Patents

Literature

39results about How to "Satisfy polishing needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

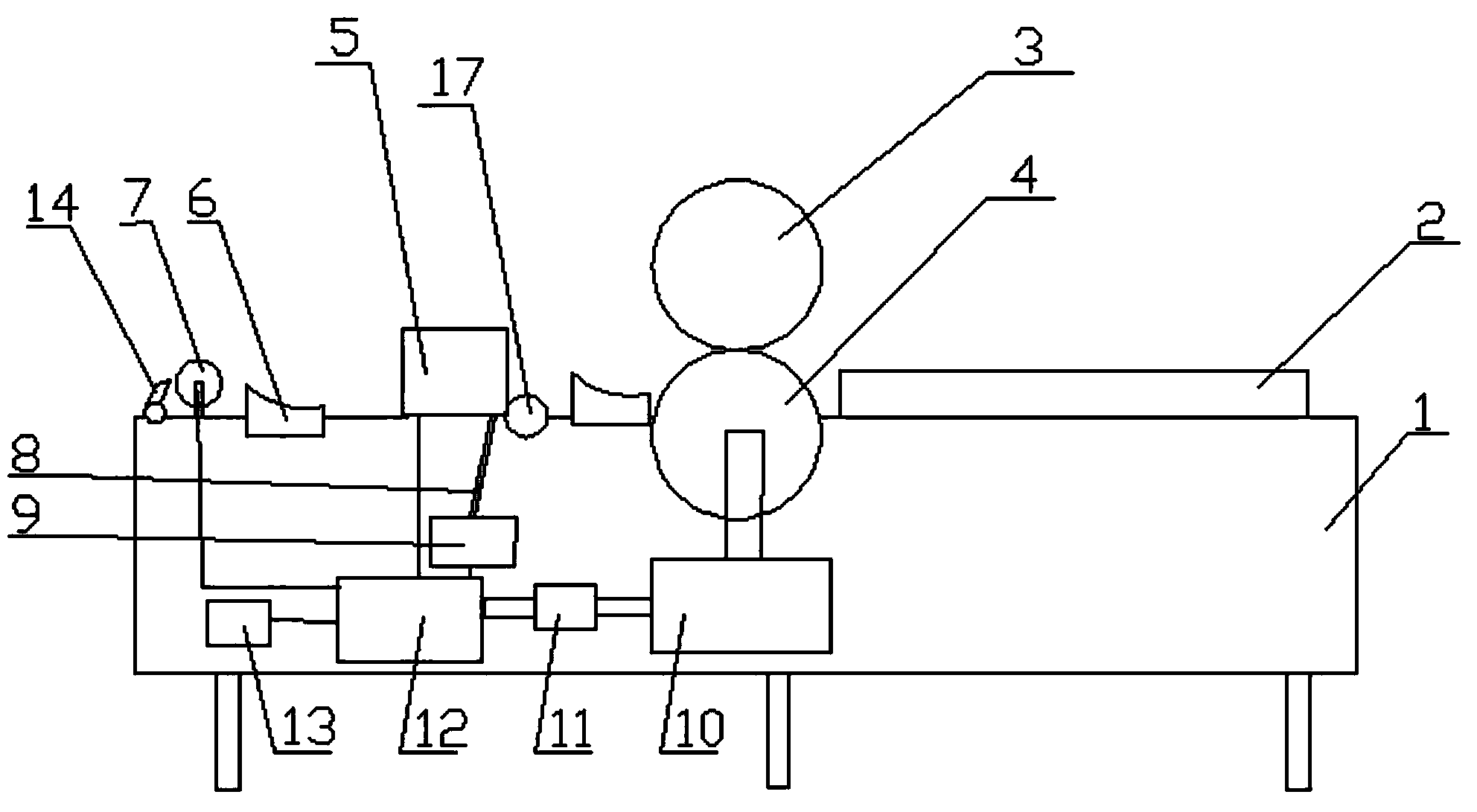

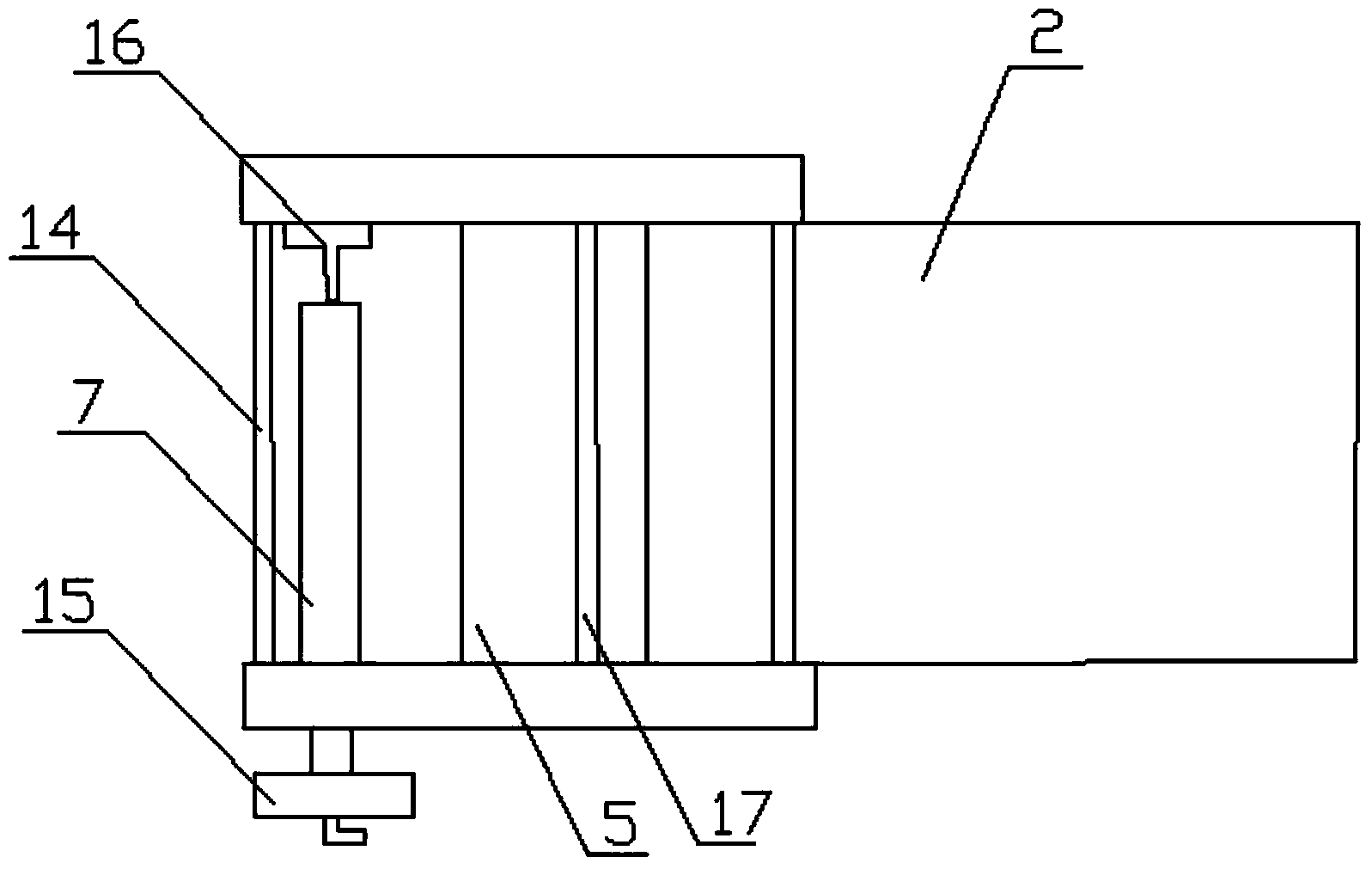

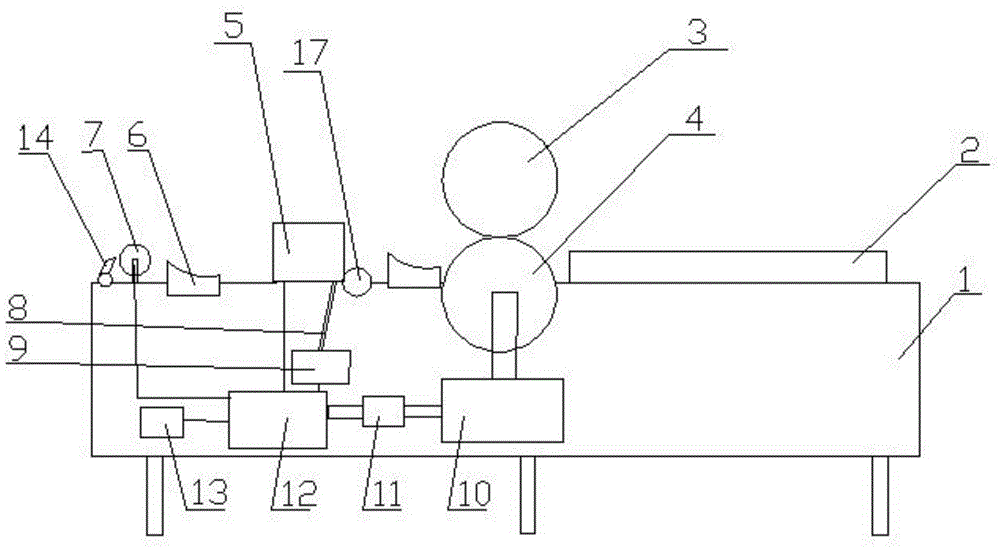

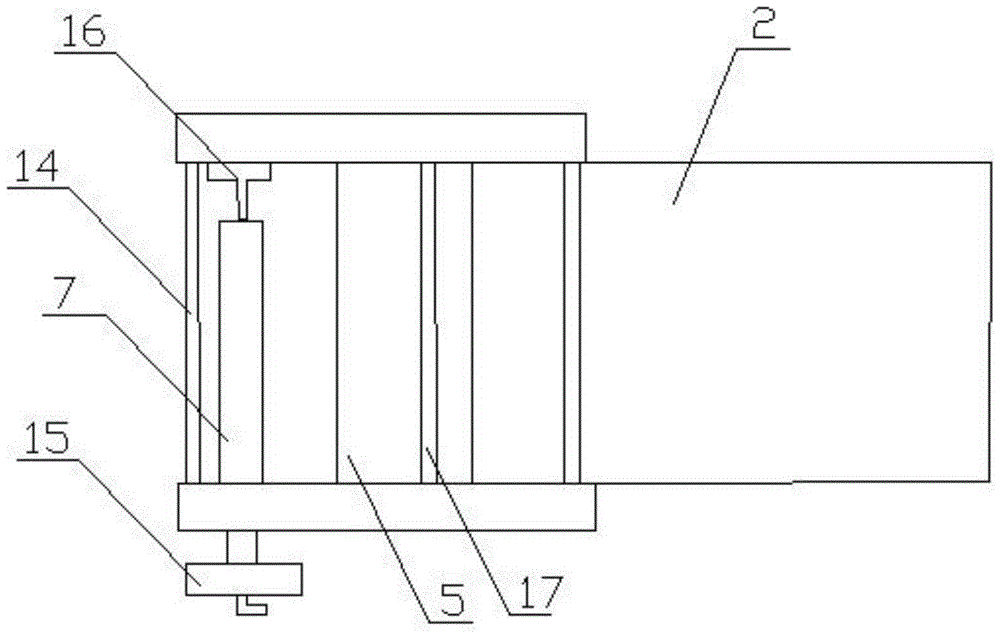

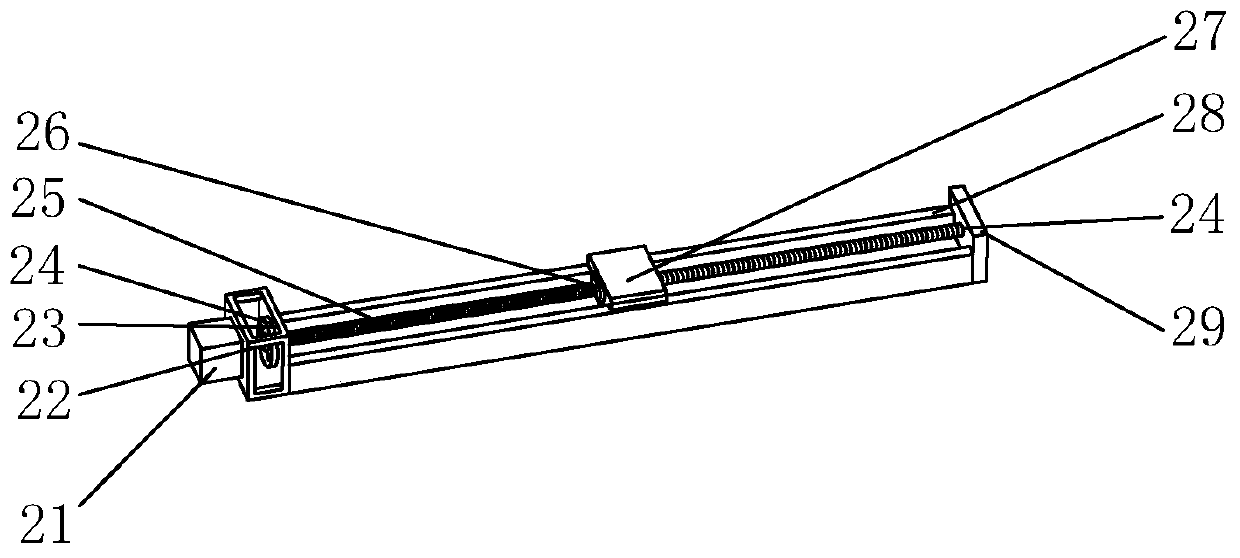

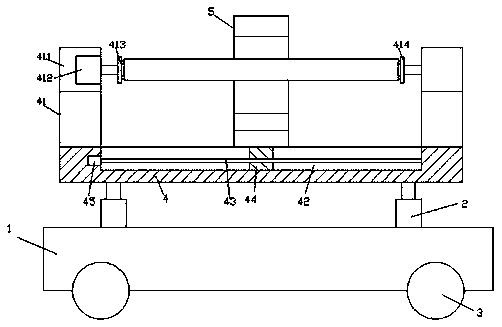

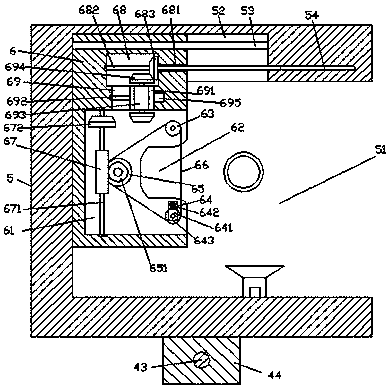

Rubber roller belt sander

The invention discloses a rubber roller belt sander, wherein a long strip-shaped support frame is positioned on a base; a driving wheel can be rotationally positioned at one end of the support frame; a driven wheel can be rotationally positioned at the other end of the support frame; the driving wheel and the driven wheel are arrayed in parallel; a ring-shaped abrasive belt is arranged on the driving wheel and the driven wheel in a sleeving manner; the driving wheel is driven by a motor to rotate; a driven shaft on the driven wheel is inserted in a shaft sleeve at the other end of the support frame; and the driven shaft can be driven by a deviation rectifying adjusting device on the shaft sleeve to rotate around a shaft perpendicular to the axial direction of the driven shaft and the length direction of the ring-shaped abrasive belt. According to the rubber roller belt sander, an adjustment of the axis parallelism of the driving wheel and the driven wheel can be realized, so that the stability of the operation of the abrasive belt can be realized; the tension adjustment of the ring-shaped abrasive belt is convenient, so that the ring-shaped abrasive belt can be adapted to processing of different materials, and the replacement of the ring-shaped abrasive belt is facilitated, the rotation of the whole ring-shaped abrasive belt around an axial line of the driving wheel can be realized, the contact angle of the abrasive belt and a workpiece can be changed, the contact position of the abrasive belt and the workpiece can be changed, and different processing demands can be met.

