Self-propelled insect suction machine

A self-propelled and suction fan technology, which is applied in the field of insect removal machinery and self-propelled insect suction machine, can solve the problems of narrow working width, affecting the life of working parts such as fans, and insect crushing and loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

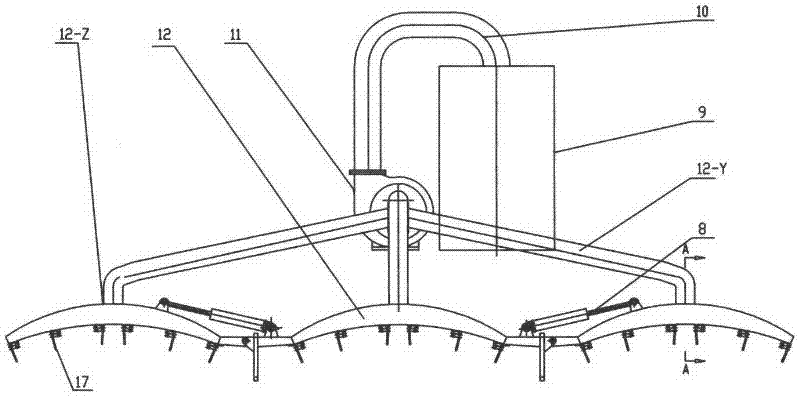

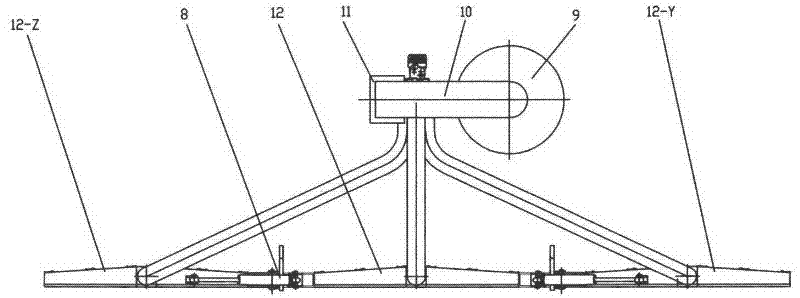

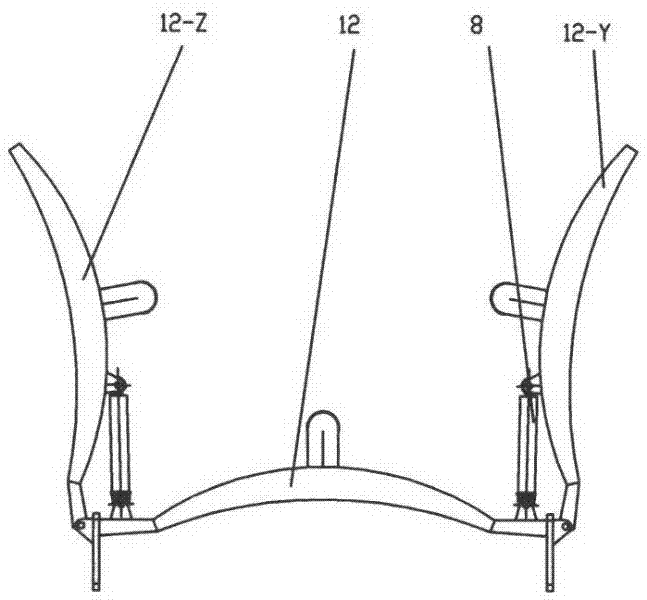

[0015] The self-propelled insect fluke of the present embodiment is as Figures 1 to 5 Shown, comprise the suction blower 11 that is attached on the walking machine (for example tractor etc.), the air outlet of this suction blower leads to filter bag 9 by connecting pipe 10, the air inlet of suction blower 11 passes through air inlet pipe and middle fluke head 12 Connect, and connect with the left and right fluke heads 12-Z, 12-Y on both sides of the middle fluke head through the air inlet hose 6 at the same time. The two ends of the middle fluke head 12 are also provided with hanger openings 7 for fixing it on the walking machine, and such installation structure is very secure. Each fluke head has a fluke head shell extending perpendicular to the direction of travel, the shell has a structure such as Figure 5 As shown, the lower surface has a slit insect suction mouth for installing the miscellaneous net 2, and the upper end communicates with the air inlet pipe or the air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com