Patents

Literature

169results about How to "Improve grip stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

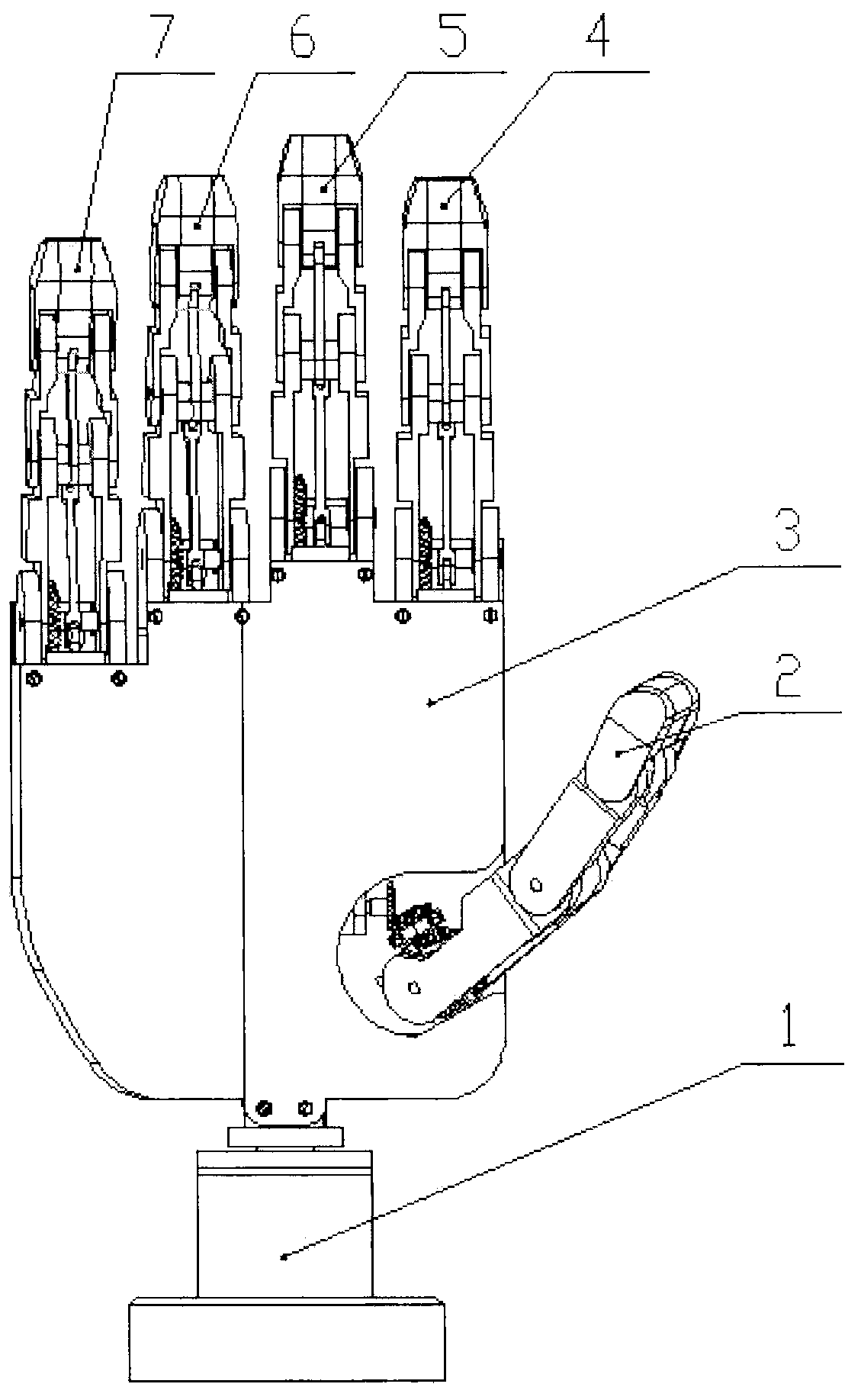

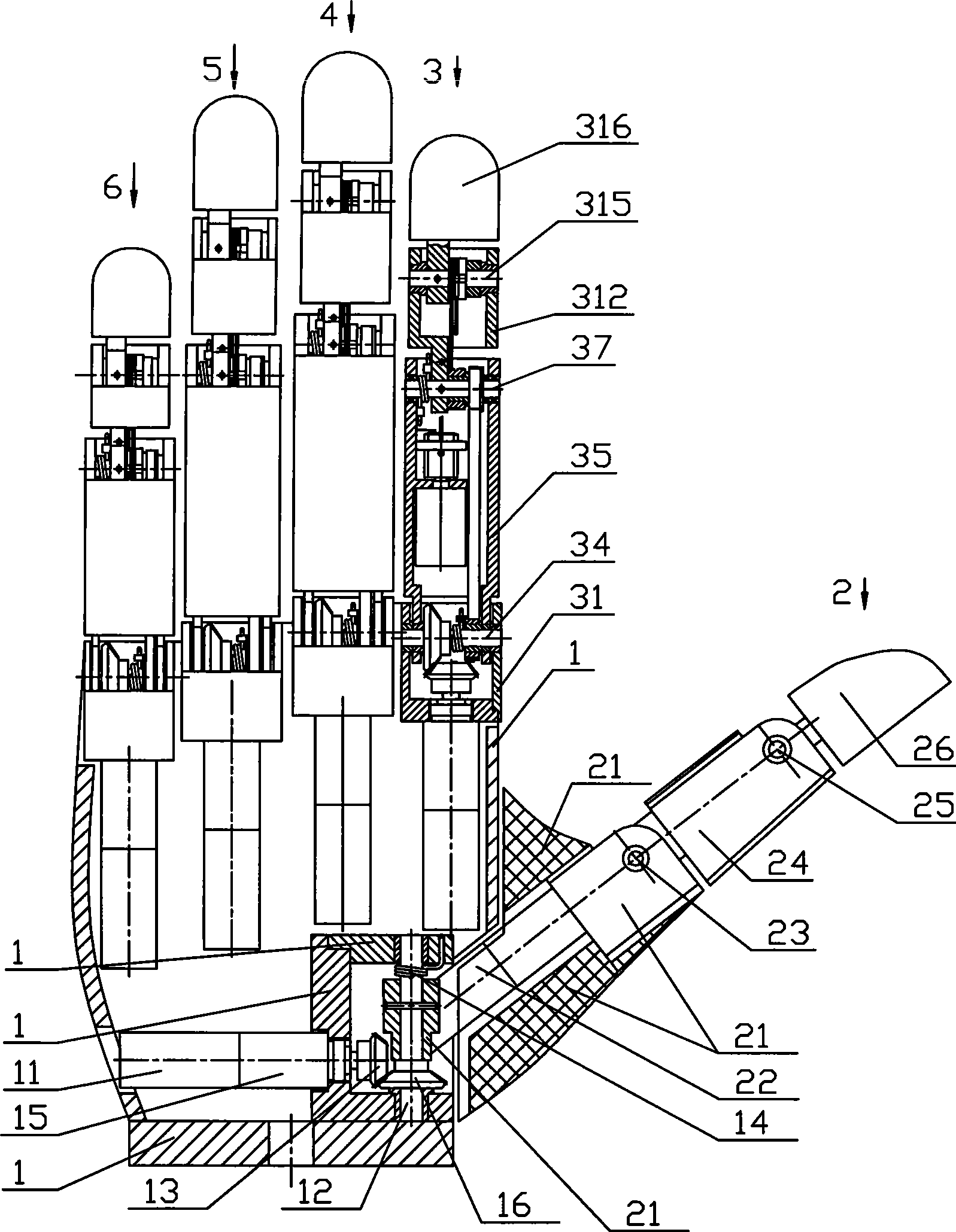

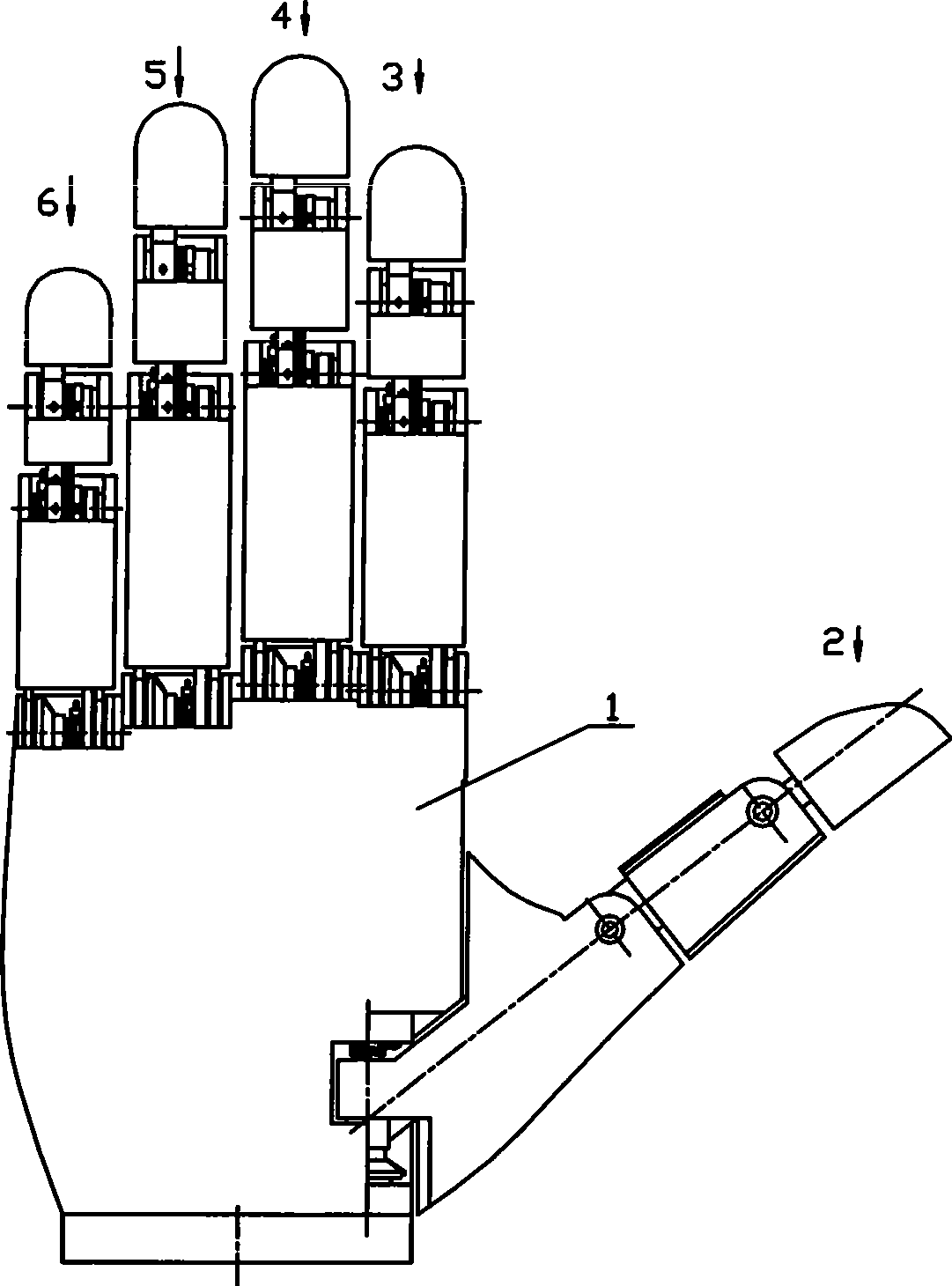

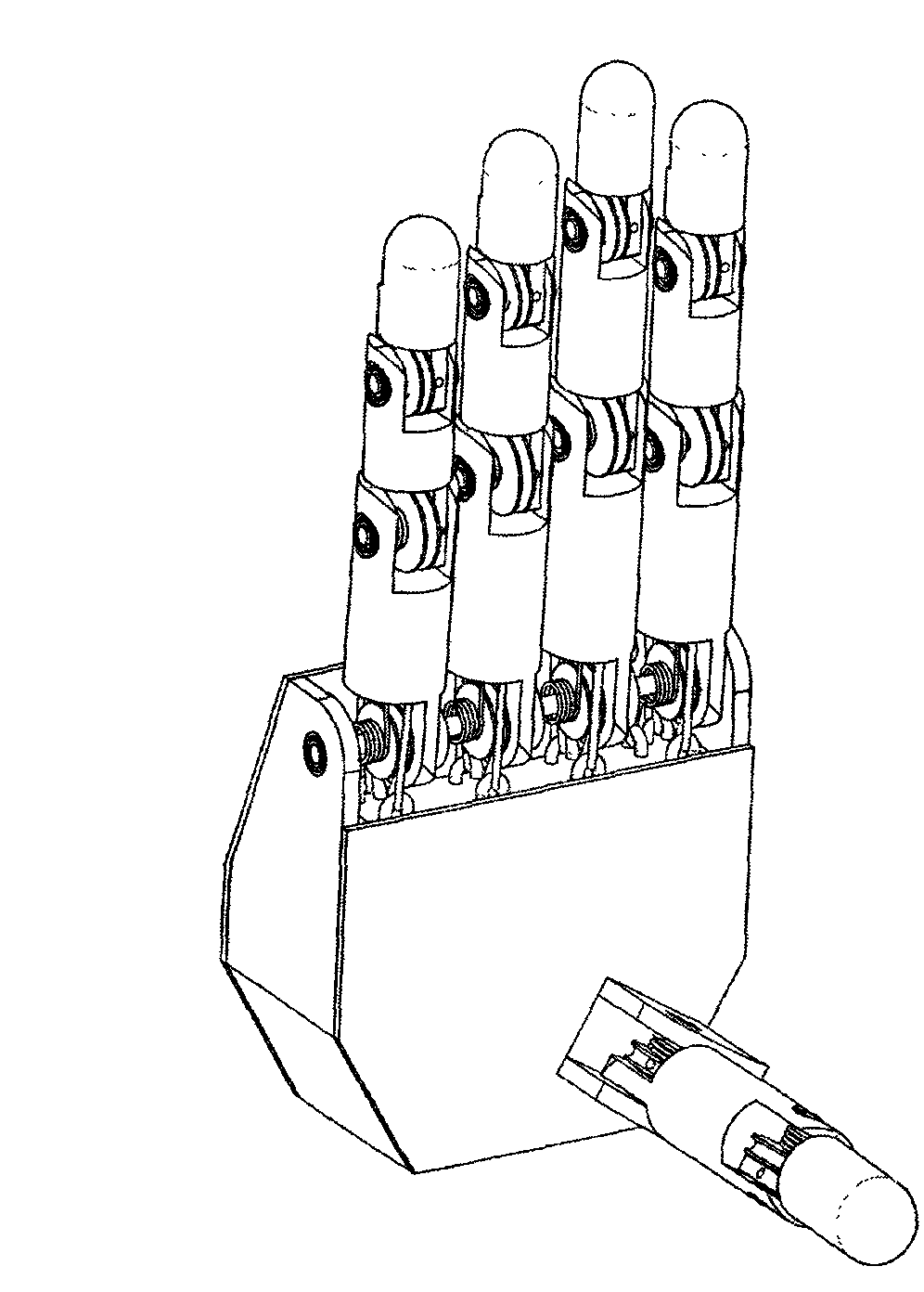

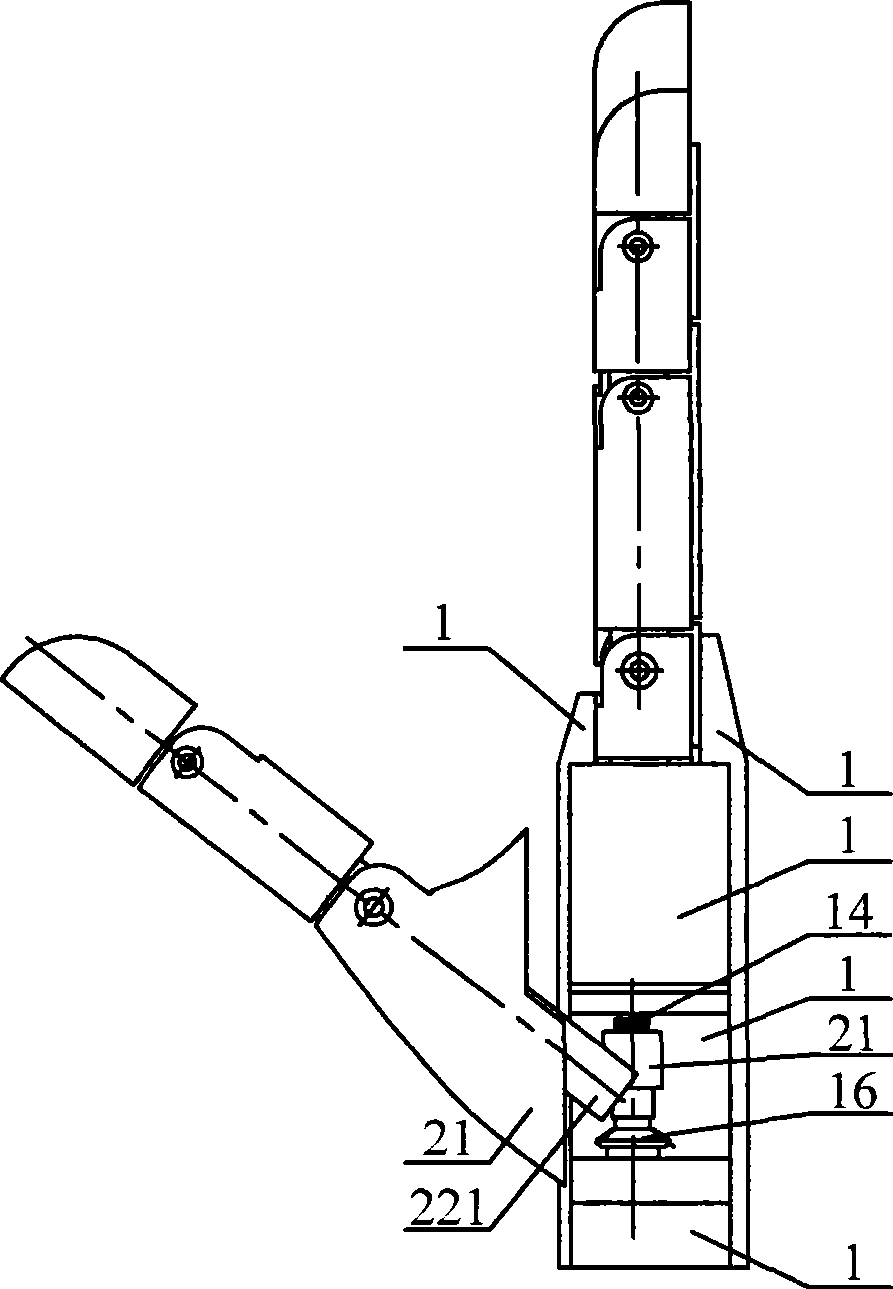

Humanoid flexible mechanical arm device

InactiveCN103128744AImprove grip stabilityIncrease stiffnessJointsGripping headsEngineeringTransmission system

The invention discloses a humanoid flexible mechanism arm device which comprises five fingers which are driven by six motors. Modular structures with same structures are adopted on four fingers (an index finger, a middle finger, a third finger and a little finger). Special effects of finger coupling transmission are achieved by a manner that the one motor, a reduction gearbox, a transmission mechanism and a flexible body are comprehensively utilized on the modular fingers. A thumb is driven by two motors, a pair of duplex bevel gears and a cross-shaped shaft are applied on a base joint transmission system to achieve buckling and side-sway movements, and good transmission effects and arrangement of the thumb and a palm are achieved. Each finger is provided with three joints which include a base joint, a middle joint and a far joint, the speed ratio is close to 1: 1: 1, and the mechanical arm is enabled to be close to a movement pattern of a hand. The humanoid flexible mechanical arm device has the advantages of being large in fingertip output force and rigidity, compact in structural arrangement, high in humanization degree, stable in grab and the like.