Owner:昆山诺丹舜蒲胶辊有限公司

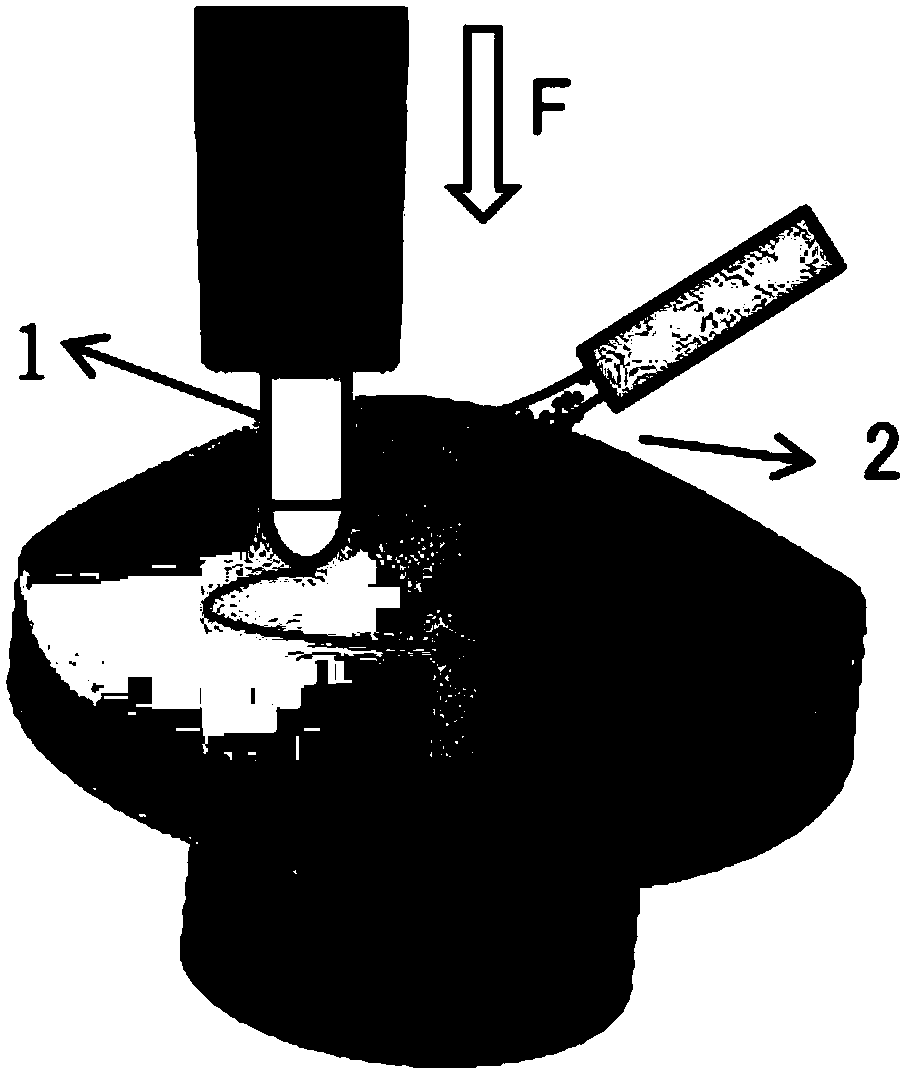

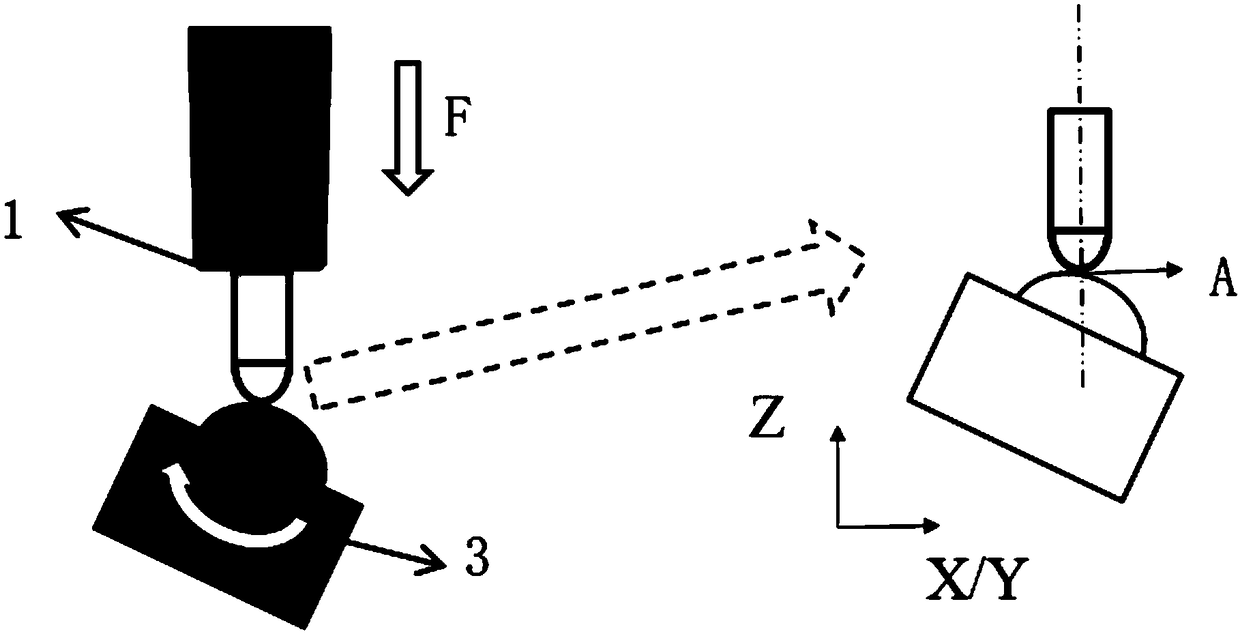

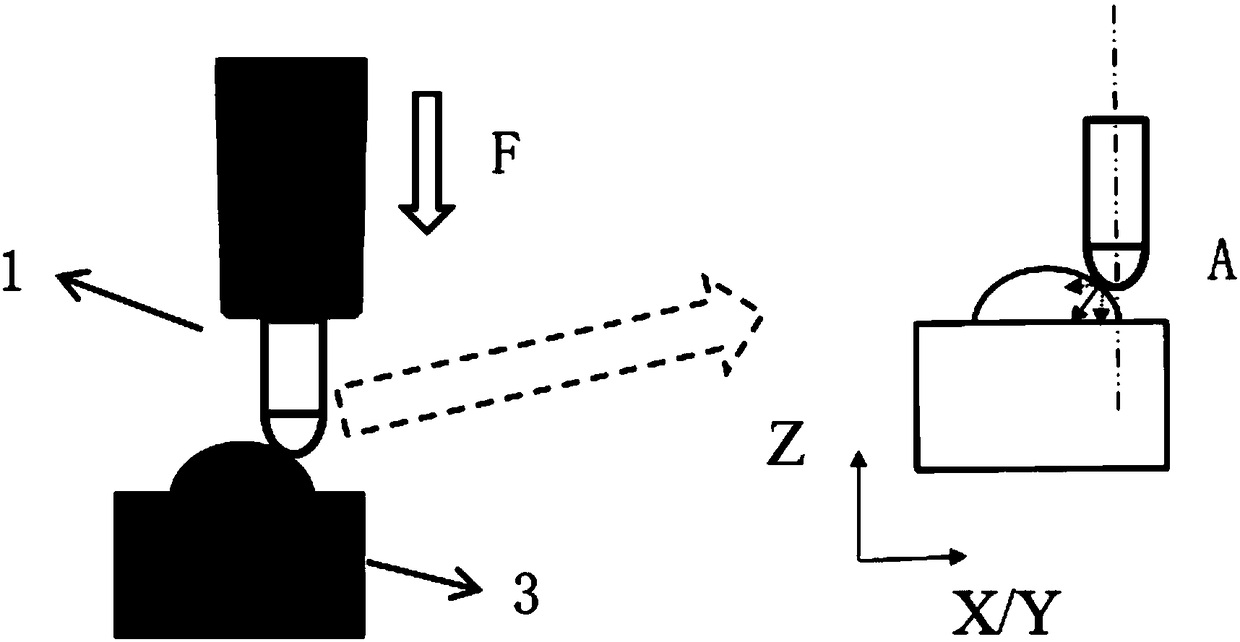

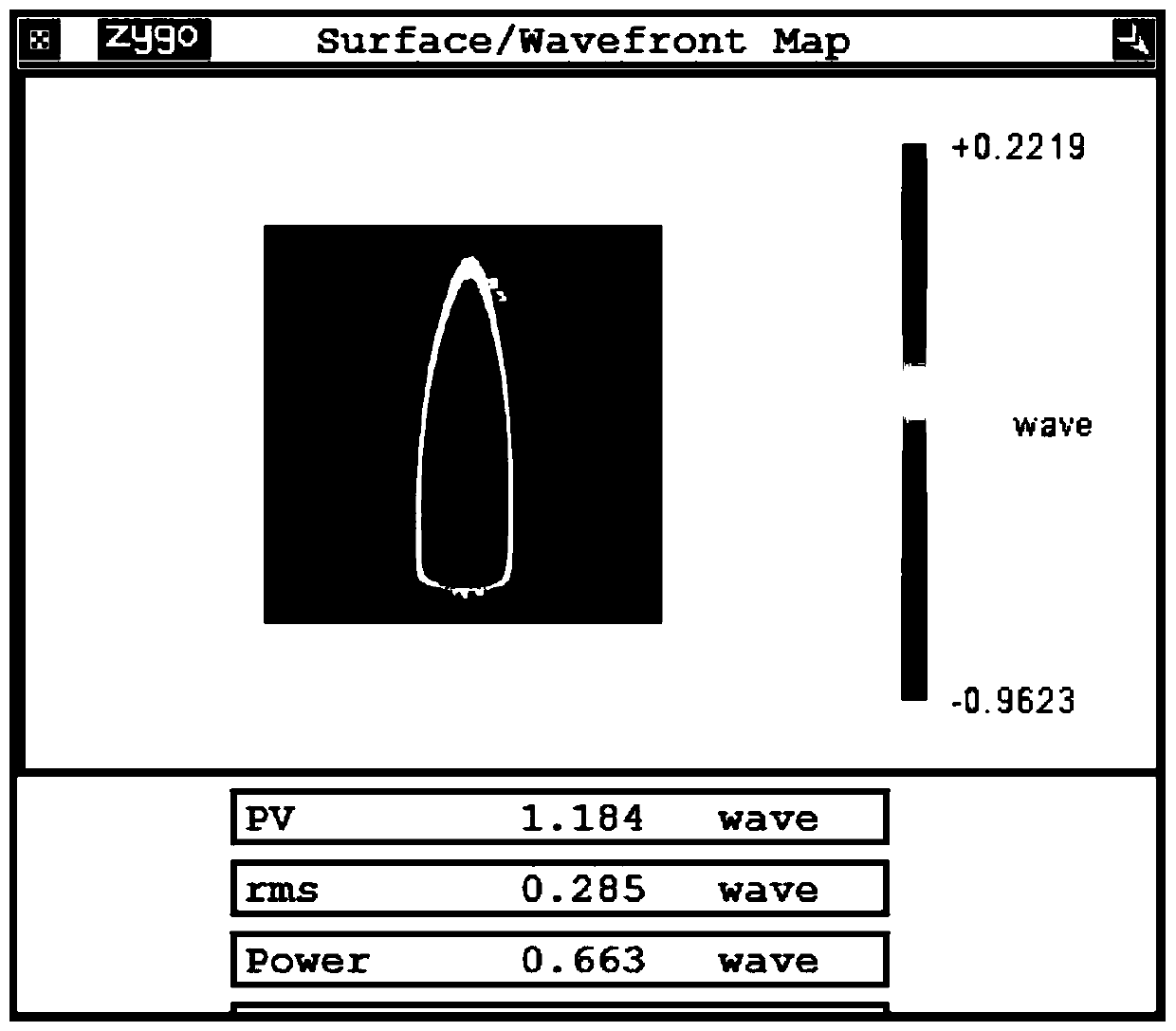

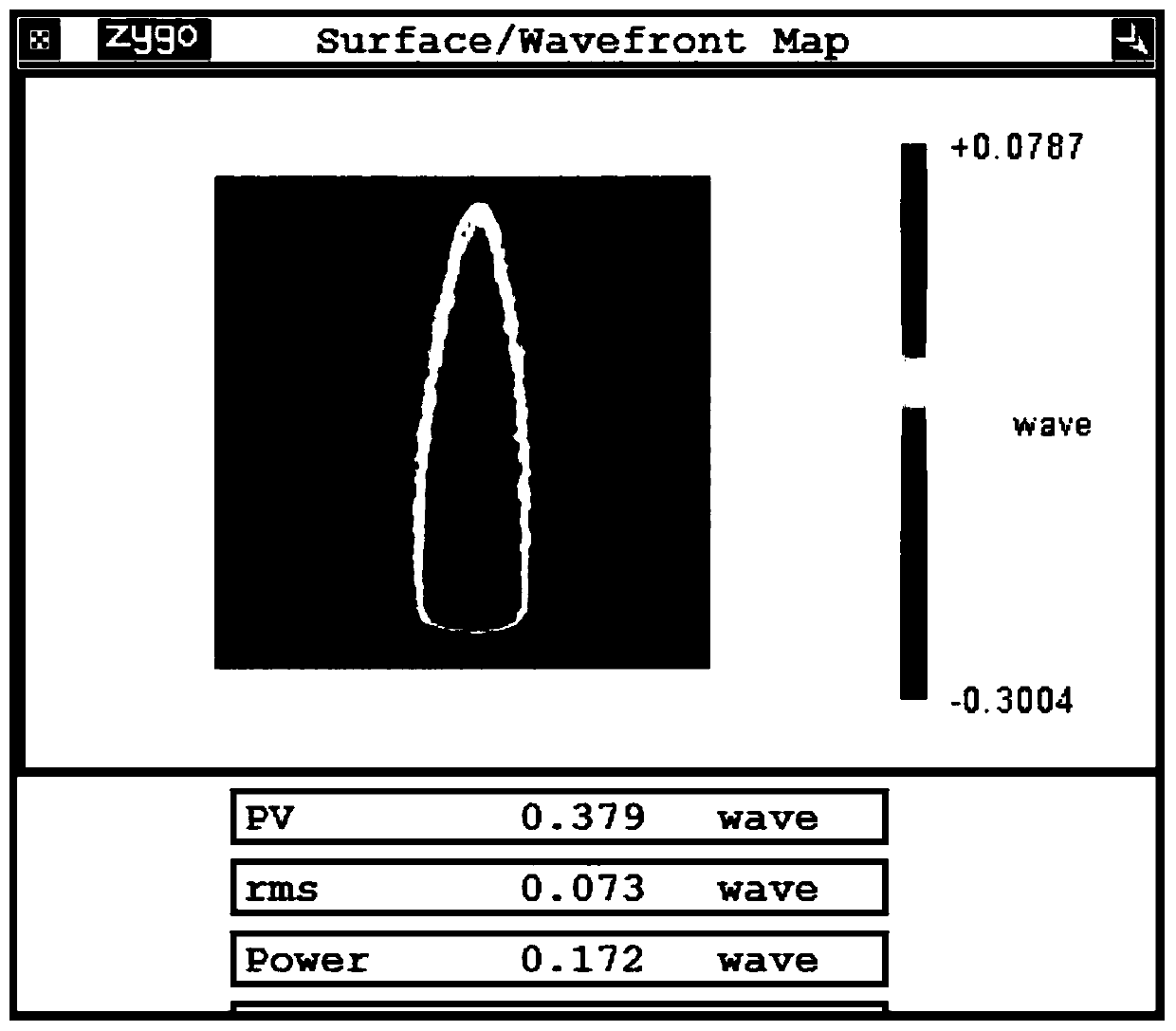

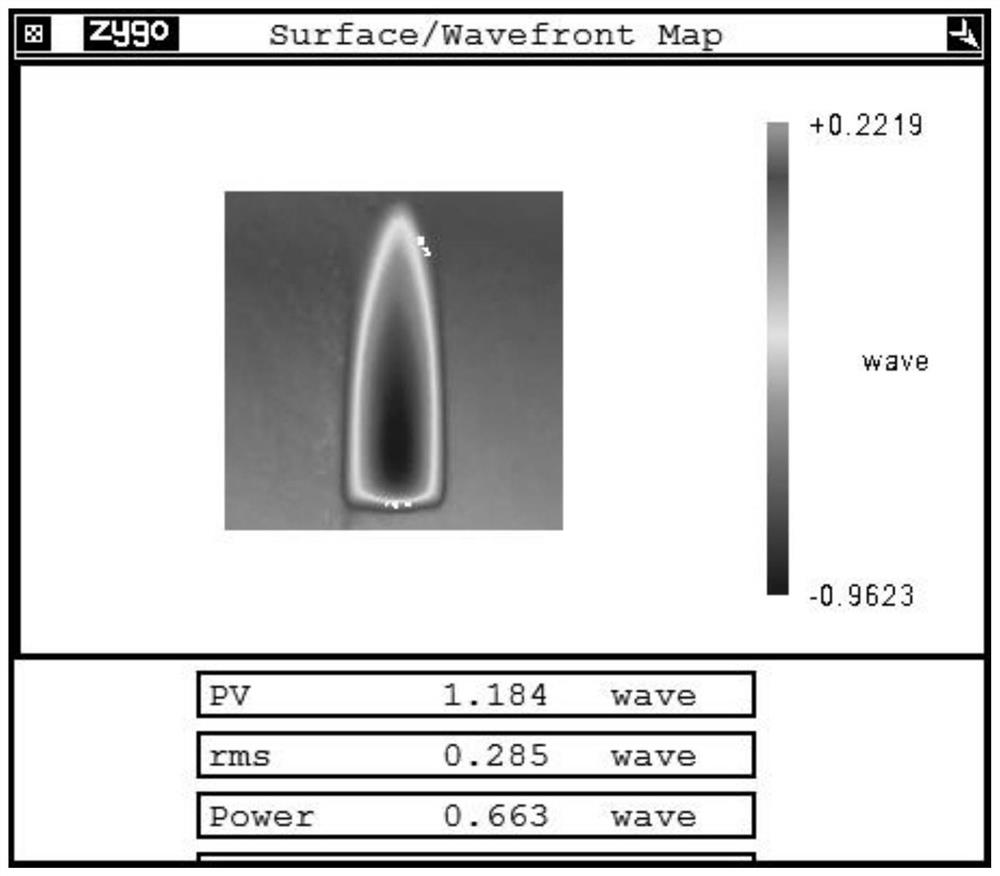

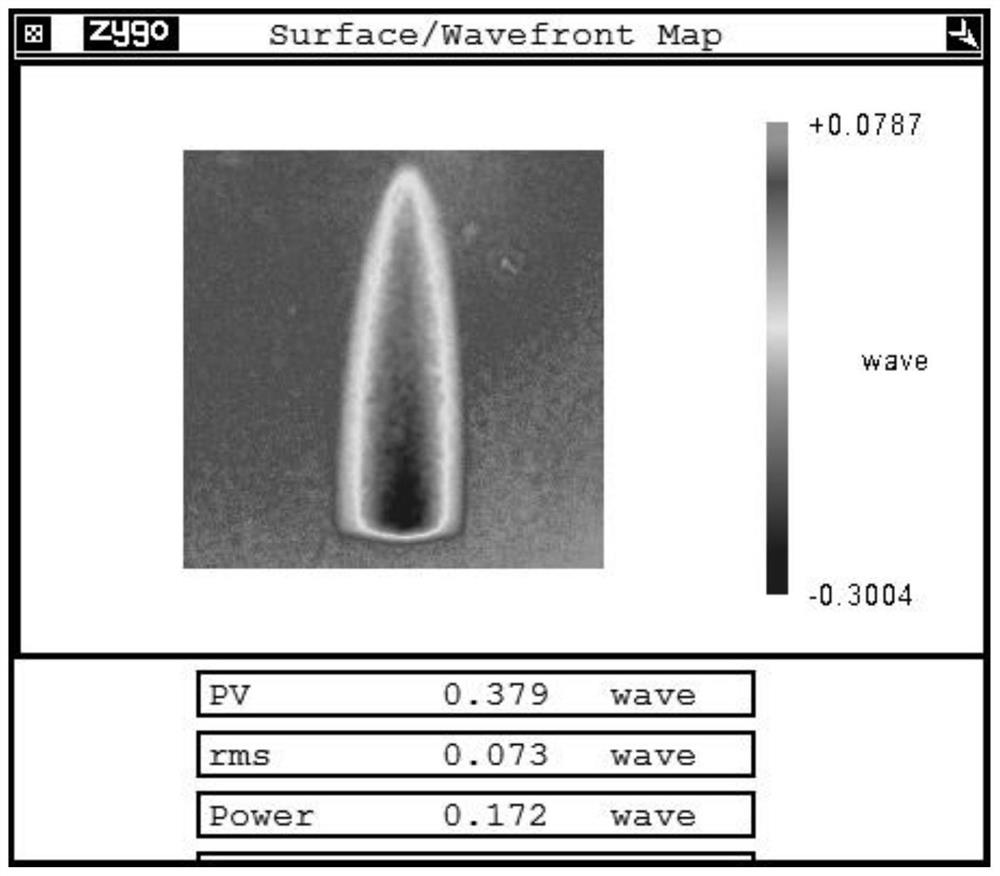

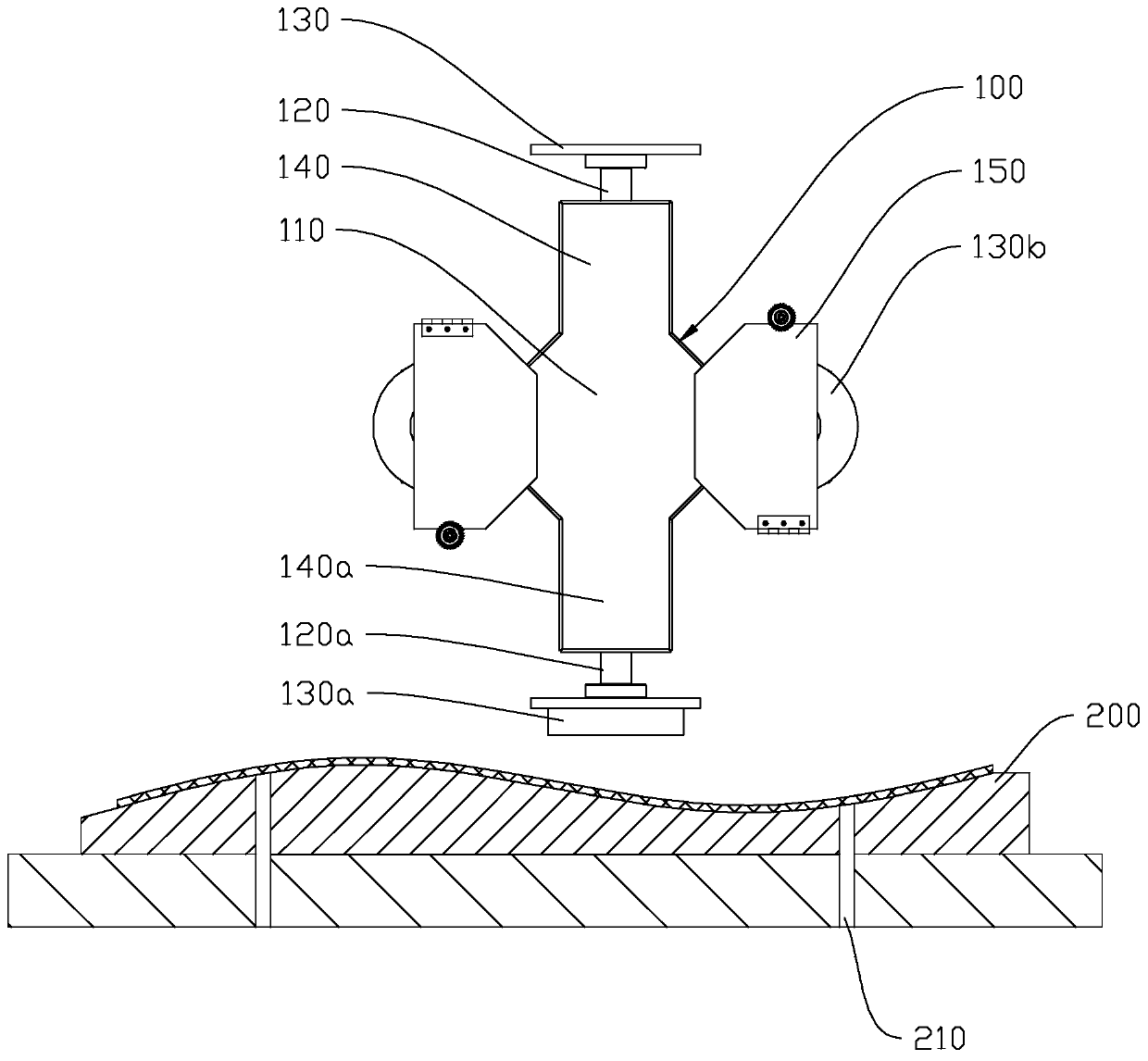

Optical free curved surface polishing device and method

PendingCN108311960AReduce volumeEasy to moveOptical surface grinding machinesAutomatic grinding controlNumerical control systemControl system

The invention discloses an optical free curved surface polishing device and method, and belongs to the field of optical manufacturing. A vibration polishing device comprises a vibration polishing head, a control system, a PC computer, a five-axis numerical control platform and a polishing pressure control mechanism. The control system and the PC computer are respectively positioned above and belowa movable worktable; a driver in the control system is connected with the vibration polishing head; a numerical control system communicates with the five-axis numerical control platform; a controlleris connected with the polishing pressure control mechanism; the PC computer is connected with the control system, and sets polishing parameters for transmission to the control system to control the whole polishing device; and a micro displacement driving device in the polishing pressure control mechanism is connected with the polishing head. A vibration auxiliary polishing mode is adopted; aimingat continuous surfaces, such as axial symmetry and off-axis non-spherical surfaces, real-time precise control of a polishing head vibration mode, a polishing trajectory and a polishing pressure can be realized at the same time, and the submicron surface figure accuracy and the subnanometer surface roughness can be achieved; and the polishing device has the advantages of system integration, smallsize, convenience to move and the like.

Owner:DALIAN UNIV OF TECH

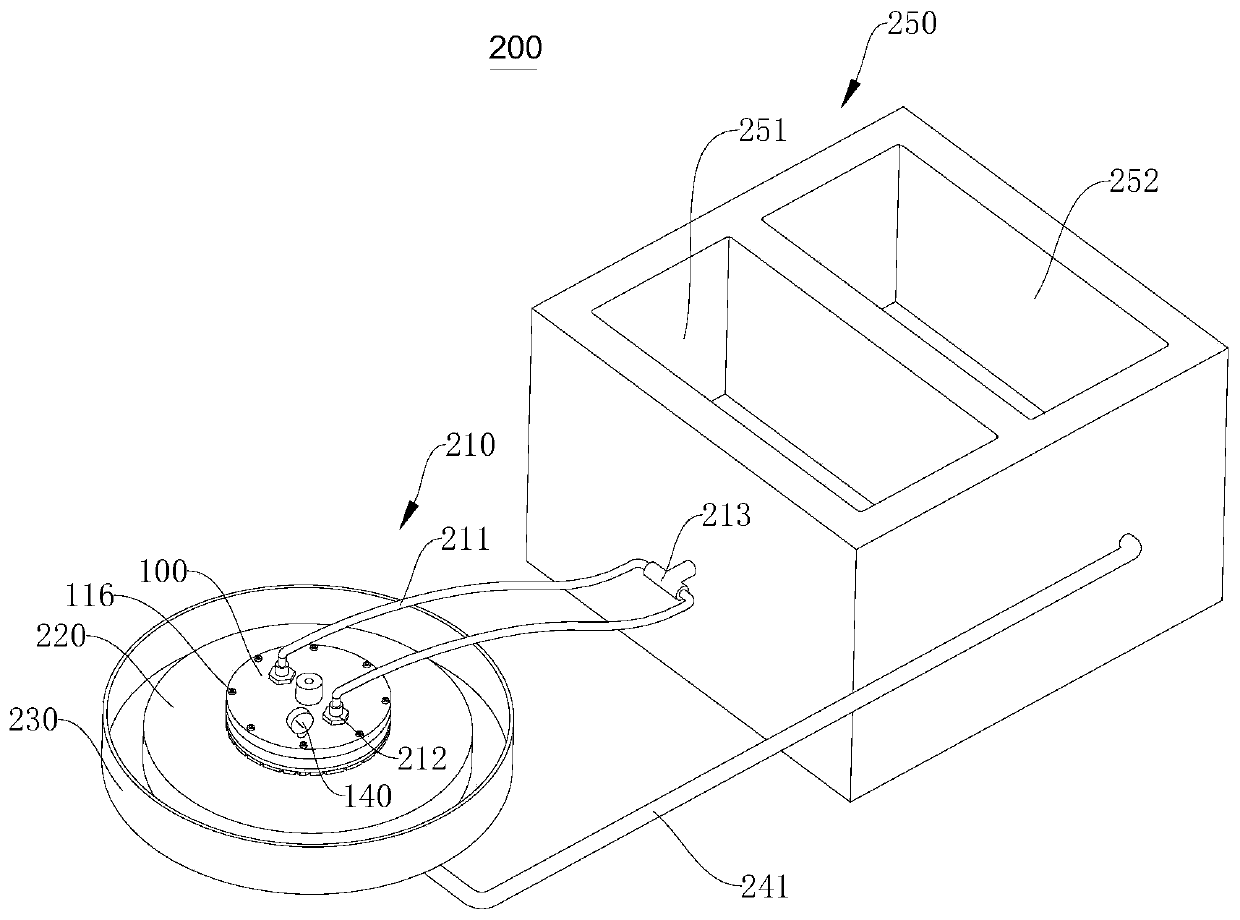

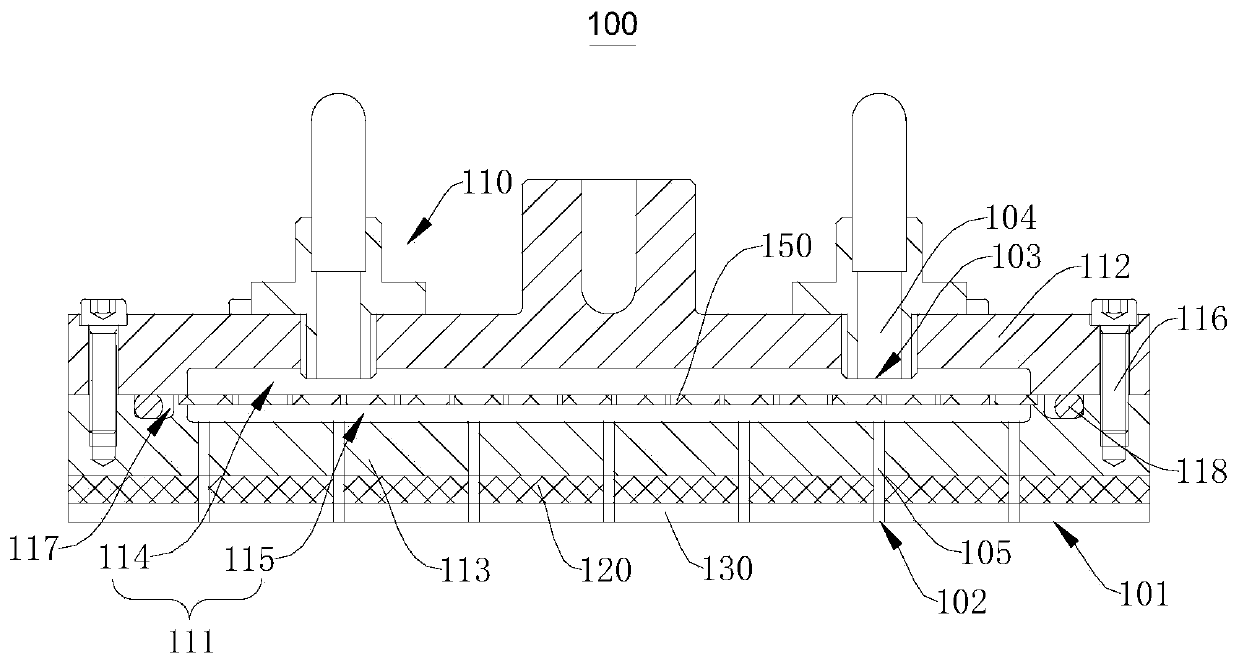

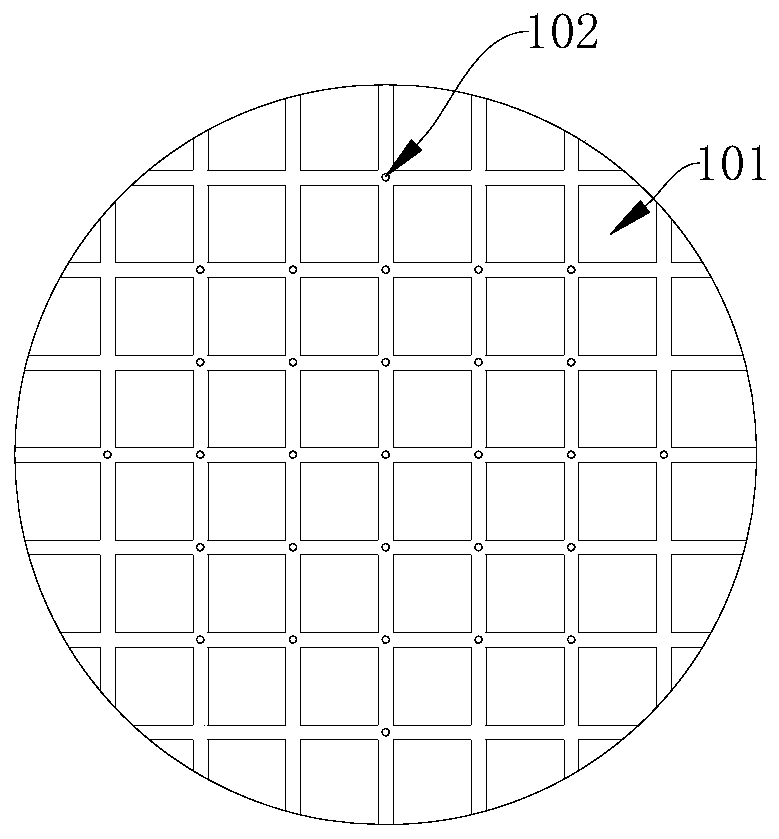

Polishing disc and polishing system

PendingCN110788699APressure monitoringPressure can be adjusted at any timeOptical surface grinding machinesGrinding feed controlPolishingMachining

The invention provides a polishing disc and a polishing system, and relates to the technical field of optical element precise machining. The interior of the polishing disc is provided with a storing cavity used for storing polishing liquid, the polishing face of the polishing disc is provided with liquid outlets, and the liquid outlets communicate with the storing cavity through channels arrangedin the polishing disc. The polishing liquid is stored in the storing cavity of the polishing disc, when polishing is conducted, the polishing layer of the polishing disc makes close contact with an element, the polishing liquid flows out through the liquid outlets, the effect that the polishing liquid is evenly distributed on the surface of the element in the polishing process is achieved, the condition that the polishing liquid is sprayed again after polishing is stopped multiple times is avoided, and the polishing efficiency is improved. The polishing liquid flows out from the storing cavitythrough the liquid outlets, therefore, the amount and the pressure of the polishing liquid flowing out from the different liquid outlets are approximately equal, and the polishing liquid on the surface of the element can be evenly distributed.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

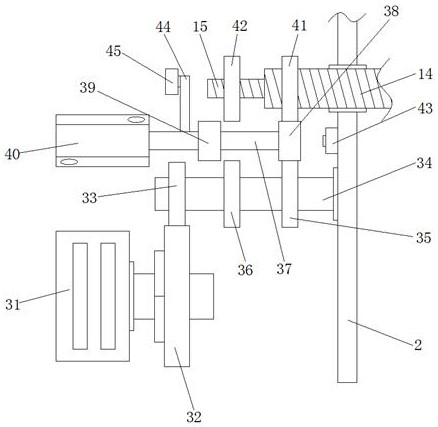

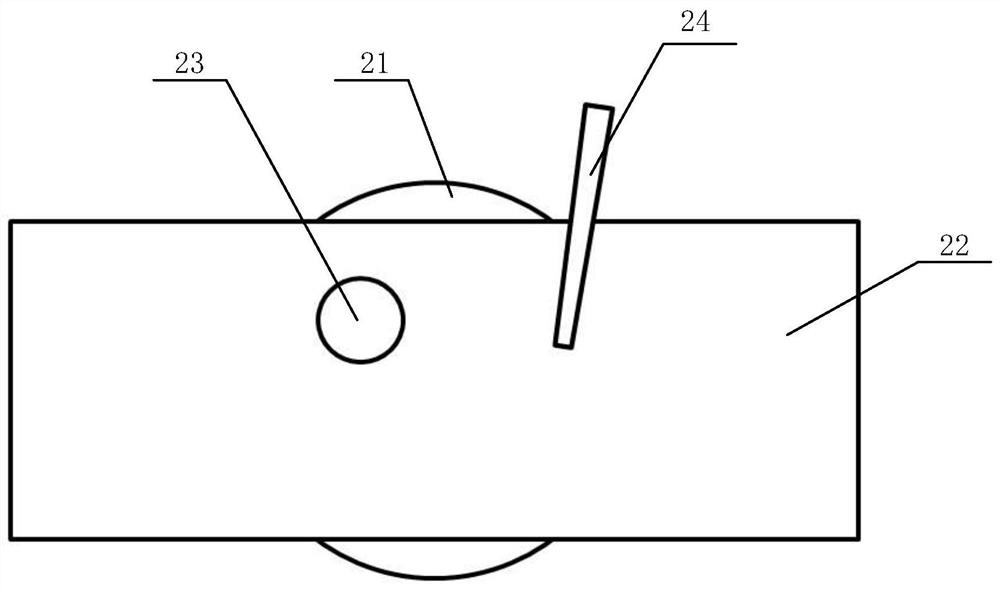

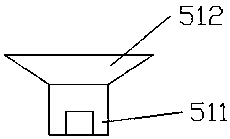

Wax conveying mechanism for polishing machine

InactiveCN104057399APlay a protective effectCannot interfere with normal movementPolishing machinesWaxEngineering

The invention provides a wax conveying mechanism for a polishing machine. The wax conveying mechanism for the polishing machine comprises a support. A pushing device, a stabilization rack and a power device are arranged on the support, wherein the pushing device is used for pushing rod wax to move to be in friction with a cloth roller, the stabilization rack is used for keeping the rod wax stable, and the power device is used for driving the pushing device and the stabilization rack to be mutually matched. The stabilization rack is connected with the power device through a positioning mechanism and the power device drives the stabilization rack and the rod wax to move in the same direction. The special pushing device is used for fixing the rod wax and making the rod wax continuously be in contact with or abut against the cloth roller, the special stabilization rack is arranged for the rod wax, the rod wax is protected in a reinforced mode and is not prone to breakage, and it is required that the stabilization rack protects the rod wax and cannot block normal movement of the rod wax. When the cloth roller and the rod wax are consumed and shortened, both the rod wax and the stabilization rack move downwards, and it is guaranteed that only a small section of the rod wax is exposed out of the stabilization rack. Thus, the stabilization rack and the pushing device are kept to move in the same direction.

