Method for calibrating drill hole of circuit board

A calibration method and circuit board technology, which is applied in metal processing and other directions, can solve the problems of low production efficiency of circuit boards, achieve the effects of reducing drill bit swing, precise drilling position, and reducing hole-entry burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

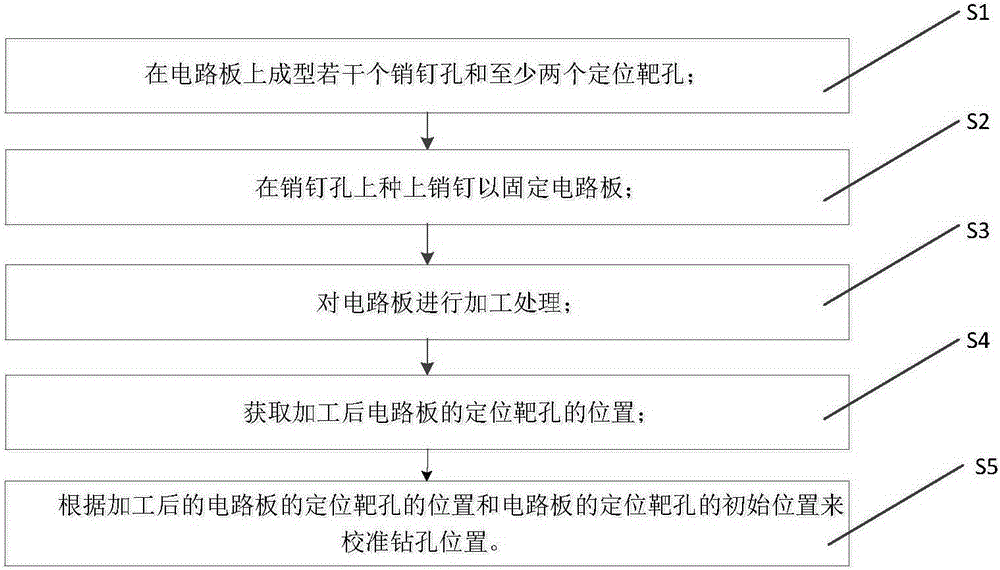

[0047] This embodiment provides a circuit board drilling calibration method, such as figure 1 shown, including the following steps,

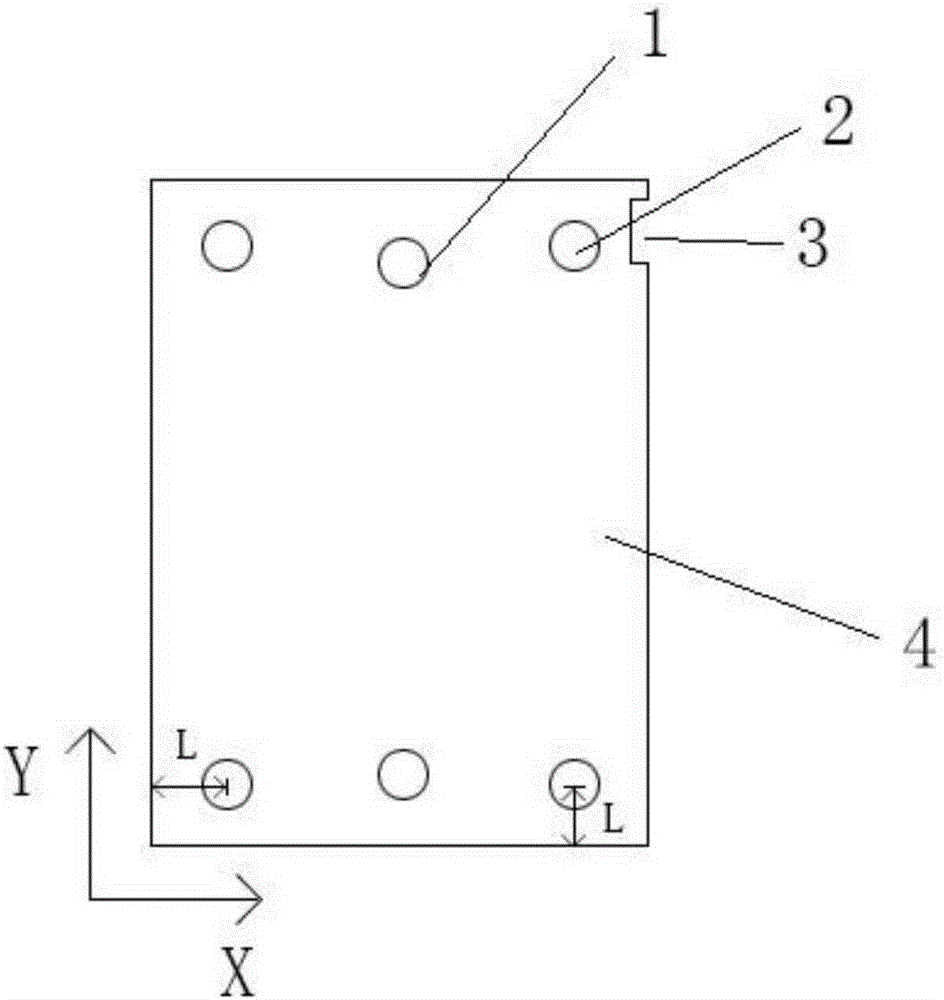

[0048] S1: forming several pin holes 1 and at least two positioning target holes 2 on the circuit board, see figure 2 ;

