Glass drilling machine performing firm positioning and clamping

A drilling equipment and glass technology, applied in the direction of stone processing equipment, stone processing tools, work accessories, etc., can solve the problems of inability to realize quick loading and unloading of plates, glass drilling work, unstable glass fixing, etc. The effect of area reduction, product quality improvement, and requirement reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

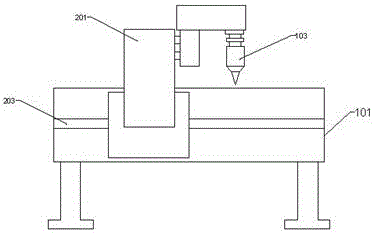

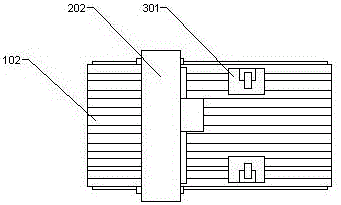

[0014] A glass drilling equipment for firm positioning and clamping, comprising a machine bed 101, a conveyor belt 102 arranged on the machine bed 101 for supporting and transporting glass to be drilled, and a drilling machine 103 for drilling glass. The body 101 is provided with a feed end and a discharge end, and the conveying direction of the conveyor belt 102 is consistent with the direction of the length of the machine bed 101. The drilling rig 103 used for drilling glass is a general drilling rig 103 on the market, which can reach The purpose of drilling the glass is enough, so I won’t discuss it too much here.

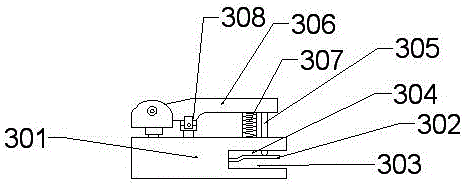

[0015] It also includes a displacement unit that carries and drives the drilling machine 103 to adjust the drilling position, and a fixing unit that fixes the glass. The displacement unit includes a column 201 and a beam 202. There are multiple transverse guide rails parallel to each other on both sides of the machine bed 101. The column There is a chute at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com