Owner:NINGBO ZHENHE ELECTRICAL EQUIP

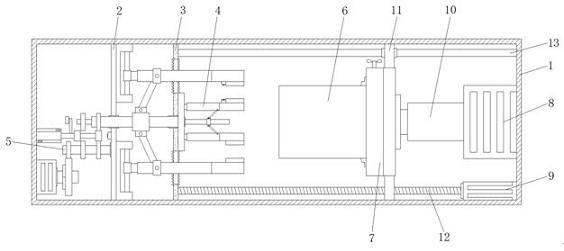

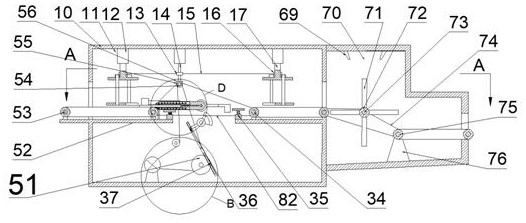

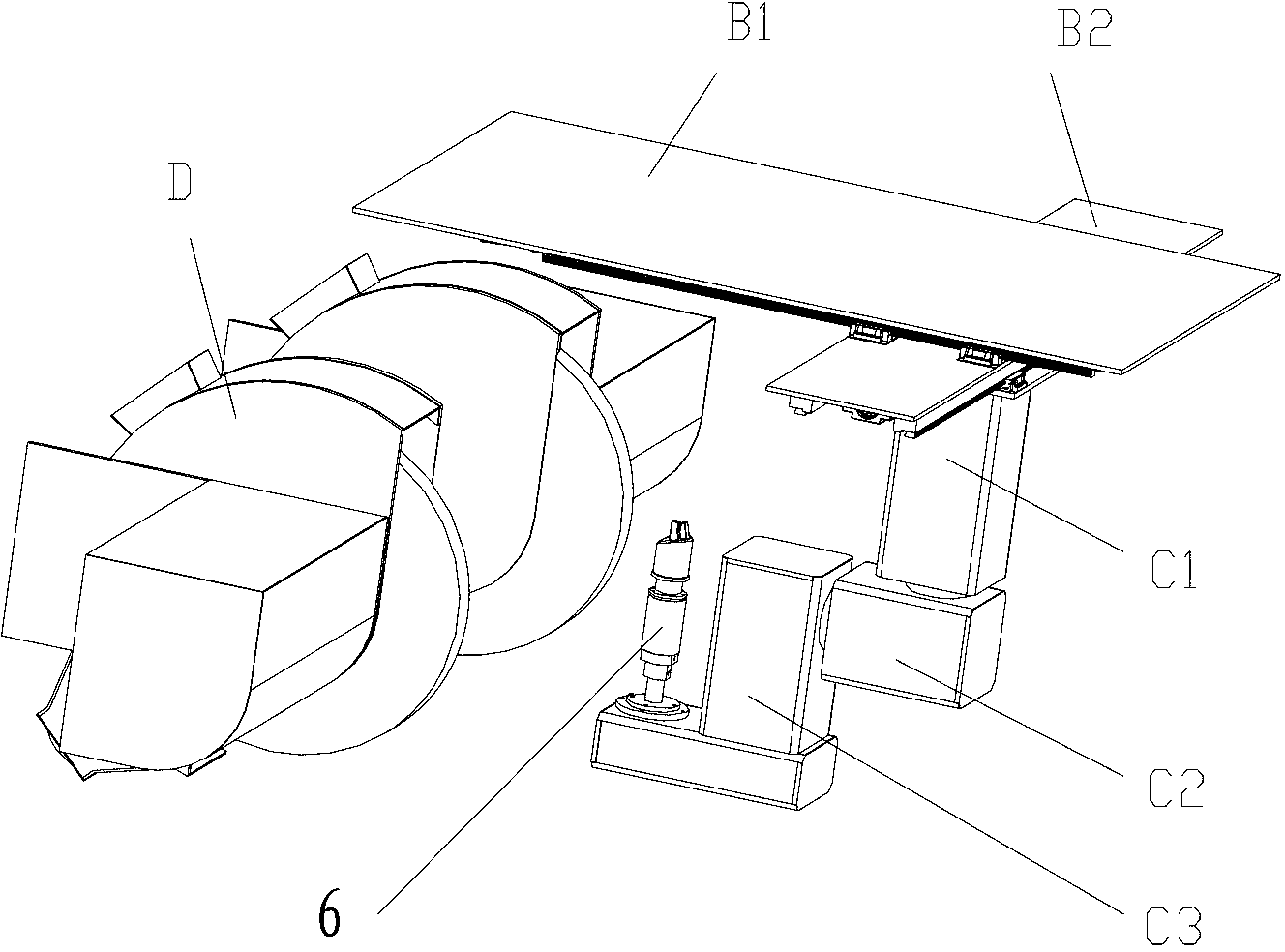

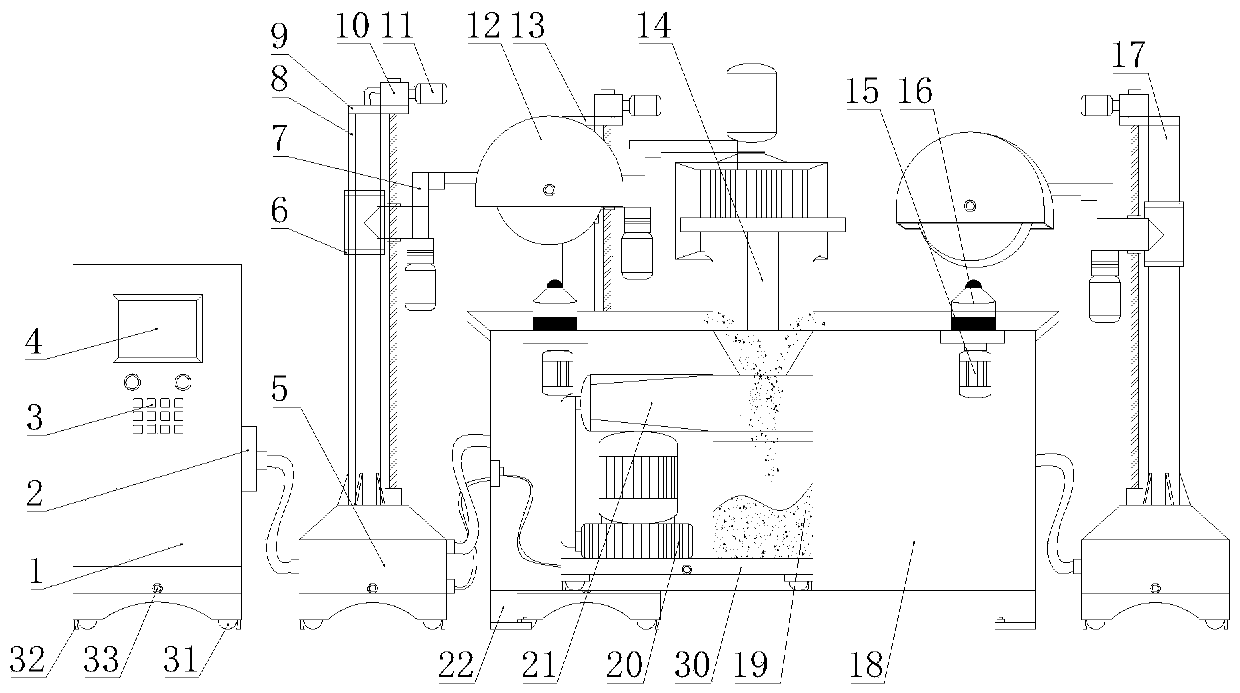

Automatic polishing equipment for inner wall and outer wall of pipe body and using method thereof

PendingCN113977445ASatisfy polishing needsImprove work efficiencyGrinding carriagesPolishing machinesElectric machinePolishing

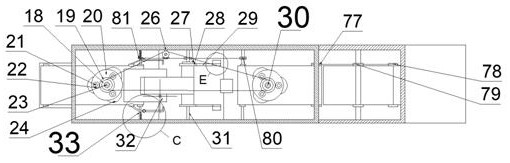

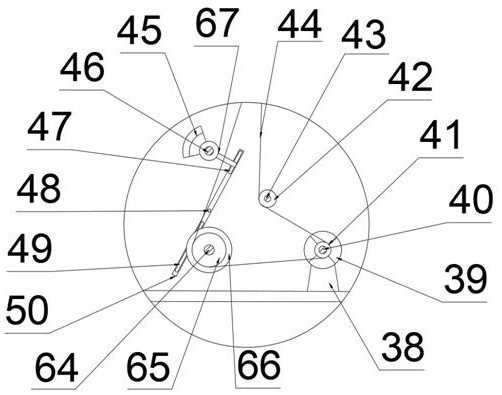

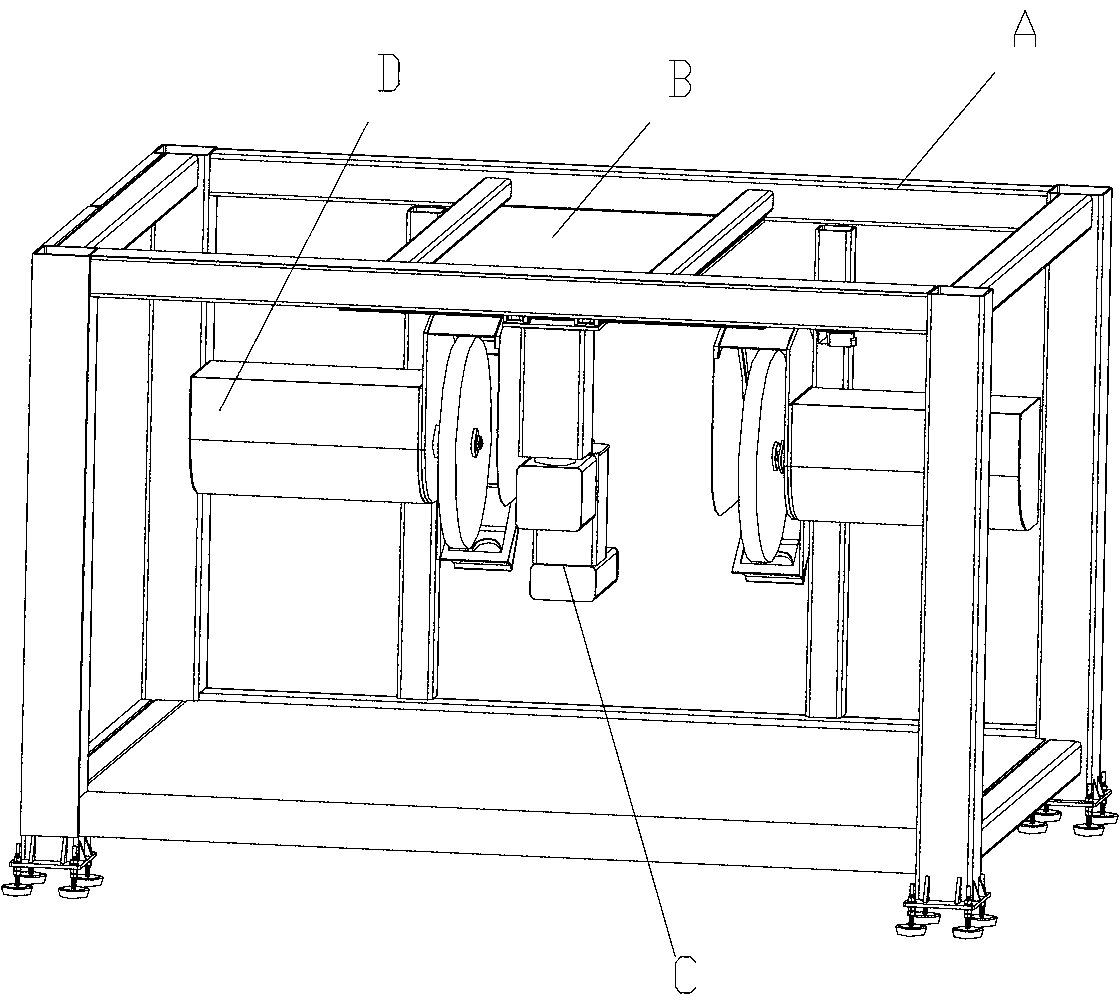

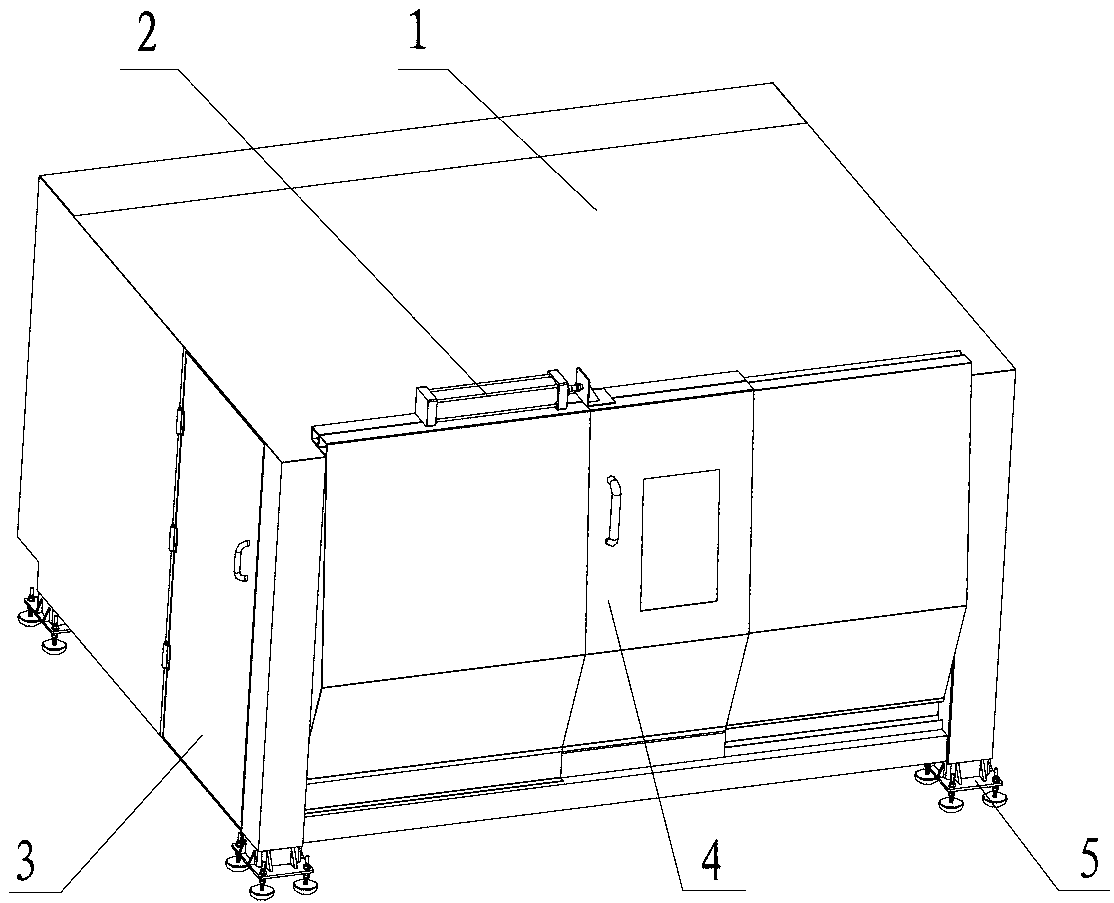

The invention relates to the technical field of pipe body polishing, and discloses automatic polishing equipment for the inner wall and the outer wall of a pipe body. The automatic polishing equipment comprises a working box, a first partition plate, a second partition plate, a polishing mechanism, a driving mechanism, the pipe body, a three-jaw chuck, a rotating motor and a horizontal motor, wherein the first partition plate and the second partition plate are fixedly installed in the working box, and the second partition plate is located on the right side of the first partition plate; meanwhile, a driving mechanism is arranged on the left side of the first partition plate, the driving mechanism and a polishing mechanism are connected together, the polishing mechanism is arranged in the first partition plate and the second partition plate, an outer clamping rod and an inner clamping rod are arranged in the polishing mechanism, the inner side face and the outer side face of the pipe body are synchronously polished and ground through the outer clamping rod and the inner clamping rod, and the working efficiency is higher; and the outer clamping rod and the inner clamping rod are installed through a first connecting rod and a second connecting rod correspondingly, the driving mechanism drives the outer clamping rod and the inner clamping rod to be adjusted, the polishing mechanism is suitable for pipe bodies with different diameters, the applicability of the device is improved, and the polishing and grinding requirements of the pipe bodies with different diameters are met.

Owner:溧阳市嘉雄不锈钢设备有限公司

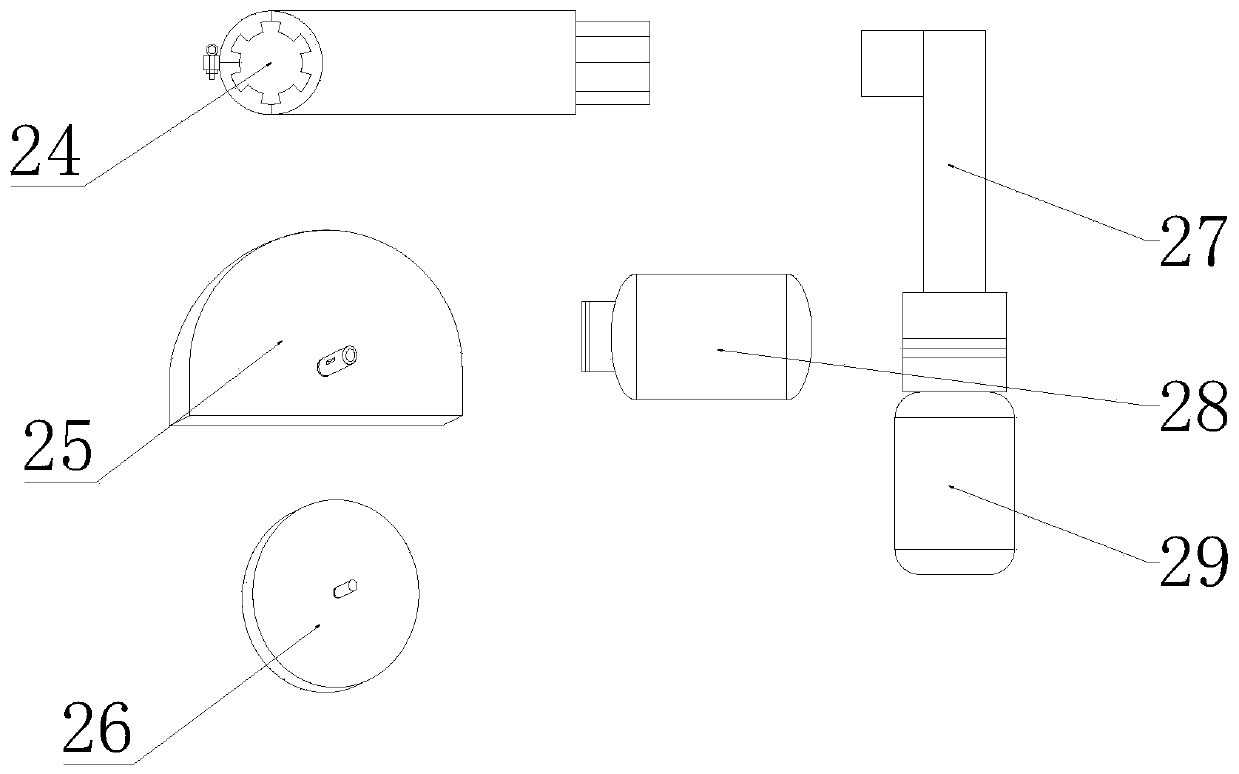

A magnetic polishing component

ActiveCN110480423BSatisfy polishing needsRealize automatic polishingGrinding drivesGrinding work supportsCircular discElectric machine

