Flow guide gate

A deflector and arm body technology, applied in the field of diversion doors, can solve the problems of inconvenient disassembly and assembly of diversion doors, small working width, etc., and achieve good passability, increase working width, and improve collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

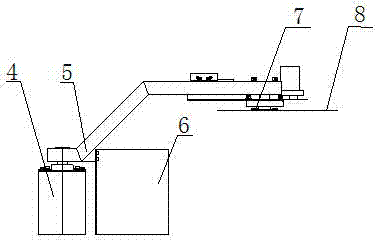

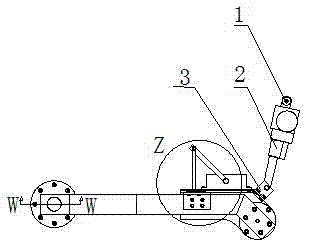

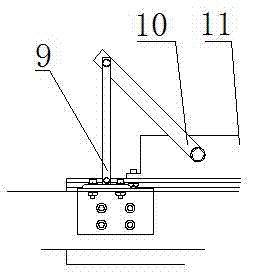

[0015] A deflector door, including a rear support shaft 1, an electric push rod 2, a connecting seat 3, a nylon brush 4, a deflector arm body 5, a deflector 6, a buffer support 7, a deck 8, a connecting rod 9, and a crank 10. Rotating buffer 11, connecting block 12, transmission barrel 13 and built-in motor 14.

[0016] Such as figure 1 It is a schematic diagram of the structure of the present invention. A guide door includes a push-pull module, a buffer module, a rotating module, and a deflector. The push-pull module is supported by an electric push rod 2, a connecting seat 3 connected to the electric push rod 2, and a rear support The buffer module is composed of a buffer support 7, a rotating buffer 11 fixed on the buffer support 7, a crank 10 and a connecting rod 9. The rotation module is composed of a connecting block 12 located at the front end of the guide arm 5 , It is composed of a built-in motor 14, a transmission barrel 13 and a nylon brush 4. The deflector 6 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com