Transport belt for transporting fibre bundle for compacting

A conveyor belt and fiber technology, applied in textiles and papermaking, drafting equipment, spinning machines, etc., can solve problems such as pollution in the air-permeable work area, and achieve the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

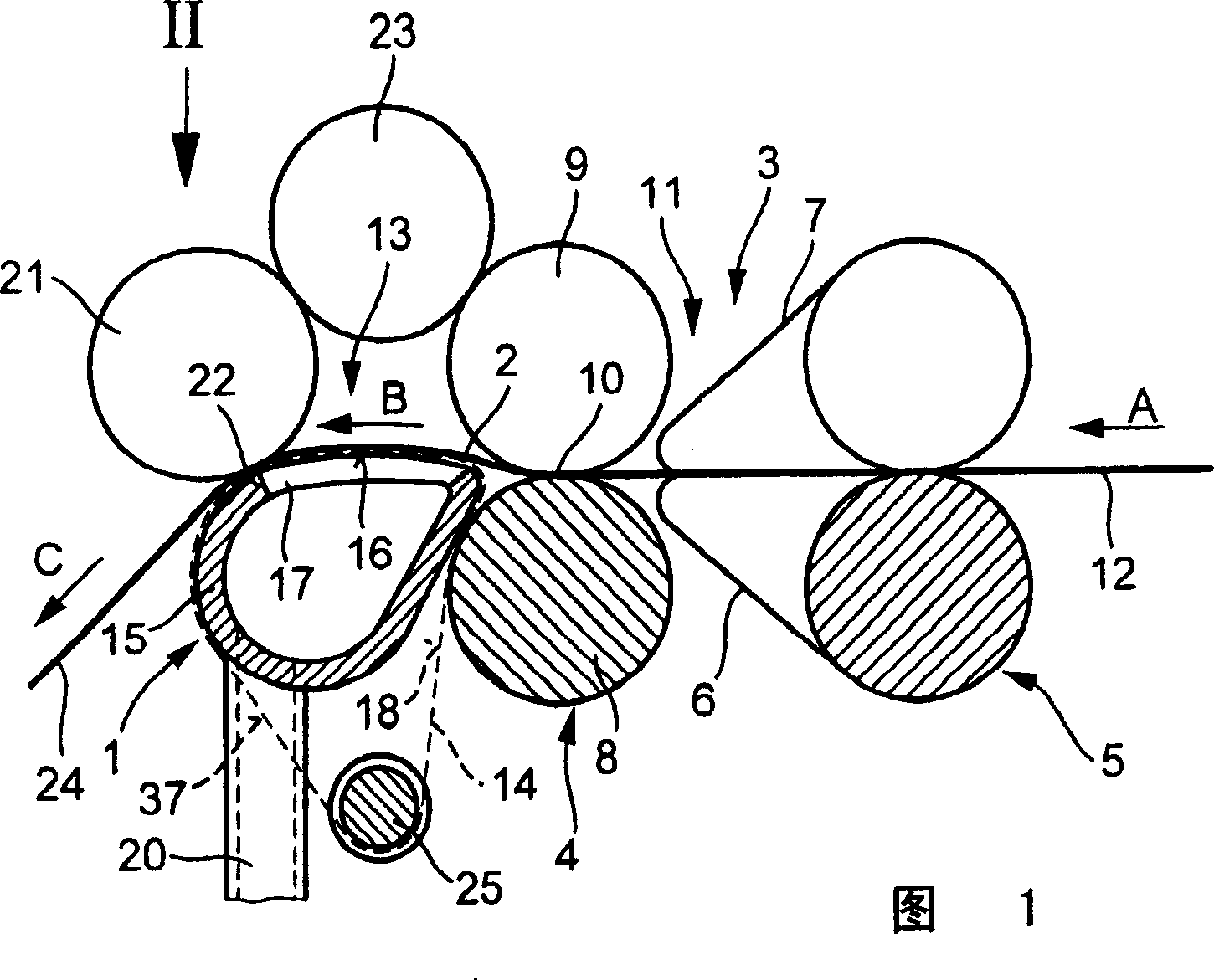

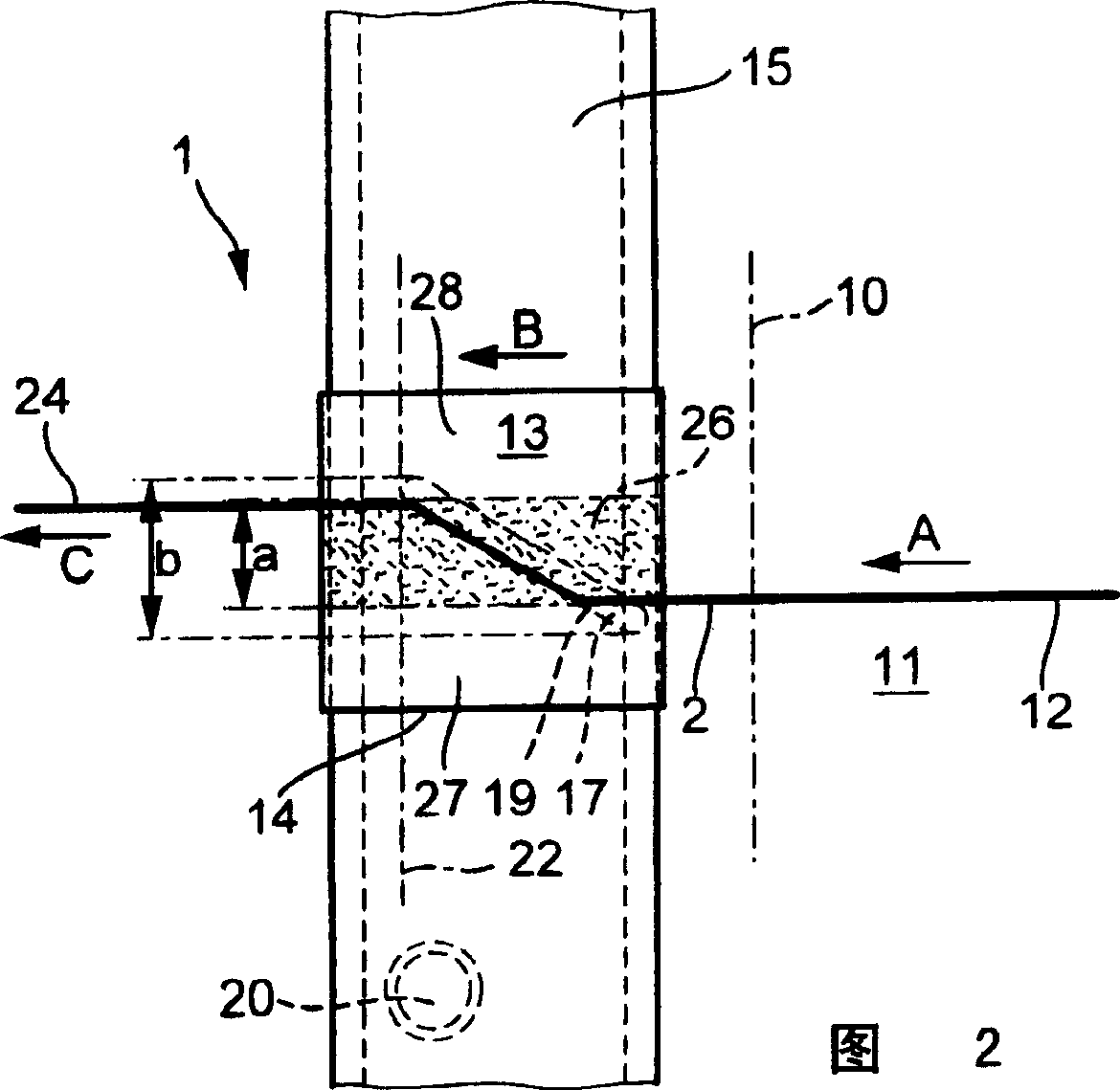

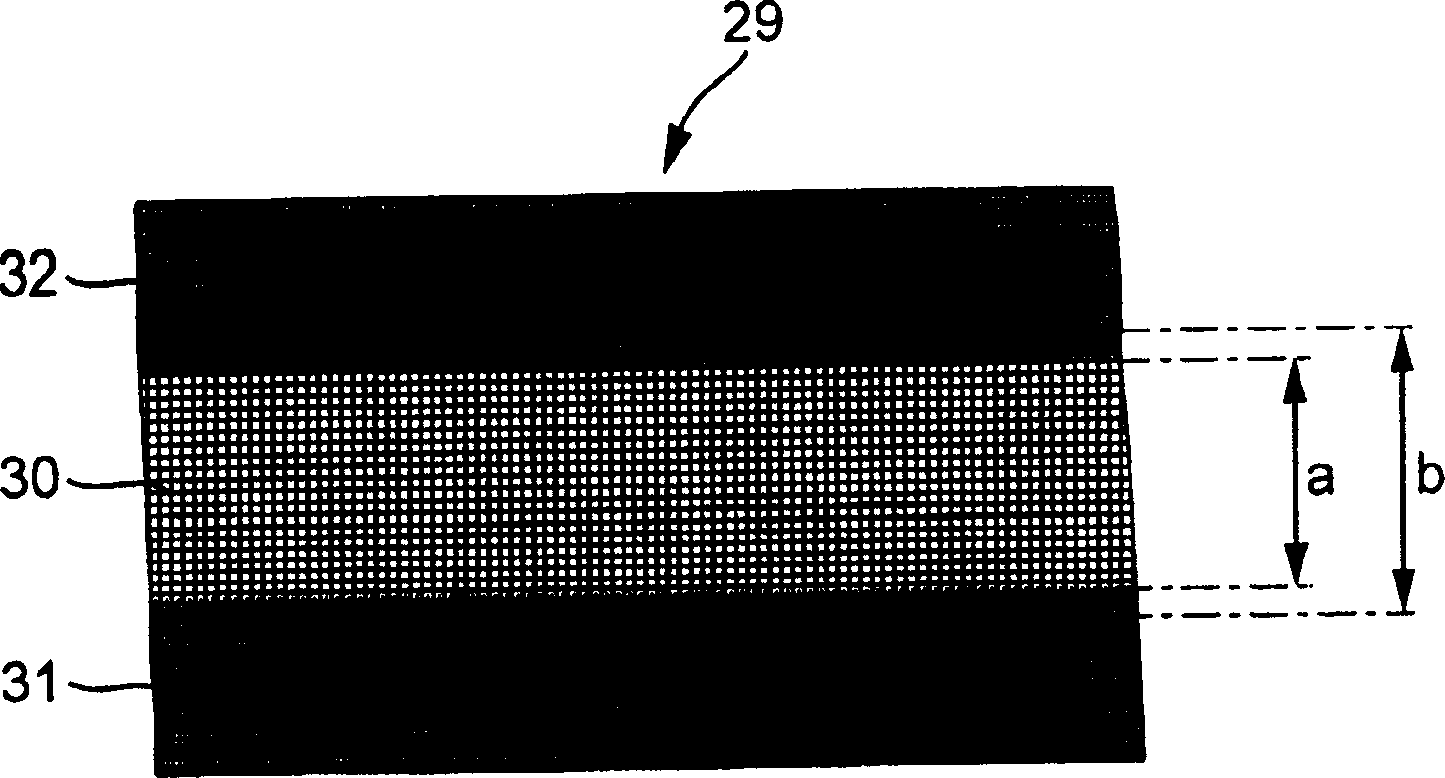

[0015] In FIGS. 1 and 2 only the area of the device 1 for compacting the drawn fiber strand 2 of a spinning machine, in particular a ring spinning machine, is shown. The device 1 shows a pair of output rollers 4 directly connected to a drafting device 3 and a pair of apron rollers 5 arranged upstream in the conveying direction A. The apron roller 5 guides a lower apron 6 and an upper apron 7 . The delivery roller pair 4 includes a driven delivery groove roller 8 and a delivery pressure roller 9 elastically pressed against the delivery groove roller. The delivery roller pair 4 thus delimits a delivery nip line 10 which forms the end of the drafting zone 11 of the drafting device 3 .

[0016] In the drafting device 3, a fiber sliver or roving 12 is drawn in the conveying direction A to the desired fineness in a known manner. This drafting effect ends at the output nip line 10, so the fiber strands 2 that have been drafted but not yet twisted are laid flat forward from this p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com