Owner:WUHAN SUNSHINE LASER & TECH

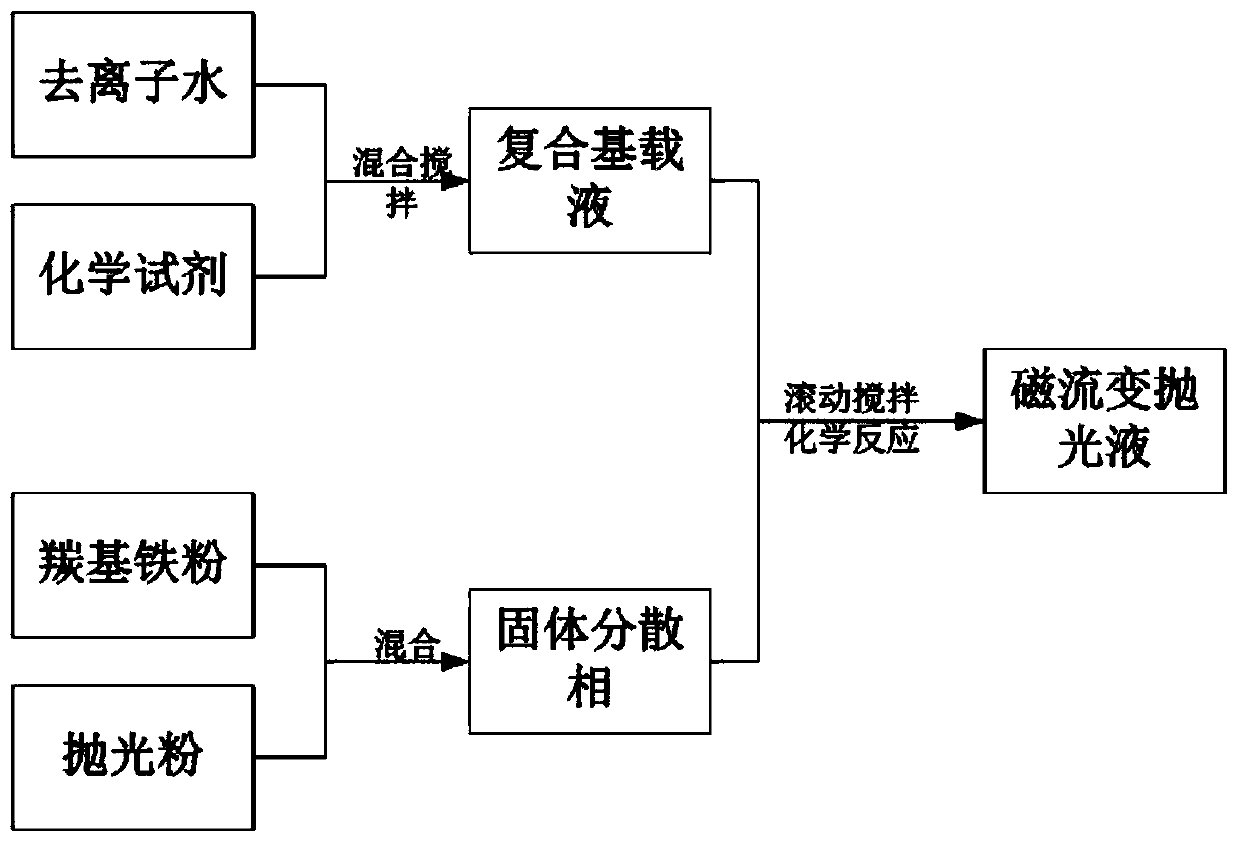

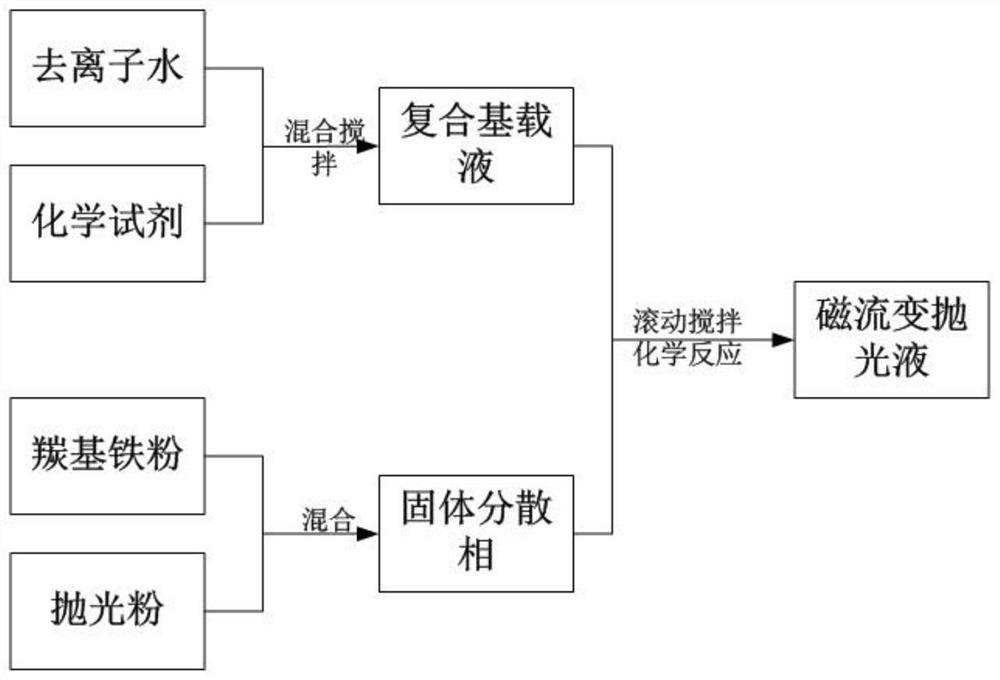

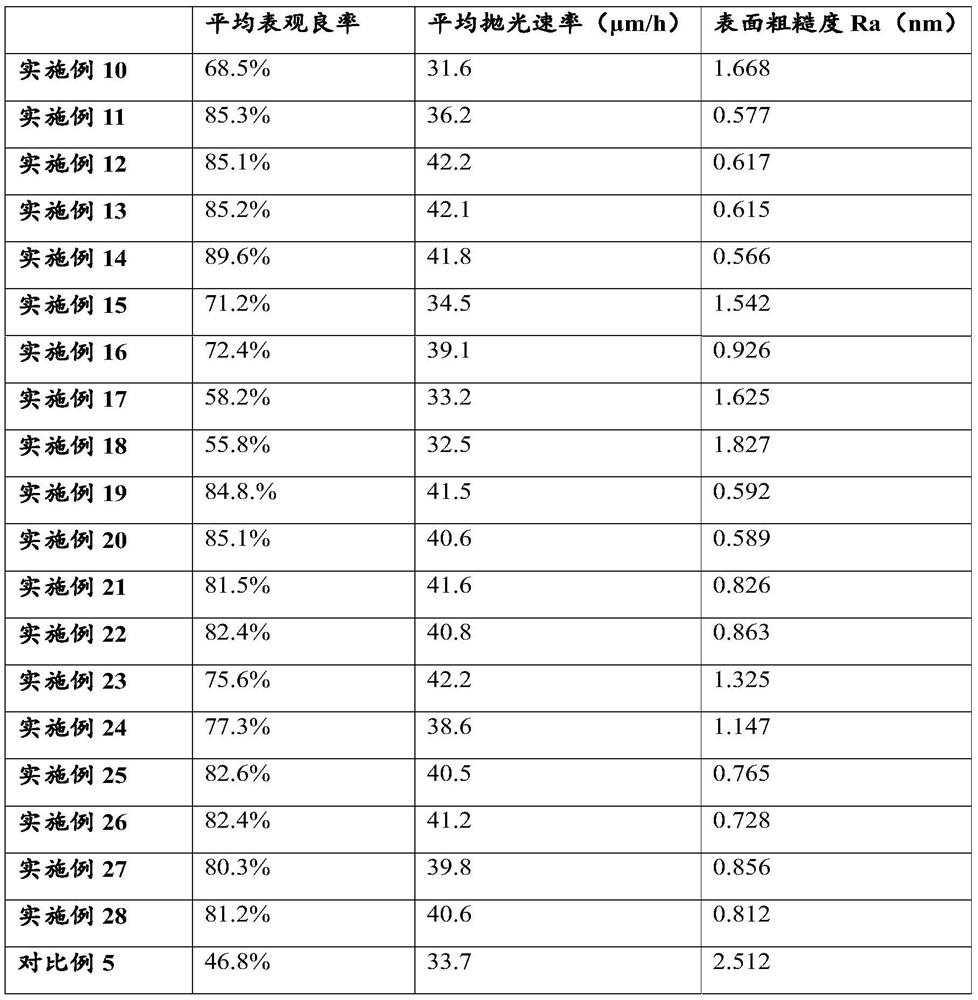

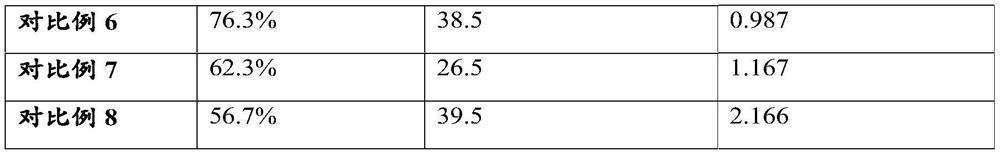

Water-based magneto-rheological polishing solution and preparation method thereof

ActiveCN111100559AZero magnetic field viscosity reductionImprove viscosity stabilityPolishing compositions with abrasivesSolventOxidizing agent

The invention belongs to the technical field of optical precision machining and manufacturing, and particularly relates to a water-based magneto-rheological polishing solution and a preparation methodthereof. The water-based magneto-rheological polishing solution provided by the invention comprises the following components: 77-88 wt% of magnetic particles, 0.001-8 wt% of non-magnetic polishing powder, 0.2-0.5 wt% of a dispersion stabilizer, 0.5-1 wt% of a wetting agent, 0.1-0.4 wt% of a chelating agent, 0.01-0.02 wt% of an antioxidant, 0.2-0.5 wt% of a pH conditioning agent, and water as a solvent, wherein the dispersion stabilizer is polyphosphate and / or citrate, the wetting agent is polyol, and the chelating agent is an amino carboxylic acid compound and / or organic phosphate. The water-based magneto-rheological polishing solution provided by the invention has good dispersion stability and viscosity stability, low zero magnetic field viscosity and high material removal efficiency.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Automatic turning-over polishing equipment for hardware plates

InactiveCN111791138ALower skill requirementsSatisfy polishing needsGrinding carriagesPolishing machinesMultiple devicePolishing

The invention discloses automatic turning-over polishing equipment for hardware plates. An shell comprises a working cavity, a turning-over mechanism is arranged in the working cavity, a motor fixingframe is fixedly arranged on the position, located at the lower end of the working cavity, of the shell, a motor is fixedly arranged at the upper end of the motor fixing frame, a first rotating shaftis rotatably arranged at the front end of the motor, and a first belt pulley is fixedly arranged on the first rotating shaft. According to the equipment, the structure is simple, the operation is convenient, the requirement on the skill of an operator is low, one person can control multiple devices, the production efficiency is improved, the labor intensity is reduced, a lot of manpower is saved,the product quality is improved, and the quality difference between products is reduced. The equipment can be adjusted as required to meet the polishing requirements of the plates with different thicknesses.

Owner:东阳坎层电子科技有限公司

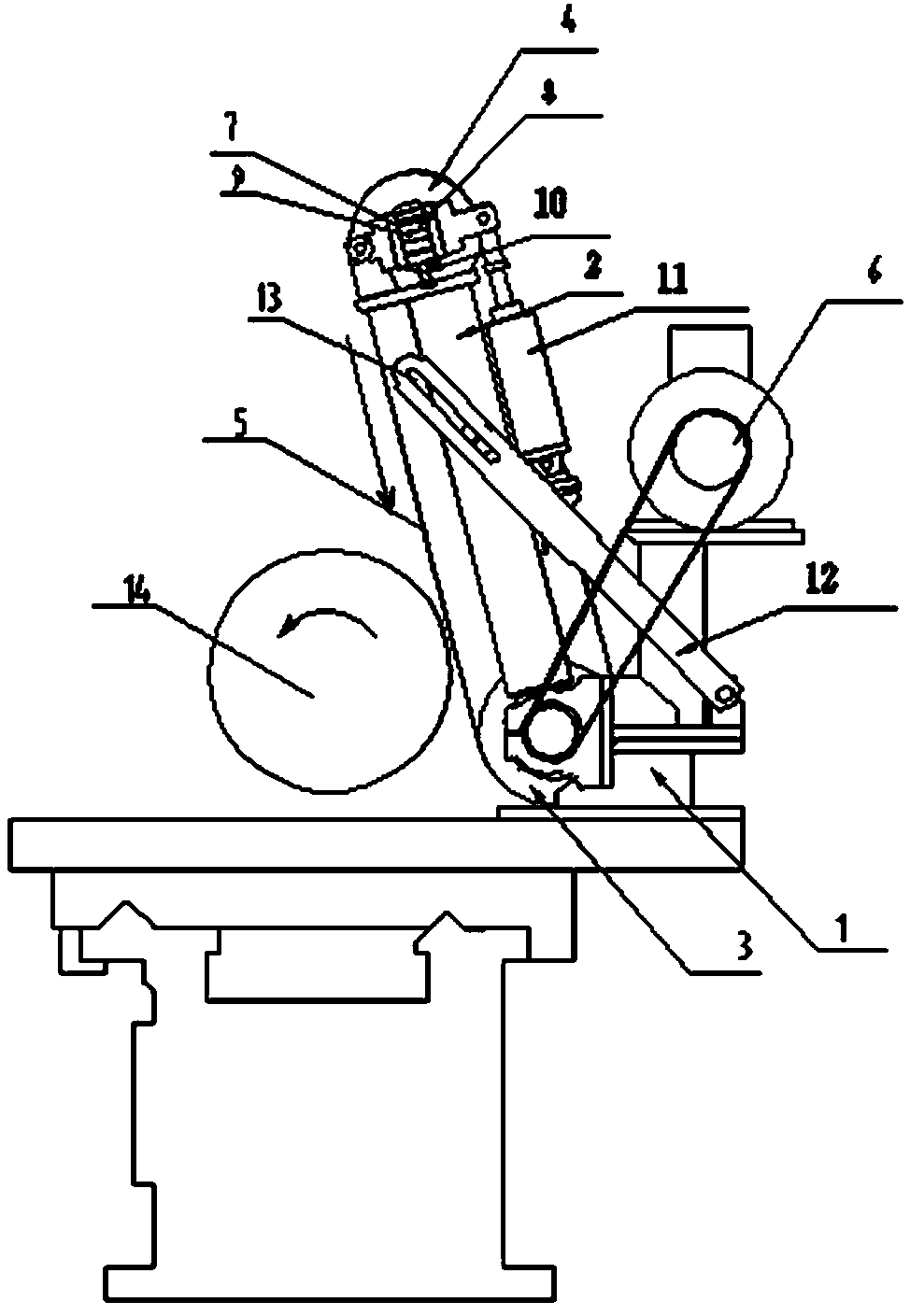

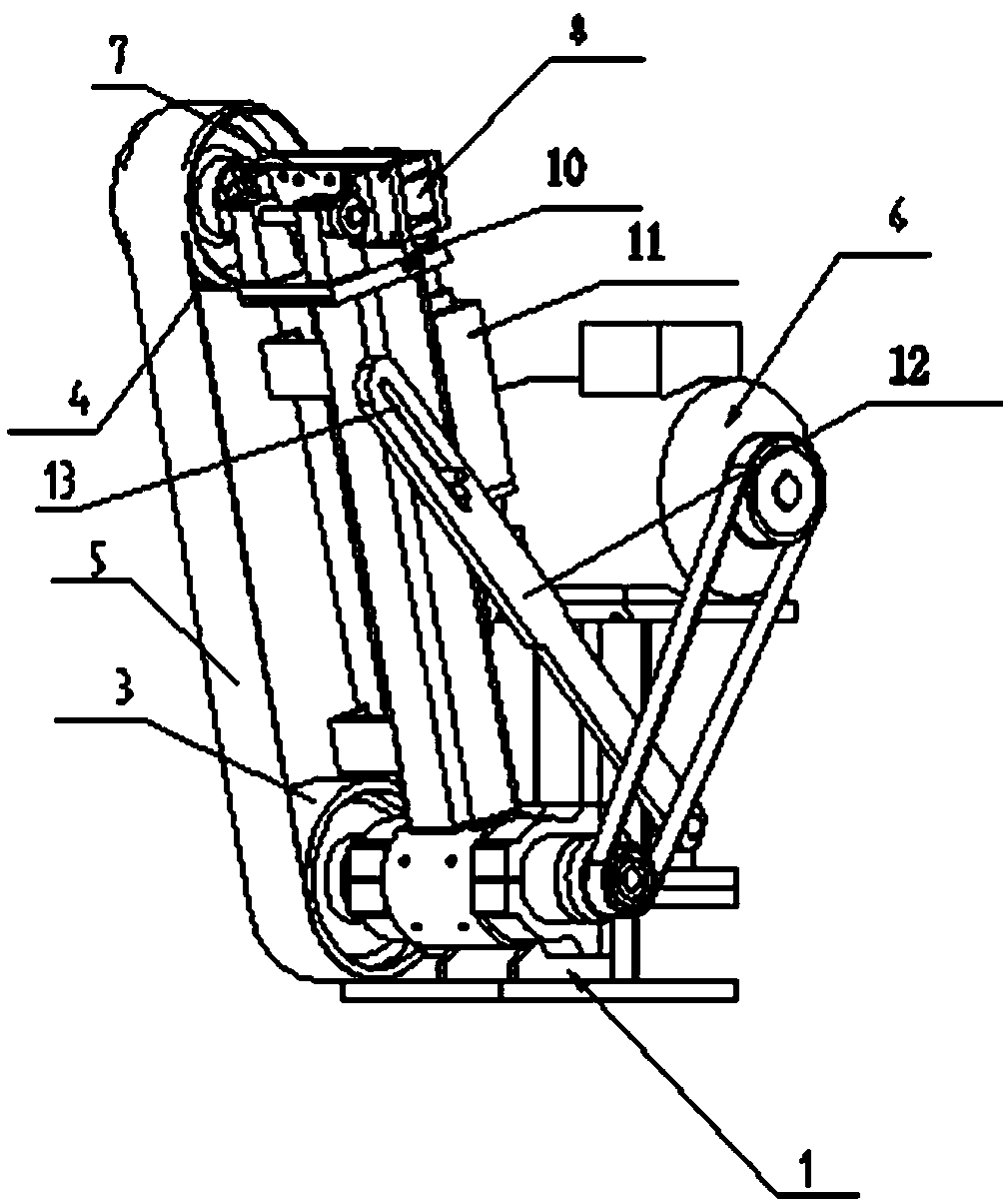

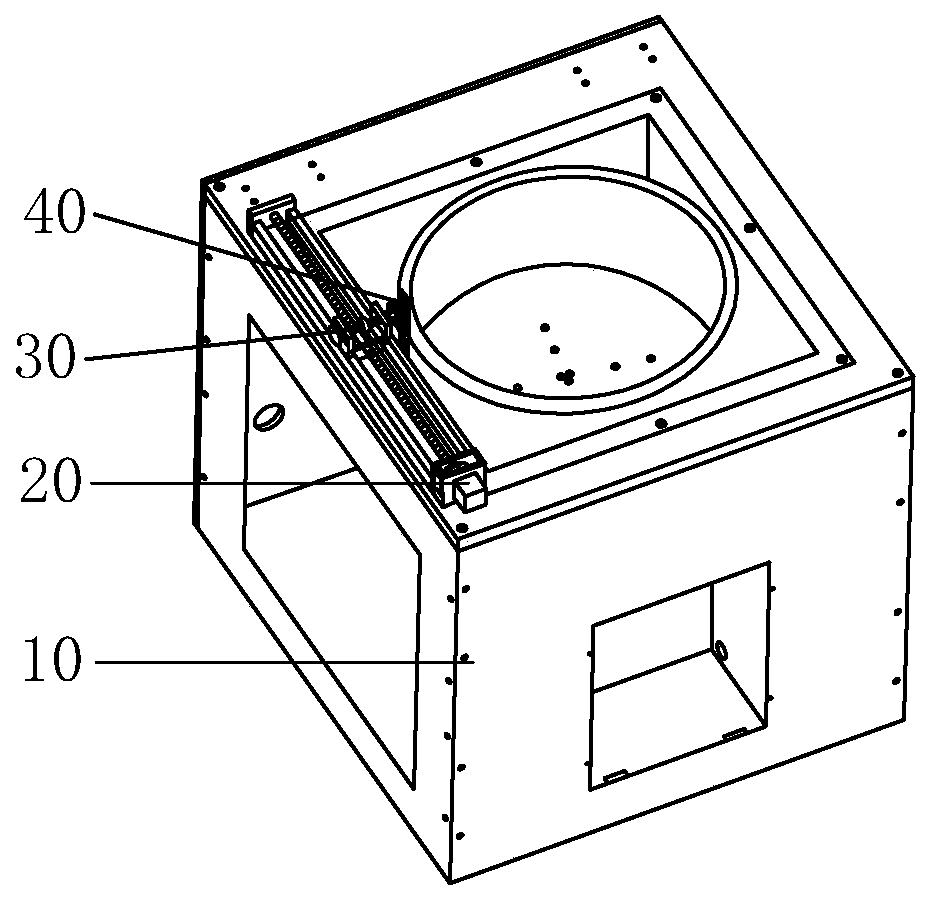

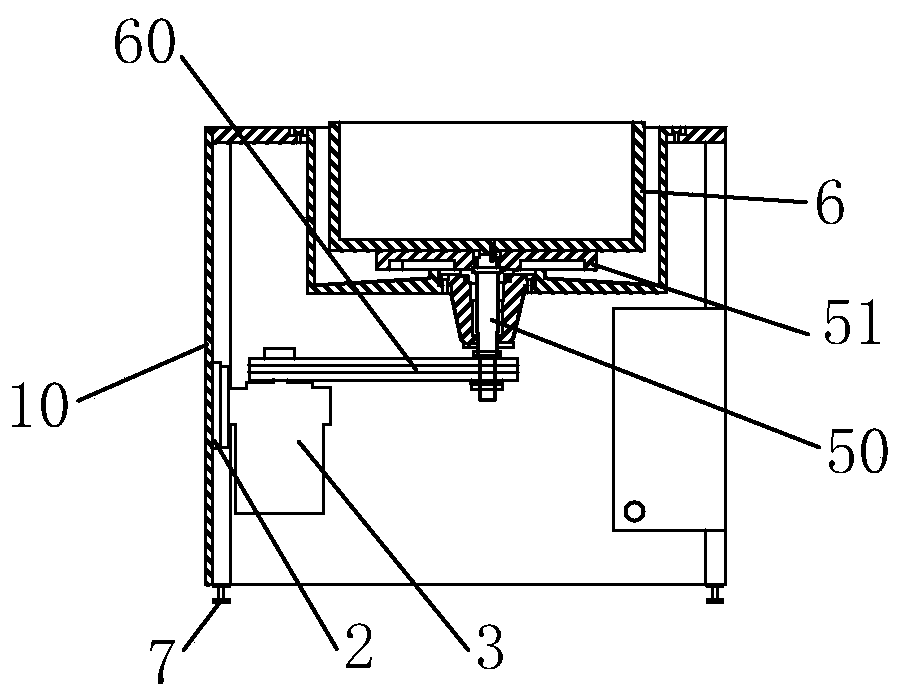

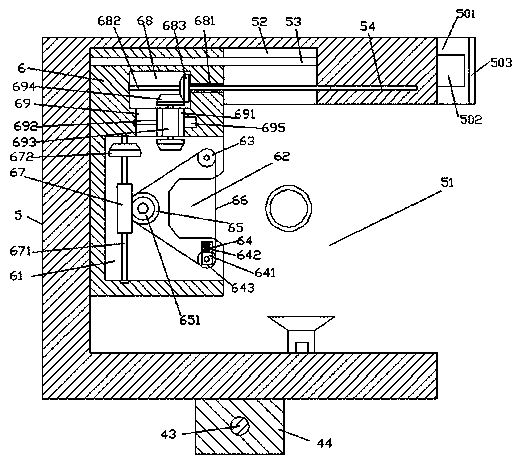

Full-automatic polishing machine of profiled component

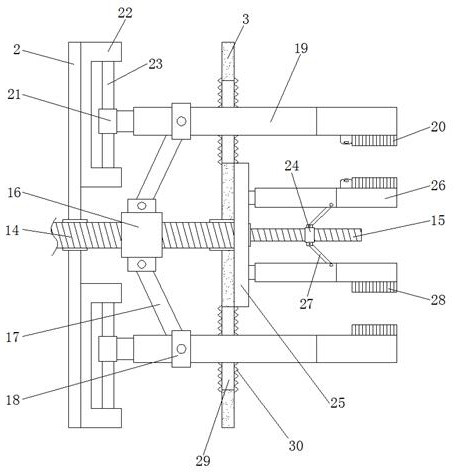

ActiveCN103264343AGood processing flexibilityImprove processing efficiencyPolishing machinesEngineeringFlange

The invention provides a full-automatic polishing machine of a profiled component and relates to a polishing machine. The full-automatic polishing machine is provided with a peripheral metal plate protective module, an XY-axis module, a mechanical arm module and a polishing wheel module, wherein the peripheral metal plate protective module is provided with a metal plate protective cover, an air cylinder, a side door, a pneumatic protective door and a base; the XY-axis module is provided with an X-axis sub-module and a Y-axis sub-module; each of the X-axis sub-module and the Y-axis sub-module is provided with a bottom plate, a screw rod nut, a screw rod, a screw rod seat, a wire rail and a servo motor; the mechanical arm module is provided with an A-axis sub-module, a B-axis sub-module, a C-axis sub-module, a clamp base and a belt wheel mechanism; the A-axis sub-module is provided with an A-axis motor, an A-axis outer arm and an A-axis flange; the B-axis sub-module is provided with a B-axis motor, a B-axis outer arm and a B-axis flange; the C-axis sub-module is provided with a C-axis motor, a C-axis outer arm and a C-axis flange; and the polishing wheel module is provided with a polishing wheel, a polishing wheel protective cover, a shaft coupler and a polishing motor. The automatic polishing machine is high in efficiency, good in machining flexibility, safe, reliable, and free from pollution.

Owner:厦门万久科技股份有限公司

Wax-changing device of polishing machine

ActiveCN104057400AGuaranteed StrengthPlay a protective effectPolishing machinesGrinding/polishing safety devicesWaxEngineering

The invention provides a wax-changing device of a polishing machine. The wax-changing device of the polishing machine comprises a support. A pushing device, a stabilization rack and a power device are arranged on the support, wherein the pushing device is used for pushing rod wax to move to be in friction with a cloth roller, the stabilization rack is used for keeping the rod wax stable, and the power device is used for driving the pushing device and the stabilization rack to be mutually matched. The stabilization rack is composed of an upper cover board and a lower cover board. A sliding hole for containing the rod wax is arranged between the two cover boards. An opening and closing control device is arranged between the two cover boards. The lower cover board is connected with the power device through a positioning mechanism. The power device drives the stabilization rack and the rod wax to move in the same direction and the pushing device drives the rod wax to slide in the sliding hole. The special pushing device is arranged to satisfy the polishing requirements of products, the special stabilization rack is arranged for the rod wax, and the rod wax is protected in a reinforced mode and is not prone to breakage.

Owner:NINGBO ZHENHE ELECTRICAL EQUIP

Automatic winder for glass polishing wheels

InactiveCN103831745AEvenly distributedPrevent uneven thicknessGrinding devicesTemperature controlGear drive

The invention provides an automatic winder for glass polishing wheels. One shaft end of a driving press roll is connected with a driven press roll by means of gear drive, the driving press roll and the driven press roll are parallel to each other and matched in a squeezing manner, two ends of each of the driving press roll and the driven press roll form a squeezing matching input end and a squeezing matching output end respectively, the squeezing matching input ends are connected with a tail end of a feed platform, the squeezing matching output ends are connected with a gumming machine, the other end of the gumming machine is connected with a core rod, one shaft end of the core rod is connected with a handle drum while the other shaft end of the same is connected with a core rod fixing device, a temperature control machine is connected with the gumming machine through a heat guide pipe, and a strap adhesive fixing barrel is arranged at the inlet end of the gumming machine. Adhesive is distributed uniformly through the temperature control machine and the strap adhesive fixing barrel, the adhesive is prevented from being too thick or too thin to be non-uniform, a variator is used for regulating the speed of fabric wound in the core rod, further density of the fabric in the polishing wheels is regulated, and different requirements are met.

