Mechanical hand for edible mushroom box transportation

A technology of manipulator and bacteria box, applied in the field of manipulator, can solve the problems of complex structure of manipulator, reduced income, and reduced degree of mechanization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

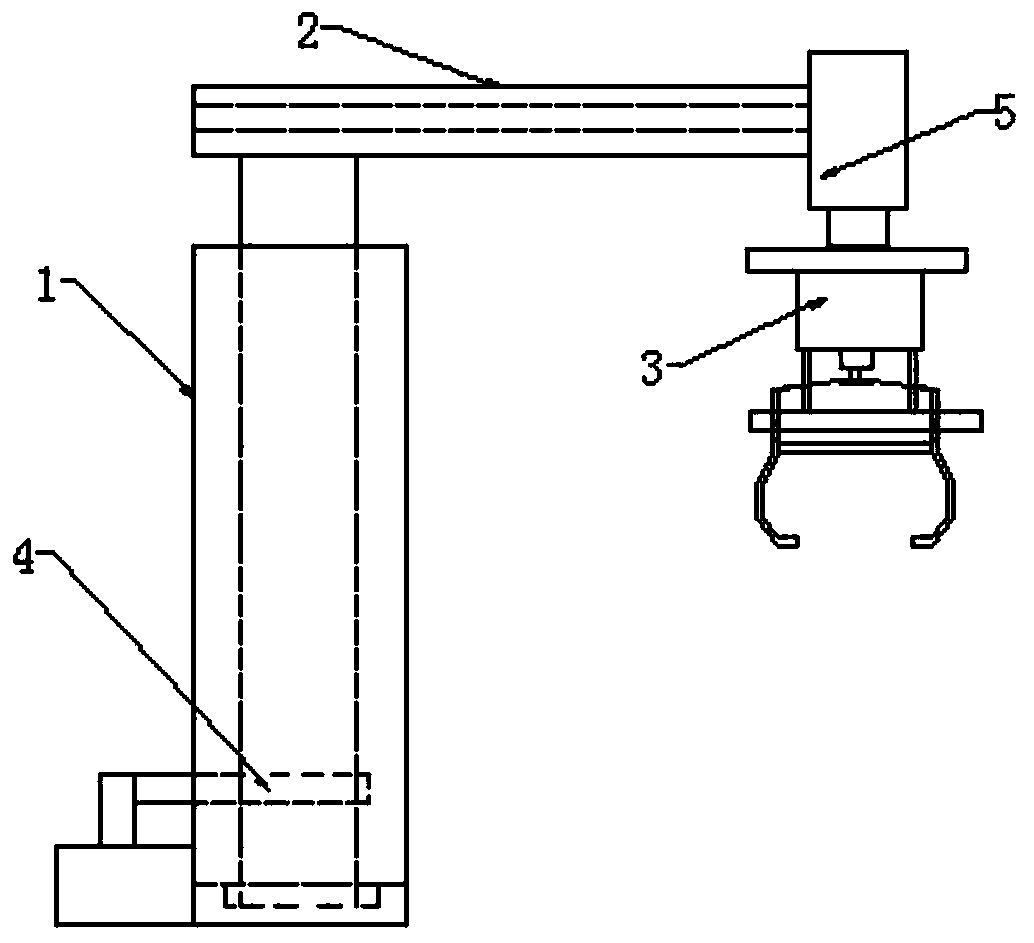

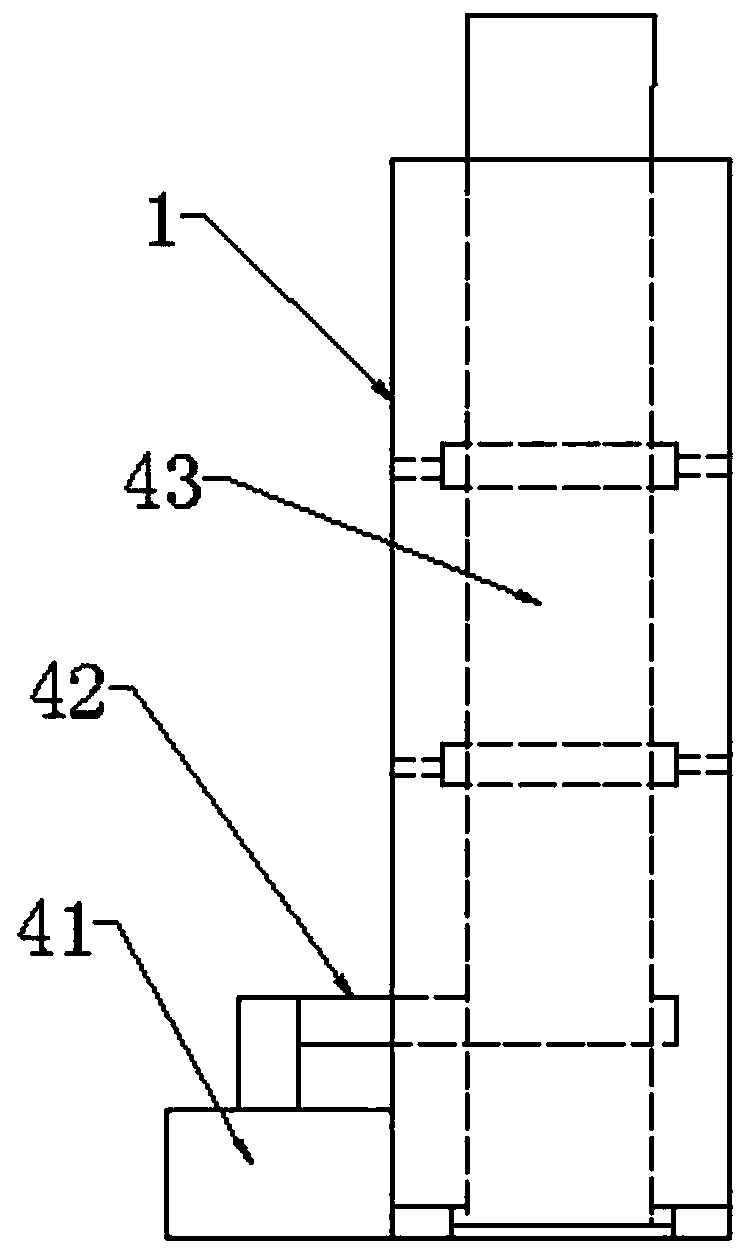

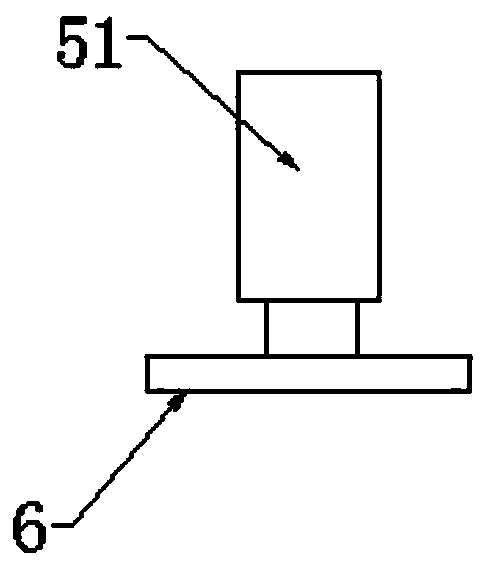

[0027] Such as Figure 1-6 Shown: this embodiment is a kind of manipulator used for the transportation of edible fungus boxes, including a fixed stand 1, a mechanical arm 2 and a mechanical claw 3, the inside of the fixed stand 1 is provided with a rotating mechanism 4, and the lower part of the fixed stand 1 The side is provided with a through hole, the mechanical arm 2 is arranged on the top of the fixed stand 1, one end of the mechanical arm 2 is connected to the fixed stand 1 through the rotating mechanism 4, and the mechanical arm 2 is rotated in a plane through the rotating mechanism 4, and the mechanical arm 2 The lifting drive mechanism 5 is set at the execution end of the lifting drive mechanism 5, the execution end of the lifting drive mechanism 5 is vertically downward, the mechanical claw 3 is fixedly connected with the execution end of the lifting drive mechanism 5, and the mechanical claw 3 is driven by the lifting drive mechanism 5 to move up and down in a straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com