Spreading machine and ironing device thereof

A screed and screed technology, which is applied in the field of paver and its screed device, can solve the problems of heavy weight of the extended screed, large pre-tightening force of connecting bolts, easy loosening, etc., to reduce labor intensity and facilitate installation , The effect of speeding up the installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and examples.

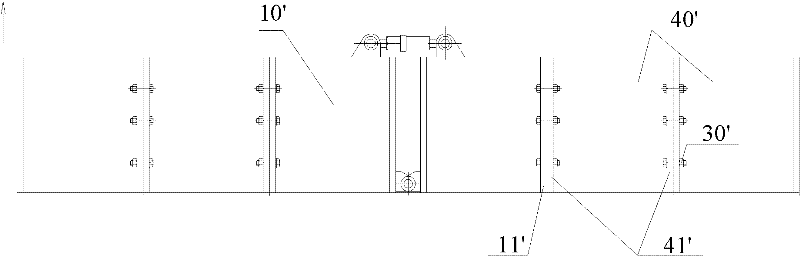

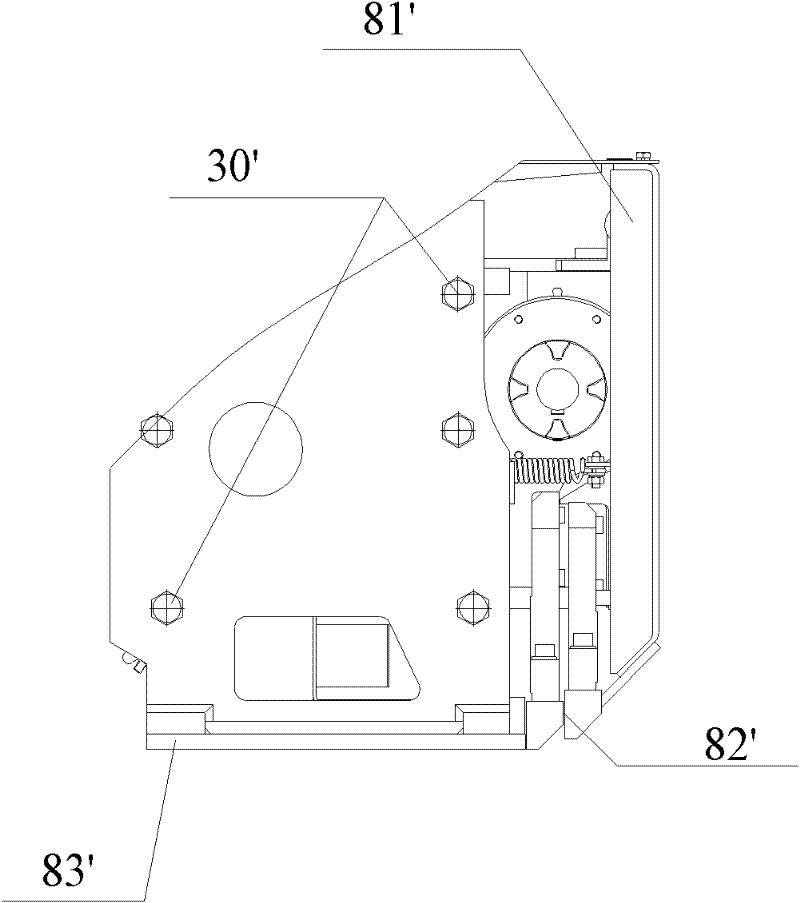

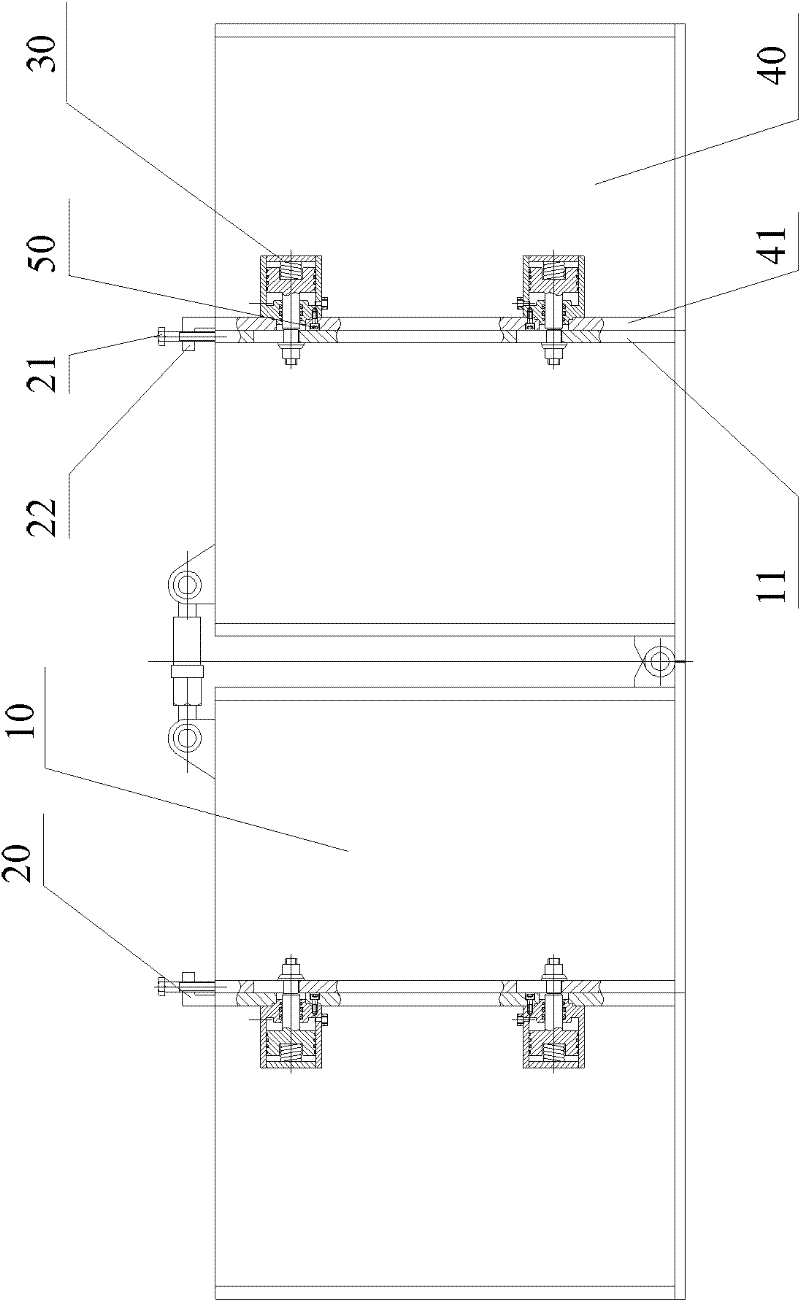

[0036] like image 3 As shown, the screed device according to the present invention includes a basic screed 10 and an extended screed 40 connected thereto, and also includes a clamping mechanism 30 connecting the basic screed 10 and the extended screed 40 . like Figure 4 As shown, the clamping mechanism 30 includes: a drive system, including a cylinder 331, a piston 333 and a support rod 335, the support rod 335 passes through the basic screed 10 and the extended screed 40, the support rod 335 is connected with the piston 333, and the cylinder The first end of 331 presses against the extended screed 40; the power system includes a pressure source, and the pressure source communicates with the cylinder body 331; the energy storage system includes a spring assembly 321, and the first end of the spring assembly 321 presses against the cylinder The second e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com