Owner:NANJING HONGSHENG FELT PRODION

A glass polishing wheel automatic winding machine

InactiveCN103831745BEvenly distributedAvoid uneven thicknessGrinding devicesTemperature controlGear drive

The invention provides an automatic winder for glass polishing wheels. One shaft end of a driving press roll is connected with a driven press roll by means of gear drive, the driving press roll and the driven press roll are parallel to each other and matched in a squeezing manner, two ends of each of the driving press roll and the driven press roll form a squeezing matching input end and a squeezing matching output end respectively, the squeezing matching input ends are connected with a tail end of a feed platform, the squeezing matching output ends are connected with a gumming machine, the other end of the gumming machine is connected with a core rod, one shaft end of the core rod is connected with a handle drum while the other shaft end of the same is connected with a core rod fixing device, a temperature control machine is connected with the gumming machine through a heat guide pipe, and a strap adhesive fixing barrel is arranged at the inlet end of the gumming machine. Adhesive is distributed uniformly through the temperature control machine and the strap adhesive fixing barrel, the adhesive is prevented from being too thick or too thin to be non-uniform, a variator is used for regulating the speed of fabric wound in the core rod, further density of the fabric in the polishing wheels is regulated, and different requirements are met.

Owner:NANJING HONGSHENG FELT PRODION

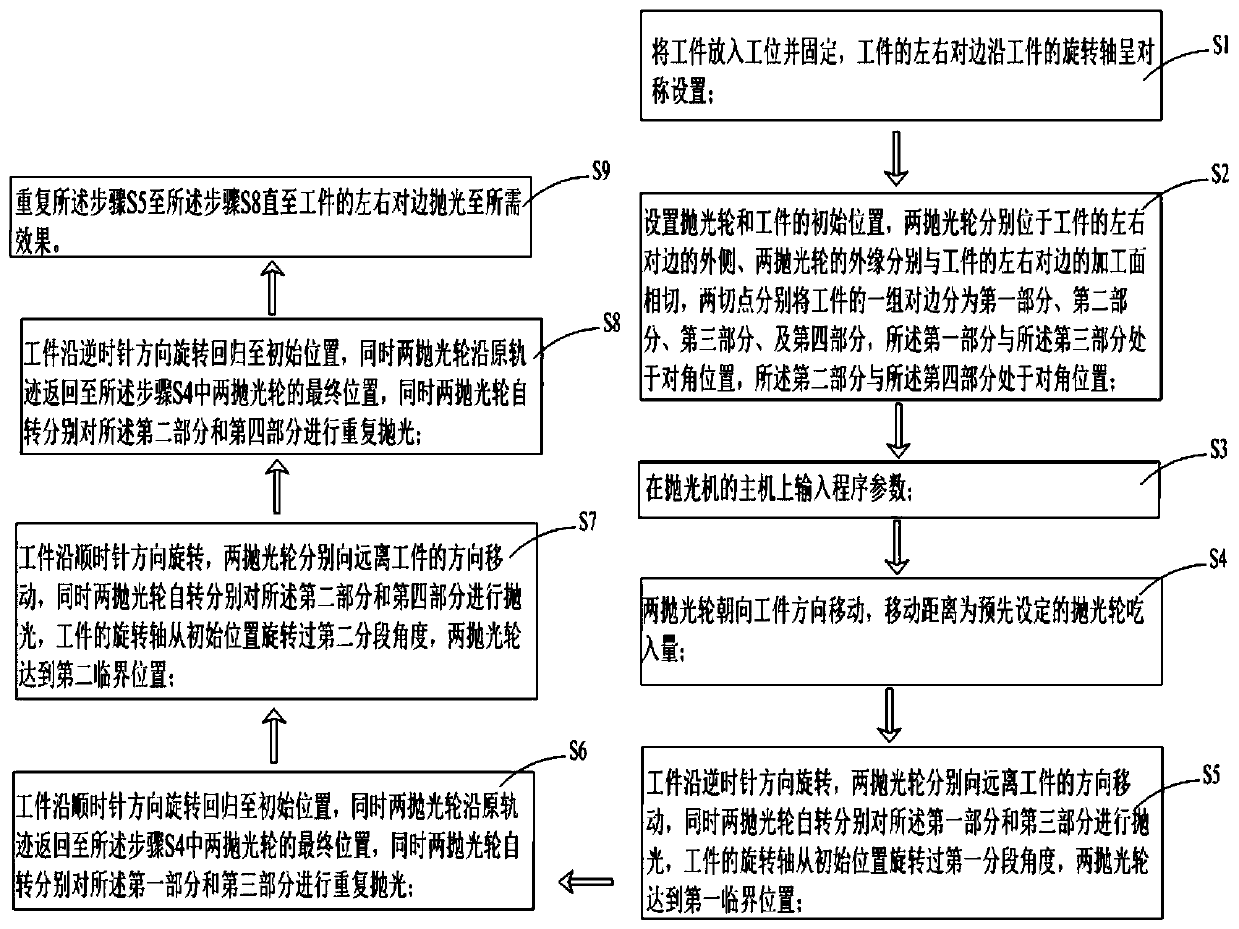

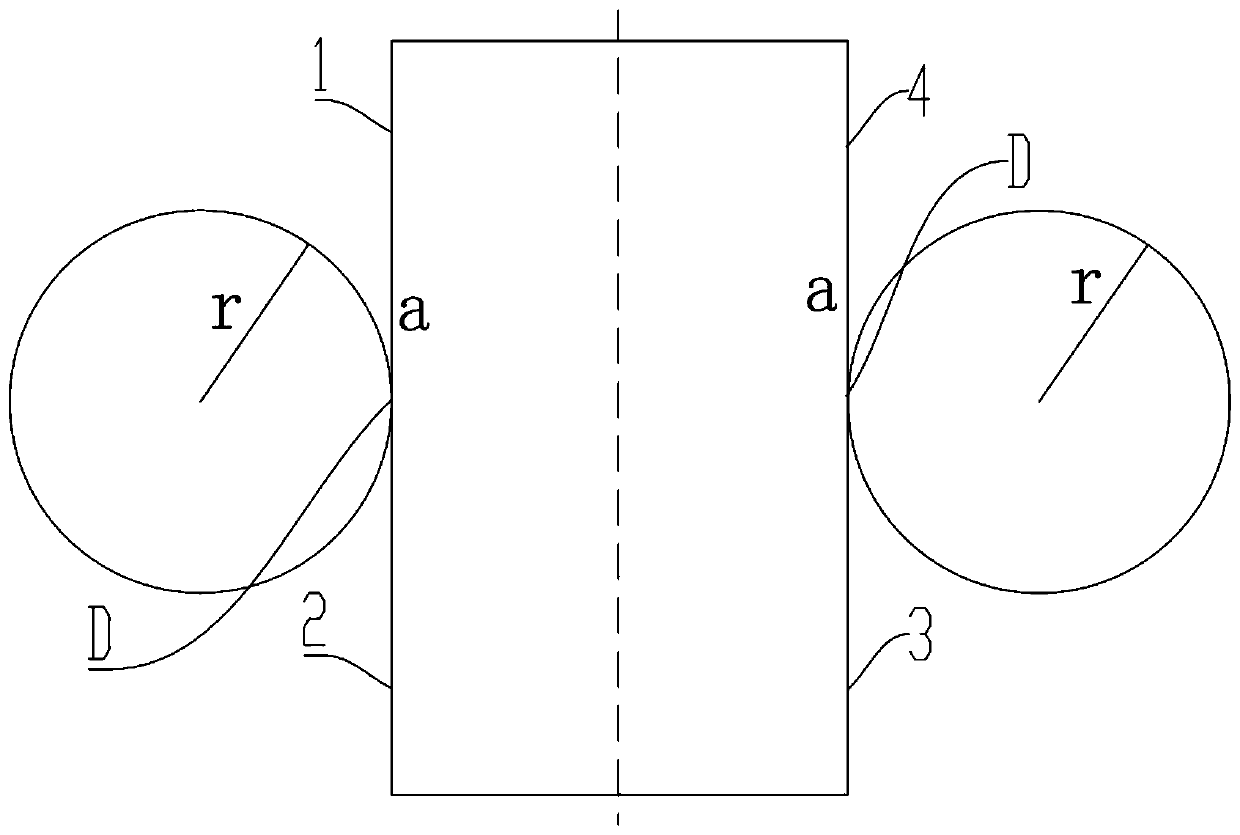

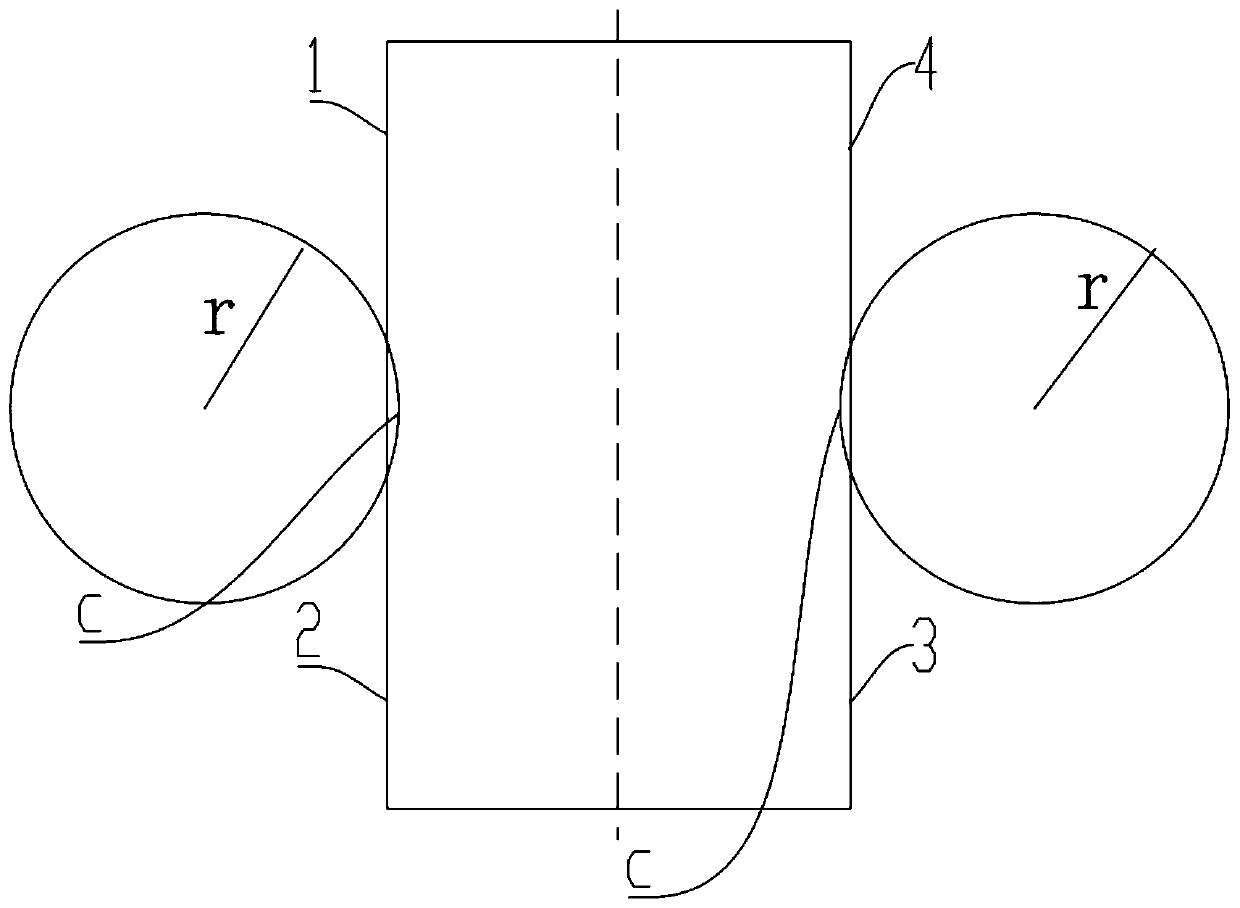

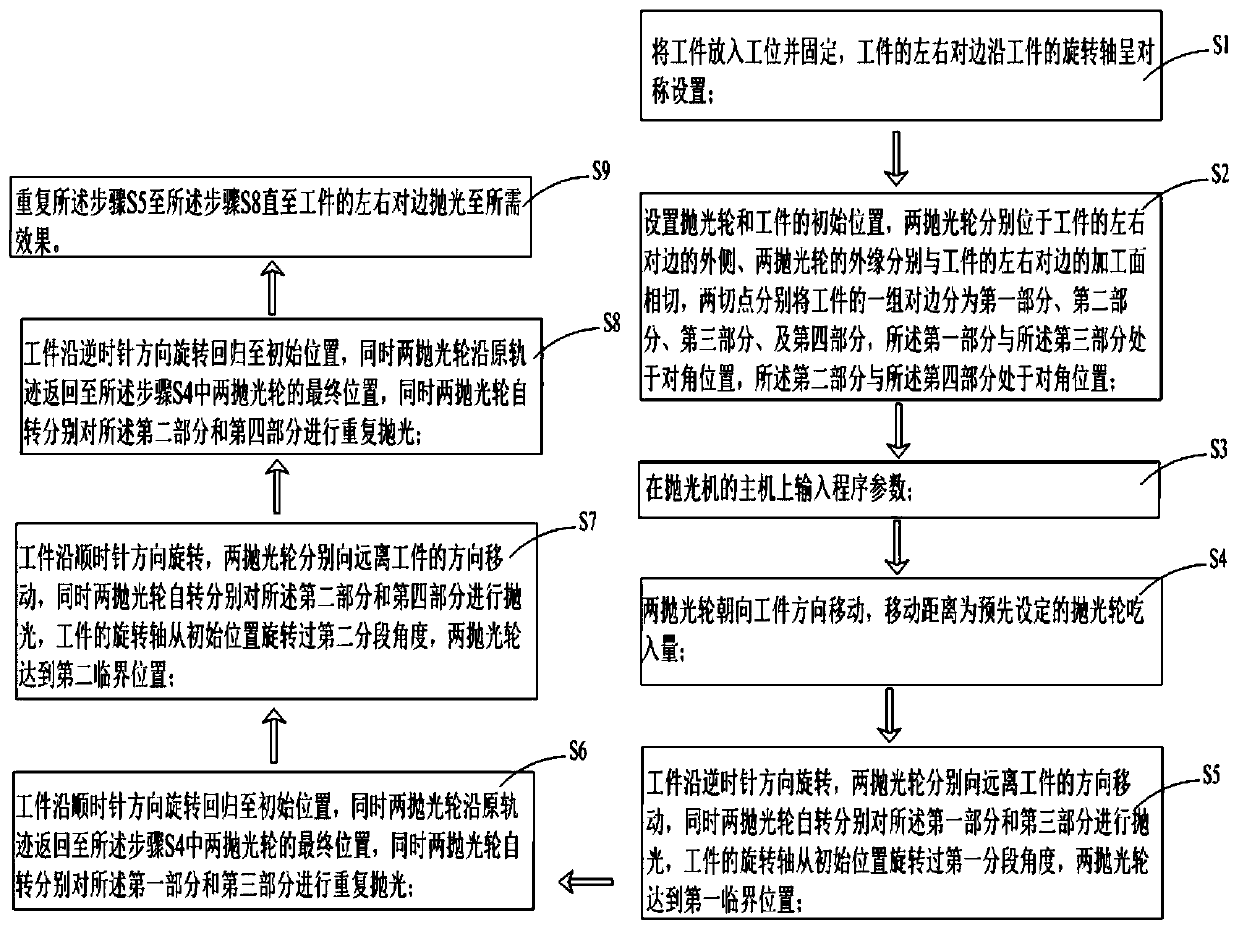

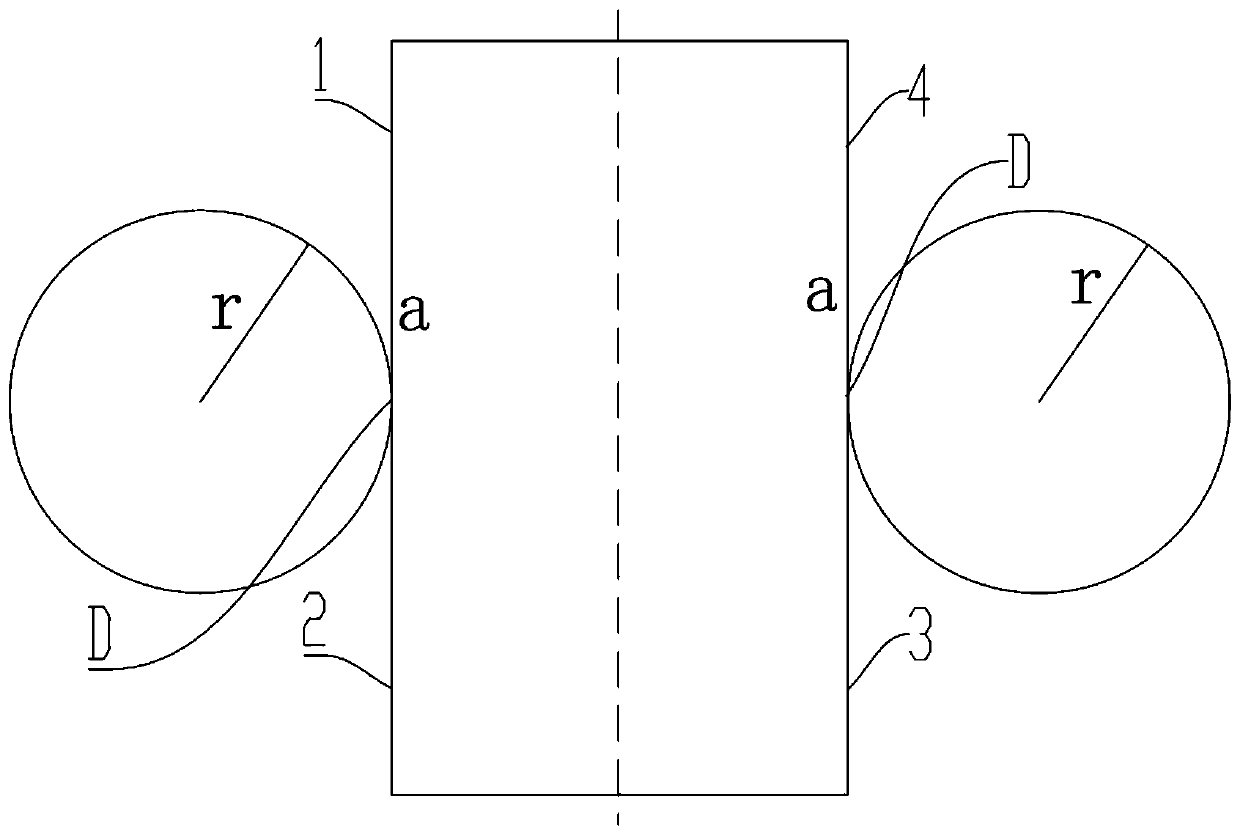

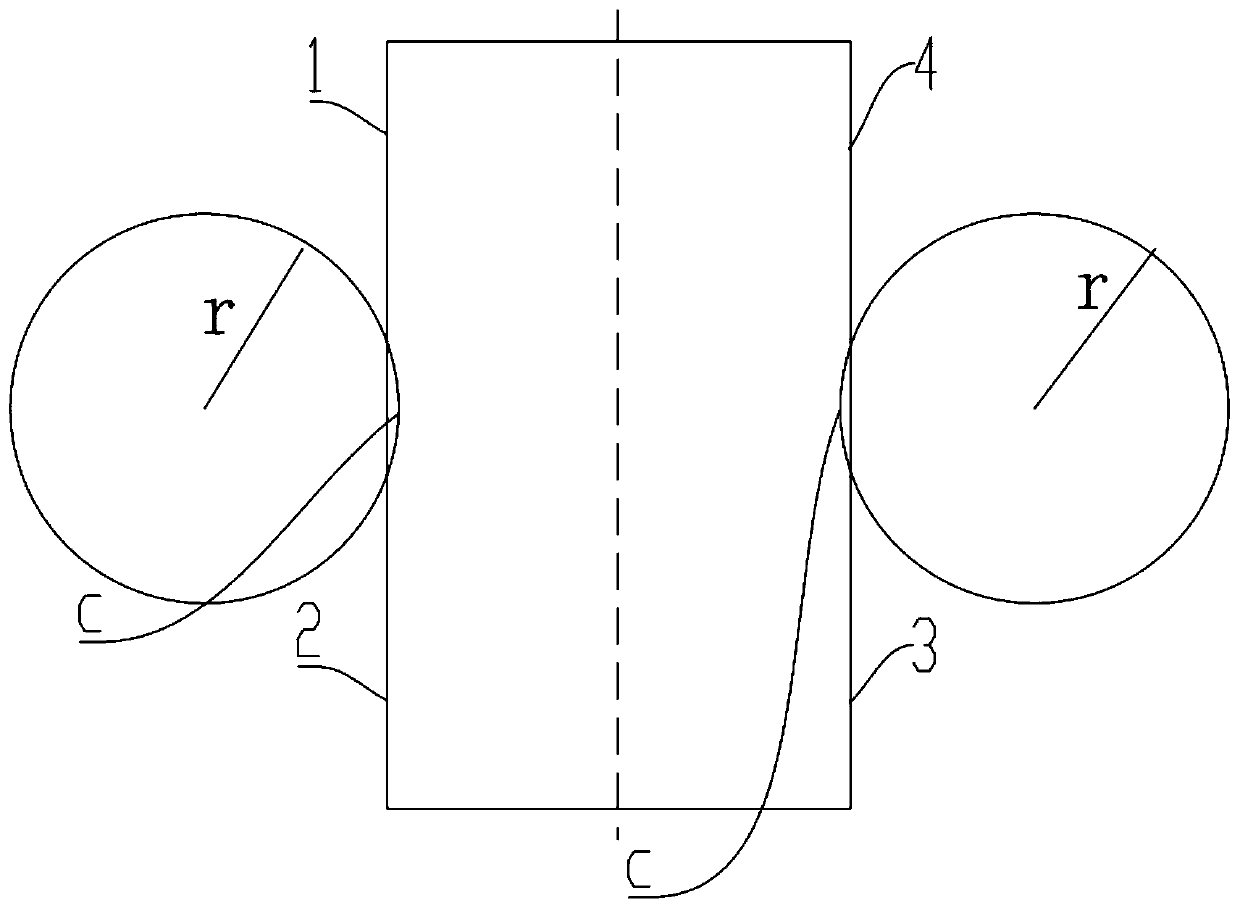

A segmental polishing method for rectangular glass

ActiveCN109834574BGuaranteed uniformityDo not avoid enteringPolishing machinesGrinding machinesPolishingMachine

The invention discloses a rectangular glass segmented polishing method. The rectangular glass segmented polishing method comprises the steps that S1, a workpiece is placed into a station and fixed; S2, initial positions of two polishing wheels and the workpiece are set; S3, program parameters are input into a host computer of a polishing machine; S4, the two polishing wheels move towards the workpiece; S5, the workpiece rotates counterclockwise; S6, the workpiece rotates clockwise to return to the initial position; S7, the workpiece rotates clockwise; S8, the workpiece rotates counterclockwiseto return to the initial position; and S9, the steps S5 to S8 are repeated. The process steps of the rectangular glass segmented polishing method are simple and reasonable in design, and the uniformity of polishing of the workpiece can be ensured; the segment polishing can avoid corners of the glass workpiece entering the polishing wheels, thereby protecting the corners of the glass workpiece from being polished, and meeting the polishing requirements of certain glass workpieces of which arc corners cannot be polished; and automatic computer programming is highly automated, and the polishinguniformity can be ensured.

