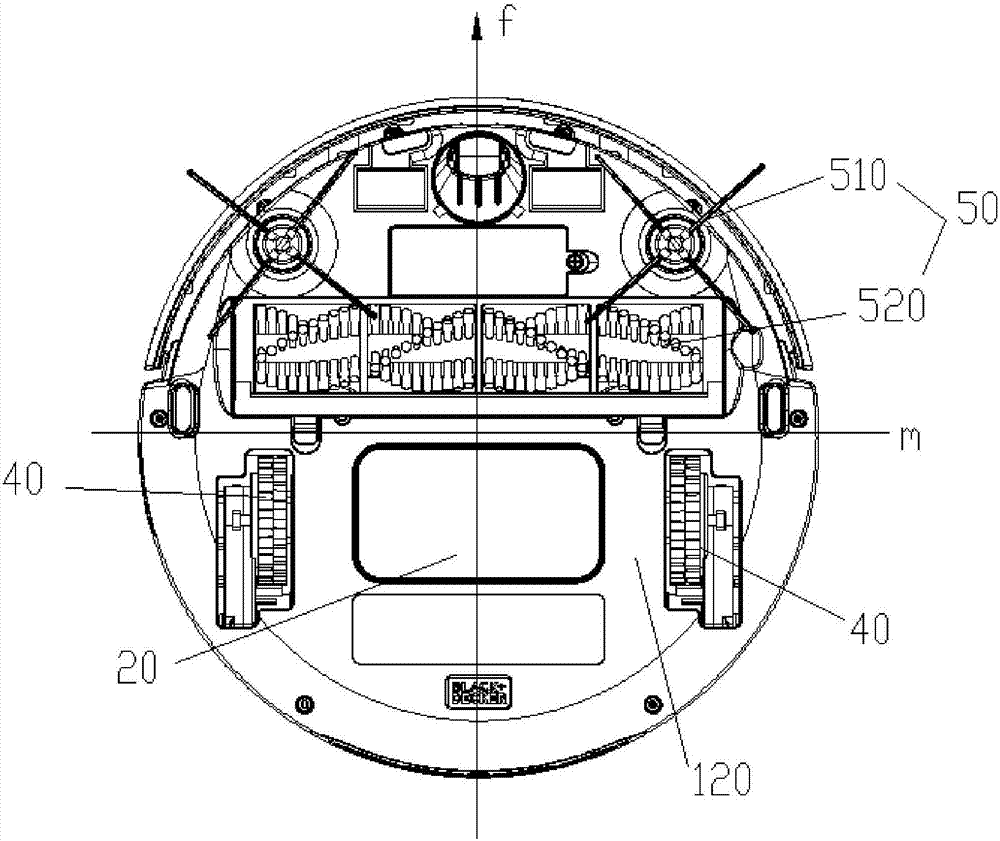

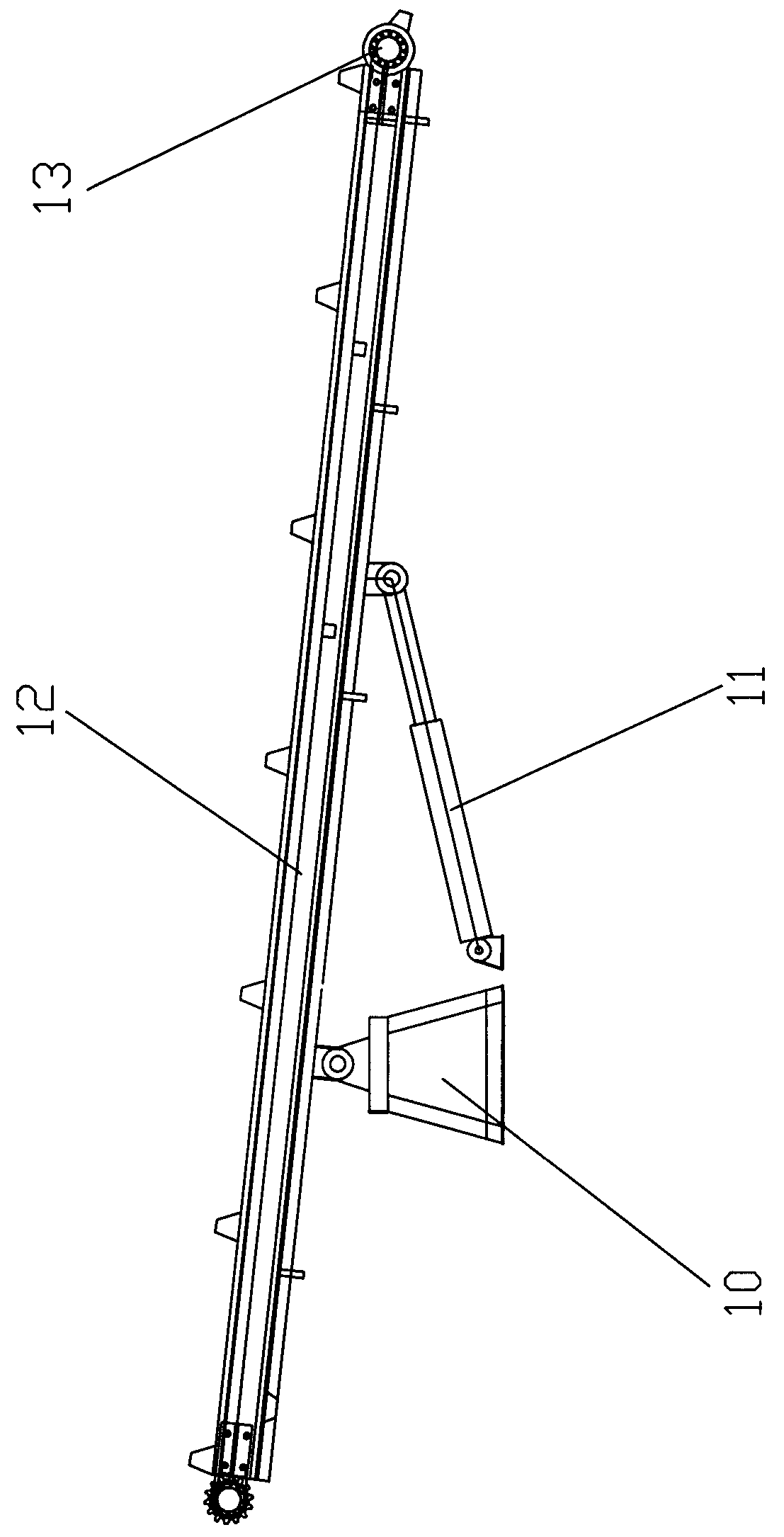

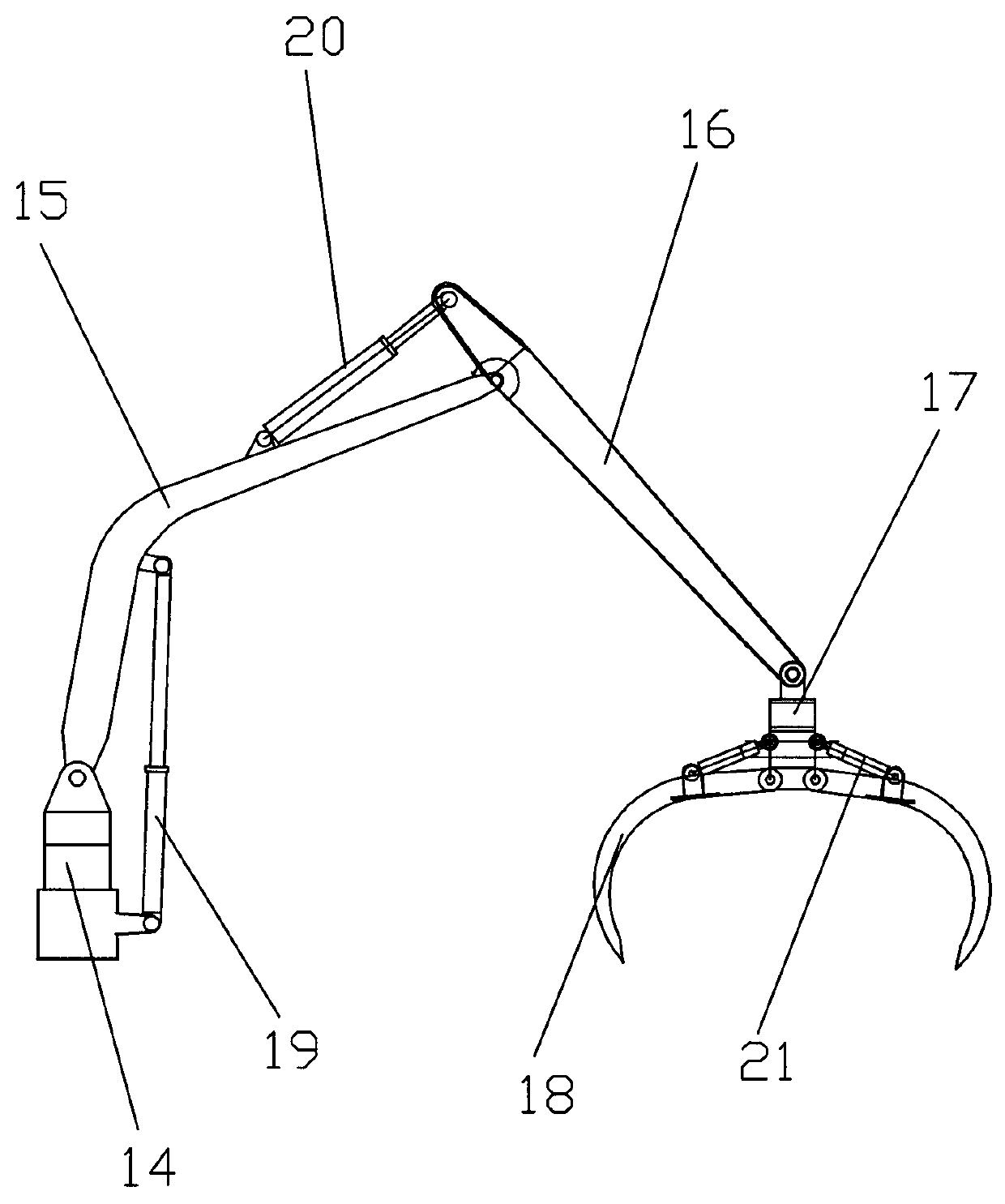

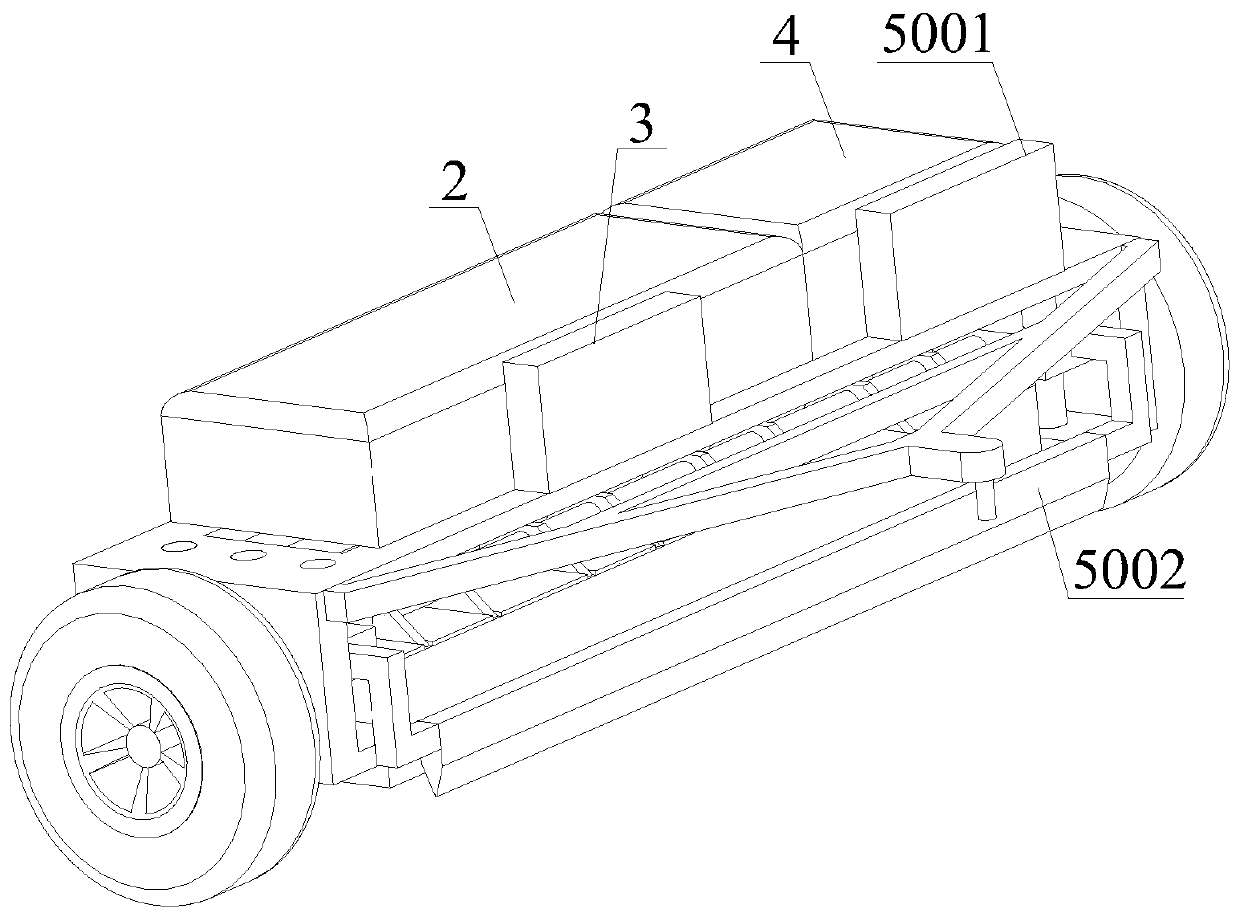

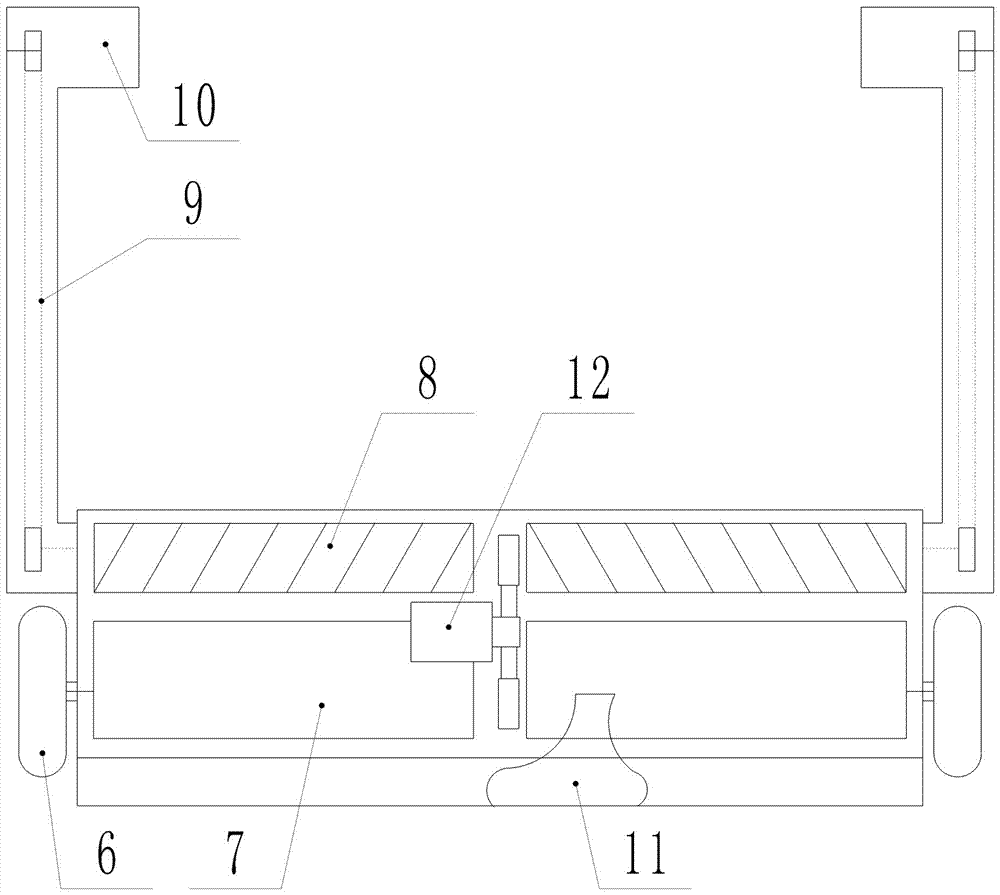

Full-automatic floating object cleaning boat for large objects of moso bamboos and trees

InactiveCN104309774AIncrease speedIncrease working widthWater cleaningWaterborne vesselsPropellerWorking range

The invention discloses a full-automatic floating object cleaning boat for large objects of moso bamboos and trees. The full-automatic floating object cleaning boat comprises a boat body, and a control room, a collection device, a storage compartment, a back storage and unloading compartment, a hydraulic large object grabbing machine, an engine and a stern shaft propeller which are arranged on the boat body, wherein the collection device, the storage compartment and the back storage and unloading compartment are sequentially arranged on the boat body from a stem to a stern of the boat body, have the same structure, and respectively comprise a plate-shaped main frame, driving wheels and a stainless steel belt hook plate chain conveying belt, the driving wheels are arranged at the two ends of the corresponding plate-shaped main frame, each stainless steel belt hook plate chain conveying belt is arranged on the corresponding driving wheels, is positioned at the corresponding plate-shaped main frame, and is punched with a plurality of rows of water filtering holes, the hydraulic large object grabbing machine is arranged at the stem of the boat body, and the control room is positioned at the right side of the stem of the boat body. The full-automatic floating object cleaning boat has the advantages that the structure is reasonable, the working range is wide, the loading and unloading are convenient, the floating object cleaning capability is high, and the floating objects with larger thickness and larger size can be cleaned.

Owner:ZHANGJIAGANG HAIFENG WATER SURFACE ENVIRONMENTAL PROTECTION MACHINERY

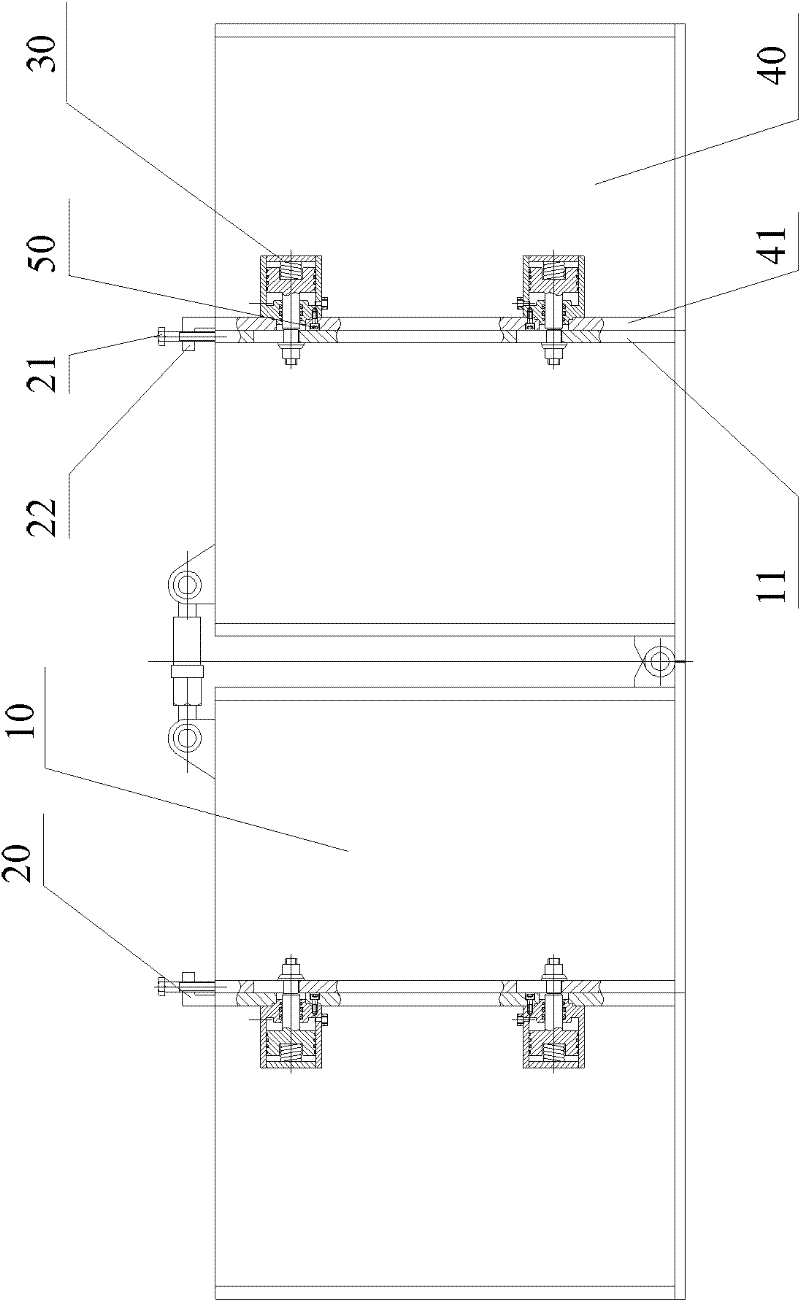

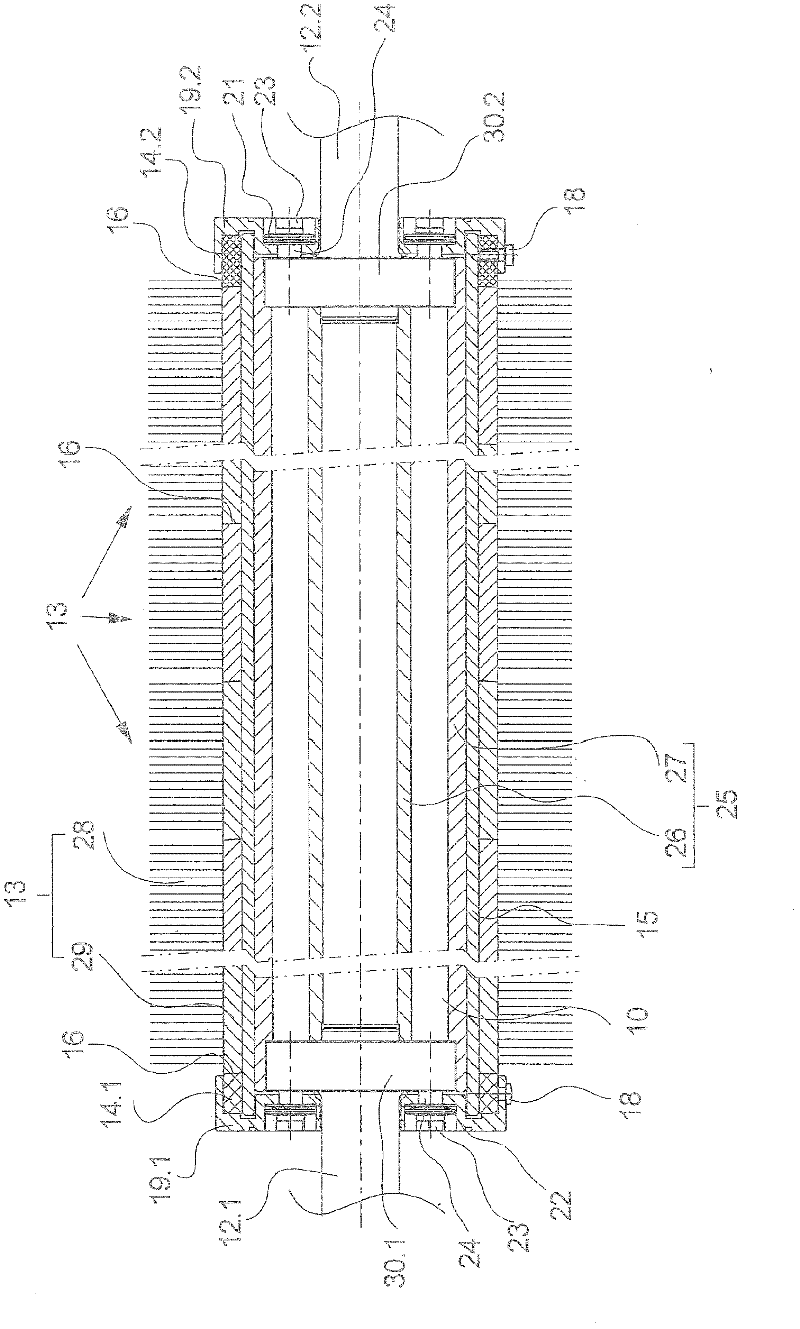

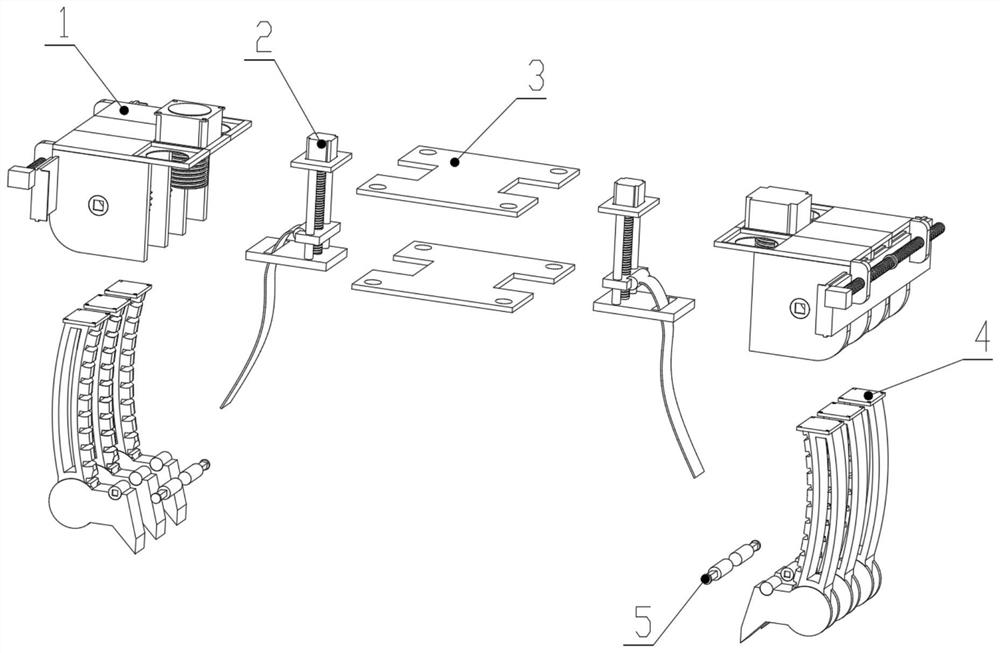

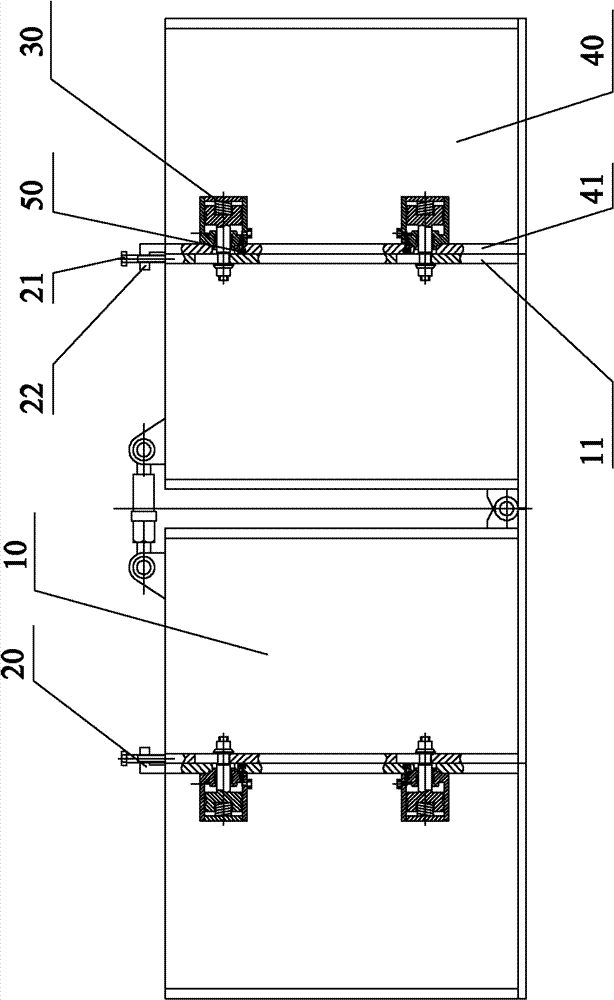

Spreading machine and ironing device thereof

The invention provides a spreading machine and an ironing device thereof. The ironing device comprises a basic ironing plate, a lengthening ironing plate which is connected with the basic ironing plate and a clamping mechanism, wherein the clamping mechanism comprises a driving system, a power system, an energy storage system and a limit adjustment system; the driving system comprises a cylinder body, a piston and a supporting rod; the supporting rod passes through the basic ironing plate and the lengthening ironing plate; a first end of the cylinder body is pressed against the lengthening ironing plate; the power system comprises a pressure source which is communicated with the cylinder body; the energy storage system comprises a spring component; a first end of the spring component is pressed against a second end of the cylinder body; the limit adjustment system comprises a first limit adjustment part; and the first limit adjustment part and the supporting rod are provided with a first position which passes through the basic ironing plate and a second position which is pressed against the basic ironing plate. The spreading machine comprises the ironing device. When the ironing plate is lengthened, the spreading machine and the ironing device are easy to mount, and fastening pieces are not required to be screwed up manually, so that the labor intensity of operators is reduced, and the mounting speed of the lengthening ironing plate is increased.

Owner:ZOOMLION HEAVY IND CO LTD

Efficient cyclone high-speed air circulation road sweeper

The invention discloses an efficient cyclone high-speed air circulation road sweeper which comprises a sweeper body and a cyclone dust sweeping collector, and further comprises a side sweeping cyclone blowing opening, wherein the side sweeping cyclone blowing opening is formed in the side face of the sweeper body and is communicated with an air outlet pipe of a cyclone generator in the cyclone dust sweeping collector through a ventilating pipeline. When the efficient cyclone high-speed air circulation road sweeper works, the side sweeping cyclone blowing opening blows air to the sweeper body; a sweeping hair rolling shaft of the cyclone dust sweeping collector is connected with a motor; the cyclone dust sweeping collector is arranged below the rear part of the sweeper body; the sweeping hair rolling shaft is arranged in front of an air blowing opening of the air outlet pipe of the cyclone generator; a waste collection trough is arranged in front of the sweeping hair rolling shaft; a spiral collection rolling shaft is arranged in the waste collection trough; and two ends of the spiral collection rolling shaft are communicated with a waste collection and separation tank through an air flow and mechanical hybrid waste conveying pipe. The sweeper has the advantages of larger sweeping width, less flying dust, lower energy consumption, better sweeping effect and more successful waste conveying.