Owner:CHINA UNIV OF MINING & TECH

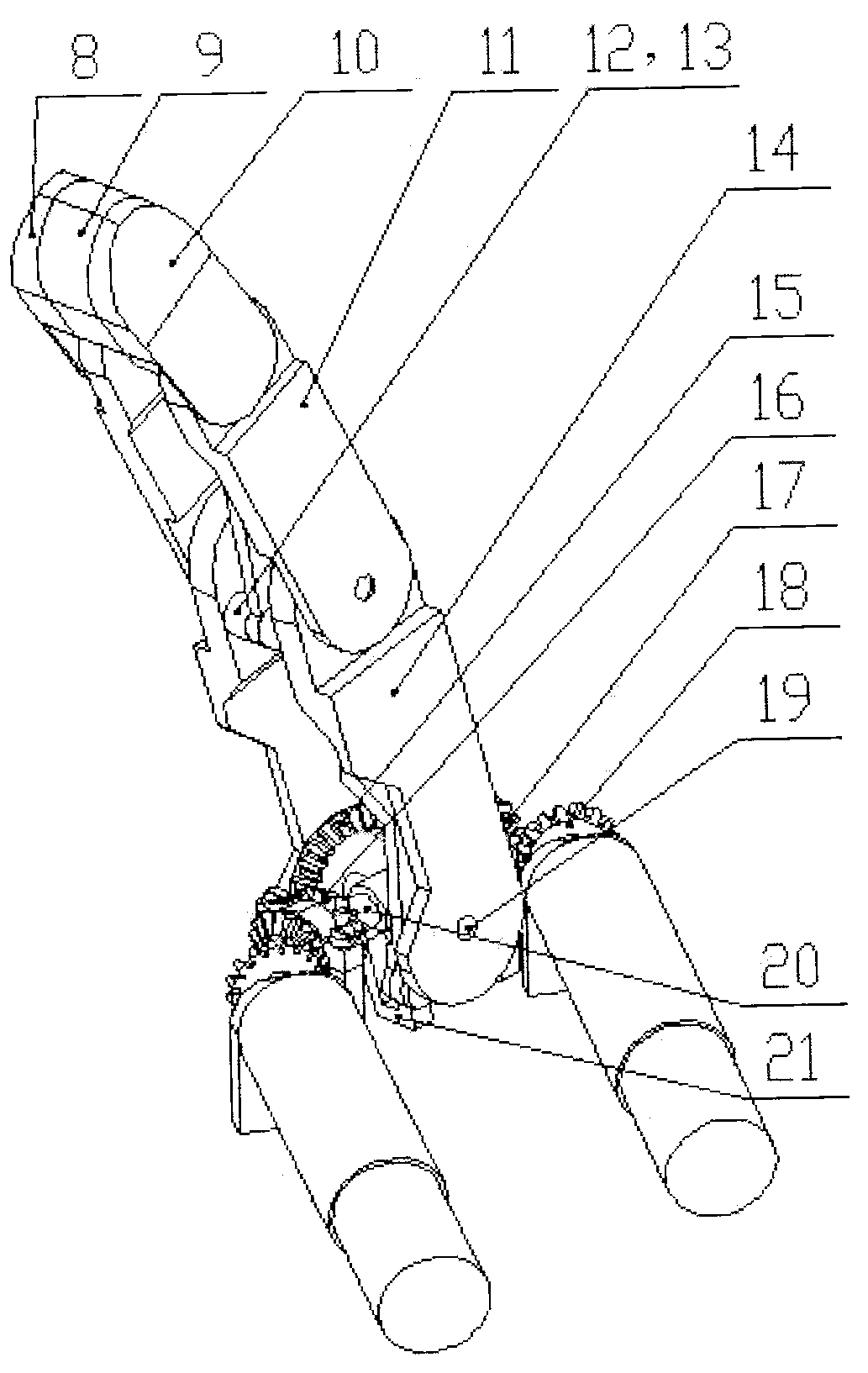

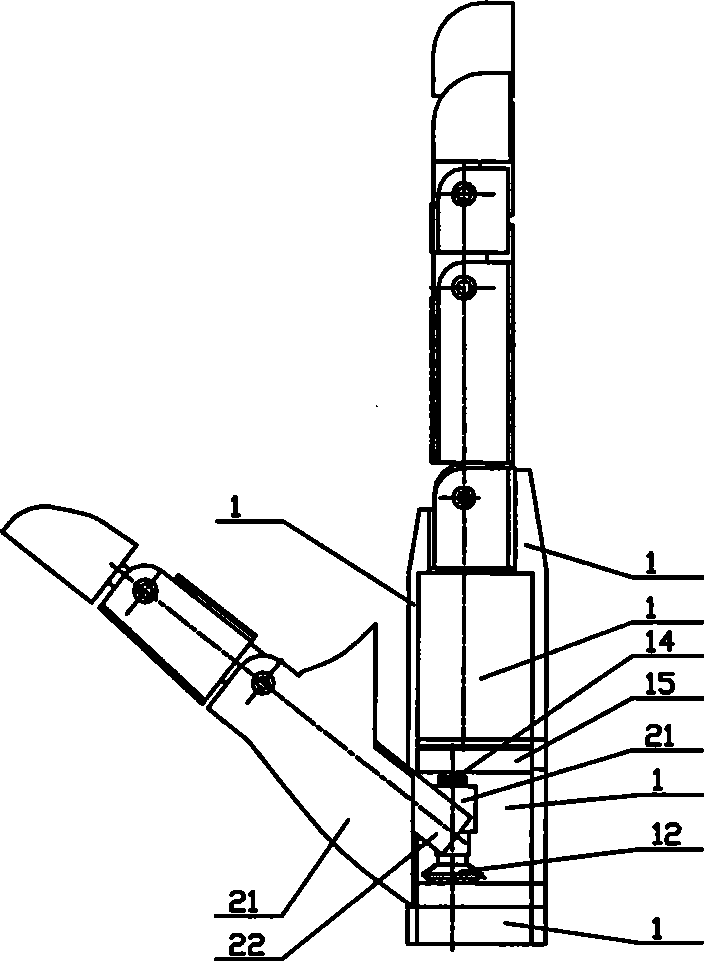

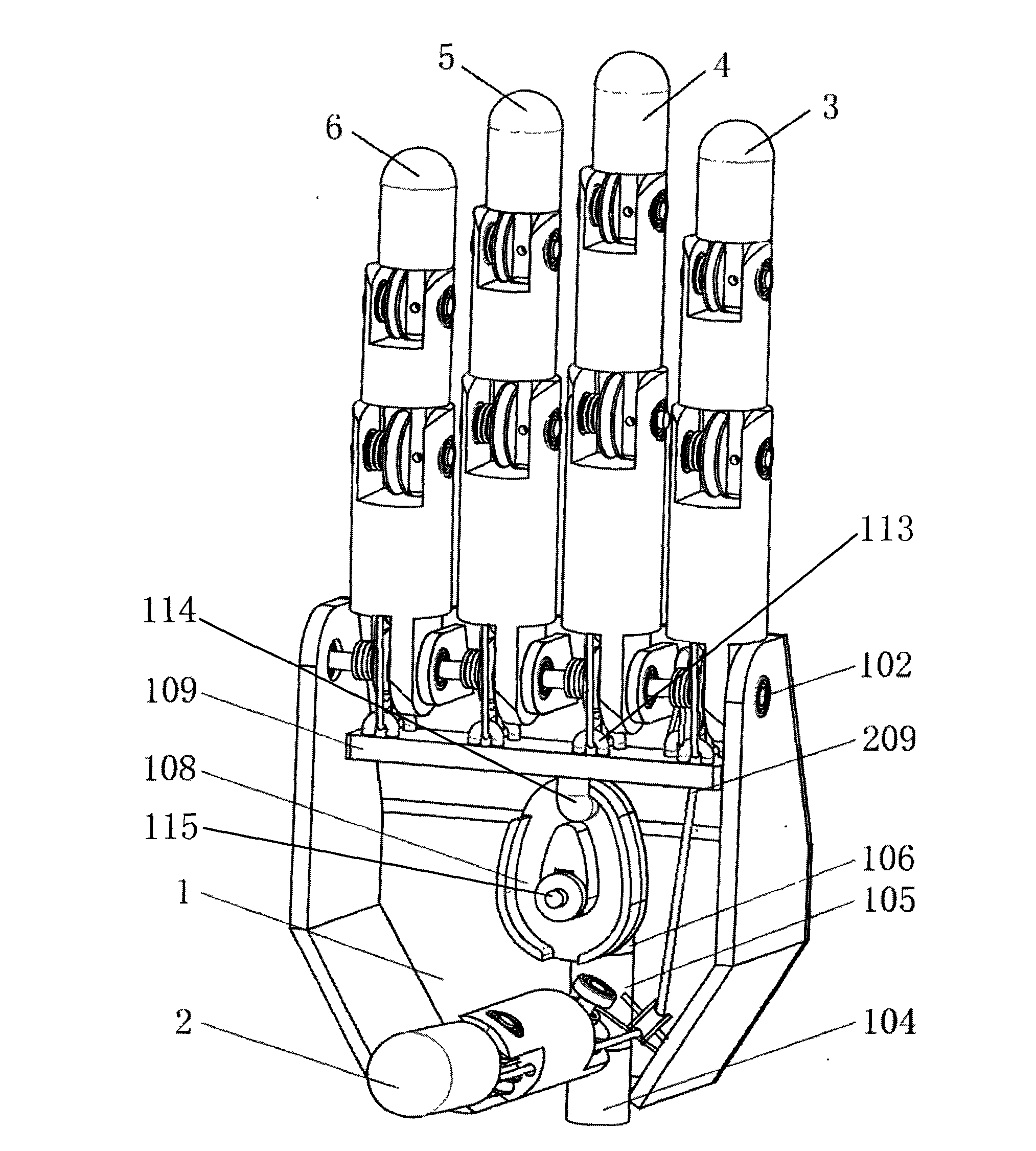

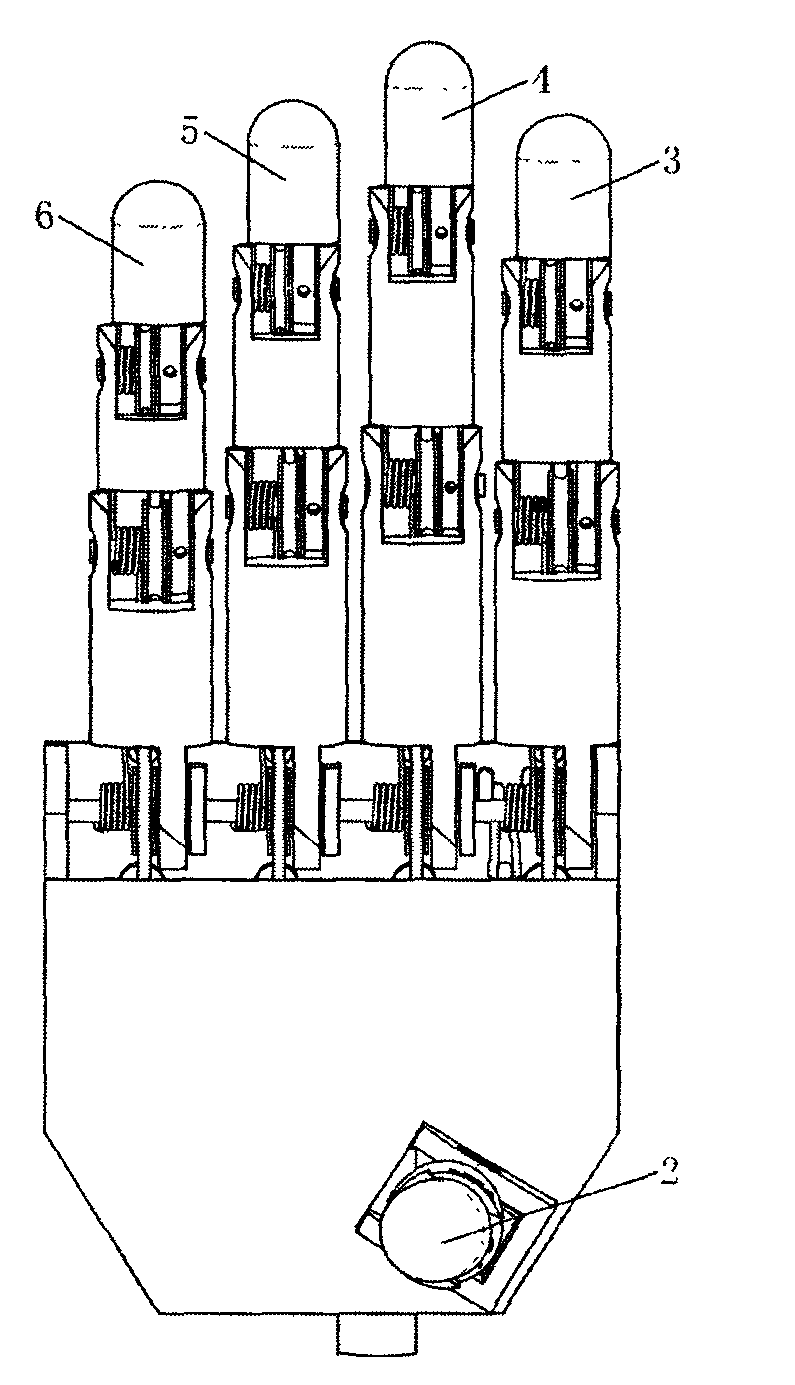

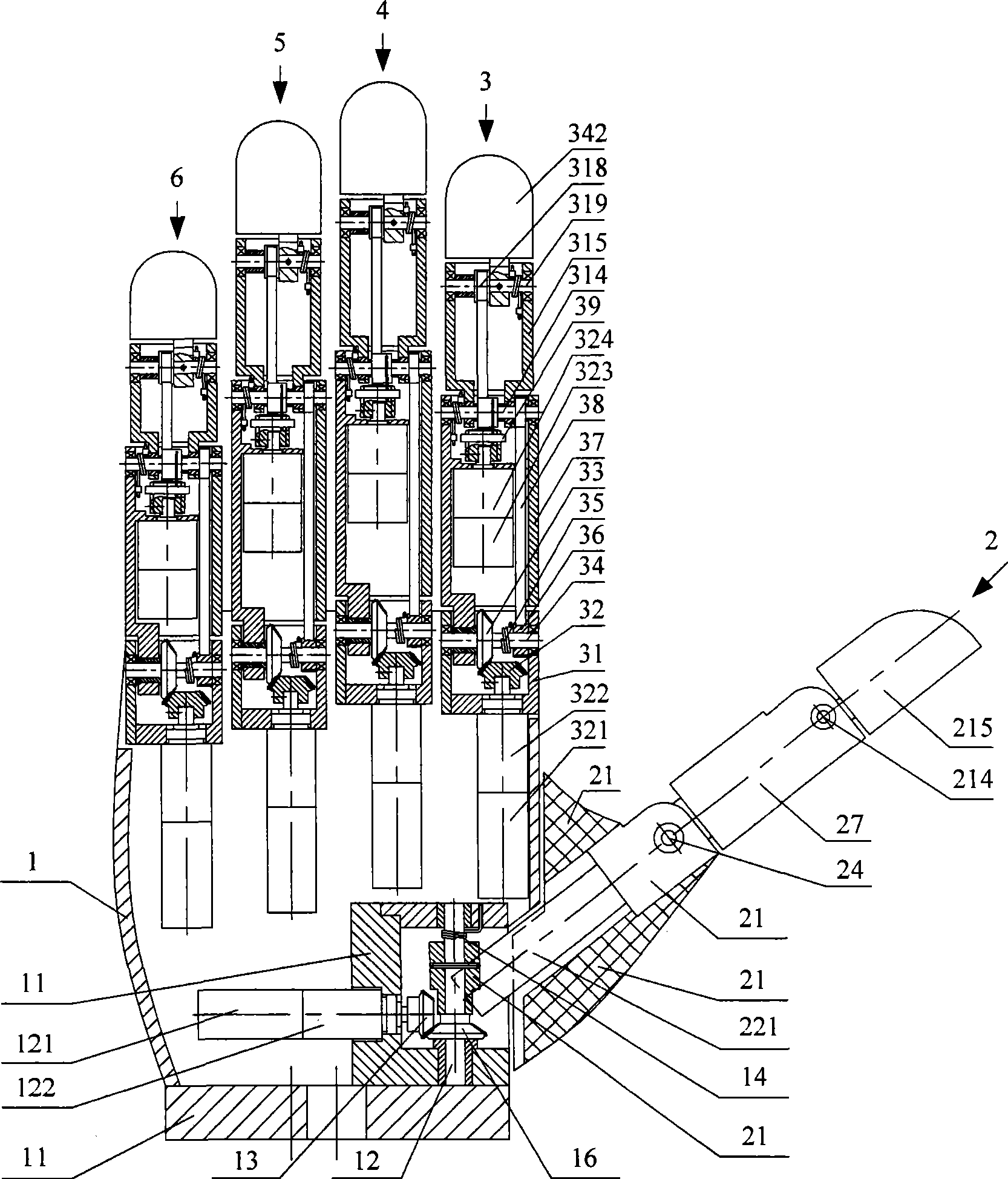

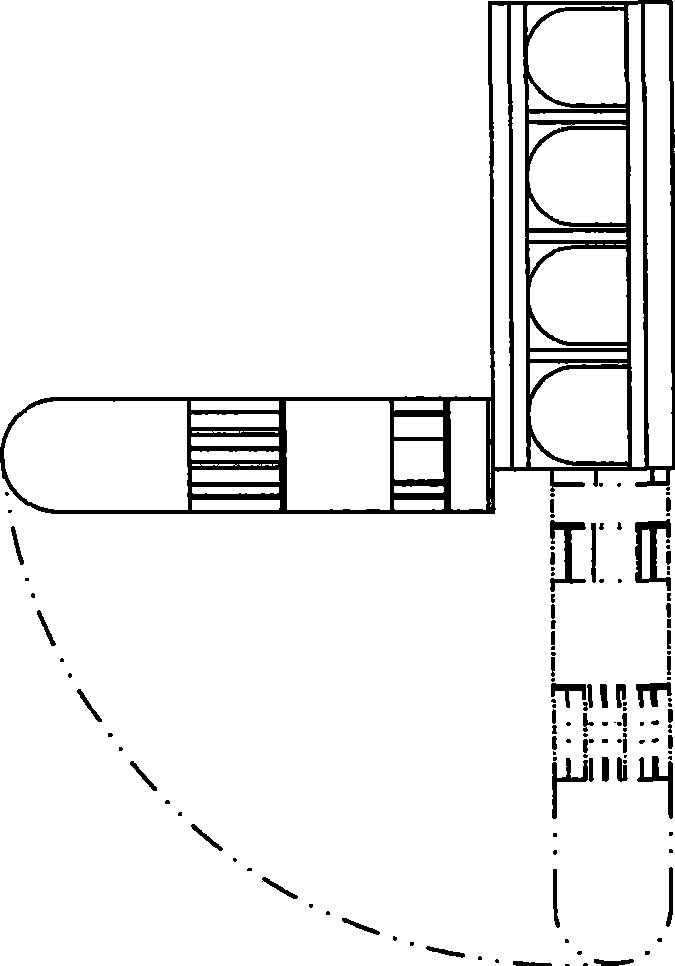

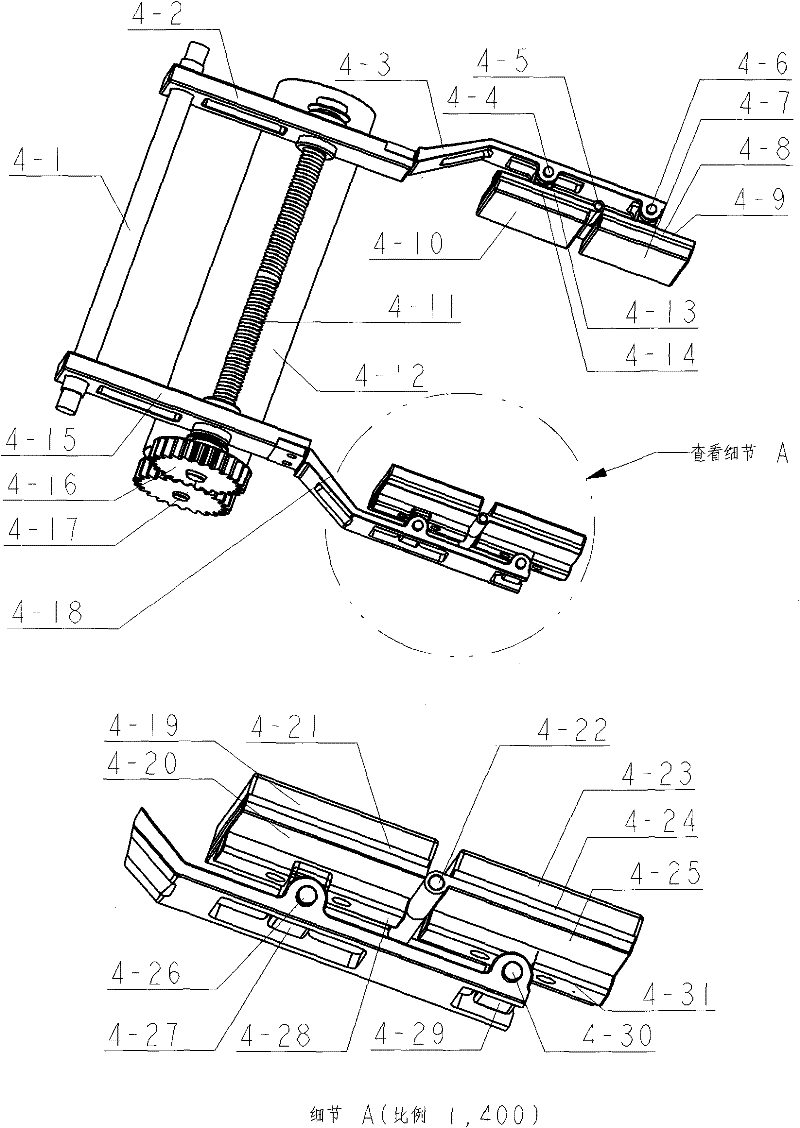

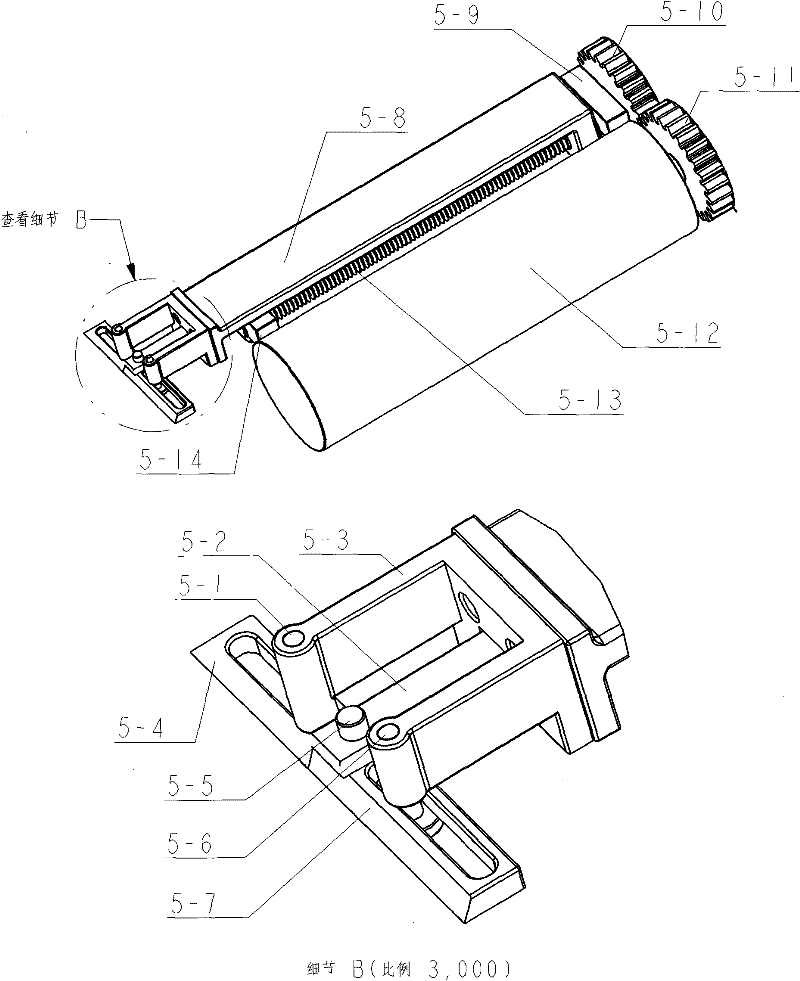

Bionic robot under-actuated delicacy hand device

InactiveCN101474794ALower requirementImprove grip stabilityGripping headsGearingLittle fingerRobot hand

A bionic robot under-driven flexible hand device belongs to the technical field of anthropomorphic robot, and mainly comprises a thumb, a forefinger, a middle finger, a ring finger, a little finger and a palm. The device is provided with five independently controller fingers and fifteen joint freedoms, and is controlled by ten motors. The structures of four fingers (the forefinger, the middle finger, the ring finger and the little finger) are same. The variable initial configuration of finger and special effect of partial-coupling self-adapting grasping are realized through double motors, a transmission mechanism, a flexible component and reed component. The four fingers bend the second middle finger segment before grasping an object and the bottom finger segment bends for obtaining an excellent grasping preparing gesture. The robot hand is closer to man hand. The device of the invention has the advantages of compact structure, high integrity, external appearance, dimension and shape closer to man hand, capability for stably grasping and automatically adopting for objects with different shapes and dimensions. The device of the invention is used for anthropomorphic robot.

Owner:TSINGHUA UNIV

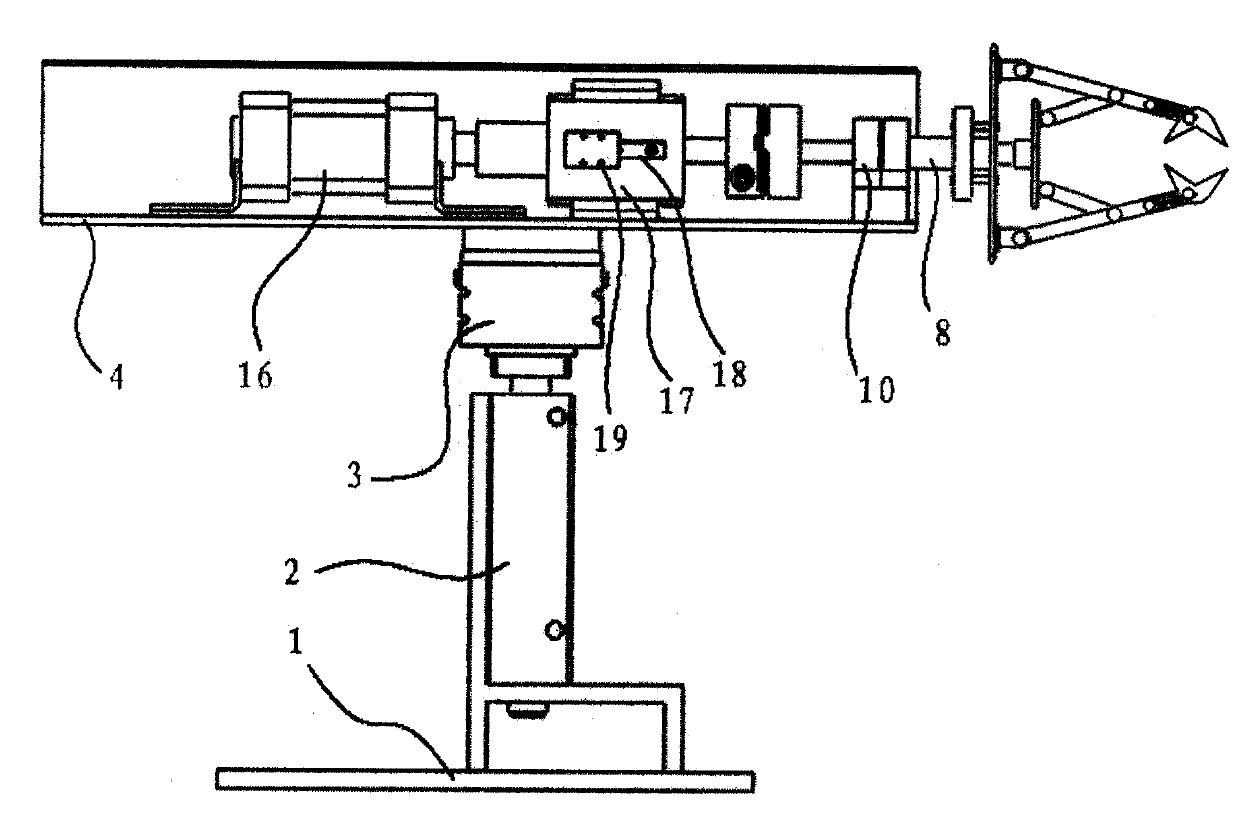

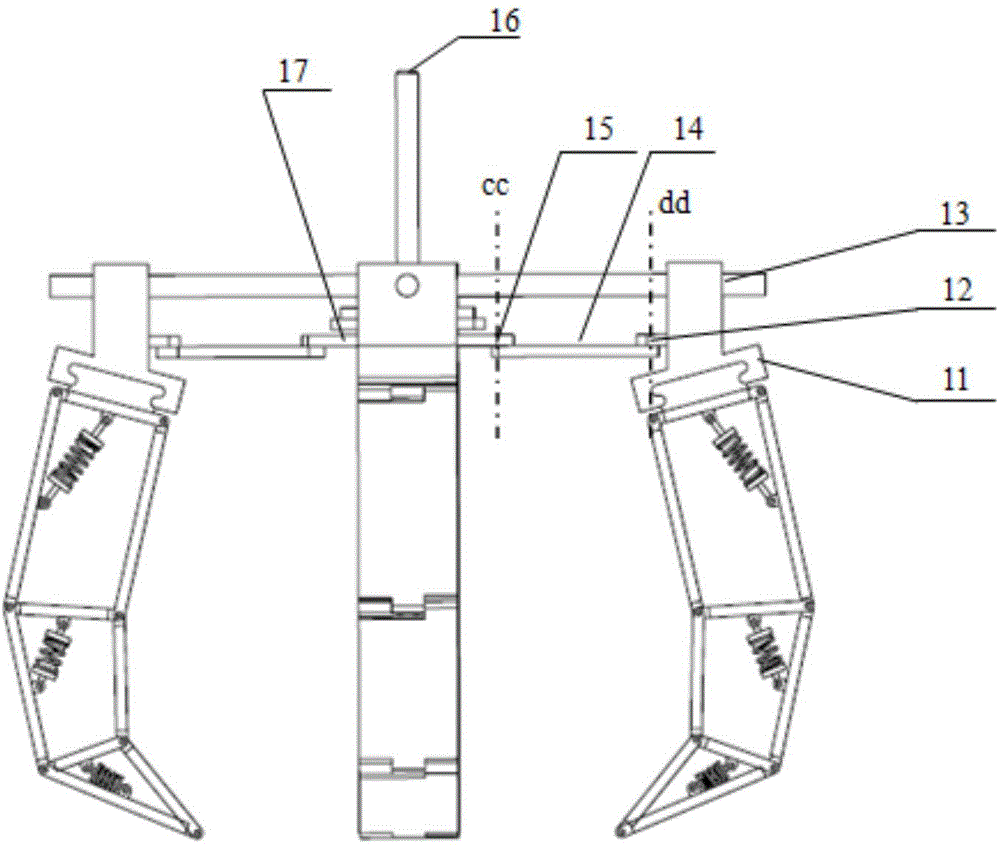

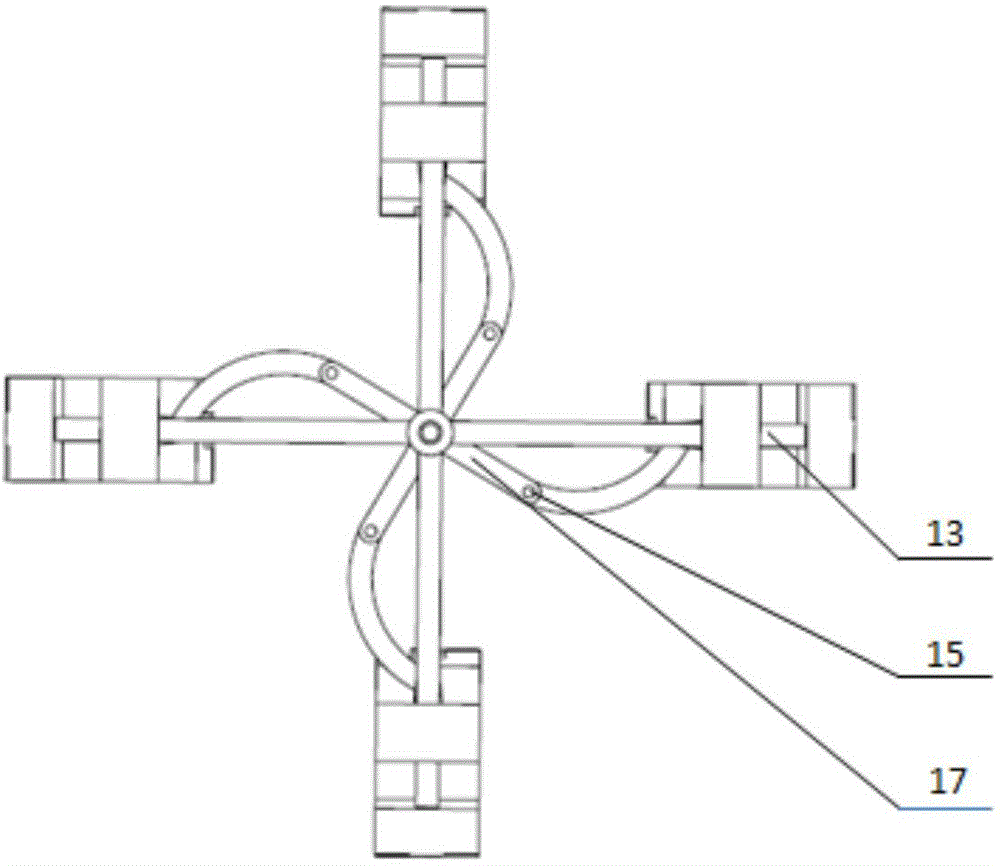

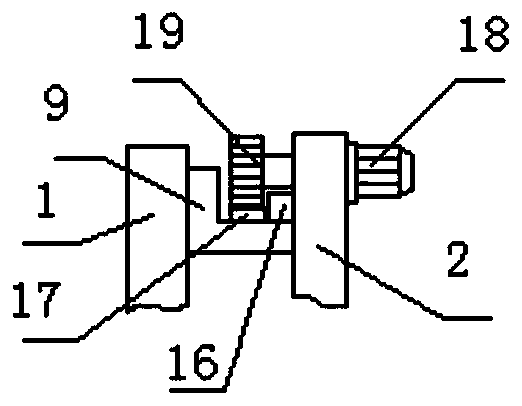

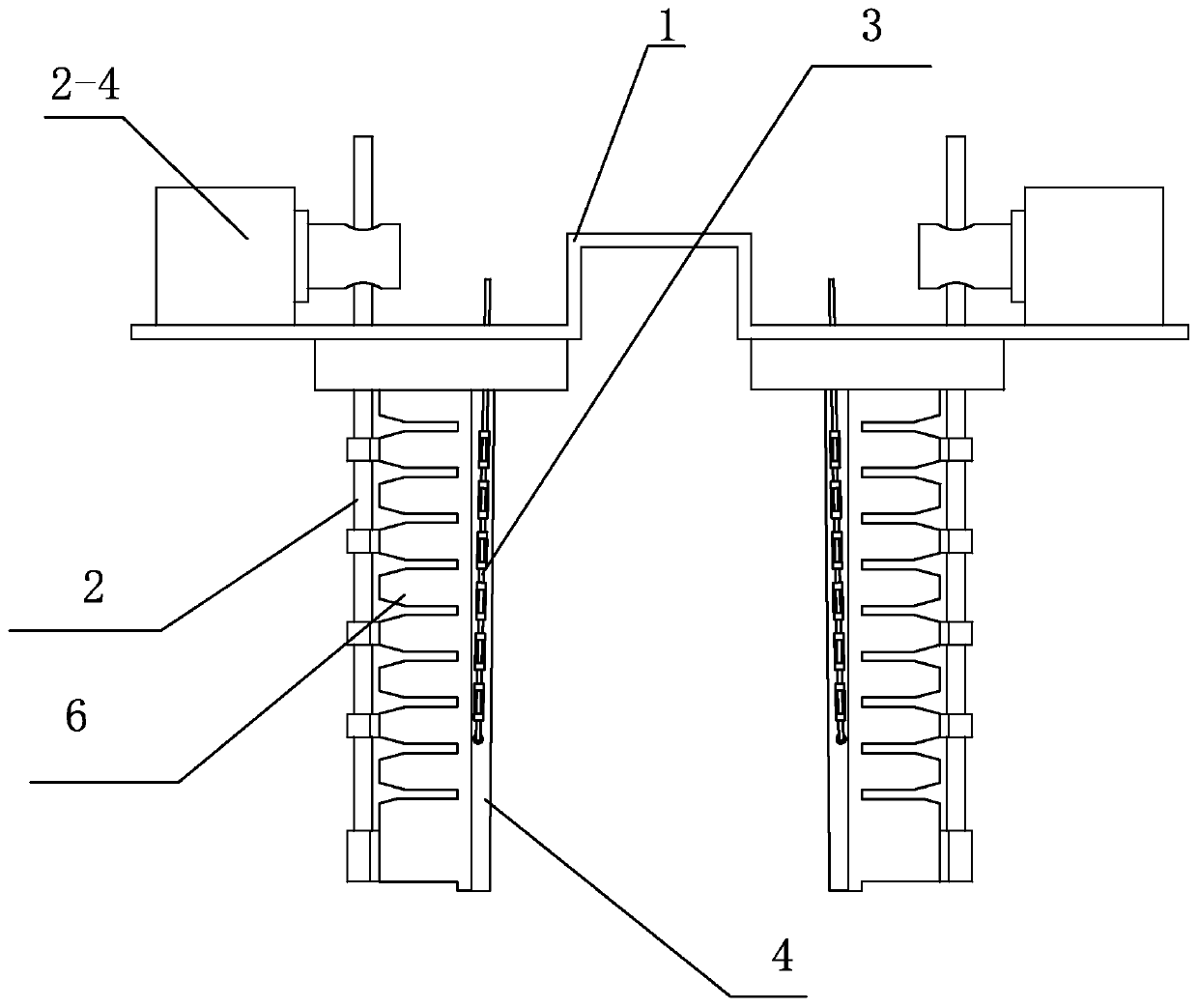

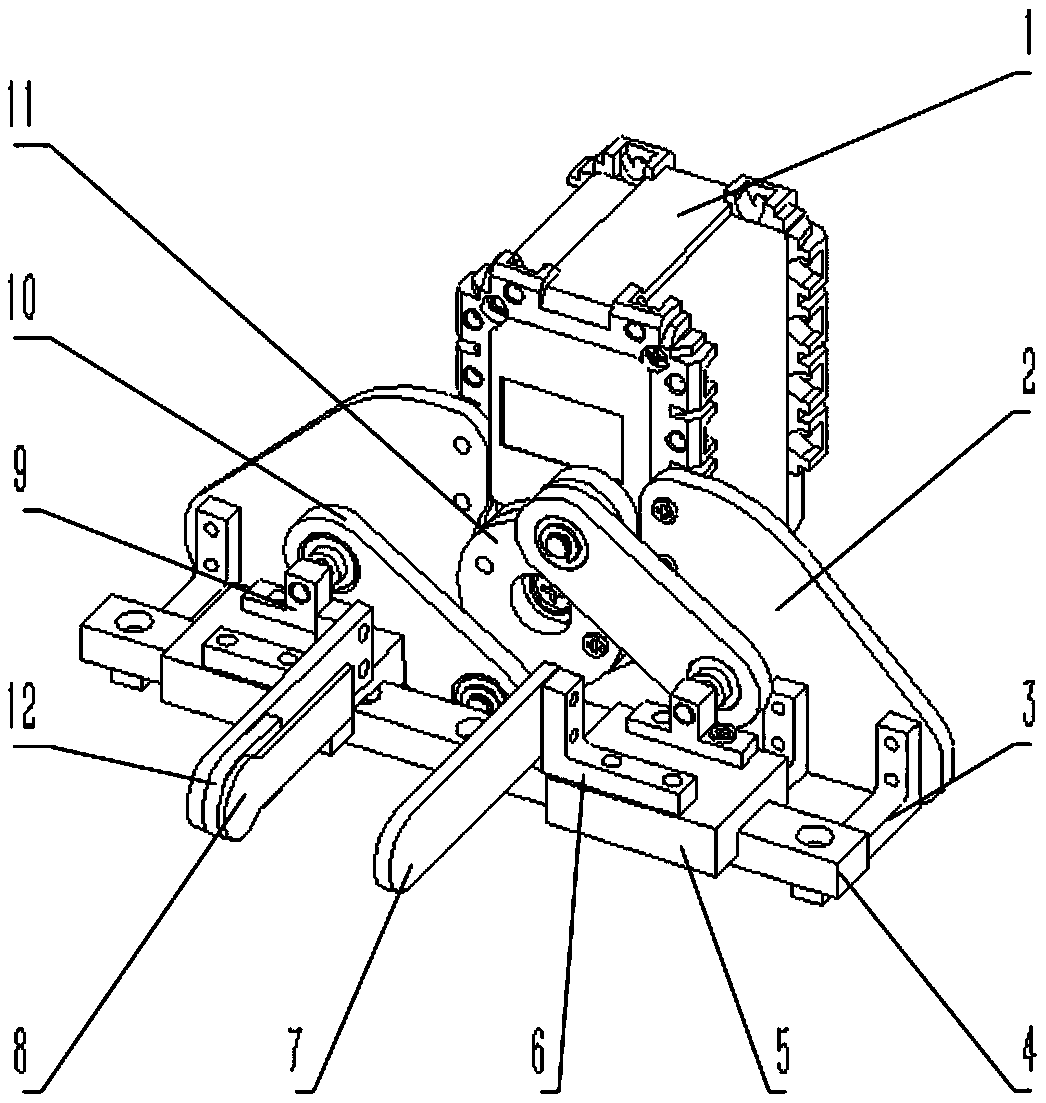

Novel part carrying device

ActiveCN103846914AImprove grip stabilityAdaptableProgramme-controlled manipulatorGripping headsEngineeringManipulator

The invention discloses a novel part carrying device. The novel part carrying device comprises a machine frame, a lifting air cylinder, a rotating air cylinder and a carrying mechanism, wherein the lifting air cylinder is arranged on the machine frame; the rotating air cylinder is arranged on the upper end of the lifting air cylinder; the carrying mechanism is arranged on the upper end of the rotating air cylinder and comprises a shell and a manipulator claw device arranged on one end of the shell; the manipulator claw device comprises a fixed cross plate and a pulling plate; the pulling plate is connected with a rotating shaft; the rotating shaft is sleeved in a casing sleeve; one end of the casing sleeve pushes against the fixed cross plate and the other end is fixed to a fixing base in the shell; a bearing chuck is connected to the casing sleeve through a bearing arranged on the outer diameter and is connected with the fixed cross plate through a pin shaft; a connecting rod is respectively hinged to each of the two sides of the fixed cross plate; the other end of each connecting rod is hinged to a jack catch; a cross rod is respectively hinged to each of the two sides of the pulling plate; the other end of each cross rod is hinged to the middle position of each connecting rod; a clamping air cylinder and a turning air cylinder are arranged in the shell; the clamping air cylinder is connected with the turning air cylinder; an output shaft of the turning air cylinder is connected with the rotating shaft. The novel part carrying device is high in loading capacity, good in grabbing stability, accurate and quick in action, and easy to operate.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

Cam type quick grabbing under-actuated robot hand device

InactiveCN103213137AImprove crawling efficiencyGood gripping stabilityGripping headsElectric machineryHand palms

The invention discloses a cam type quick grabbing under-actuated robot hand device, and belongs to the technical field of robot hands. The device mainly comprises a palm, at least two fingers, a main shaft, a motor, a speed reducer, a first bevel gear, a second bevel gear, an incomplete groove cam, a movable plate, a sensor for detecting whether the fingers are opened in place or not, a sensor for detecting whether an object is in place or not, a control module and the like, wherein each finger is a tendon rope-torsion spring type multi-joint finger. The device has a function of automatically and quickly grabbing the object, and a grabbing process comprises four processes of energy storage opening of the fingers, detection of whether the fingers are opened in place or not, detection of whether the object is in place or not and instantaneous grabbing releasing; the device can be used for realizing quick grabbing; the object can be automatically grabbed after being detected to be in place; objects with different shapes and sizes can be adaptively grabbed; the device is compact in structure, the palm is large in size, and a grabbing space is large; the device is stable and accurate in transmission and high in transmission efficiency; and a plurality of joints of a plurality of fingers can be driven by only one motor, and the appearance and the actions of a human hand can be simulated by the device; and the device can be used for an anthropomorphic robot.