Owner:蒙马科技(深圳)有限公司

A kind of water-based magnetorheological polishing fluid and preparation method thereof

ActiveCN111100559BZero magnetic field viscosity reductionImprove utilization efficiencyPolishing compositions with abrasivesMetallurgyCarboxylic acid

The invention belongs to the technical field of optical precision machining and manufacturing, and in particular relates to a water-based magnetorheological polishing liquid and a preparation method thereof. The water-based magnetorheological polishing liquid provided by the invention comprises: magnetic particles 77-88wt%; non-magnetic polishing powder 0.01wt‰-8wt%; dispersion stabilizer 0.2-0.5wt%; wetting agent 0.5-1wt%; chelating agent 0.1-0.4wt%; antioxidant 0.01-0.02wt%; pH adjuster 0.2-0.5wt%; solvent is water; the dispersion stabilizer is polyphosphate and / or citrate; the wetting agent is Polyol; the chelating agent is an aminocarboxylic acid compound and / or an organic phosphate. The water-based magnetorheological polishing liquid provided by the invention has good dispersion stability and viscosity stability, low zero magnetic field viscosity and high material removal efficiency.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

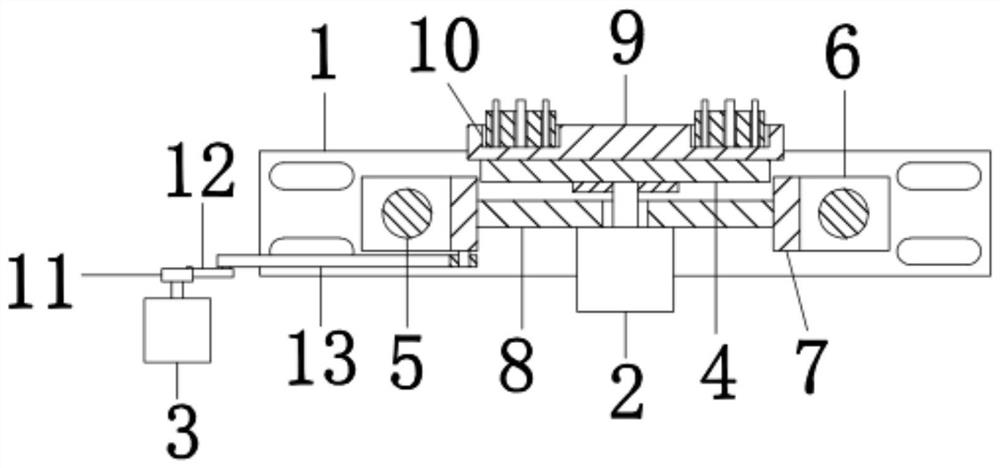

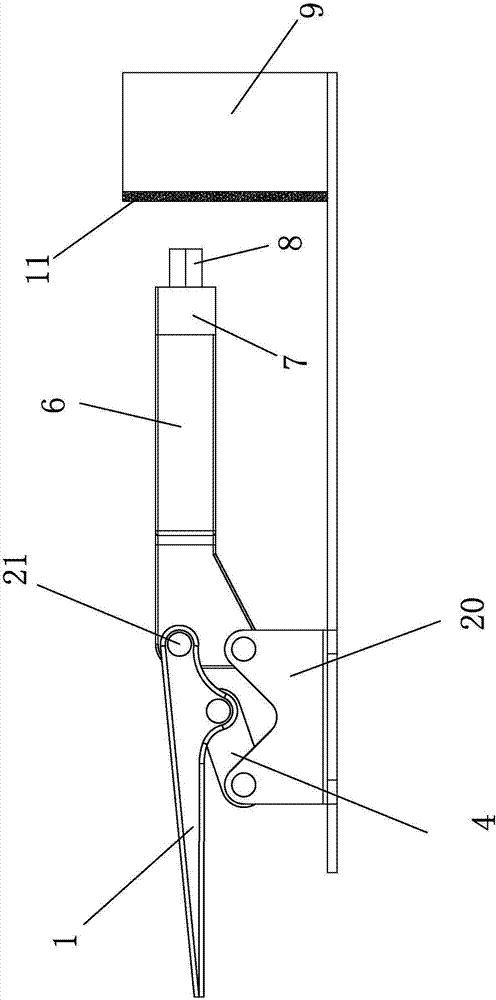

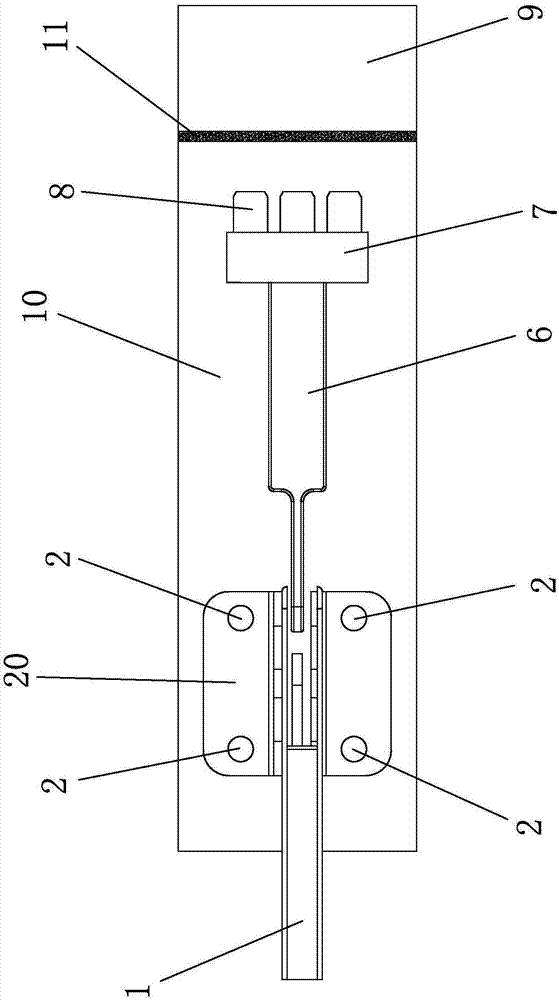

Rapid gasket pressing device and application method thereof

InactiveCN106975689ASolve bad problems and save a lot of debugging timeSimple structureOptical surface grinding machinesEngineeringGasket

The invention discloses a rapid gasket pressing device and an application method thereof. The rapid gasket pressing device comprises a fixing bottom plate. An elastic base used for containing a pressed gasket is arranged at one end of the fixing bottom plate, and an installing base is arranged at the other end of the fixing bottom plate. A rapid positioning main rod is hinged to the installing base. A pressure head is arranged at the front end of the rapid positioning main rod. A transverse pressing handle capable of driving the pressure head on the rapid positioning main rod to move towards the elastic base is hinged to the rear end of the rapid positioning main rod, and the transverse pressing handle is hinged to the installing base. The problems that precision is not enough, the deflection amount is large, and consequently badness is caused in the optical lens polishing procedure is solved, longer debugging time is saved, the structure is simple, and using is convenient.

Owner:舜宇光学(中山)有限公司

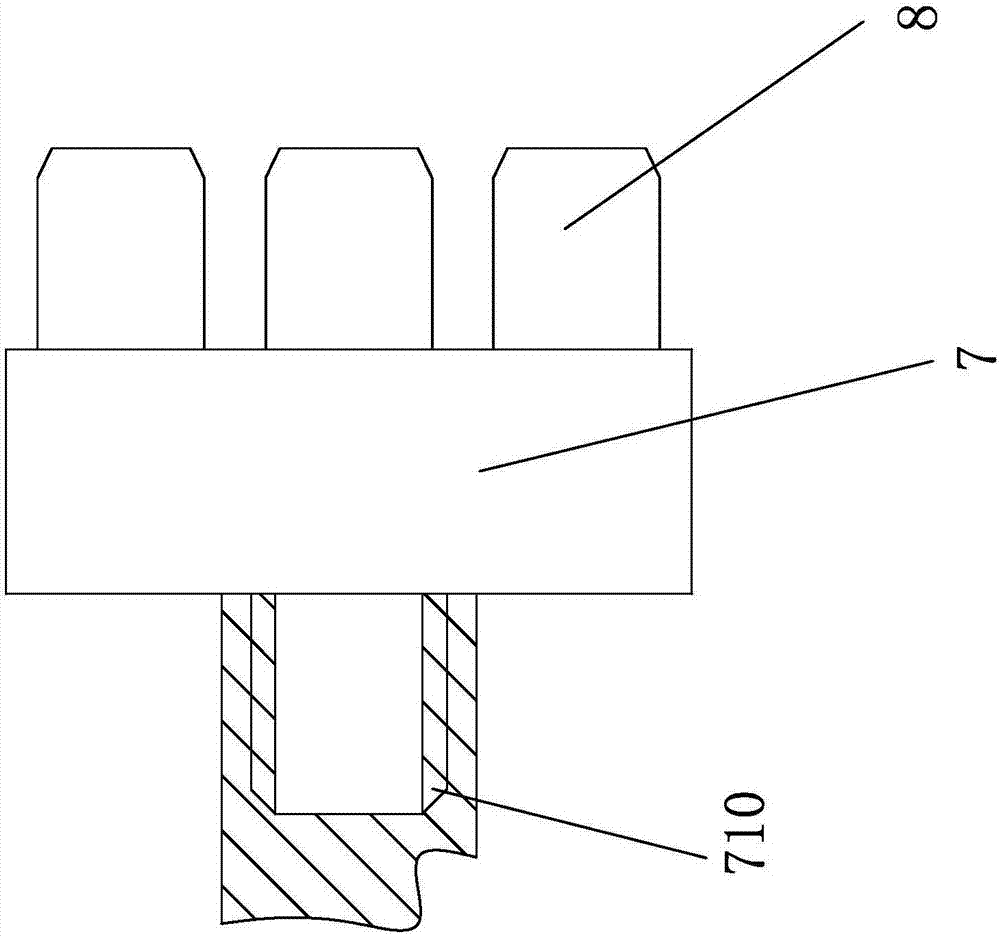

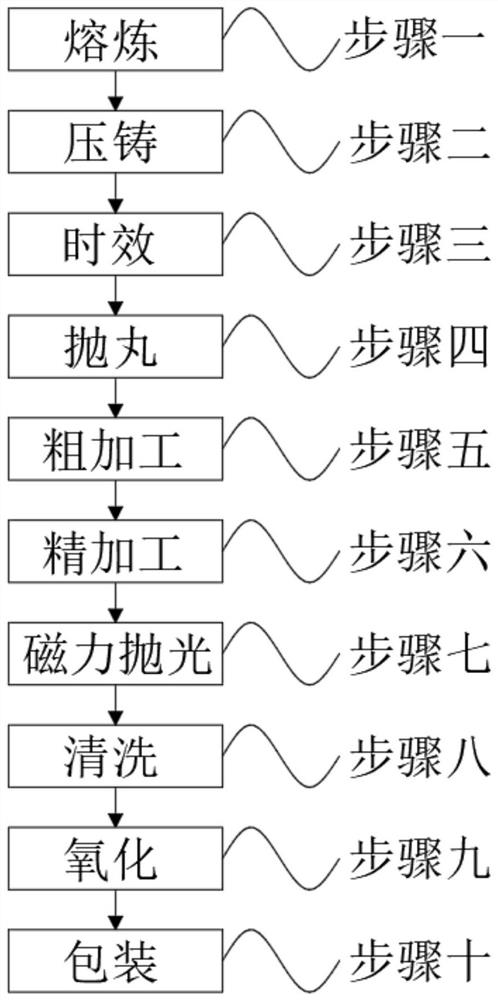

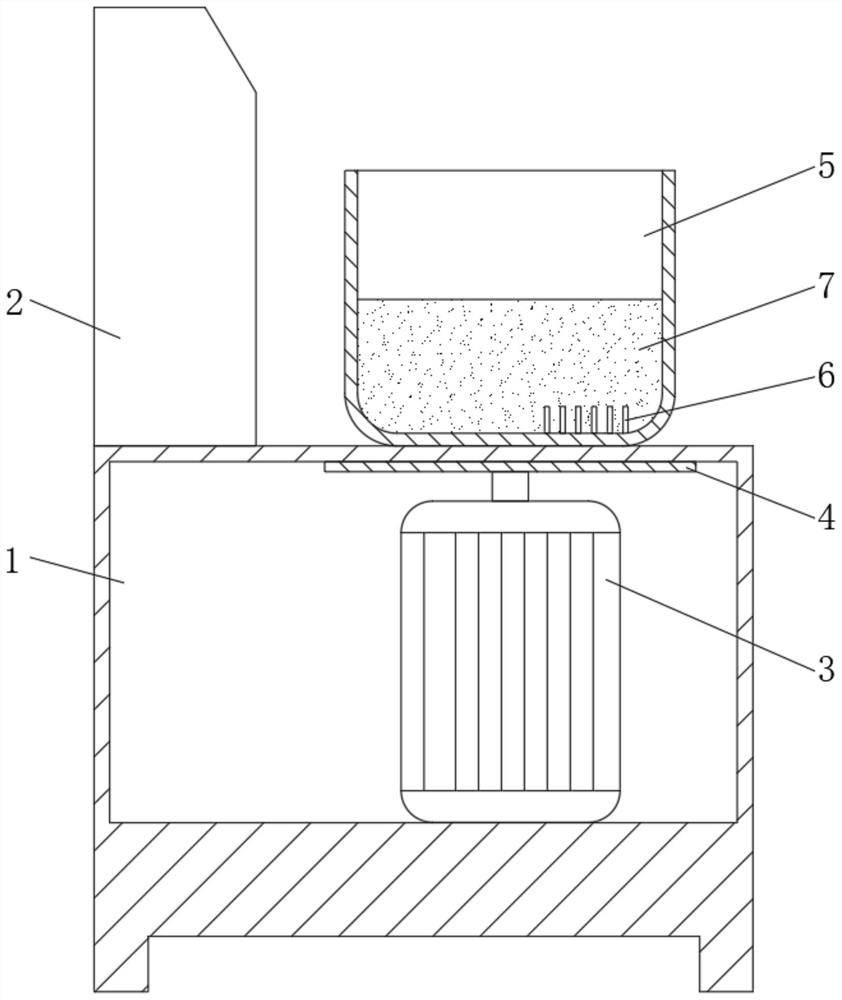

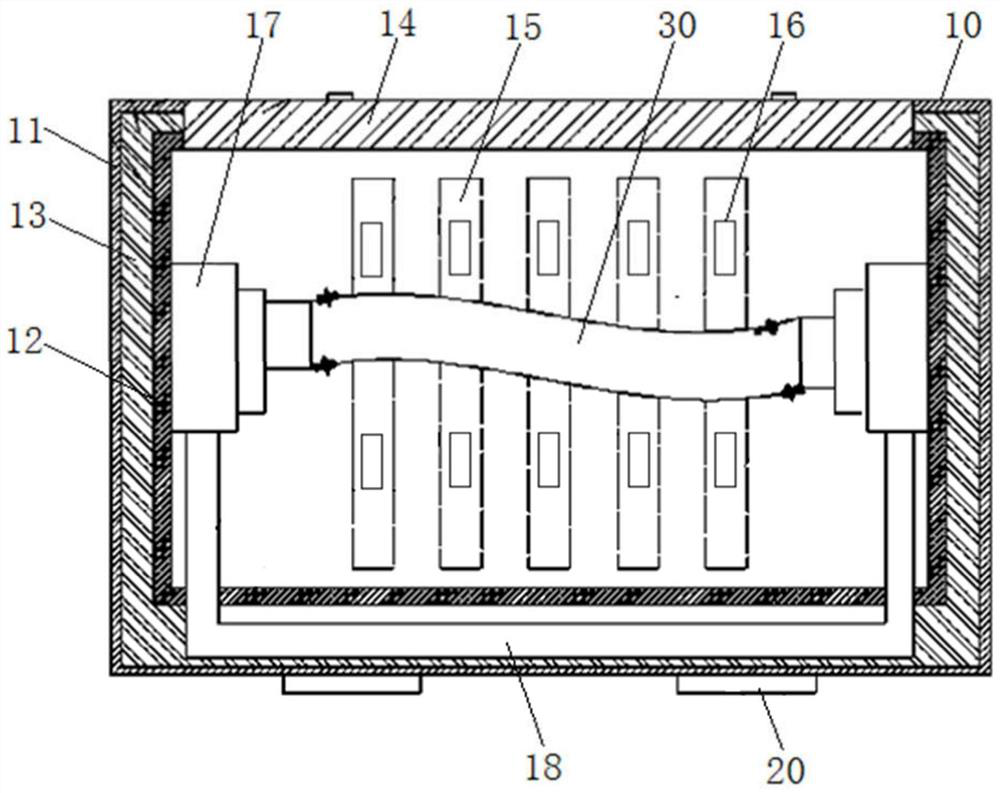

Ultra-precision machining process for aluminum alloy die-casting gearbox valve sleeve

PendingCN114227521ARealize chamferAchieve polishEdge grinding machinesPolishing machinesPolishingDie casting

The invention discloses an ultra-precision machining technology for an aluminum alloy die-casting gearbox valve sleeve. The ultra-precision machining technology comprises the following steps that firstly, smelting is conducted; step 2, die casting; step 3, aging; step 4, shot blasting; 5, rough machining; step 6, finish machining; seventhly, magnetic polishing is conducted; step 8, cleaning; step 9, oxidation; and step 10, packaging. The polishing machine has the beneficial effects that multiple effects of deburring, chamfering, polishing, cleaning, environmental protection and the like can be achieved; the grinding and polishing device is suitable for grinding and polishing nonmetal workpieces such as metal workpieces, hard plastic workpieces, ceramic workpieces and silicon wafers; irregular parts, hole-shaped parts, pipe-shaped parts, cracks and the like can be polished, polishing is free of dead angles, the ground workpieces are never deformed, the surfaces are never damaged, and the precision is never affected; customization time is short, processing speed is high, and operation is easy and convenient; variable frequency adjustment is achieved, various polishing requirements are met, and voltage, current, frequency and time can be monitored.

Owner:德阳上川科技有限公司

A magnetic special-shaped tube inner wall polishing equipment

ActiveCN109352508BAccuracy is not affectedStrong and stable magnetic effectEdge grinding machinesPolishing machinesMetallic materialsEngineering

The invention discloses a polishing device for the inner wall of a magnetic special-shaped tube. Two magnetic needle suspension collection and pumping components are installed in the polishing box. The special-shaped tube is rotatably installed between the two magnetic needle suspension collection and pumping components. The magnetic needle suspension is in the The magnetic needle suspension collects the flow between the pump out component and the inner cavity of the special-shaped tube; there are multiple sets of guide rails in the polishing box, and each set of guide rails is equipped with an electromagnetic coil assembly. The electromagnetic coil assembly is generated by the change of input current, voltage and current direction. The magnetic field distribution and magnetic field conversion frequency drive the magnetic needle in the magnetic needle suspension to impact the special-shaped tube at the required speed for polishing. The invention utilizes its unique magnetic field distribution to produce a strong and stable magnetic induction effect, so that the magnetic steel needle and the inner cavity of the special-shaped tube can be fully impacted and ground in all directions and from multiple angles, and quickly polished. After polishing, the surface can reach the level of the mirror surface without damage And the surface of the special-shaped tube, does not affect the precision of the special-shaped tube, and at the same time has a certain strengthening effect on the metal material special-shaped tube.

Owner:HUBEI SANJIANG SPACE WANSHAN SPECIAL VEHICLE

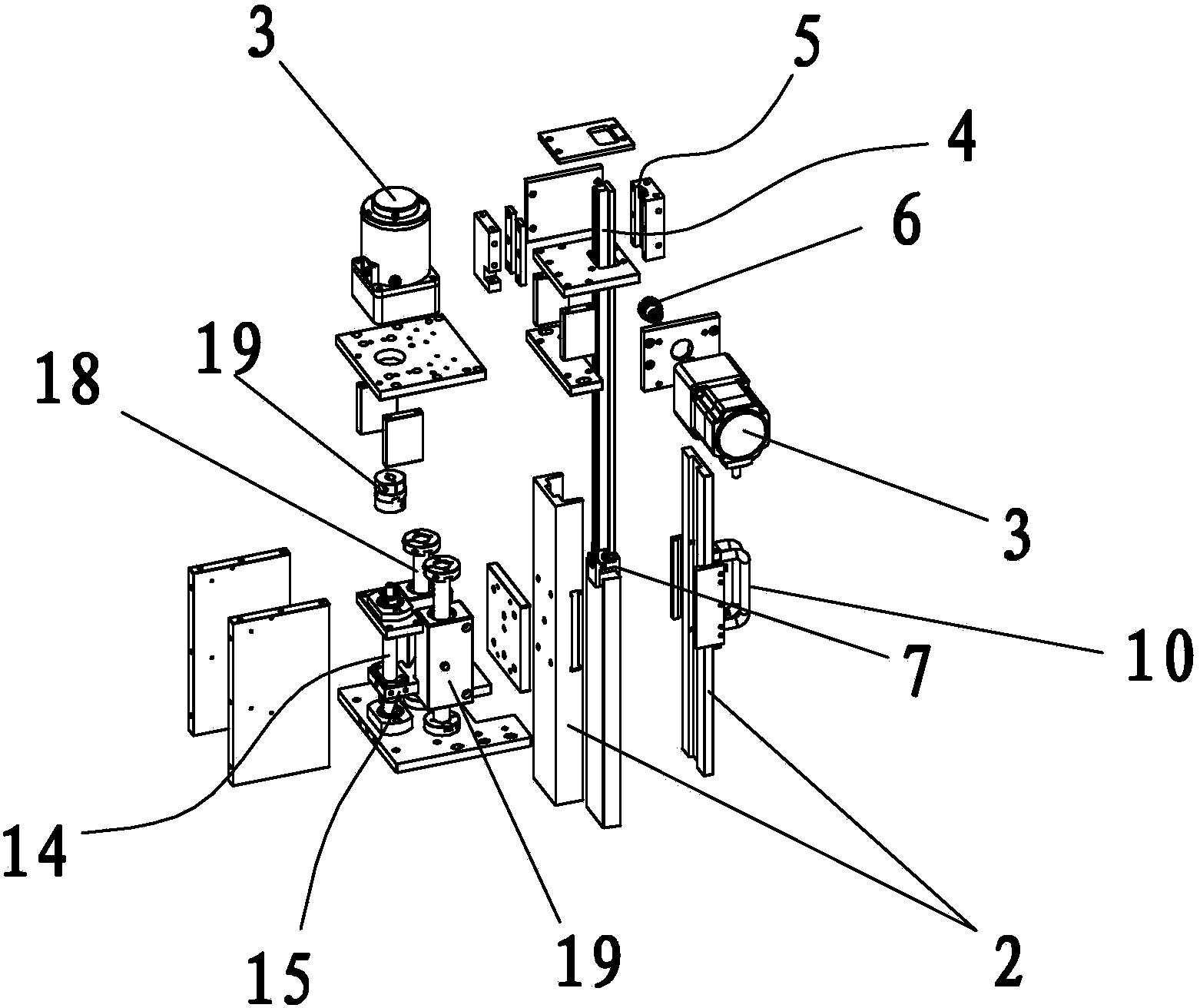

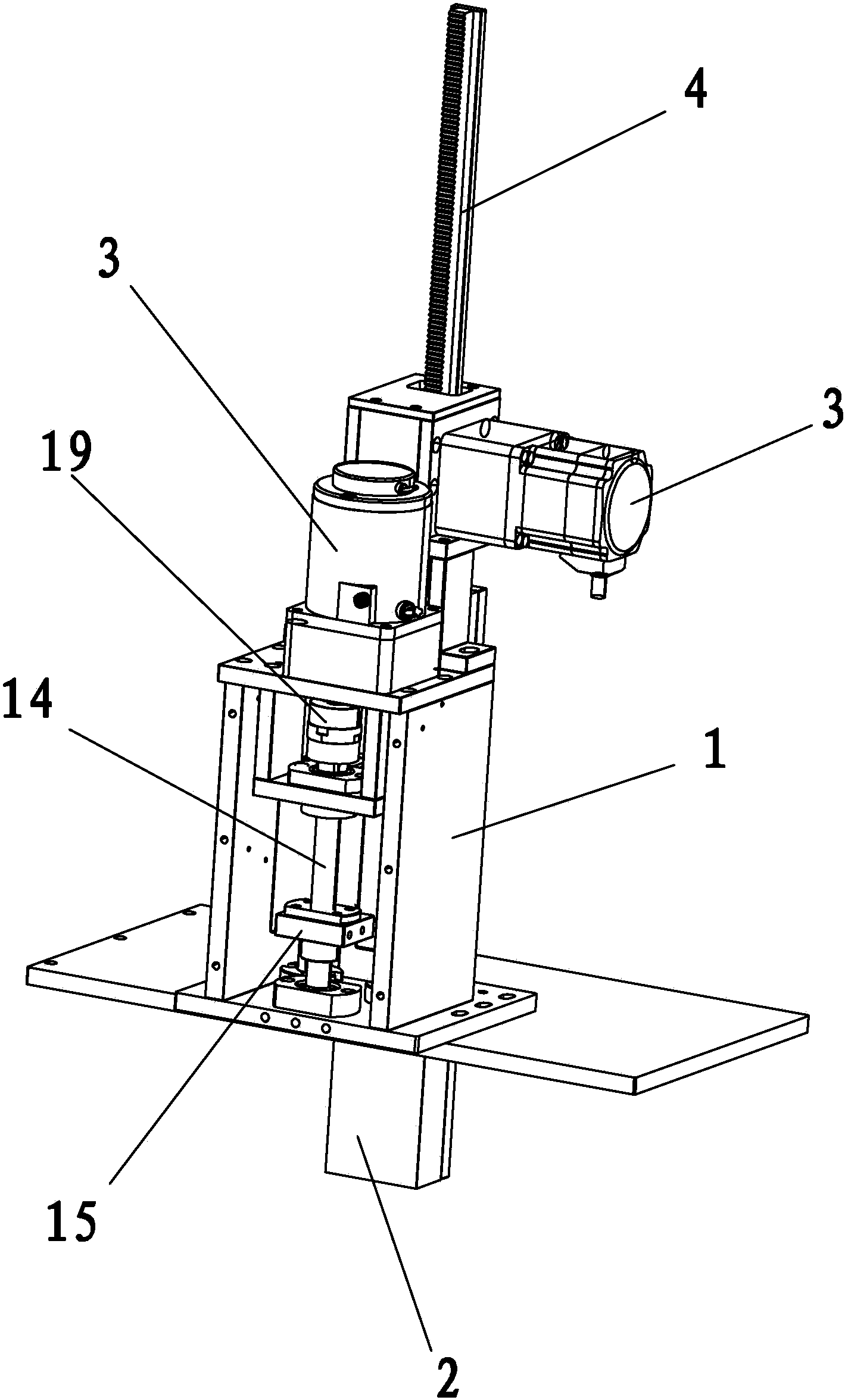

Non-contact polishing device

PendingCN111451918ALarge diameterThe required speed is smallPolishing machinesGrinding drivesPhysicsPolishing