Owner:重庆司科朗环卫服务有限公司

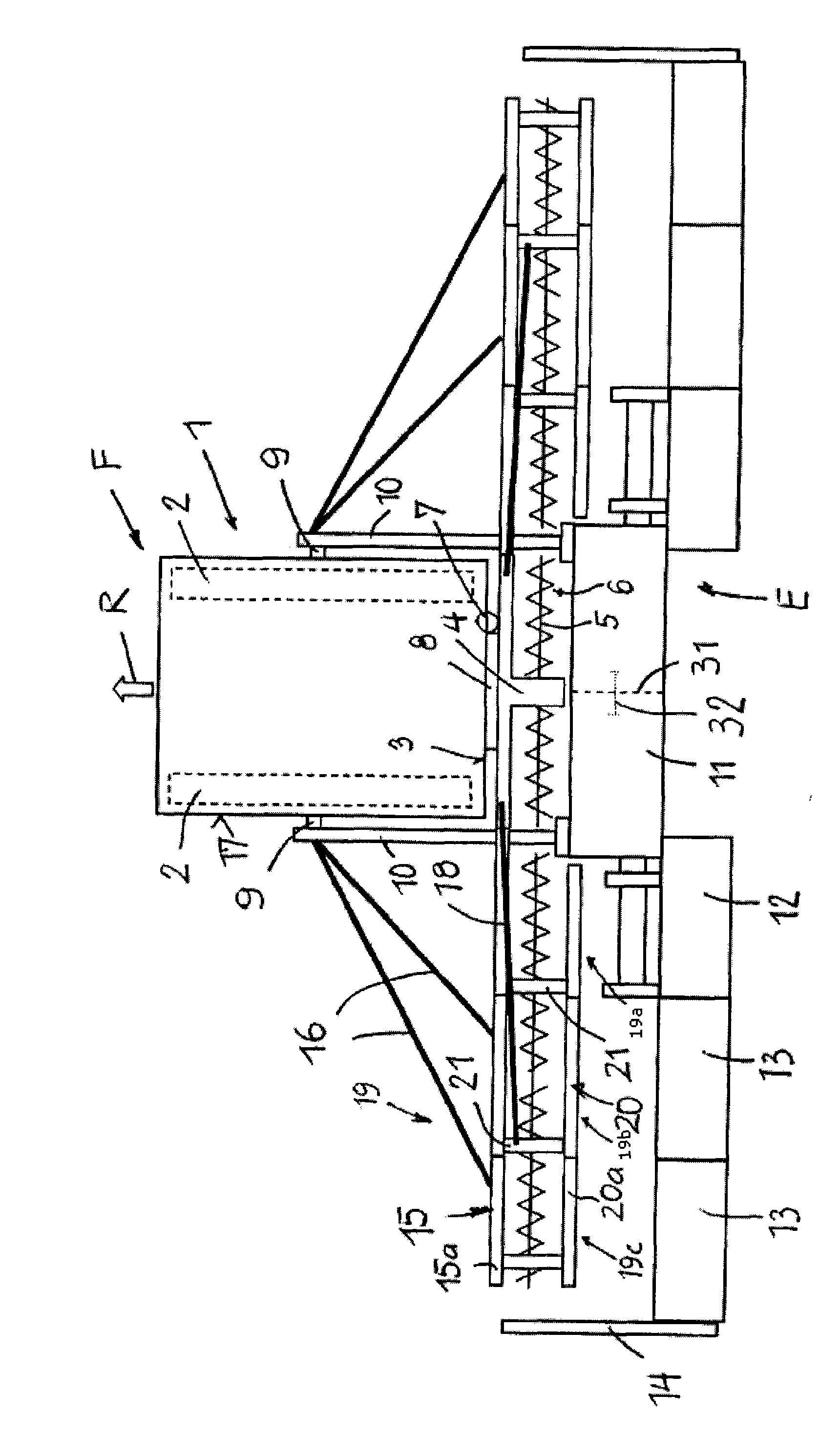

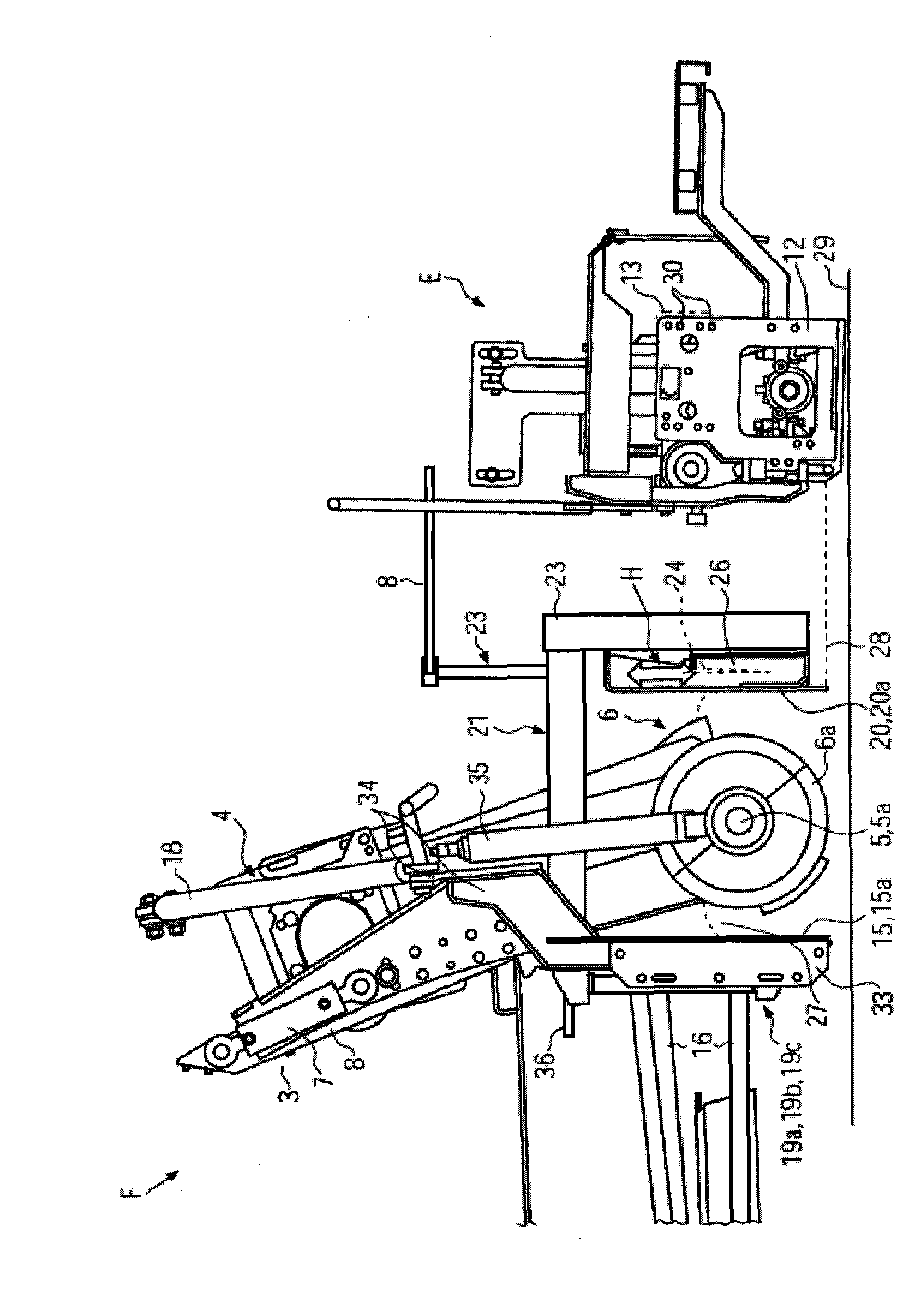

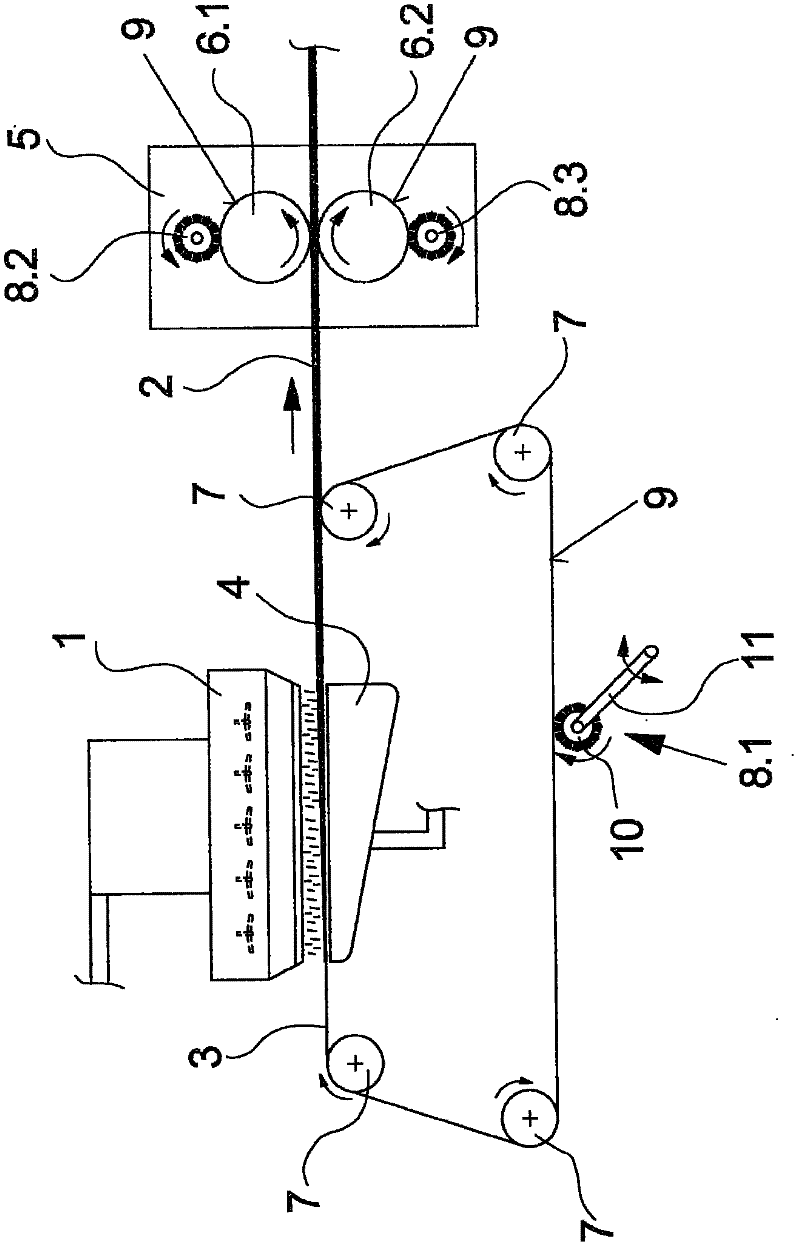

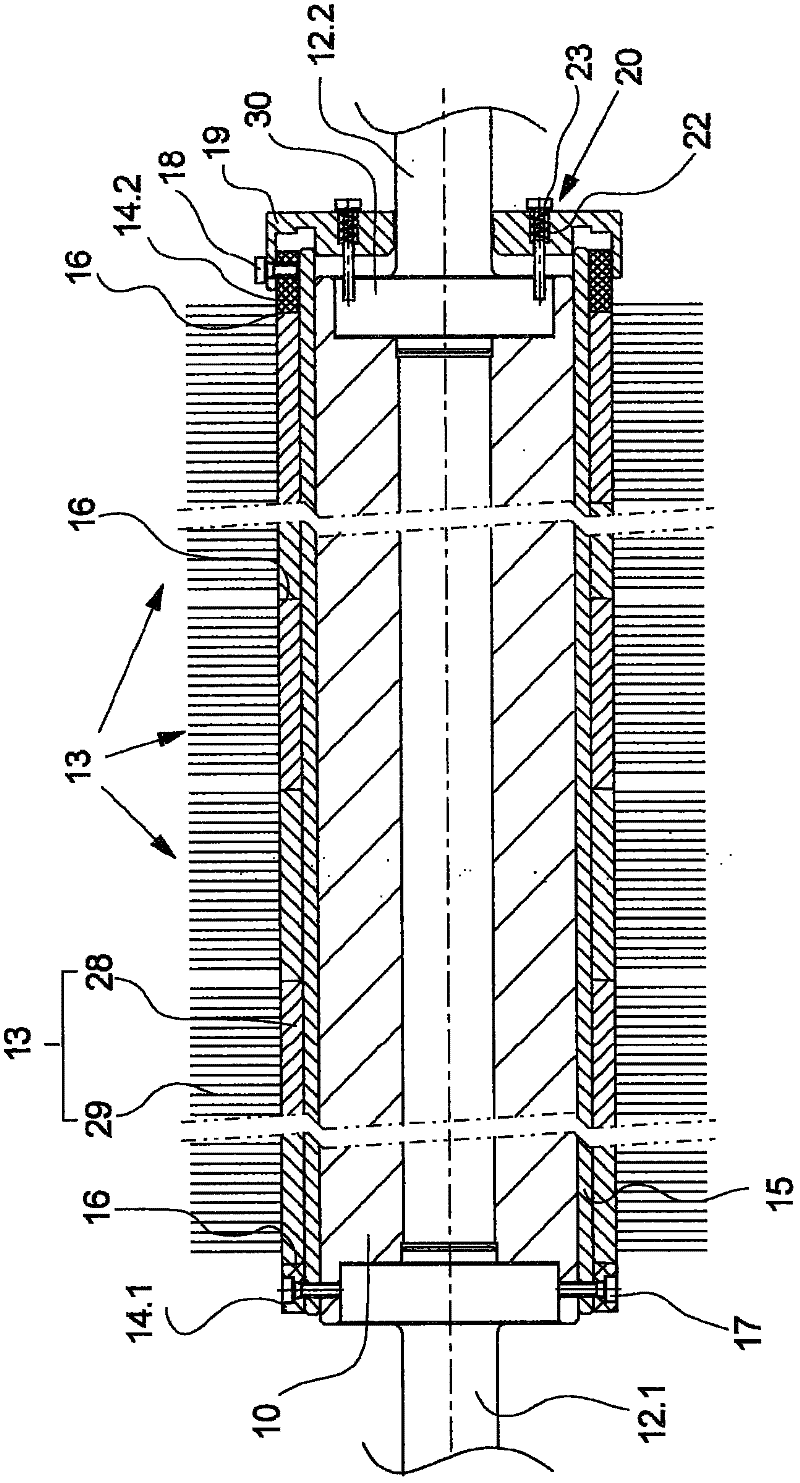

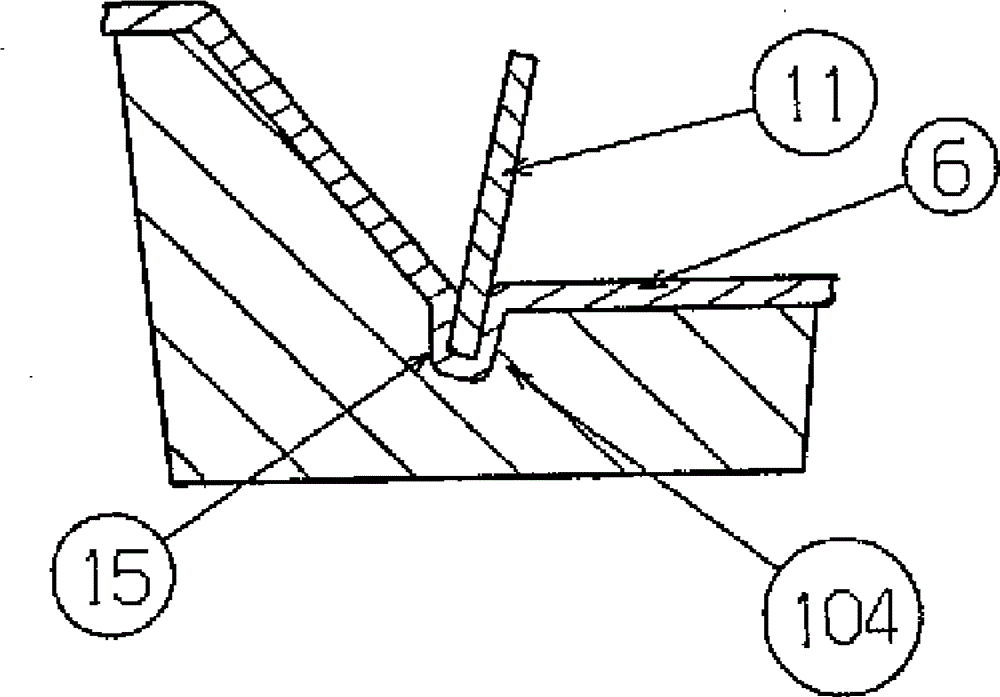

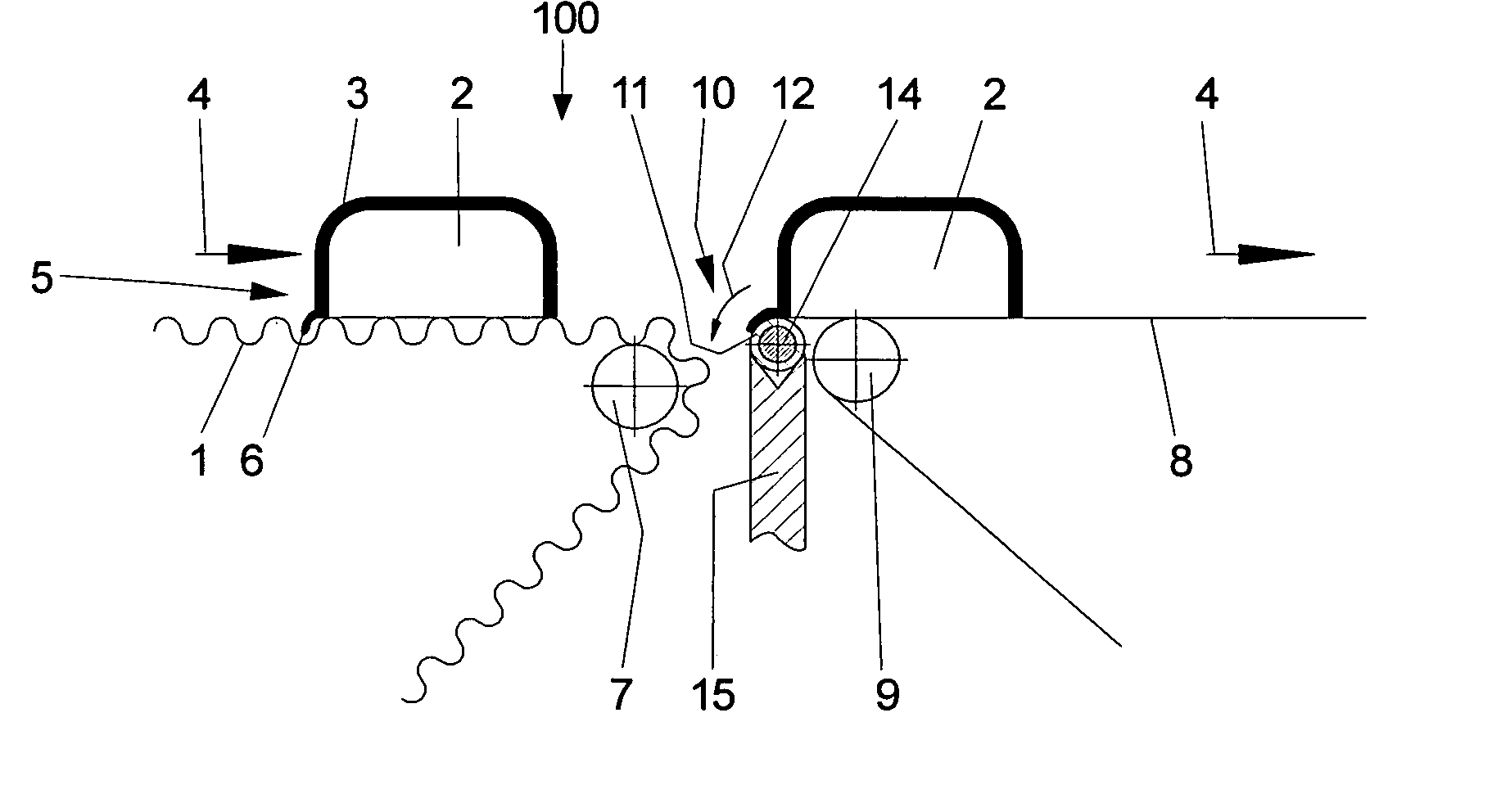

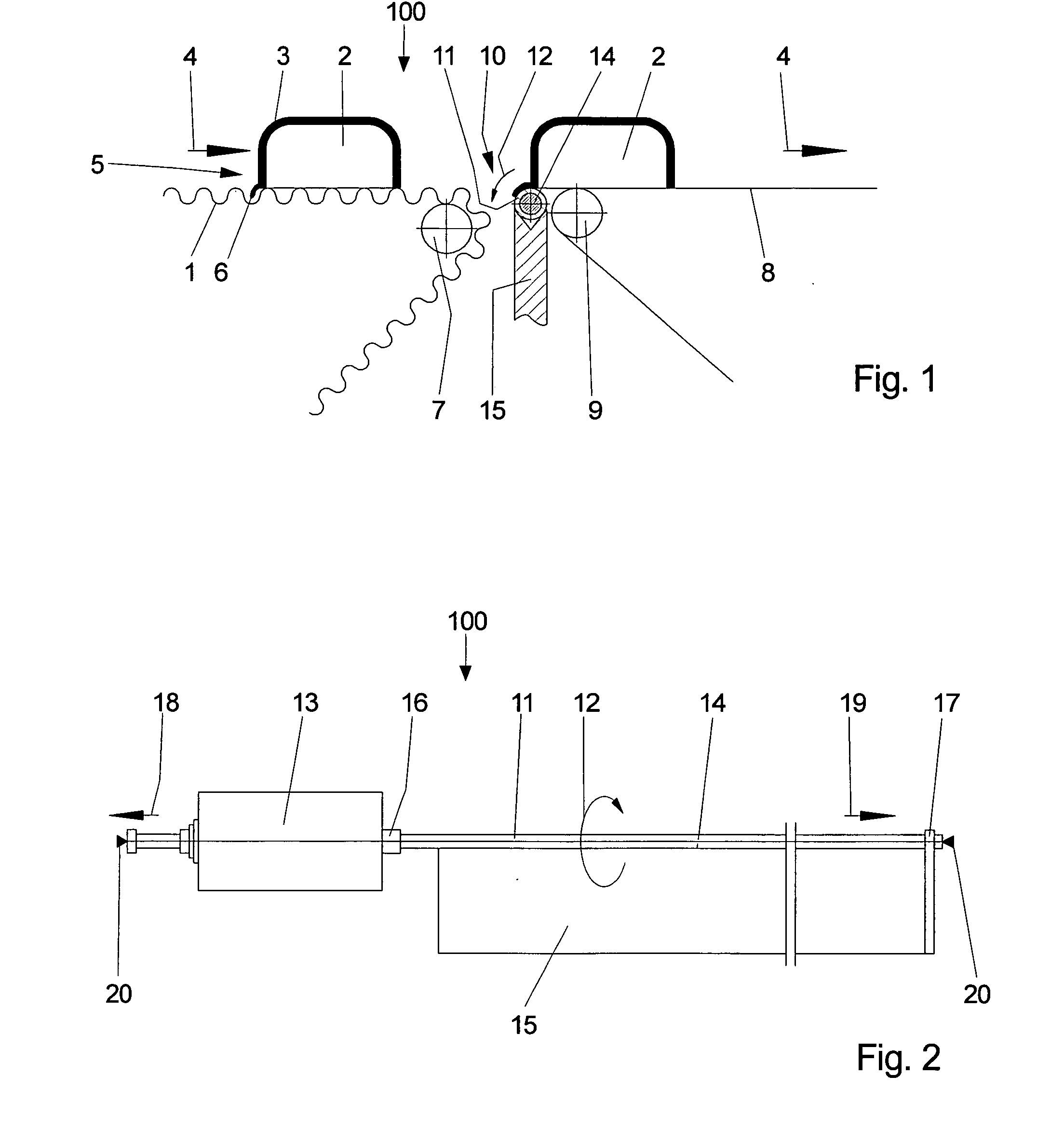

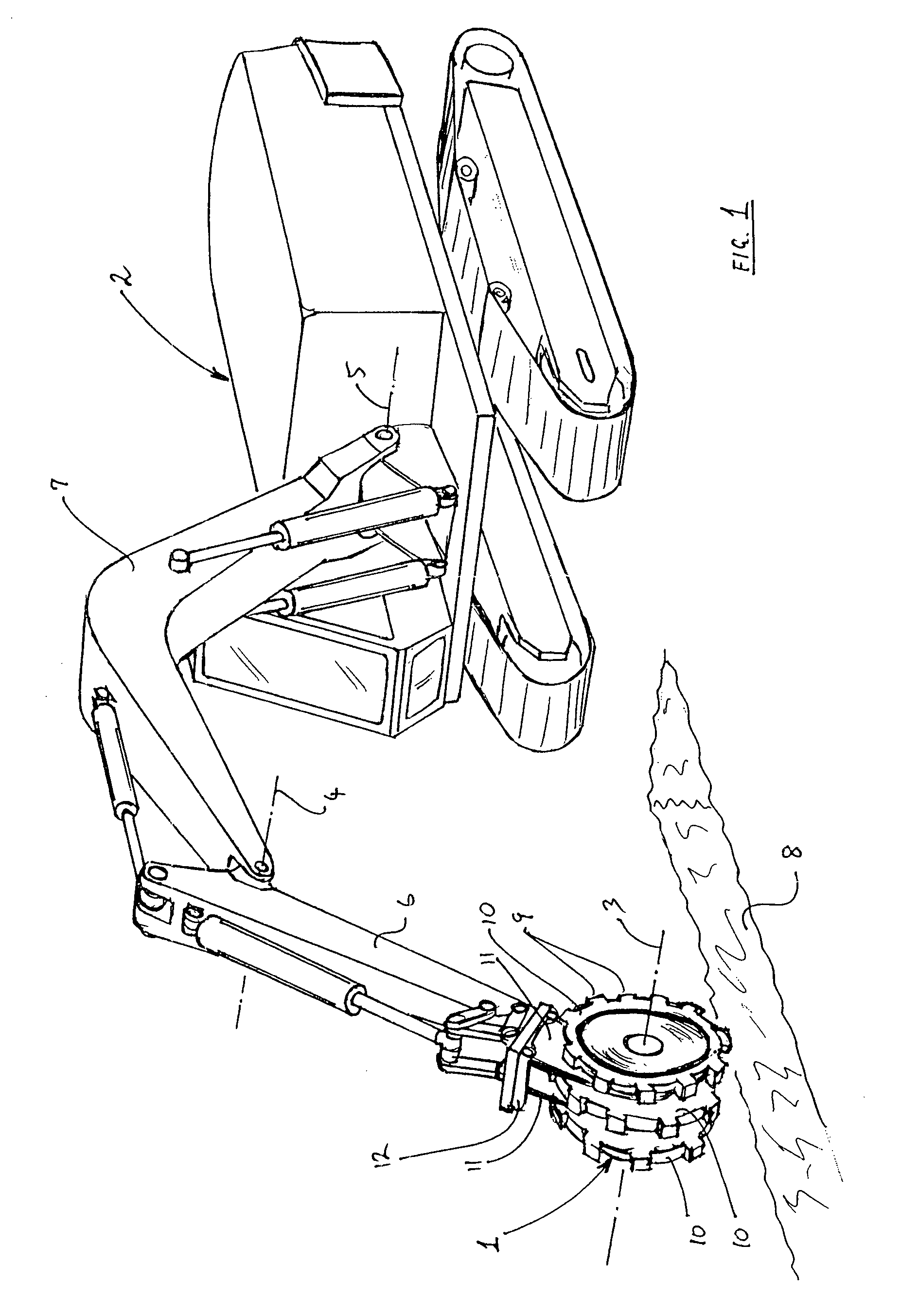

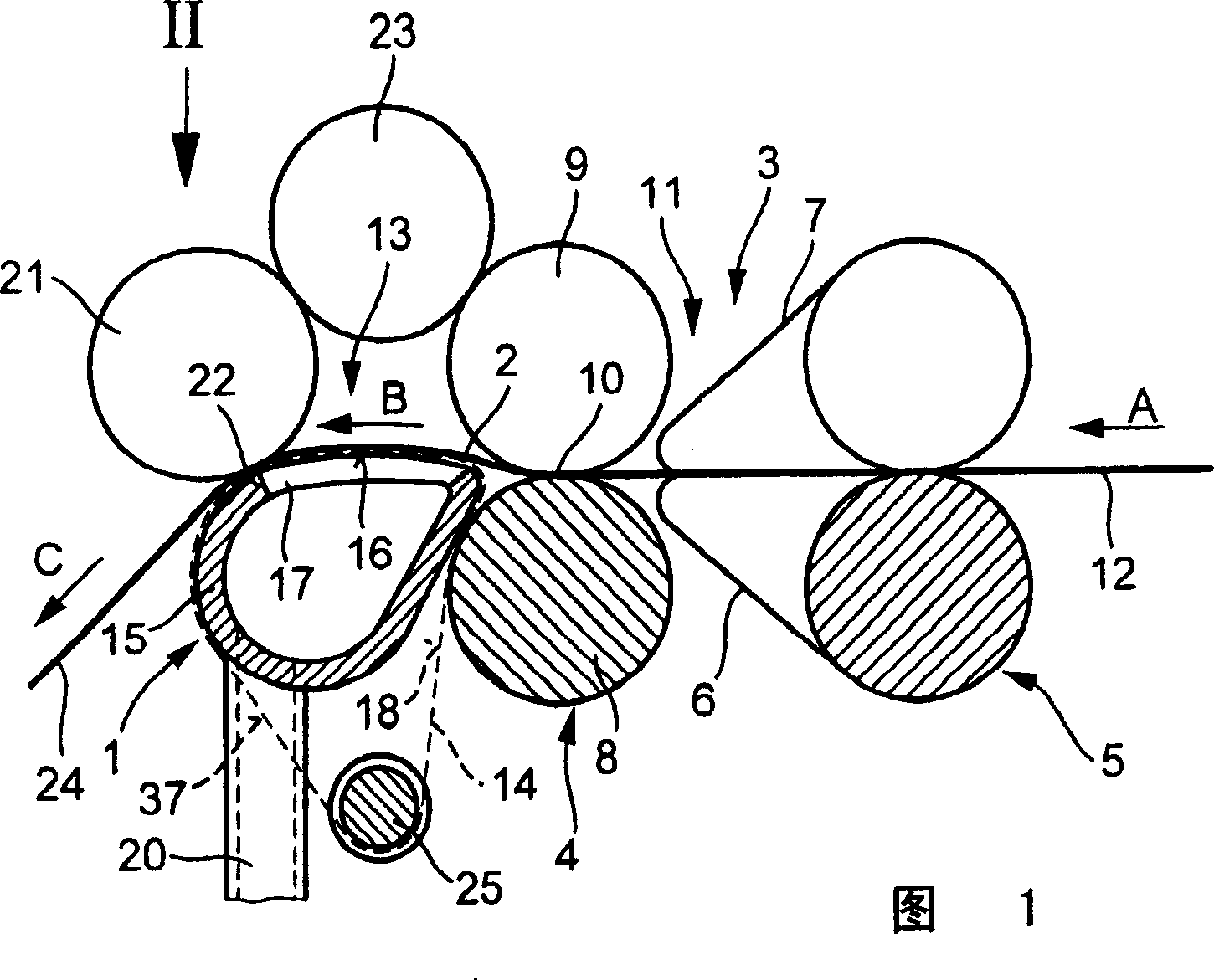

Road finisher

A road paver (F) has a paving screed E the working width of which can be adjusted continuously. In order to further enlarge the working width in steps at least one paving screed extension can be mounted. A distributing auger (6) is supported in a distributing auger support (4). Distributing auger extensions (19a, 19b, 19c) can be mounted to the distributing auger (6). Scraper blades (20) are arranged in casting travelling direction behind distributing auger (6). At least a scraper blade section (20a) functionally associated to a mounted paving screed extension (13) is carried by a channel sheet steel plate (15) being part of the mounted distributing auger extension (19a, 19b, 19c). The scraper blade section (20a) can be adjusted in height direction together with the distributing auger support (4) via a drive (7) which can be remotely controlled during a casting process.

