Tail end executing mechanism for picking manipulator

An end-execution and manipulator technology, which is applied in the direction of picking machines, manipulators, agricultural machinery and implements, etc., can solve the problems of inability to judge the position of fruits, bump into other fruits, and unstable grasping force, so as to avoid fruit damage and reduce Good effect on mechanical damage and grasping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

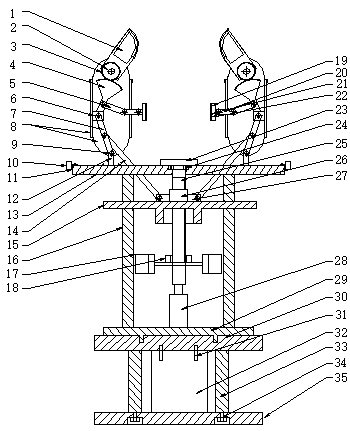

[0028] refer to figure 1 , an end effector of a picking manipulator, comprising: a finger mechanism, a support and transmission mechanism, a drive mechanism and a vision system; the finger mechanism is connected to the support and transmission mechanism, the support is connected to the transmission mechanism and the drive mechanism, and the The vision system and the support are connected with the transmission mechanism.

[0029] according to figure 1, the finger mechanism includes: finger tip 1, pinion shaft 2, pinion 3, sector gear 4, first connecting rod 5, fixing member 6, intermediate connecting rod 7, housing 8, fixing bolt 9, fixing rod 12. Contact plate 19, second connecting rod 20, silica gel pad 21, pressure sensor 22 and driving connecting rod 14; the middle connecting rod 17 of the finger mechanism has 3 holes, and the middle hole is hinged with the driving connecting rod 14, and the two The holes at the end are respectively hinged with the rod at the end of the s...

Embodiment 2

[0035] The terminal actuator of a picking manipulator according to the present invention is divided into a driving part and an executing part according to its working principle; the working principle of the driving part is: the motor 32 drives the screw shaft to rotate, and the screw shaft 25 drives the sliding block 26 moves, and the sliding block 26 is hinged with three drive links 14 to drive it to move together; the rotating block 27 is fixed on the shaft, and the mating disc 15 that cooperates with the rotating block 27 is fixed below the sliding block 26 to jointly complete the rotating action; the execution part is composed of Composed of three finger mechanisms (three finger mechanisms are centrally symmetrical, only two of them are drawn in the figure), the three finger mechanisms have the same configuration, and the three fingers are installed on the tray 13 at an angle of 120° to each other. A finger mechanism is fixed on the tray 13 by a fixed rod 12, and the middle...

Embodiment 3

[0037] The present invention uses the visual system to locate the picking target, and controls the terminal actuator to pick the target fruit through the controller. In the initial state, each finger of the terminal actuator is in an open state, and the screw shaft 25 is driven by the motor 32 to rotate. , the sliding block 26 moves linearly along the vertical direction of the screw shaft 25, and the drive link 14 hinged with the sliding block 26 drives the three fingers to move toward each other; the contact plate 19 is close to the fruit until it touches the fruit, and the sliding block 19 touches the fruit. 26 drives the drive connecting rod 14 to continue to move, thereby making the sector gear 4 in the housing 8 rotate clockwise, driving the pinion 3 meshed with it to rotate counterclockwise, and the rotation of the pinion 3 drives the fingertip 1 to rotate, so as to realize the rotation of the fruit. Hold fast; the surface of the contact plate 19 and the fingertip 1 is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com