Integrated cleaning equipment for water conservancy diversion canal

A technology for cleaning equipment and water channels, applied in the field of integrated cleaning equipment for water diversion channels, can solve the problems of removal, easy adhesion of impurities, poor cleanliness of the inner walls on both sides of water diversion channels, etc., to achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

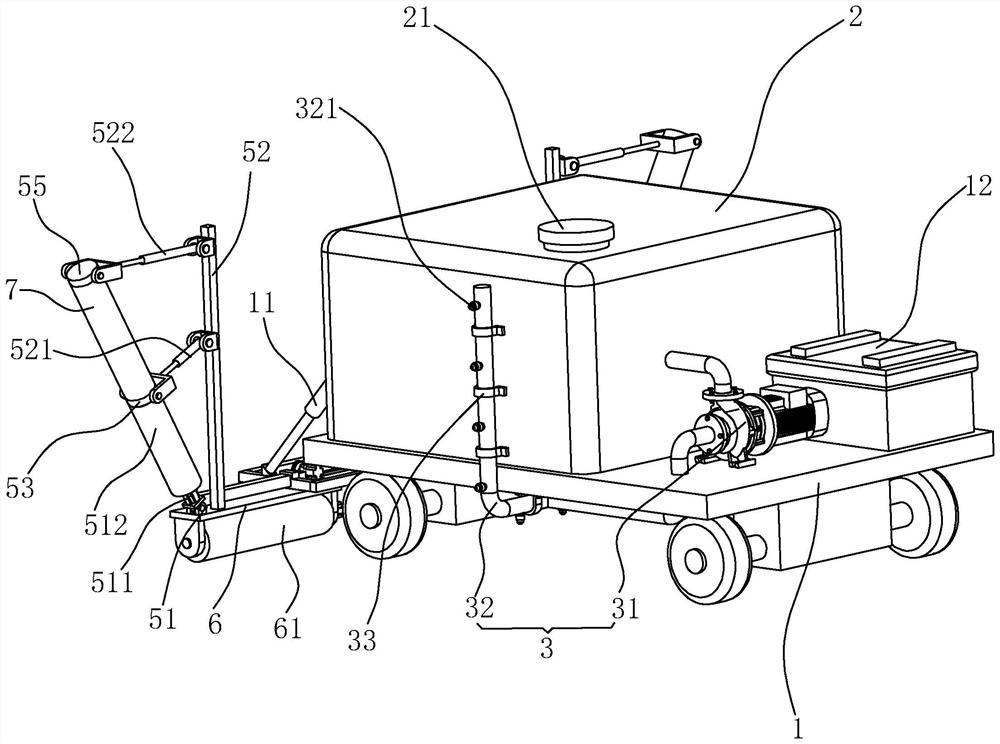

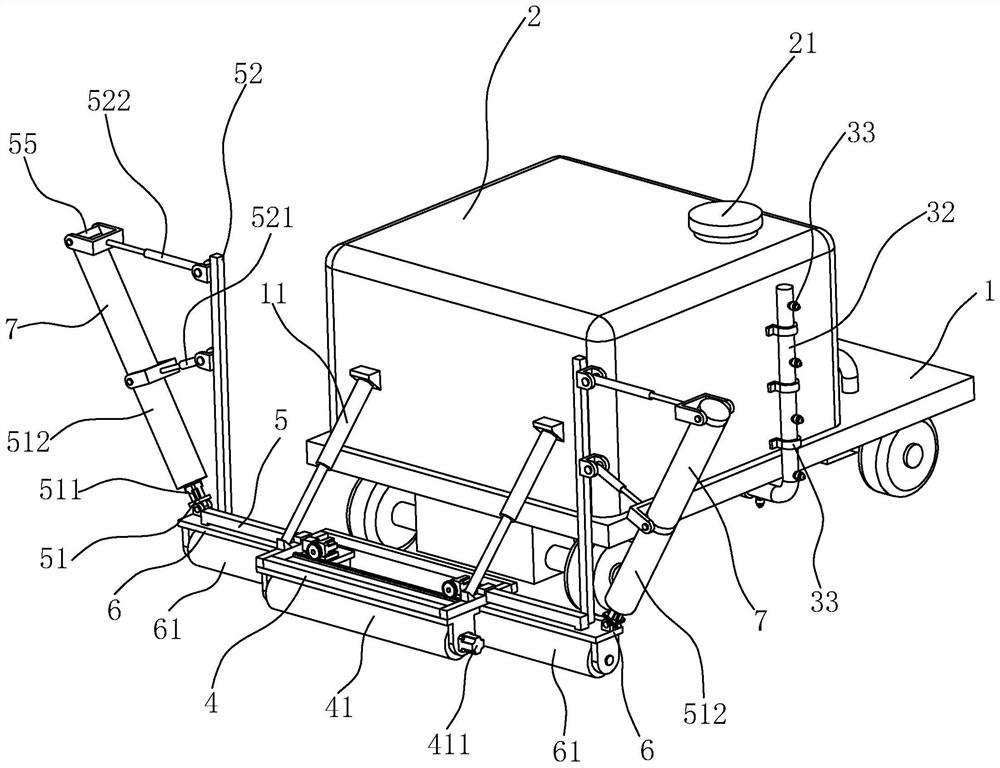

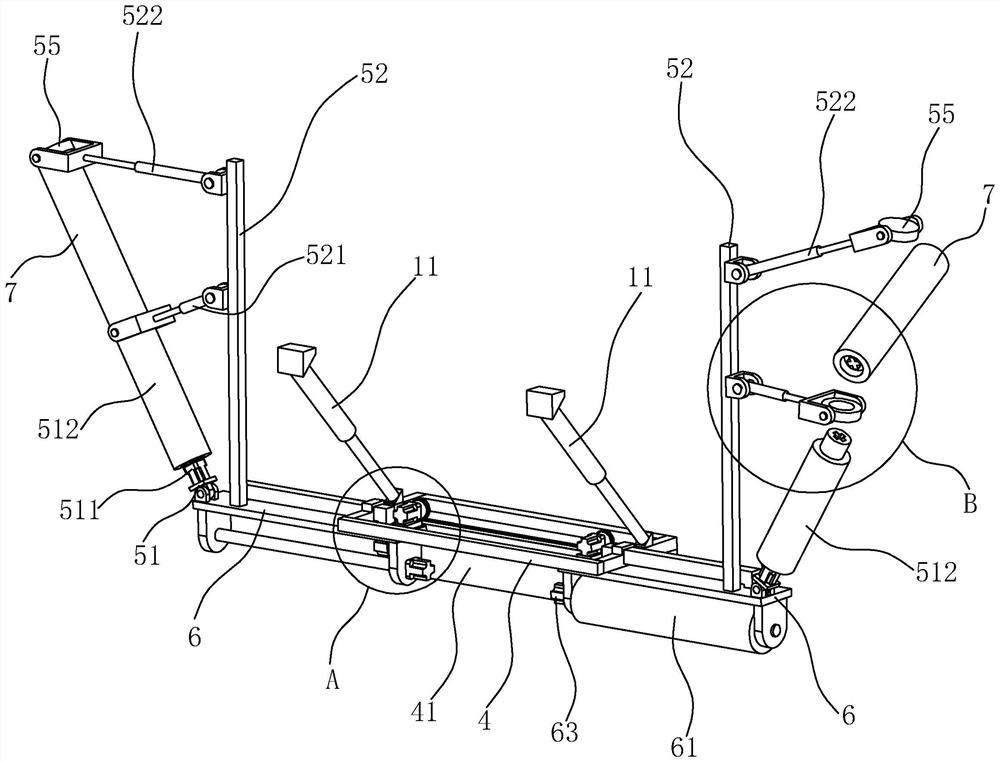

[0028] The following is attached Figure 1-6 The application is described in further detail.

[0029] The embodiment of the present application discloses an integrated cleaning device for a water conservancy diversion canal. refer to figure 1 , this kind of cleaning equipment includes a trolley 1 and a water tank 2 installed on the trolley 1 for loading water bodies, the trolley 1 is a flat plate 6-car structure; the water tank 2 is fixed on the upper end surface of the trolley 1, the water tank 2 is a cuboid, and the width of the water tank 2 is less than The width of the trolley 1; the horizontal upper end surface of the water tank 2 is provided with a cover plate 21, which is convenient for injecting water into the water tank 2 through the cover plate 21.

[0030] The rear of the trolley 1 is equipped with a spraying device 3, and the spraying device 3 continuously sprays the water body inside the water tank 2 to the inner bottom surface and the inner walls of both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com