Owner:JOSEPH VOEGELE AG

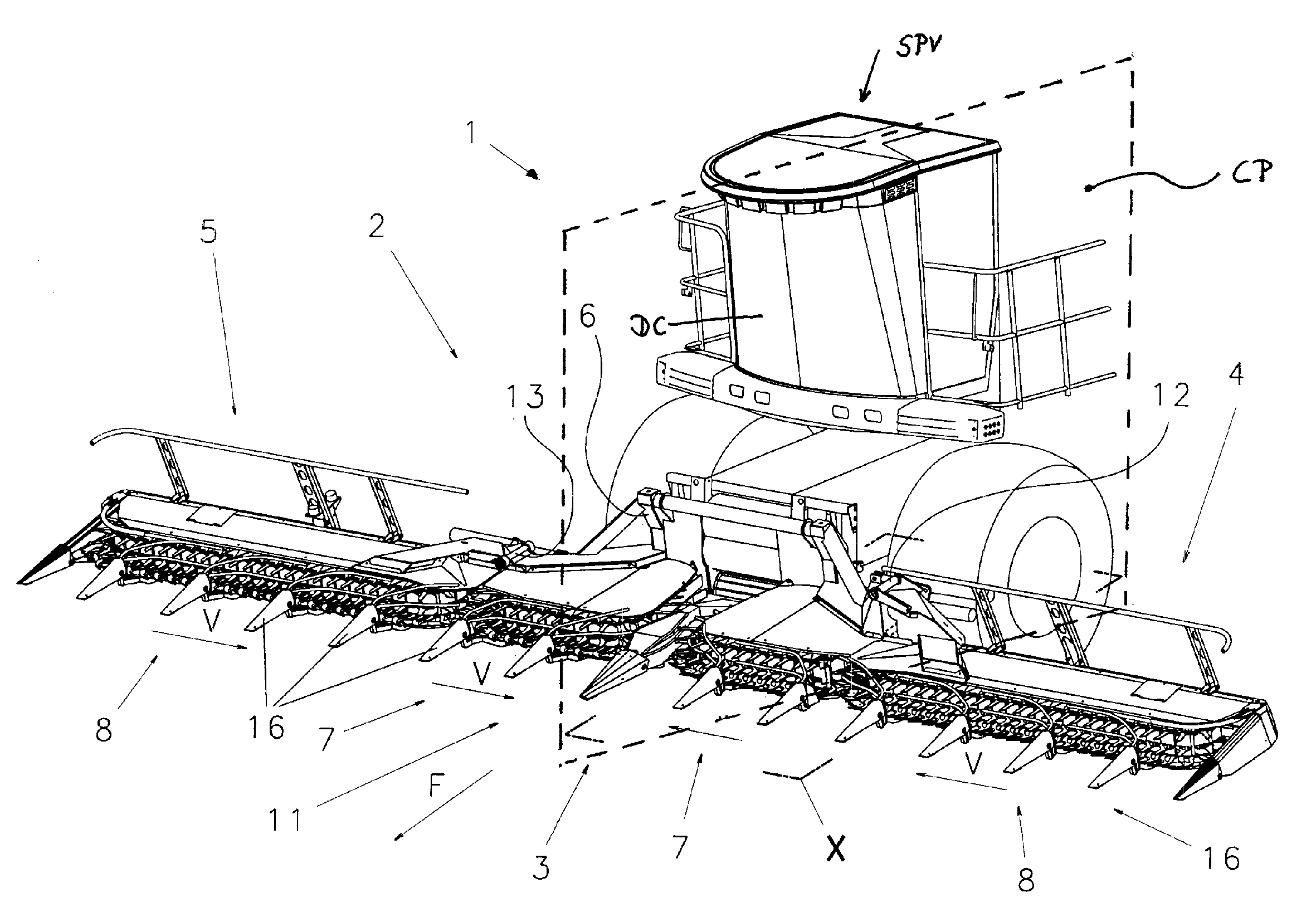

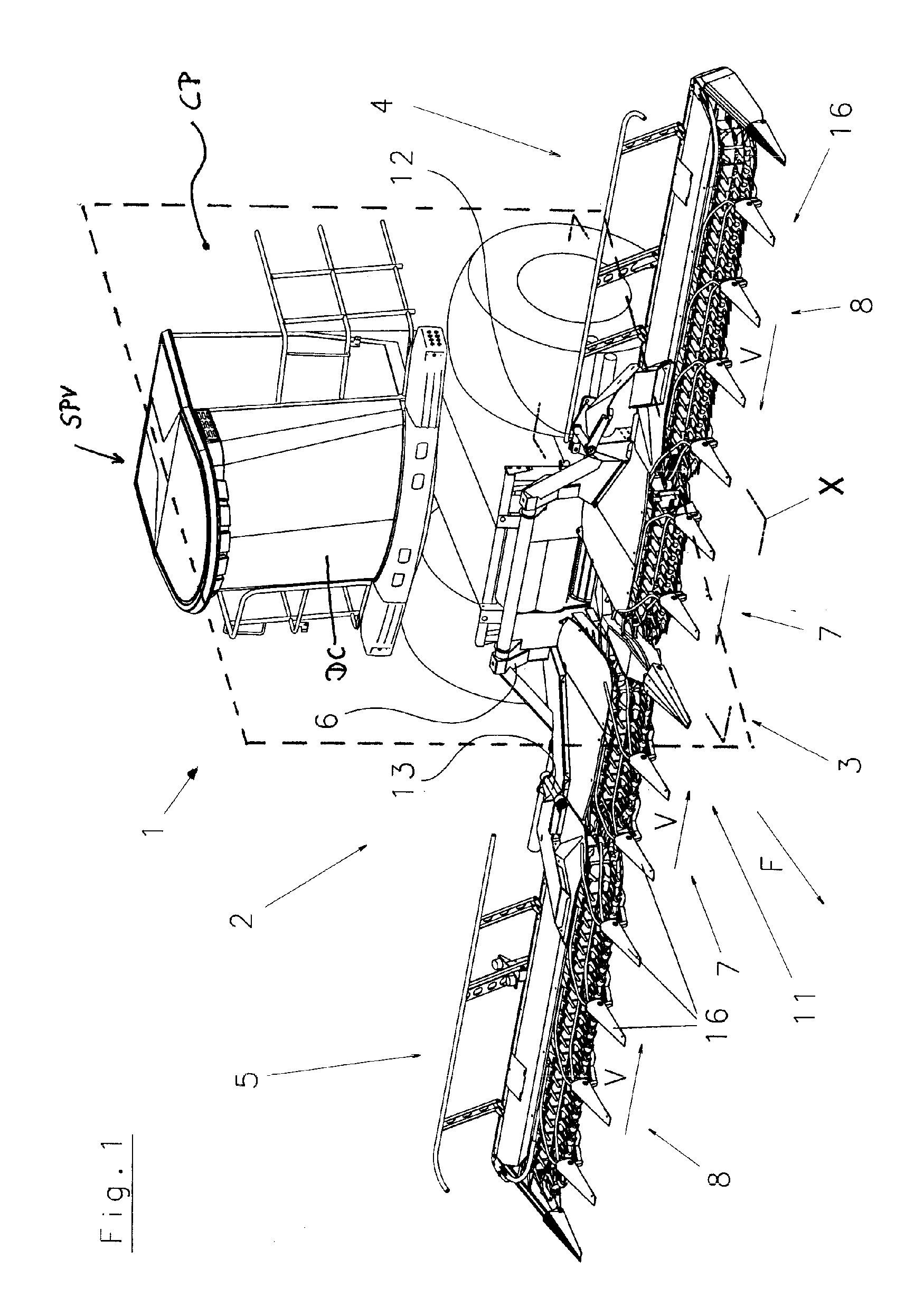

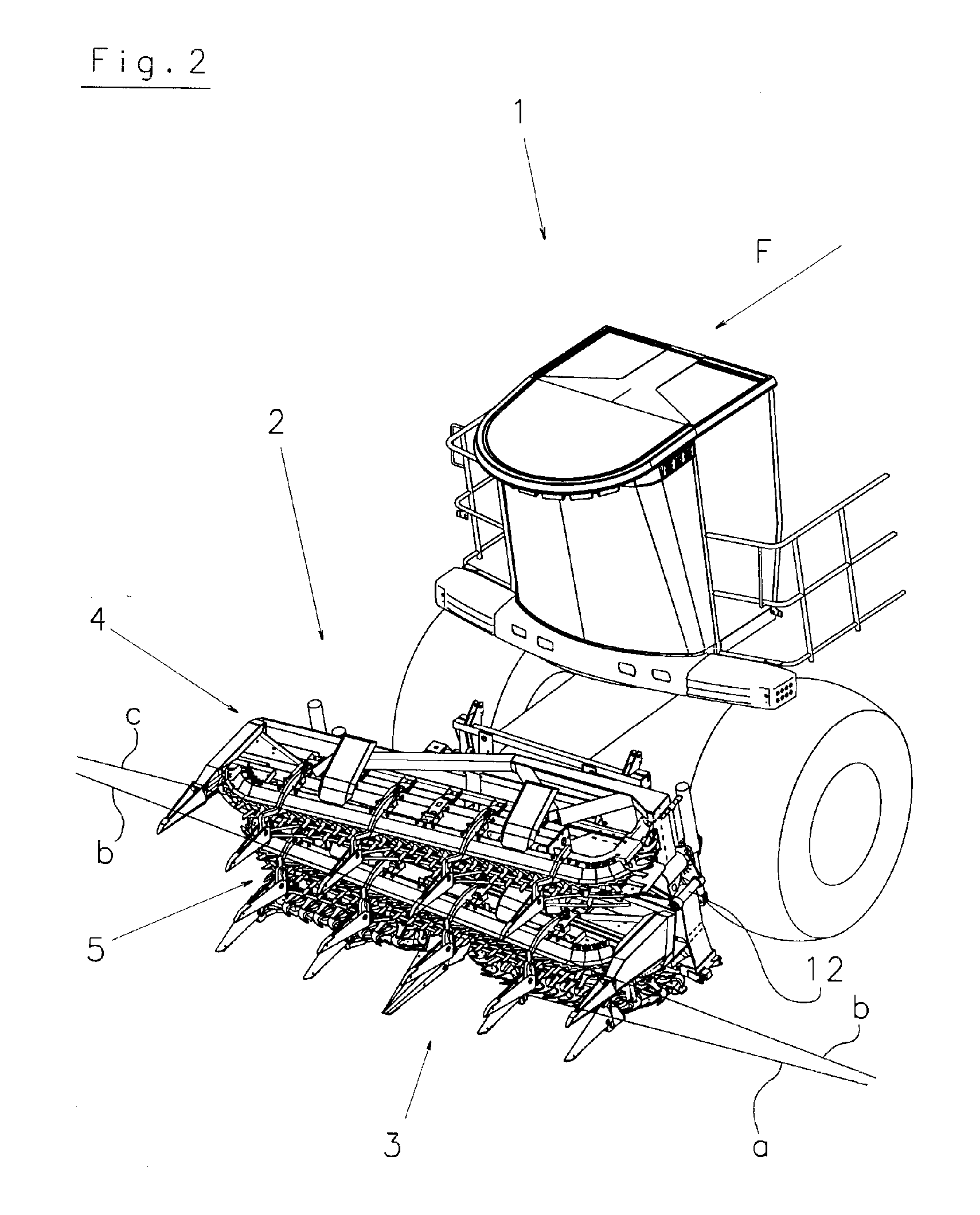

Self-Propelled Agricultural Harvester

InactiveUS20060196161A1Improve traffic safetyReduce weightAgricultural machinesMowersMechanical engineeringAgriculture

Owner:MASCHFAB BERNARD KRONE GMBH

Device for cleaning a functional surface for guiding or treating a material web

InactiveCN102469873AAxial tension loss avoidanceImprove wear resistanceBristle carriersAxial forceEngineering

The invention relates to a device for cleaning a functional surface for guiding or treating a material web, preferably a non-woven web. The device comprises a pivotably mounted roller body, a plurality of hollow cylindrical brush segments being disposed on the circumference thereof and positively connected to each other and tensioned between two adjusting rings disposed at the circumference of the roller body. According to the invention, in order to ensure secure tensioning of the brush segments regardless of the surrounding conditions, at least one of the adjusting rings is axially flexibly retained at the circumference of the roller body and a compression ring rotational fixed to the flexible adjusting rings is axially tensioned against the roller body by means of at least one spring element, such that an axial force acting on the brush segments is generated.

Owner:OERLIKON TEXTILE GMBH & CO KG

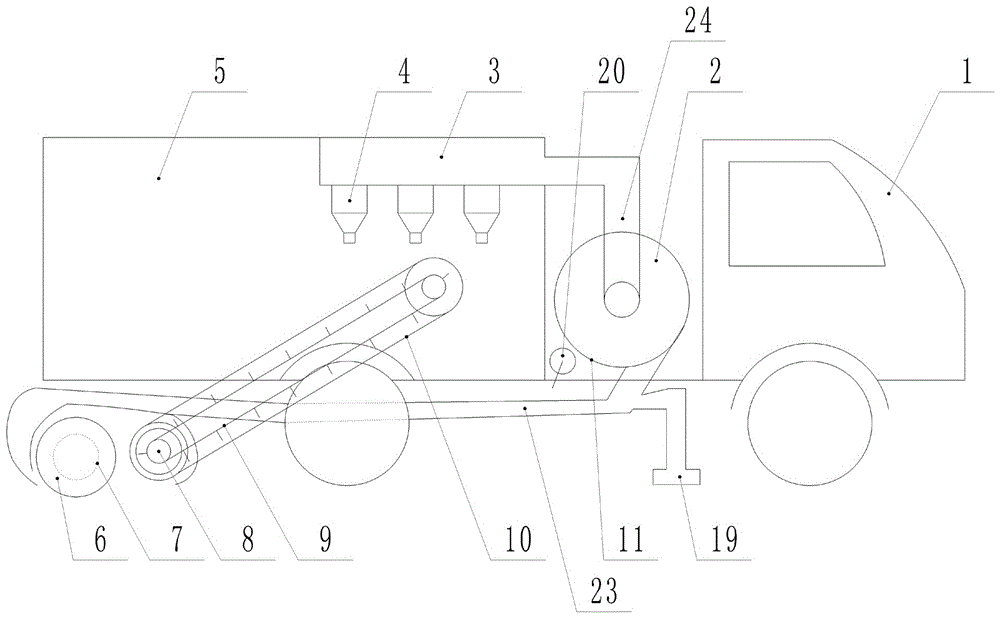

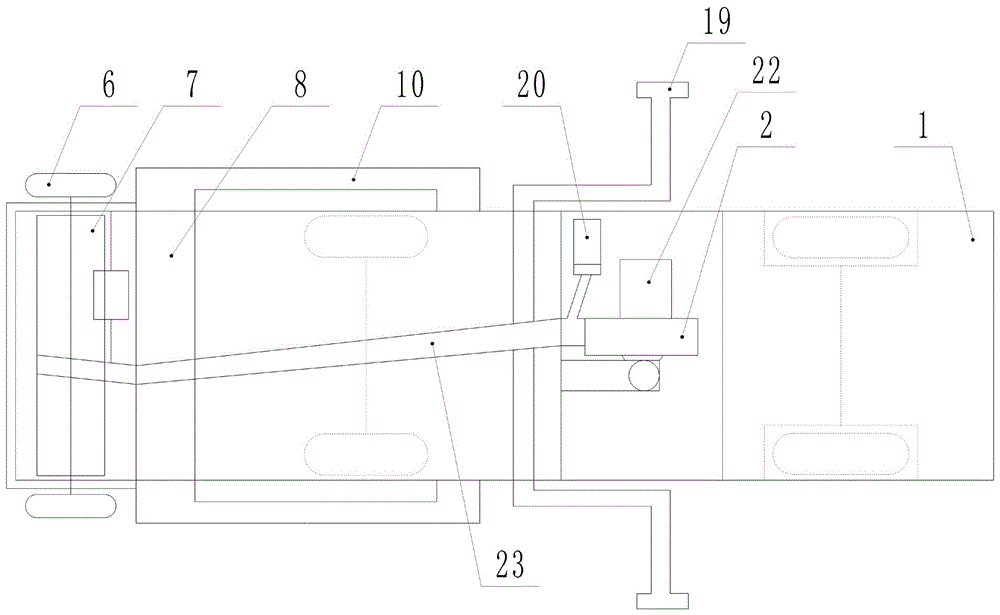

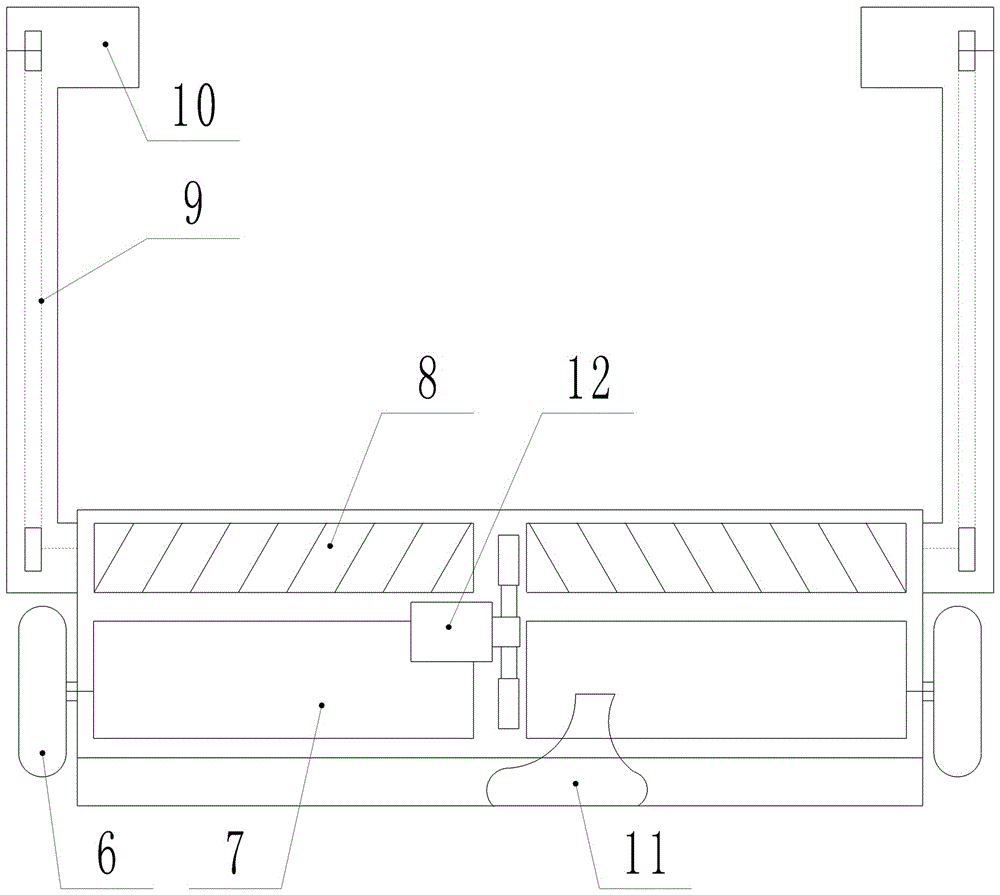

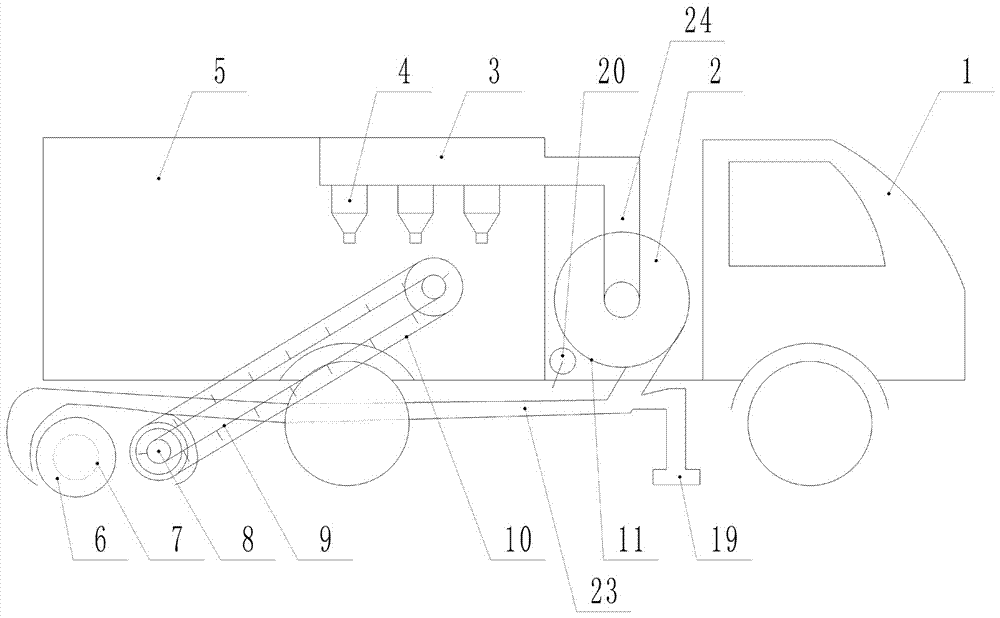

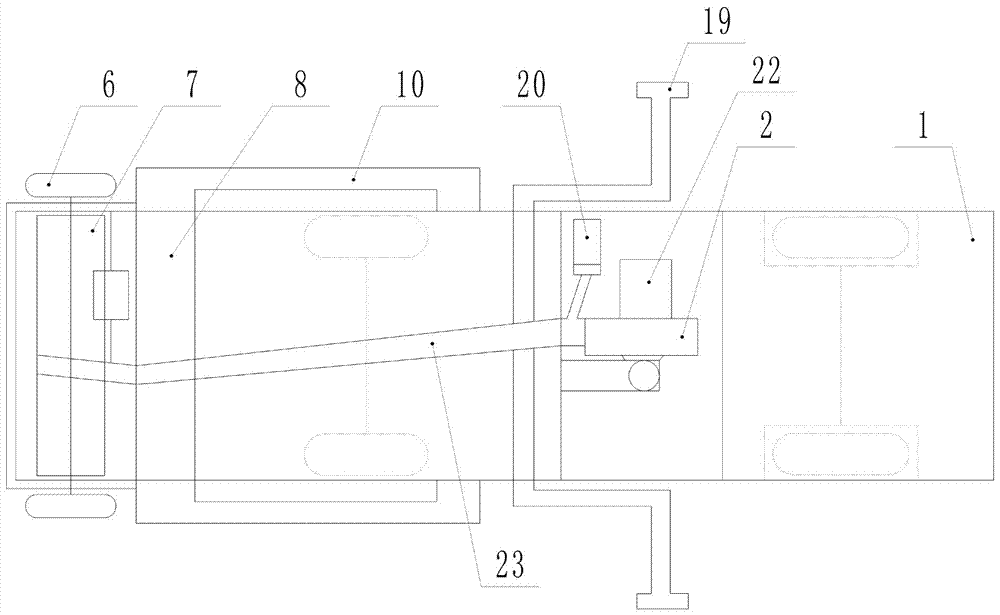

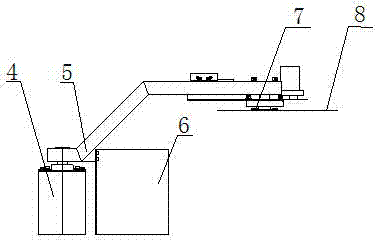

Self-propelled insect suction machine

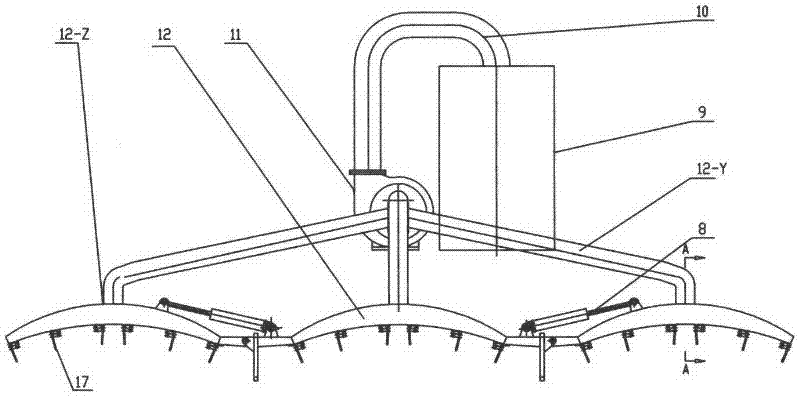

ActiveCN102388853AIncrease working widthSmall turning radiusInsect catchers and killersEngineeringPollution

The invention relates to a self-propelled insect suction machine and belongs to the technical field of agricultural and forestry machines. The air outlet of the suction fan of the self-propelled insect suction machine leads to a filter bag. The air inlets of the suction fan are divided into three loops and are respectively connected with a middle insect suction nozzle, a left insect suction nozzle and a right insect suction nozzle through air inlet hoses. Slip insect suction ports with a sundries preventing net are arranged on the lower surface of the shell of each insect suction nozzle. The two sides of the middle insect suction nozzle are respectively hinged with the adjacent ends of the left insect suction nozzle and the right insect suction nozzle. A telescopic cylinder is installed at each hinged position. When the telescopic cylinders are in an extended state, the left insect suction nozzle, the right insect suction nozzle and the middle insect suction nozzle are arranged at thesame level; and when the telescopic cylinders are in a contracted state, the length directions of the left insect suction nozzle and the right insect suction nozzle are perpendicular to the length direction of the middle insect suction nozzle, and the left insect suction nozzle and the right insect suction nozzle are in a folded state. When the self-propelled insect suction machine works, the suction fan continuously sucks in air flows with insects from the insect suction nozzles, the air flows are delivered to the filter bag, the insects are intercepted into the filter bag through filtrationand therefore the pollution-free physical deinsectization is realized.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

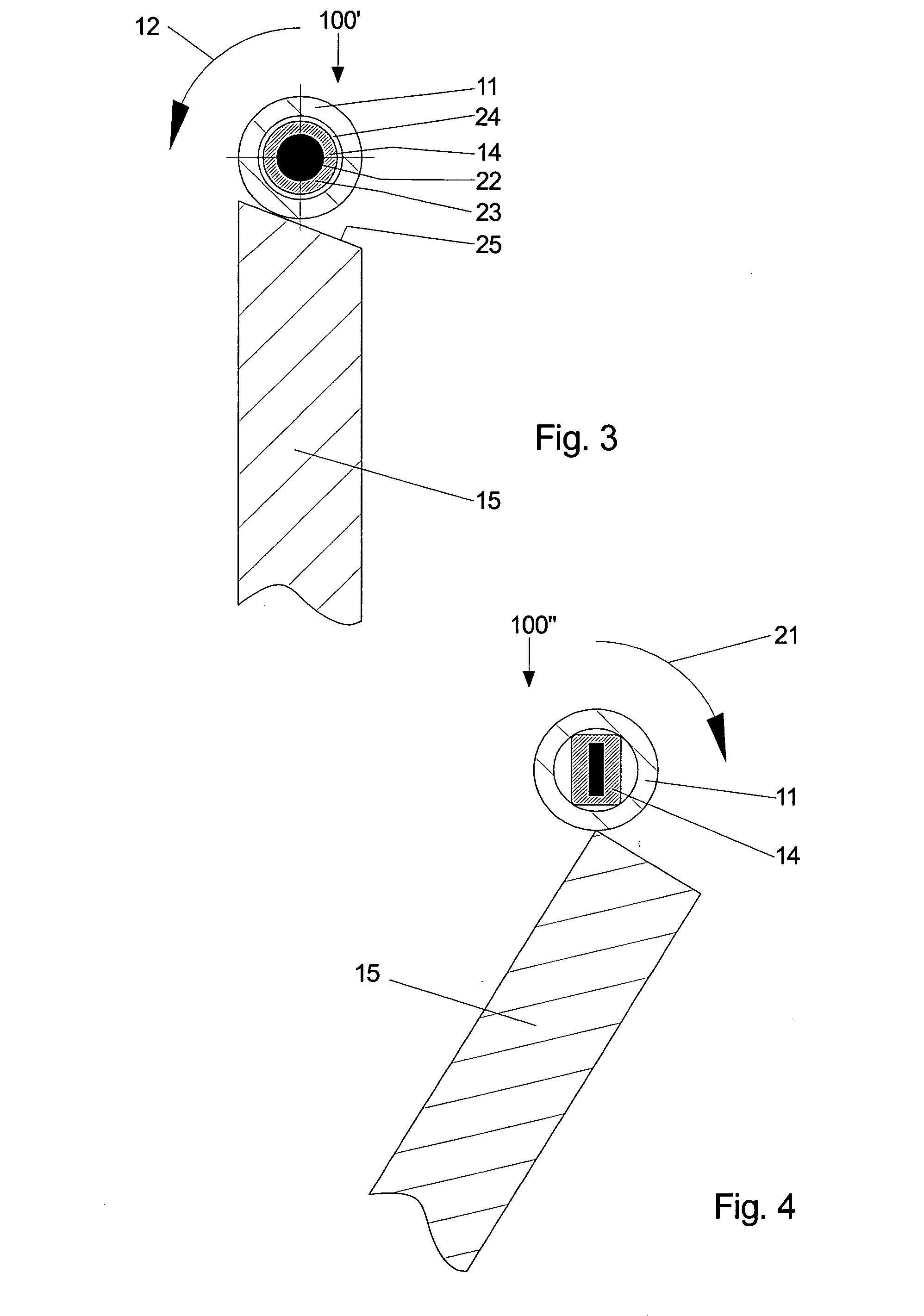

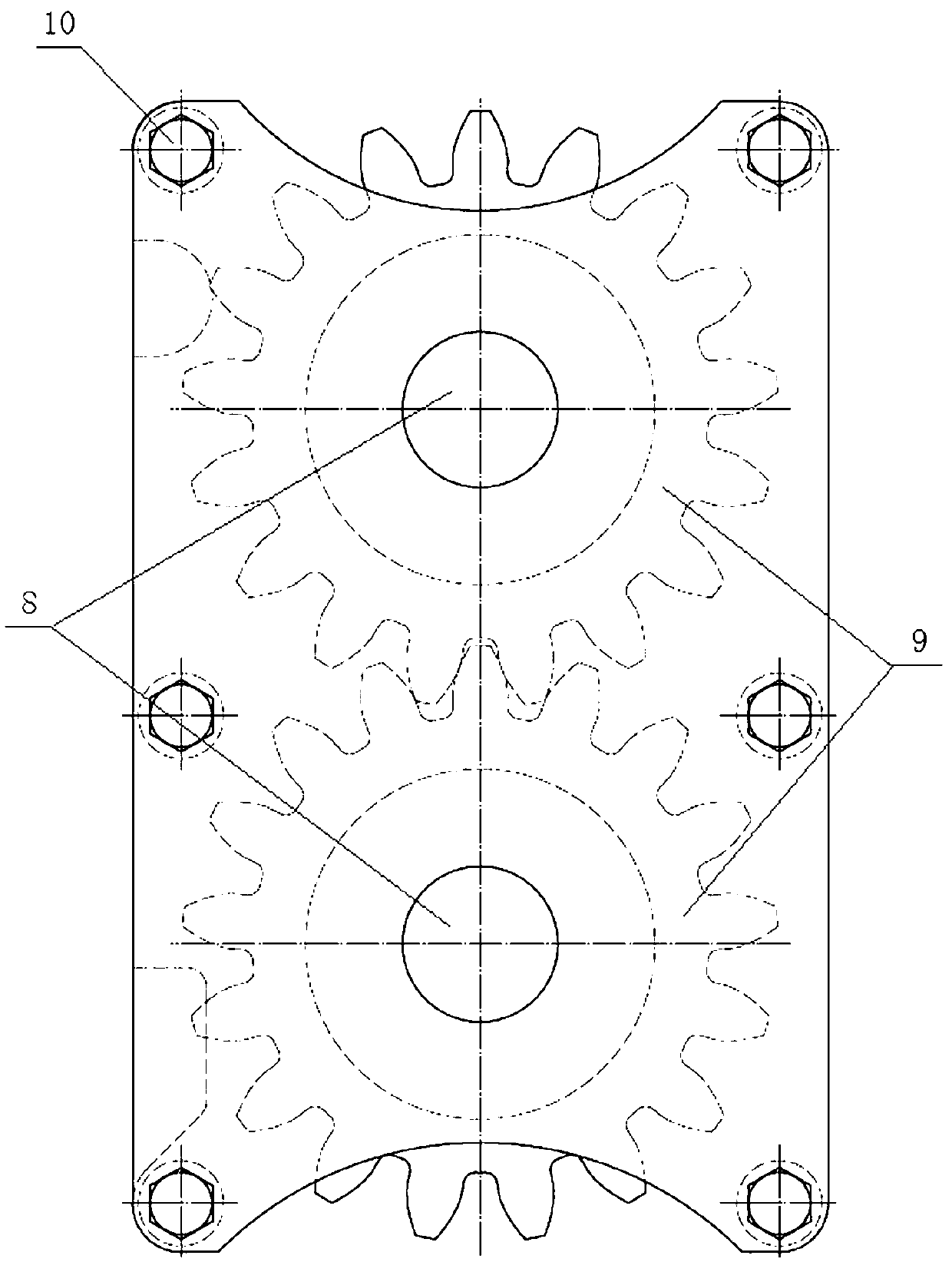

Plastic looping tool guide bar

The invention relates to a plastic looping tool guide bar 1, which comprises a main body 2. The main body 2 comprises an upper wall 4 forming an upper side, a lower wall 6 forming a lower side and a hollow chamber assembly. It is desired to make the working speed of a warp knitting machine as high as possible. To the end, the hollow chamber assembly comprises at least two hollow chambers 8, 9 which are separated through a reinforcing part 10.