Owner:TSINGHUA UNIV

Electrically Insulated Screen and Method of Erecting an Electrically Insulated Screen

ActiveUS20140326882A1Improve grip stabilityAccurately magnitude and directionRadiation pyrometryForce measurement by measuring optical property variationEngineering

Owner:ONROBOT HUNGARY KFT

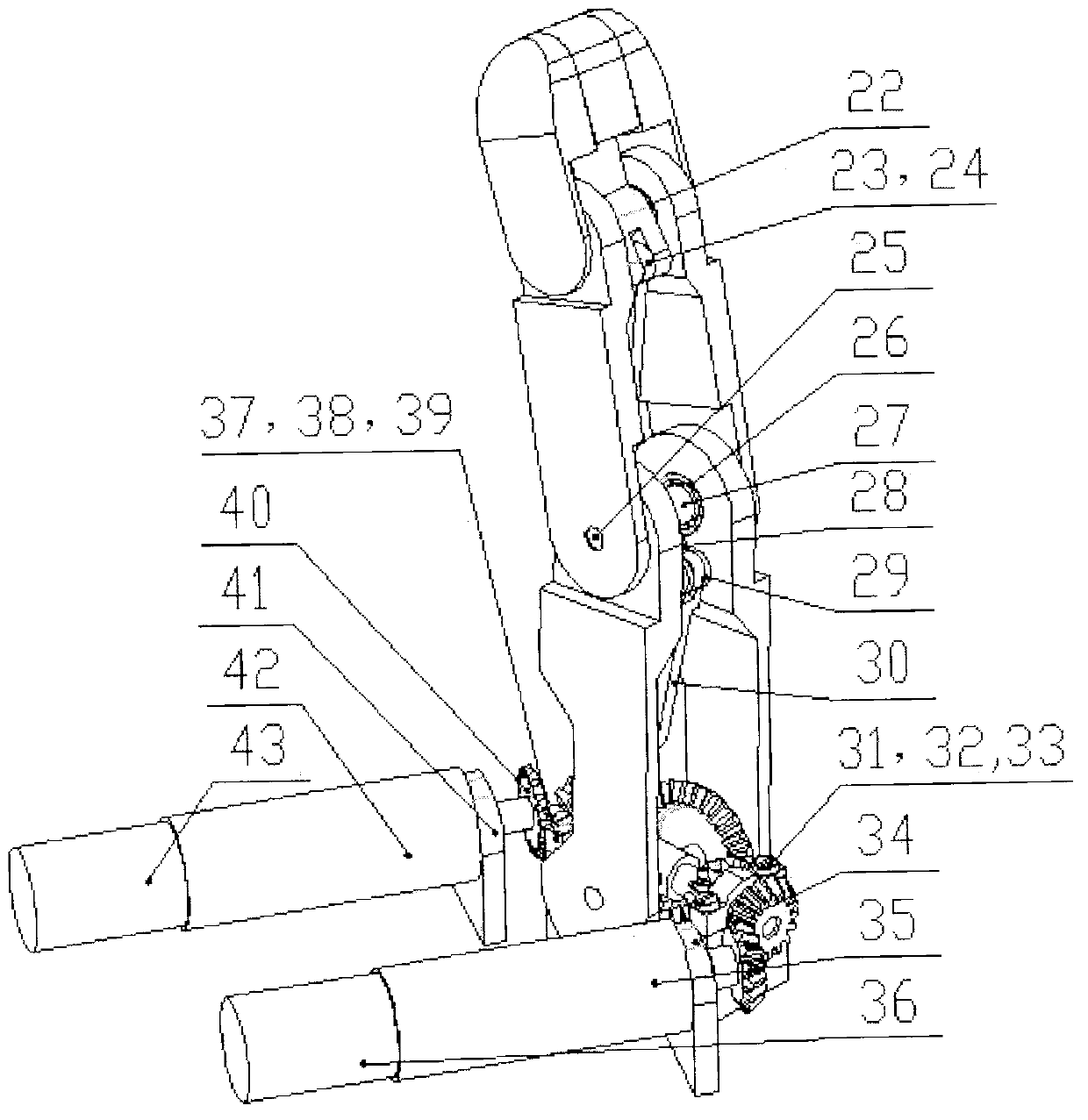

Displacement under-actuated robot hand apparatus

The invention discloses a position-variable under-actuated robot hand device, which belongs to the technical field of anthropomorphic robots. The device has five independent control fingers and 15 joint degrees of freedom and is driven by 10 motors, wherein the middle finger, the third finger, the litter finger and the forefinger have the same structure and adopt double motor-driven three-joint rotation, and the thumb is capable of swinging laterally and adopts double motor-driven three-joint rotation. The structures of the fingers are similar and realize the initial configuration-changing self-adaptive grabbing functions of the fingers by using the motors, a transmission mechanism, a flexible piece and a spring piece, namely, the finger bends the middle joint before grabbing to assume a desirable preparation gesture to adapt to the size of an object automatically during grabbing. Through the adjustment of the initial configurations of the fingers, the grabbing stability is improved greatly. The device is compact in structure, high in integration level, similar to human hand in appearance, dimension, shape and motion, capable of stably grabbing and automatically adapting to objects with different shapes and dimensions, and applicable to the anthropomorphic robots.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

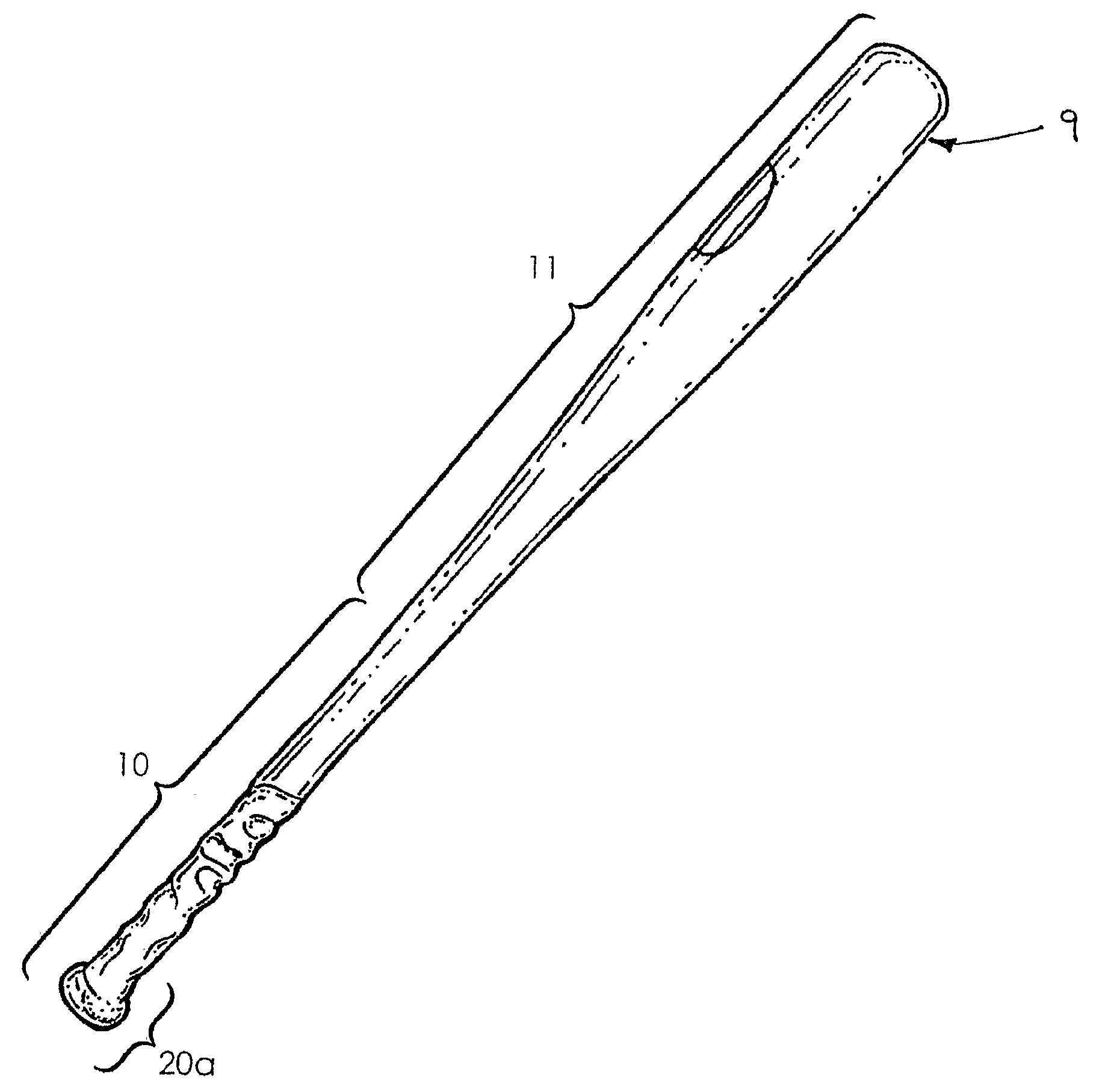

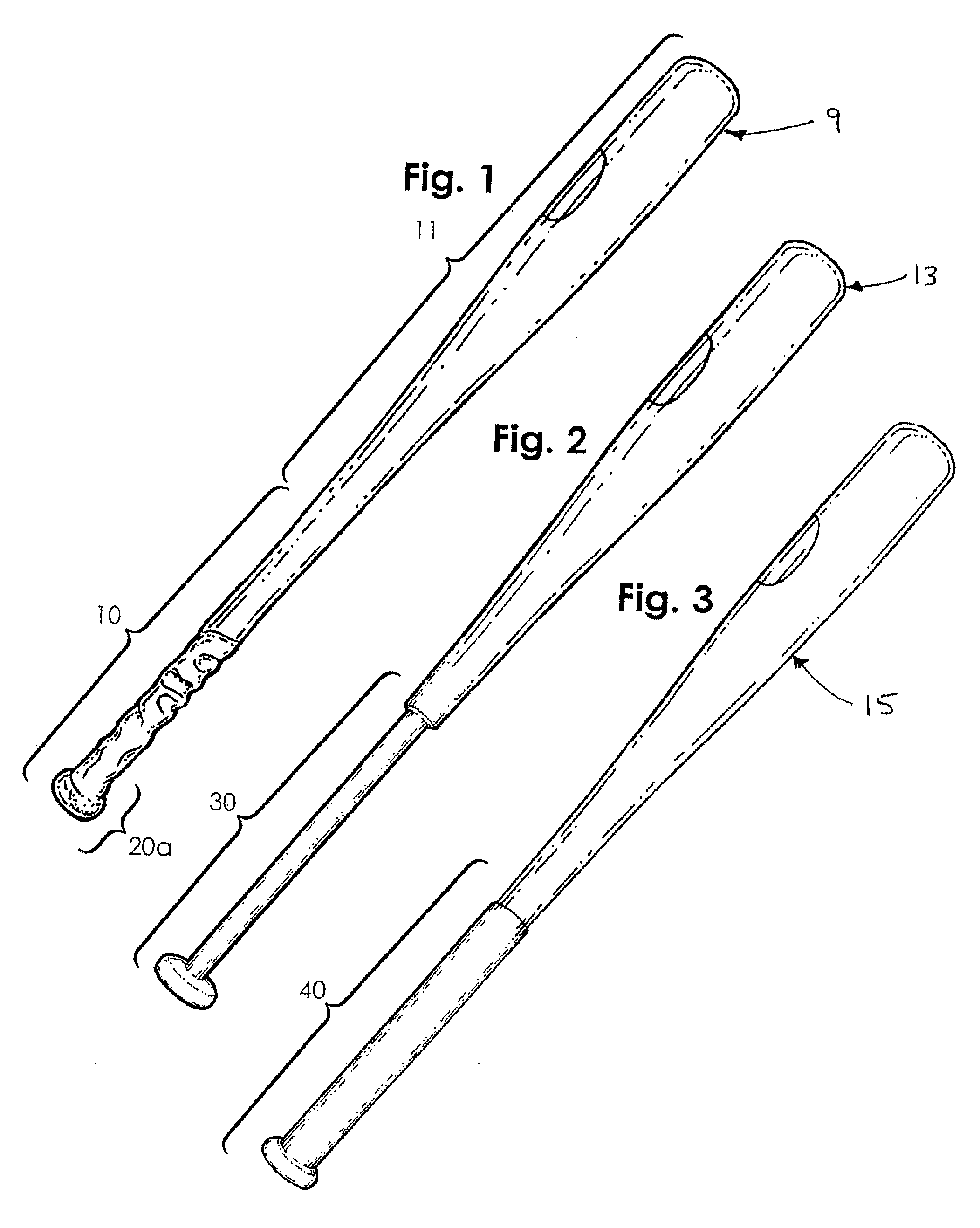

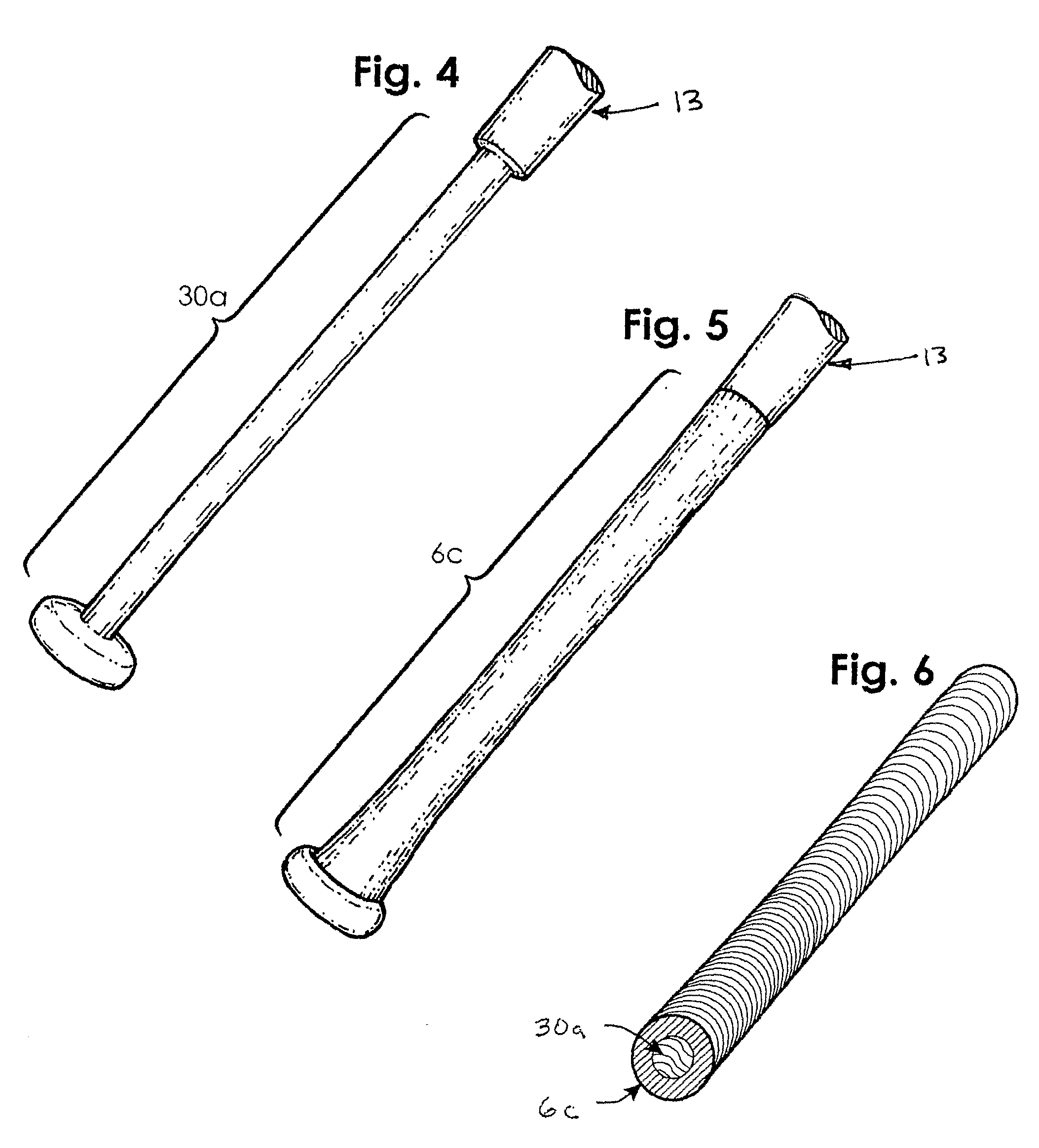

Swinging Implement

ActiveUS20080200288A1Improve grip stabilityImprove accuracyGolf clubsStringed racketsEngineeringGradual transition

A swing implement, such as a baseball bat (9), adapted for gripping by the hands of a user having a support surface (10) between the knob (20) and the handle (30) of the swinging implement. The support surface provides a gradual transition between the knob and the handle. The support surface supports the hand of the user while gripping the swinging implement. Another swinging implement (10) comprises a support surface extending at a shallow angle from the handle between the handle and the end surface of the knob for supporting the hand of the user while gripping the swinging implement. A support sleeve (6c) adapted to cooperate with a handle and knob of a conventional baseball bat including a support surface for providing added support for the hands of a user gripping the bat.

Owner:PROXR LLC

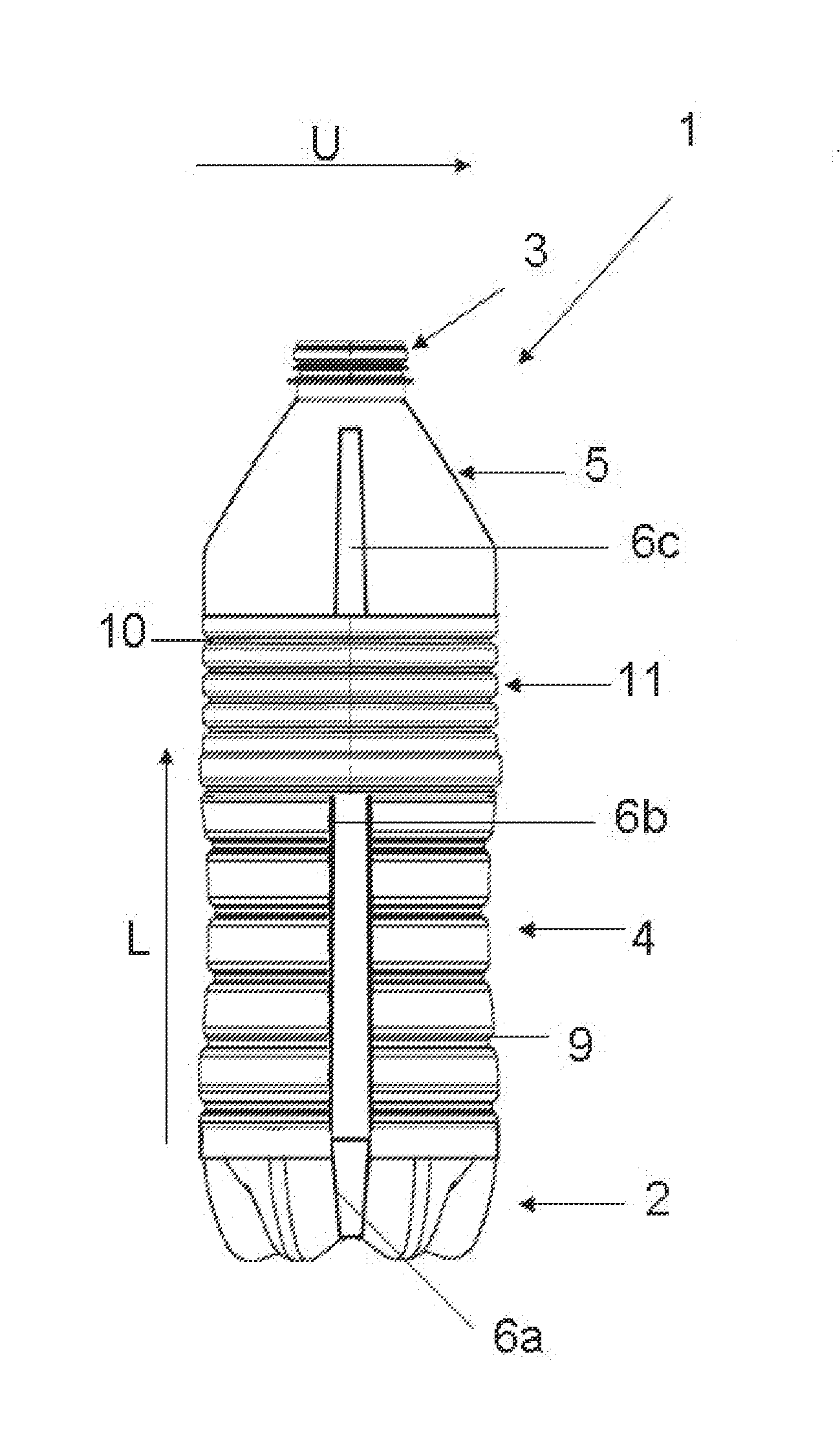

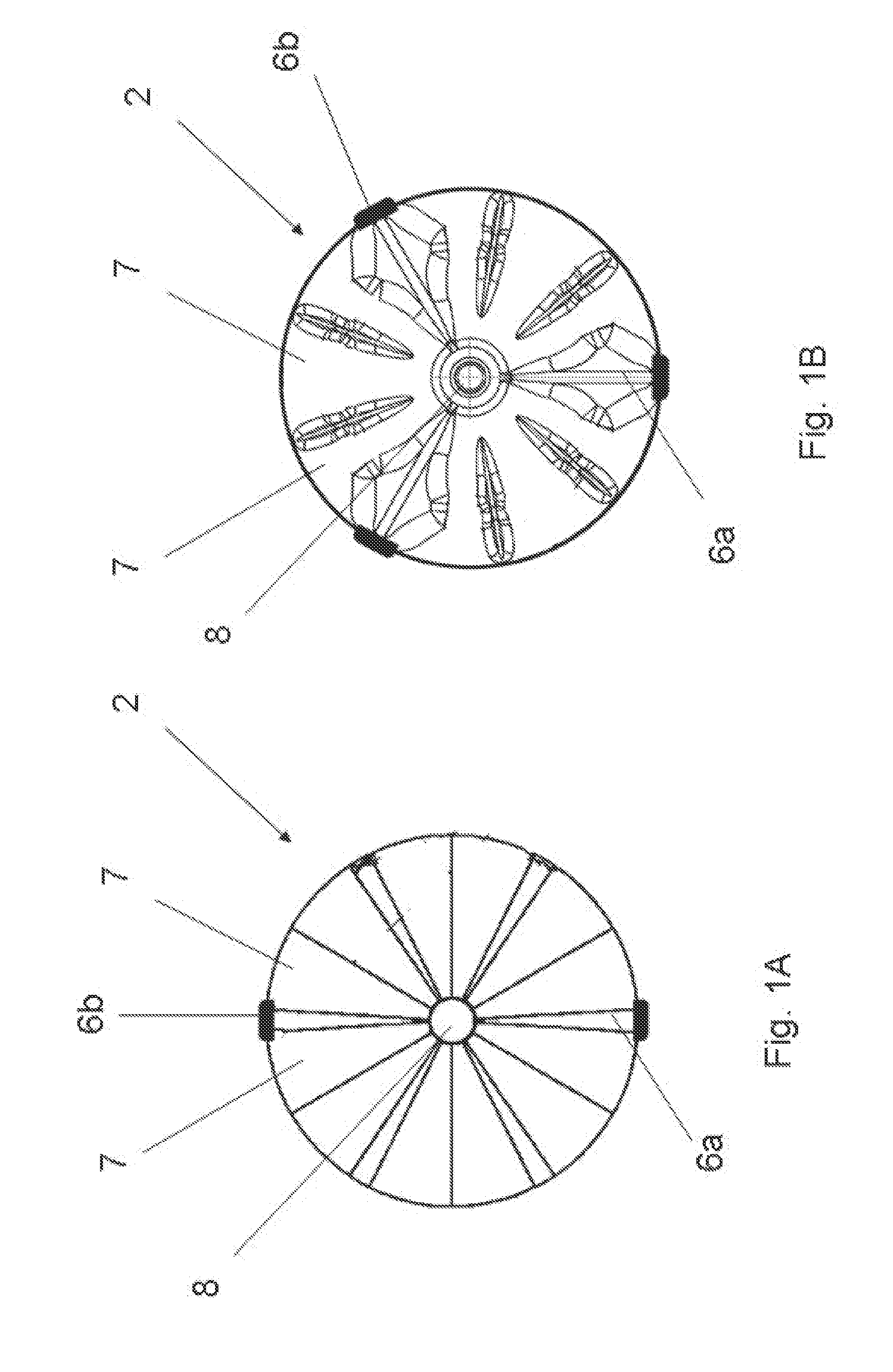

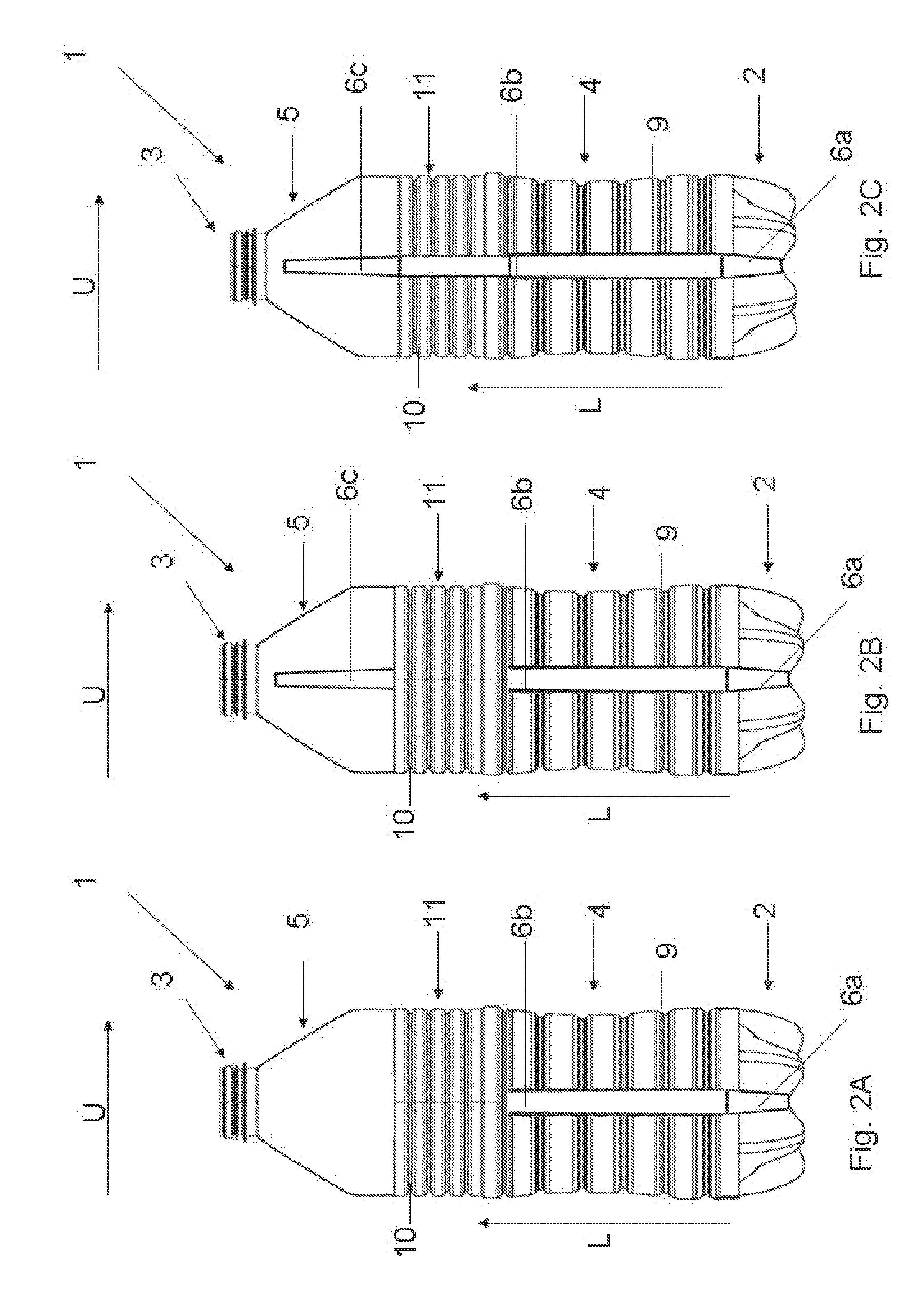

Plastic container

ActiveUS20140238951A1Improve stabilityImprove stress resistanceBottlesLarge containersEngineeringMechanical engineering

