Screed assembly comprising a work station

A technology of screeds and assemblies, applied in the directions of roads, road repairs, roads, etc., can solve problems such as restriction and slipping, and achieve the effect of easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

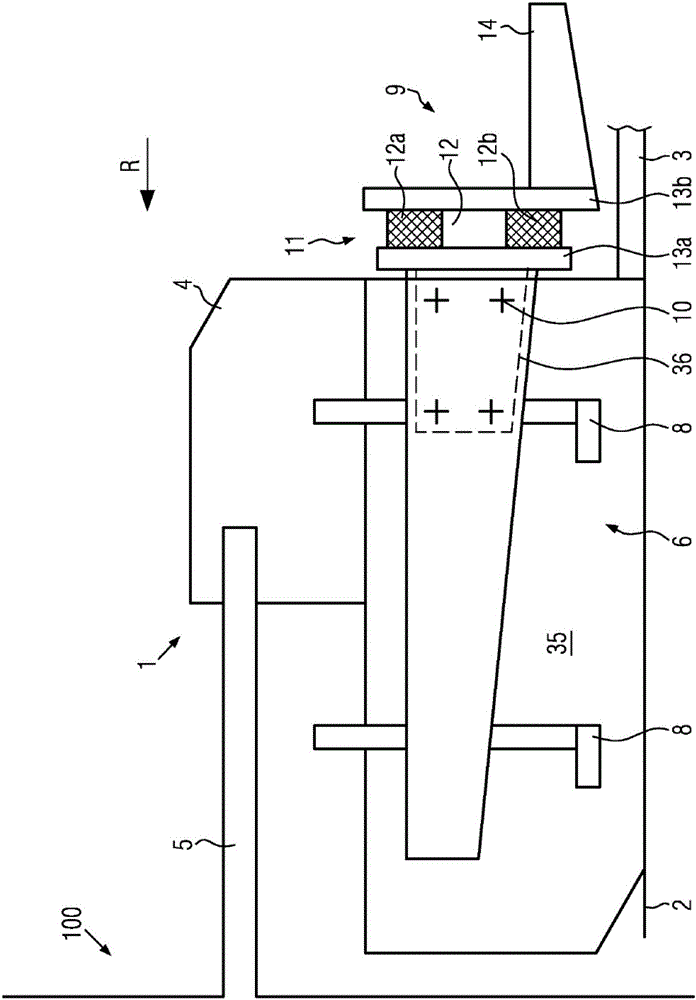

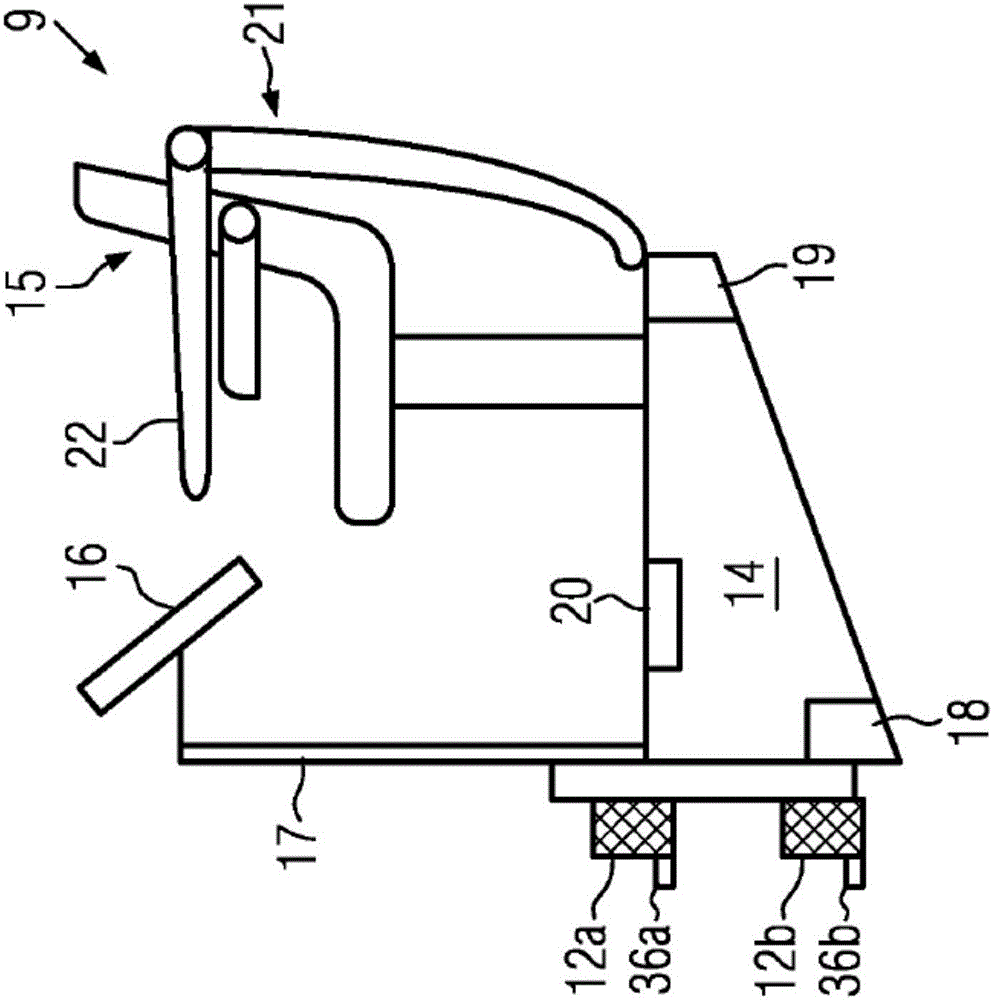

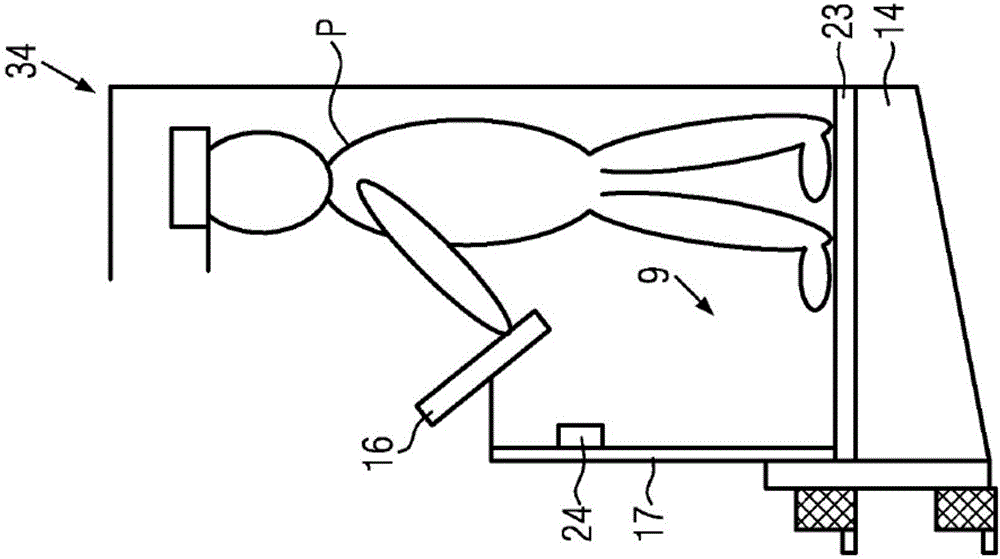

[0046] figure 1 A side view of a road finishing machine 100 is shown with a screed assembly 1 attached thereto. The screed assembly 1 is pulled in the working direction R on a plane 2 by a road finishing machine 100 in order to construct a new road surface 3 . The road surface consists in particular of bituminous material.

[0047] The screed assembly 1 provides a main screed 4 secured to the chassis of a road finishing machine 100 via tension arms 5 . Viewed from the working direction R, side plates 6 are mounted on the outside of the main screed 4 . The side panels 6 form the working width W of the road surface 3 to be constructed (see Figure 5 ) and prevent the placement material distributed in front of the screed assembly 1 from being displaced laterally from the screed assembly 1 . The side panels 6 are mounted on the main screed 4 via side panel brackets 7 . A setting module 8 is installed on the side plate support 7 , through which the height of the side moving pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com