Owner:KARL MAYER STOLL R&D GMBH

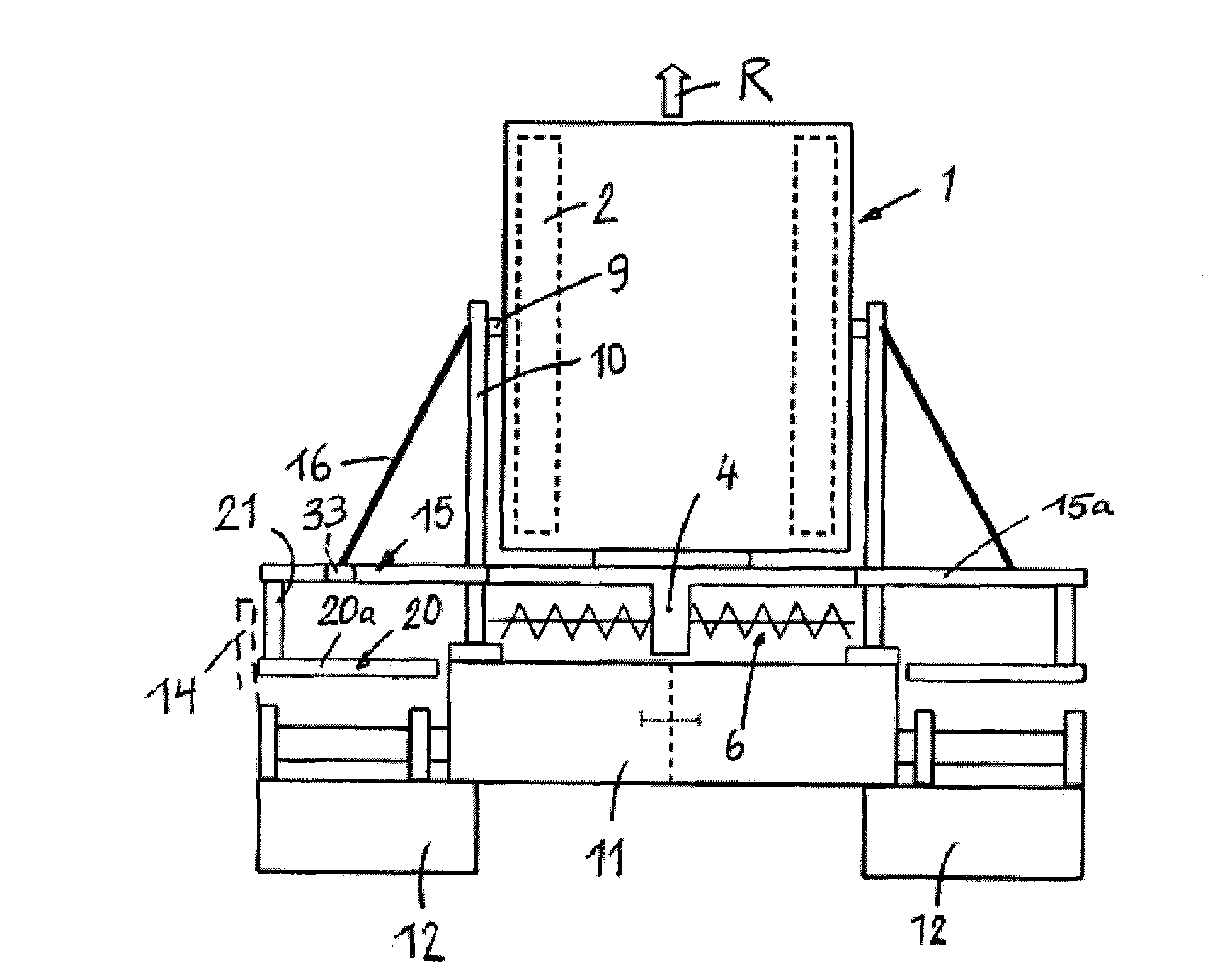

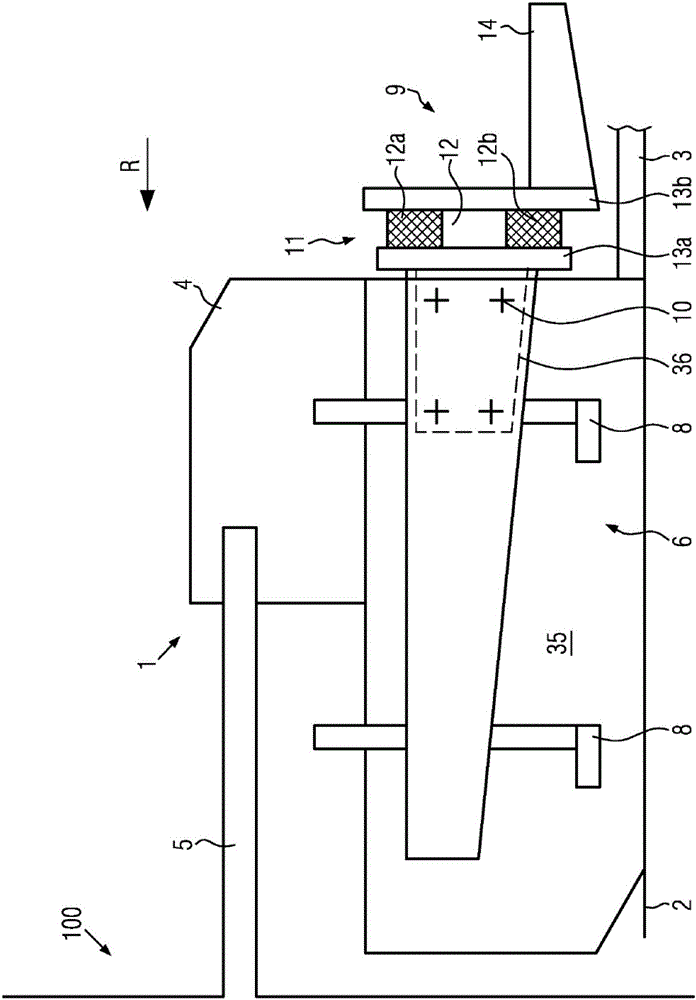

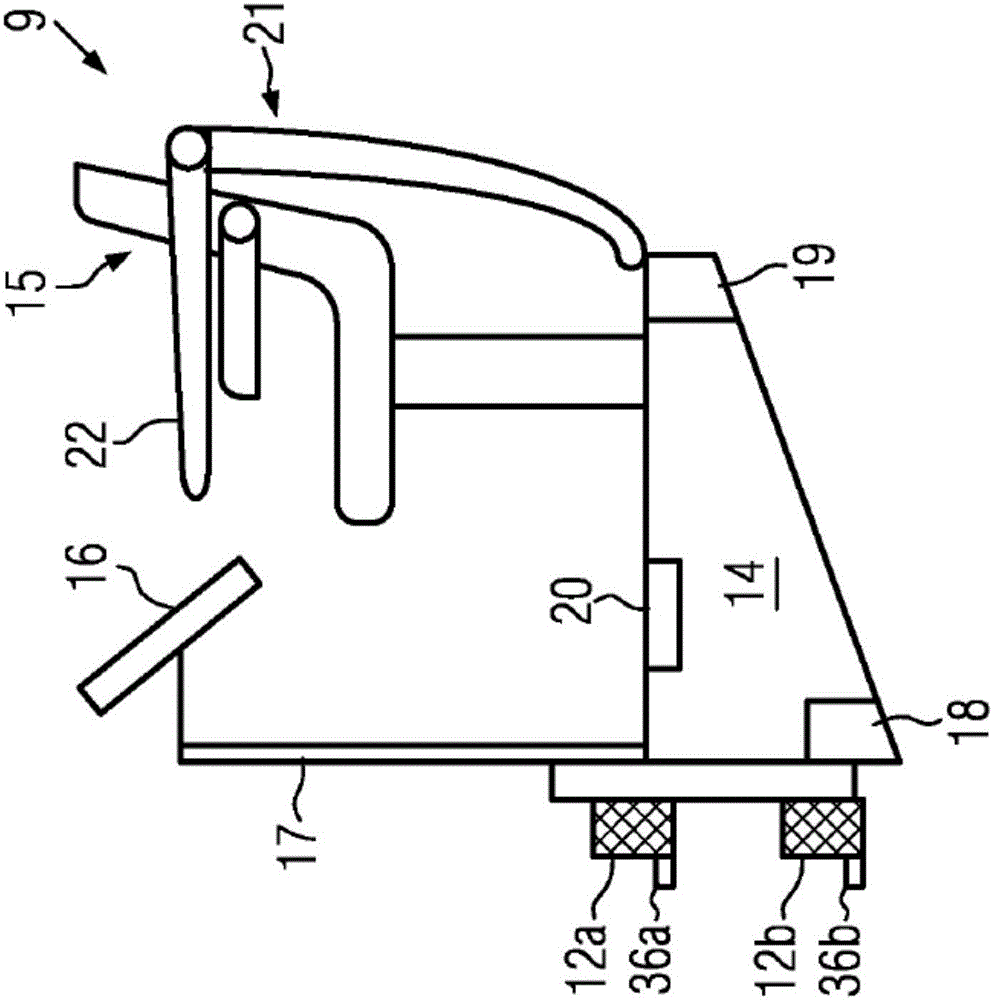

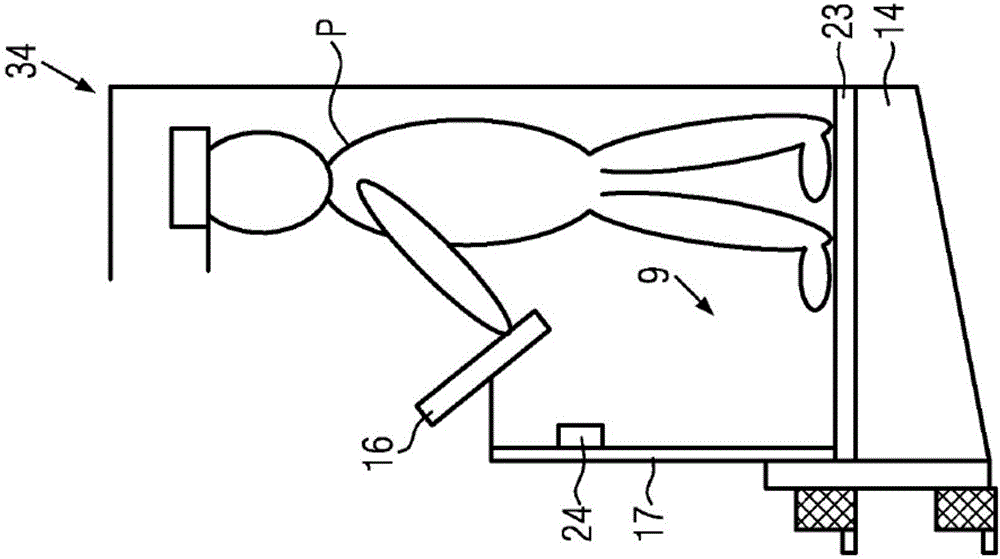

Screed assembly comprising a work station

The application relates to a screed assembly (1) for laying a road surface (3), said screed assembly (1) determining a working width (W), viewed in the working direction (R), for the laying of the road surface (3), and a working station (9) for an operator (P) being mounted on the screed assembly (1). The working station (9) is mounted on the screed assembly (1) in a vibration-decoupled manner, such that the transmission of vibrations from the screed assembly (1) to the working station (9) can be reduced or prevented.

Owner:JOSEPH VOEGELE AG

Apparatus for removing molten mass from confectionaries

ActiveUS20070163491A1Reliable wayIncrease working widthLiquid surface applicatorsConfectioneryEngineeringConveyor belt

An apparatus for removing molten mass, especially chocolate mass, from a rear bottom portion of items, especially confectionaries, includes a first and a second conveyor belt for transporting the items in a conveying direction perpendicular to the working width of the apparatus. The second conveyor belt is located adjacent to the fist conveyor belt and downstream of the first conveyor belt as seen in the conveying direction. A driven hollow shaft is located in a gap portion between the two conveyor belts, it extends over the working width, and it is supported from its inside and within the working width.

Owner:SOLLICH GMBH & CO KGAA

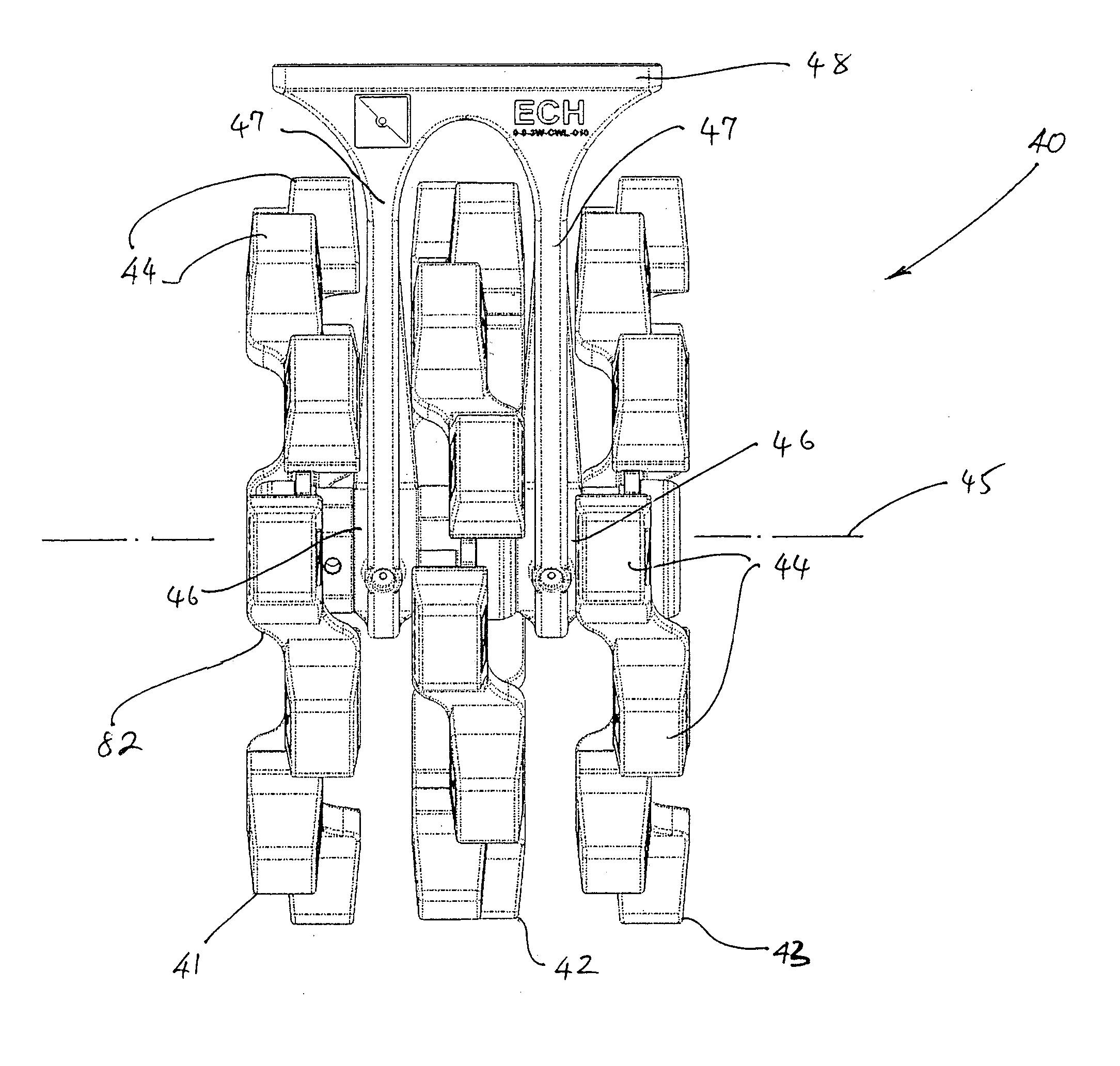

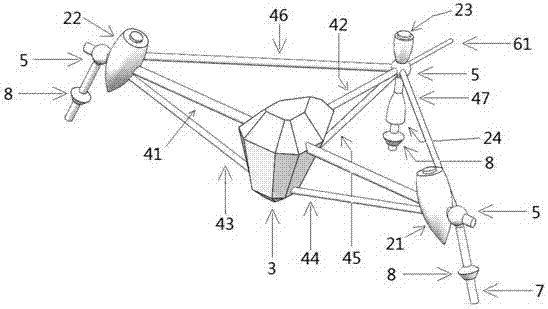

Trench compacting apparatus

InactiveUS8215867B2Increase working widthAgricultural rollersRoads maintainenceGround contactMechanical engineering

A compacting device (40) for attachment to an earthmoving machine (2) to compact a substrate is described. The compacting device (40) includes a plurality of wheel assemblies (41, 42, 43) mounted for rotation in bearings (46). A support is also provided, having a base part (48) that is adapted to be mounted to the earthmoving machine (2). One or more bearing support members (47) extend from the base part (48) and between the wheel assemblies (41, 42, 43) to support the bearings (46). Each wheel assembly (41, 42, 43) includes a set of ground-contacting feet (44) secured to and peripherally spaced apart around a rim portion of the wheel assembly (41, 42, 43). In this arrangement, when the device (40) is rolled over the substrate a first foot of said set of ground engaging feet (44) contacts the substrate between axial width limits that differ from axial width limits of a second foot of said set of ground engaging feet (44).