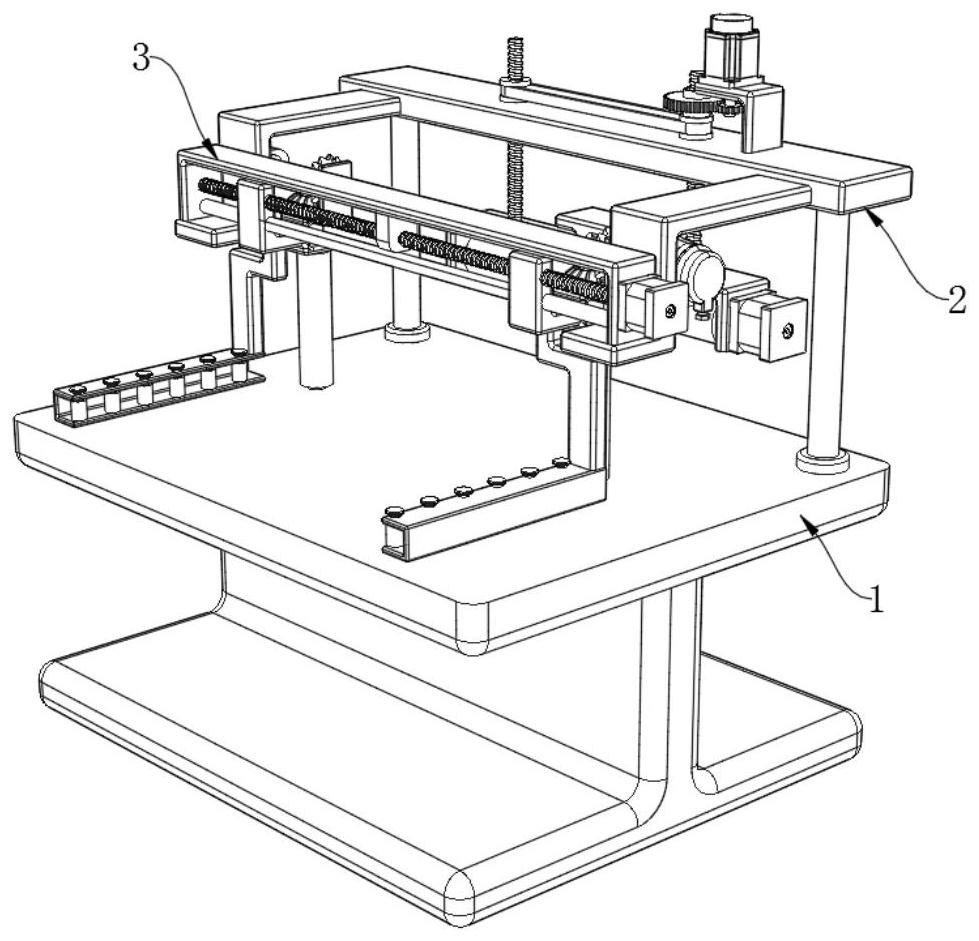

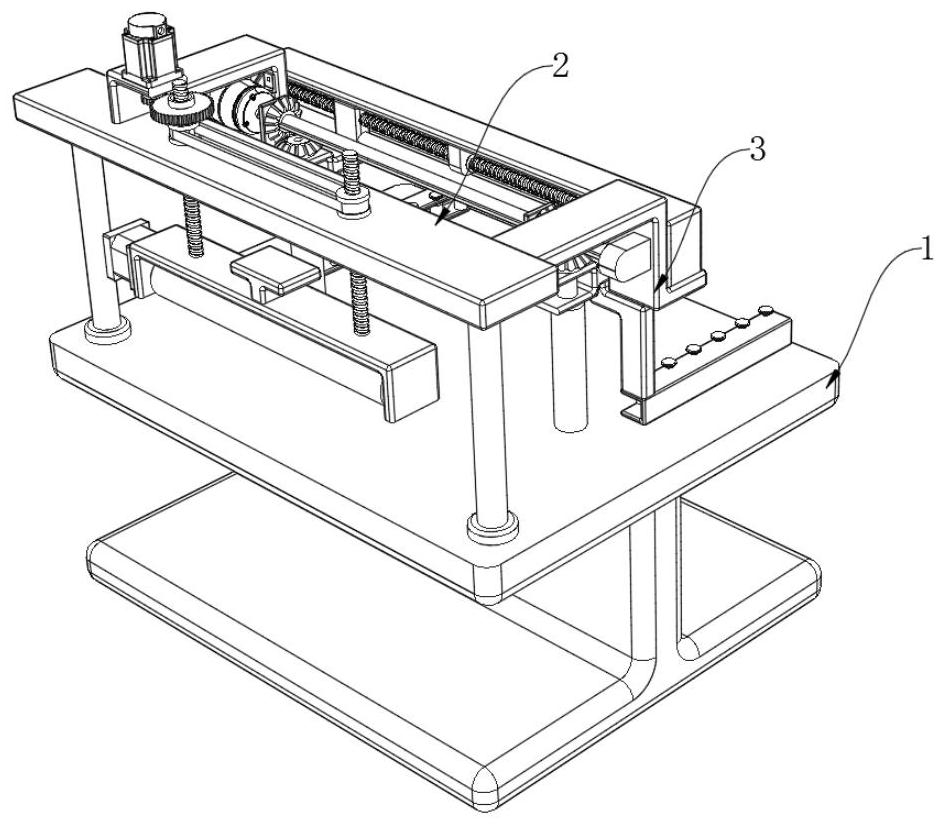

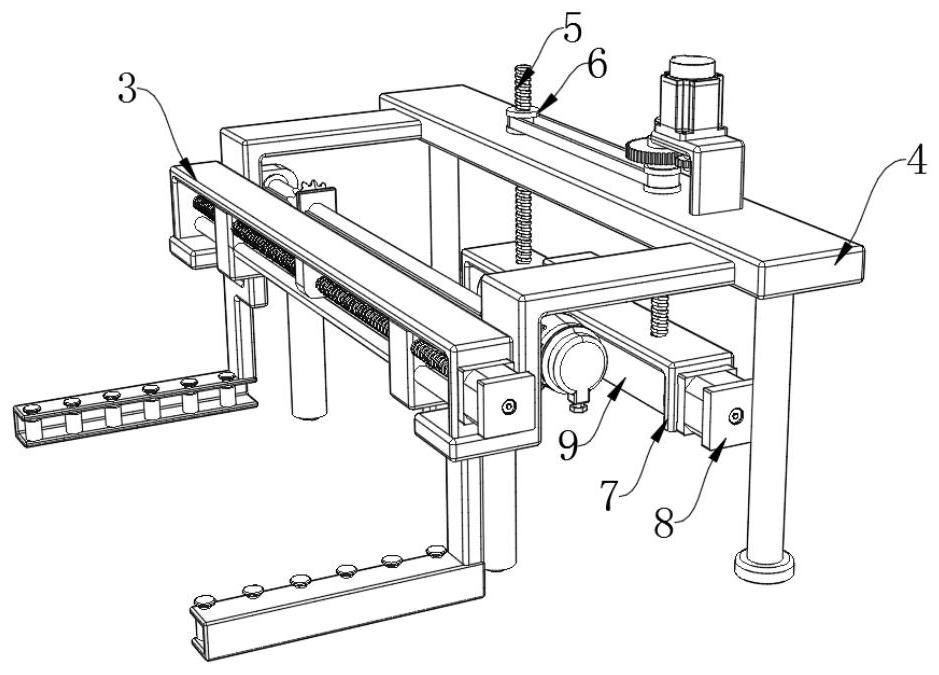

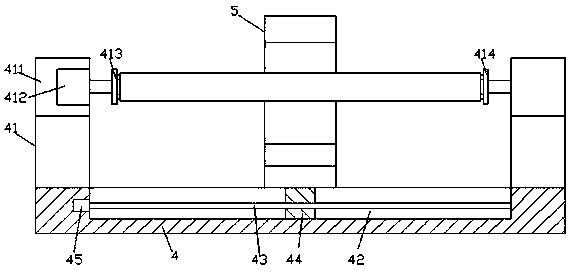

The invention relates to a non-contact polishing device. The non-contact polishing device comprises a machine base, and further comprises a motor, a polishing roller, a linear reciprocating feeding mechanism for adjusting feeding of a workpiece, a longitudinal fine adjustment mechanism for adjusting a polishing gap of fluid, a vertical lifting mechanism for ensuring that the workpiece is positioned within the height of the polishing roller, and a main shaft system; a motor plate is installed on the machine base, and the motor is installed on the motor plate; the main shaft system is installedon the machine base and driven by the motor in a transmission mode, and comprises a roller bracket on which the polishing roller is installed. According to the polishing device, the linear reciprocating feeding mechanism, the longitudinal fine adjustment mechanism and the vertical lifting mechanism are arranged, the linear reciprocating feeding mechanism is accurate, constant in speed and stable,generation of surface ripples of machined parts is reduced, the longitudinal fine adjustment mechanism is high in precision, the polishing gap can be adjusted within a large range, and machining conditions under different requirements are met.

Owner:ZHEJIANG UNIV OF TECH

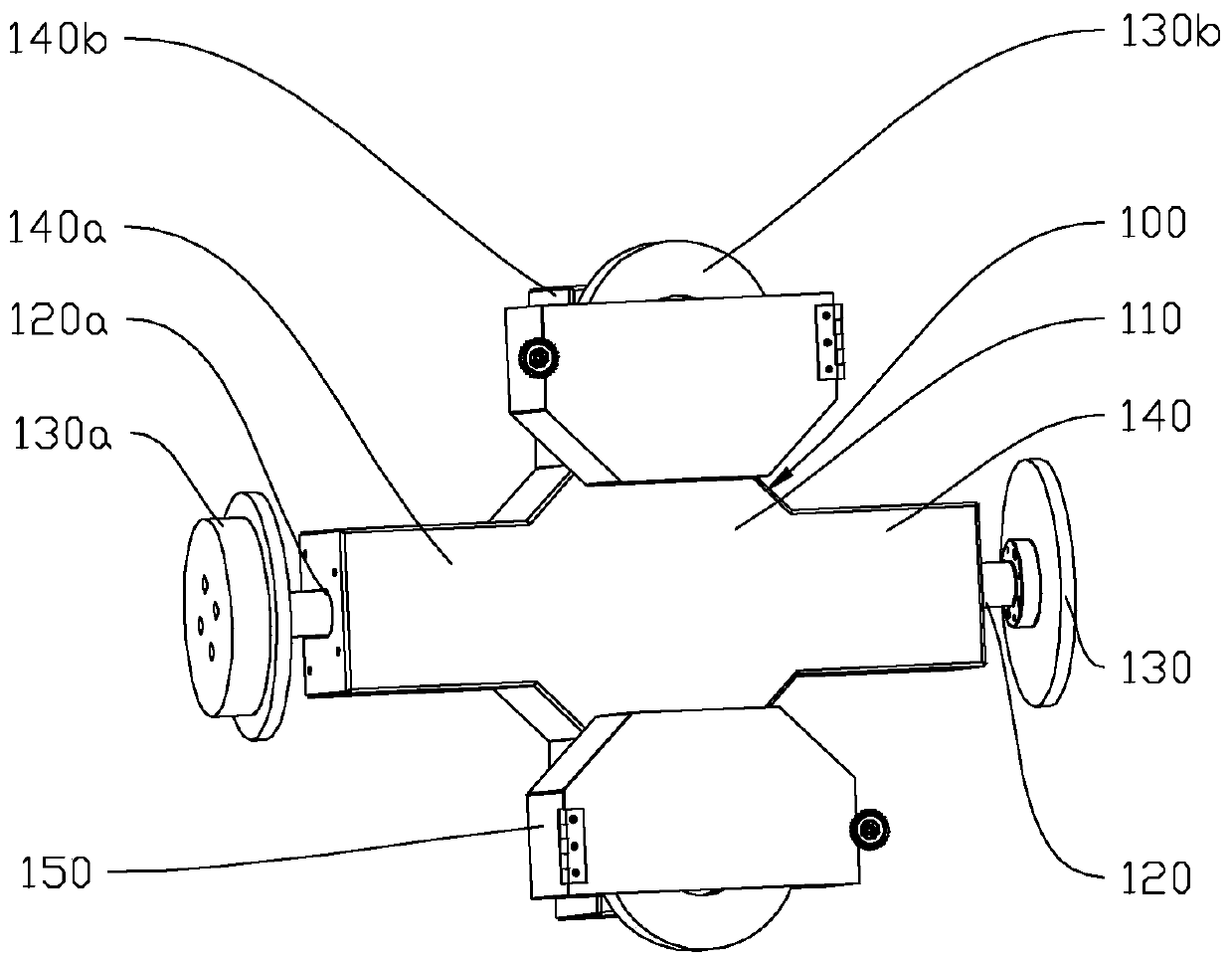

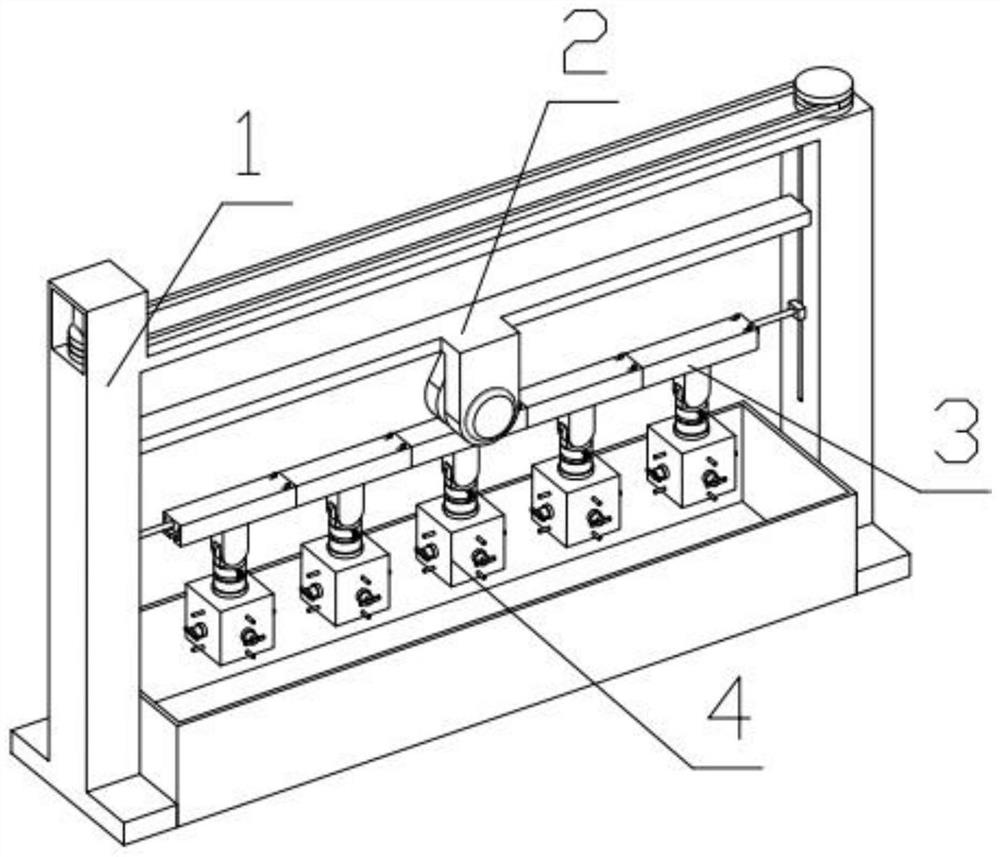

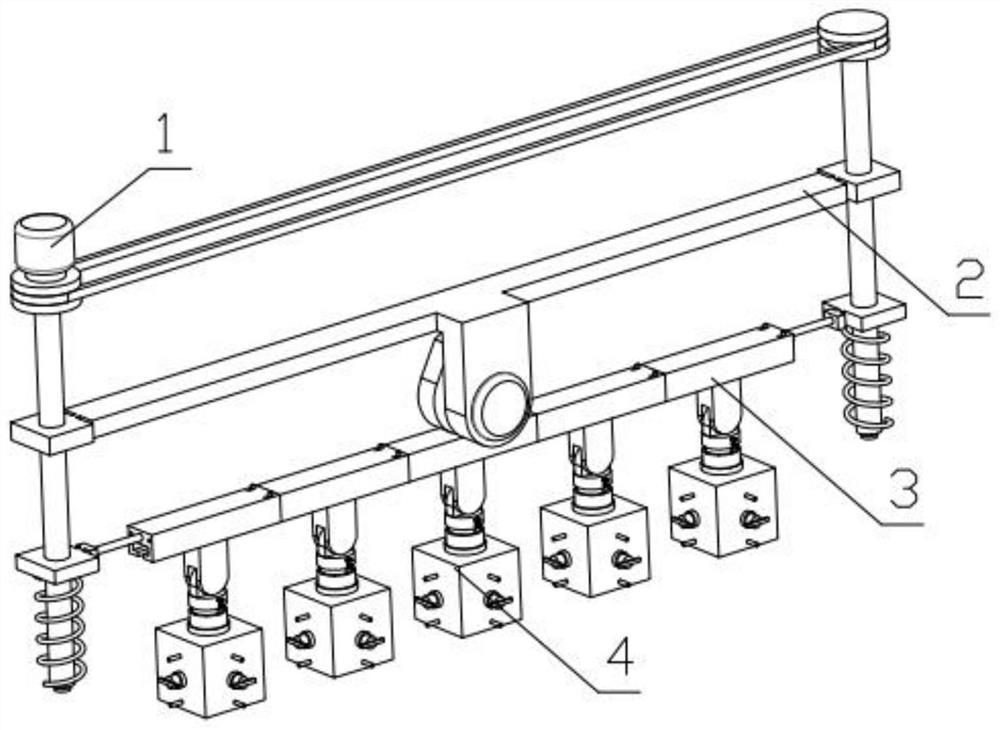

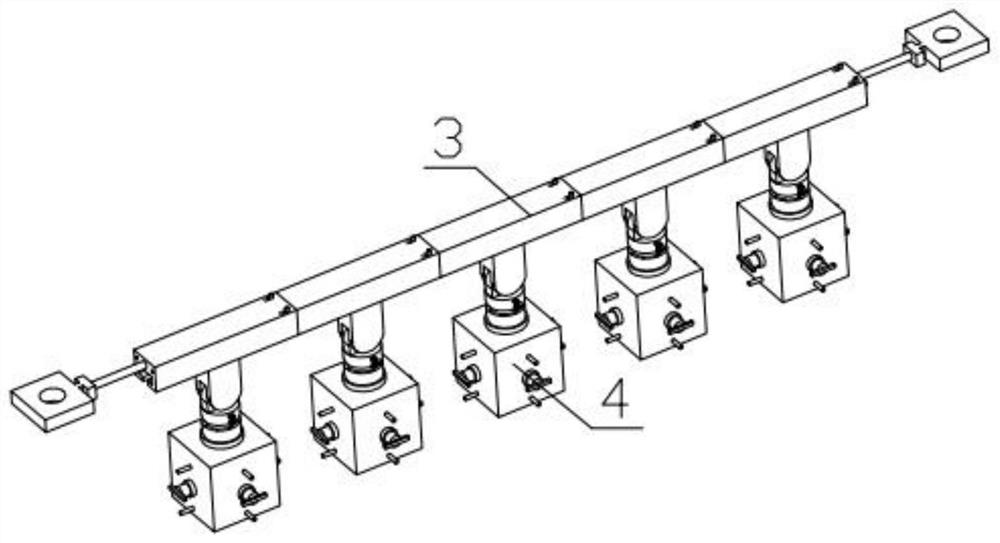

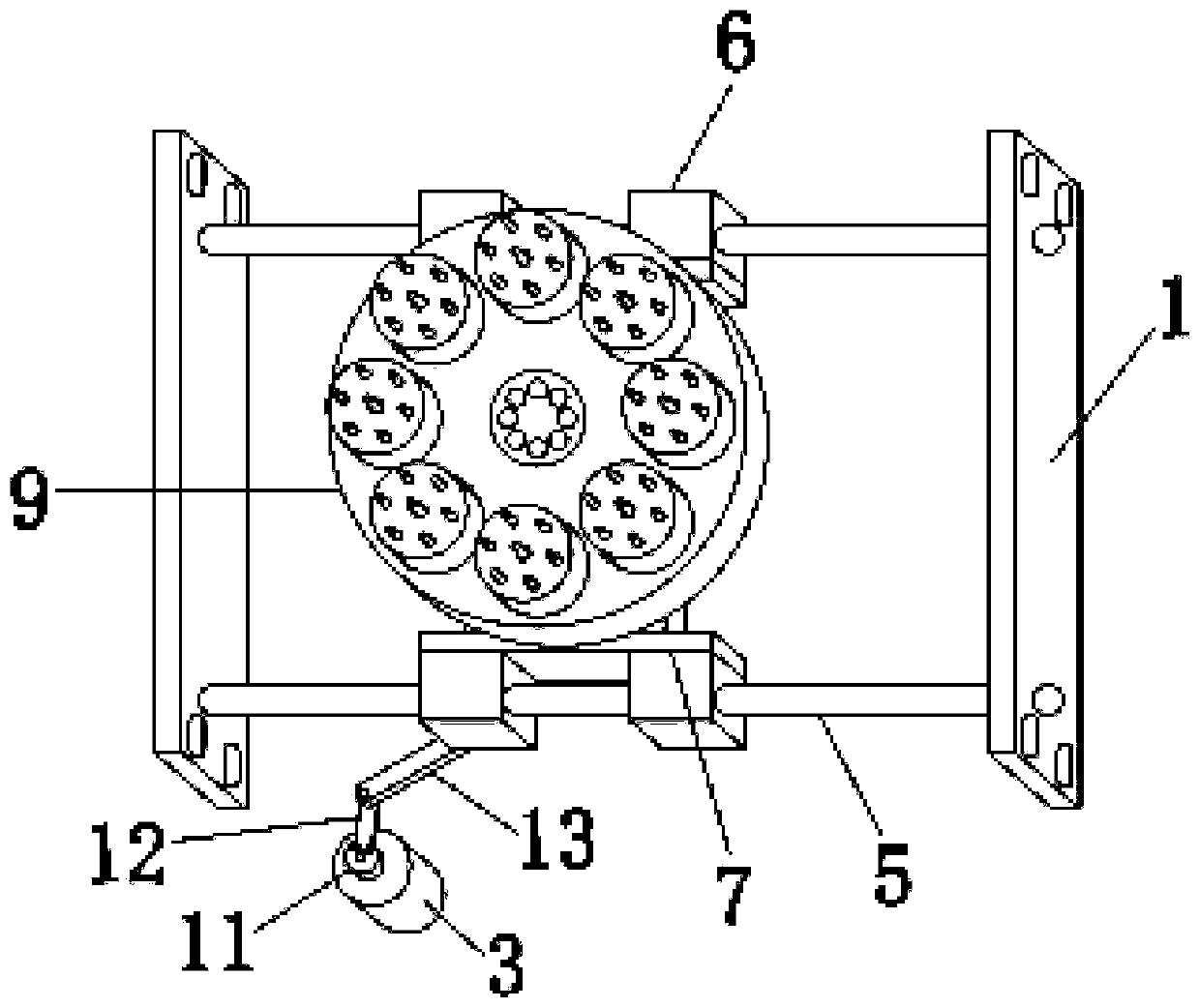

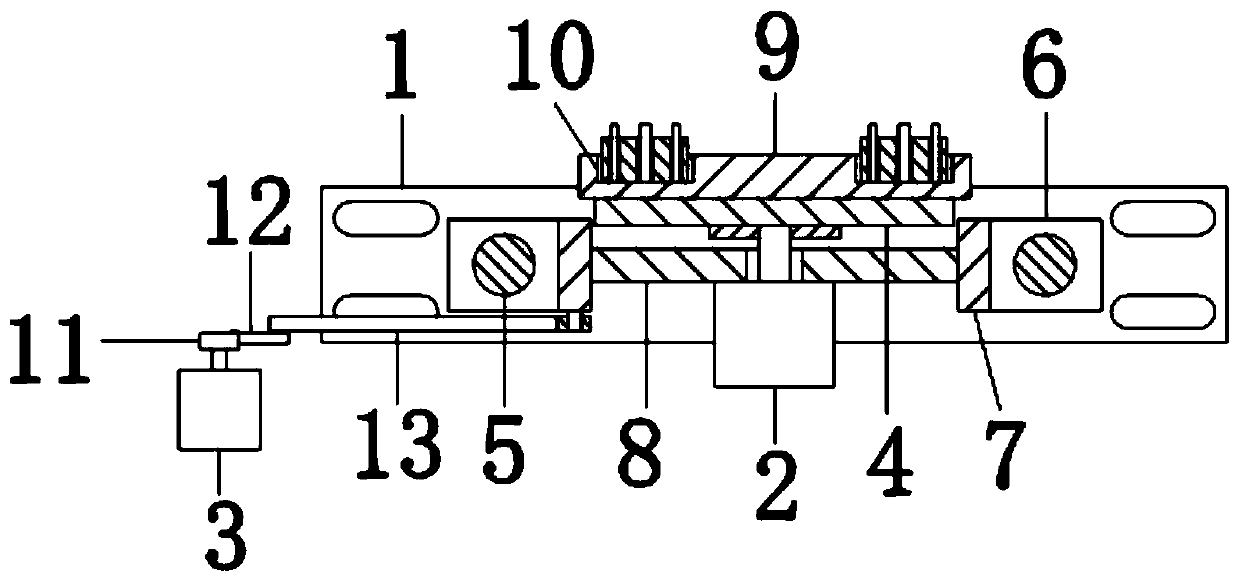

Polishing mechanism and polishing equipment with same

PendingCN111070062AImprove work efficiencyIncrease the number ofGrinding carriagesPolishing machinesRotational axisPolishing

The invention discloses a polishing mechanism and polishing equipment with the same. The polishing mechanism comprises a driving frame, a plurality of polishing wheels, a driving motor and a rotatingmechanism; the driving frame is provided with a plurality of rotating shafts; the plurality of polishing wheels are respectively connected with each rotating shaft, and are arranged in parallel or perpendicular to the driving frame; the driving motor is used for driving each rotating shaft to rotate; and the rotating mechanism is connected with the driving frame and is used for driving the drivingframe to alternately rotate. According to the technical scheme of the polishing mechanism and the polishing equipment with the same, multiple types of the polishing wheels can be installed accordingto different polishing requirements of different products, and polishing production can be carried out on planar or curved products by automatically and alternately rotating the polishing wheels, so that the working efficiency is effectively improved.

