Fruits and vegetables sorting manipulator

A technology for manipulators, fruits and vegetables, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of low production efficiency and high labor input, and achieve the effects of strong practicability, prevention of mechanical damage, and improvement of grasping accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

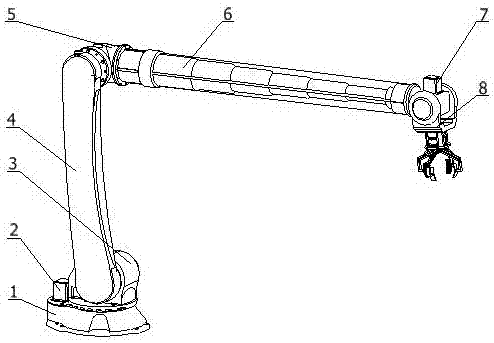

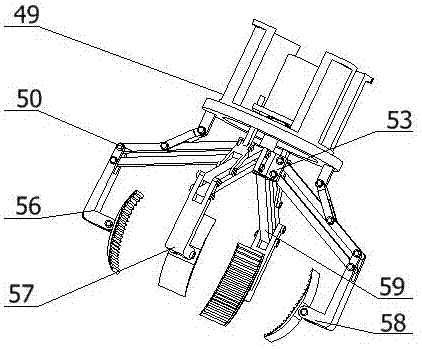

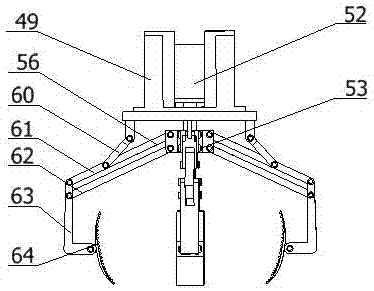

[0041] Embodiment 1: as Figure 1-11 As shown, a fruit and vegetable sorting manipulator is characterized in that it includes a base 1, a shaft transmission device 2, a shaft transmission device 3, a large arm 4, a shaft transmission device 5, a small arm 6, a shaft transmission device 7 and Grabbing claw 8;

[0042] The I shaft transmission device 2 is installed in the base 1, the II shaft transmission device 3 is fastened on the rotating seat 22 of the I shaft transmission device 2, one end of the big arm 4 is installed on the II shaft transmission device 3, and the other end is connected to the III shaft transmission device. The shaft transmission device 5 is connected, the III shaft transmission device 5 is installed on the upper end of the boom 4, one end of the small arm 6 is installed on the III shaft transmission device 5, and the other end is installed on the IV shaft transmission device 7, and the grasping claw 8 is installed on the small arm 6, and is connected wit...

Embodiment 2

[0059] Embodiment 2: as Figure 1-11 As shown, a fruit and vegetable sorting manipulator includes base 1, shaft I transmission device 2, shaft II shaft transmission device 3, big arm 4, shaft III shaft transmission device 5, small arm 6, shaft IV shaft transmission device 7 and grasping gripper 8;

[0060] The I-axis transmission device 2 is installed in the base 1, the II-axis transmission device 3 is firmly installed on the rotating seat 22 of the I-axis transmission device 2, one end of the boom 4 is installed on the II-axis transmission device 3, and the other end is connected to the III-axis transmission device. The device 5 is connected, the III-axis transmission device 5 is installed on the upper end of the boom 4, one end of the small arm 6 is installed on the III-axis transmission device 5, and the other end is installed on the IV-axis transmission device 7, and the grasping claw 8 is installed on the small arm 6 , and is connected with the Ⅳ shaft transmission devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com