Owner:ARMAGH (VIC) PTY LTD

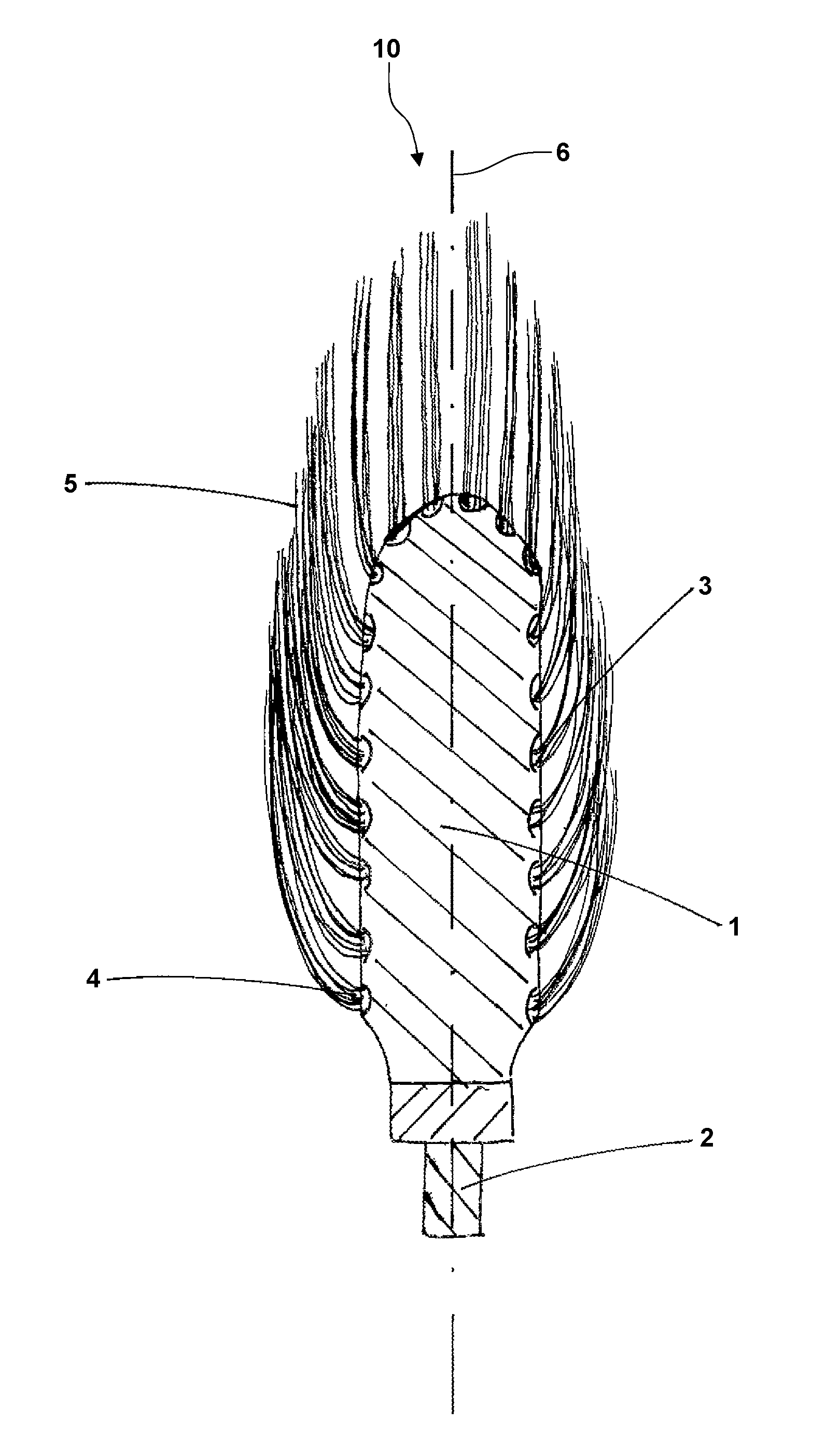

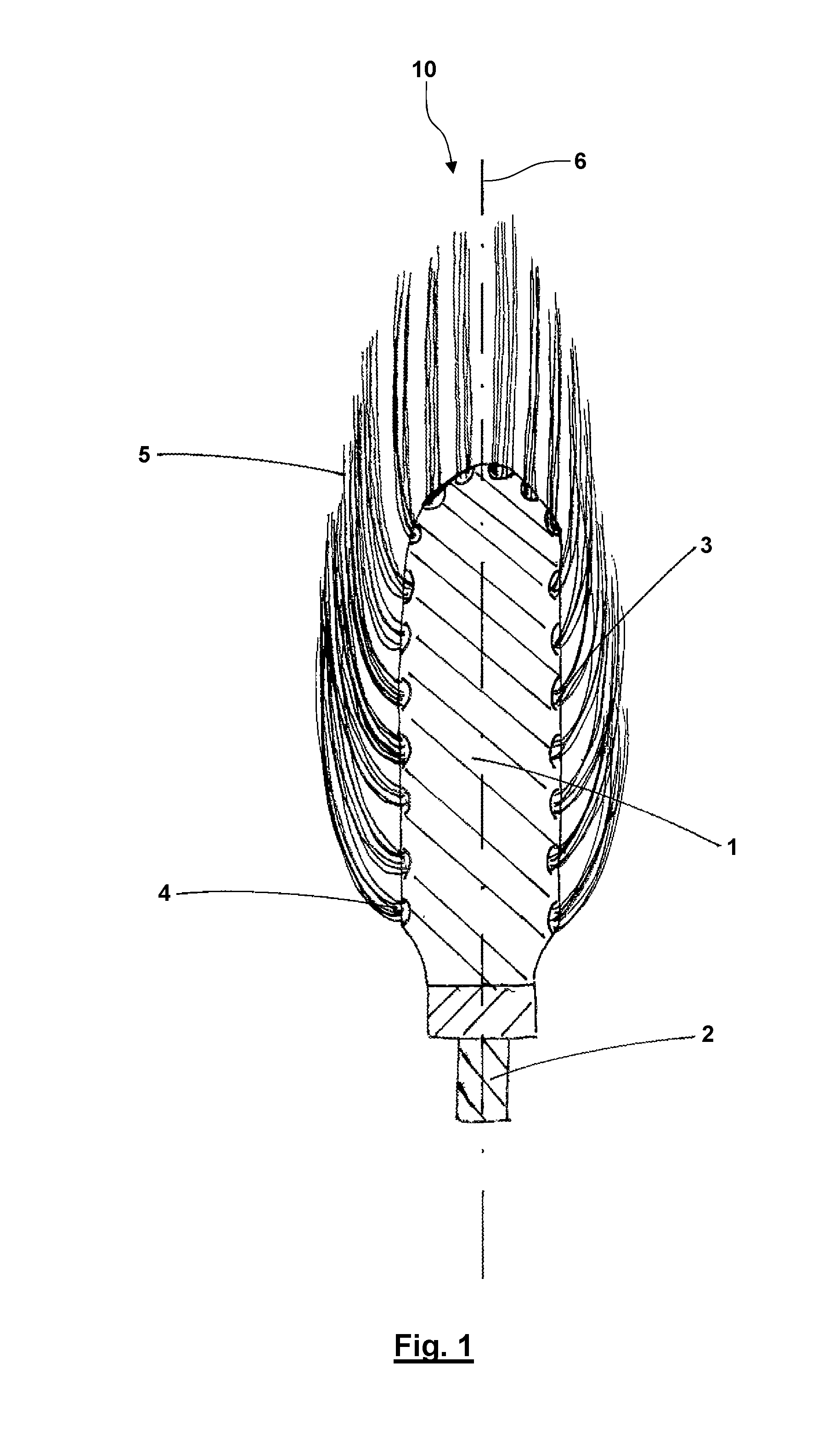

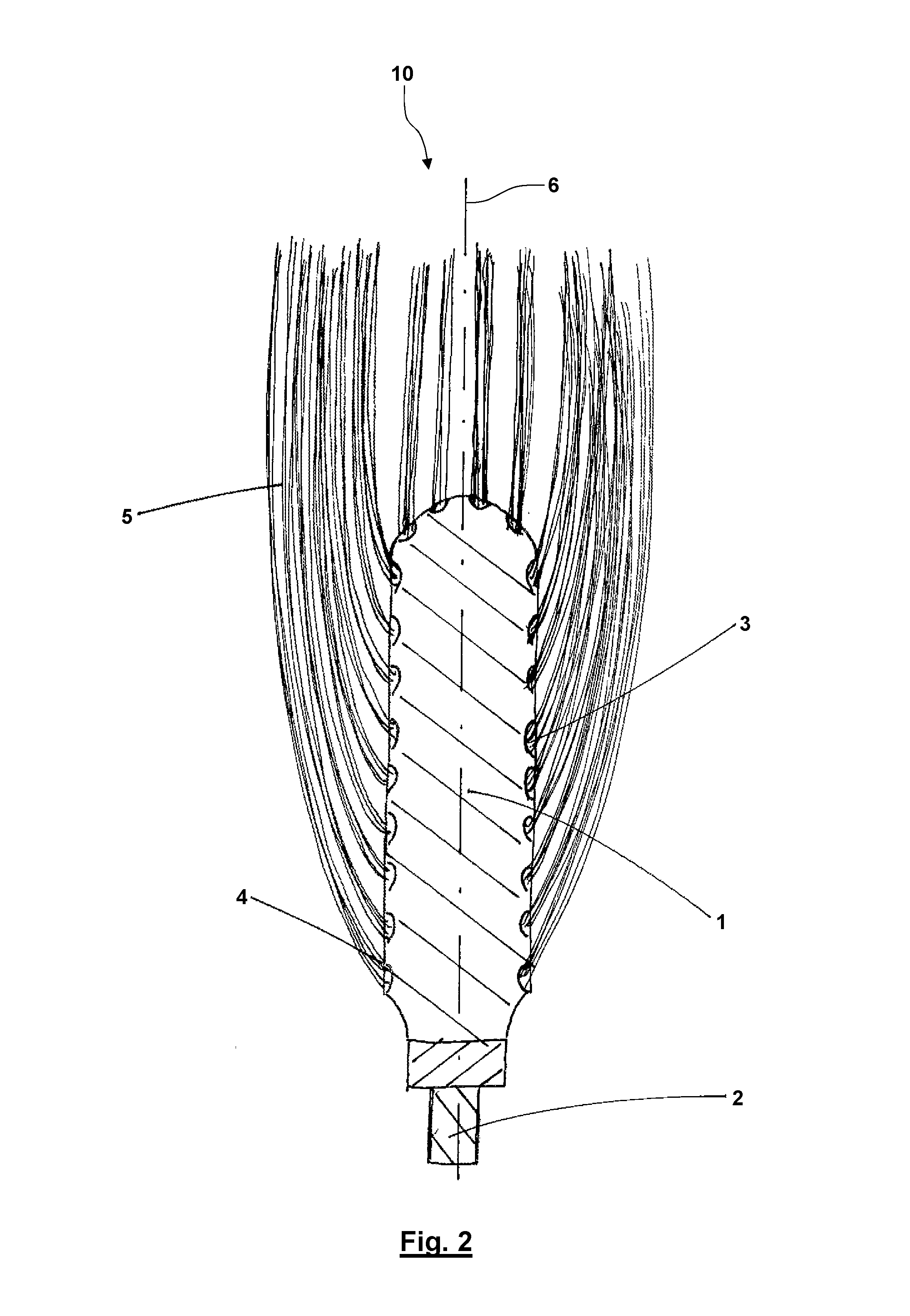

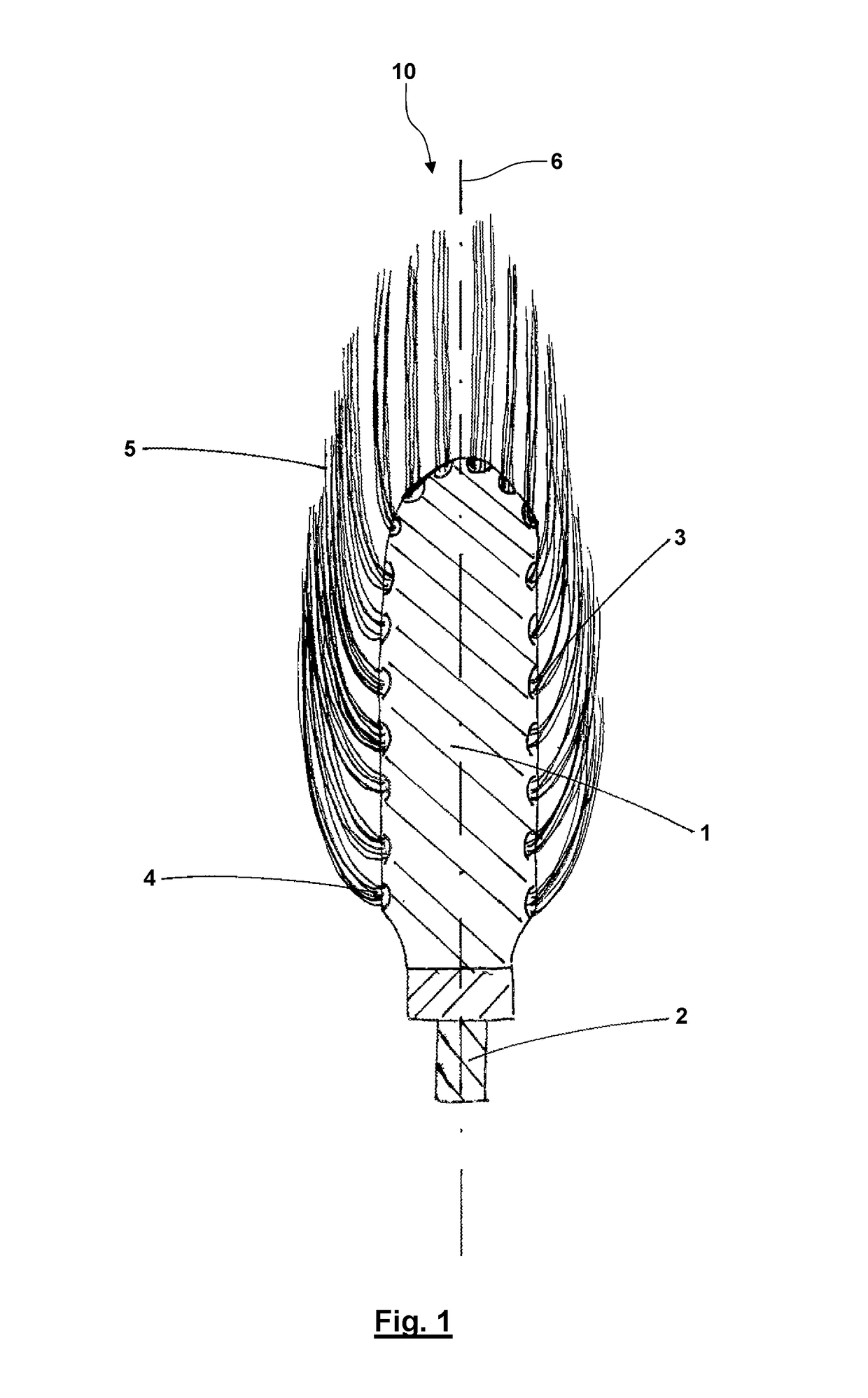

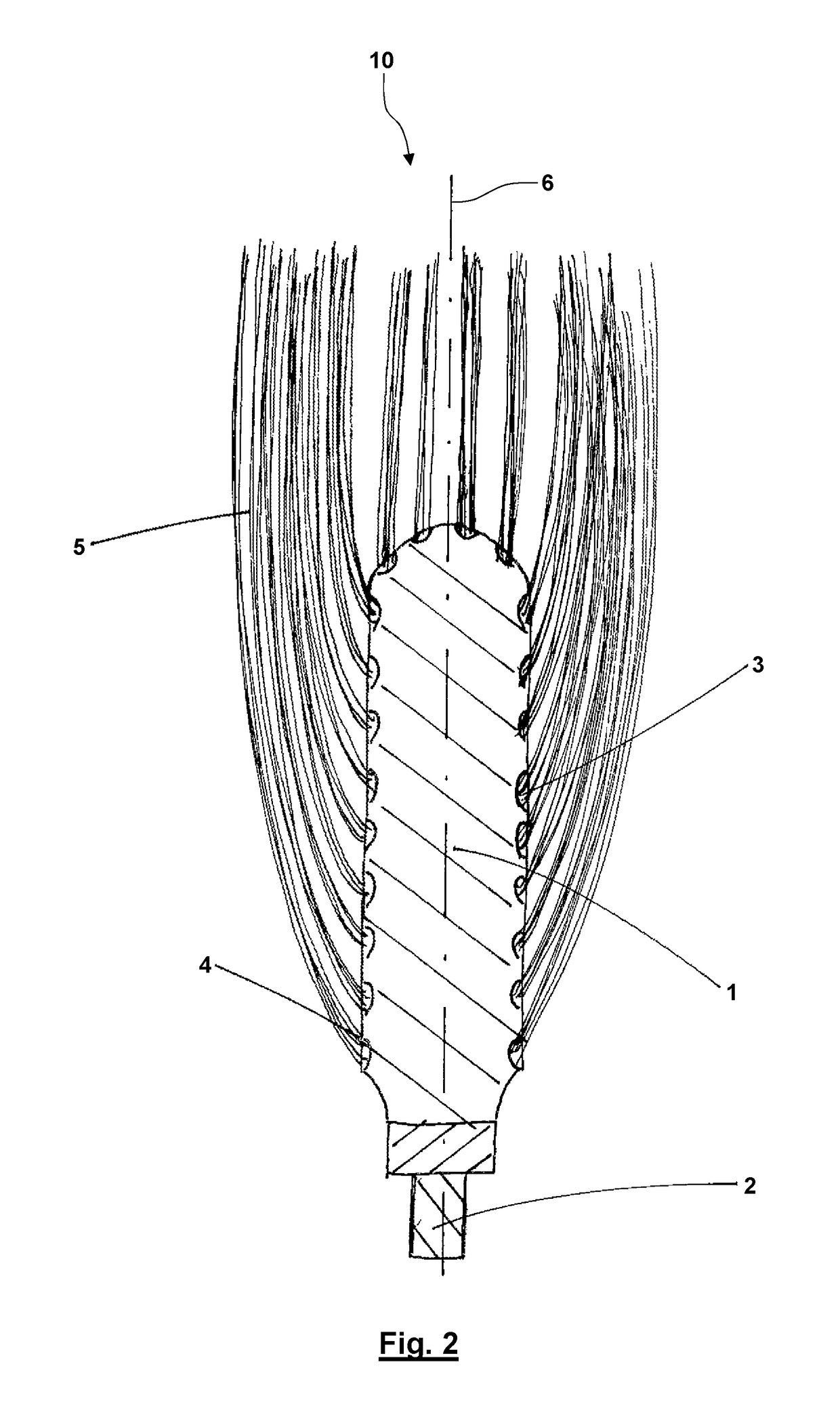

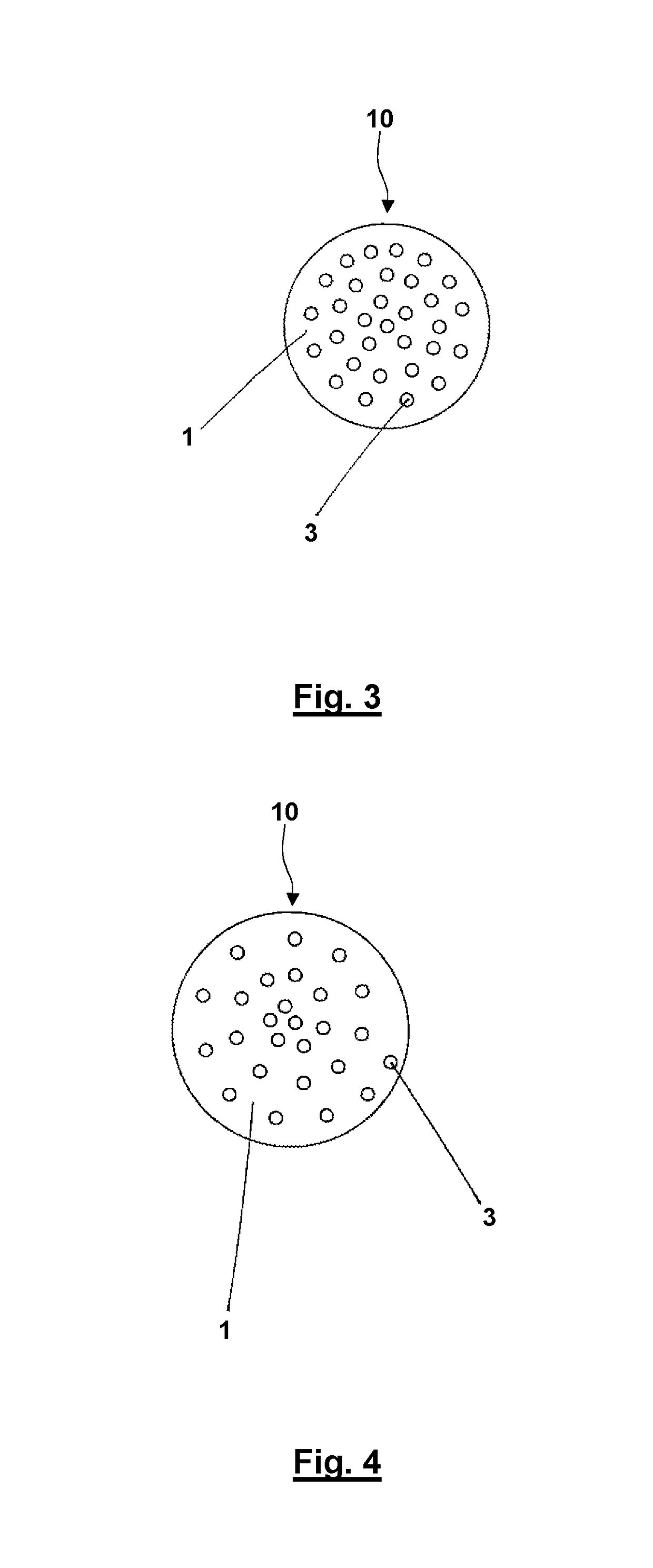

Rotating cleaning brush

A rotating cleaning brush (10) includes a connection pin (2) to be clamped in a chuck of a machine for rotatingly driving the cleaning brush (10) about its longitudinal axis (6). The cleaning brush (10) includes a bristle carrier (1) including a plurality of openings (3). The bristle carrier (1) includes a first bristle bundle (4) and a second bristle bundle (4) being adjacent along the longitudinal axis (6). The first bristle bundle (4) is located closer to the first end region of the cleaning brush (10) than the second bristle bundle (4). Each of the bristle bundles (4) includes a plurality of bristles (5) and is located in one of the openings (3). The bristles (5) of the first bristle bundle (4) are designed to be bent towards the longitudinal axis (6) such that they overlap the opening (3) in which the second bristle bundle (4) is arranged.

Owner:DURCHLAUB THOMAS DR

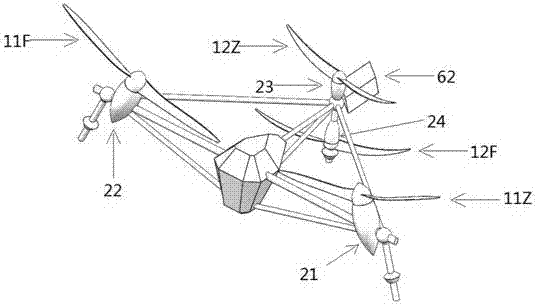

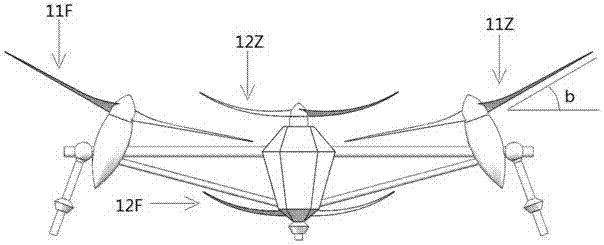

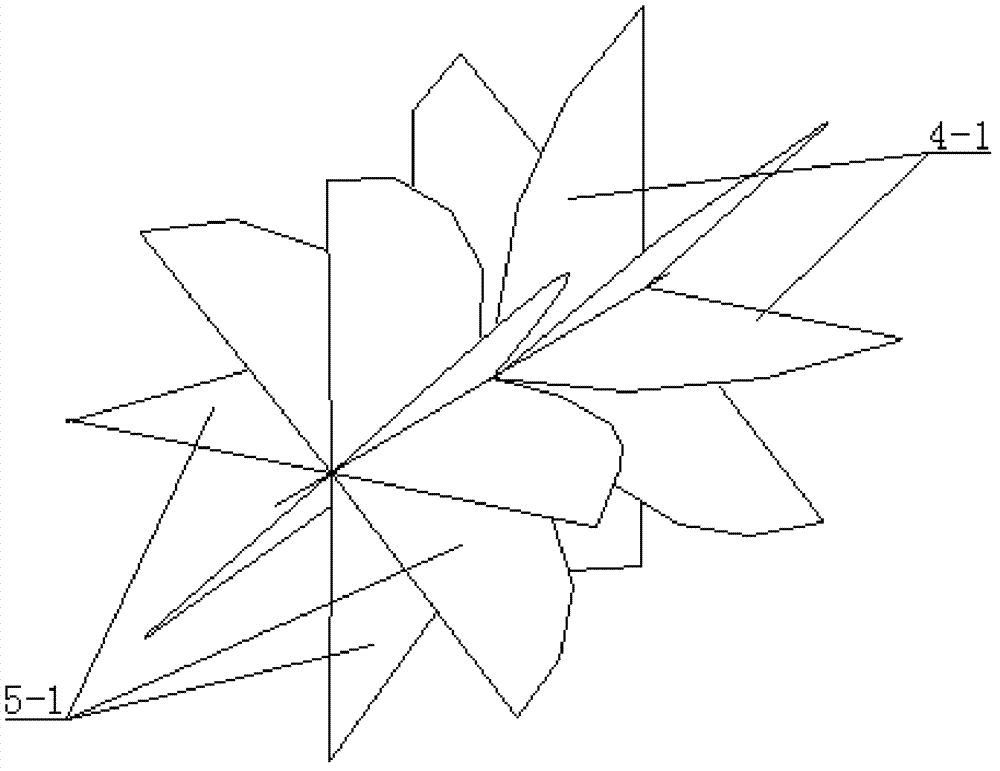

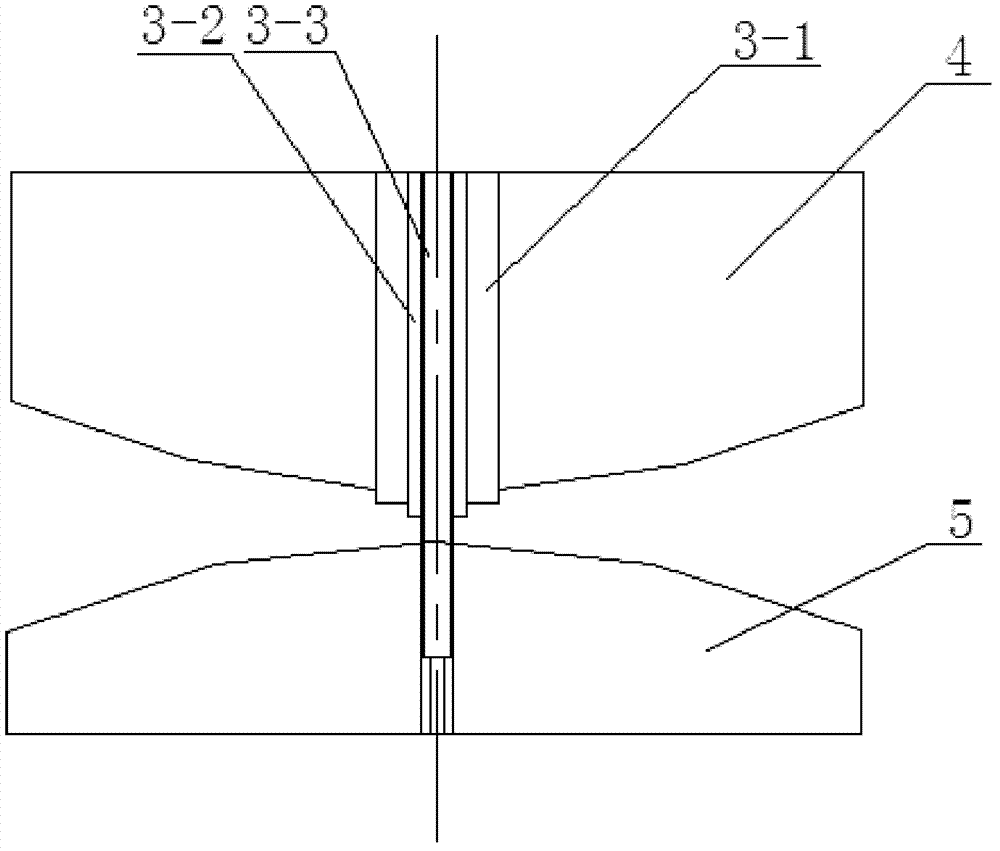

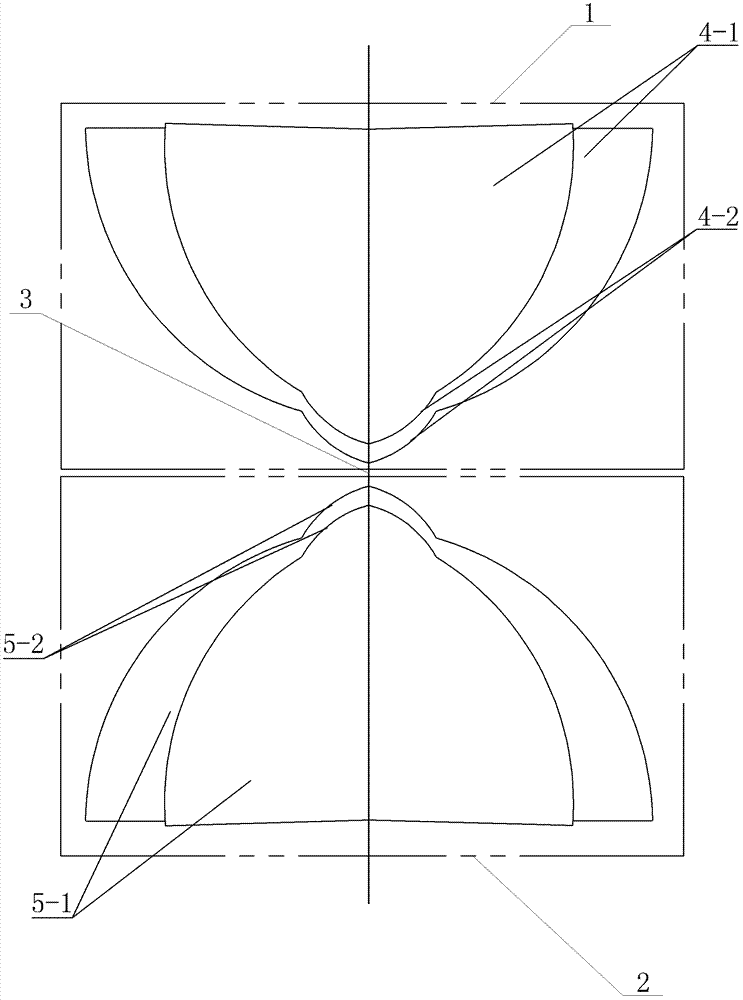

Four-rotor agricultural unmanned aerial vehicle with blades in cambered surface distribution

A pair of large propellers is used for constructing ''reversing propellers with a common rod'', rotating shafts of two propeller disks and a rod form an isoceles triangle, the lower surfaces of the two propeller disks are positioned at an arc line, and the length of the rod is longer than the diameter of the propeller disks; a pair of small propellers is used for constructing ''reversing propellers with a common shaft'', and the small propellers are made in the shape of arcs; through several carbon fiber tubes and connecting fixing pieces, the ''reversing propellers with a common rod'' and the ''reversing propellers with a common shaft'' form a four-rotor unmanned aerial vehicle structure which is in mirror symmetry in left and right and asymmetrical in front and back, and the rod is perpendicular to the shaft; the direction of downwash flow is the direction of an outward normal of cambered surfaces; therefore, the four-rotor agricultural unmanned aerial vehicle with the blades in cambered surface distribution is named. Compared with a four-rotor unmanned aerial vehicle with blades in the structure of horizontal distribution and central symmetry sold in the market, the four-rotor agricultural unmanned aerial vehicle with the blades in cambered surface distribution has the advantages that the flow rate of the downwash flow is effectively reduced, the area of the downwash flow is enlarged, crops are protected, and the working performance is improved.

Owner:张文星

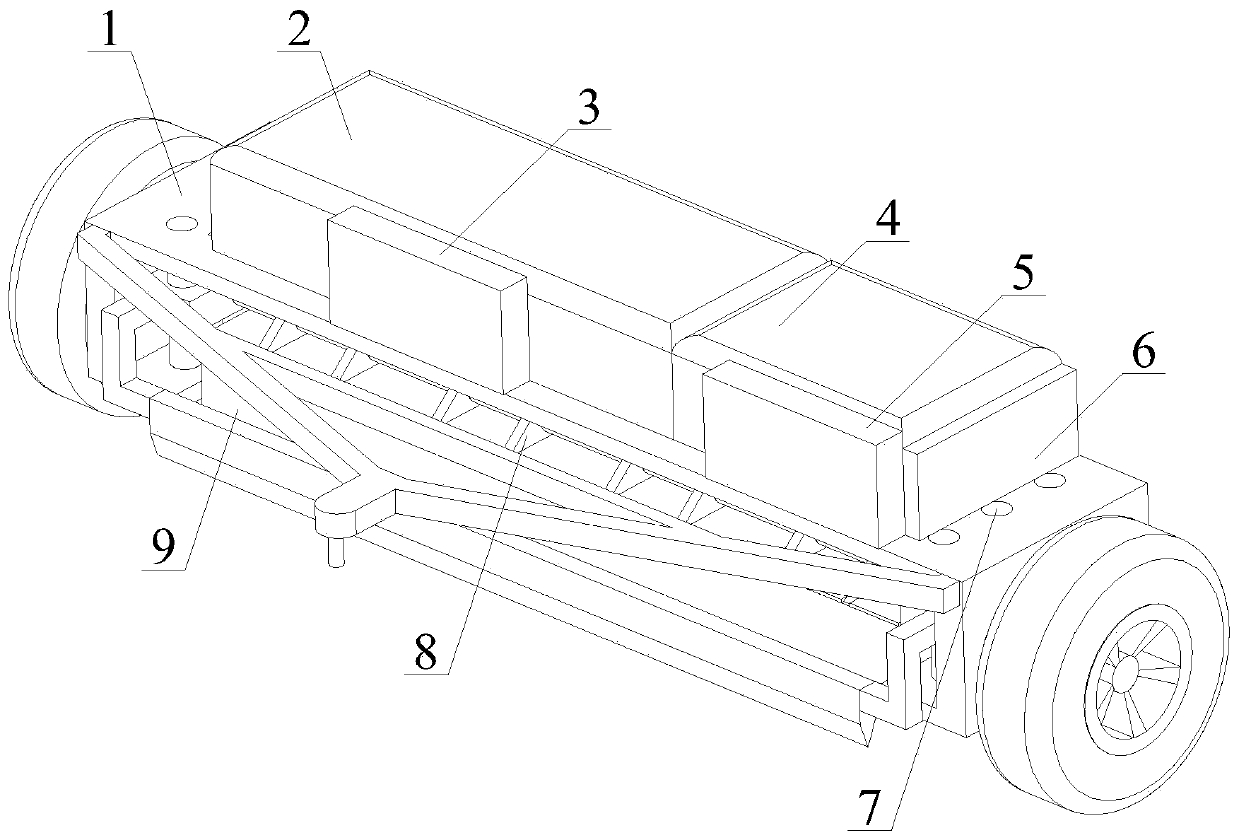

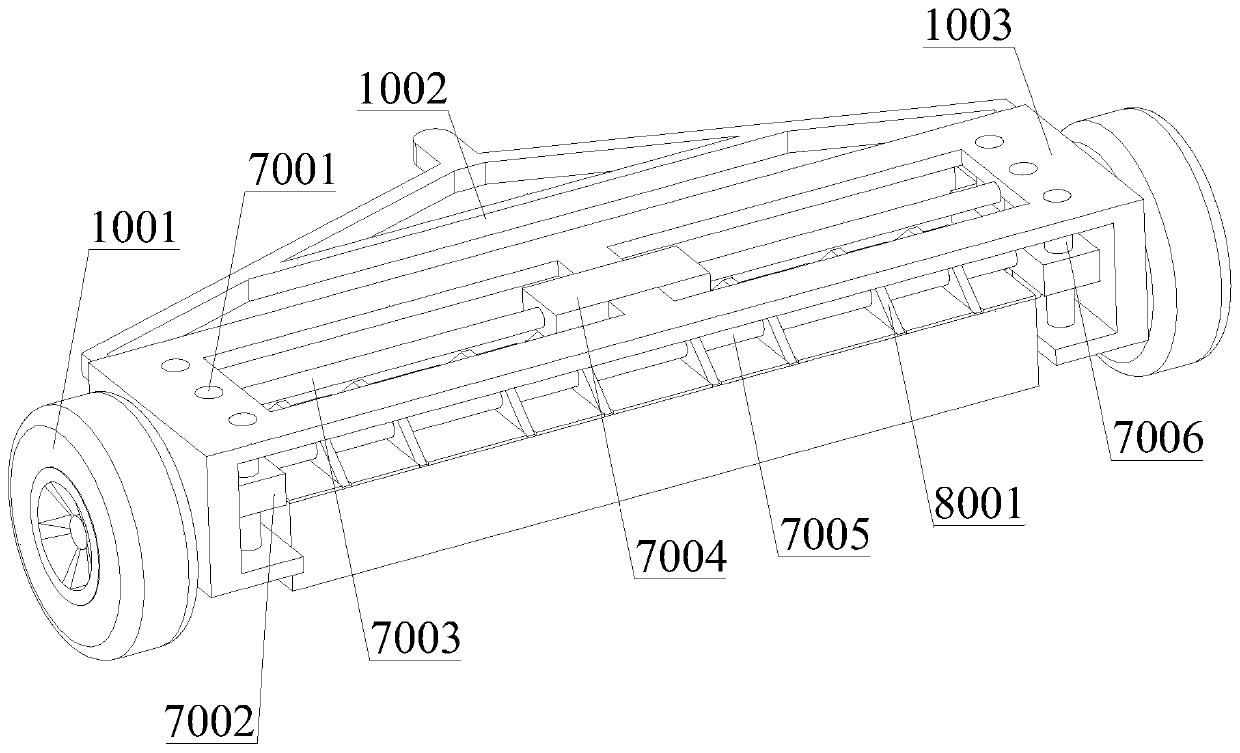

Field road electromagnetic sweeping trailer

PendingCN110396973AImprove adsorption capacityLow costElectromagnets without armaturesRoad cleaningElectricityElectrical battery

The invention belongs to technical field of field road cleaning equipment, and particularly relates to a field road electromagnetic sweeping trailer. The electromagnetic sweeping trailer comprises a vehicle body, a controller, a battery management system, a battery module, a direct current converter and an electromagnetic system, wherein the controller, the battery management system, the battery module, the direct current converter and the electromagnetic system are arranged on the vehicle body, the vehicle body is used for providing a travelling and working platform, the controller is electrically connected with the vehicle body and the battery management system, the battery management system is electrically connected with the battery module, the battery module is electrically connected with the direct current converter, the direct current converter is electrically connected with the electromagnetic system, and the electromagnetic system is installed on the vehicle body. The electromagnetic system of the trailer is powered by the battery module, and the trailer has the characteristics of being low in cost, safe, reliable, flexible in working condition, convenient to use and greenand environment-friendly.

