Road finisher

A technology of paving machine and distributing screw, which is applied in the direction of roads, roads, road repairs, etc. It can solve the problems that the distribution and height of the roadbed thickness cannot be adjusted, and achieve the effect of simple structure, sensitive fine-tuning, and prevention of out-of-control adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

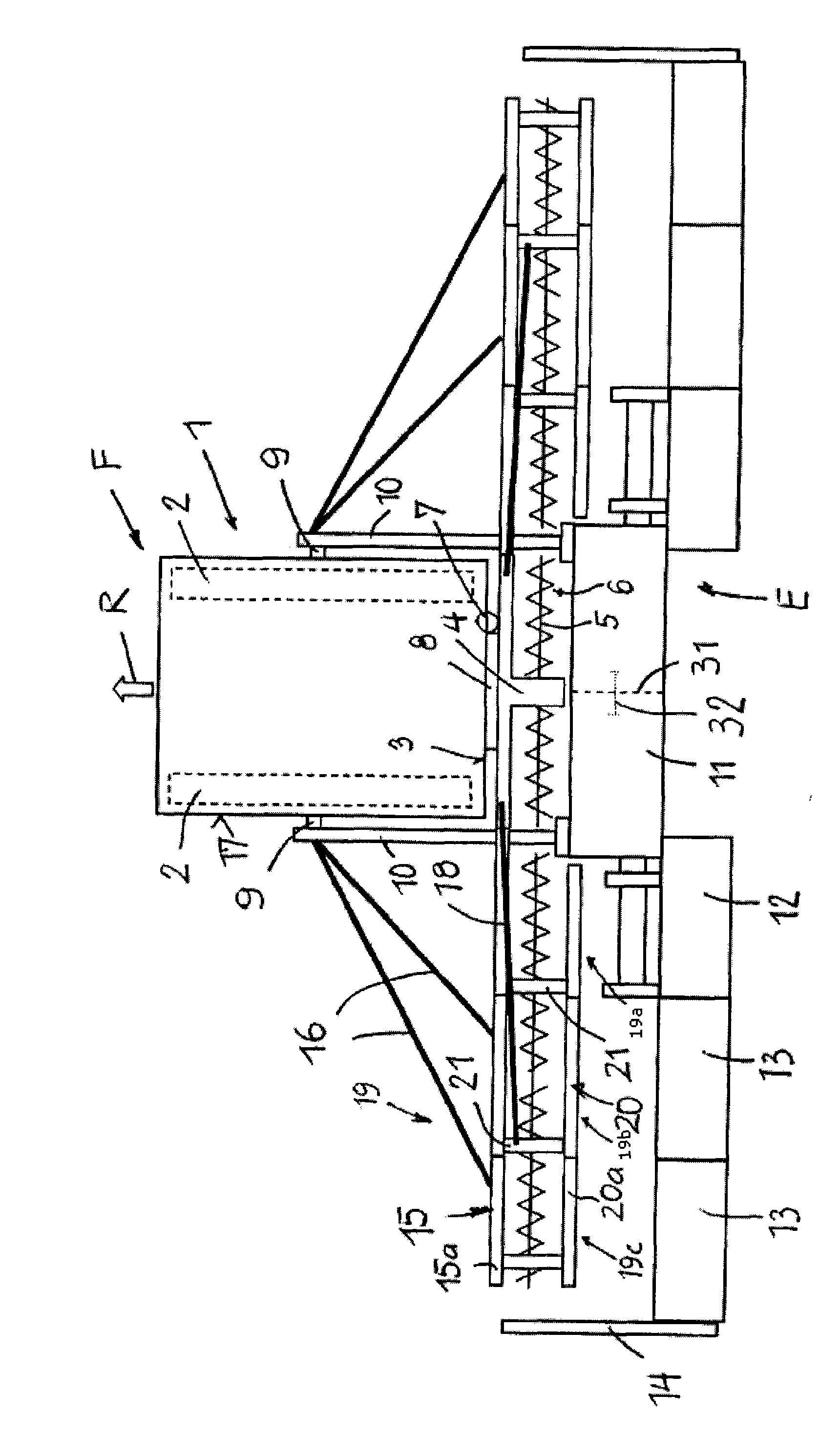

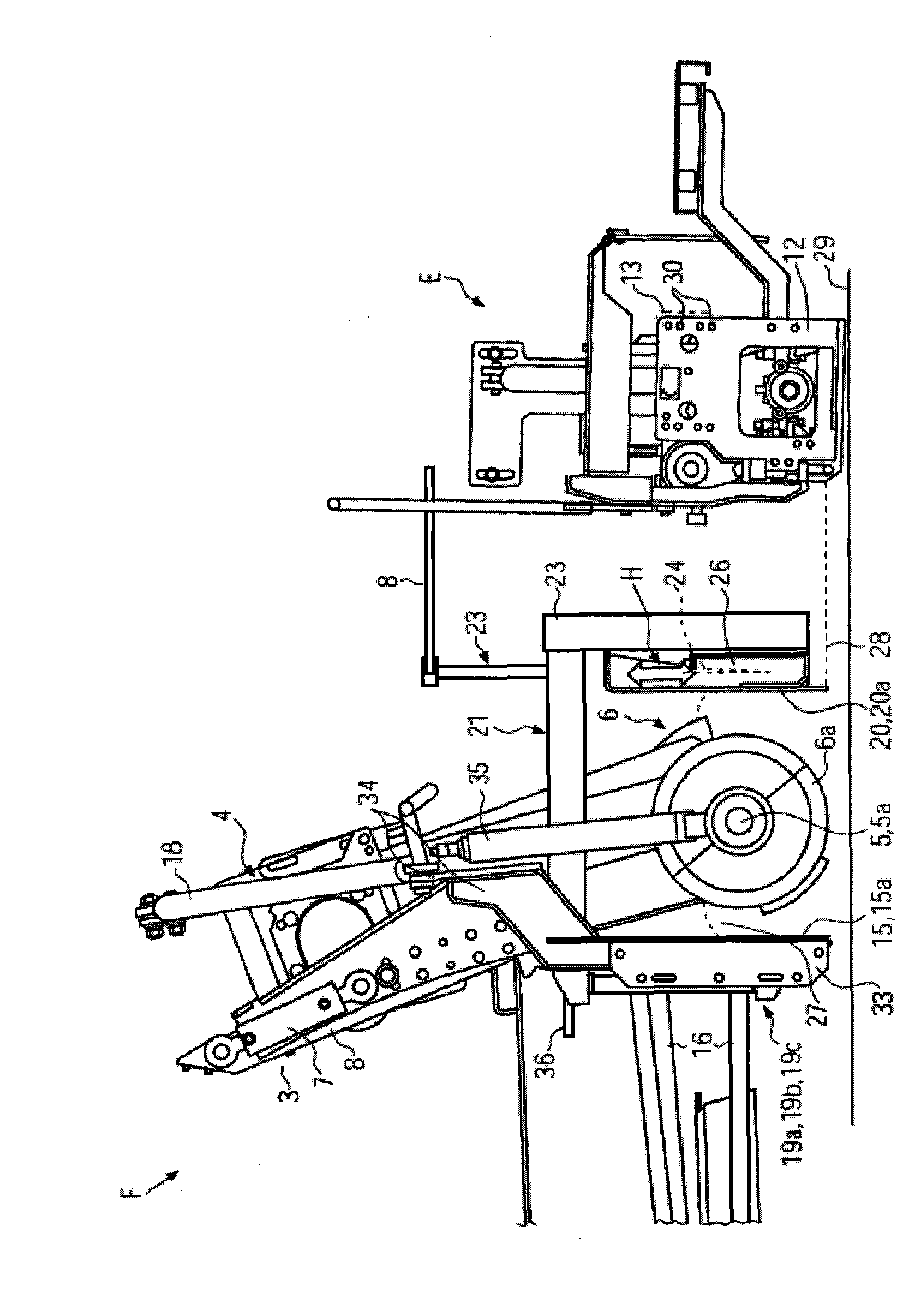

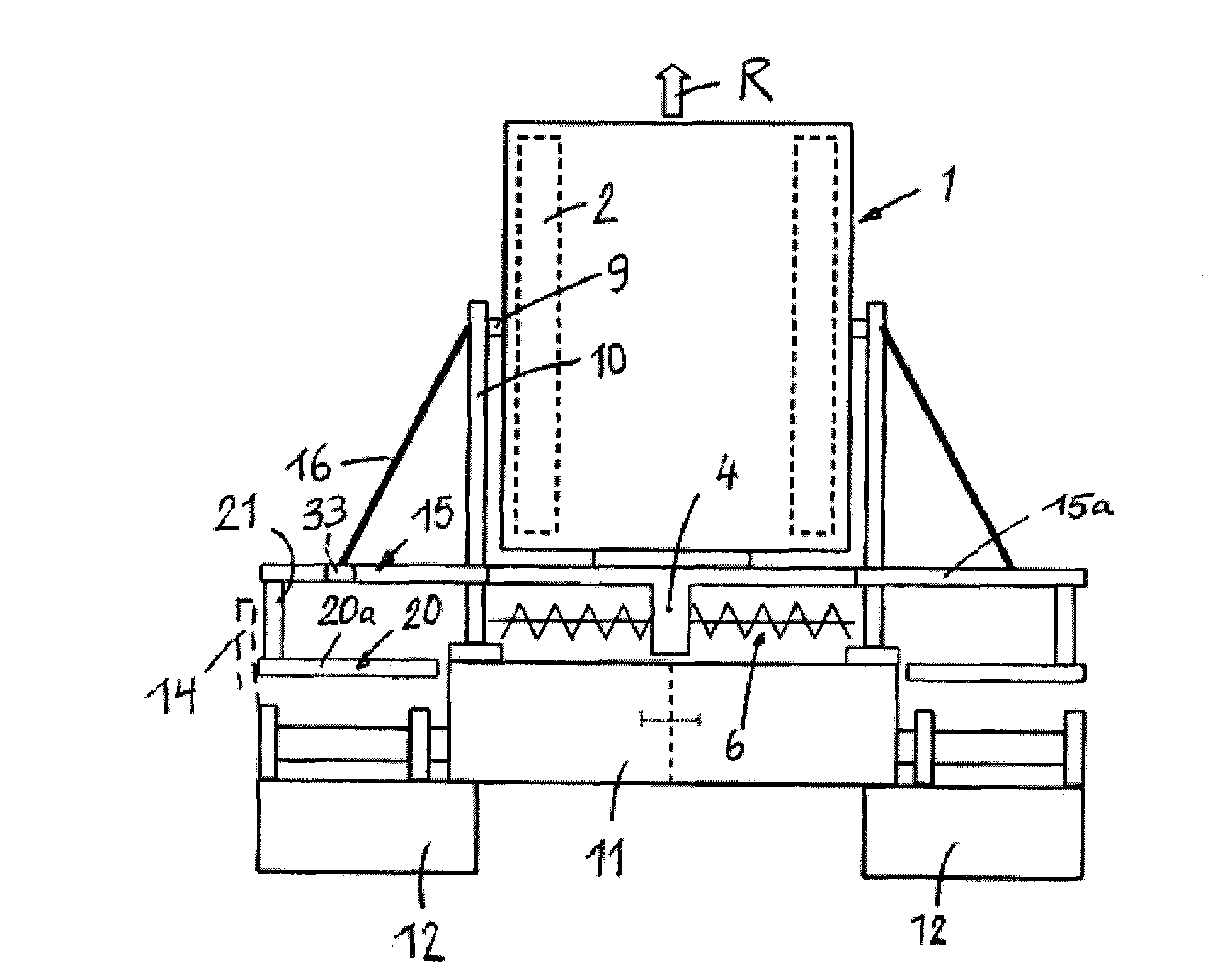

[0024] figure 1 A schematic top view showing the main components of a paving machine F, in particular a paving machine F for work with larger working widths. The tractor 1 has a chassis (not shown in detail) and an undercarriage 2 . On the rear side 3 of the chassis at least one distribution screw 4 is arranged in a vertical rail 8 so that the distribution screw 4 can be adjusted in its height position by means of a remote control drive 7 . The distribution screw support 4 is functionally connected to a rotary drive not shown in detail and carries a distribution screw 6 with a screw shaft 5 , positioning the distribution screw and the screw shaft laterally behind the tractor 1 . Optionally, two adjacent distributing screw supports 4 are provided for the two distributing screw halves, each support being adjustable in its height direction (not shown).

[0025] A laterally arranged tow bar 10 is connected to a tow point 9 arranged at the tractor 1 or the chassis of the tractor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com