Drilling rig

A technology for drilling jigs and products, which is applied in the direction of drilling/drilling equipment, manufacturing tools, boring machines/drilling machine components, etc. It can solve the problems of large drilling diameter, large roundness tolerance, and inaccurate drilling position, etc. problem, to achieve the effect of accurate drilling position, accuracy and roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

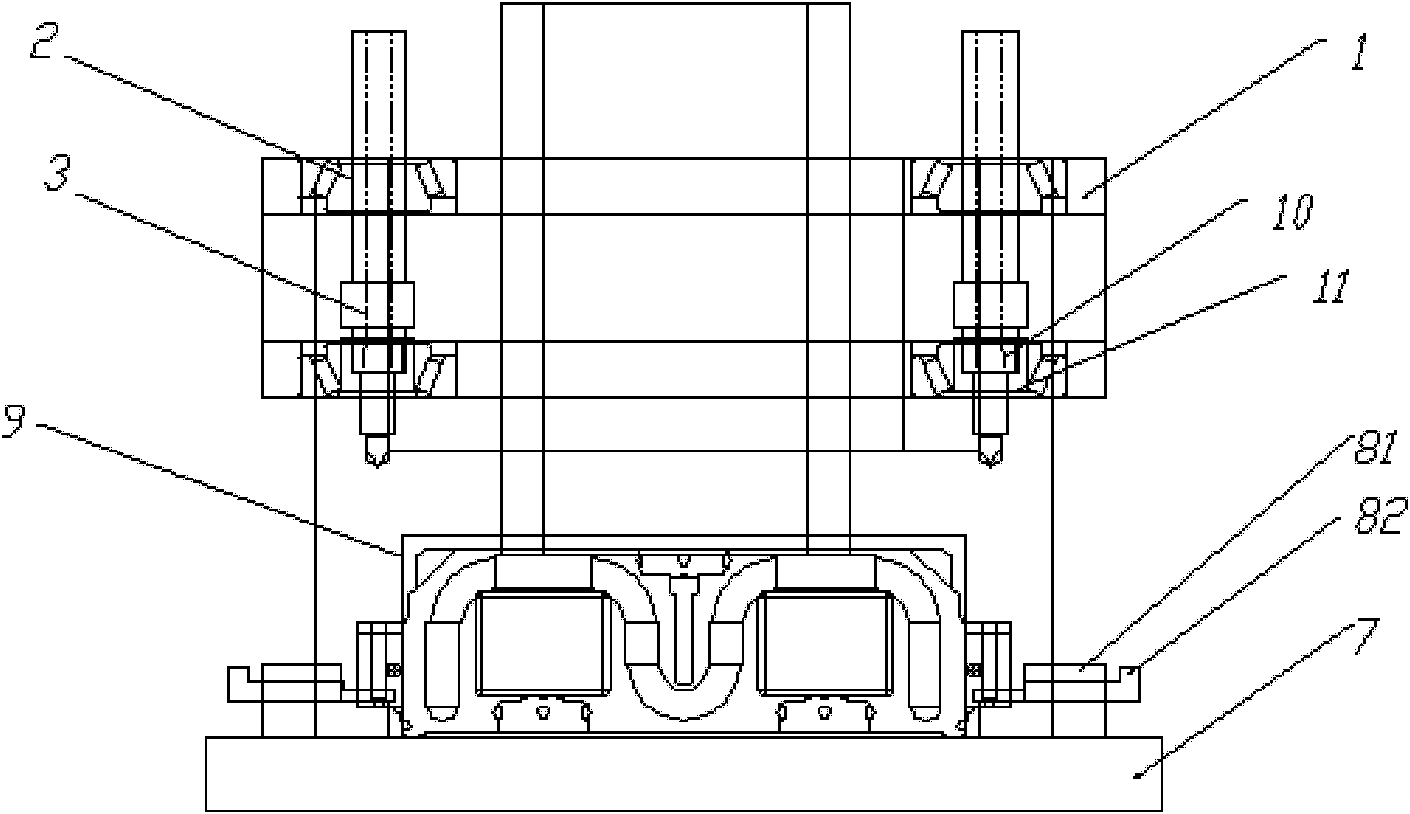

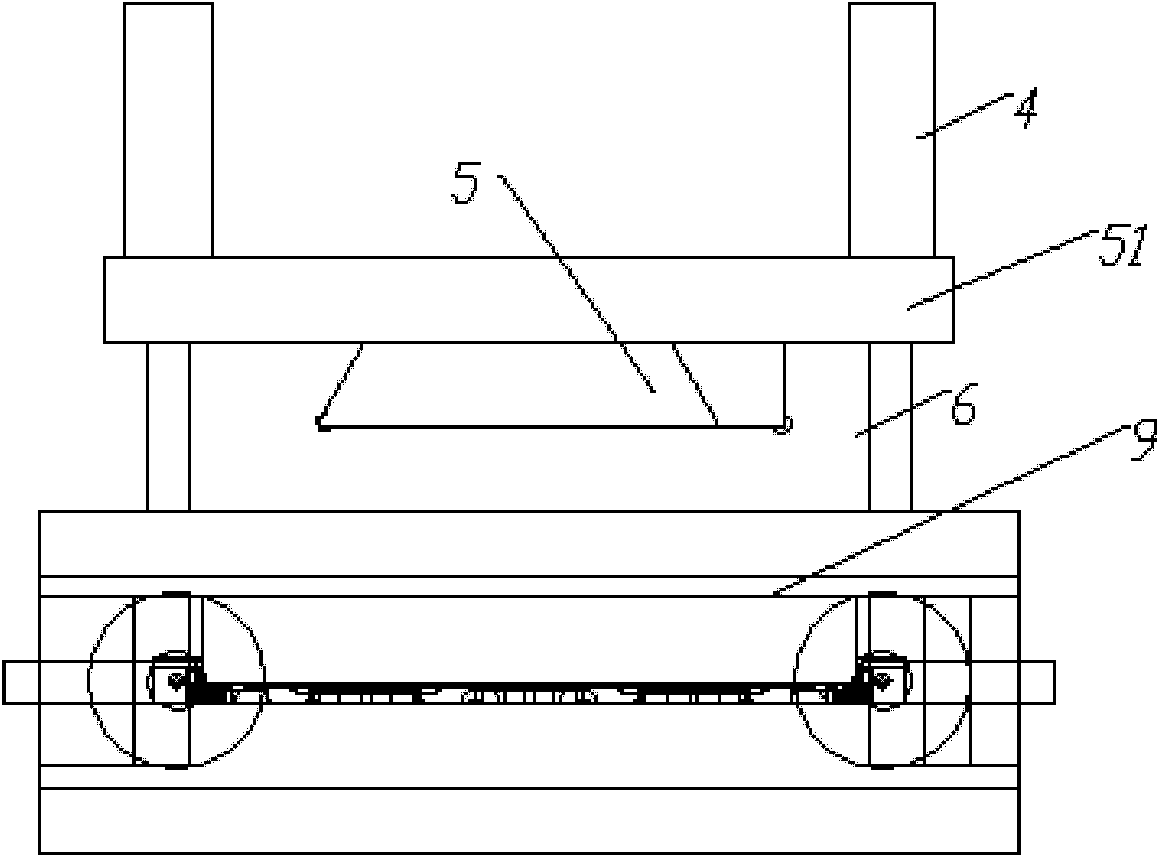

[0010] Embodiment: A drilling jig, including a bearing fixing plate 1, a tapered roller bearing 2, an extension rod 3, a support plate 4, a slide rail 5, a slider 6, a bottom plate 7 and a product fixing device, based on the direction of use , the upper side of the base plate 7 is provided with a product fixing device, the product fixing device can fix the product that needs to be drilled on the base plate, the upper side of the base plate 7 is also fixed with a support plate 4, and the support plate 4 is fixed with a slide rail fixing plate 51 , the slide rail fixing plate 51 is provided with a longitudinal slide rail 5, and the slide block 6 is provided with a longitudinal slideway. The fixed plate 1 is fixed on the slider 6, and the bearing fixed plate 1 is provided with at least one pair of tapered roller bearings 2. The pair of tapered roller bearings 2 are coaxial and longitudinally symmetrically arranged, and the upper end of the extension rod 3 is fixedly inserted in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com