Round pipe drilling assisting device

A technology of auxiliary device and round tube, which is applied in drilling/drilling equipment, parts of boring machine/drilling machine, measurement of positioning in boring machine/drilling machine, etc. It can solve the difficulties of processing and clamping, poor positioning, and drill bit slippage and other problems, to achieve the effect of accurate drilling position, lower production cost and avoid deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

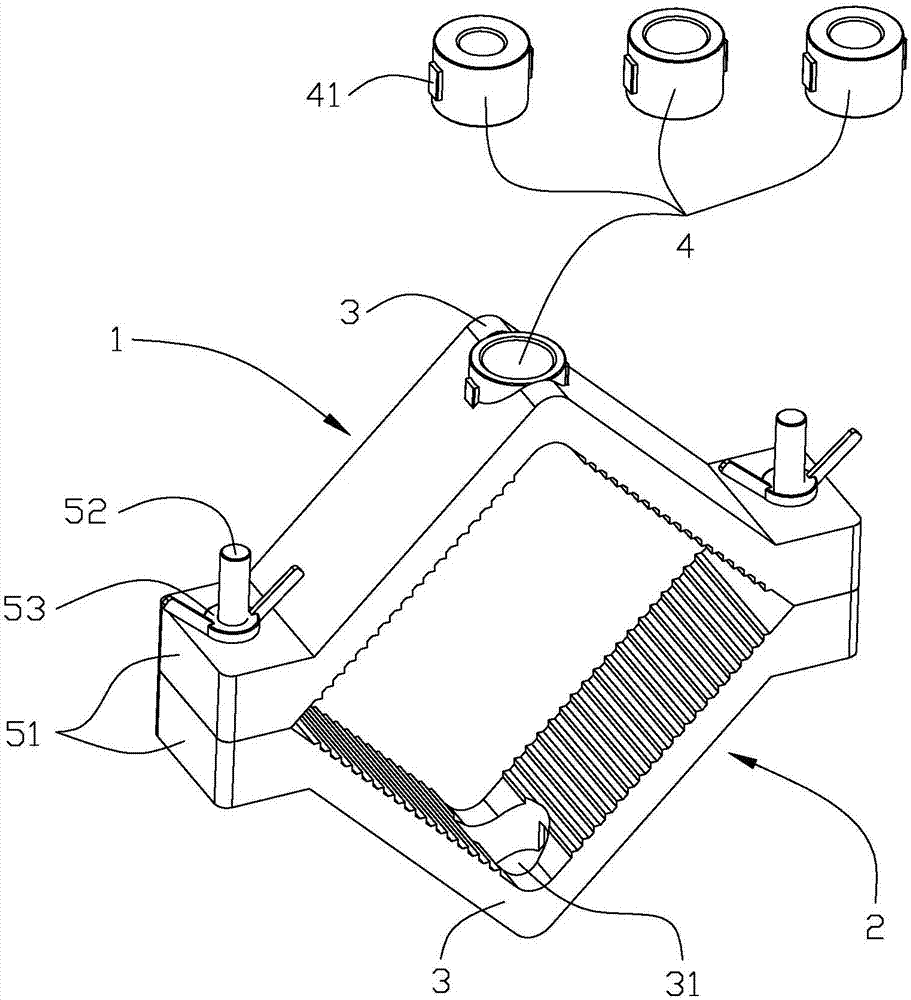

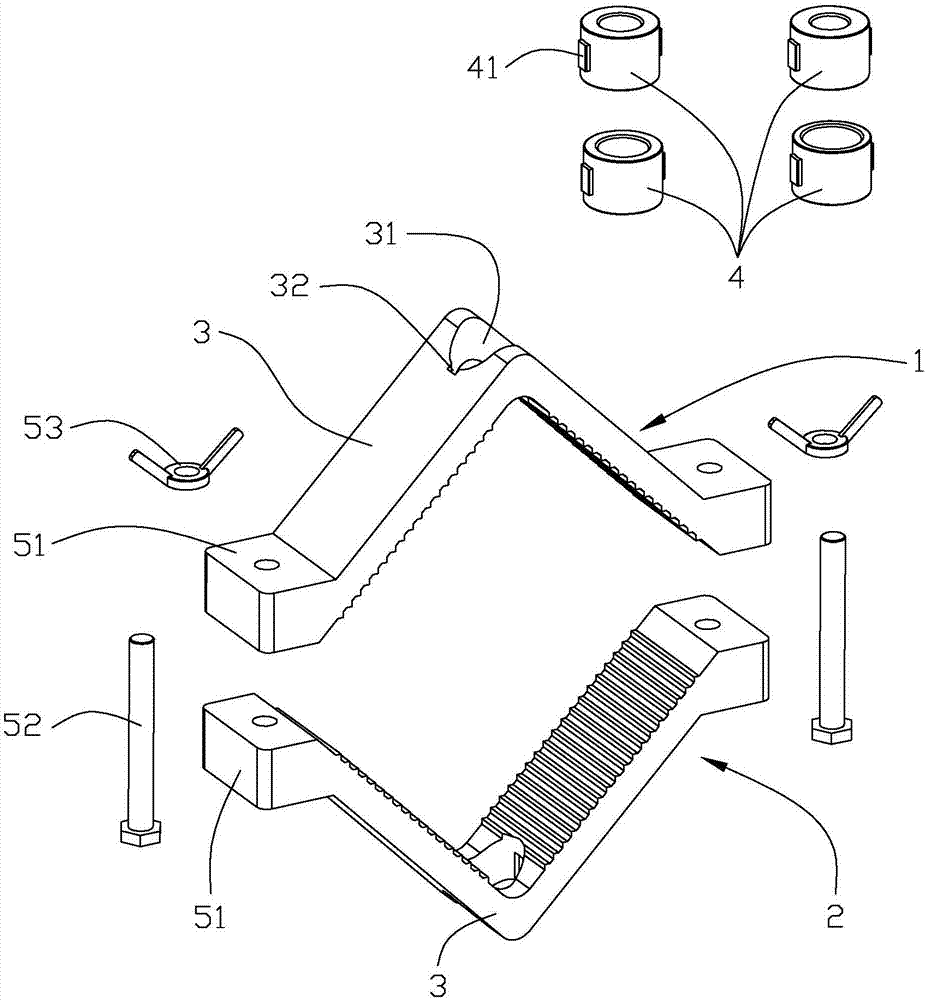

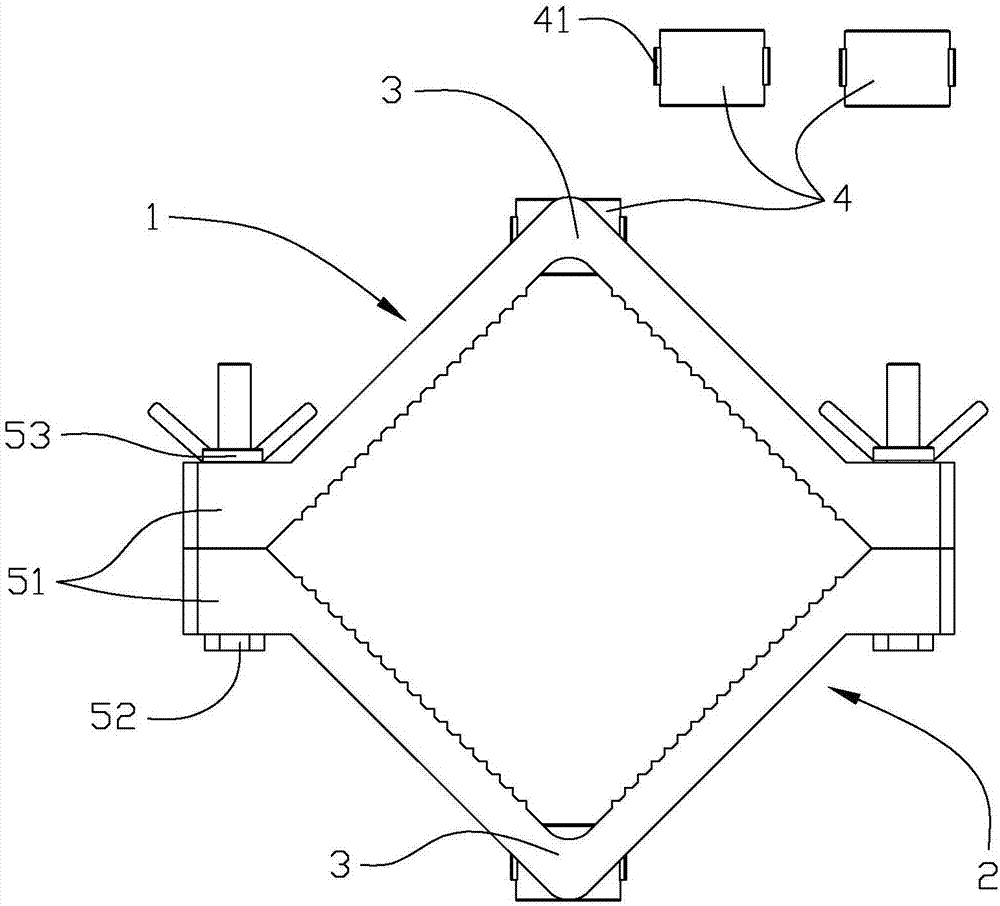

[0019] refer to Figure 1 ~ Figure 3 , a round pipe drilling aid, including an upper locking part 1 and a lower locking part 2, the middle part of the upper locking part 1 and the lower locking part 2 is provided with a splint 3 bent at a right angle, two The two splints 3 are relatively arranged to form a square hole for clamping the round pipe. The inner side of the splint 3 is provided with anti-slip lines, and the left and right ends of the upper locking part 1 and the lower locking part 2 are respectively provided with locks. tightening mechanism so that the two clamp the round tube. In this embodiment, preferably, the locking mechanism includes mounting seats 51 and bolts arranged at the left and right ends of the upper locking part 1 and the lower locking part 2 52 and a nut 53, the middle part of the mounting seat 51 is provided with a through mounting hole, the bolt 52 passes through the mounting hole and then connects the nut 53, and the upper locking part 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com