Method for preparing composite material through ionic liquid modified carbon nano tube

A technology of ionic liquids and composite materials, which is applied in the field of carbon nanotube dispersion and carbon nanotube composite materials, can solve the problems of migration and exudation of ionic liquids, reduction of material structure and performance, and performance degradation of composite materials, etc., to achieve environmental compatibility , enhance interface bonding, improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

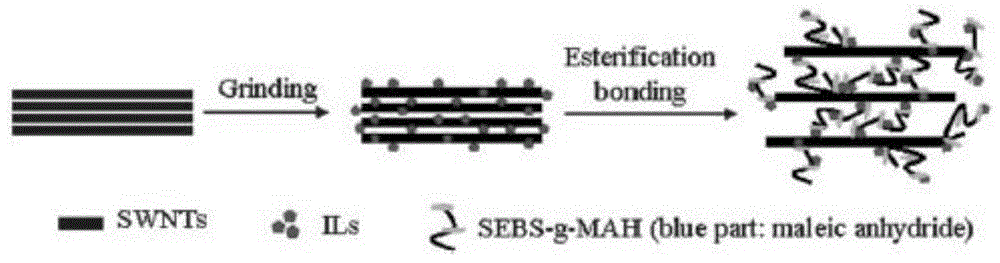

[0039] Weigh 50 mg of carbon nanotubes (CNTs) and 100 mg of ionic liquid containing reactive group hydroxyl (-OH), mix them in an agate mortar, and grind them thoroughly for 30 minutes to obtain ionic liquid-modified carbon nanotubes (labeled as IL- CNTs). 250mg of maleic anhydride-grafted PP was dissolved in 100ml of toluene to form a solution. Add the above-mentioned ionic liquid modified carbon nanotubes (IL-CNTs) to the prepared PP toluene solution, add 5mg DMAP, 15mgEDC, pass into N 2After 30 minutes of air protection, the temperature was raised to 60° C., and the reaction was performed under magnetic stirring for 24 hours under a nitrogen atmosphere. After cooling to room temperature, a large amount of methanol solution was added to obtain a black precipitate, which was centrifuged at 3000 rpm to obtain a composite material (carbon nanotube filling amount 20 wt%).

Embodiment 2

[0041] Weigh 37.5mg CNTs and 75mg containing reactive group amine (-NH 2 ) ionic liquid, mixed in an agate mortar, and fully ground for 30 minutes to obtain ionic liquid-modified carbon nanotubes (marked as IL-CNTs). 250mg of maleic anhydride-grafted PP was dissolved in 100ml of toluene to form a solution. The above-mentioned ionic liquid modified carbon nanotubes (IL-CNTs) were added to the prepared PP toluene solution, 5 mg DMAP, 15 mg EDC were added, and N 2 After 30 minutes of air protection, the temperature was raised to 60° C., and the reaction was performed under magnetic stirring for 24 hours under a nitrogen atmosphere. After cooling to room temperature, a large amount of methanol solution was added to obtain a black precipitate, which was centrifuged at 3000 rpm to obtain a composite material (carbon nanotube filling 15 wt%).

Embodiment 3

[0043] Weigh 25mg of CNTs and 50mg of amine containing reactive groups (-NH 2 ) ionic liquid, mixed in an agate mortar, and fully ground for 30 minutes to obtain ionic liquid-modified single-walled carbon nanotubes (marked as IL-CNTs). 250mg of maleic anhydride-grafted PP was dissolved in 100ml of toluene to form a solution. The above-mentioned ionic liquid modified carbon nanotubes (IL-CNTs) were added to the prepared PP toluene solution, 5 mg DMAP, 15 mg EDC were added, and N 2 After 30 minutes of air protection, the temperature was raised to 60° C., and the reaction was performed under magnetic stirring for 24 hours under a nitrogen atmosphere. After cooling to room temperature, a large amount of methanol solution was added to obtain a black precipitate, which was centrifuged at 3000 rpm to obtain a composite material (carbon nanotube filling 10 wt%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com