Wax conveying mechanism for polishing machine

A polishing machine and wax feeding technology, used in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve problems such as low efficiency and unsafe manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

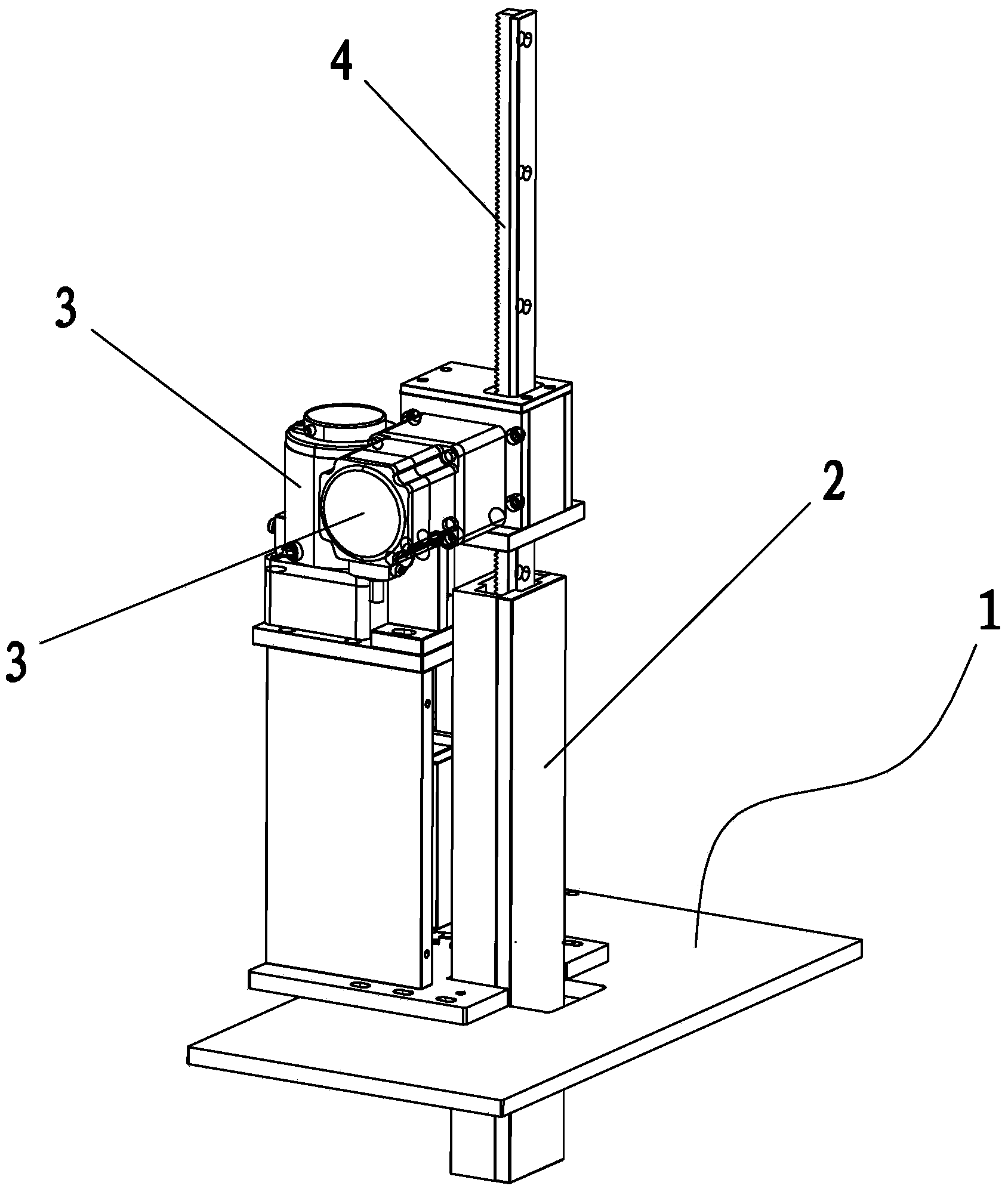

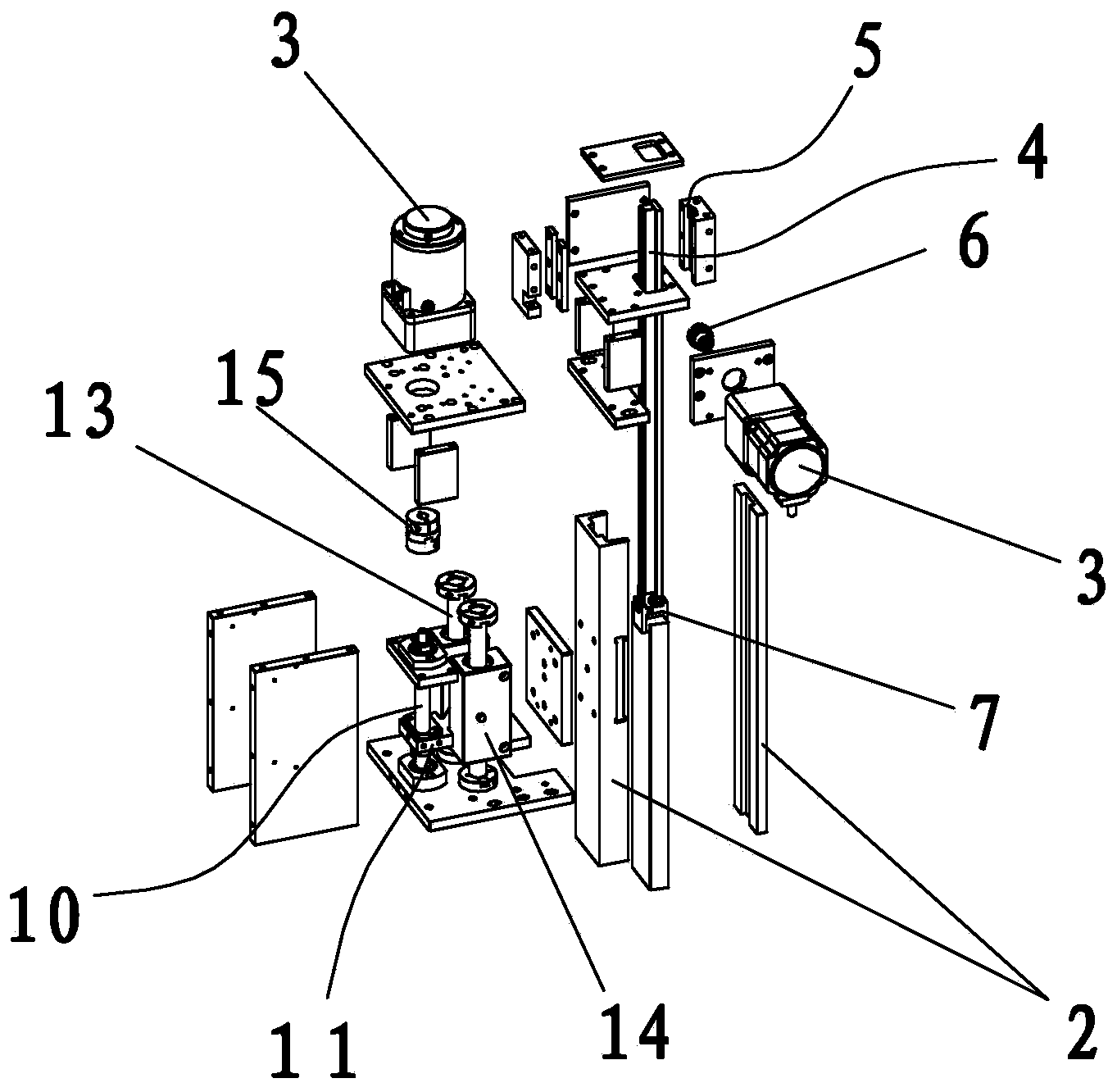

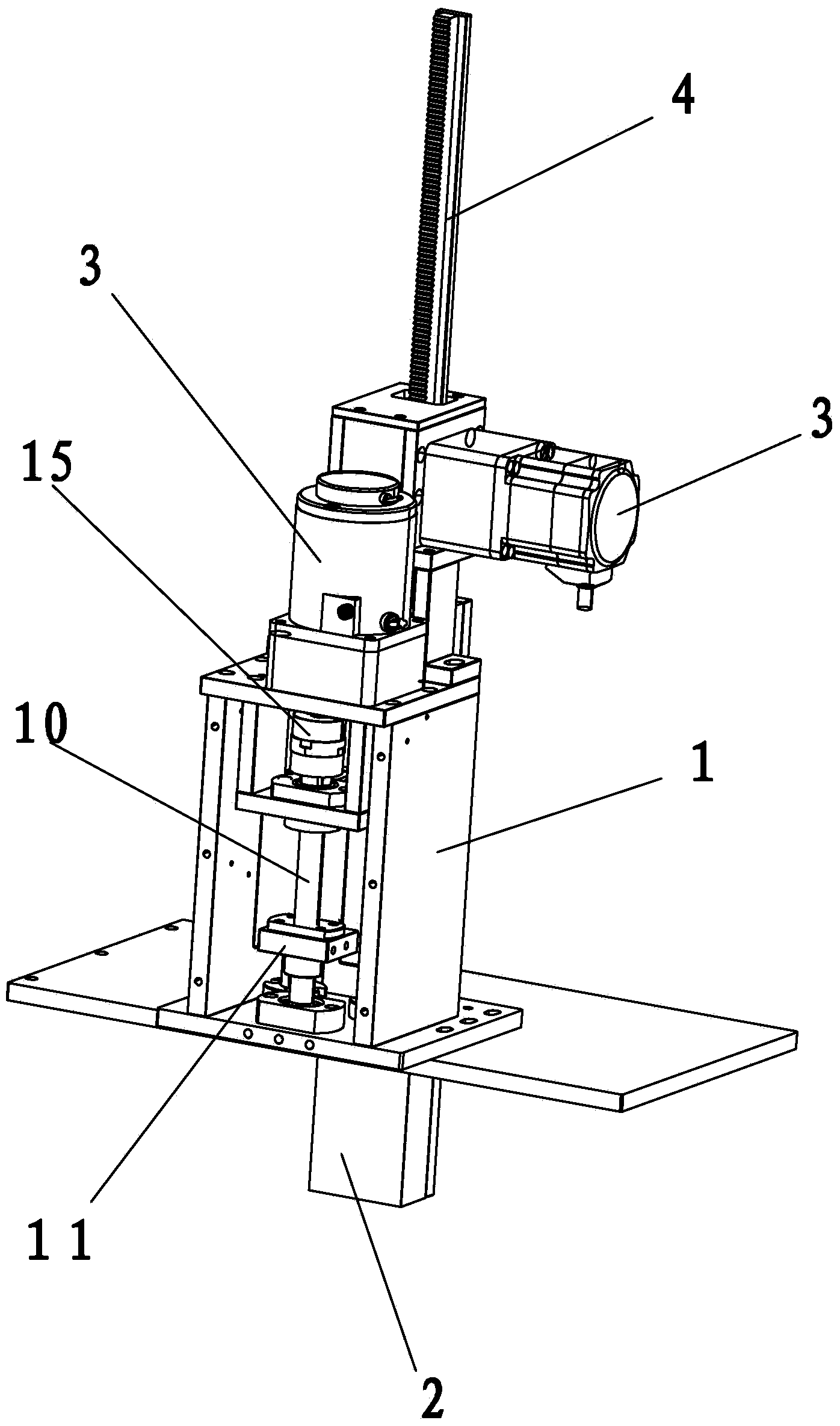

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 Shown, the wax sending mechanism of polishing machine of the present invention, it comprises the support 1 that is used to support various parts, is used for pushing the pushing device that wax strip moves and rubs with cloth wheel, is used to maintain the stable stabilizer 2 of wax strip and uses To respectively drive the driving device and the power device that cooperates with the stabilizer 2, the above-mentioned components are all assembled and fixed by the bracket 1. Wherein, the stabilizing frame 2 is connected with the power unit through the position adjustment mechanism, and the stabilizing frame 2 and the wax strip are moved in the same direction under the drive of the power unit, and the pushing device drives the wax strip to slide in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com