Teeth-like self-cleaning top comb for cotton comber

A combing machine and self-cleaning technology, which is applied in the direction of combing machines, textiles and papermaking, fiber processing, etc., can solve the problems of reducing work efficiency and performance, and achieve the effect of improving quality, improving quality, and increasing carding length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

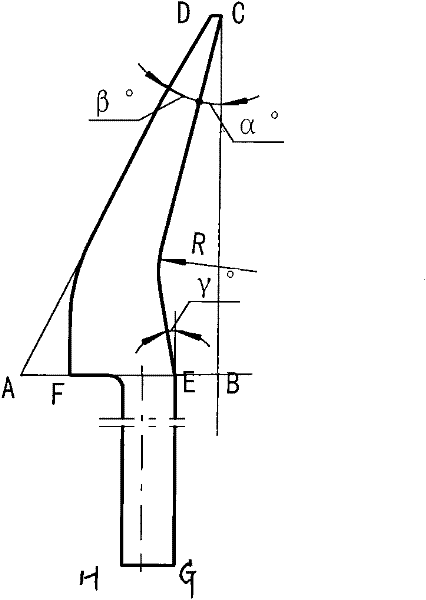

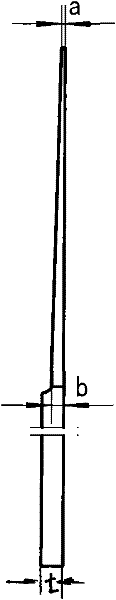

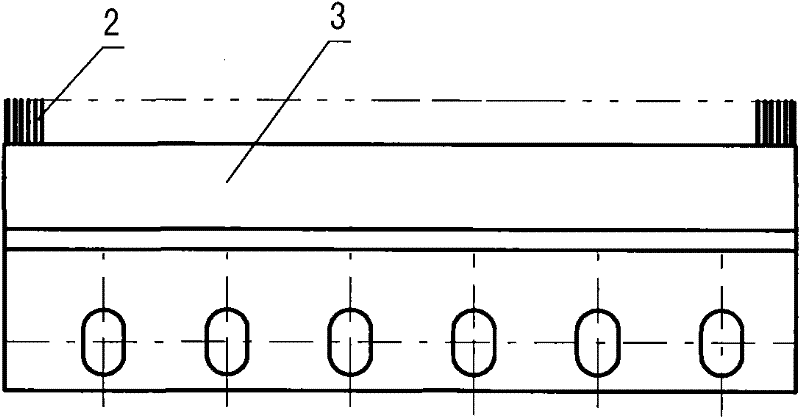

[0023] A toothed self-cleaning top comb for cotton combing machines, which includes a straight plate 1, a toothed plate 2 and a curved plate 3, a row of toothed plates 2 are connected between the straight plate 1 and the curved plate 3, and the toothed plates 2 are selected from high-quality High-carbon structural steel, the surface of the gear piece is polished, the roughness is Ra0.4μm, and the heat treatment hardness is HV740±40. The cross section of gear piece 2 is wedge-shaped, where ∠α is 12°, ∠β is 18°, and ∠γ is 10°. The CEs are connected by circular arcs. The R value is 2.5mm. The CE cutting edge is clear and free of burrs. CD value is 0.2 0 -0.05 mm, the BC value of the working height of the tooth piece section is 5.5±0.015mm. This excellent tooth structure, in addition to having excellent carding performance, the short fibers, neps and impurities that are combed are not easy to accumulate and fall, and it can also prevent combing The short staples and neps that co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com