Owner:高洪江

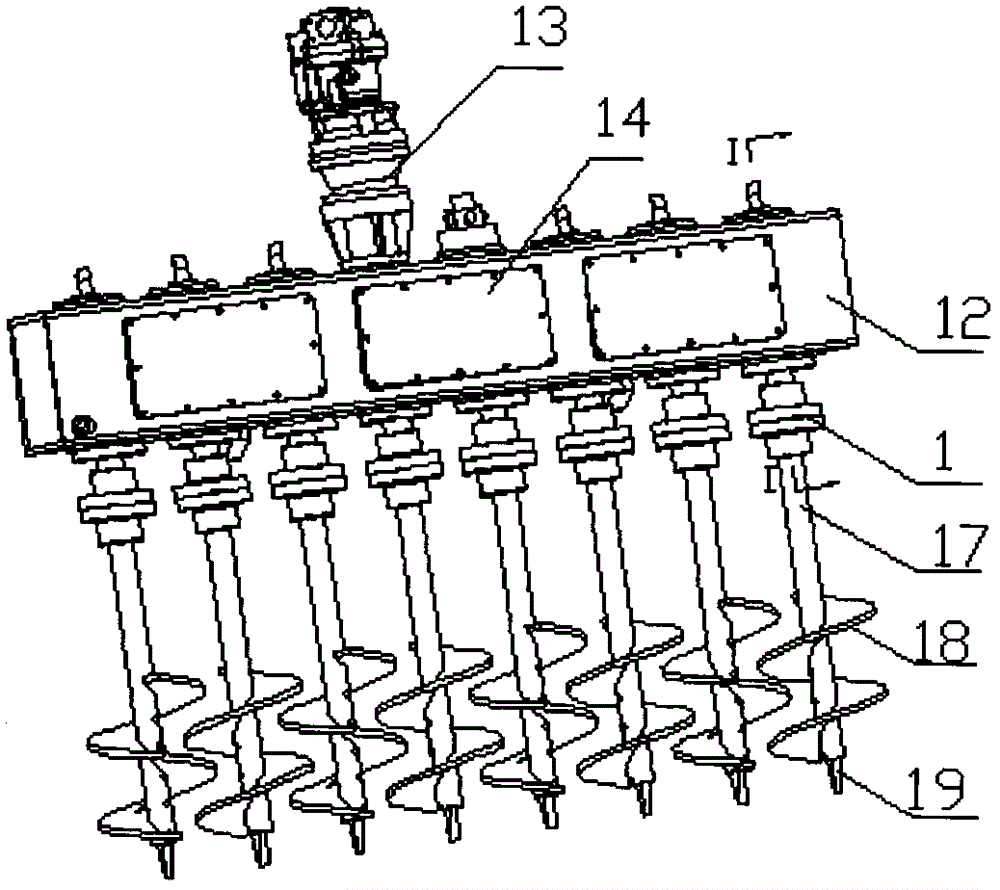

Mechanical transmission cultivation device adopting sliding bearings

InactiveCN104685991AIncrease working widthImprove the efficiency of arable landTilling equipmentsLubricationReamer

The invention discloses a mechanical transmission cultivation device adopting sliding bearings. The mechanical transmission cultivation device comprises a box body, wherein a power rotating shaft is arranged at the top of the box body; a plurality of detachable maintenance windows are formed in one side of the box body; a fixing rod is arranged on the other side of the box body; a bearing pedestal is arranged at each of the top and the bottom of the box body; a second sliding bearing is mounted in the bearing pedestal at the top of the box body; a first sliding bearing is mounted in the bearing pedestal at the bottom of the box body; rotating shafts are mounted in the first sliding bearing and the second sliding bearing; the middle parts of the rotating shaft are sleeved with transmission members. According to the mechanical transmission cultivation device, a mechanical transmission manner is adopted to enable the reamer to revolve, and the first sliding bearing and the second sliding bearing are respectively arranged at two ends of the rotating shafts and grease lubrication is adopted, so that no oil leakage phenomenon occurs; and the mechanical transmission cultivation device has the advantages of greatly reducing the workload of the farmer and being cheaper than large-scale agricultural machinery in the aspect of cost and suitable for popularization.

Owner:GUANGXI WUFENG MACHINERY CO LTD

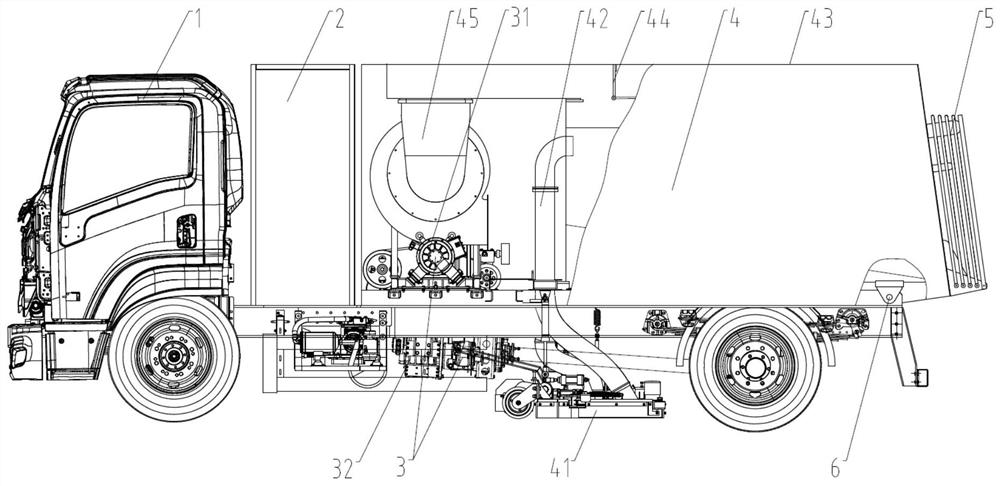

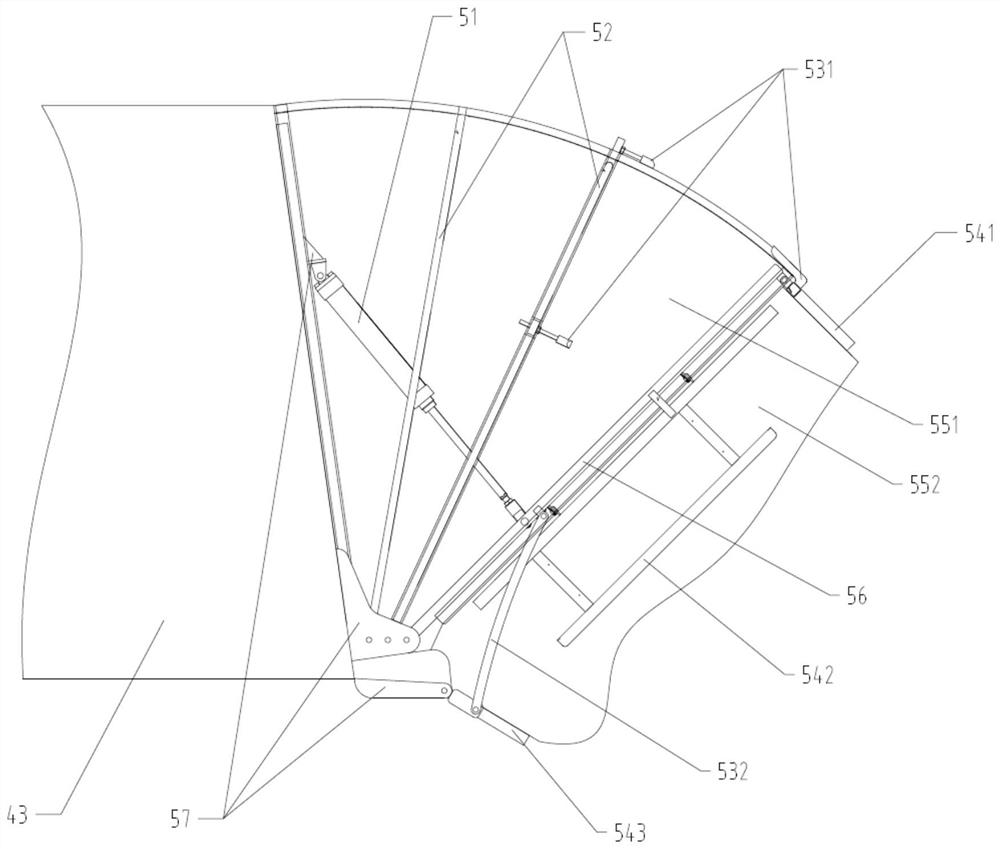

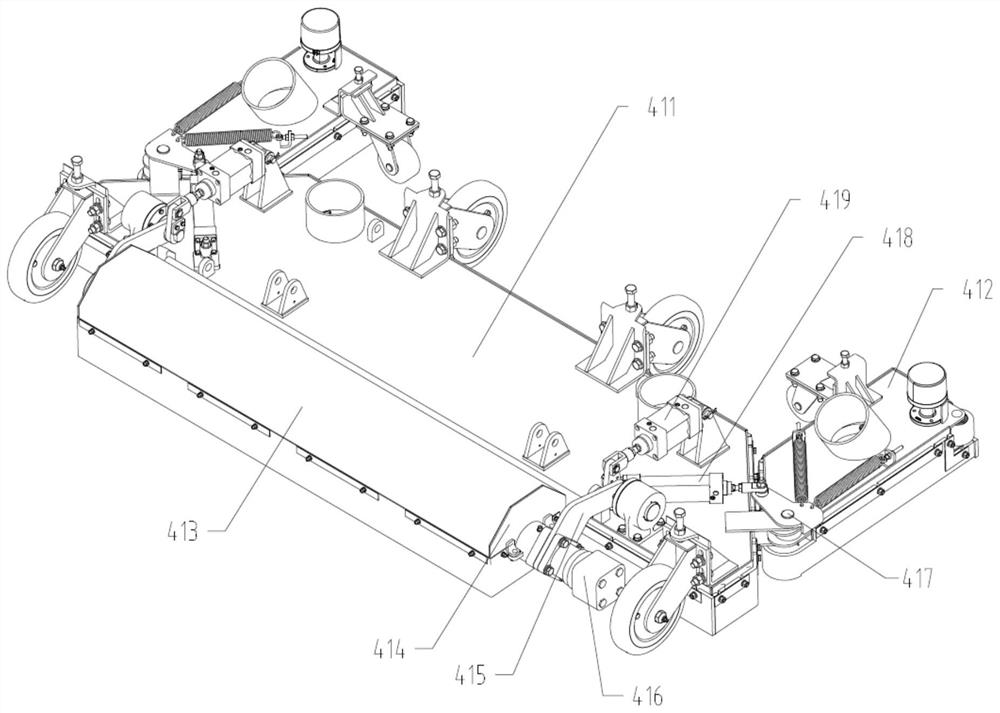

Environment-friendly vacuum sweeper

PendingCN112176923AImprove dust removal efficiencyMeet all-weather operationsRoad cleaningDrivetrainElectrical battery

The invention provides an environment-friendly vacuum sweeper. The environment-friendly vacuum sweeper comprises a pure electric vehicle body, an air path system, a discharging dust suppression device, a power transmission system and a battery. The air path system comprises a dust suction device, an air pipe, a dust removal device, a conversion door and a fan, the dust suction device is arranged at the bottom of the vehicle body and communicated with the dust removal device through the air pipe, the dust removal device is communicated with the air suction port of the fan through an air duct, and the conversion door is arranged between the air duct and the dust removal device. The conversion door can selectively seal the air outlet of a dry dust flow channel or the air outlet of a wet dustflow channel, so that dust-carrying airflow from the dust collection device selectively passes through a dry dust removal space or a wet dust removal space to remove dust. The dust removal device canbe arranged above the vehicle body in a lifting mode along a turnover shaft, and the discharging dust suppression device can be arranged at the rear end of the dust removal device in an unfolding andfolding mode; and the power transmission system comprises an upper power transmission system and a chassis power transmission system. The operation process is simple in operation, energy-saving, environment-friendly, zero-emission and low in noise.

Owner:SHAANXI AUTOMOBILE GROUP

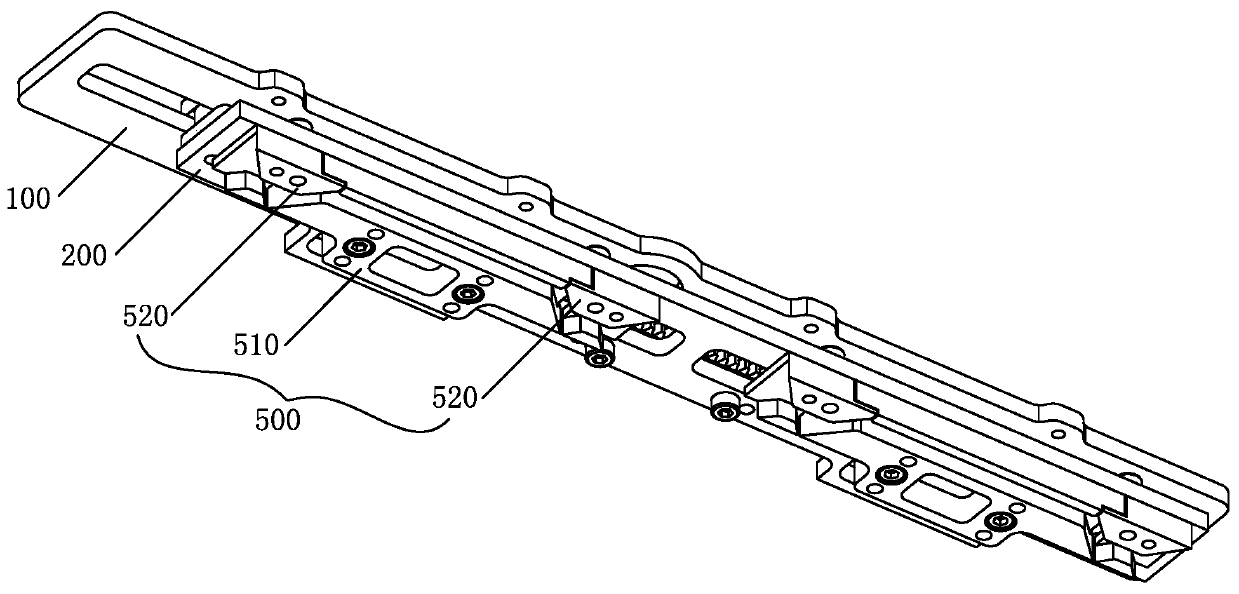

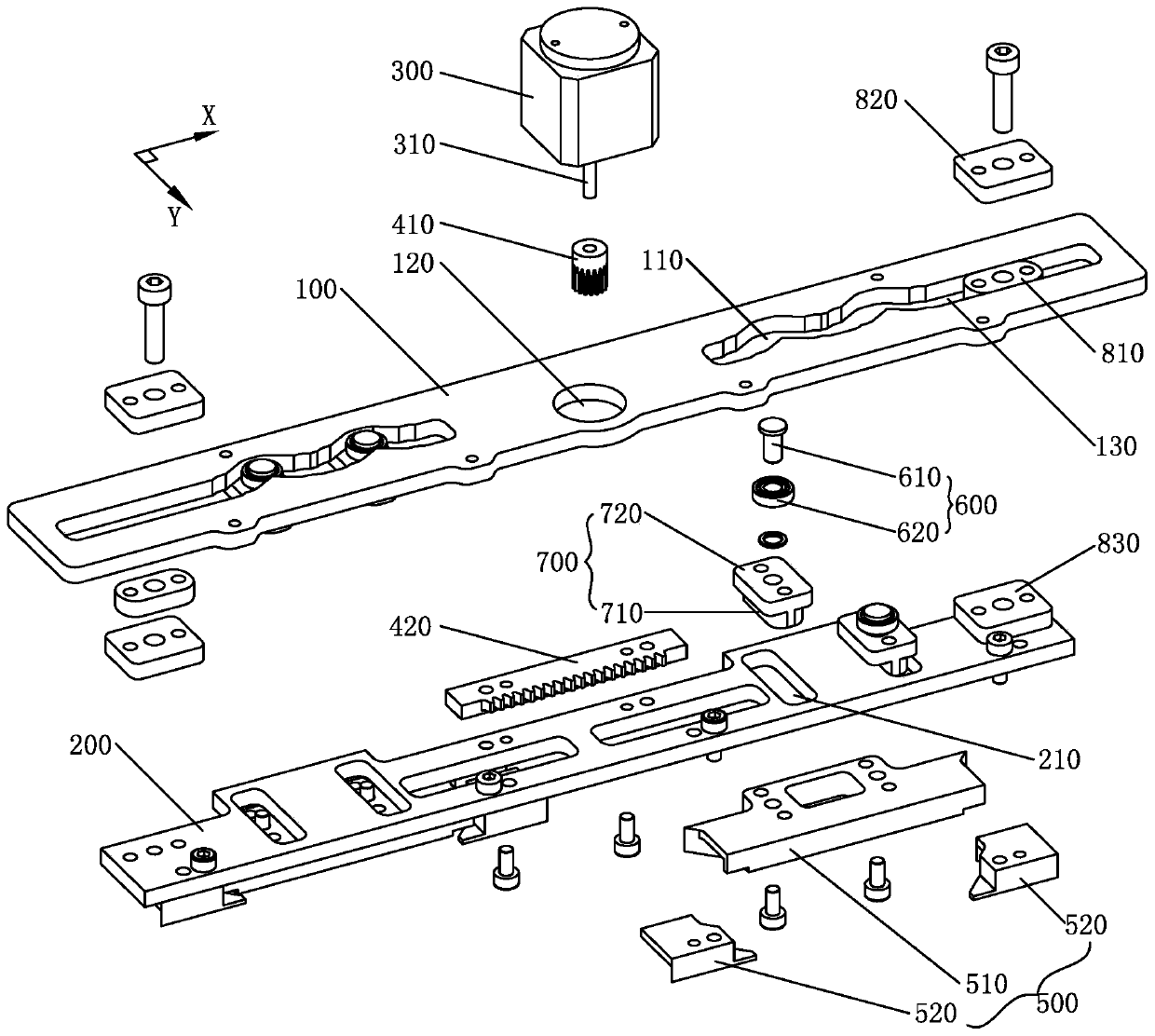

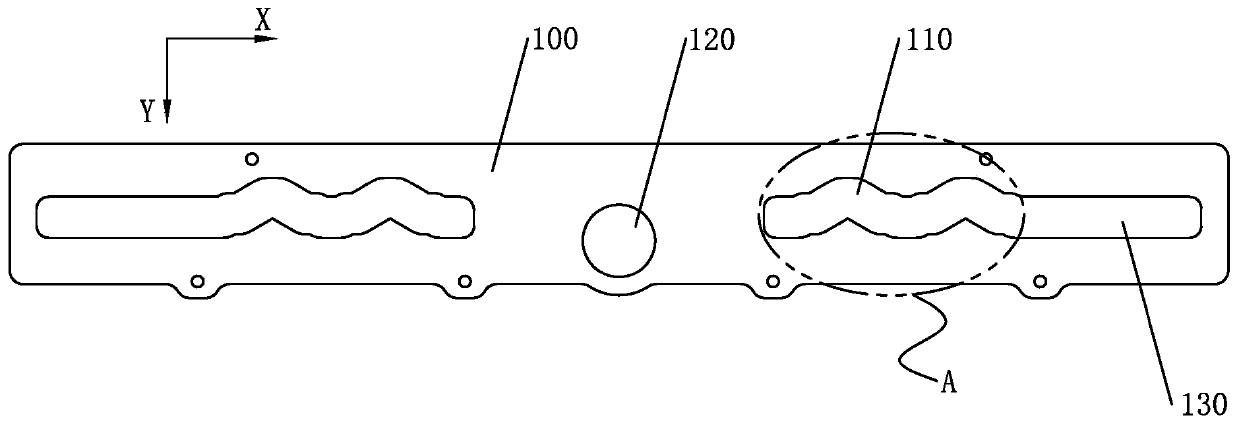

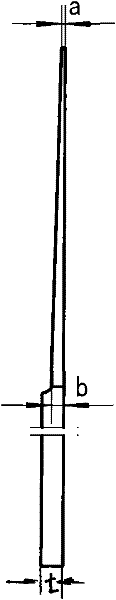

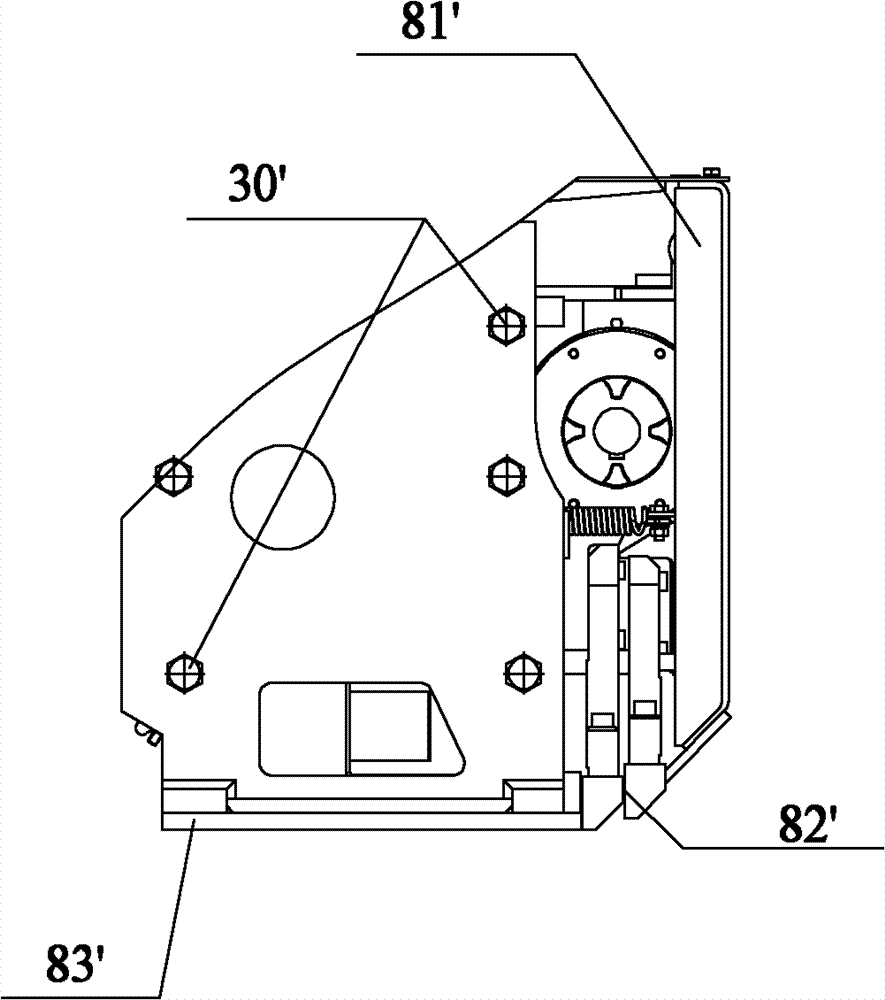

Sinker device for flat knitting machine head, flat knitting machine head and flat knitting machine

ActiveCN109853120AImprove weaving performanceIncrease working widthWeft knittingTextile/flexible product manufactureEngineeringCam

The invention discloses a sinker device for a flat knitting machine head, the flat knitting machine head and a flat knitting machine, and belongs to the field of flat knitting machines. The sinker device comprises a bottom plate, a sliding bar, a motor, a transmission structure and sinker cam sets, wherein the sliding bar is arranged on the bottom of the bottom plate and can move forth and back inthe transverse direction, the sinker cam sets are arranged on the bottom face of the sliding bar, and each sinker cam set comprises a pushing cam and restoration cams. When the motor works, the sliding bar is driven by the transmission structure to move forth and back in the transverse direction to achieve transverse movement of the sinker cam sets, and the pushing cams are movably connected to the sliding bar. A driving groove is formed in the bottom plate, the driving groove is partly inclined relative to the transverse direction, a driving piece connected to the pushing cams is arranged inthe driving groove, and during translation of the sliding bar, the driving piece drives the pushing cams to move in the direction inclined relative to the transverse direction by cooperating with thedriving groove, so that longitudinal movement of the sinker cam sets is achieved. While a sinker has a high work width, it is ensured that the pressing depth of the sinker can be adjusted, and the knitting effect can be improved.

Owner:ZHEJIANG FENGFAN NC MACHINERY

A high-efficiency cyclone high-speed air circulation road sweeper

The invention discloses an efficient cyclone high-speed air circulation road sweeper which comprises a sweeper body and a cyclone dust sweeping collector, and further comprises a side sweeping cyclone blowing opening, wherein the side sweeping cyclone blowing opening is formed in the side face of the sweeper body and is communicated with an air outlet pipe of a cyclone generator in the cyclone dust sweeping collector through a ventilating pipeline. When the efficient cyclone high-speed air circulation road sweeper works, the side sweeping cyclone blowing opening blows air to the sweeper body; a sweeping hair rolling shaft of the cyclone dust sweeping collector is connected with a motor; the cyclone dust sweeping collector is arranged below the rear part of the sweeper body; the sweeping hair rolling shaft is arranged in front of an air blowing opening of the air outlet pipe of the cyclone generator; a waste collection trough is arranged in front of the sweeping hair rolling shaft; a spiral collection rolling shaft is arranged in the waste collection trough; and two ends of the spiral collection rolling shaft are communicated with a waste collection and separation tank through an air flow and mechanical hybrid waste conveying pipe. The sweeper has the advantages of larger sweeping width, less flying dust, lower energy consumption, better sweeping effect and more successful waste conveying.

Owner:重庆司科朗环卫服务有限公司

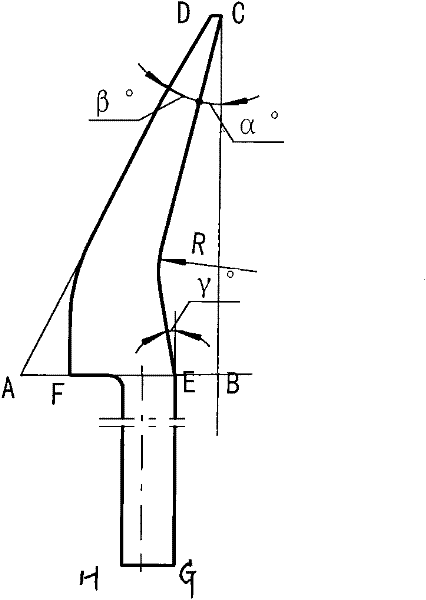

Teeth-like self-cleaning top comb for cotton comber

The invention relates to a teeth-like self-cleaning top comb for a cotton comber. Tooth sheets (2) are connected between a straight panel and a bent plate (3); the cross section of the tooth sheets (2) is of a wedge shape, wherein an alpha angle is 11 to 13 degrees; a beta angle is 17 to 19 degrees; and a gamma angle is 9 to 11 degrees; C and E are connected through an arc, the value of R is 2.3 to 3 mm, and edges of the C and the E are clearance angles and have no burr; the values of the C and D are 0.200 to 0.05 mm, the BC value of a working height of a tooth sheets section is 5.5+ / -0.015 mm, the value of AB is 3 mm, the value of BE is 0.6 to 0.8 mm, and the value of BF is 2.06 mm; and the alpha value of the lower end of the tooth sheets section thickness is 0.06 to 0.08 mm, and the beta value of the upper end of the tooth sheets section thickness is 0.20 to 0.25 mm. The top comb has the good carding effect, and self-cleans carded neps, flocks and impurities in the process of carding, so that the use performance of the top comb is improved and the working efficiency is improved.