Owner:NIAGARA BOTTLING

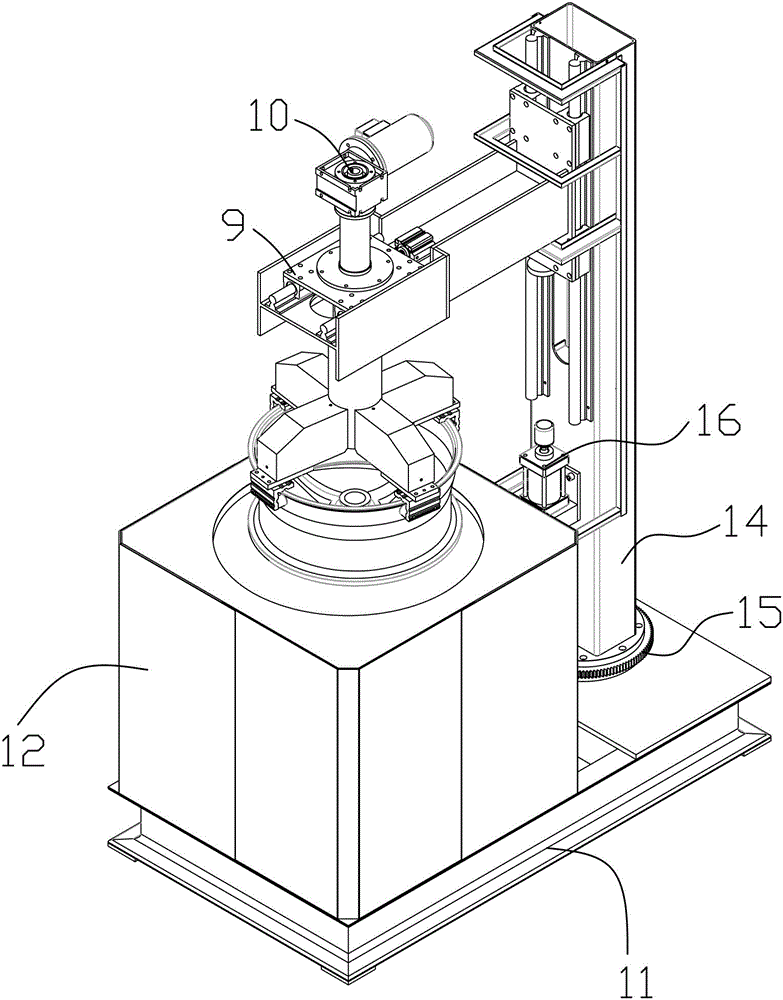

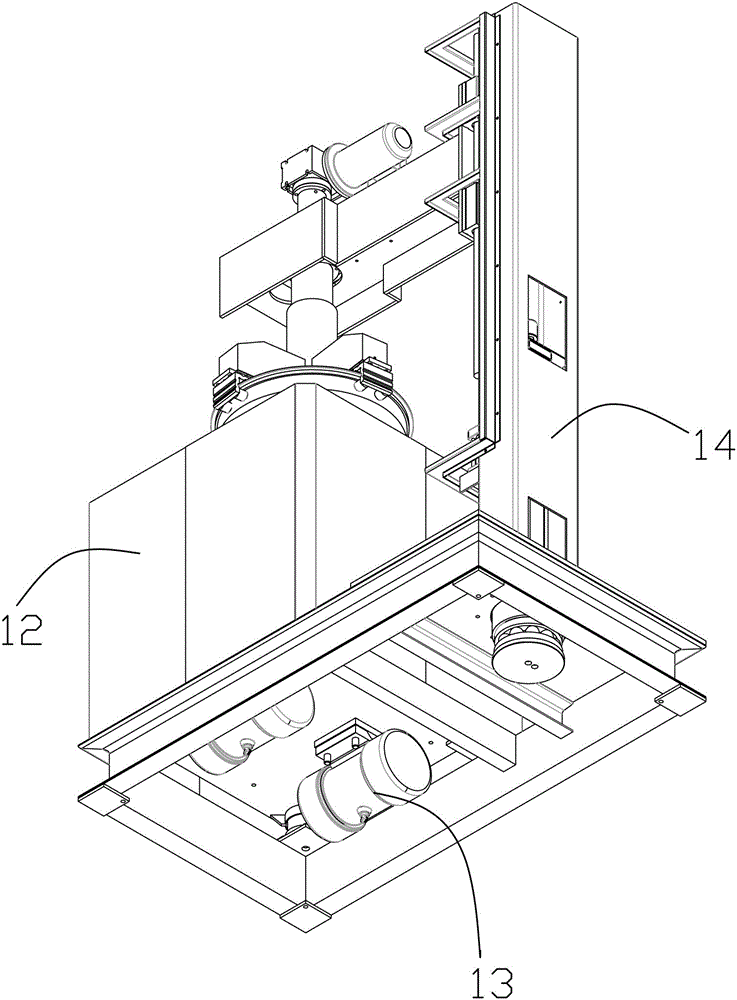

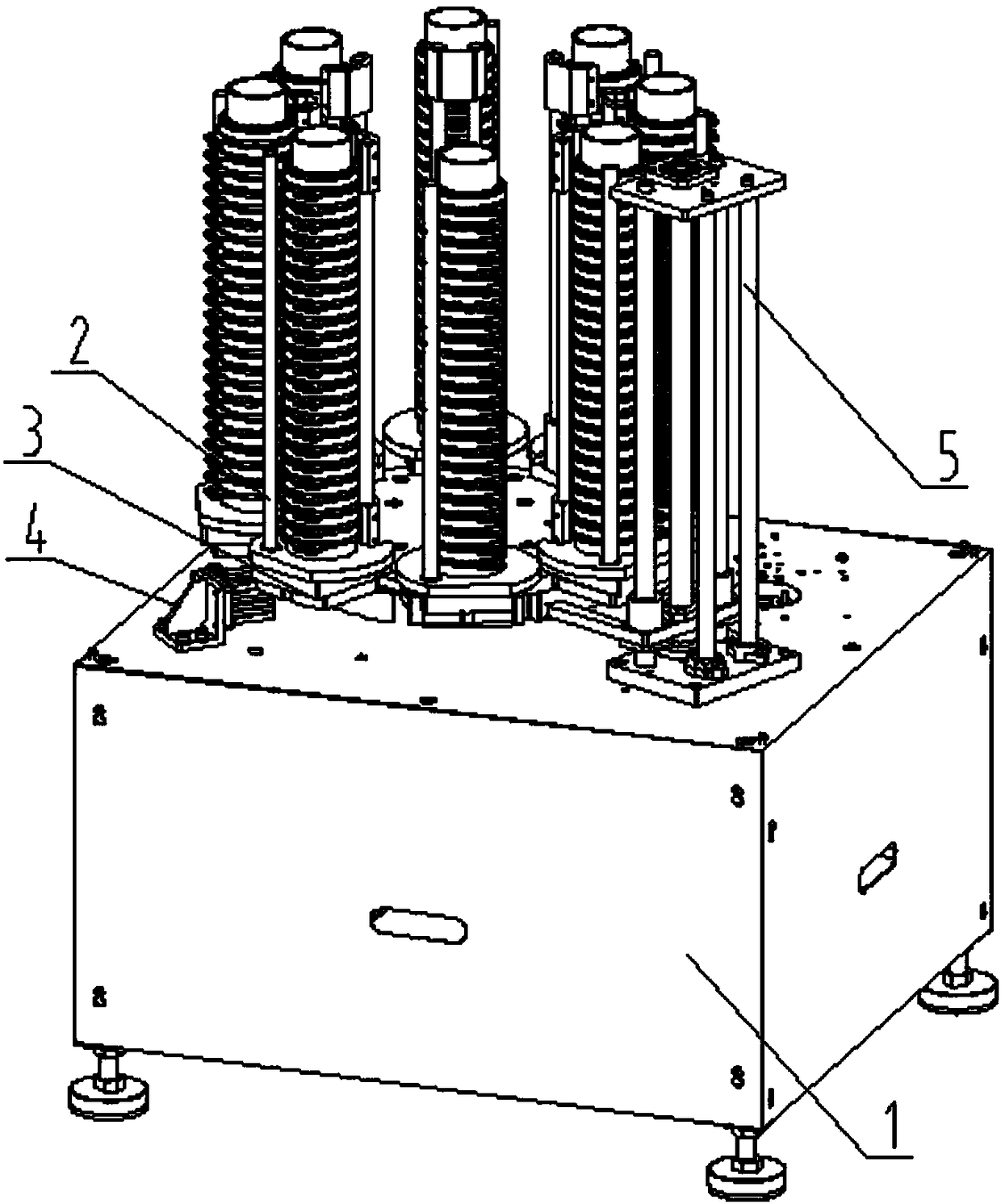

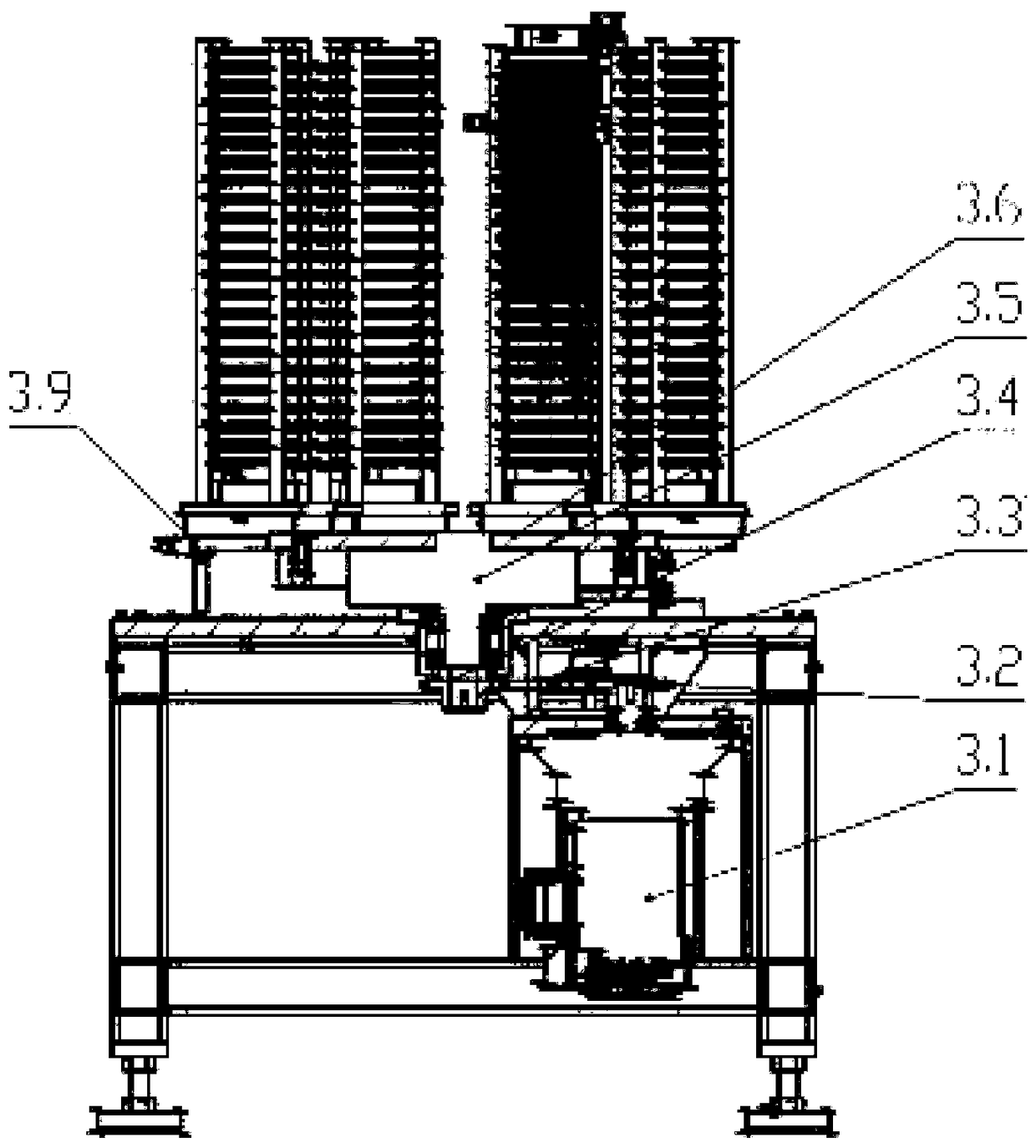

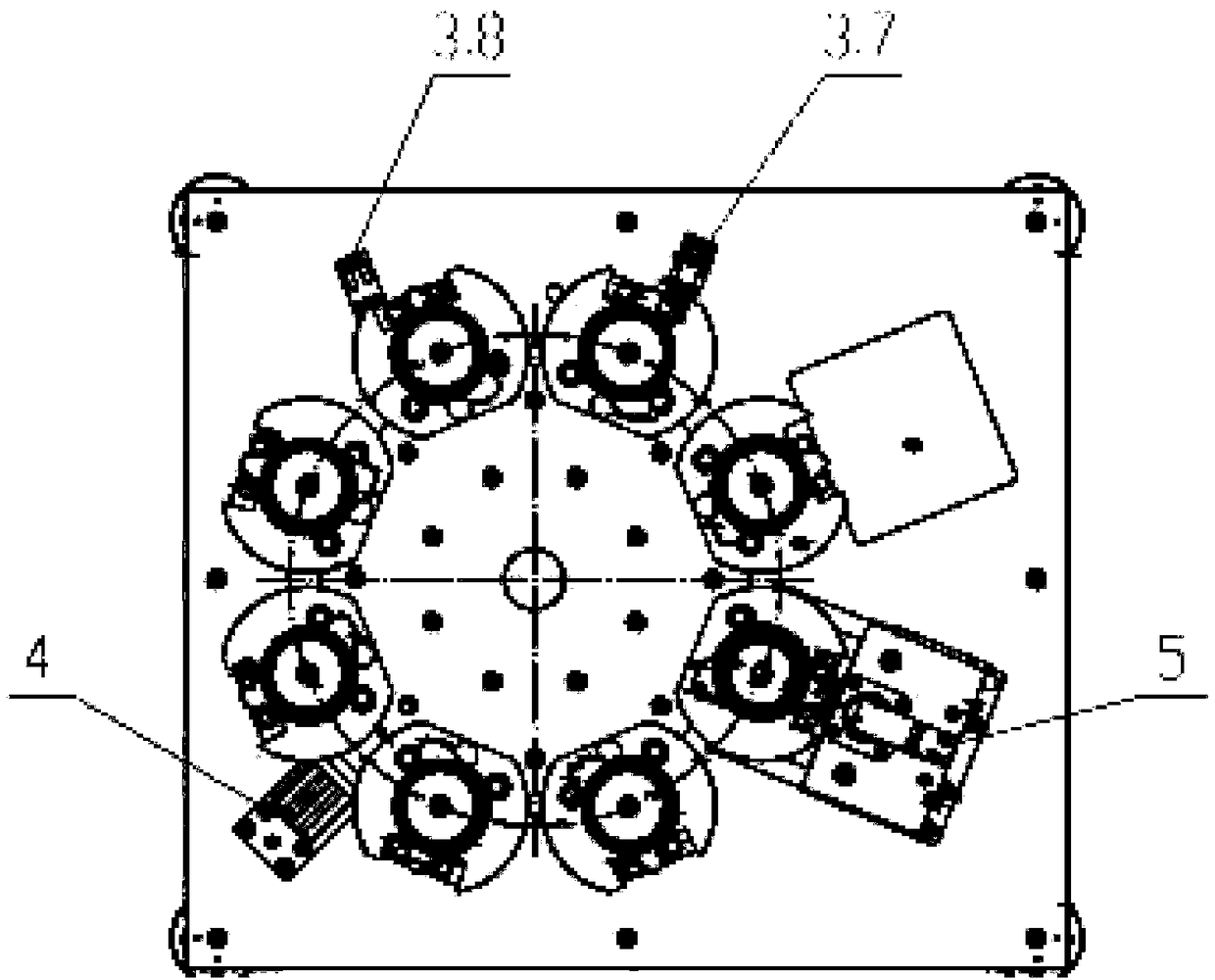

Vibration grinding polishing machine

InactiveCN104690634AFast clamping speedGood effectEdge grinding machinesPolishing machinesEngineeringMechanical engineering

The invention relates to a vibration grinding polishing machine. The vibration grinding polishing machine comprises a supporting base, wherein a polishing barrel, a vibrating motor, a rotating arm and a rotating driving portion are arranged on the supporting base; the polishing barrel is driven to vibrate by the vibrating motor; the rotating driving portion is used for driving the rotating arm to rotate; the rotating arm is provided with a transverse moving device, a vertical driving portion, a clamping jaw device and a rotating device; the vertical driving portion is used for driving the transverse moving device to move vertically; the clamping jaw device is arranged on the transverse moving device; and the rotating device is used for driving the clamping jaw device to rotate. The vibration grinding polishing machine is suitable for polished objects with various specifications; the capturing stability is high; and the polishing effect and the polishing efficiency on the fixed polished objects are high.

Owner:黄尚进

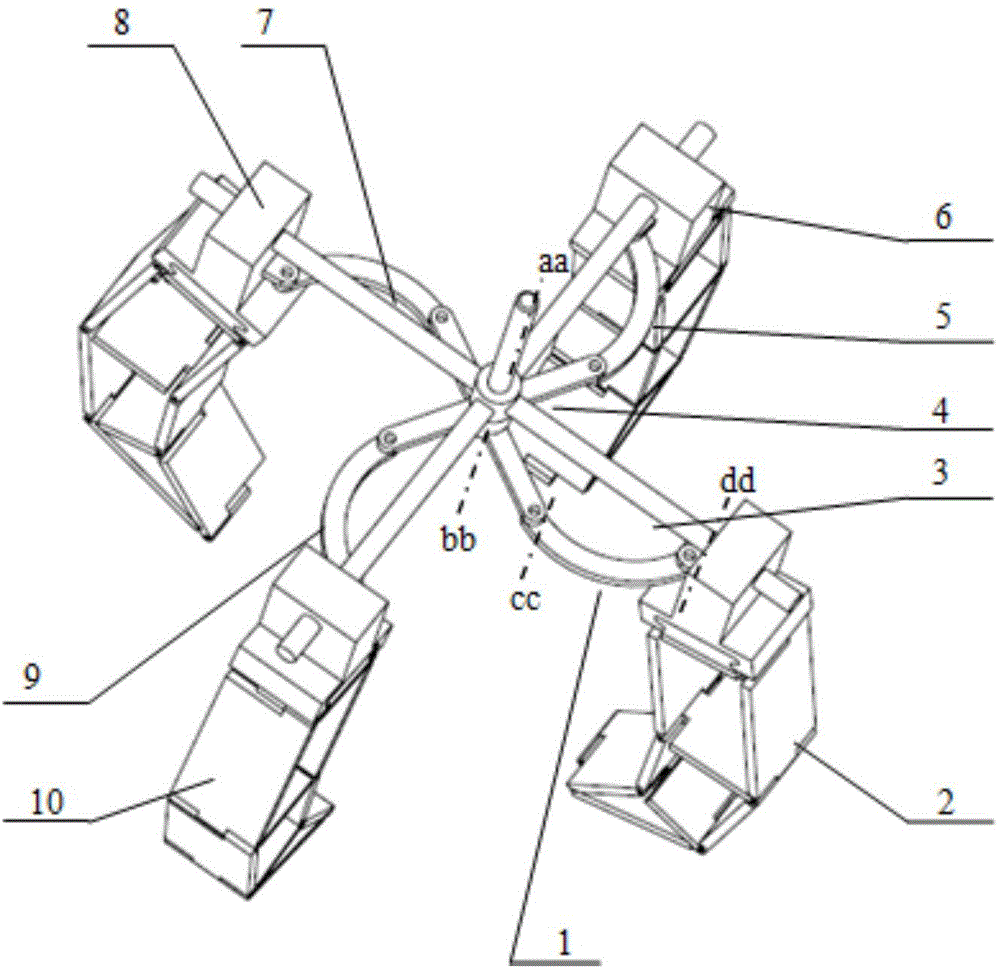

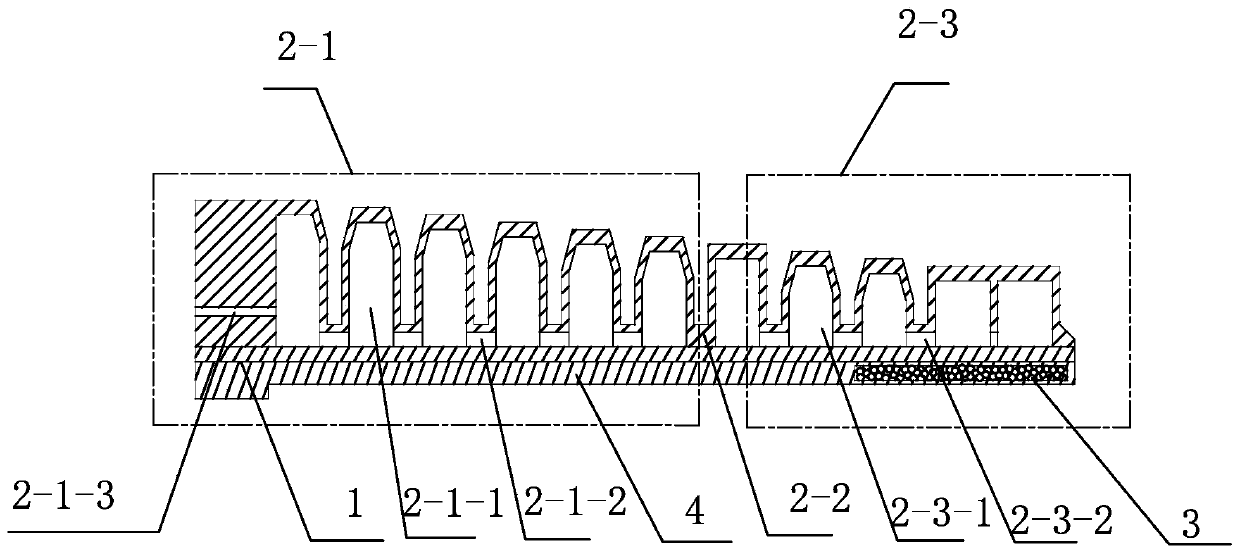

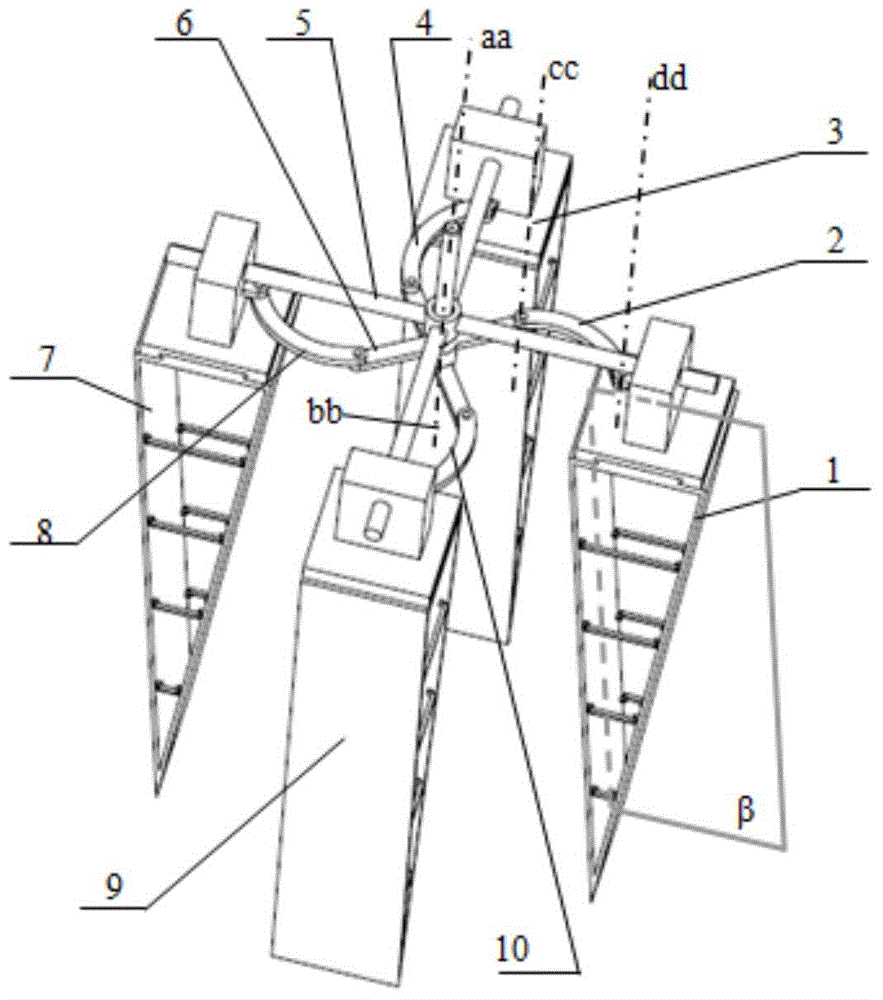

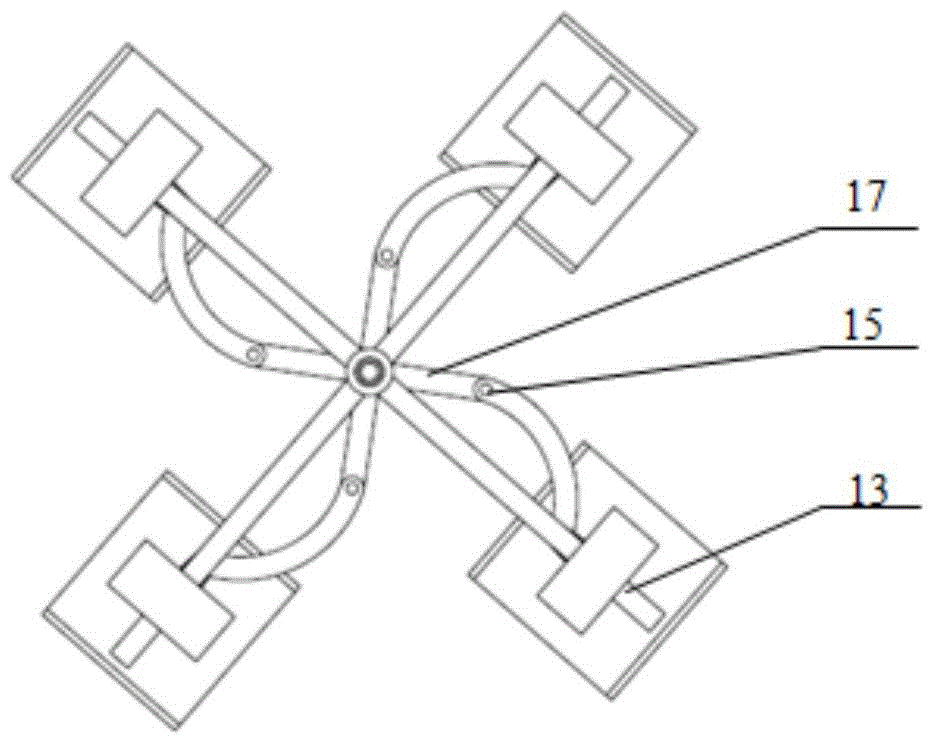

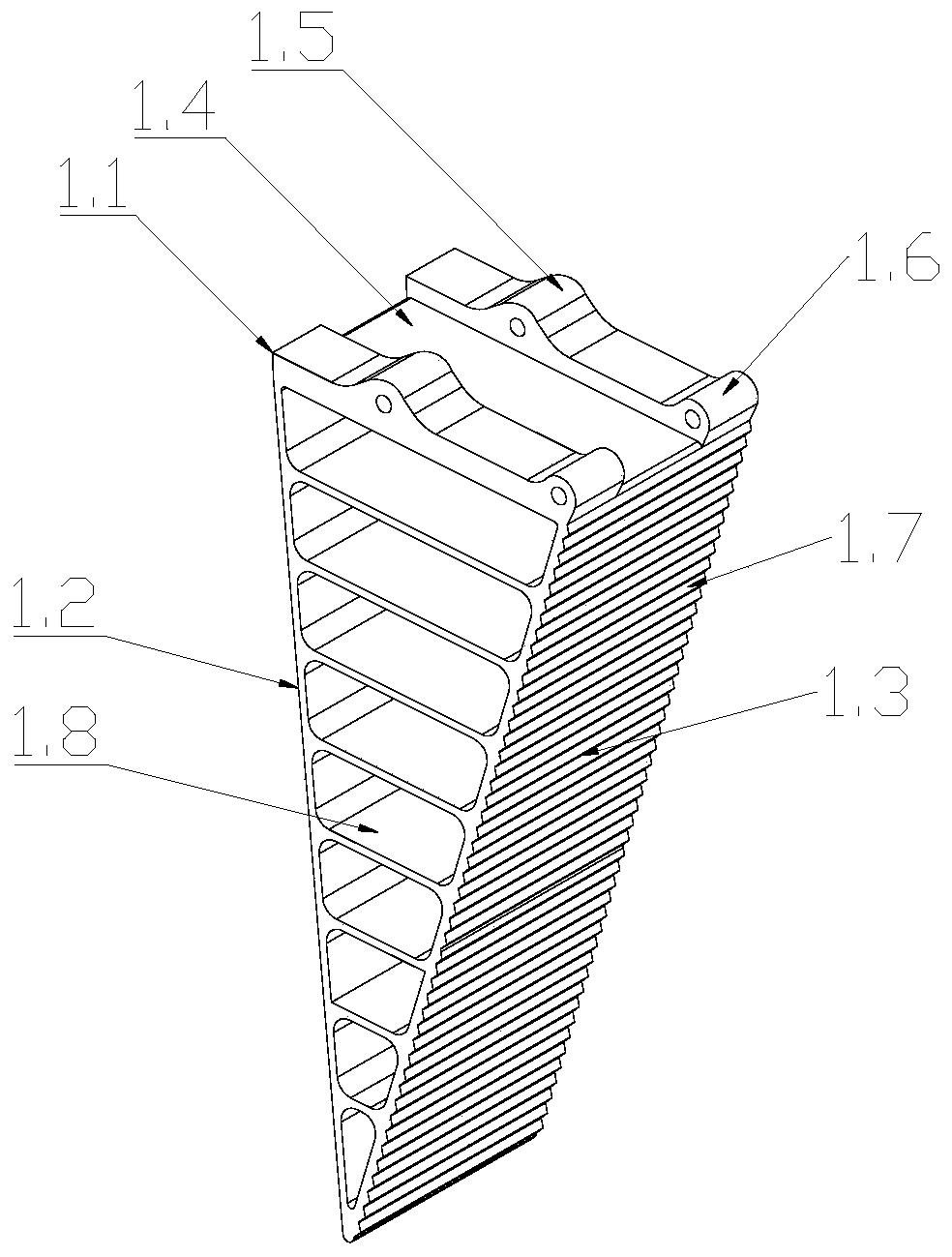

Variable-palm type bionic mechanical gripper capable of achieving passive enveloping

ActiveCN104858883ARealize passive flexible envelopeSimple structureGripping headsFixed frameEngineering

The invention discloses a variable-palm type bionic mechanical gripper capable of achieving passive enveloping. The mechanical gripper comprises a driving platform, guiding and positioning platforms, four passive fingers and four active branch chains; the four passive fingers are evenly distributed with a 90-degree included angle formed between every two adjacent passive fingers; each passive finger is composed of beam plates, outer side plates, inner side plates, springs, plate rotating pairs and spring rotating pairs; the connecting rod ends of the active branch chains are connected with the driving platform through driving platform rotating pairs, and the other ends of the active branch chains are connected with finger fixing frames through finger fixing frame rotating pairs; the guiding and positioning platforms are connected with the finger fixing frames through guiding and positioning platform cylindrical pairs, and the lower surfaces of the finger fixing frames are fixedly connected to the passive fingers. The mechanical gripper is simple in structure, only single driving is needed, application flexibility is high, and passive enveloping on articles in complicated shapes can be achieved; control and design are facilitated, and the mechanical gripper can be widely applied to the occasions, where passive flexible enveloping needs to be conducted on fragile articles in complicated shapes, of mechanical manufacturing, the light industry and medical care.

