Palings or fence production line capable of achieving full-automatic threading

A production line, fully automatic technology, applied in mechanical equipment, sugarcane machining and other directions, can solve the problems of reduced fence durability and flexibility, no fence durability, flexibility, high fence production cost, and achieves simple process, high degree of automation, High straightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

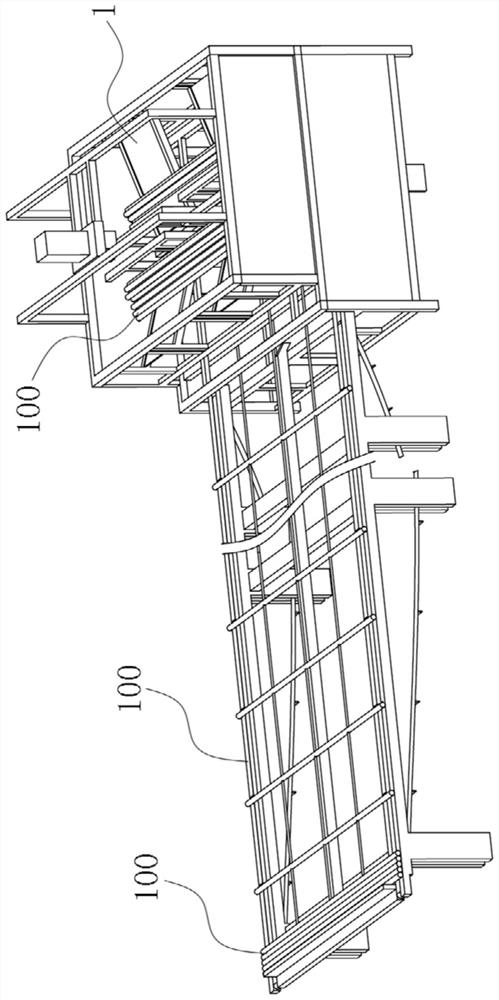

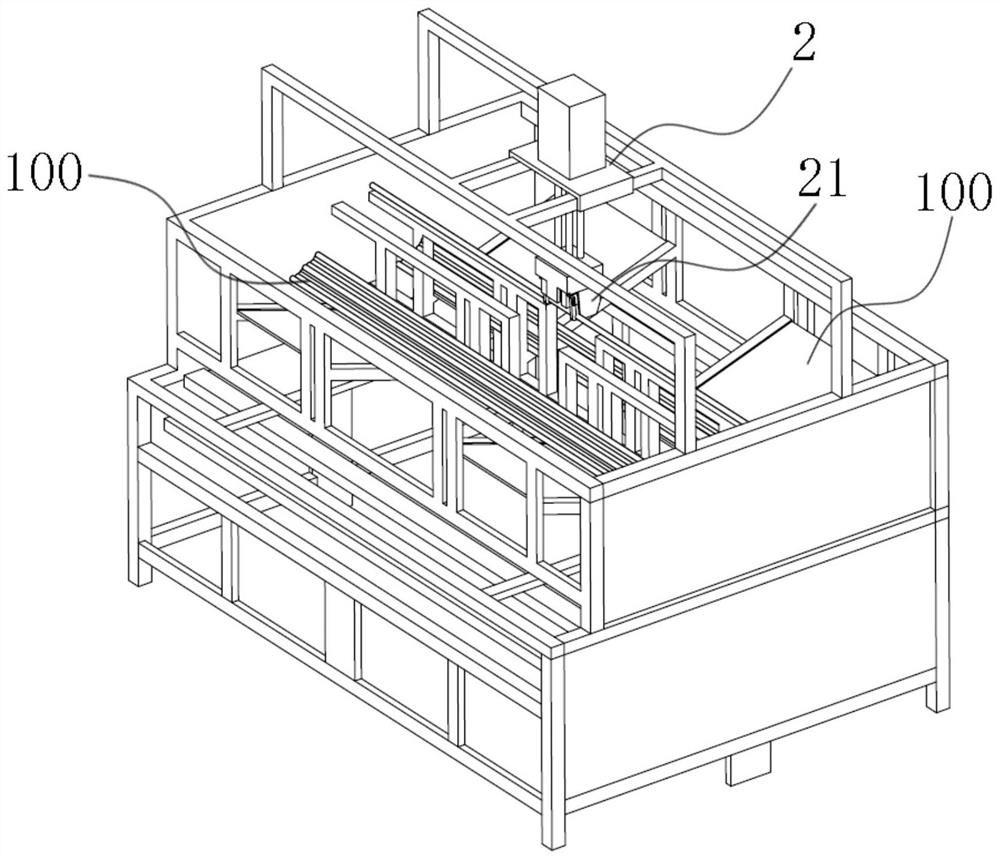

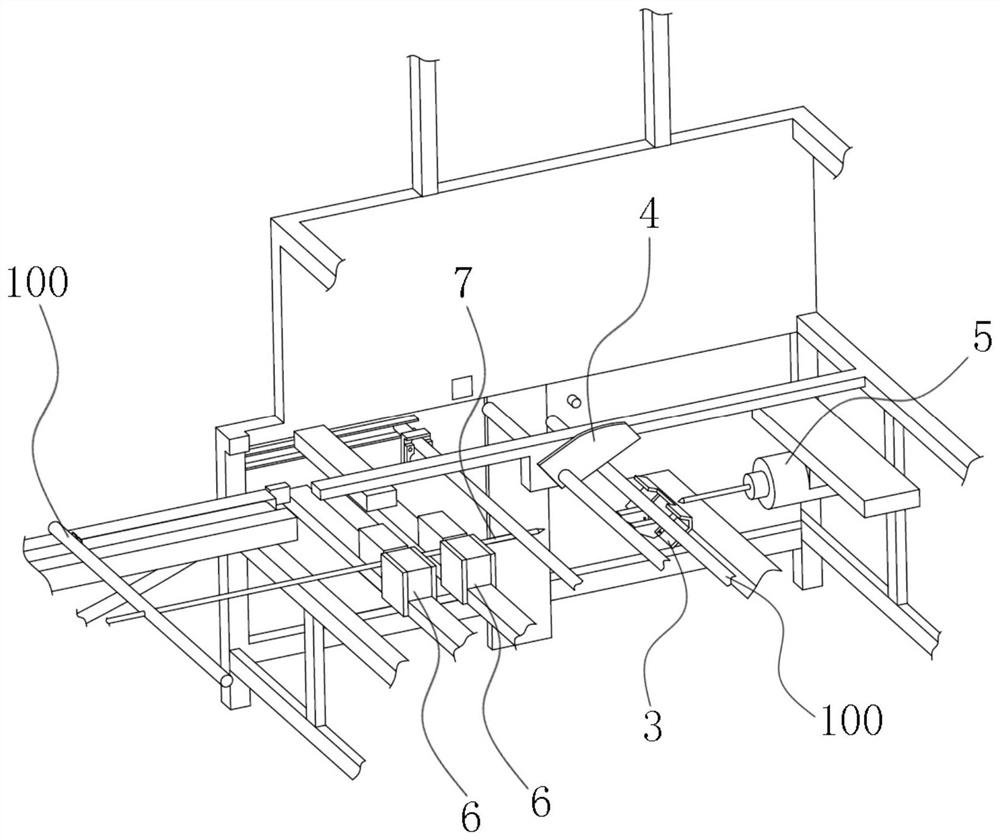

[0060]Such asFigure 4 ,Figure 5 ,Image 6 As shown, the working mode of the fully automatic fence or fence production line of the present invention is as follows:

[0061]After storing a number of bamboo poles 100 in the storage table, pneumatic equipment, the pneumatic gripper of the grasping mechanism starts to work, first grabs the bamboo pole 100 of one of the storage tables and returns to the center, the pneumatic gripper is released, and the bamboo pole 100 falls to the material shifting mechanism Then, the bamboo pole 100 is moved to the first clamp mechanism 3 at the front and bottom through the paddle on the material changing mechanism. At this time, the brush of the alignment mechanism starts to rotate (it needs to be explained that the direction of rotation of the brush It can be clockwise or counterclockwise) to move the bamboo pole 100 closer to one side. After this action is completed, the pressing piece of the material pressing mechanism 4 rotates downward and presses aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com