Drilling positioning mold based on clamping piece of transformer

A technology for clamping parts for transformers and positioning molds, which is applied to the drilling molds for workpieces and other directions, can solve the problems of large deviation of workpiece drilling positions, low production efficiency, labor-intensive and other problems, and achieves simple channel steel clamping and improved production efficiency. , The effect of accurate drilling position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

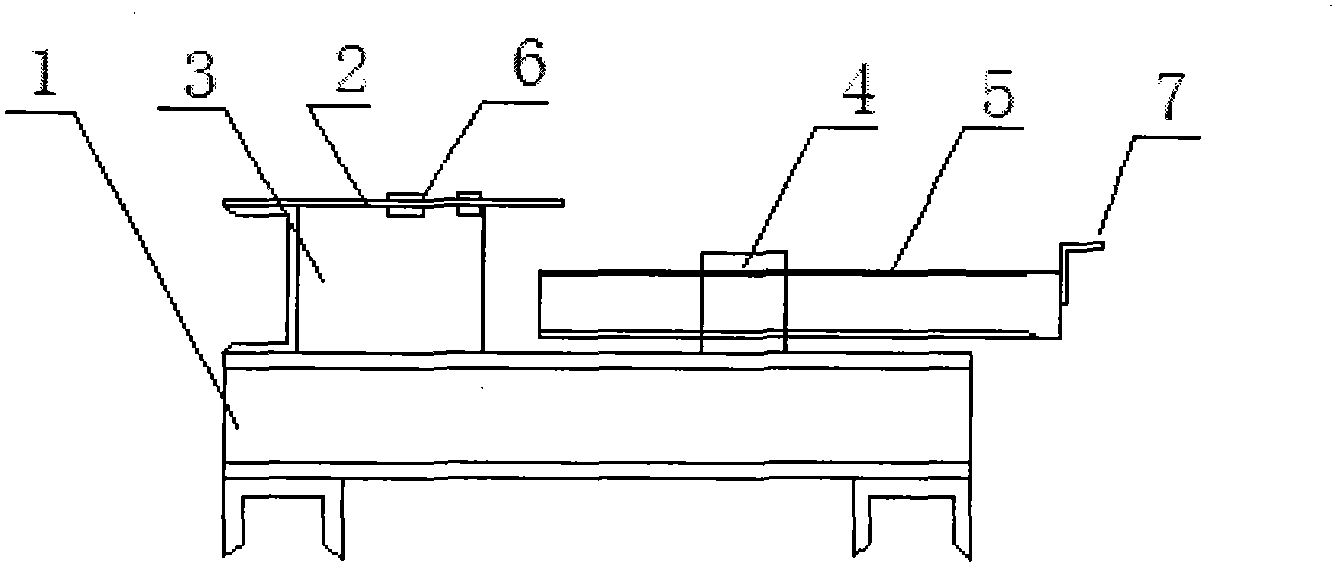

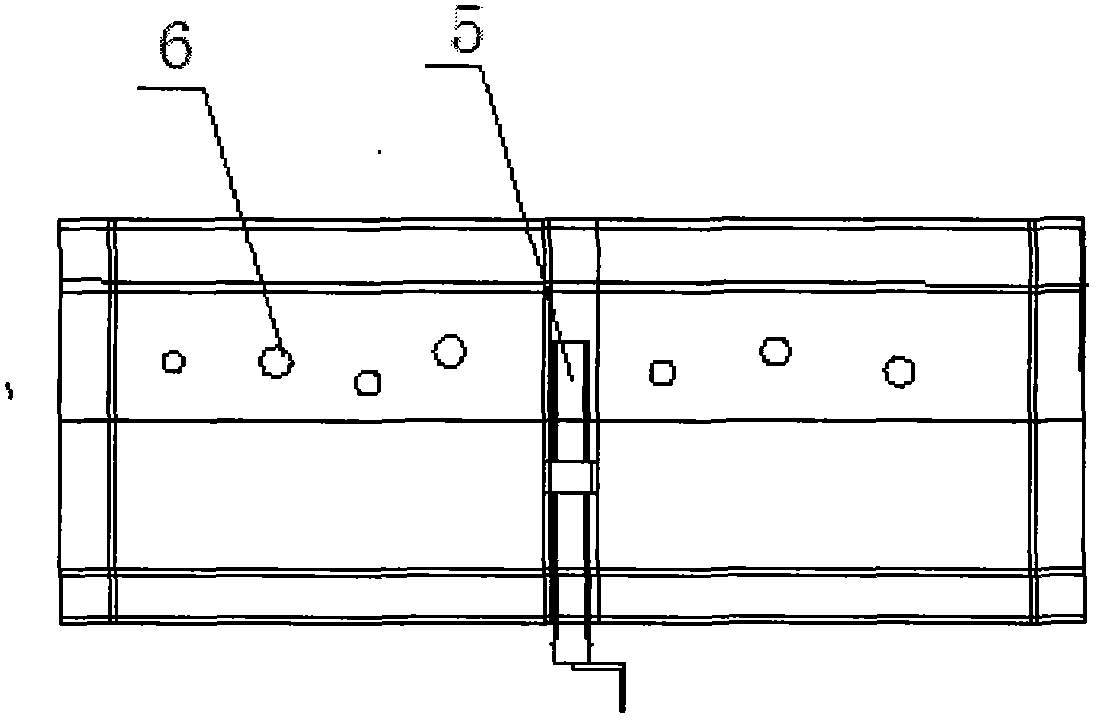

[0012] Embodiment one: if figure 1 , 2 As shown, the drilling positioning mold includes a base 1, a drill sleeve template 2, a positioning baffle plate 3, a bolt fixing seat 4, and a tightening bolt 5. The base 1 is provided with a drill sleeve template 2, a positioning baffle plate 3, and a bolt fixing seat 4. The drill sleeve template 2 is provided with a plurality of positioned drill sleeve holes 6, the bolt fixing seat 4 is provided with a jacking bolt 5, and the rear end of the jacking bolt 5 is provided with a handle 7. When in use, place the channel steel between the positioning baffle plate 3 and the jacking bolt 5 on the base 1, turn the handle 7 on the jacking bolt 5, so that the channel steel is clamped between the jacking bolt 5 and the positioning baffle plate 3 At this time, the drill sleeve hole 6 on the drill sleeve template 2 on the top of the channel steel just in time positions the drilling position of the channel steel, and the drill bit drills the channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com