Owner:TIANJIN UNIV

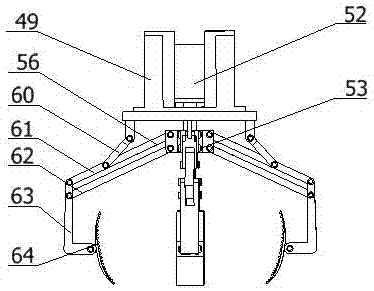

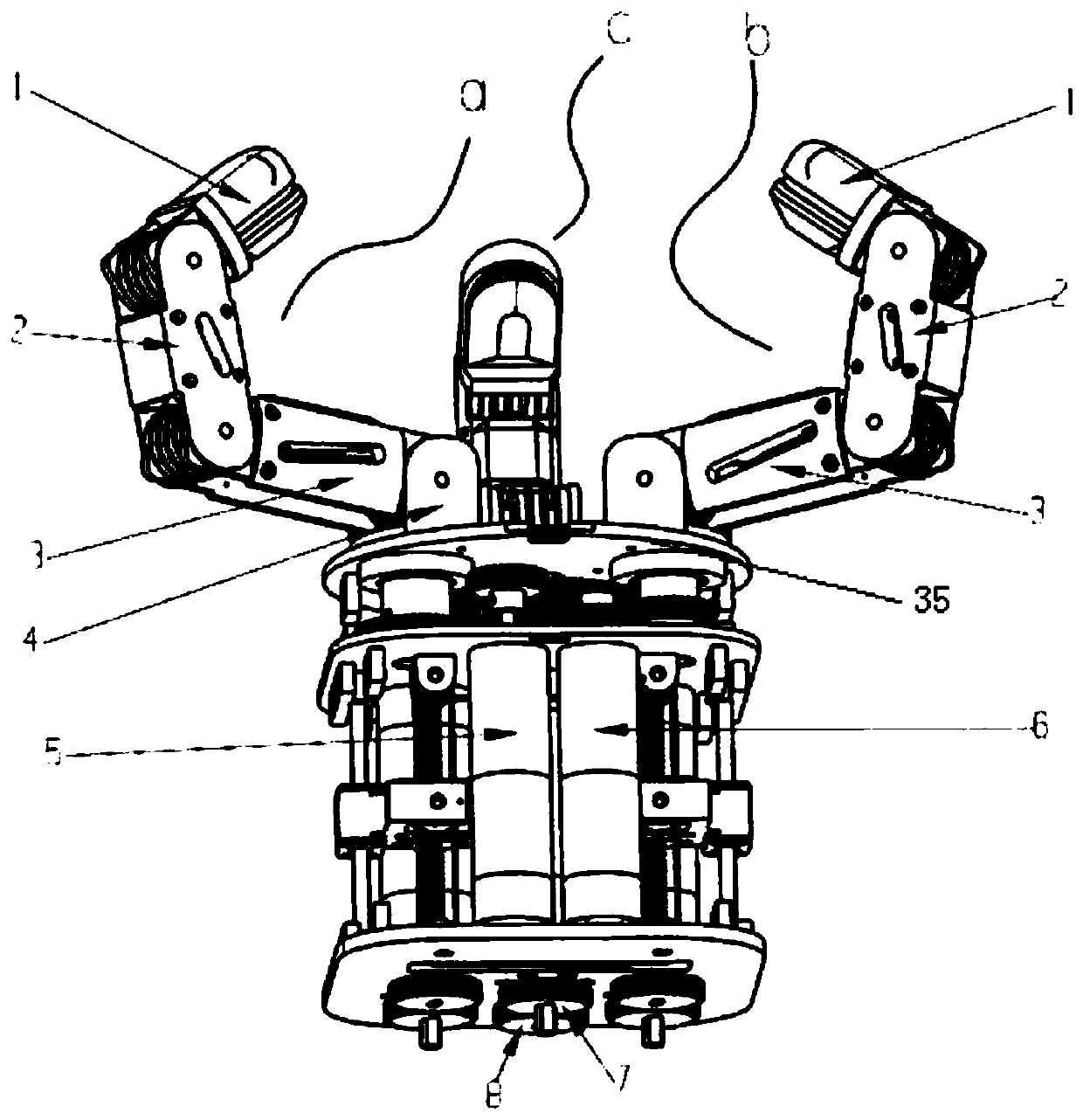

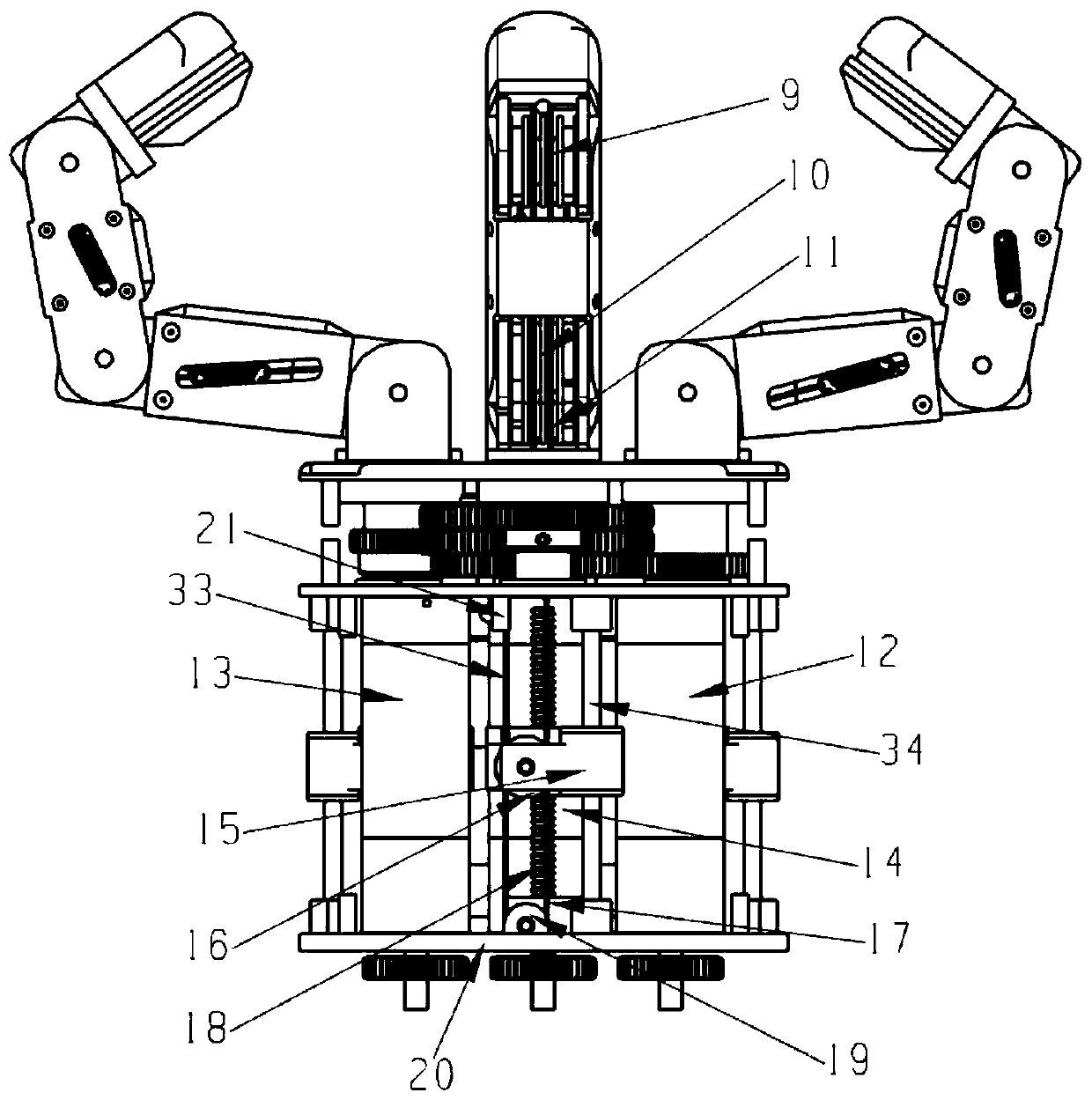

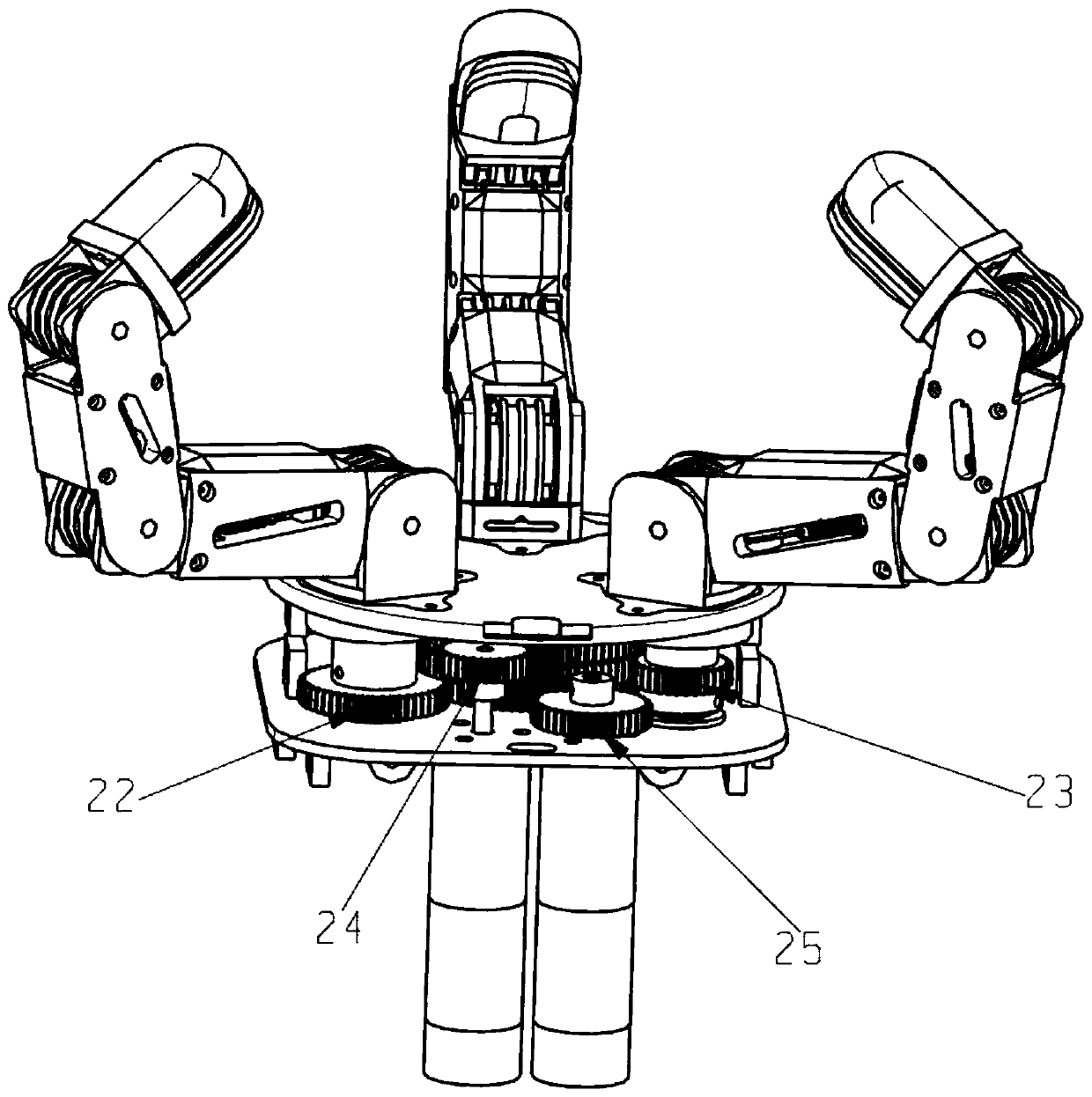

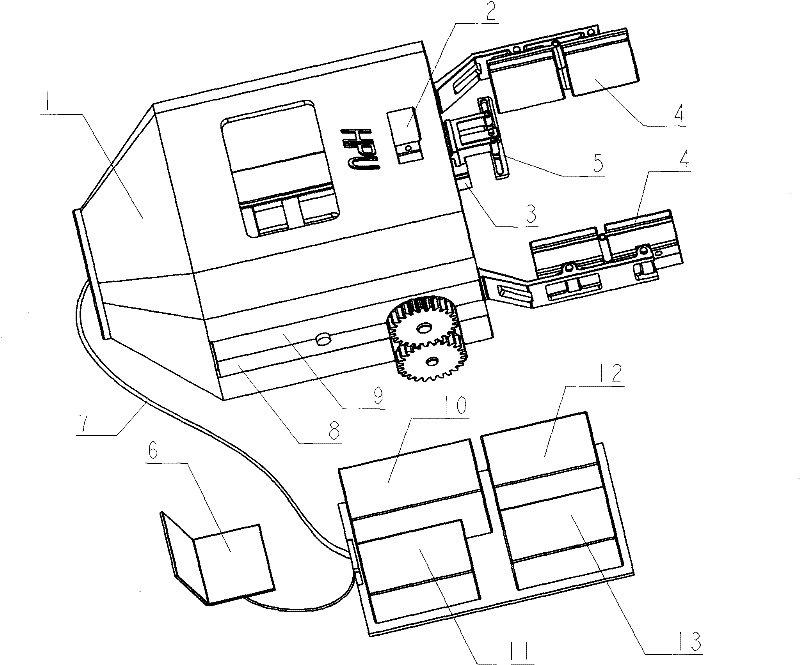

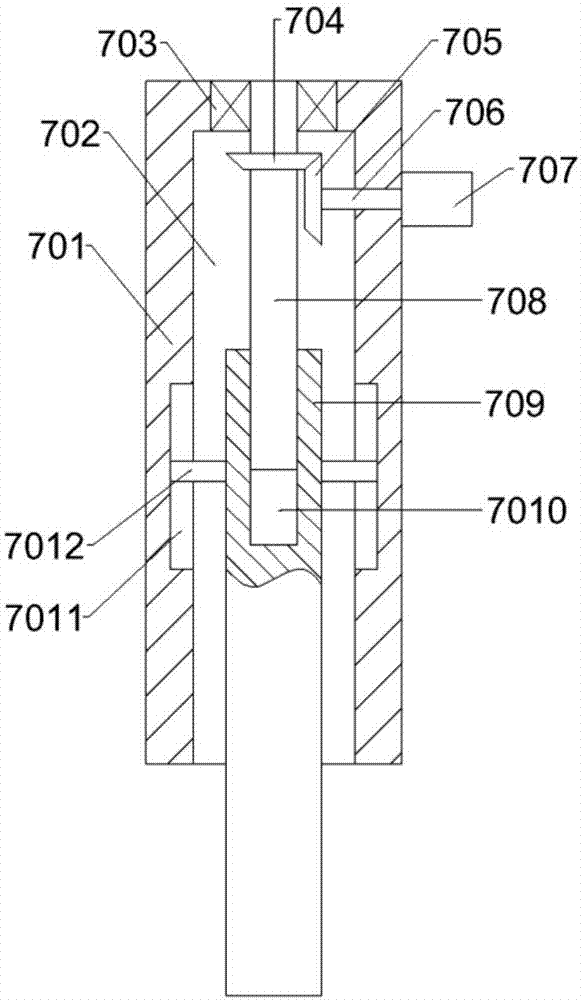

Tail end executing mechanism for picking manipulator

InactiveCN109500834ARealize the effect of multi-finger underactuationImprove grip stabilityGripping headsPicking devicesClosed loopSelf locking

The invention discloses a tail end executing mechanism for a picking manipulator. The tail end executing mechanism comprises finger mechanisms, a support and transmission mechanism, a driving mechanism and a vision system. The finger mechanisms are connected with the support and transmission mechanism, the support and transmission mechanism is connected with the driving mechanism, and the vision system is connected with the support and transmission mechanism. According to the tail end executing mechanism, the closed-loop real-time control of a controller over the tail end executing mechanism for the picking manipulator is realized through a driving motor and pressure sensors, a target object is flexibly grabbed, and mechanical damage caused during picking is reduced. According to the tailend executing mechanism, grabbing and picking are realized through the forward rotation and reverse rotation of the motor, other mechanisms are driven to move through the rotation of a lead screw shaft, and the self-locking function of a lead screw is utilized, so that it is ensured that the motor does not work and fruits do not loosen and fall off after grabbing of the fruits is completed.

Owner:DONGGUAN UNIV OF TECH

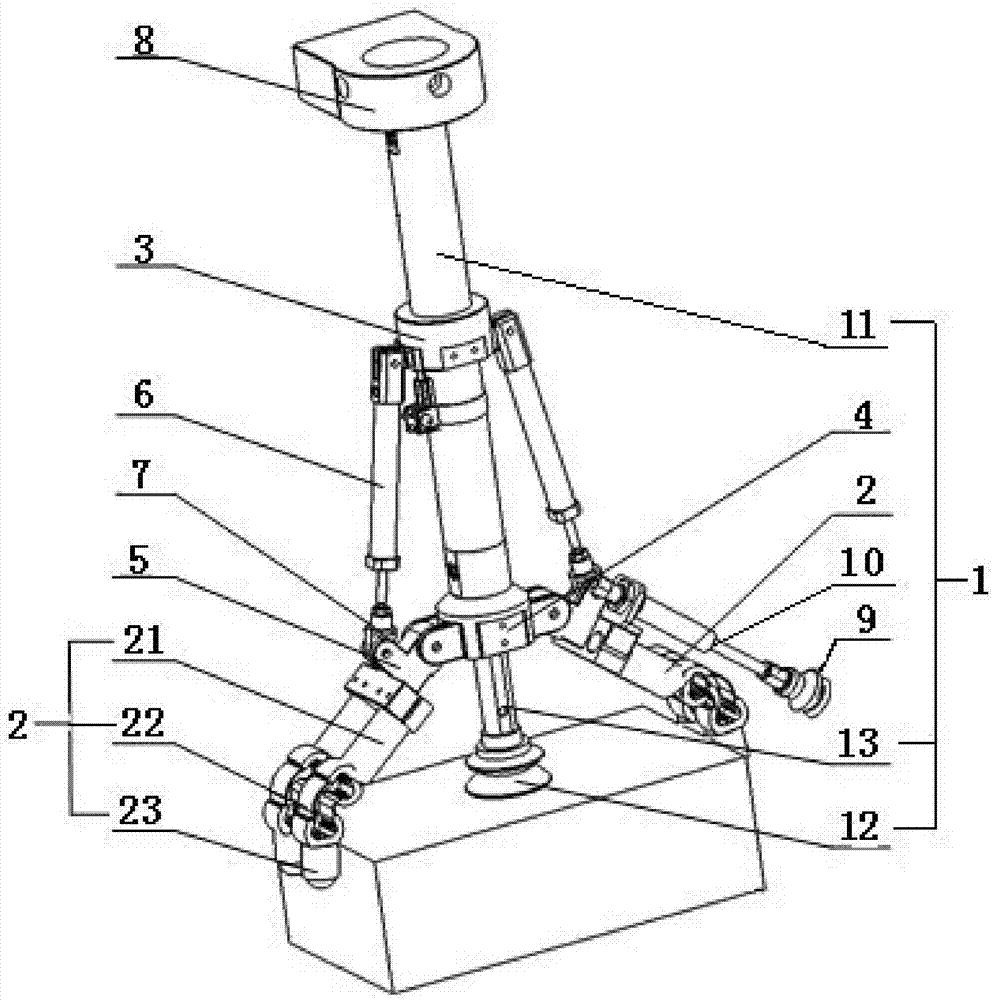

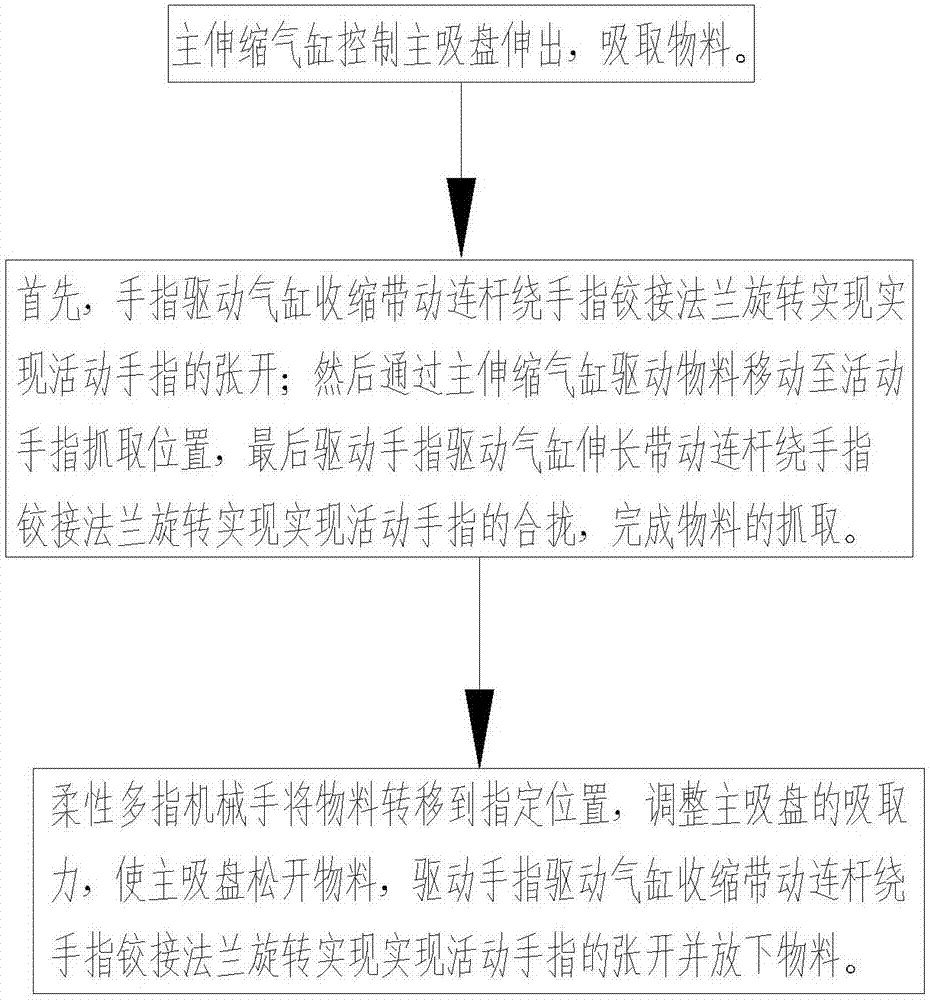

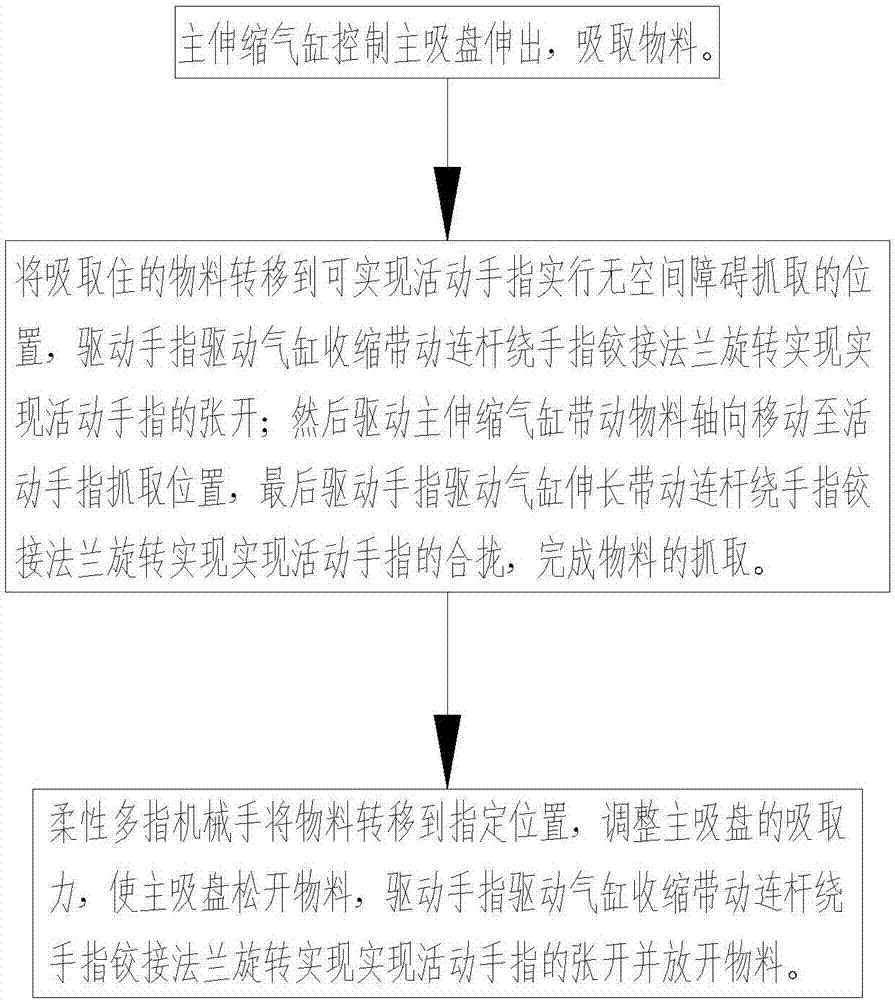

Flexible multi-finger mechanical arm for logistics and method for grabbing materials with same

PendingCN107471244ACompact structureImprove crawling efficiencyGripping headsLogistics managementRobot hand

The invention relates to the technical field of robot suction devices, in particular to a flexible multi-finger mechanical arm for logistics. The flexible multi-finger mechanical arm for the logistics comprises a main suction cup mechanism and moveable fingers. A main suction cup is driven by a main telescopic air cylinder. The main telescopic air cylinder is externally and fixedly sleeved with a locking flange and a finger hinged flange. The movable fingers are movably arranged on the finger hinged flange through connection rods. Finger drive air cylinders are movably hinged to the locking flange. The finger drive air cylinders drive the connection rods so as to enable finger tips to be close to or far away from the main suction cup, and therefore gathering or stretching of the movable fingers is achieved. The finger drive air cylinders are arranged on the periphery of the main suction cup in a matched manner to drive the movable fingers to achieve accurate grabbing of irregular materials; and according to a method for grabbing the materials with the flexible multi-finger mechanical arm for the logistics, different grabbing actions and different grabbing steps can be selected according to the three-dimensional posture information of the materials and the surrounding information, and efficient and stable grabbing of materials of different sizes in various shapes in different grabbing environments is achieved.

Owner:武汉库柏特科技有限公司

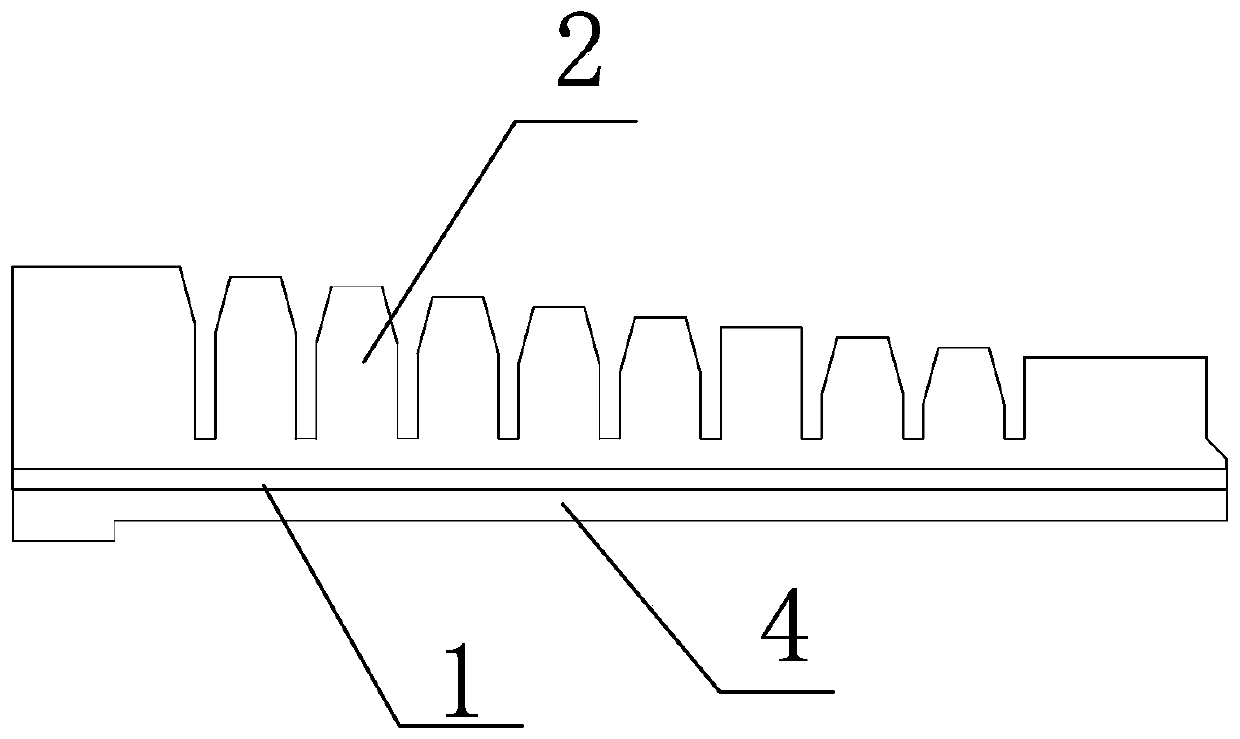

Novel soft mechanical hand capable of realizing vertical plane grabbing

The invention discloses a novel soft mechanical hand capable of realizing vertical plane grabbing, and aims to provide the novel soft mechanical hand capable of realizing vertical plane grabbing and improving the grabbing stability, a soft body actuator which can adapt to the use requirements of irregular articles and a soft mechanical hand composed of the soft body actuator. The soft mechanical hand comprises a clamp and at least two soft body actuators symmetrically installed on the clamp, the soft actuator comprises a restraint layer and a base body positioned on one side of the restraint layer, wherein the base body comprises a pneumatic bending module and a grabbing module, one end of the pneumatic bending module is fixedly connected with the clamp, the tail end of the grabbing moduleis a free end, the grabbing module is of an air mesh type structure, and the grabbing module is driven by the pneumatic bending module to enable the grabbing module to realize the grabbing action ofthe vertical plane. The soft mechanical hand provided can be used for grabbing objects in a vertical plane, the contact area between the grabbing module and the grabbing object is large, the grabbingstability is high, and the mechanical hand can adapt to the shape of an object and is beneficial to grabbing of irregular objects.

Owner:TIANJIN UNIV

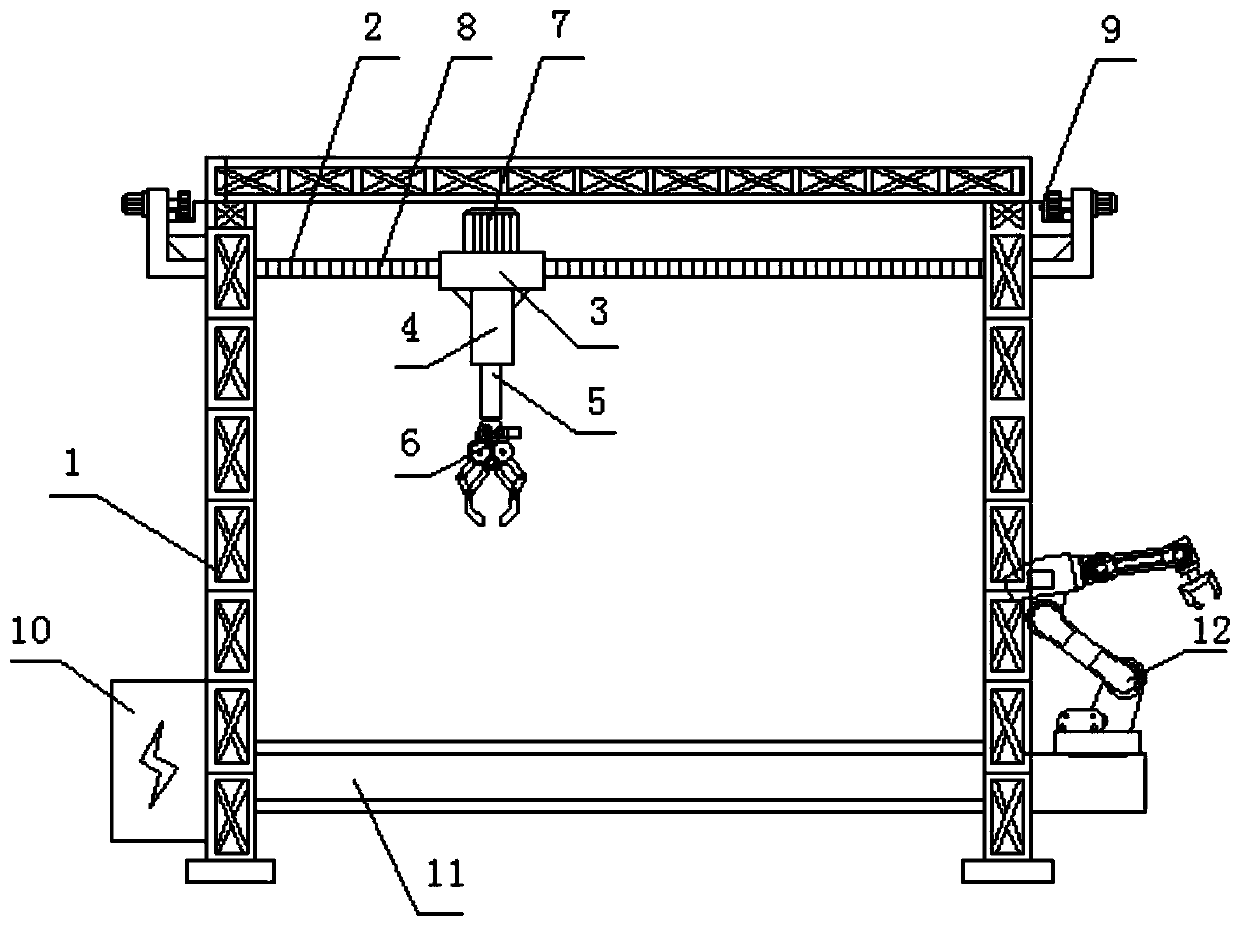

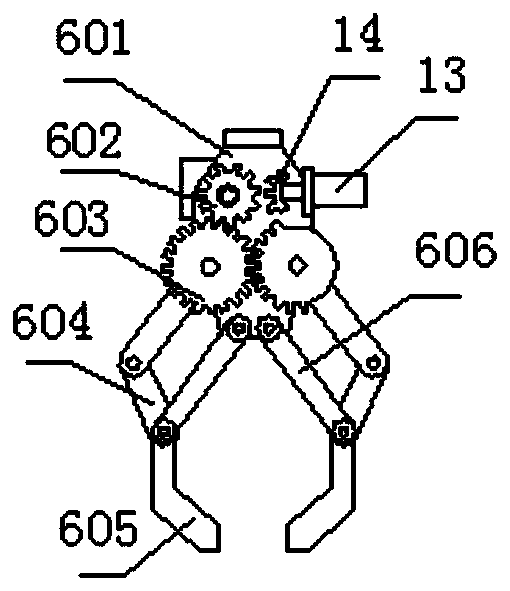

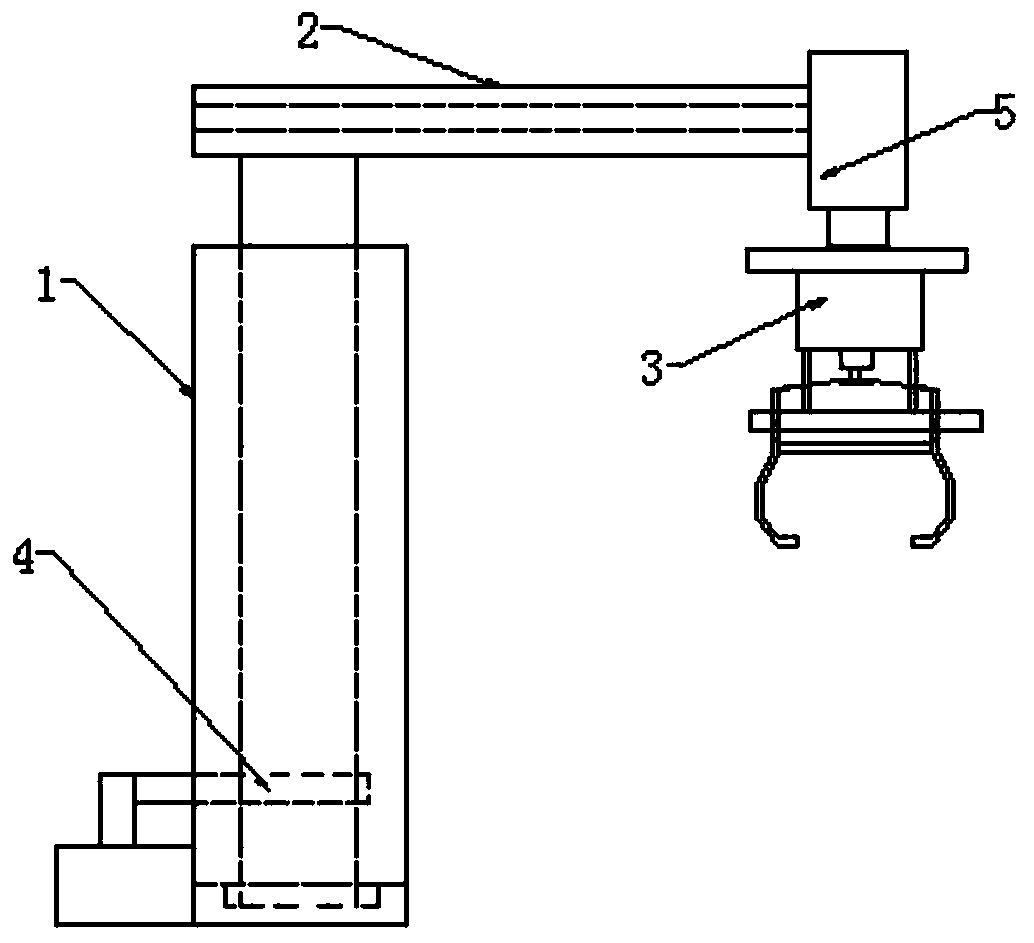

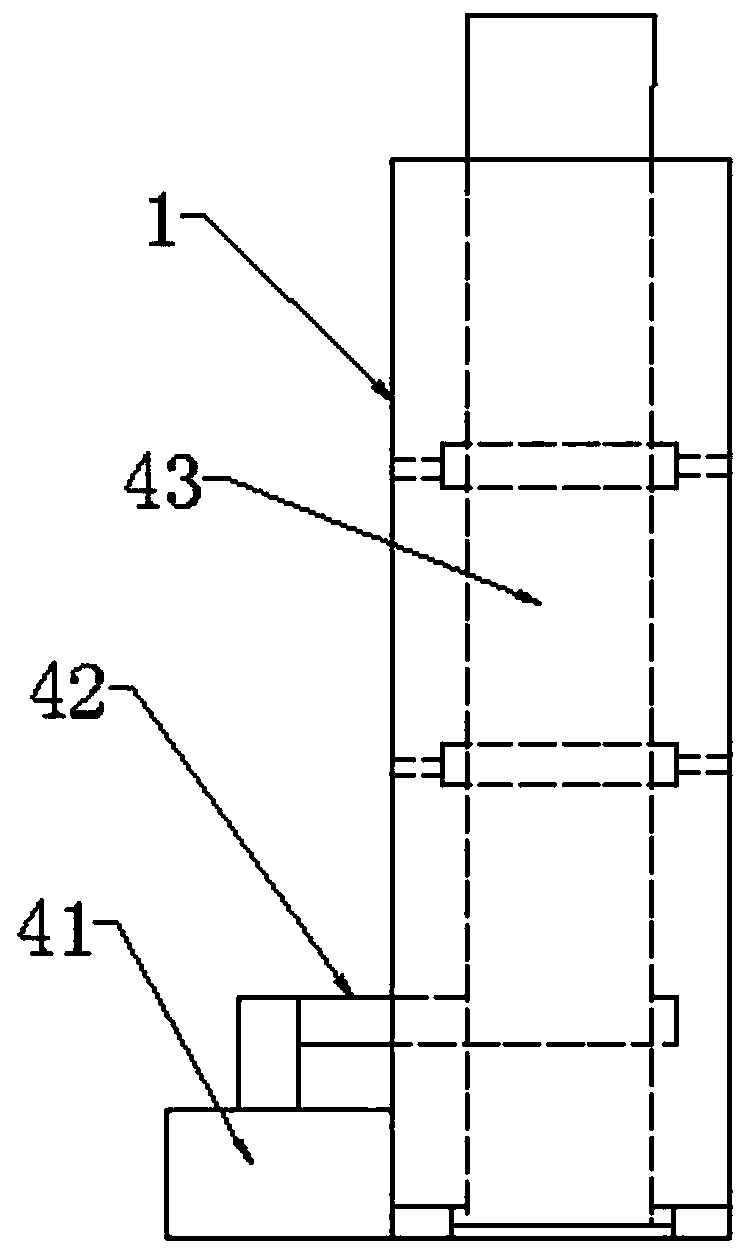

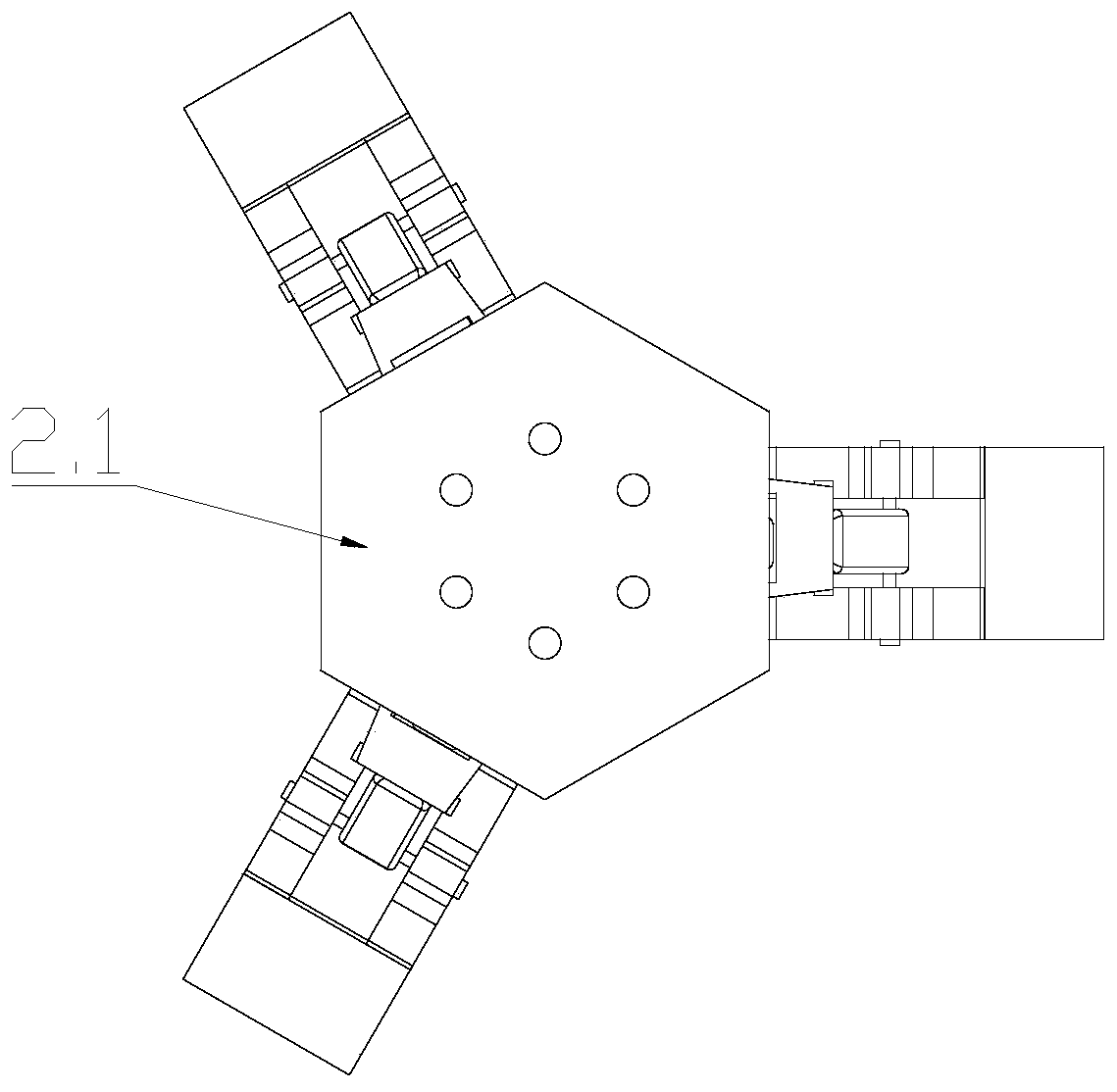

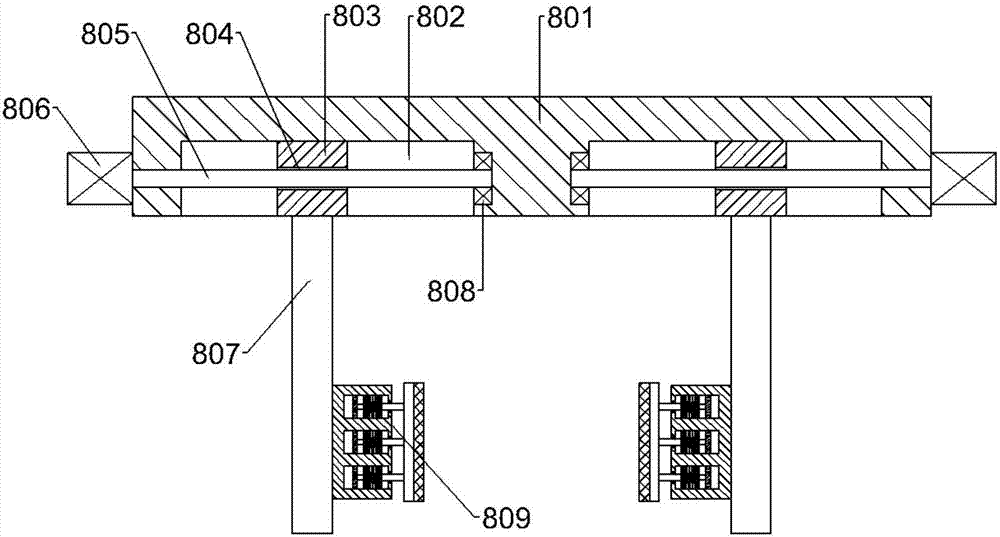

Multi-manipulator integrated system of truss robot

InactiveCN109702722APrevent accidental dropImprove processing efficiencyProgramme-controlled manipulatorGripping headsHydraulic cylinderLocking mechanism

