End effector of intelligent harvesting robot

An end effector and robot technology, which is applied in the field of harvesting robots, can solve the problems of poor versatility, poor operation effect, and low degree of intelligence, so as to improve the grasping stability, improve the separation method of fruit stems, and improve the general sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

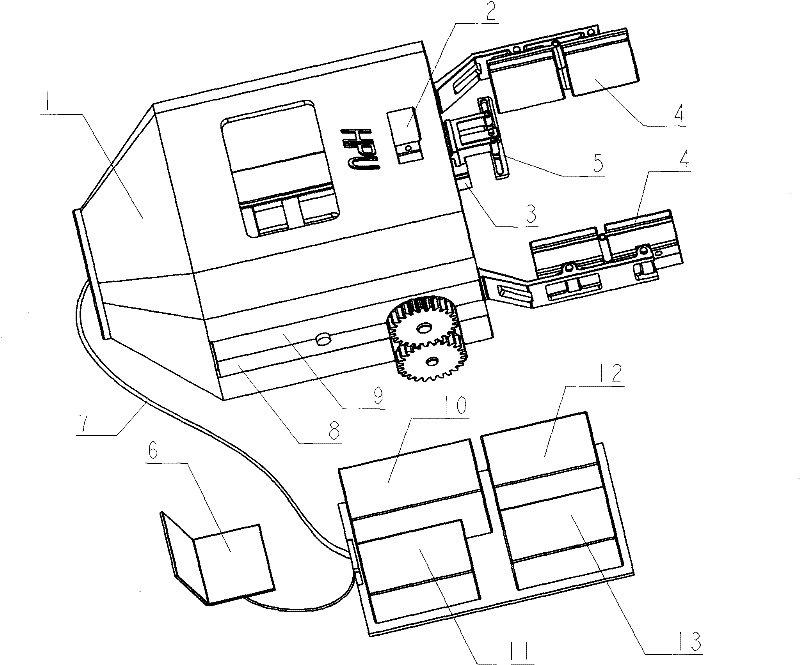

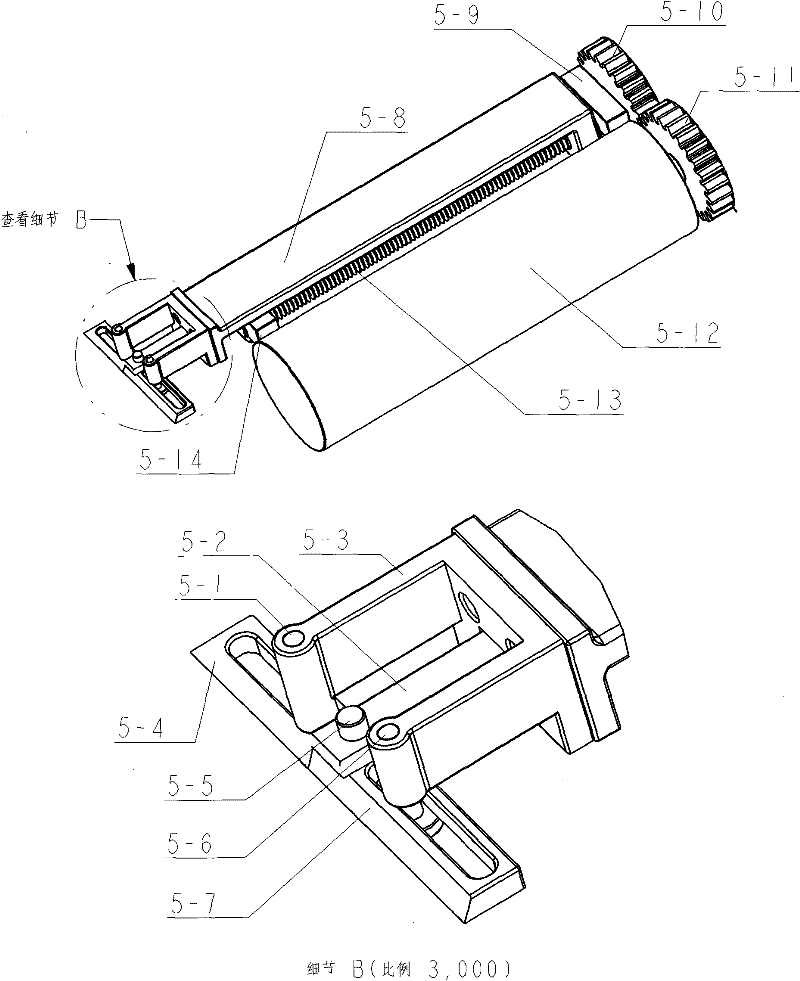

[0010] Intelligent harvesting robot end effector (such as figure 1 ) consists of mechanical system, control system, perception system and power supply system. Wherein the mechanical system is composed of a finger grasping mechanism (4), a stem separation mechanism (5) and a housing support