Owner:何银康

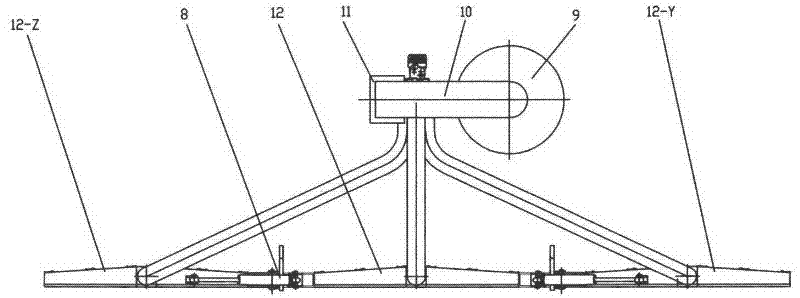

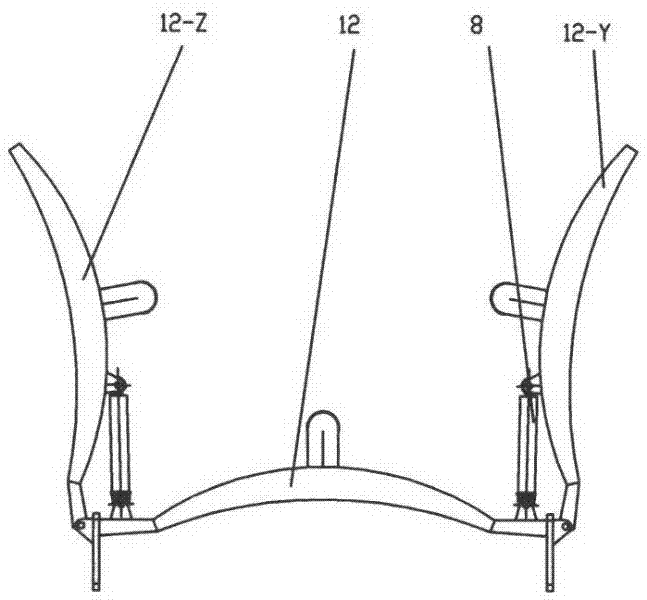

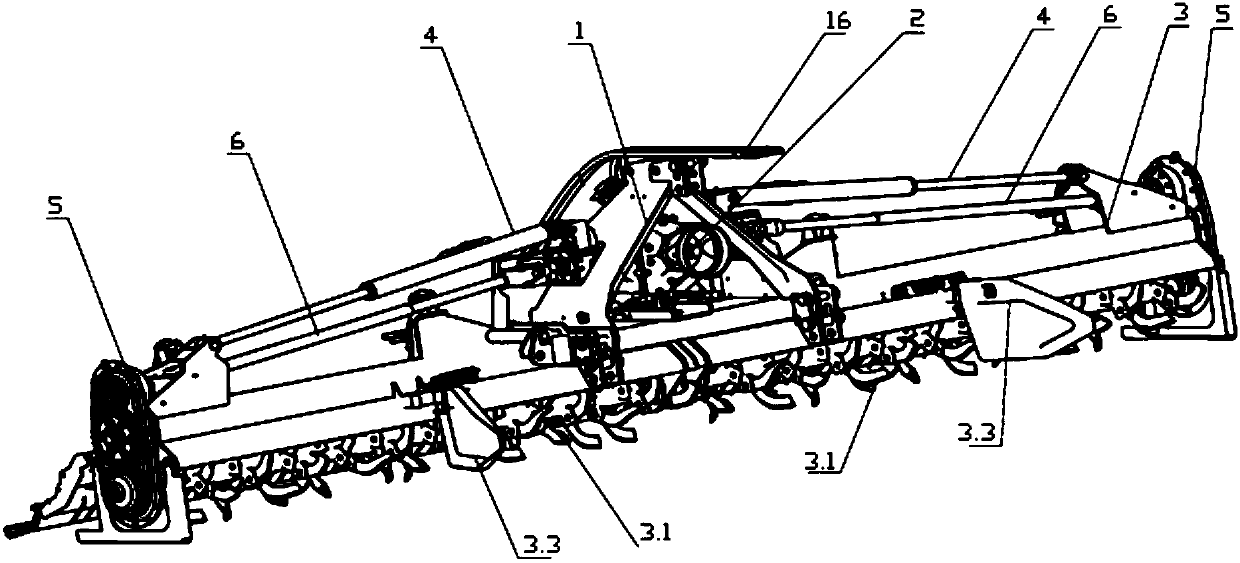

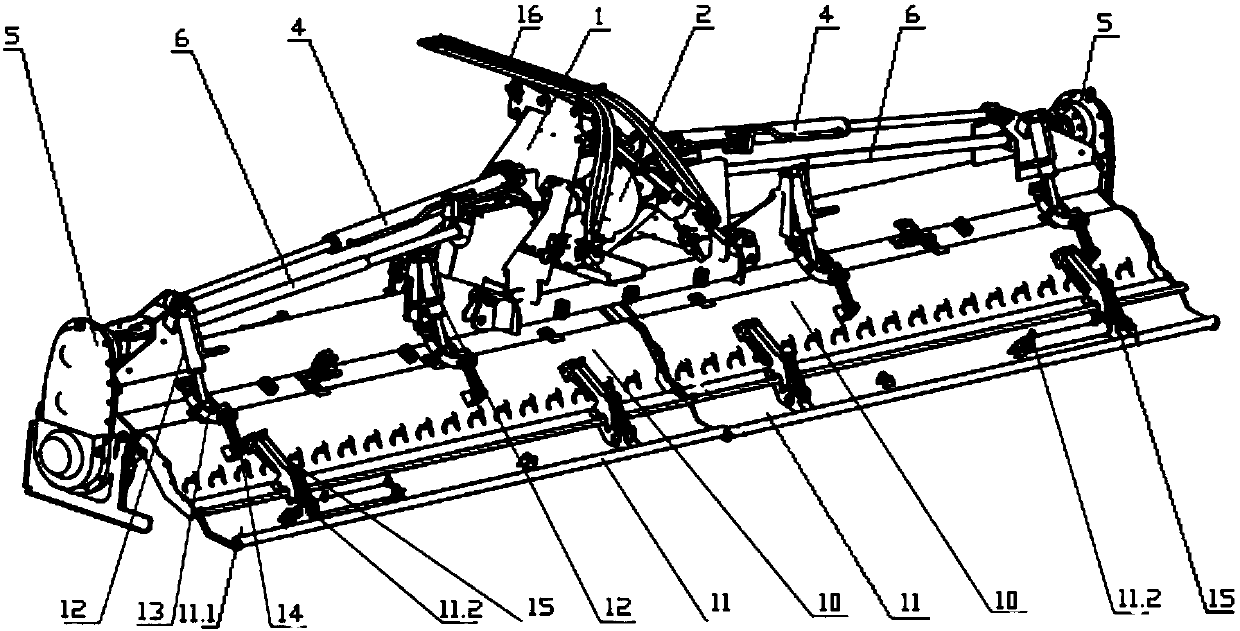

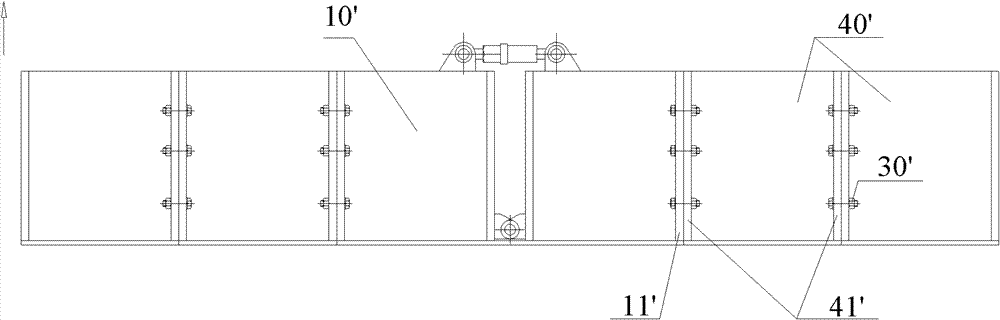

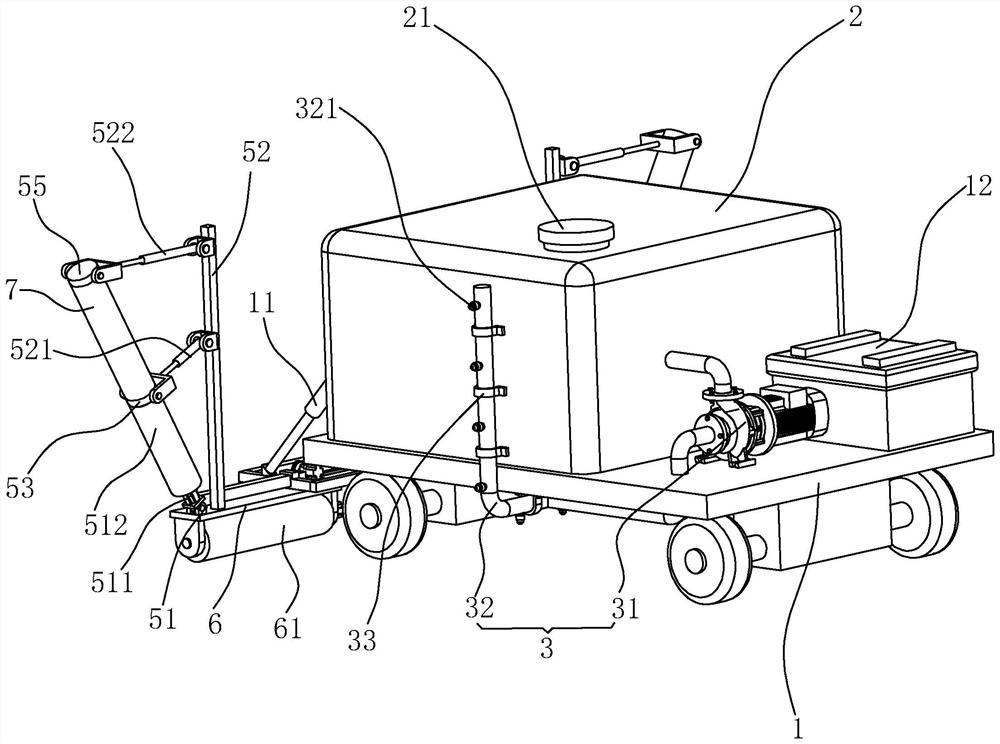

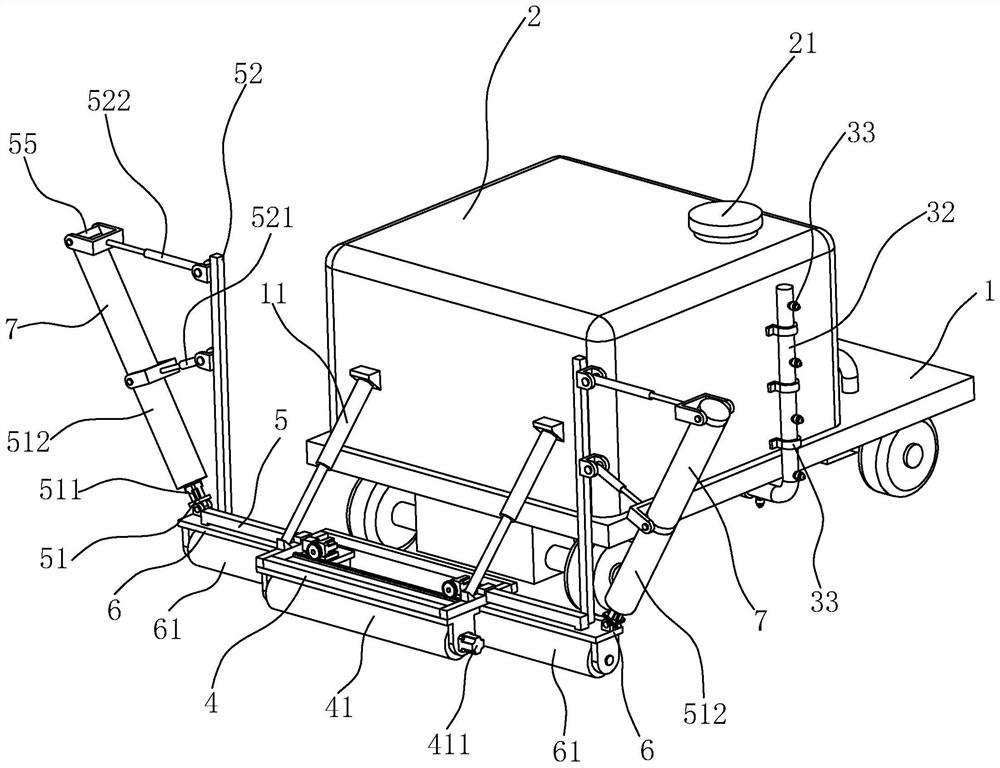

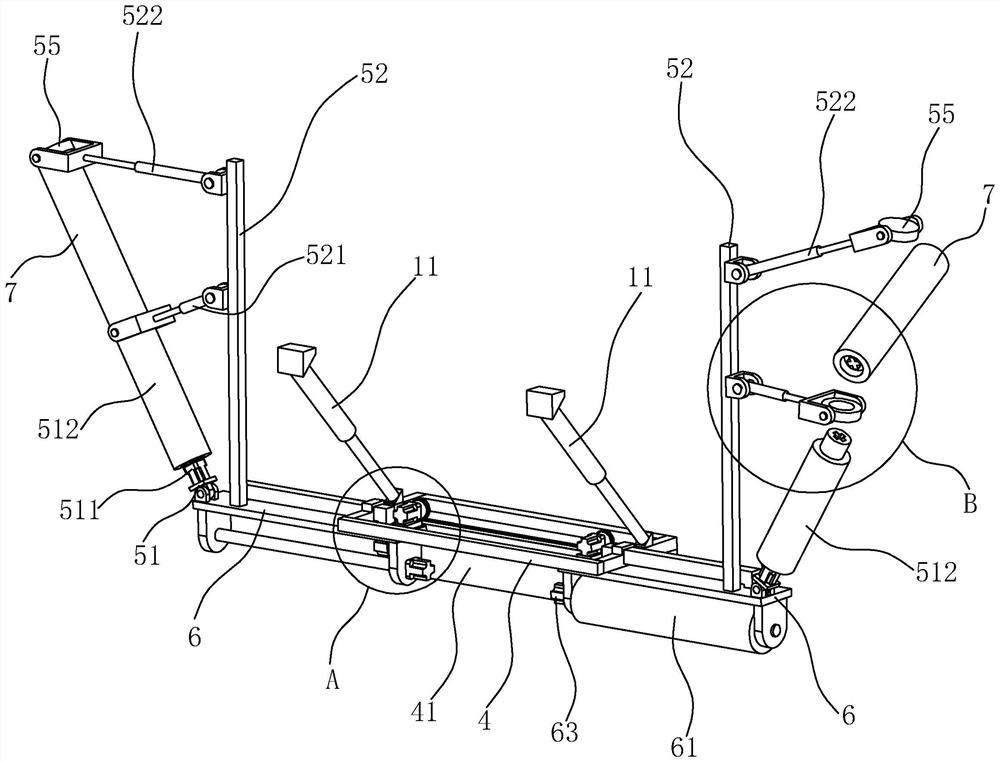

Large width hydraulic folding intelligent paddy field stubble machine

ActiveCN105766088BFlipThe structure is symmetrical and neatTilling equipmentsAgricultural undercarriagesWork performanceDrive shaft

The invention belongs to the technical field of stubble burying machines, and particularly relates to a large-width hydraulic folding type intelligent paddy field stubble burying machine.The large-width hydraulic folding type intelligent paddy field stubble burying machine comprises a three-point type suspension bracket and an intermediate gearbox.The intermediate gearbox is arranged in the middle of the suspension bracket, and the suspension bracket is provided with a rack unit eudipleural about the suspension bracket.The rack unit comprises racks, transmission mechanisms and folding control mechanisms.The ends of the inner sides of the racks are movably connected with the suspension bracket, and one end of each folding control mechanism is connected with the outer side of the upper portion of the corresponding rack.The suspension bracket is provided with a locking mechanism, and the locking mechanism is arranged in bilateral symmetry about the suspension bracket and movably connected with the other ends of the folding control mechanisms.Tool shafts are arranged at the bottom of the racks and connected with the transmission mechanisms, the transmission mechanisms are connected with the intermediate gearbox through transmission shafts, and a control unit for controlling the folding control mechanism is further arranged on the suspension bracket.The work width is large, the working performance is high, the width is reduced to be minimum after folding, and road transportation and field transfer of the stubble burying machine are convenient.

Owner:常州汉森机械股份有限公司

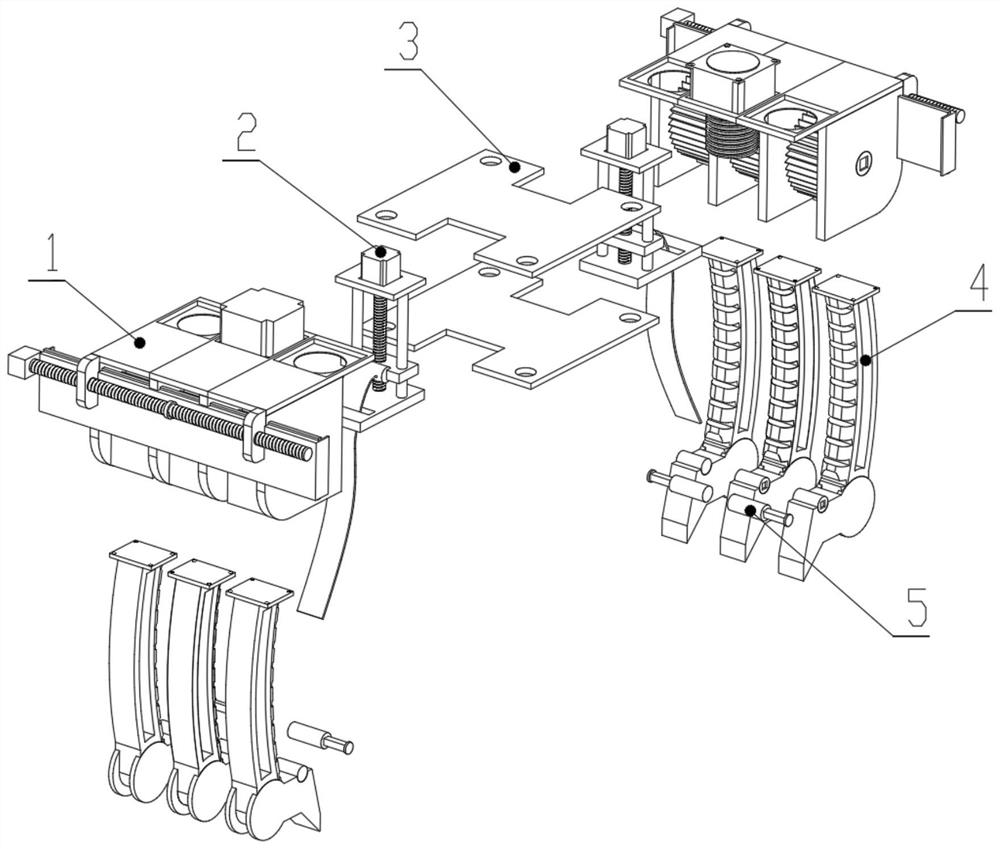

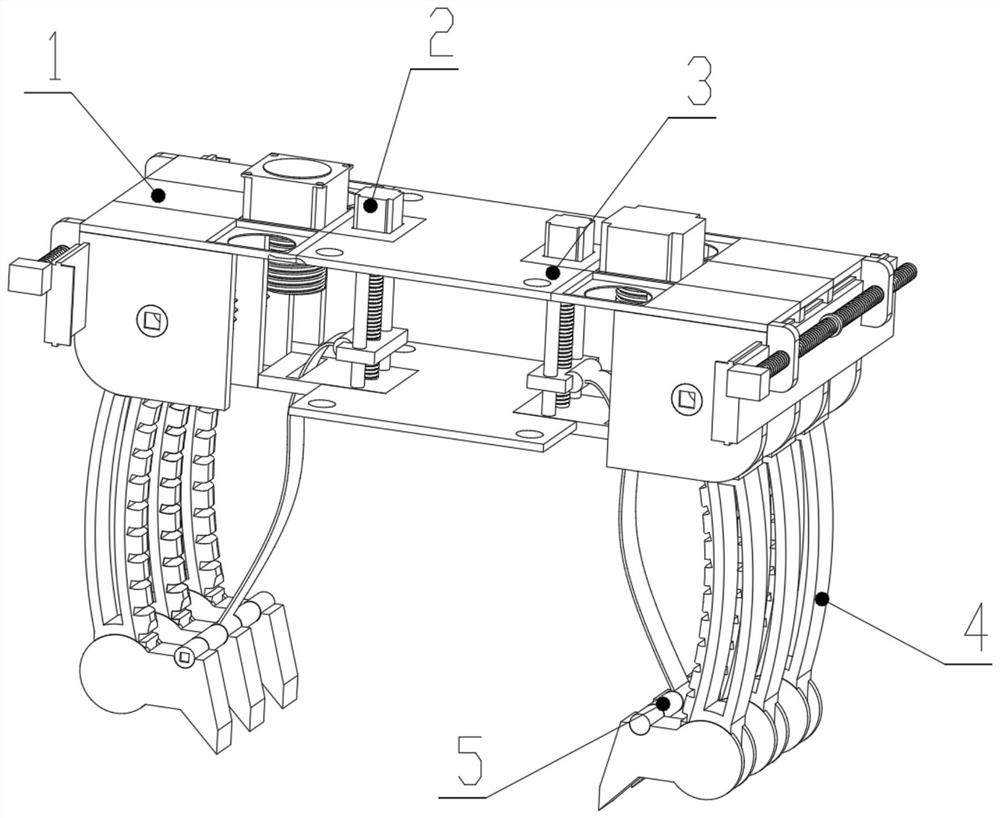

Material limiting mechanism with strong stability and for discharging machine during machining

ActiveCN111807042AImprove crawling efficiencyImprove grip stabilityConveyor partsElectric machineryProcess engineering

The invention discloses a material limiting mechanism with strong stability and for a discharging machine during machining. The material limiting mechanism comprises adjustment mechanisms, tighteningmechanisms, connecting plates, clamping mechanisms and guide rods, wherein the tightening mechanisms for limiting are symmetrically and fixedly connected to the side end faces of the connecting plates, and each tightening mechanism comprises a locating motor, a locating plate, a threaded clamping plate, a connecting base, a connecting belt, a first turnover shaft and a threaded shaft. According tothe material limiting mechanism, by arranging the adjustment mechanisms, the tightening mechanisms and the clamping mechanisms, the degree of freedom of a device in grabbing various materials can beeffectively increased through cooperation of the adjustment mechanisms and the clamping mechanisms, so that the adaptability of the device is stronger, and the efficiency and stability of grabbing thematerials in different shapes are improved; and meanwhile, the adjustment mechanisms can quickly adjust the working width between the clamping mechanisms, so that the grabbing width distribution of the materials by the device is broader, the device can adapt to longer and heavier materials, and the uniformity and stability of material grabbing are improved.

Owner:浙江三禾精密机械股份有限公司

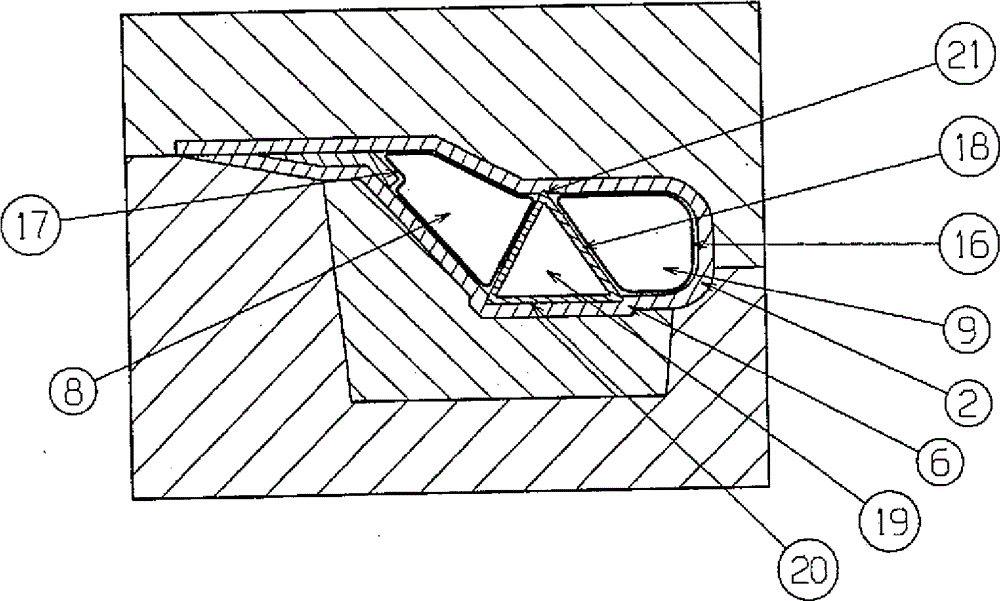

Spreading machine and ironing device thereof

ActiveCN102337720BIncrease working widthImprove installation speedRoads maintainenceUltimate tensile strengthEnergy storage

The invention provides a spreading machine and an ironing device thereof. The ironing device comprises a basic ironing plate, a lengthening ironing plate which is connected with the basic ironing plate and a clamping mechanism, wherein the clamping mechanism comprises a driving system, a power system, an energy storage system and a limit adjustment system; the driving system comprises a cylinder body, a piston and a supporting rod; the supporting rod passes through the basic ironing plate and the lengthening ironing plate; a first end of the cylinder body is pressed against the lengthening ironing plate; the power system comprises a pressure source which is communicated with the cylinder body; the energy storage system comprises a spring component; a first end of the spring component is pressed against a second end of the cylinder body; the limit adjustment system comprises a first limit adjustment part; and the first limit adjustment part and the supporting rod are provided with a first position which passes through the basic ironing plate and a second position which is pressed against the basic ironing plate. The spreading machine comprises the ironing device. When the ironing plate is lengthened, the spreading machine and the ironing device are easy to mount, and fastening pieces are not required to be screwed up manually, so that the labor intensity of operators is reduced, and the mounting speed of the lengthening ironing plate is increased.

Owner:ZOOMLION HEAVY IND CO LTD

Integrated cleaning equipment for water conservancy diversion canal

ActiveCN113976561AImprove practicalityOvercoming the Defects of CleaningHollow article cleaningElectric machineryStructural engineering

Owner:广东平润建设工程有限公司

Rotating cleaning brush

A rotating cleaning brush includes a connection pin to be clamped in a chuck of a machine for rotatingly driving the cleaning brush about its longitudinal axis. The cleaning brush includes a bristle carrier including a plurality of openings. The bristle carrier includes a first bristle bundle and a second bristle bundle being adjacent along the longitudinal axis. The first bristle bundle is located closer to the first end region of the cleaning brush than the second bristle bundle. Each of the bristle bundles includes a plurality of bristles and is located in one of the openings. The bristles of the first bristle bundle are designed to bend towards the longitudinal axis and then run parallel to the longitudinal axis so as to overlap the opening in which the second bristle bundle is arranged.

Owner:DURCHLAUB THOMAS DR

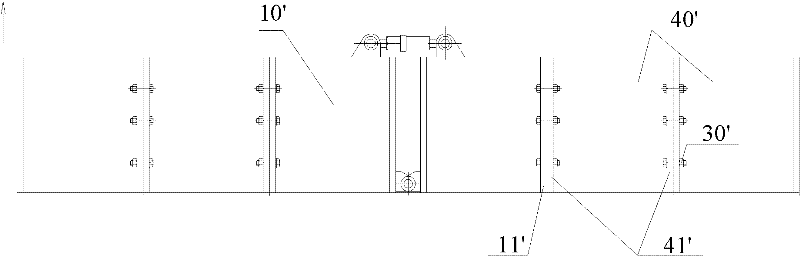

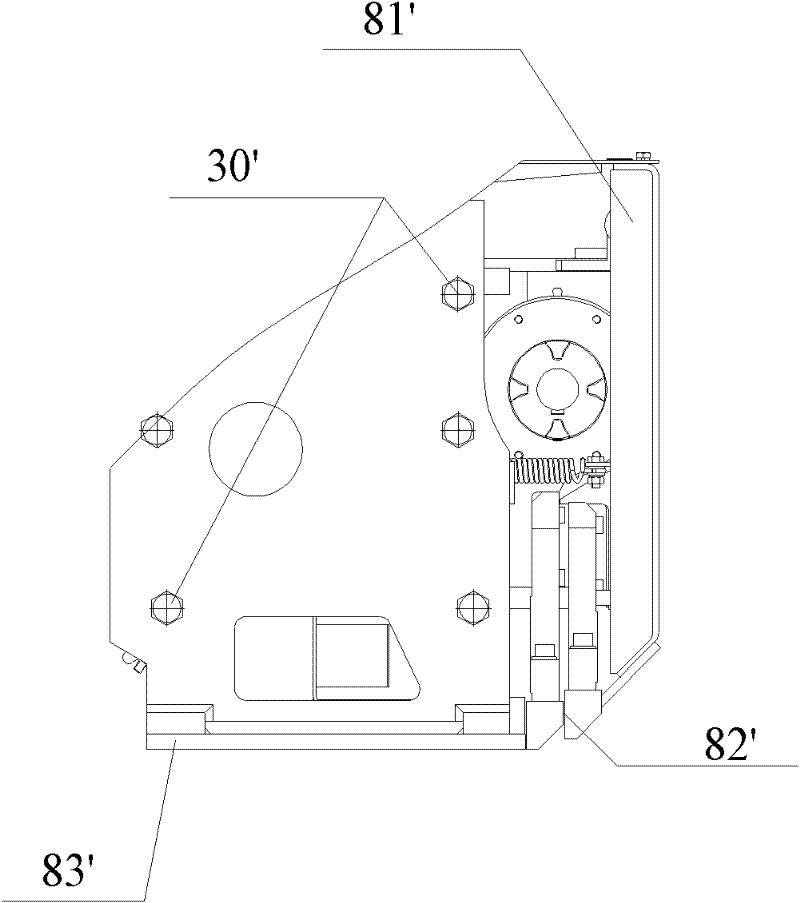

Flow guide gate

ActiveCN101967813BControl opening and closing angleIncrease working widthWater cleaningWaterborne vesselsPush and pullSurface cleaning

The invention relates to a flow guide gate relating to the technical field of lake surface cleaning ships. The flow guide gate comprises a push-and-pull module, a buffer module, a rotating module and a flow guide plate, wherein the push-and-pull module comprises an electric push rod, a connecting seat and a rear supporting shaft, wherein the connecting seat is connected with the electric push rod; the buffer module comprises a buffer support, a rotating buffer, a crank and a connecting rod; the rotating module comprises a connection block, a built-in motor, a transmission barrel and a nylon brush, wherein the connection block is positioned on the front end of a flow guide arm body; and the flow guide plate is fixed on the flow guide arm body and positioned at the rear side of the nylon brush. The device increases the operation width and also gathers the rubbishes positioned on a water surface to an effective position, thereby greatly enhancing the collection efficiency; and in addition, the nylon brush can complete the work, i.e. revetment cleaning and the like which are difficult to complete by the traditional cleaning device. The buffer module plays a role of protecting the flowguide gate; and the push-and-pull module controls the opening and closing angle of the flow guide arm body, therefore the flow guide gate can not only provide an optimal upstream face during normal work, but also achieves good through capacity in a complex water area.