The invention discloses a multi-manipulator integrated system of a truss robot. The multi-manipulator integrated system comprises a truss, a transport manipulator assembly and a feeding six-axis manipulator, supporting bases are welded to the two sides of the upper end of the truss, a transverse sliding rail is installed on the lower sides of the supporting bases through supporting blocks, a firstrack is arranged on one side of the transverse sliding rail, the outer side of the transverse sliding rail is sleeved with a sliding block, a telescopic hydraulic cylinder is installed on the lower side of the sliding block, a telescopic rod is in driving connection with the lower side of the telescopic hydraulic cylinder, one end of the telescopic rod is provided with the transport manipulator assembly, a machining table is transversely welded to the lower side of the truss, and the upper side of one end of the machining table is provided with the feeding six-axis manipulator. According to the multi-manipulator integrated system of the truss robot, materials can be transported to the machining table through the feeding six-axis manipulator, the materials can be moved and transported through the transport manipulator assembly, and accident falling in the grabbing process of the transport manipulator assembly is avoided through an arranged locking mechanism.

Owner:深圳市拓野智能股份有限公司

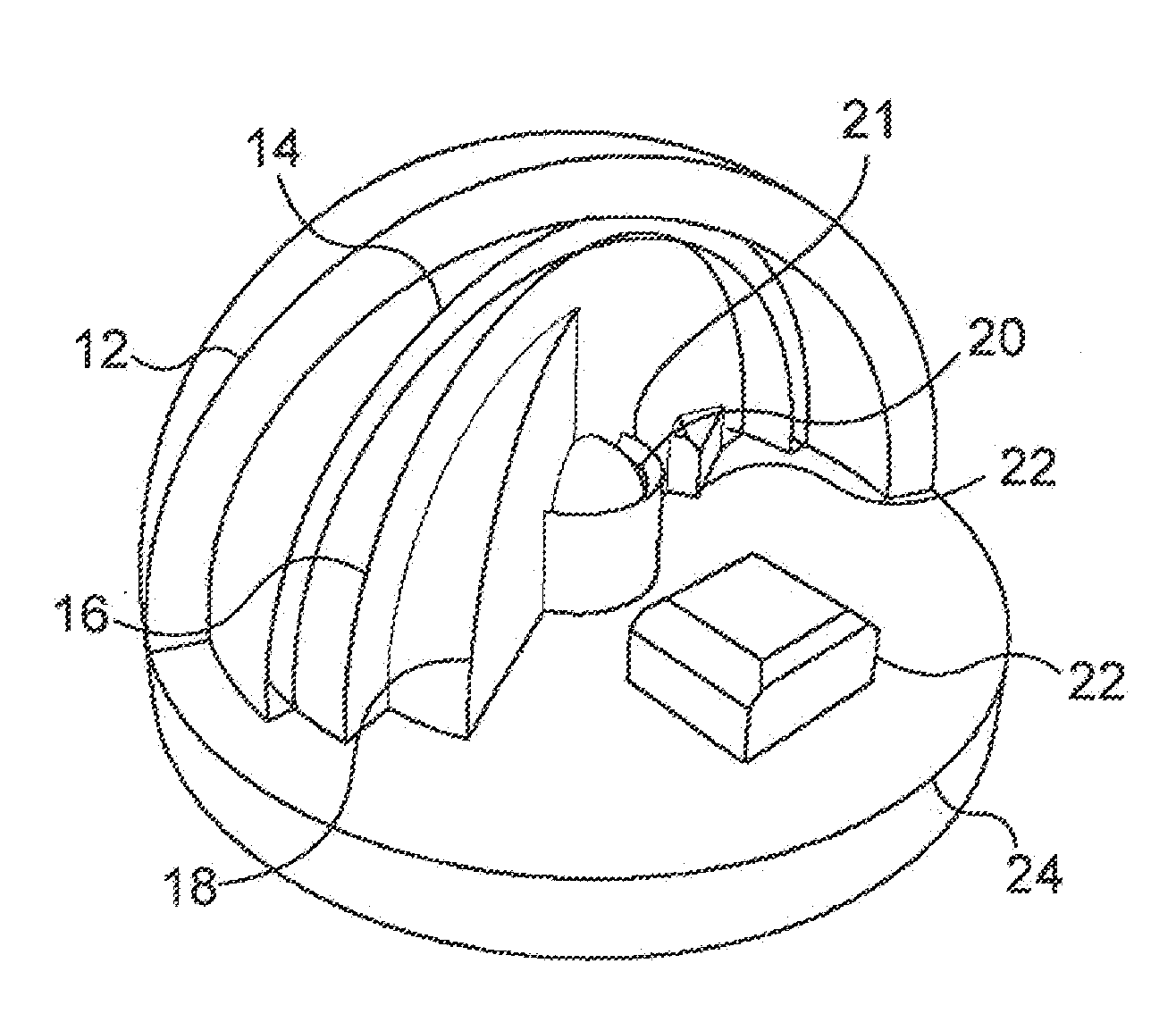

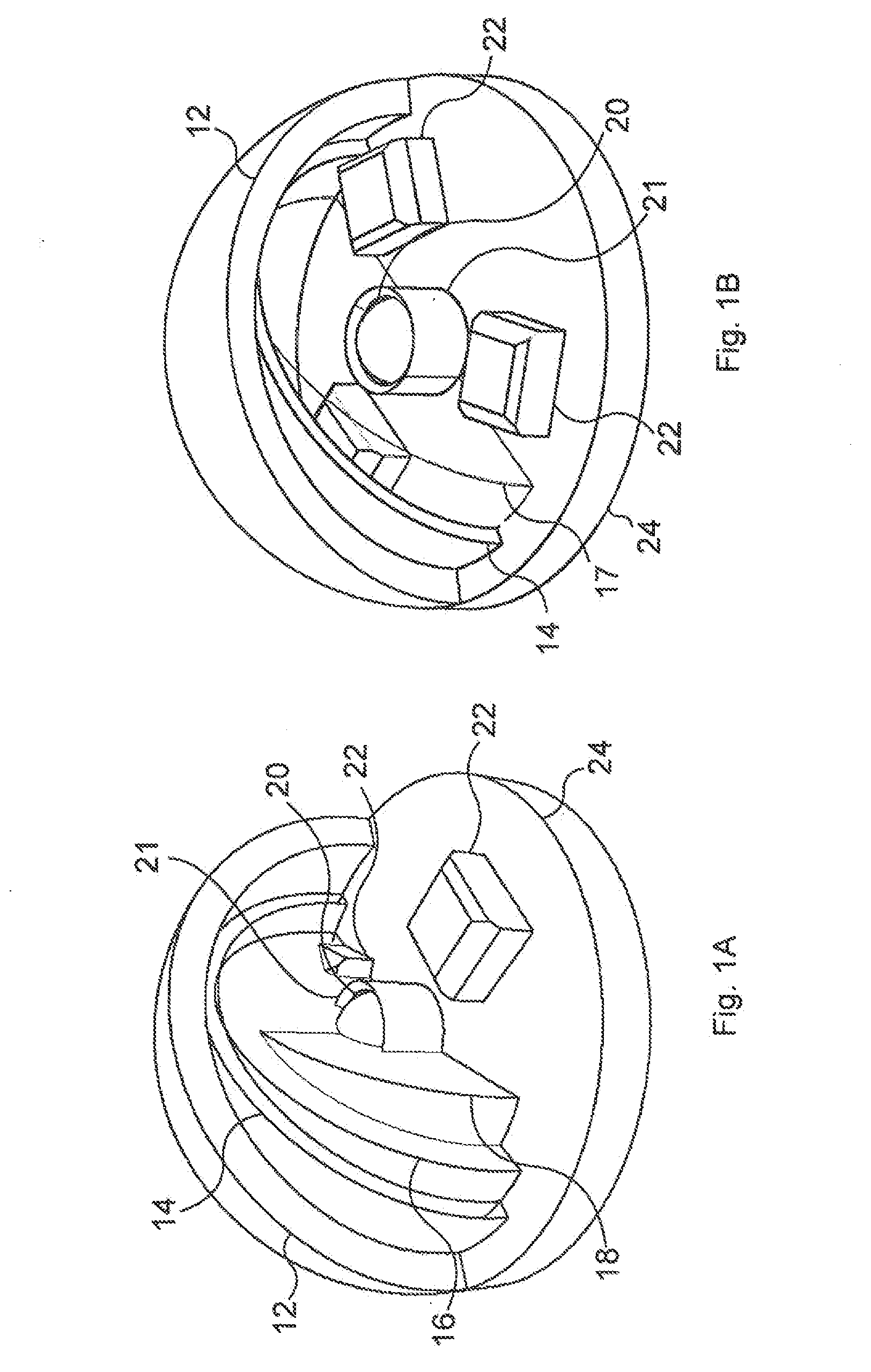

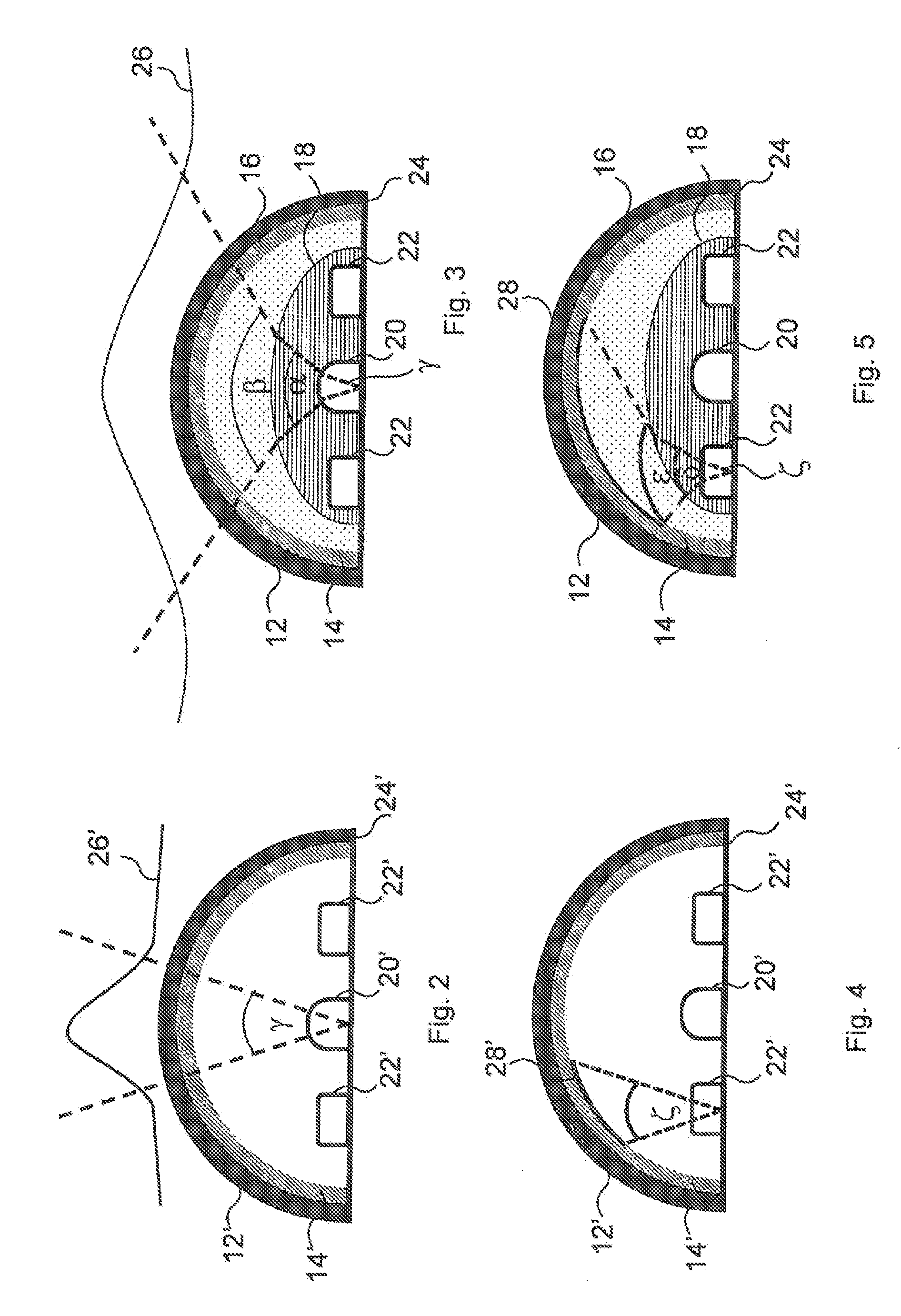

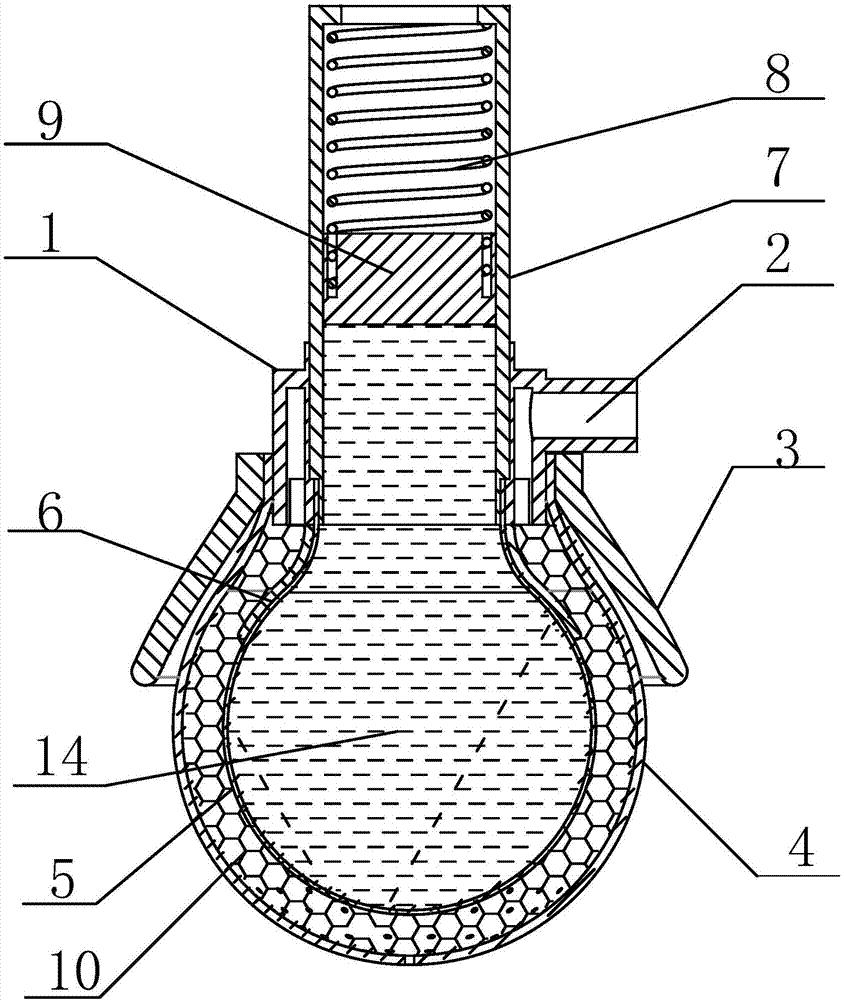

Porous double-layered fluid self-adaptive robot hand device

PendingCN107457797AGet Multidimensional Adaptive EffectsImprove grip stabilityGripping headsRobot handSimulation

The invention relates to a porous double-layered fluid self-adaptive robot hand device and belongs to the technical field of robot hands. The porous double-layered fluid self-adaptive robot hand device comprises a substrate, an air inlet, an external bowl-shaped supporting piece, an internal bowl-shaped supporting piece, a first flexible film, a second flexible film, a piston cylinder assembly and the like. A multi-dimensional self-adaptive active grasping function is comprehensively achieved by means of positive and negative pressures provided by an air source, the piston cylinder assembly, small holes in the first flexible film, a porous flexible material, the internal bowl-shaped supporting piece, the external bowl-shaped supporting piece, a fluid and the like, so that objects of different shapes and dimensions can be self-adaptively grasped. The porous double-layered fluid self-adaptive robot hand device can be adaptive to the object in multiple directions to obtain the multi-dimensional self-adaptive effect, and is high in grasping stability. By combining the advantages of the spherical self-adaptive hand and a sucking disc, the porous double-layered fluid self-adaptive robot hand device provided by the invention not only can be adaptive to grasp an object with a counteractive surface, but also can be adaptive to grasp an object without the counteractive surface, and is large in grasping range and high in grasping weight; and the porous double-layered fluid self-adaptive robot hand device is simple in structure, low in cost and easy to control.

Owner:清研(洛阳)先进制造产业研究院

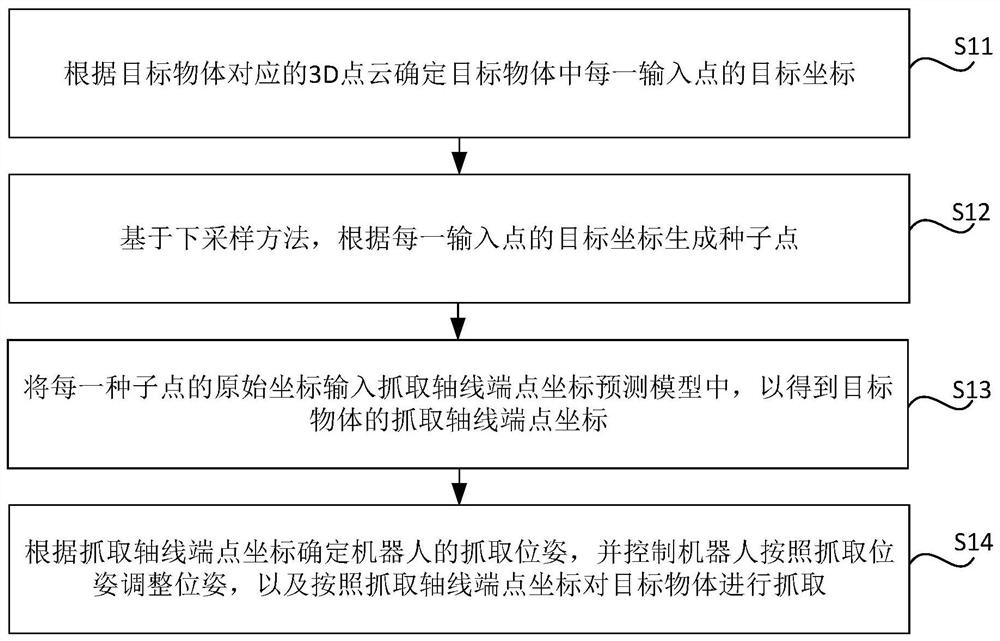

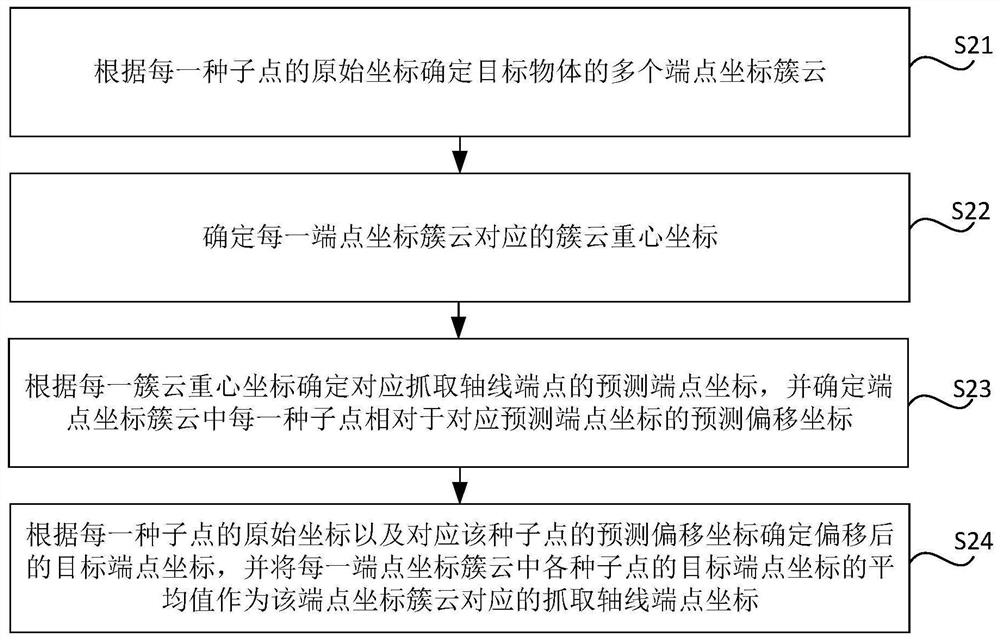

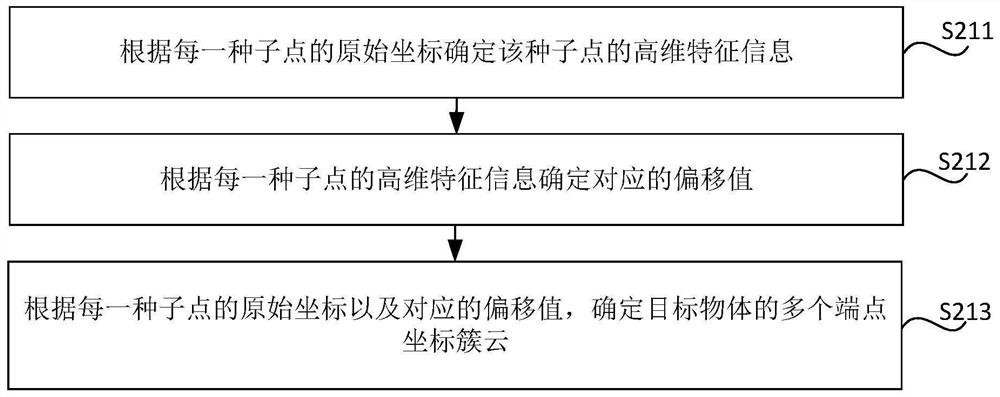

Target object grabbing method and device, storage medium and electronic device

ActiveCN112720459AImprove grab position selection accuracyImprove grip stabilityProgramme-controlled manipulatorPoint cloudEngineering

The invention relates to a target object grabbing method and device, a storage medium and an electronic device, and aims to solve the problem of relatively low grabbing position selection accuracy of a target object in related technologies. The method comprises the following steps of determining a target coordinate of each input point in the target object according to 3D point cloud corresponding to the target object; on the basis of a down-sampling method, generating seed points according to the target coordinate of each input point; inputting the original coordinate of each seed point into a grabbing axis endpoint prediction model to obtain a grabbing axis endpoint coordinate of the target object; and determining a grabbing pose of a robot according to the grabbing axis endpoint coordinate, controlling the robot to adjust the pose according to the grabbing pose, and grabbing the target object according to the grabbing axis endpoint coordinate. In this way, the grabbing position selection accuracy of the target object is improved.

Owner:CLOUDMINDS SHANGHAI ROBOTICS CO LTD

Air line double-drive support type soft body hand

The invention discloses an air line double-drive support type soft body hand, and aims at providing a soft body hand which can adopt different drive manners according to different grabbed objects, andis high in grabbing strength and grabbing stability. At least two finger units are included. Each finger unit comprises a soft body finger body, a restraining layer, a base body and a line drive mechanism, wherein the restraining layer is arranged between the soft body finger body and the base body, wherein the telescopic coefficient of the soft body finger body is larger than that of the restraining layer, the line drive mechanism comprises a driving line body and a plurality of line body guiding blocks arranged on the base body, one end of the driving line body is fixedly connected with thebase body through a line pipe, the other end of the driving line body is connected with a cable driving mechanism, and the driving line body is guided through the multiple line body guiding blocks. Each soft body finger body comprises a plurality of gas cavities which are in communication. A pneumatic control mechanism is used for controlling the gas pressure in the gas cavities. The soft body hand has higher grabbing strength and larger bending angle under the same gas pressure and has higher grabbing stability.

Owner:TIANJIN UNIV

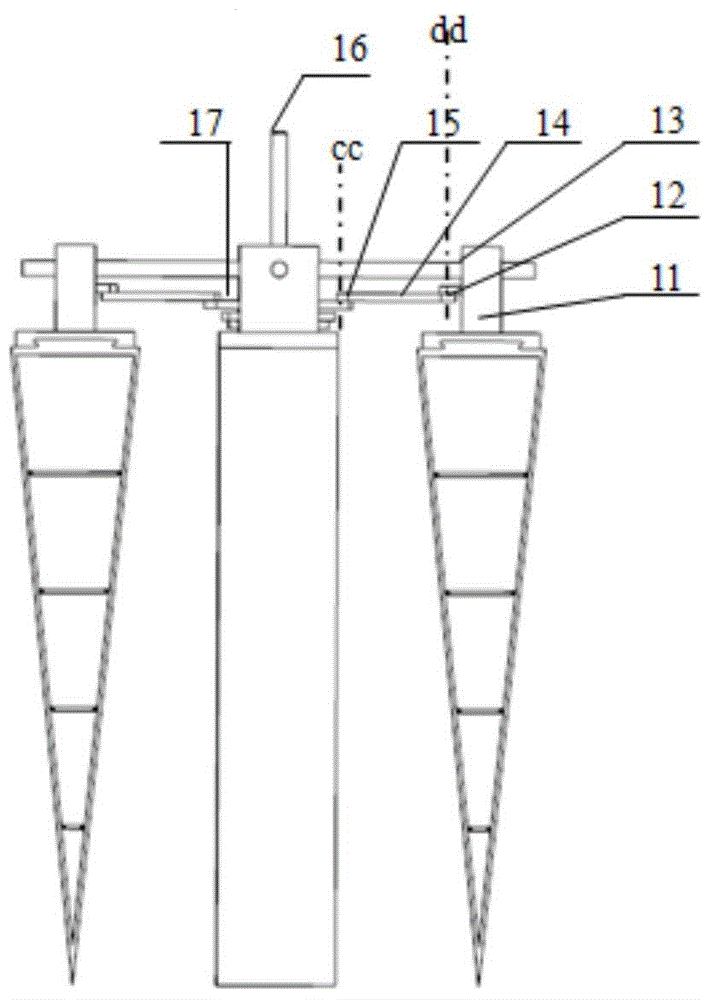

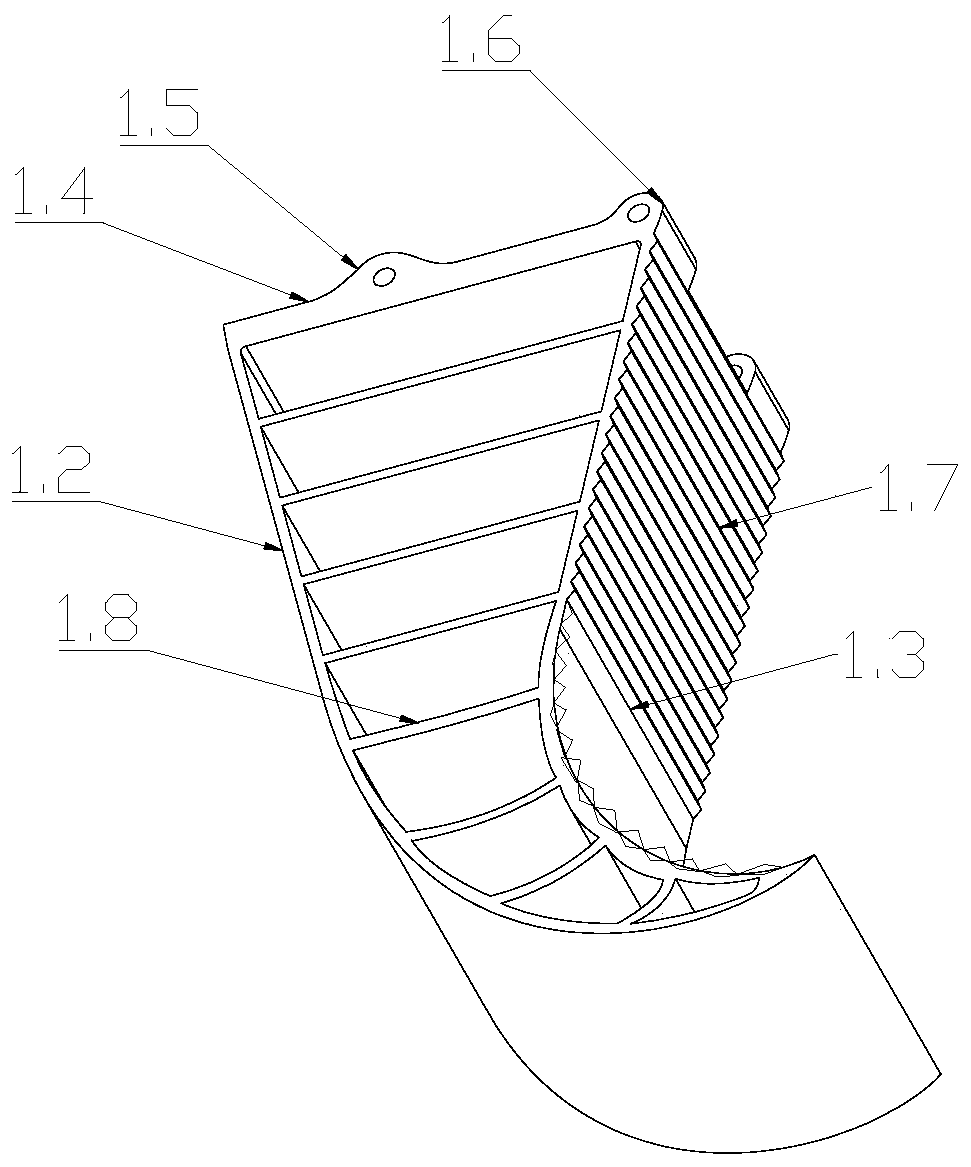

Variable palm type manipulator pawl capable of realizing passive enveloping

ActiveCN104875182ARealize passive flexible envelopeSimple structureProgramme-controlled manipulatorGripping headsFixed frameManipulator

The invention discloses a variable palm type manipulator pawl capable of realizing passive enveloping. The variable palm type manipulator pawl comprises a driving platform, a guide positioning platform, four passive fingers and four active branch chains; four passive fingers are evenly distributed with an included angle at 90 degrees, every passive finger is composed of a flexible outline, a rigid rod and a rotating pair; both ends of the rigid rod are connected with the flexible outline through the rotating pair; one end of a link rod of each of the active branch chain is connected with the driving platform through the driving platform rotating pair, and the other end is connected with the finger fixing frame through a finger fixing frame rotating pair; the guide positioning platform is connected with the finger fixing frame through a guide positioning platform columnar pair, and the lower surface of the finger fixing frame is fixedly connected to the passive fingers. The variable palm type manipulator pawl is simple in structure and only needs to drive solely; the variable palm type manipulator pawl is strong in application flexibility, able to passively and flexibly envelop complex appearance articles, convenient to control and design, and widely applied to the places with complex passive and flexible enveloping appearance and fragile articles in mechanical manufacturing, light industry, medical treatment, and others.

