Plastic looping tool guide bar

A loop-forming tool and bar technology, applied in textiles and papermaking, knitting, warp knitting and other directions, can solve the problems of loop-forming tool collision, increased risk of loop-forming tool bar deformation, etc., and achieve the effect of stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

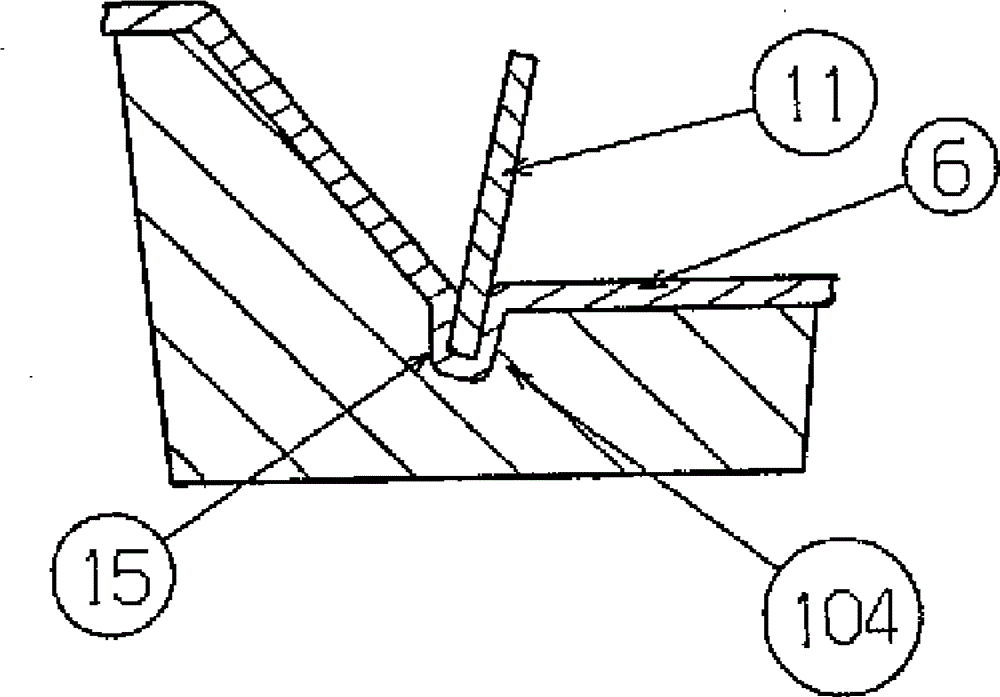

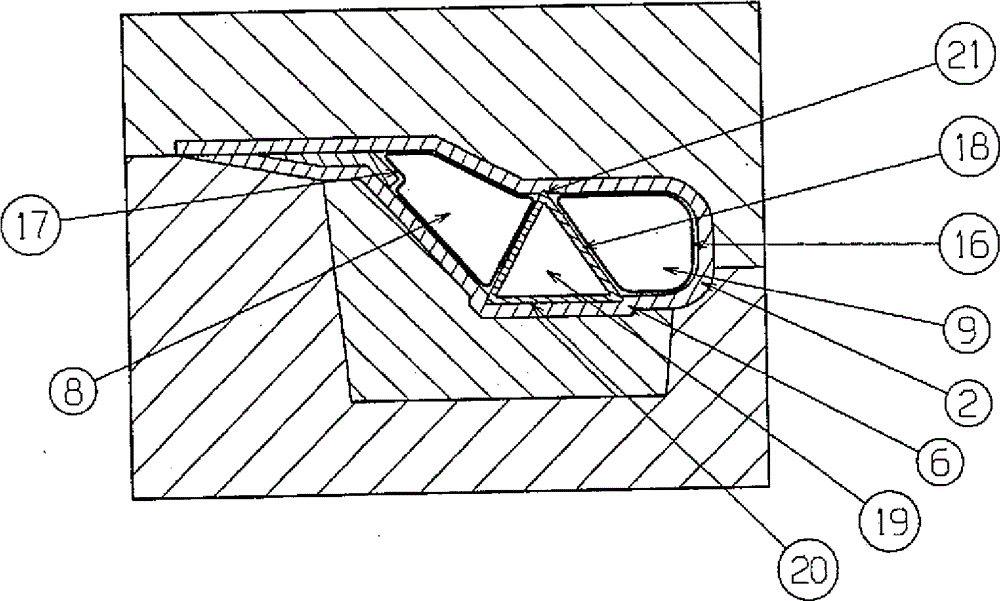

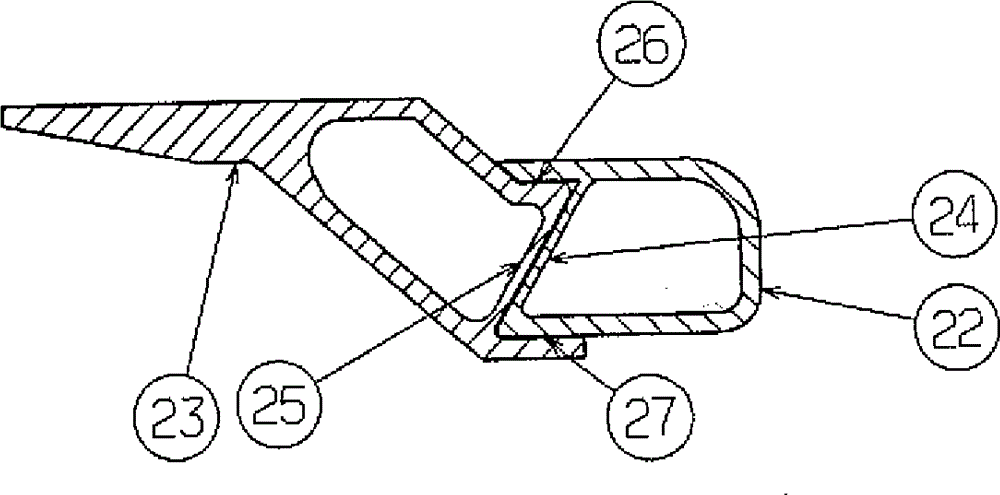

[0026] figure 1 The looping tool bar 1 is shown very schematically, which is mainly formed from plastic. The bar 1 has a body 2 with an upper wall 4 forming an upper side 3 and a lower wall 6 forming a lower side 5 . The terms “upper” and “lower” or “upper side” and “lower side” relate to the illustration in the figures and are chosen so that walls and sides can be distinguished in a simple manner. When the looping tool bar 1 is installed in the knitting machine, it does not necessarily give these relationships again. In this case, the looping tool bar 1 can be mounted rotated, for example, by 90° relative to the illustration in the drawing.

[0027] A receiving area 7 for a loop forming tool (not shown in detail) is provided on the main body 2 .

[0028] The main body 2 has a cavity assembly. In this embodiment, the cavity assembly has two cavities 8 , 9 . A reinforcement 10 is arranged between the two cavities 8 , 9 . In this embodiment, the reinforcement 10 has the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com