[0049] S2: Plant a pin on the pin hole 1 to fix the circuit board;

[0050] S3: process the circuit board;

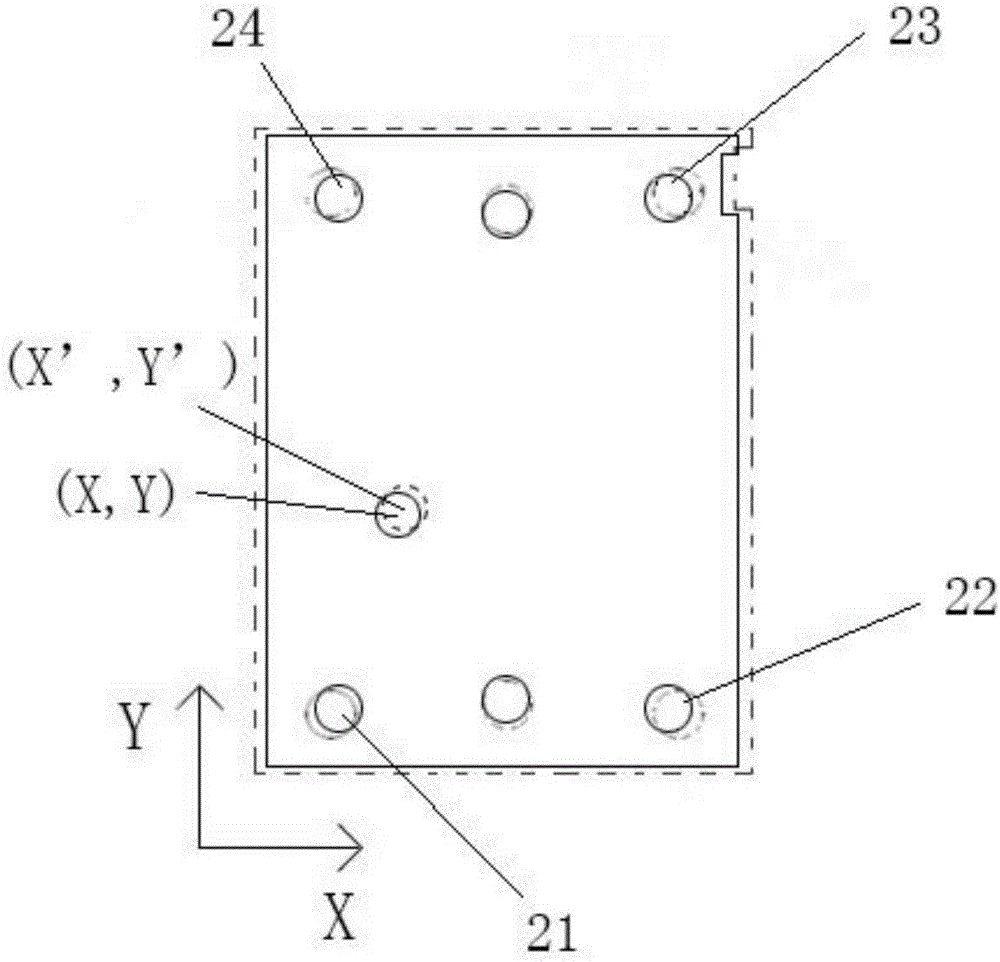

[0051] S4: obtain the position of the positioning target hole 2 of the circuit board after processing, such as image 3 shown;

[0052] S5: Calibrate the drilling position according to the position of the positioning target hole 2 of the processed circuit board and the initial position of the positioning target hole 2 of the circuit board.

[0053] The above-mentioned technical solution is the core technical solution of the present invention. It forms pin holes on the circuit board and fixes the circuit board through the pins, and then drills by obtaining the position data of the target hole 2 after the deformation...

Embodiment approach

[0055] As a preferred embodiment, the S1 step may include:

[0056] S11: a pad (PAD) corresponding to the prefabricated position of the pin hole 1 and the positioning target hole 2 is set on the circuit board;

[0057] S12: determine the pad position;

[0058] S13: Drill out the pin hole 1 and the positioning target hole 2 at the pad position.

[0059] The above steps S11-S13 can be applied to a single-layer circuit board or a multi-layer circuit board. For a common multi-layer circuit board, pads can be provided on the inner layer of the circuit board, and the pin hole 1 and the positioning target can be calibrated through the pads For the forming position of hole 2, the outer layer is laminated on the inner layer to form a multi-layer circuit board, and the position of the pad is determined by the X-ray target machine, which can accurately locate the drilling position of the pin hole 1 and the target hole 2, and prevent the hole after lamination. Drilling positions for pin...

Embodiment 2

[0090] This embodiment provides a circuit board drilling method, using the circuit board drilling calibration method described in Embodiment 1 to calibrate the drilling position before drilling; and then drilling the calibrated drilling position.

[0091] In this embodiment, the circuit board drilling calibration method as in Embodiment 1 is used before drilling, so it has the advantages as described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com