Owner:TIANJIN UNIV

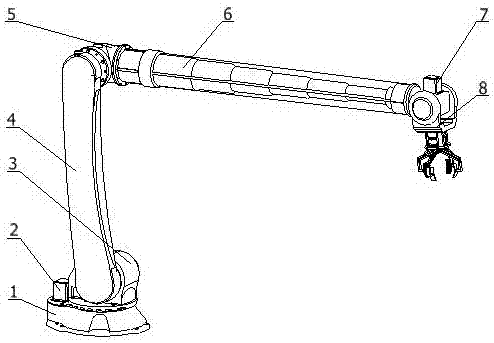

Fruits and vegetables sorting manipulator

ActiveCN106976073APrecise positioningImprove grasping accuracyProgramme-controlled manipulatorGripping headsManipulatorFruits and vegetables

The invention relates to a fruits and vegetables sorting manipulator and belongs to the technical field of an industrial robot. The fruits and vegetables sorting manipulator comprises a pedestal, a shaft drive device I, a shaft drive device II, a big arm, a shaft drive device III, a small arm, a shaft drive device IV and grasping paws, wherein the shaft drive device I is installed in the pedestal; the shaft drive device II is installed on a rotary seat of the shaft drive device I in a fastening way; one end of the big arm is installed on the shaft drive device II; the other end of the big are is connected with the shaft drive device III; the shaft drive device III is installed at the large end of the big arm; one end of the small arm is installed on the shaft drive device III; the other end of the small arm is connected with the shaft drive device IV; the grasping paws are installed on the small arm and are simultaneously connected with the shaft drive device IV. The fruits and vegetables sorting manipulator provided by the invention adopts a five-freedom-degree manipulator and can accurately position the grasping position; a grasping part adopts a pneumatic-linkage manipulator to improve the grasping accuracy and stability; and grasping fingers adopt a flexible skid-proof design, so the grasping force can be reduced and mechanical damages of the surfaces of fruits and vegetables can be prevented.

Owner:KUNMING UNIV OF SCI & TECH

Collaborative driving three-finger robot dexterous hand

ActiveCN110171011AReproduce the function of human graspingCapable of manipulating objectsGripping headsSimulationRobot

The invention discloses a collaborative driving three-finger robot dexterous hand. By the reference on the human hand grabbing characteristic design, recurrence of the human hand grabbing function canbe achieved on the dexterous hand to the maximum degree; all the fingers can conduct side swaying motion, and the dexterous hand can have an object operation function; and dexterity of the robot handis reserved as high as possible while control of the dexterous hand is simplified.

Owner:HUNAN UNIV

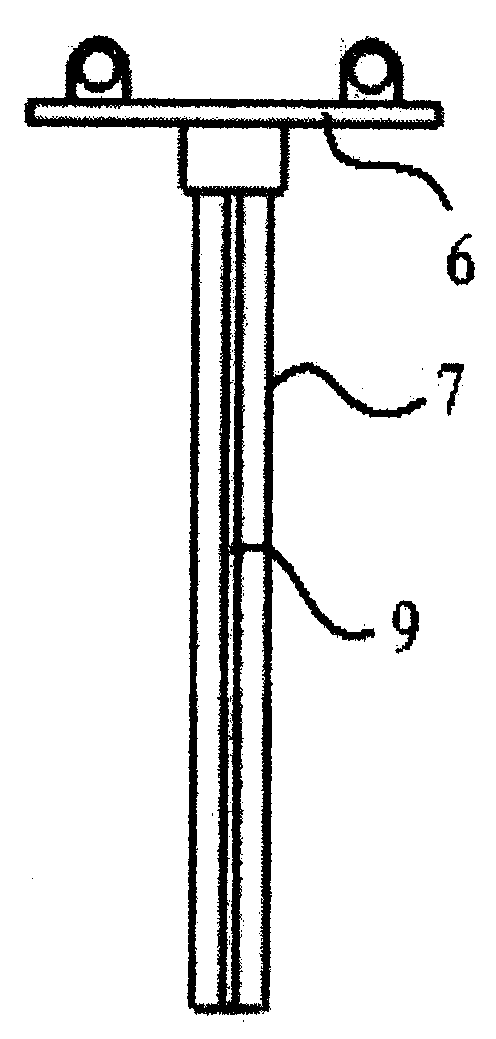

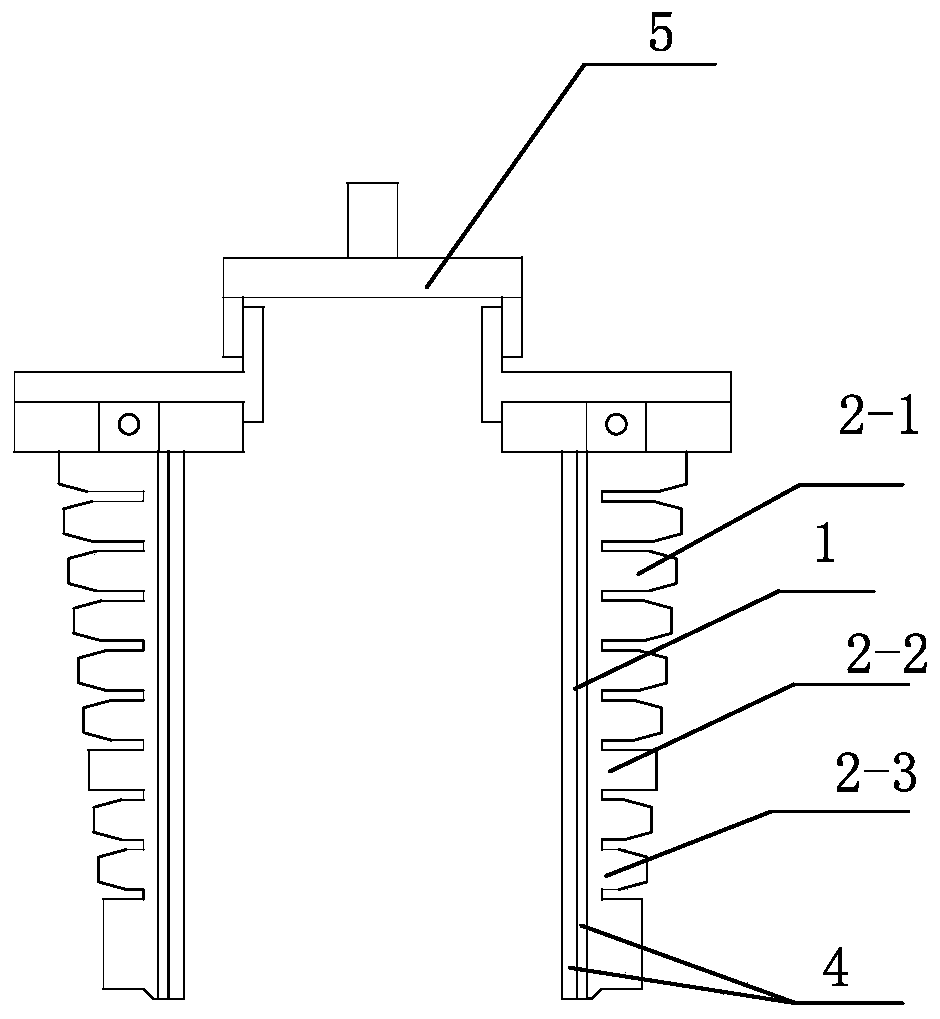

Mechanical hand for edible mushroom box transportation

PendingCN109048964ASimple structureImprove grip stabilityGripping headsArmsLinear displacementManipulator

The invention discloses a mechanical hand for edible mushroom box transportation. The mechanical hand comprises a fixing vertical frame, a mechanical arm and a mechanical claw. A rotation mechanism isarranged in the fixing vertical frame. A through hole is formed in the side face of the lower portion of the fixing vertical frame. The mechanical arm is arranged at the upper portion of the fixing vertical frame. One end of the mechanical arm is rotationally connected with the fixing vertical frame through the rotation mechanism. The mechanical arm does plane rotation through the rotation mechanism. A lifting driving mechanism is arranged at the executing tail end of the mechanical arm. The executing end of the lifting driving mechanism is vertically arranged downwards. The mechanical claw is fixedly connected with the executing tail end of the lifting driving mechanism, and the mechanical claw is driven by the lifting driving mechanism do to the up-down linear displacement. The disclosed mechanical hand for edible mushroom box transportation is simple in operation and convenient to control, the performance of stable product grabbing and protecting is achieved, and production and usage are facilitated.

Owner:JIANGSU YUBO AUTOMATION EQUIP CO LTD

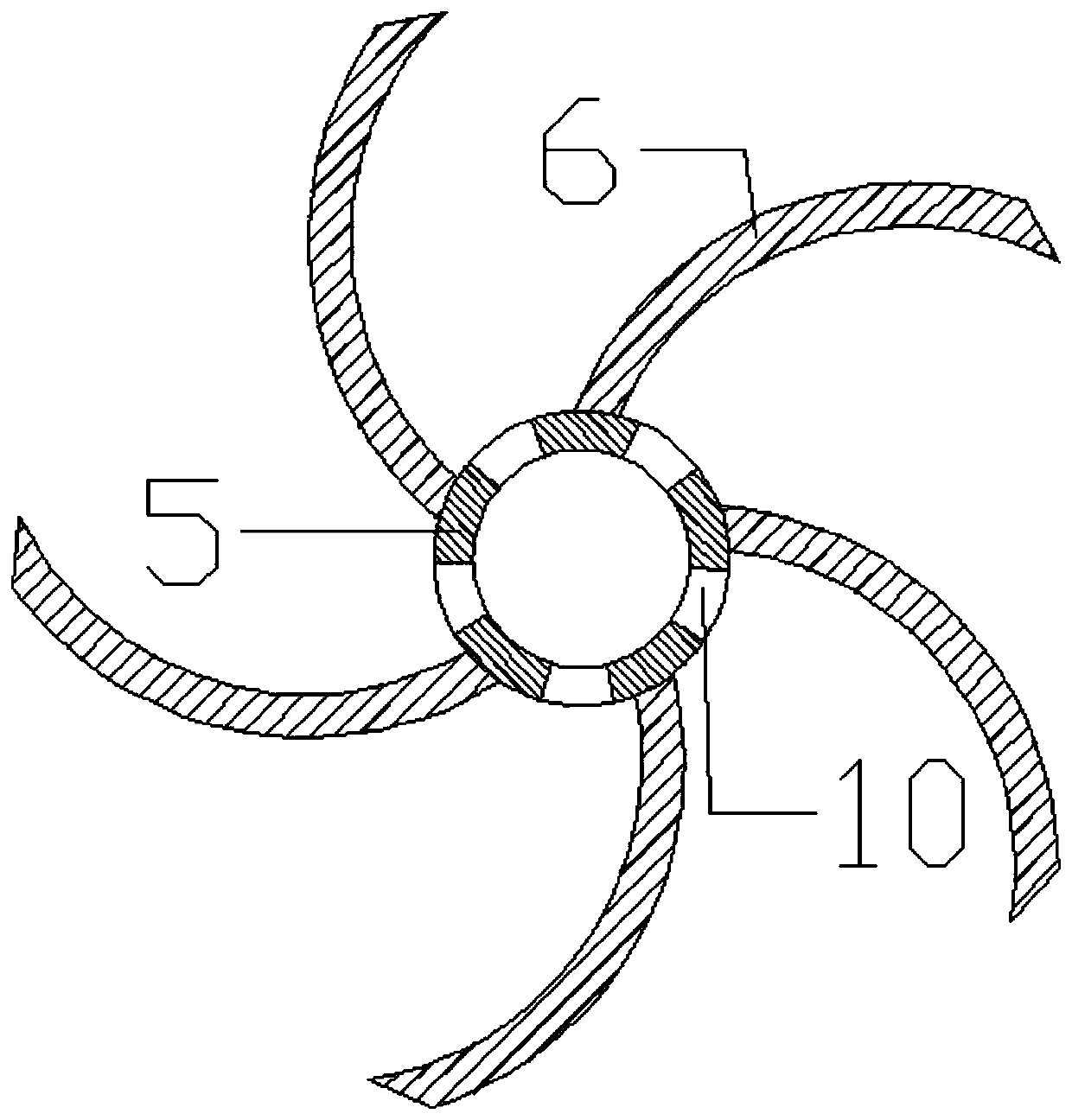

Bionic flexible claw device inspired by caudal fin of Longfeng brocade carp

The invention relates to a bionic flexible claw device inspired by the caudal fin of a Longfeng brocade carp. The bionic flexible claw device comprises a motor mounting surface, a lifting platform surface and bionic flexible mechanical claws. A motor is arranged on the motor mounting surface, and a shape coupler with an external thread is connected on an output shaft of the motor, and the liftingplatform surface is in threaded connection with the shaft coupler. A plurality of connecting rods are uniformly arranged on the periphery of the lifting platform surface. The top end of each connecting rod is movably connected on the lifting platform surface, and the tail end of each connecting rod is movably connected with one bionic flexible mechanical claw. The edge of the inner side of the upper end face of each bionic flexible mechanical claw is movably arranged on the lower end face of the motor mounting surface. The positive-negative rotation of the motor is controlled, so the lifting down or up of the lifting platform surface is realized. The lifting platform surface lifts down, so that each bionic flexible mechanical claw moves downwards to close around the edge of the inner sideof the upper end face, and the bionic flexible mechanical claw deforms according to the shape of a target object to form an enveloping surface and complete the grasping action. The lifting platform surface lifts up, each bionic flexible mechanical claw moves upwards to open around the edge of the inner side of the upper end face so as to complete the release action.

Owner:NAT UNIV OF DEFENSE TECH

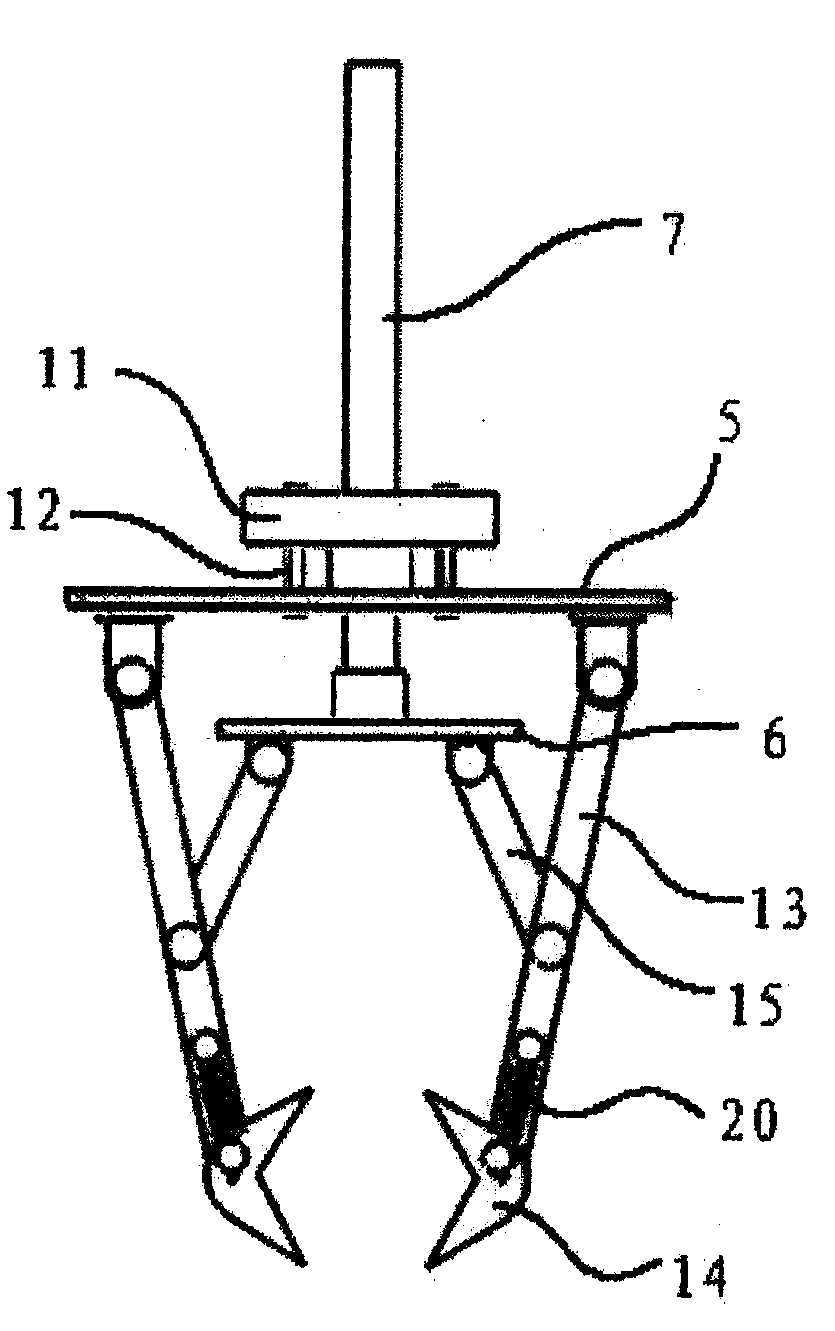

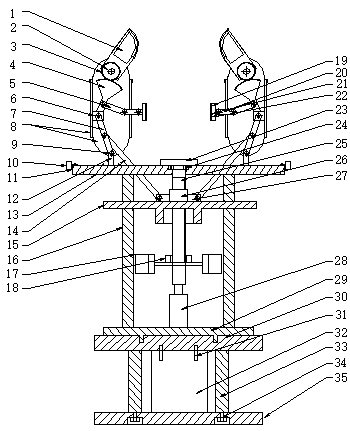

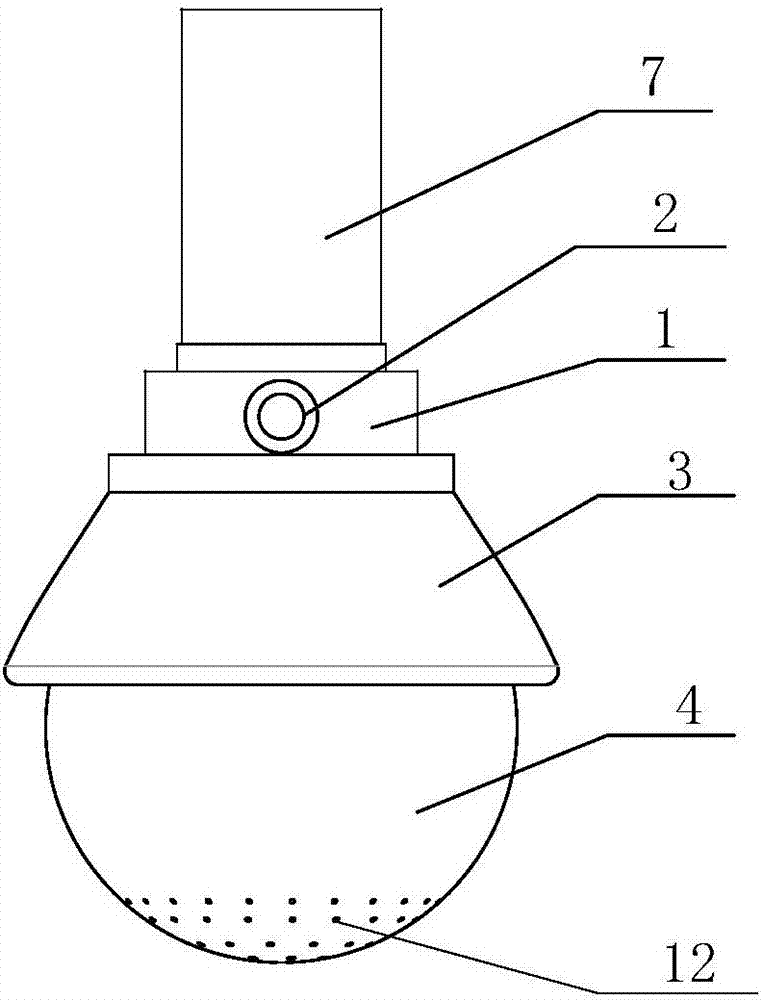

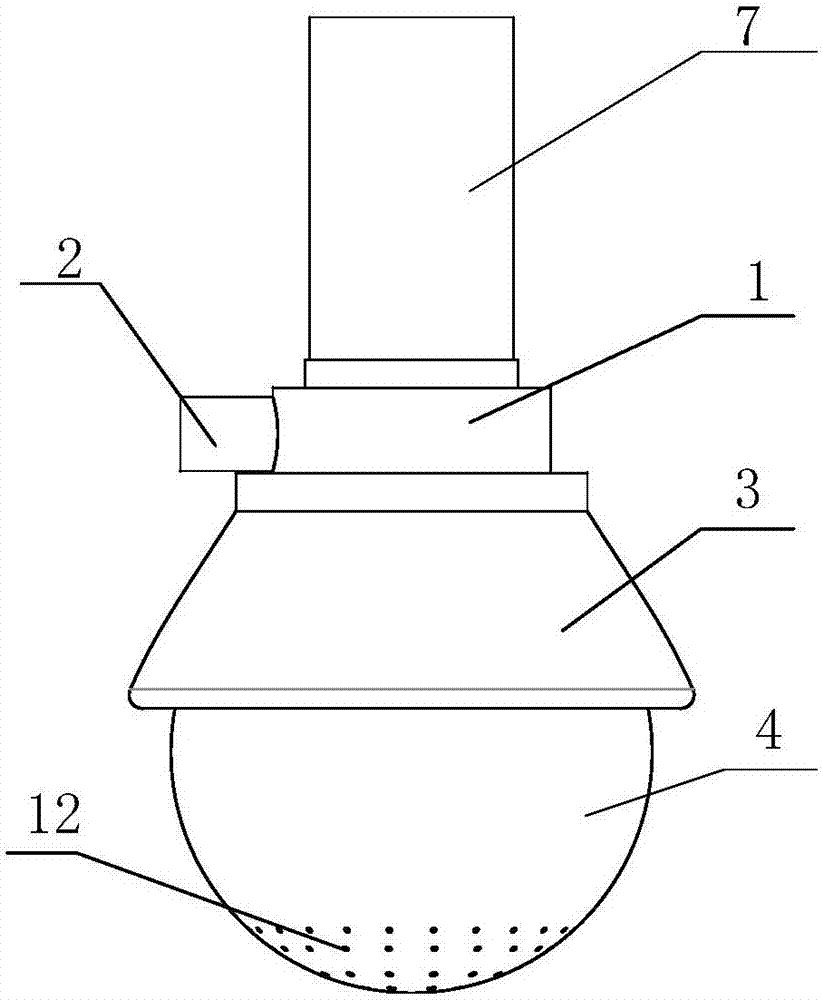

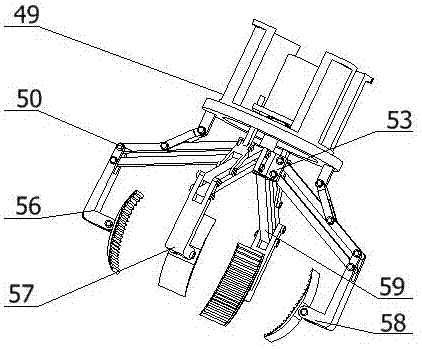

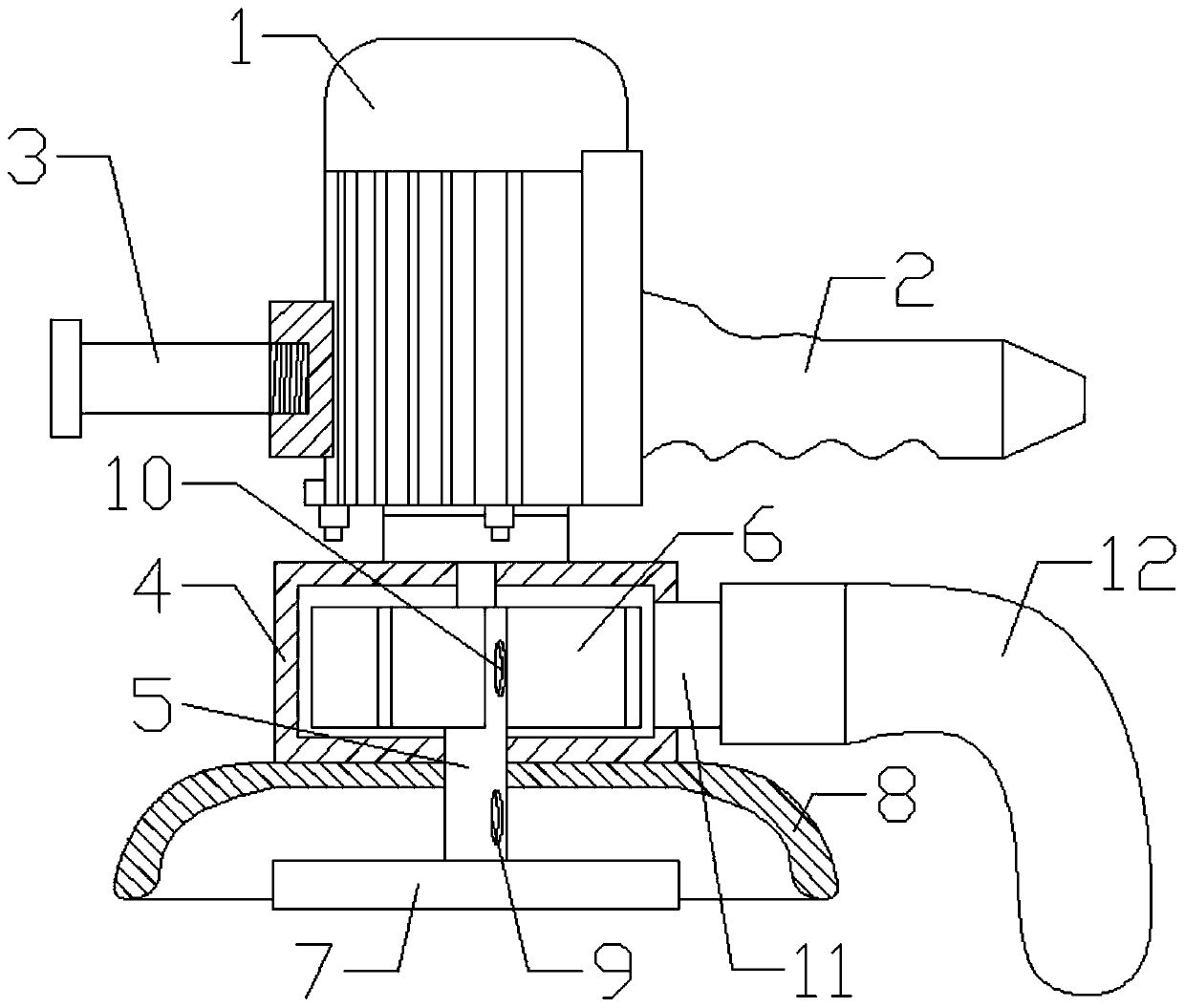

End effector of intelligent harvesting robot

InactiveCN102550216AImprove versatilityImprove grip stabilityPicking devicesDistance sensorsEngineering

An end effector of an intelligent harvesting robot is composed of a mechanical system, a control system, a sensing system and a power supply system, wherein the mechanical system is mainly composed of a finger grabbing mechanism and a stem separating mechanism. The finger grabbing mechanism adopts a four-finger structure capable of automatically adjusting inclination angles of fingers and carrying out centering grasp of fruits, and the stem separating mechanism adopts a scissors type structure capable of automatically positioning stems and adjusting opening and closing angles of blades. The sensing system is composed of a force sensor, a camera and a proximity sensor, the force sensor monitors whether the finger grasping force is overloaded in real time, the camera senses maturity and space gestures of the fruits and monitors whether relative sliding displacement occurs between the fruits and the fingers in real time, and the proximity sensor detects the space positions of the fruits. The mechanical system, the control system, the sensing system and the power supply system of the end effector are matched with each other, and intelligent harvesting of the fruits is finished. The end effector of the intelligent harvesting robot can achieve intelligent harvesting of various fruits and guarantees quality of the fruits.

Owner:HENAN POLYTECHNIC UNIV

Force controllable gripper

The invention discloses a force controllable gripper, comprising a power source, two gripping ends for realizing single degree of freedom motion, a crank sliding block structure, a gripping force control module and a center surface; wherein the crank sliding block structure comprises a crank, a slide rail, two sliding structures, two connecting rods, two first rotating pairs and two second rotating pairs. The central plane is defined as a plane rotating through a crank and is perpendicular to a sliding plane. When the crank rotates, the two sliding structures are driven to slide and are alwayssymmetrical about the central plane. A gripping force control module is added on the gripping end to achieve flexible contact with a target object and gripping force detection. There is a simple conversion relationship between the displacement of the grip end, the contact force and the rotation angle of a power source and torque, which is convenient for designing the control algorithm. The forcecontrollable gripper realizes the gripping force control, can stably grip a target object, and is easy to control. The force controllable gripper is designed to be smaller and lighter, and is suitablefor scenes that require lightweight gripping.

Owner:SHANGHAI JIAO TONG UNIV

Steel polishing device and method

InactiveCN110883659ARealize the collectionImprove grip stabilityGrinding drivesPortable grinding machinesPolishingEngineering

The invention discloses a steel polishing device and method, and belongs to the field of machining equipment. The device comprises a motor body, a first grip, an additional gripping structure, an installation box, a rotation pipe, centrifugal blades, a polishing sheet, a protective cover, an air inlet, a plurality of air outlets, an air exhaust pipe and a collection cloth bag. The device can be held by two hands instead of one hand when held, so that holding stability is increased, and polishing efficiency is improved; by using the centrifugal blades in the installation box, the centrifugal blades are driven to rotate while the polishing sheet is driven to perform polishing by rotation of the rotation pipe, air in the installation box is driven to rotate by rotation of the centrifugal blades and is thrown out by centrifugal force, the air is sucked in the air outlets from the air inlet, enters the installation box and then is exhausted to the collection cloth bag by the air exhaust pipe to be collected, so that dust generated by polishing in the protective cover is collected; and because the polishing device is not needed to be matched with an external dust collector, so that an energy saving effect is achieved.

