Positioning fixture for steel rail drilling

A technology for positioning fixtures and rails, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of complicated drilling procedures and low processing efficiency, and achieve the effects of convenient clamping, improved processing efficiency, and simple drilling procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

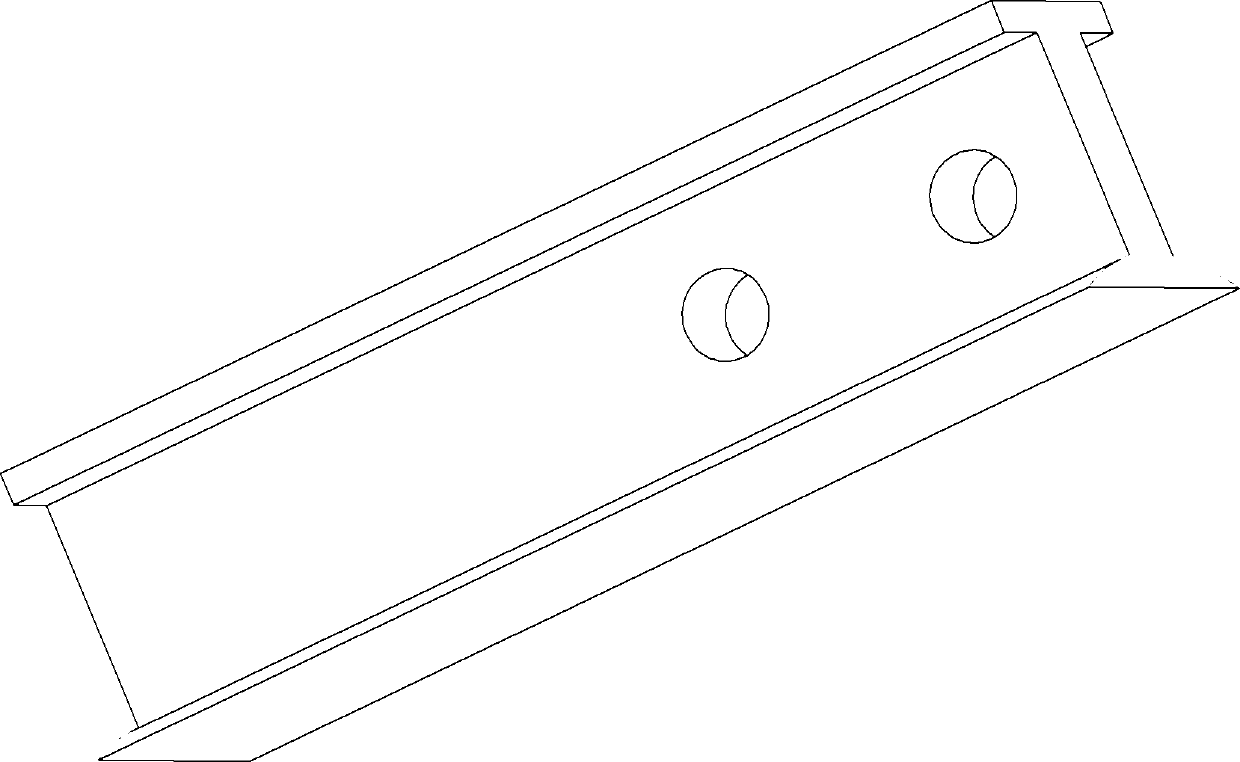

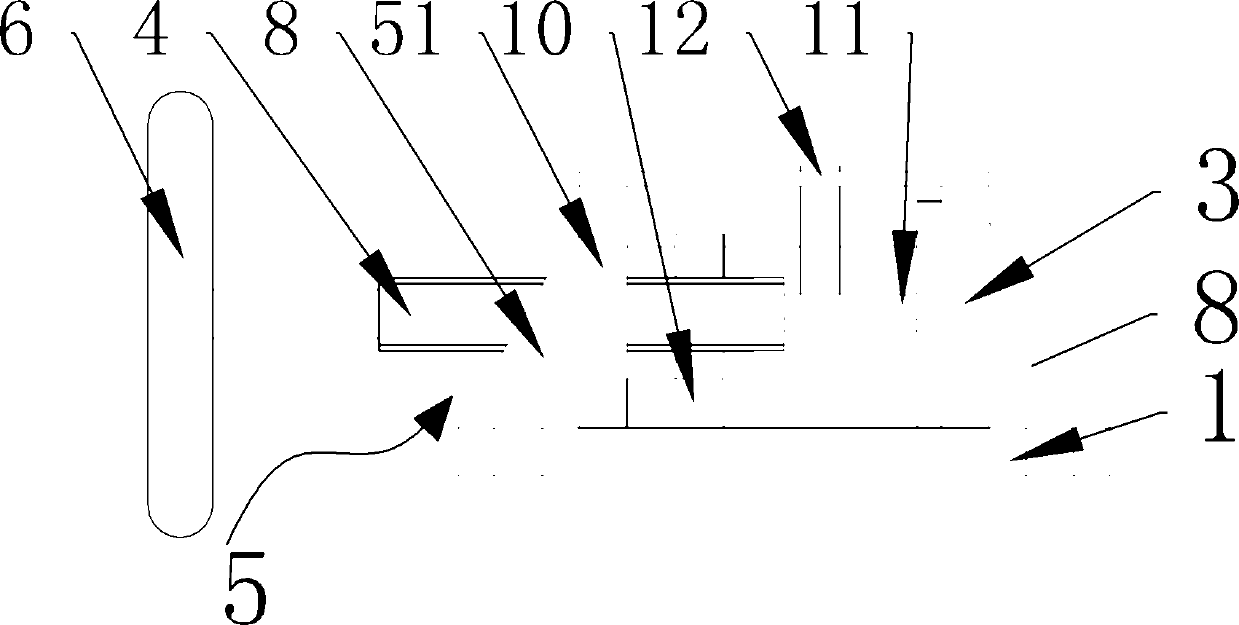

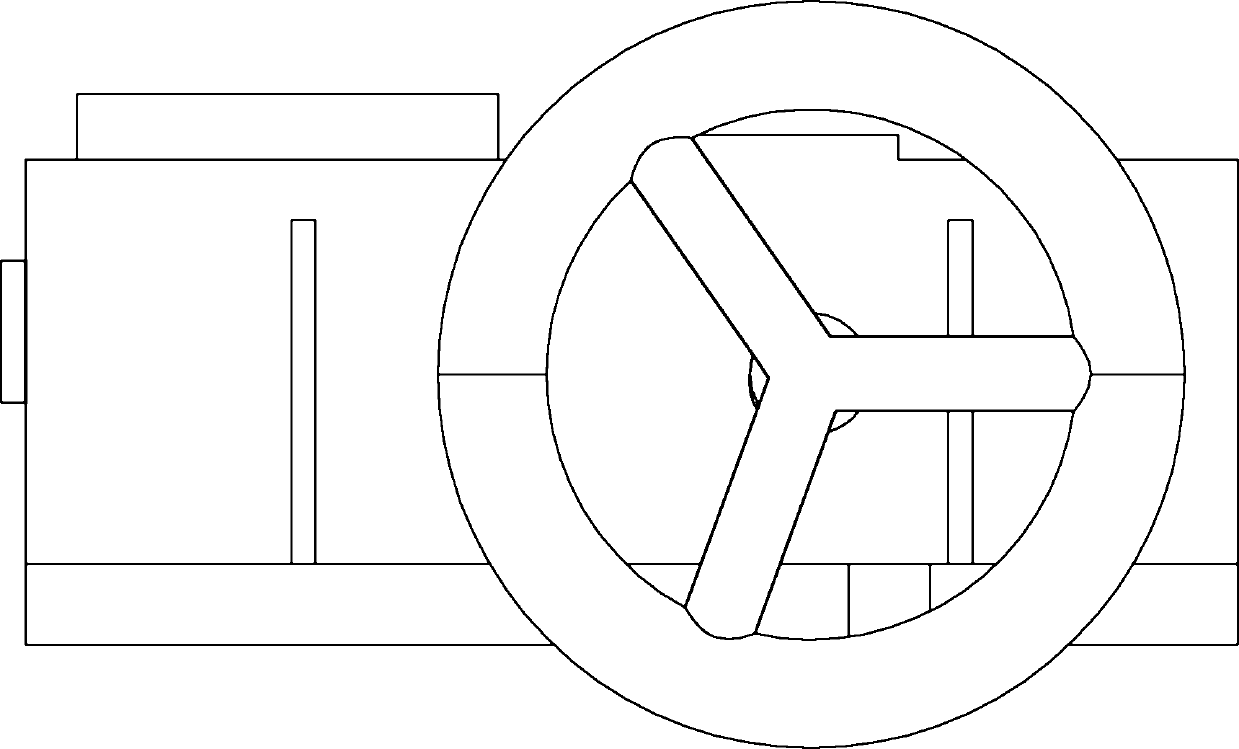

[0025] An embodiment of a rail drilling positioning fixture, such as Figure 1-3 As shown, it includes a base plate 1 for placing rails. The four corners of the base plate 1 are provided with U-shaped notches 9 for fixed connection with drill press screws, and the upper surface of the base plate 1 is provided with clamps for clamping the rails from both sides. mechanism, the clamping mechanism includes a fixed clamping block 3 which is welded and fixedly arranged on one side of the upper surface of the bottom plate 1 perpendicular to the bottom plate, a movable clamping block 4 which is set on the other side of the upper surface of the bottom plate 1, and a movable clamping block for driving The clamping block 4 moves toward and away from the fixed clamping block 3 to increase or decrease the distance between the two clamping blocks to loosen or clamp the driving mechanism 5 of the rail. The fixed clamping block 3 There are reinforcing ribs 8 welded between the outer side and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com