mechanism, and the housing support mechanism includes a housing (1), an upper support body (9) and a lower support body (8) ; The control system is composed of a motion controller (12), a driver (13) and a micro DC servo motor (4-12, 5-12); the power supply system is composed of a lithium battery pack (10) and a voltage stabilizing and transforming module (11) Composition; Perception system is made up of force-sensitive sensor (4-8, 4-14, 4-21 and 4-24), camera (2) and distance sensor (3).

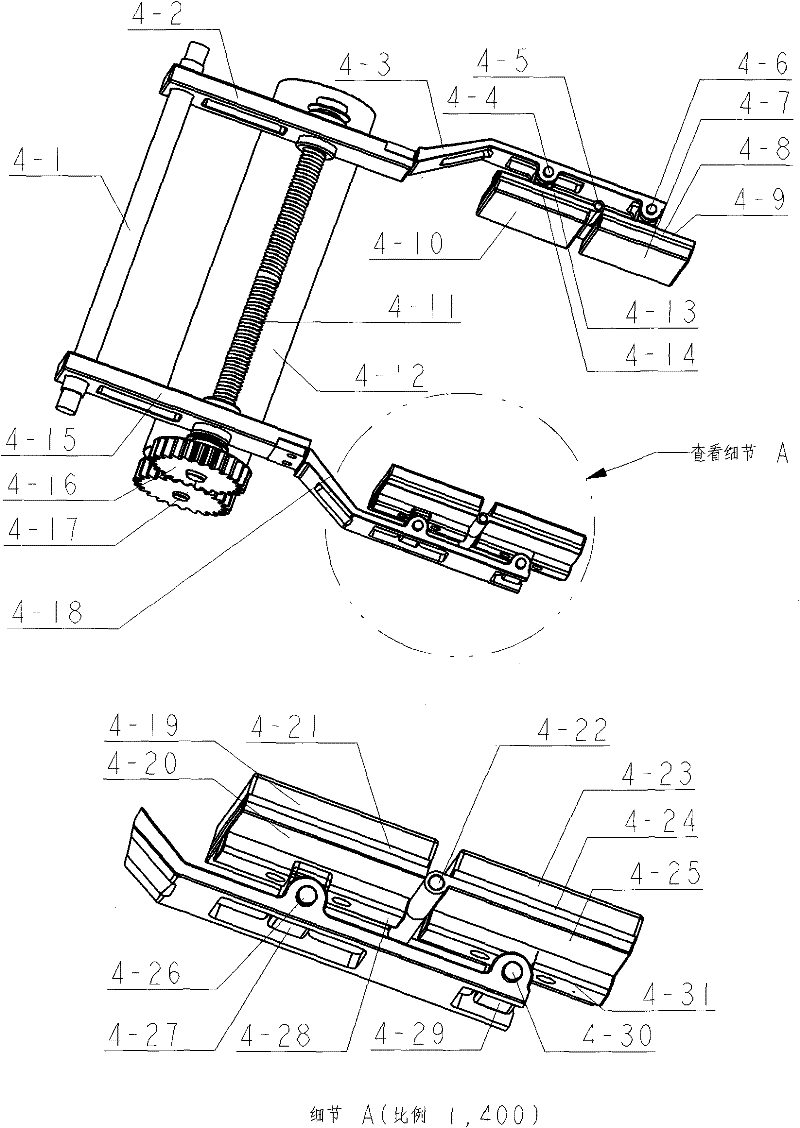

[0011] Finger gripping mechanism (4) such as figure 2 As shown, including support rods (4-1), transmission plates (4-2 and 4-15), connecting plates (4-3 and 4-18), rotating shafts (4-4, 4-5, 4-6 , 4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com