Owner:JIANGSU YONGXING FINANCIAL EQUIP CO LTD

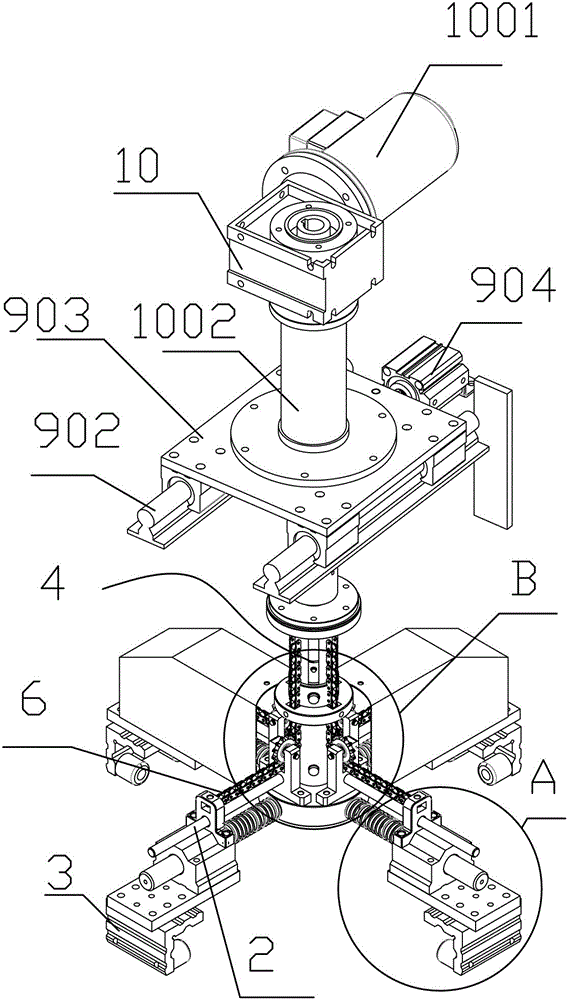

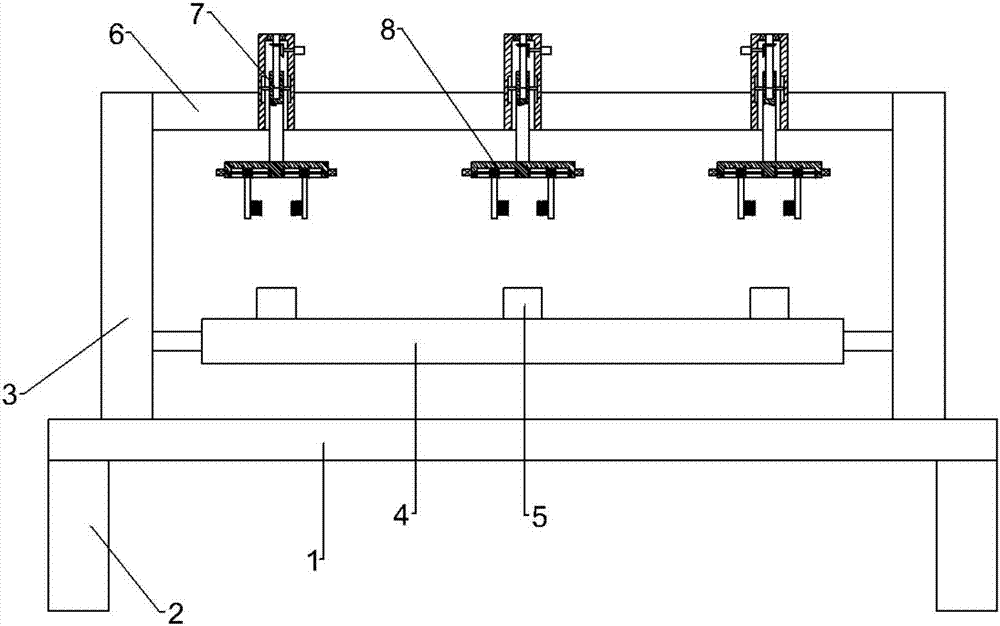

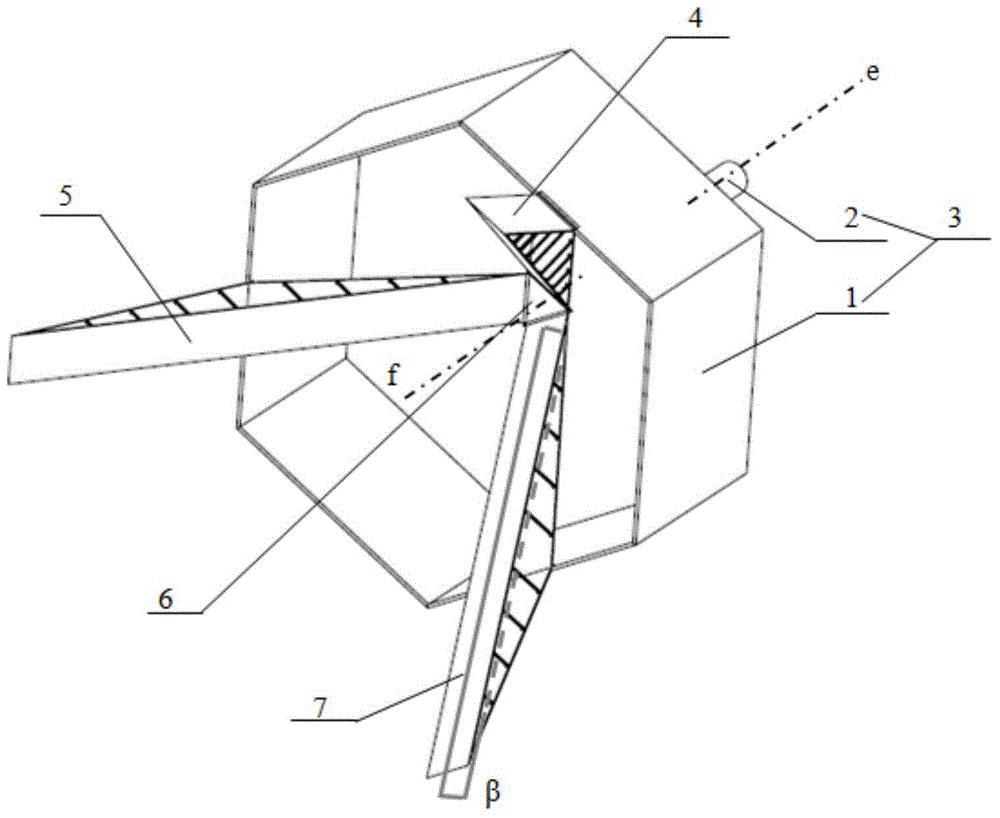

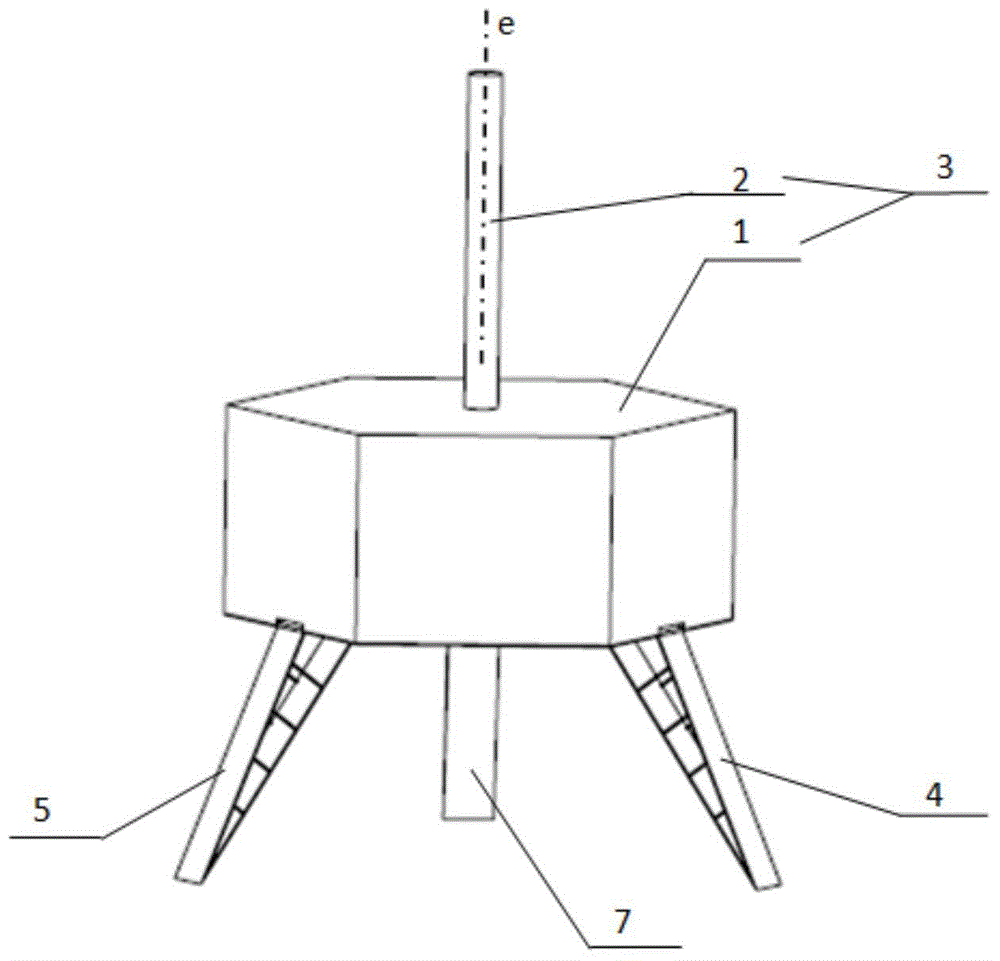

Automatic rotation storage bin for automobile component industry robot feeding

The invention relates to an automatic rotation storage bin for automobile component industry robot feeding. The automatic rotation storage bin comprises a grabbing bin rack. A rotation device is arranged at the middle portion of the grabbing bin rack. A plurality of positioning tools evenly distributed in the circumferential direction are connected to the upper end face of the rotation device. Thegrabbing bin rack is provided with a positioning device matched with the rotation device and a feeding lifting device for a robot to grab. Each positioning tool comprises a main positioning rod, a movable tray and an auxiliary positioning rod. The rotation device comprises a rotation disc, a speed reduction motor, a chain wheel transmission mechanism, a speed reduction sensor and a proximity sensor. The feeding lifting device comprises a servo lifting mechanism, a shifting fork, a descending in-place sensor, a descending in-place sensor and a workpiece grabbing detection sensor. The automaticrotation storage bin is high in automation degree, convenient to operate and high in grabbing stability, one set can achieve the integrated application function for multi-product switching mixed lineproduction, the problem about multi-product mixed line production is solved, flexible automatic production is achieved, and the production line beat is improved.

Owner:埃华路(芜湖)机器人工程有限公司

Protection device provided clamping device for electronic device machining

InactiveCN107351092AEffective protectionReasonable structural designGripping headsEngineeringThreaded rod

A clamping device for electronic device processing with a protection device, comprising a base, four support legs are fixedly connected to the lower side of the base, two mounting plates are symmetrically fixedly connected to the upper side of the base, and a conveyor belt is arranged between the mounting plates. A support plate is fixedly connected between the tops of the mounting plates, and several vertical movement devices are evenly arranged on the support plate, and the vertical movement devices include a support column, which is fixedly connected with the support plate, and the support column A groove with the opening facing downwards is opened on the top, and a first threaded rod is arranged in the groove. The beneficial effect of the present invention is that the vertical movement device is used to drive the clamping hand to move downward, and the mutual cooperation between the second threaded rod and the moving block is used to realize the encirclement of the two splints to clamp the electronic device. The invention has the advantages of reasonable structural design, high clamping efficiency, good clamping stability, etc., and has certain popularization and application value in the field of electronic device manufacturing.

Owner:牛峰

Flexible mechanical hand claw capable of achieving passive enveloping

ActiveCN104889980ARealize passive flexible envelopeSimple structureProgramme-controlled manipulatorGripping headsEngineeringFinger middle

The invention discloses a flexible mechanical hand claw capable of achieving passive enveloping. The flexible mechanical hand claw comprises a driving platform, a driven platform and three identical passive fingers. The three passive fingers are evenly distributed at included angles of 120 degrees. Each passive finger is formed by a flexible contour, rigid rods and a rotating pair. A plurality of rigid rods are positioned in the flexible contour, the two ends of the rigid rods are connected with the flexible contour through the rotating pair. A finger root part of each passive finger is connected to the driven platform through a first driven platform rotating pair, a finger middle part is connected to the driving platform through a first driving platform rotating pair, and a fingertip part extends to the outer portion of the driving platform. The flexible mechanical hand claw capable of achieving passive enveloping is simple in structure, only needs single driving, is high in application flexibility, can achieve passive flexible enveloping of an article with the complex shape, is convenient to control and design and can be widely applied to the occasions of mechanical manufacturing, light industry and medical treatment where the passive flexible enveloping of articles that are complex in shape and fragile is required.

Owner:TIANJIN UNIV

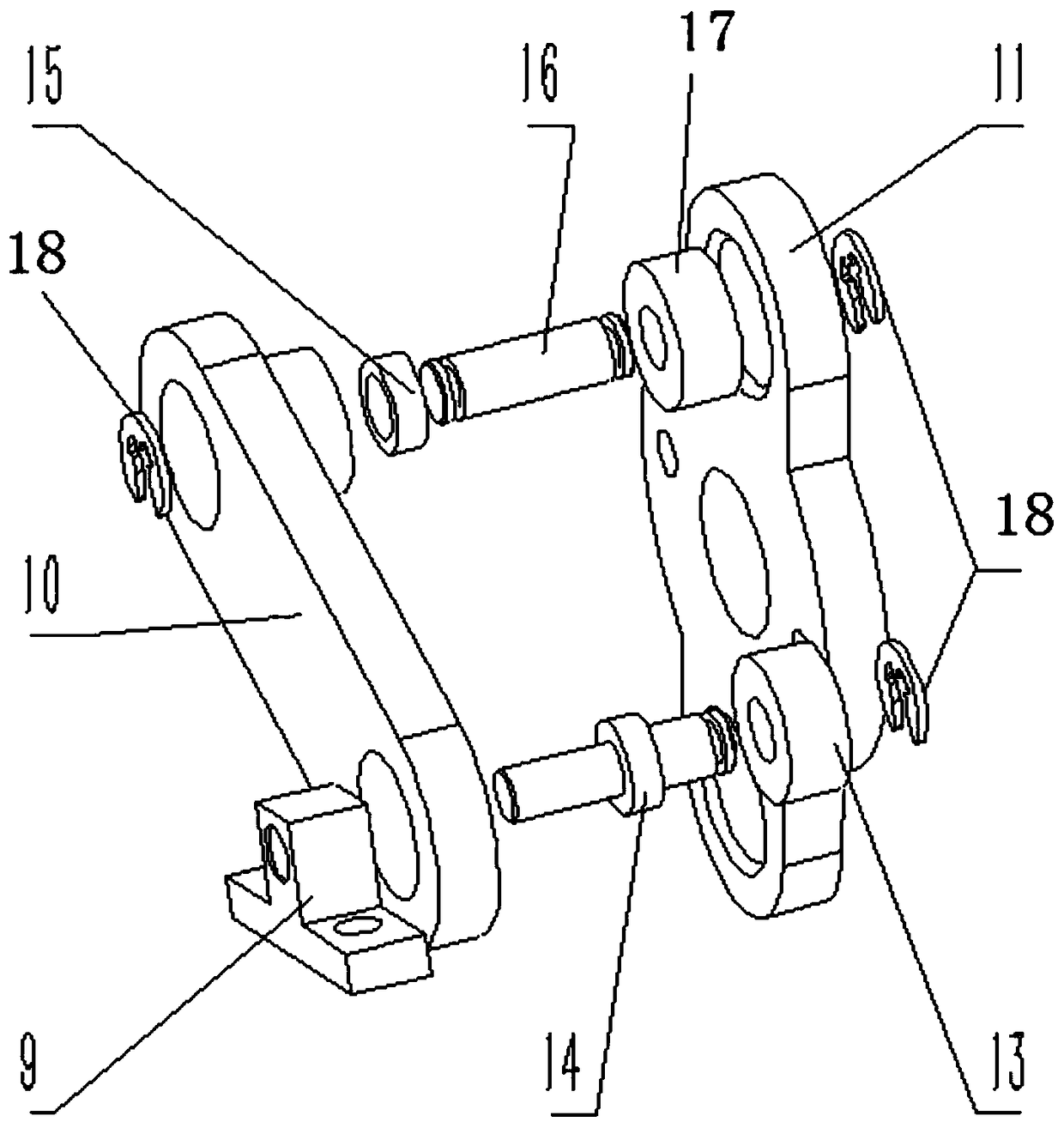

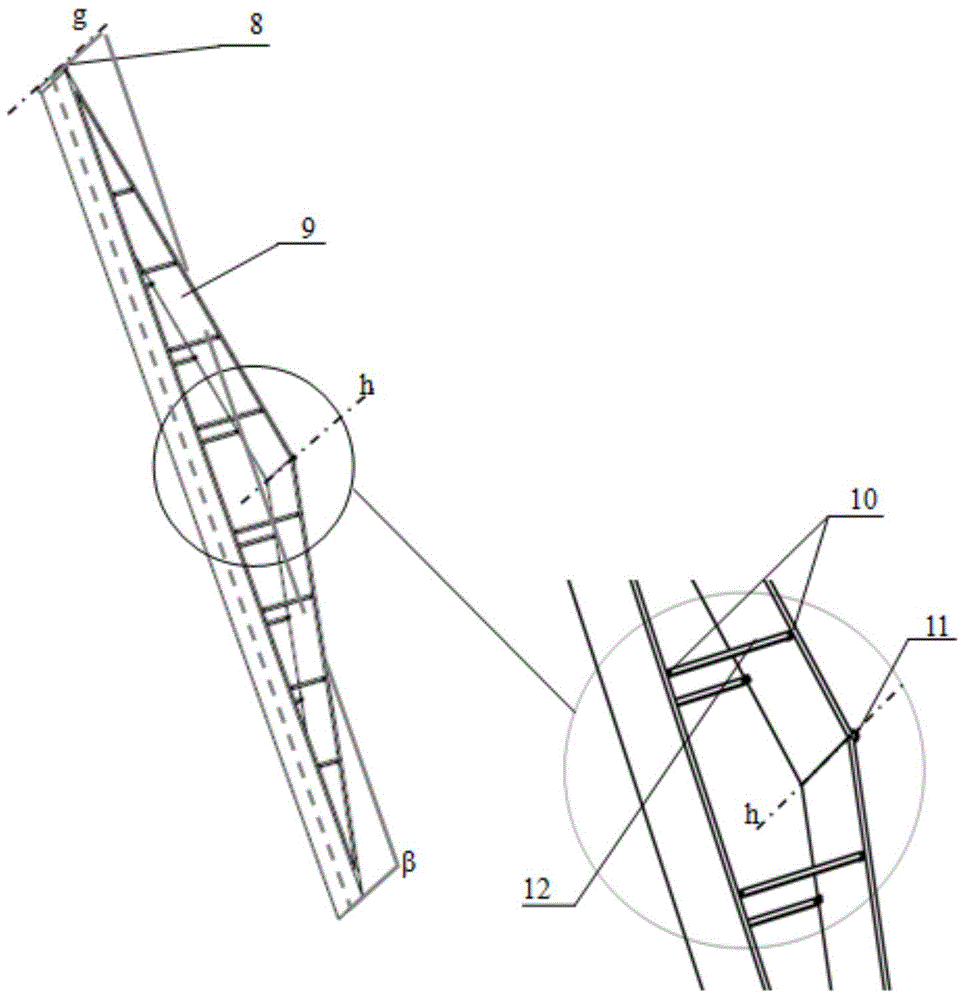

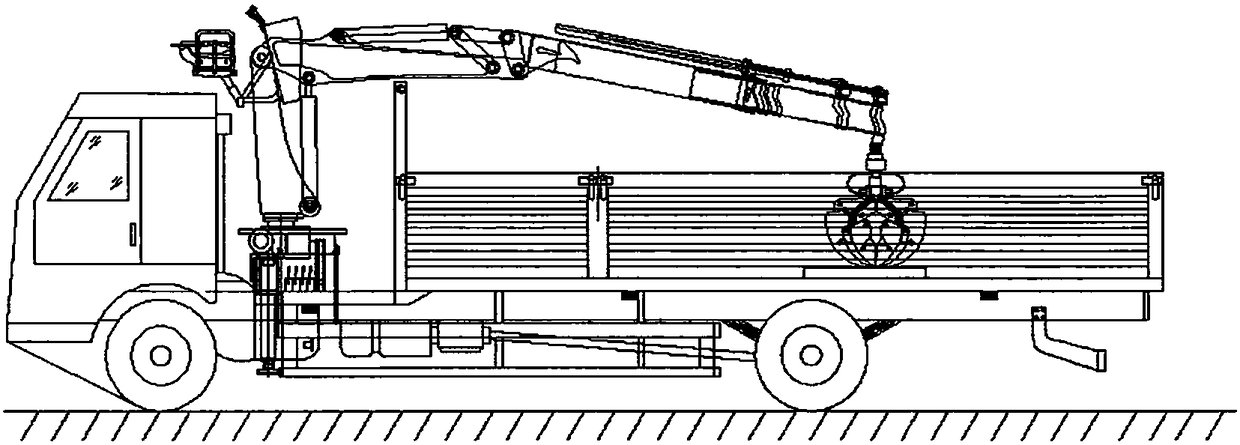

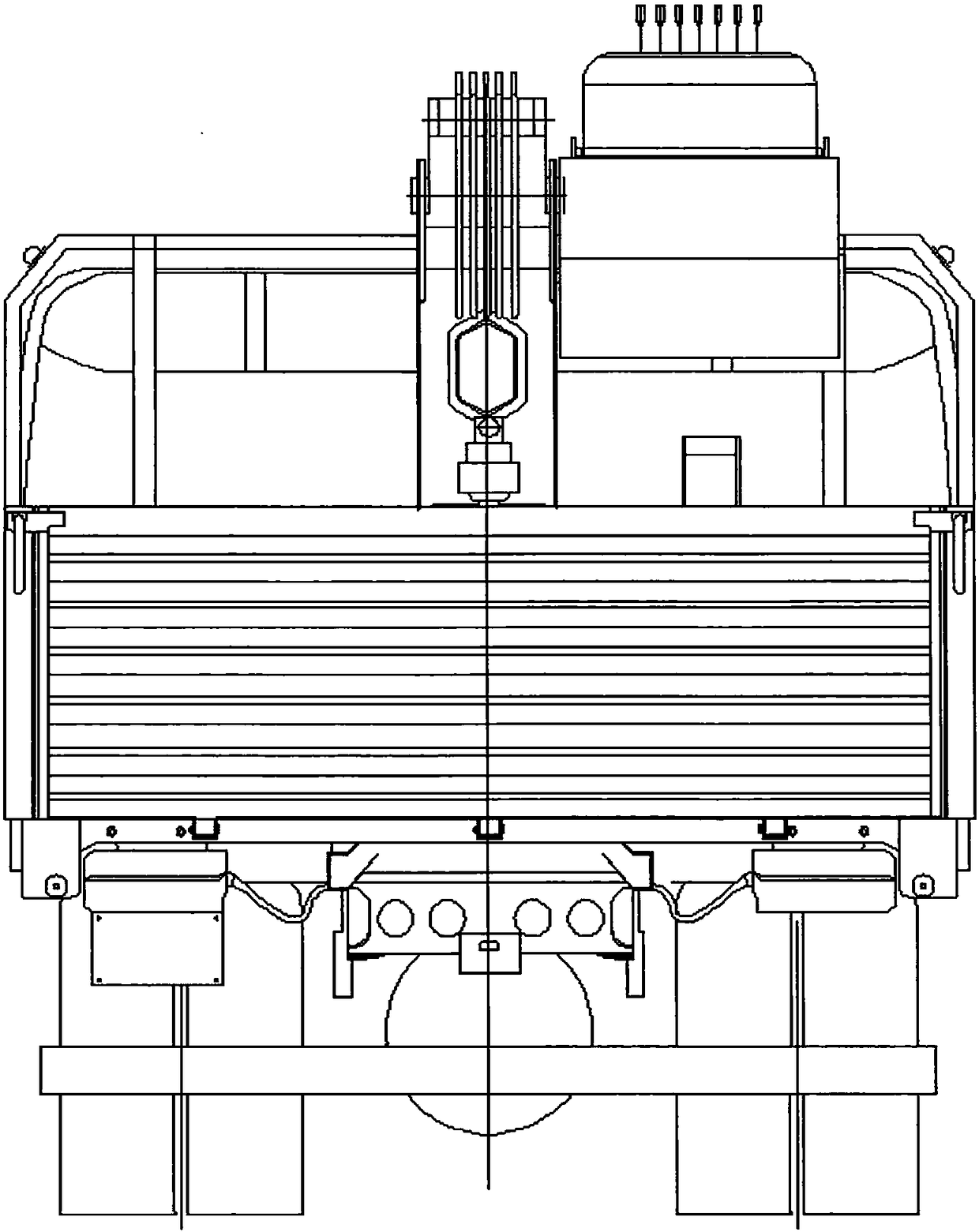

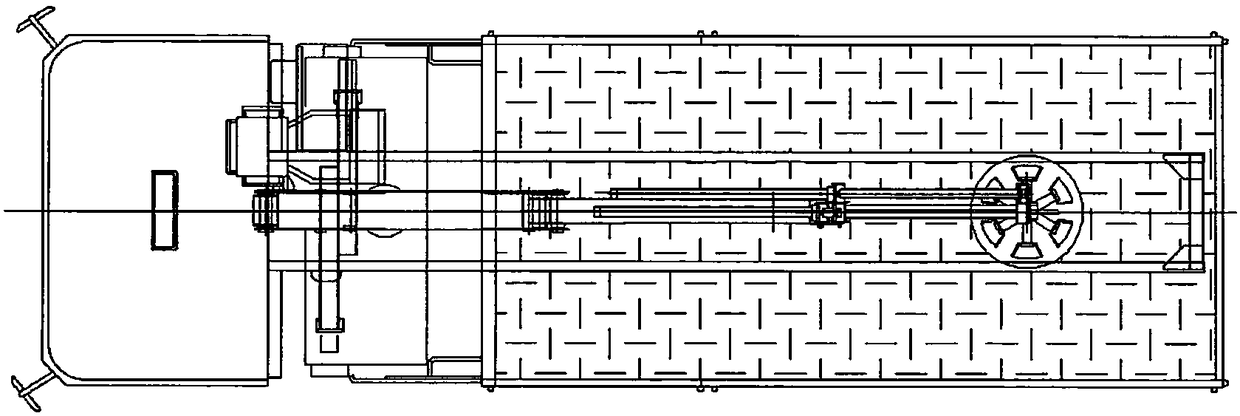

Vehicle-mounted gripping mechanism

PendingCN108408608AImprove the efficiency of self-unloading operationsPlay the role of security protectionVehicle with pivoted armsServomotorsControl theoryDriving safety

The invention relates to vehicle-mounted gripping mechanism. A large arm first hinge hole and a large arm second hinge hole are formed in the upper end of a large arm; a large arm oil cylinder hinge hole is formed in the telescoping end of a large arm oil cylinder; a variable amplitude component first hinge hole and a variable amplitude component second hinge hole are formed in one end of a variable amplitude component; a first connecting rod is provided with a first connecting rod first hinge hole and a first connecting rod second hinge hole; a second connecting rod is provided with a secondconnecting rod first hinge hole and a second connecting rod second hinge hole; the large arm first hinge hole is in pin connection with the first connecting rod first hinge hole; the large arm secondhinge hole is in pin connection with the variable amplitude component first hinge hole; the variable amplitude component second hinge hole is in pin connection with the second connecting rod first hinge hole; and the large arm oil cylinder hinge hole and the first connecting rod second hinge hole are in pin connection with the second connecting rod second hinge hole. The vehicle-mounted gripping mechanism has the advantages that the self-unloading operating efficiency is improved, the object gripping safety coefficient is raised, the driving safety performance is improved, and the service lifeof a gripping apparatus is prolonged.

Owner:江苏高德液压机械有限公司

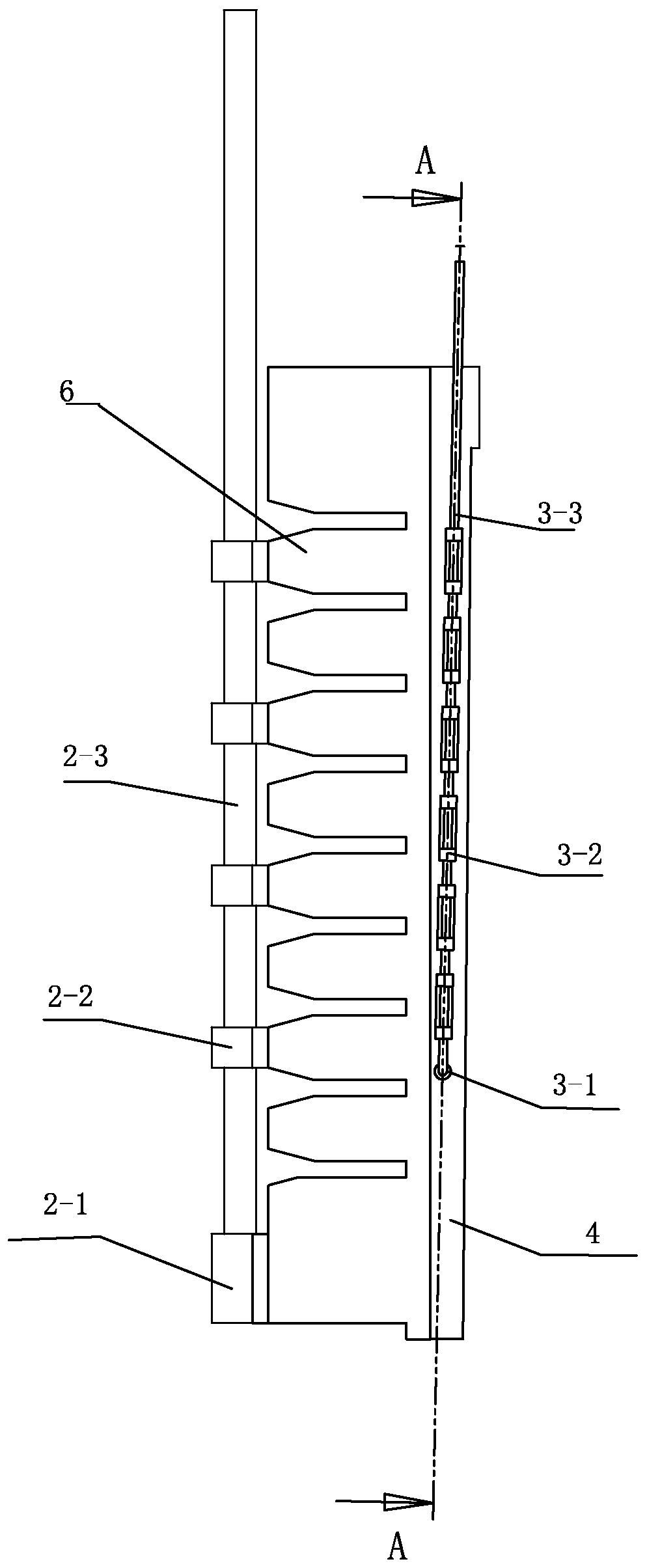

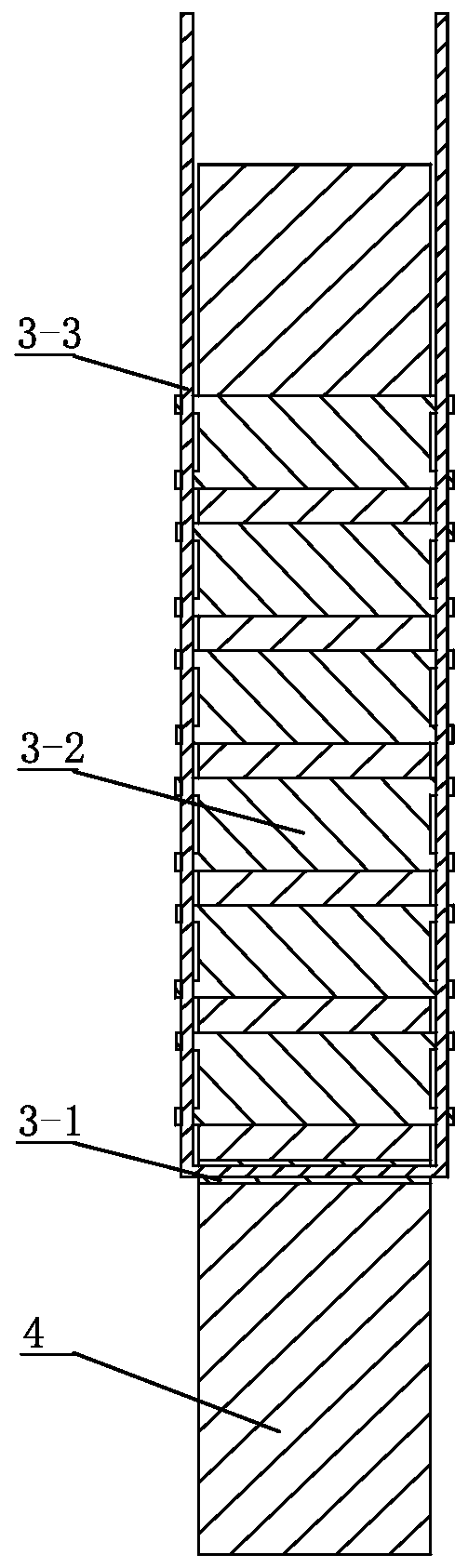

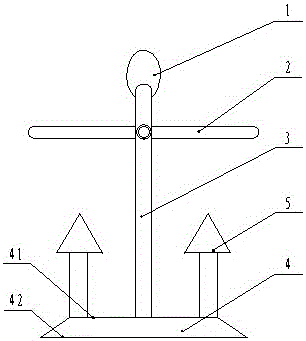

Sucker rod high-holding-power anchor

The invention discloses a sucker rod high-holding-power anchor. The sucker rod high-holding-power anchor comprises an anchor shackle, a stabilizer bar, an anchor handle, an anchor crown and anchor claws; the anchor shackle is in an O shape and is fixedly welded to the upper end of the anchor handle, and the stabilizer bar is in a long strip shape and is fixed to the upper end of the anchor handle in a balanced manner through a pin shaft; and the anchor crown is fixedly welded to the bottom end of the anchor handle, the anchor claws are fixedly welded to the upper end face of the anchor crown, and the number of the anchor claws is two to four. By means of the mode, the sucker rod high-holding-power anchor has the beneficial effects of being simple in structure, large in holding power to weight ratio and good in bottom holding stability.

Owner:SUZHOU JINYE MARINE MACHINERY PLANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com