Owner:VISIONNAV ROBOTICS SHENZHEN LTD

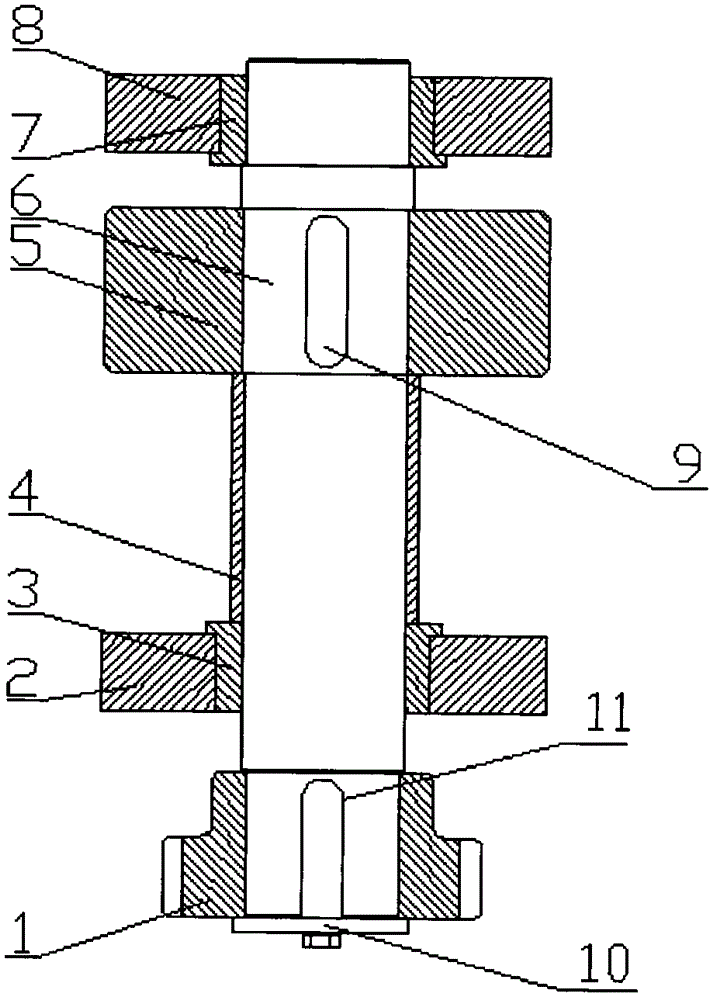

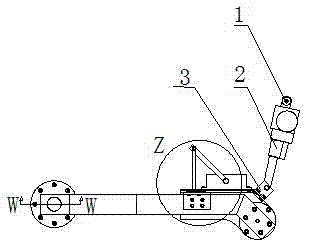

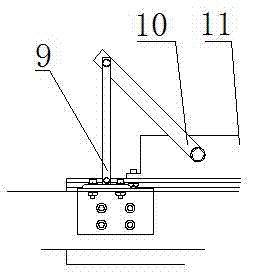

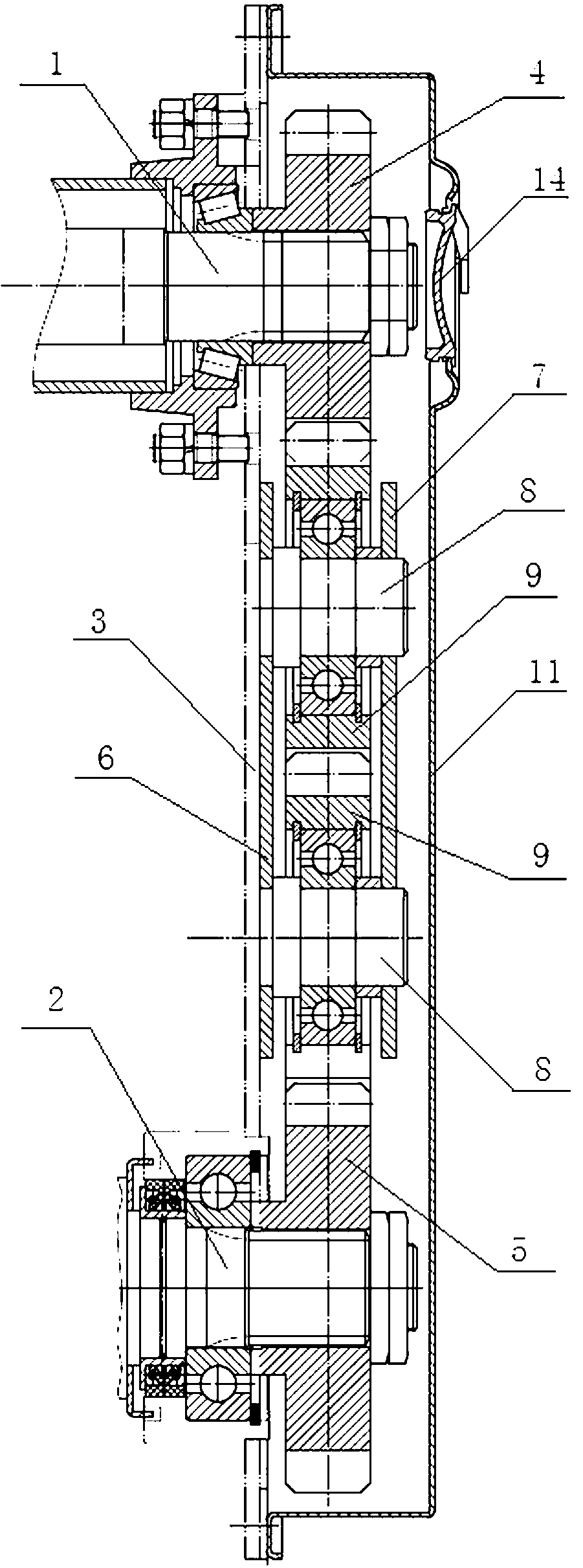

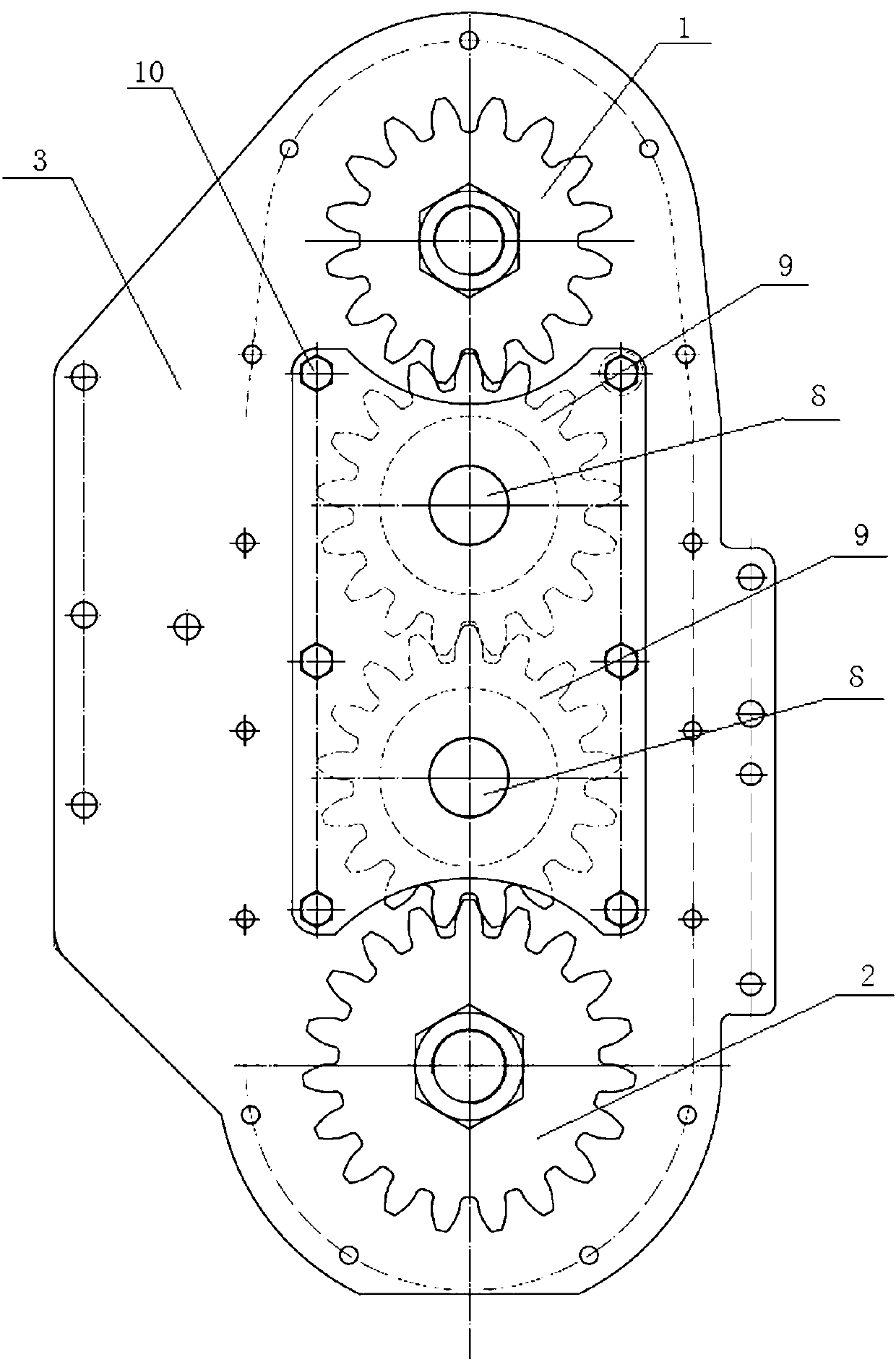

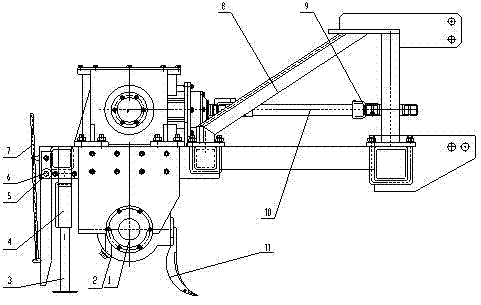

Idler gear type transmission device for lateral transmission agitator

An idler gear type transmission device for a lateral transmission agitator is characterize by comprising a power input shaft and an agitating cutter shaft. The power input shaft and the agitating cutter shaft are respectively connected to a lateral plate of the agitator through bearings, the power input shaft and the agitating cutter shaft are respectively connected with a driving gear and a driven gear on the outer side of the lateral plate, the driving gear and the driven gear are in driving connection through an idler gear pair, the idler gear pair is provided with a bottom plate and a cover plate, two idler gear shafts are fixedly connected to the bottom plate, idler gears are connected to the two idler gear shafts through bearings, one idler gear is meshed with the driving gear, the other idler wheel is meshed with the driven gear, the two idler gears are meshed, shaft holes matched wit the two idler gear shafts are formed in the cover plate, the outer ends of the two idler gear shafts are arranged in the shaft holes, and a limiting support is positioned between the bottom plate and the cover plate. The idler gear transmission device uses the idler gear pair to substitute a traditional chain, is suitable for mechanical high-speed operation, removes a gear box, can be sealed by a cover box, is simple in structure, light in weight and convenient to maintain and dismount and is large in internal space of the cover box.

Owner:黑龙江穗弘科技有限公司

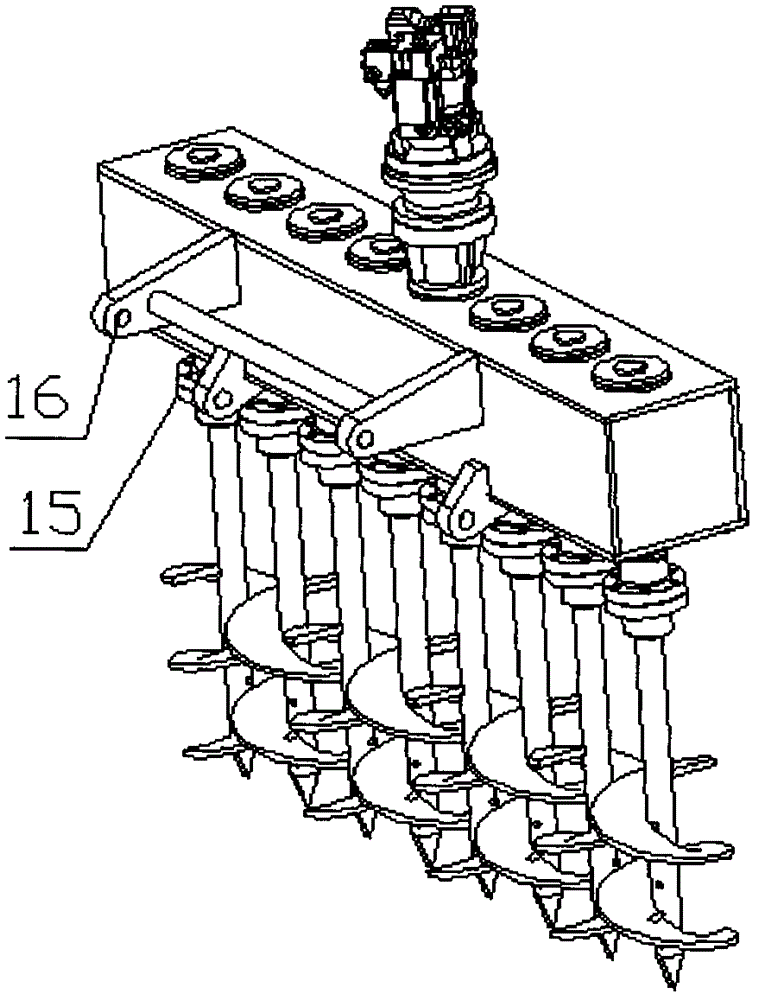

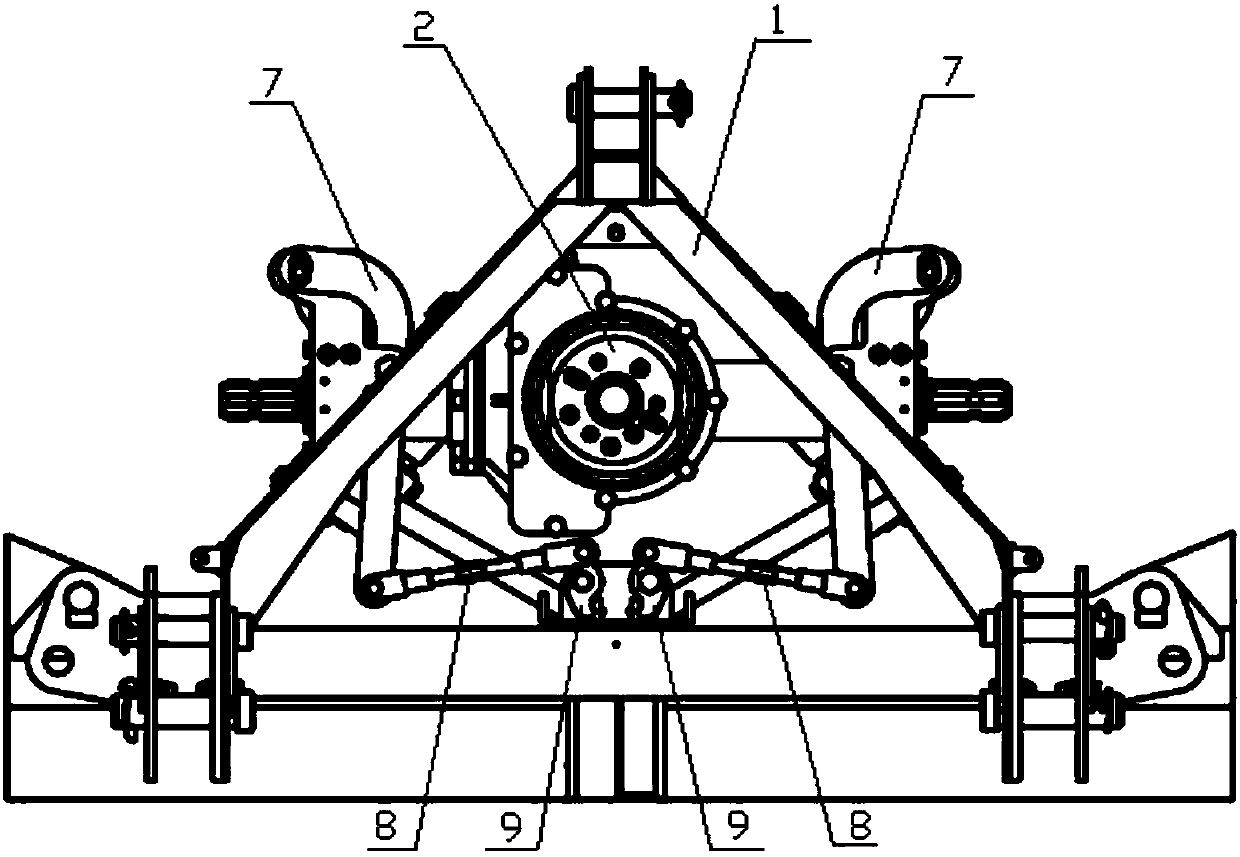

Subsoiling and rotary cultivating machine with working width of 420cm

The invention provides a subsoiling and rotary cultivating machine with a working width of 420cm. The subsoiling and rotary cultivating machine comprises a blade shaft assembly, a box assembly, landing legs, landing leg sleeves, a planker, a planker bolt, a reinforcing rod, a suspension bracket, an intermediate transition bearing block assembly, a universal joint and a break shovel, and is characterized in that subsoiling and rotary cultivating operations can be finished for one time, the working width is 420cm and in the shape of the break shovel; six rotary blades are arranged on the blade shaft assembly; the height of the landing legs can be adjusted via the landing leg sleeves; a compression spring is positioned on the reinforcing rod and used for controlling the planker; the planker is arranged on the planker bolt and used for levelling the land after the subsoiling and rotary cultivating operations under the action of the reinforcing rod; the suspension bracket is used for connecting with a tractor; and the intermediate transition bearing block assembly and the universal joint are used for transferring the power. The subsoiling and rotary cultivating machine has the advantages of large working width, simple structure, safety, reliability and easiness in operation, etc.

Owner:江苏威迪农业装备科技股份有限公司

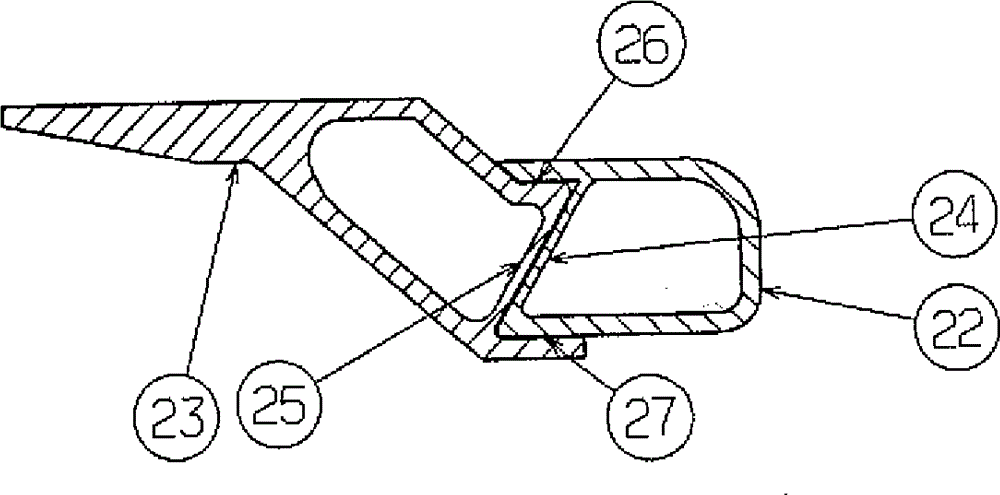

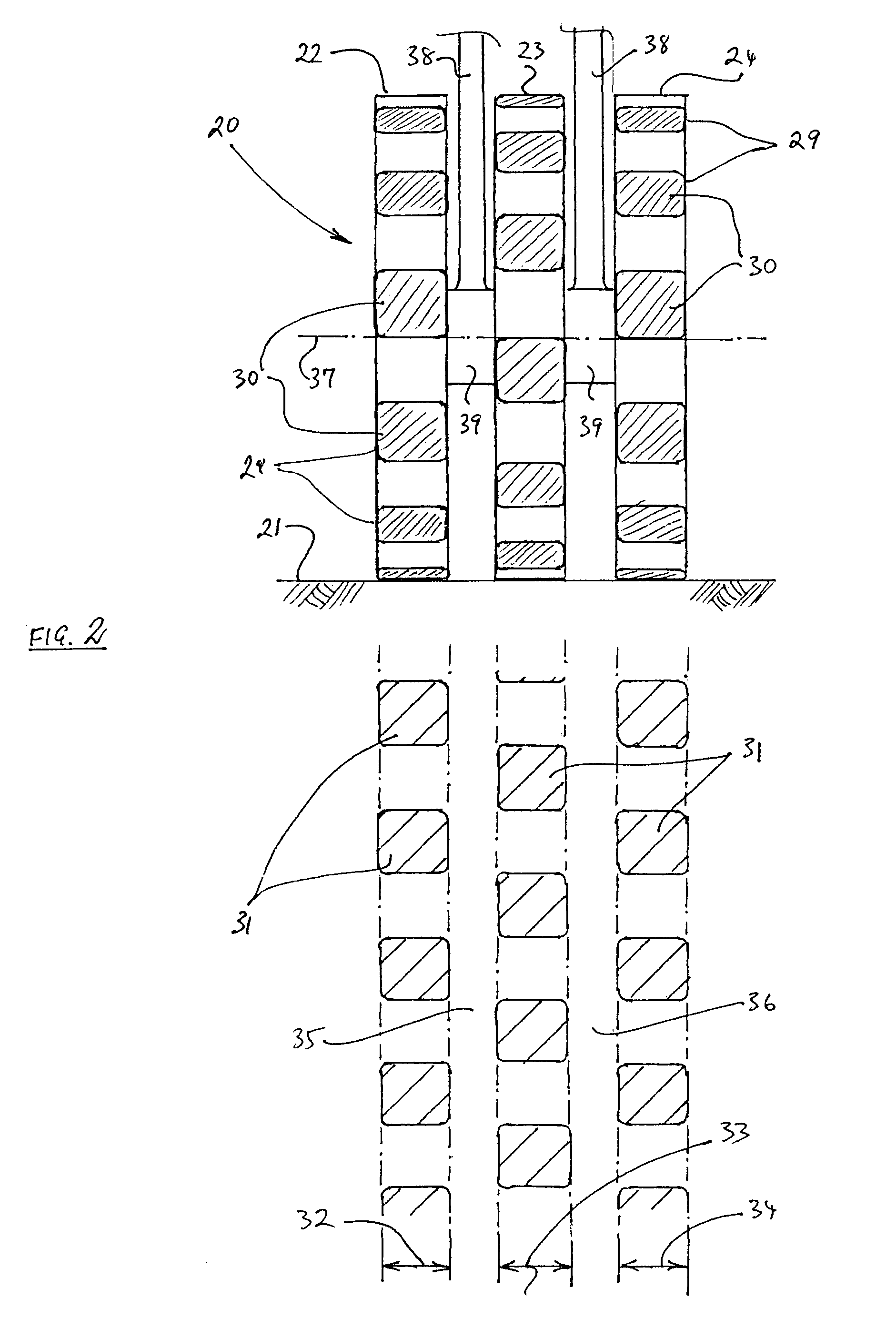

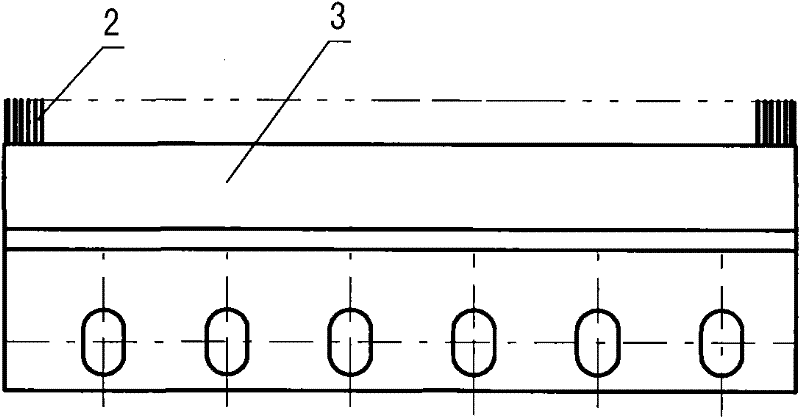

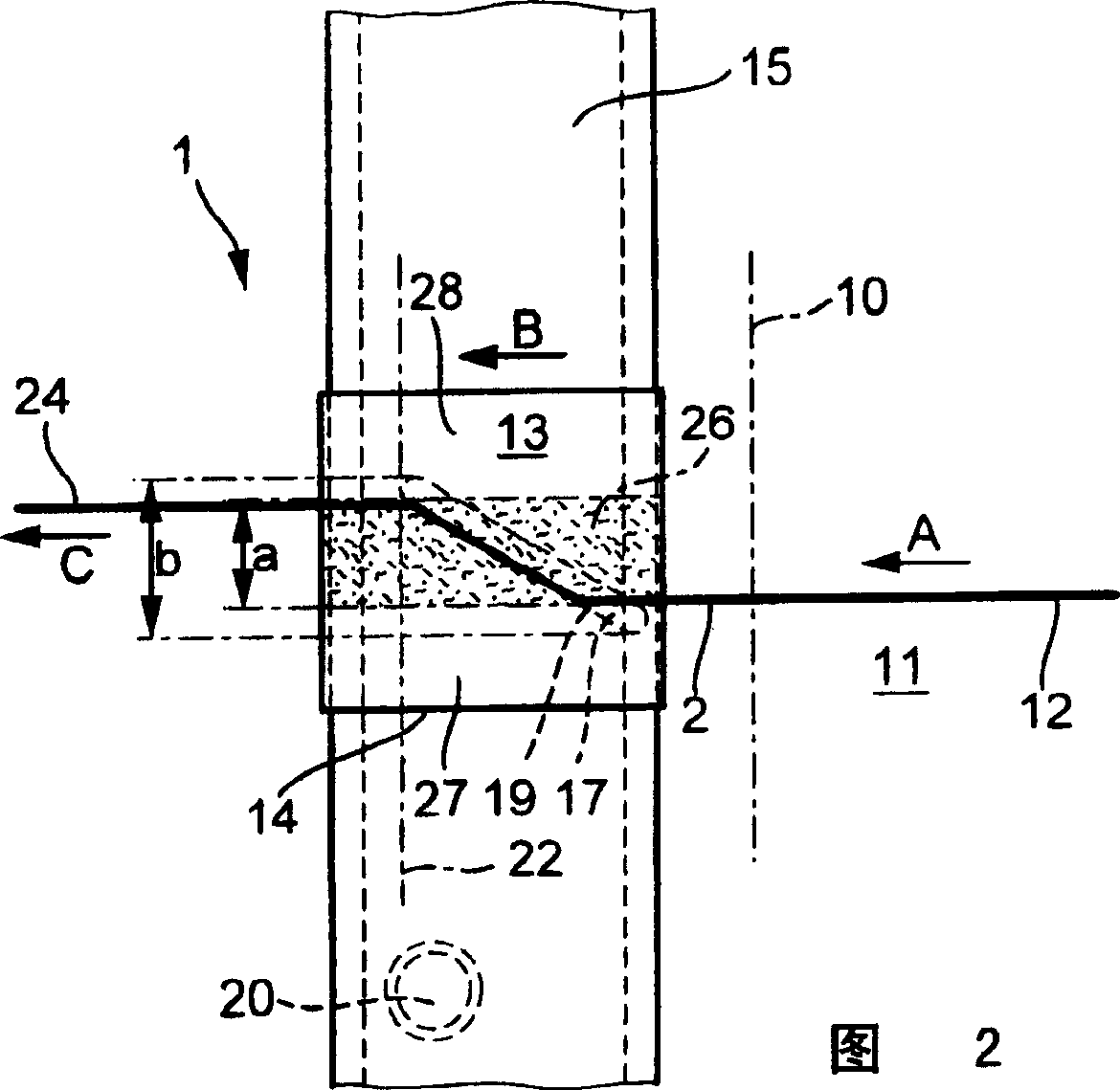

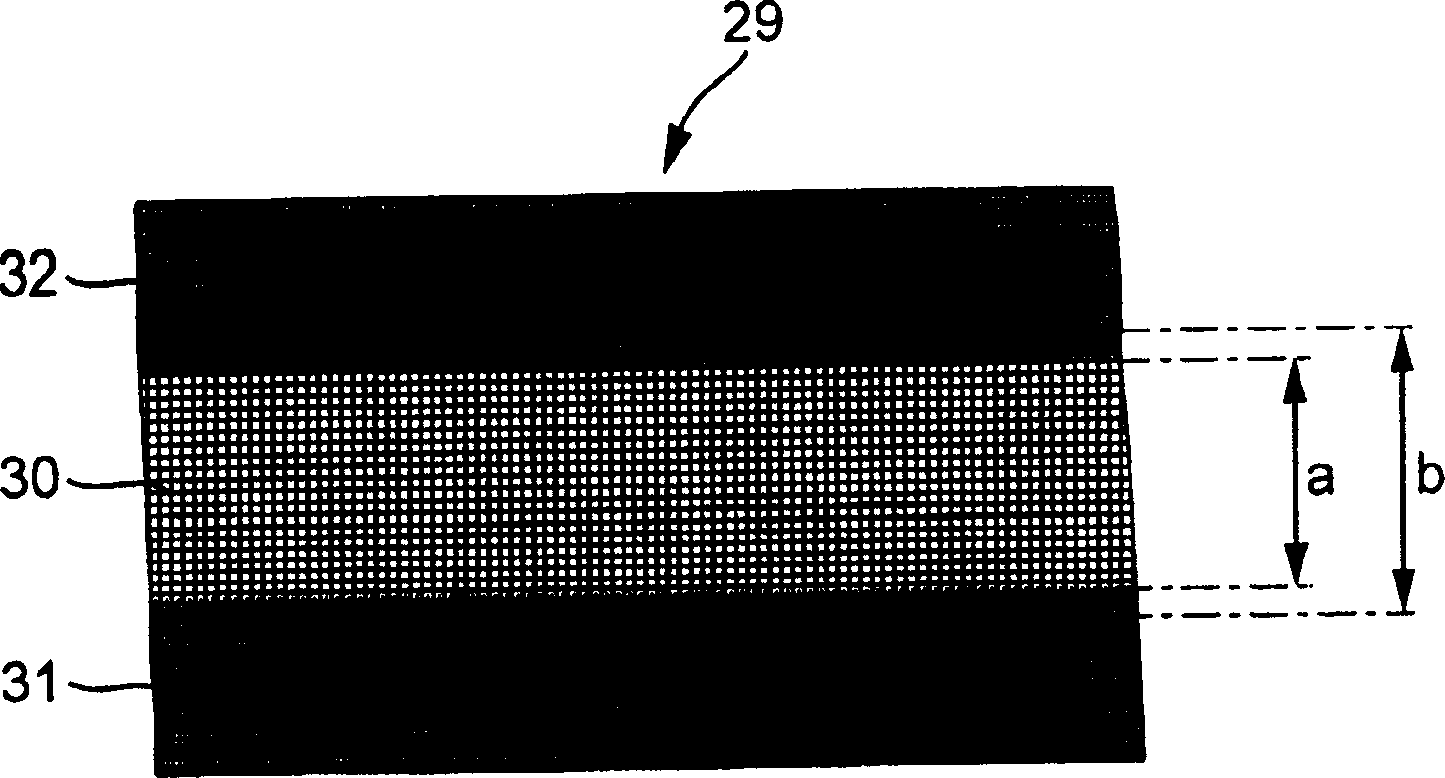

Transport belt for transporting fibre bundle for compacting

A transport belt for transporting a fibre bundle for compacting over an inclined suction slot (17) on a spinning machine compacting zone, terminating with a pinch-point is disclosed. Said transport belt comprises a support surface (18), by means of which said belt runs on a stationary slide surface (16) comprising the suction slot (17). The transport belt further comprises an air-permeable working section (26) facing the suction slot (17) and boundary regions (27, 28), laterally adjacent to the air-permeable working section (26), which are not air-permeable. The air-permeable working region (26) has a working width which is narrower than the width which is actively sucked by the suction slot (17).

Owner:MASCHINENFABRIK RIETER AG

Symmetric ultra-wideband omni-directional antenna

ActiveCN102610905BIncrease working widthCompact structureRadiating elements structural formsAntennas earthing switches associationUltra-widebandCoaxial line

The invention discloses a symmetric ultra-wideband omni-directional antenna which relates to ultra-wideband omni-directional antennas and solves the problems of the existing ultra-wideband omni-directional antenna in insufficient broadband index and unstable E plane main radiation direction. According to the symmetric ultra-wideband omni-directional antenna, a first quarter of wafer is vertically connected with a first circular arc as a whole and is located in the same plane with the first circular arc; the tail end of the circular arc of the first quarter of wafer is connected with the head end of the first circular arc located at the same side; a plurality of first metal discs are uniformly arranged by taking the vertical side as the center; a second quarter of wafer is vertically connected with a second circular arc as a whole and is located in the same plane with the second circular arc; the tail end of the circular arc of the second quarter of wafer is connected with the head end of the second circular arc located at the same side; a plurality of second metal discs are uniformly arranged by taking the vertical side as the center; the plurality of first metal discs of a first radiating unit pass through a hollow tube and are fixedly arranged on a coaxial line shielding layer; and the plurality of second metal discs of a second radiating unit which is arranged to be symmetric with the first radiating unit are fixedly arranged on a core line. The symmetric ultra-wideband omni-directional antenna is suitable for the fields, such as, electronic countermeasure, spread spectrum communication, and the like.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com