Owner:宜宾轩驰智能科技有限公司

Processing device

InactiveCN111113240AIncrease productivityImprove functionalityPolishing machinesGrinding drivesElectric machineryEngineering

The invention relates to the technical field of mechanical processing devices, in particular to a processing device. The processing device comprises a control cabinet, an operating platform and a one-station horizontal polishing machine; a base surface of the control cabinet is provided with a display screen and a control panel; a connector is fixedly mounted on the right side of the control cabinet; the one-station horizontal polishing machine is arranged on the ground on the right side of the control cabinet; the one-station polishing machine comprises a base, a positioning loop bar, a transmission mechanism, a hollow support rod, a screw drive and a screw motor; the operating platform is arranged on the ground on right side of the one-station horizontal polishing machine; a plurality ofpositioning seats distributed circumferentially are arranged at the upper end of the operating platform; a chip inlet is formed in the center of the upper end of the operating platform; a chip collecting barrel is arranged at the lower end of the chip inlet; an air suction port is fixedly mounted in the left side of the upper part of the chip collecting barrel; a mobile table is arranged at the lower end of the chip collecting barrel; and a suction fan is fixedly installed on the left side of the upper end of the mobile table. The whole processing device is good in effect, is higher in stability and practicality, and has a certain promotion value.

Owner:嘉兴君宏汽车配件有限公司

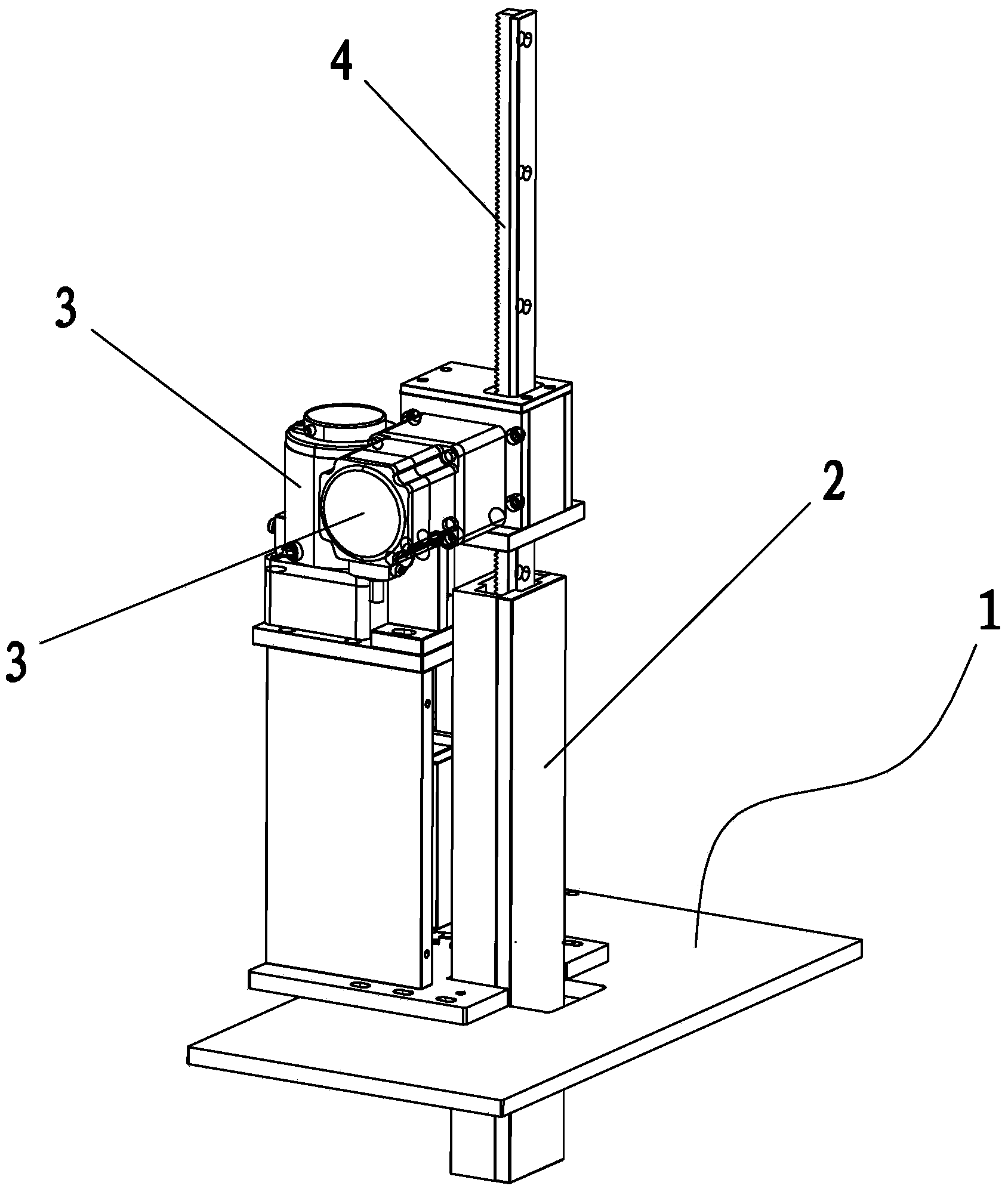

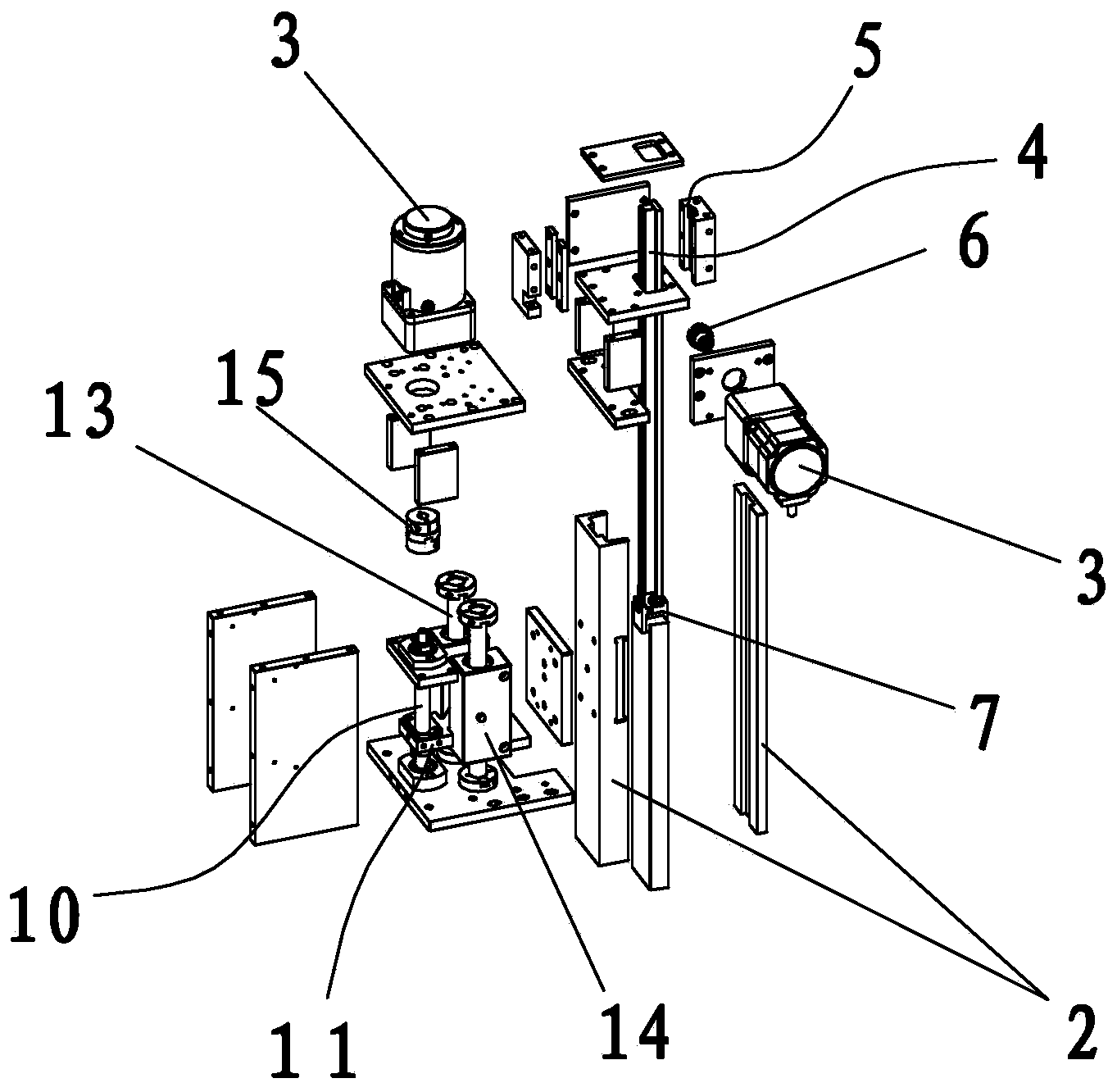

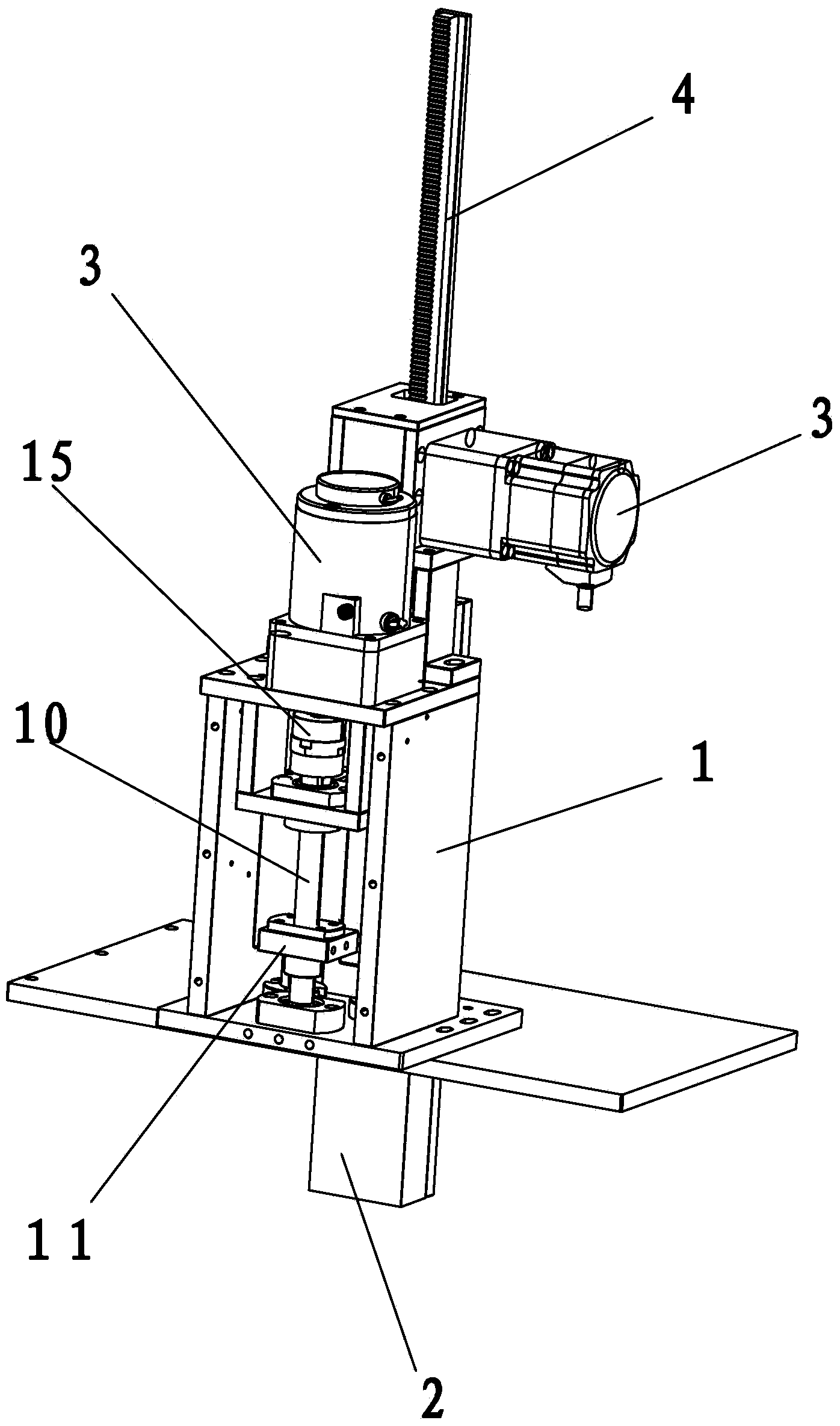

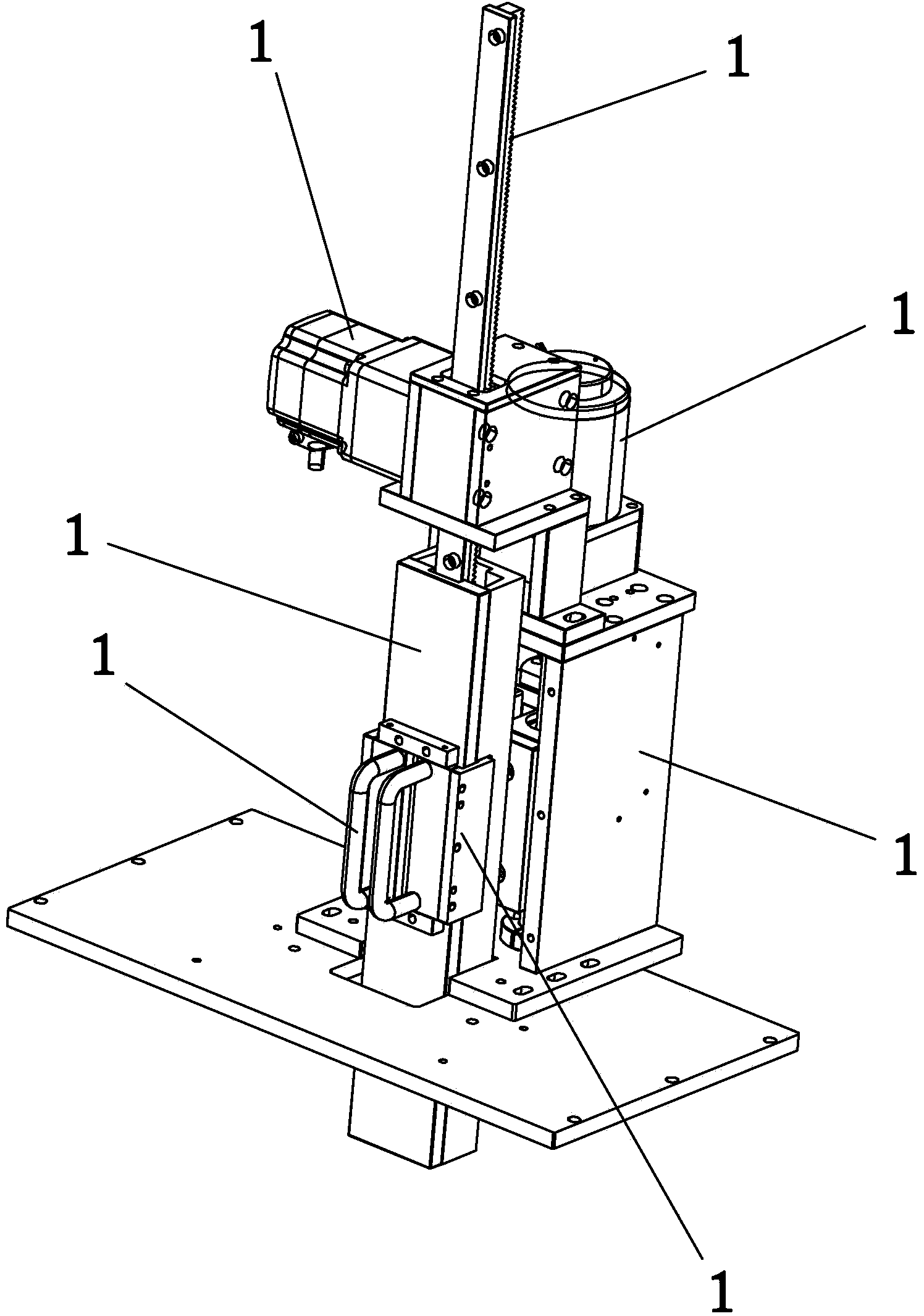

Precise small part smoothing device

ActiveCN113276011AControl flow rateImprove polishing efficiencyEdge grinding machinesPolishing machinesEngineeringScrew thread

The invention relates to a polishing device, in particular to a precise small part smoothing device which comprises a device lifting mechanism, an up-down smoothing mechanism, a combined connecting mechanism and precise smoothing mechanisms. The up-down smoothing mechanism is slidably mounted in a groove formed in the device lifting mechanism, the device lifting mechanism is in threaded connection with the up-down smoothing mechanism, and the combined connecting mechanism is fixedly mounted on the device lifting mechanism and is in hinged connection with the precise smoothing mechanisms. The device can independently polish small parts, is high in polishing efficiency and speed, can perform polishing in different motion trails according to shapes, and has the function of independently polishing large parts.

Owner:杭州临安华滢精密元件有限公司

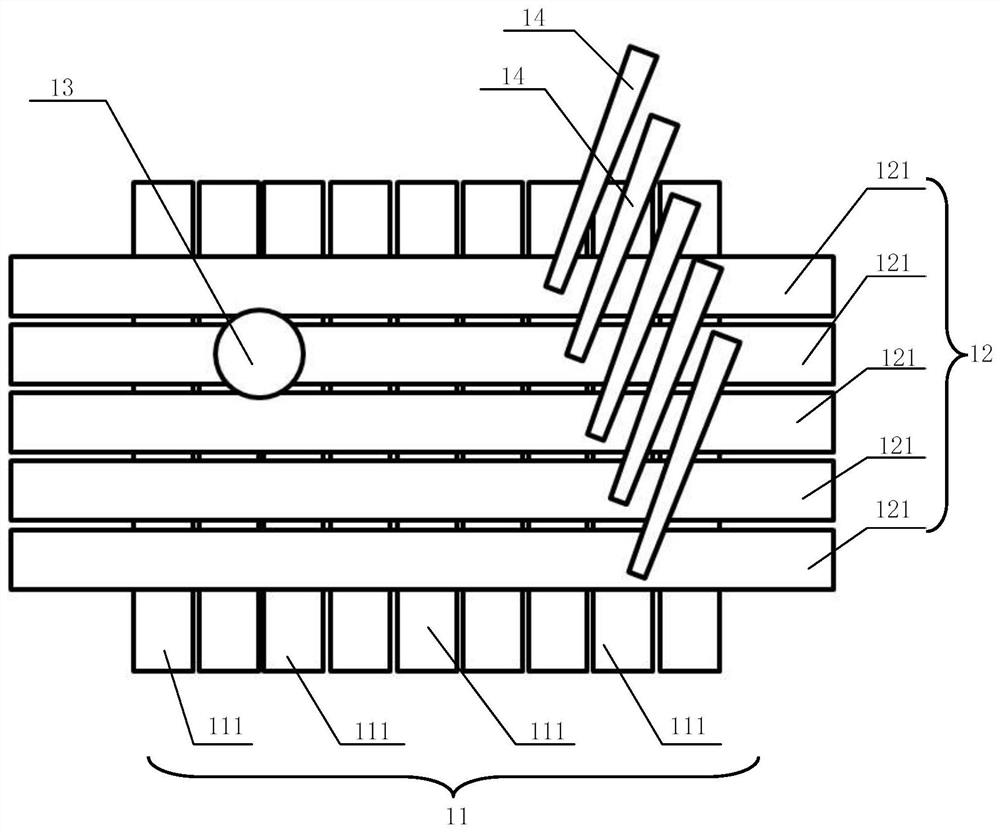

Fixed abrasive polishing device and polishing method

ActiveCN113579990BAvoid scratchesSatisfy polishing needsLapping machinesLapping toolsPolishingLiquid injection

The invention provides a fixed abrasive particle polishing device and a polishing method. The device includes a base pad, a polishing pad, a polishing liquid injection device and a clamping structure. The polishing pad is located on the base pad. One end of the polishing liquid injection device is connected to the polishing liquid source, and the other end extends above the polishing pad. The clamping structure is located on the polishing pad. The square is used to clamp the substrate to be polished, wherein the polishing pad includes a plurality of polishing belts, the plurality of polishing belts are arranged side by side, and there is a gap between adjacent polishing belts, and abrasive particles are fixed on each polishing belt. The invention creatively transforms the whole polishing pad into a plurality of polishing belts with gaps between each other, so that the impurity particles generated in the polishing process can be discharged from the gap in time, so as to avoid being retained on the polishing pad and scratching the substrate. At the same time, since the polishing areas of each polishing belt are independent of each other, one or more grinding effects can be achieved by selecting different abrasive grains and abrasive liquids in one polishing process, which can fully meet different polishing requirements.

Owner:GTA SEMICON CO LTD

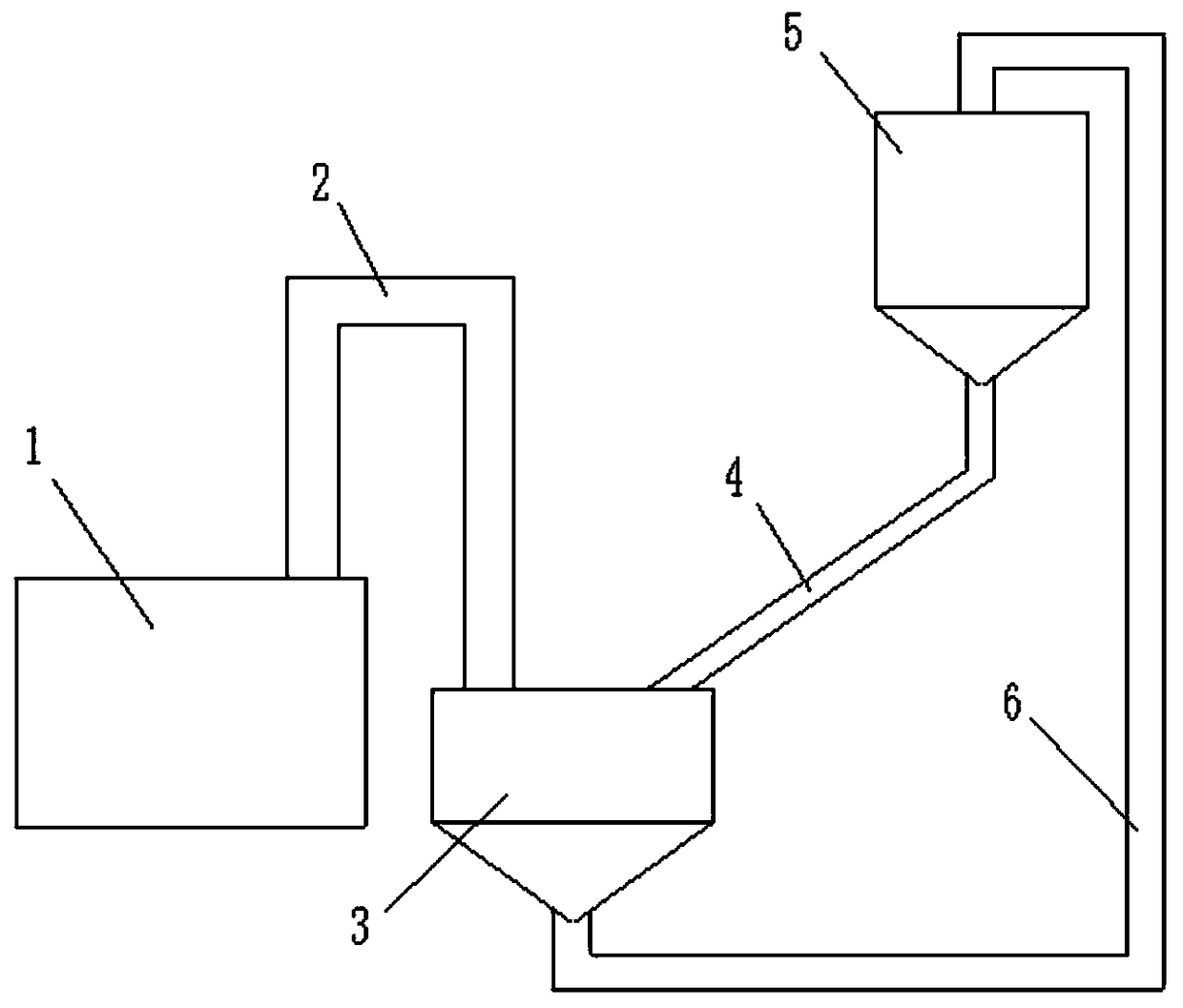

Circulating myotonin polishing device and operating method

InactiveCN109420536ASatisfy polishing needsSimple structureGrain huskingGrain polishingWaste management

The invention discloses a circulating myotonin polishing device and an operating method. The circulating myotonin polishing device comprises a storage cabin for storing finished myotonin and a polisher used for polishing the myotonin, and a transfer cabin is arranged between the polisher and the storage cabin, wherein a discharge outlet of the polisher is connected with the transfer cabin througha discharging pipeline, and the transfer cabin is connected with the storage cabin through a first lifter and further connected with a feed inlet of the polisher through a second lifter. Compared withthe prior art, multiple times of polishing can be carried out according to demands so as to meet polishing demands of products with different grades.

Owner:贵州薏米阳光产业开发有限责任公司

Nano-abrasive, polishing liquid, preparation method and application

ActiveCN110577823BReduce shockGuarantee the appearance qualityOther chemical processesPolishing compositions with abrasivesOptical instrumentationNano al2o3

The present invention provides a kind of nano-abrasive, polishing liquid and preparation method and application, relate to the technical field of abrasive material, described nano-abrasive comprises first abrasive material, and described first abrasive material comprises nano-alumina, and the outer surface of described nano-alumina Covered with the first polymer, it improves the technical problem that the existing polishing liquid obtained by using nano-alumina as an abrasive will cause microscopic defects on the surface of the processed medium, reduce the strength of the processed medium, and fail to meet the polishing requirements of optical glass and optical instruments , the nano-abrasive provided by the present invention, by coating the polymer on the outer surface of the nano-alumina, the polymer can play a buffer role in the polishing process, so as to effectively reduce the microscopic defects on the surface of the processed medium caused by the abrasive, so as to ensure the surface of the processed medium The apparent quality and strength of the processing medium can meet the polishing needs of optical glass and optical instruments.

Owner:LENS TECH CHANGSHA

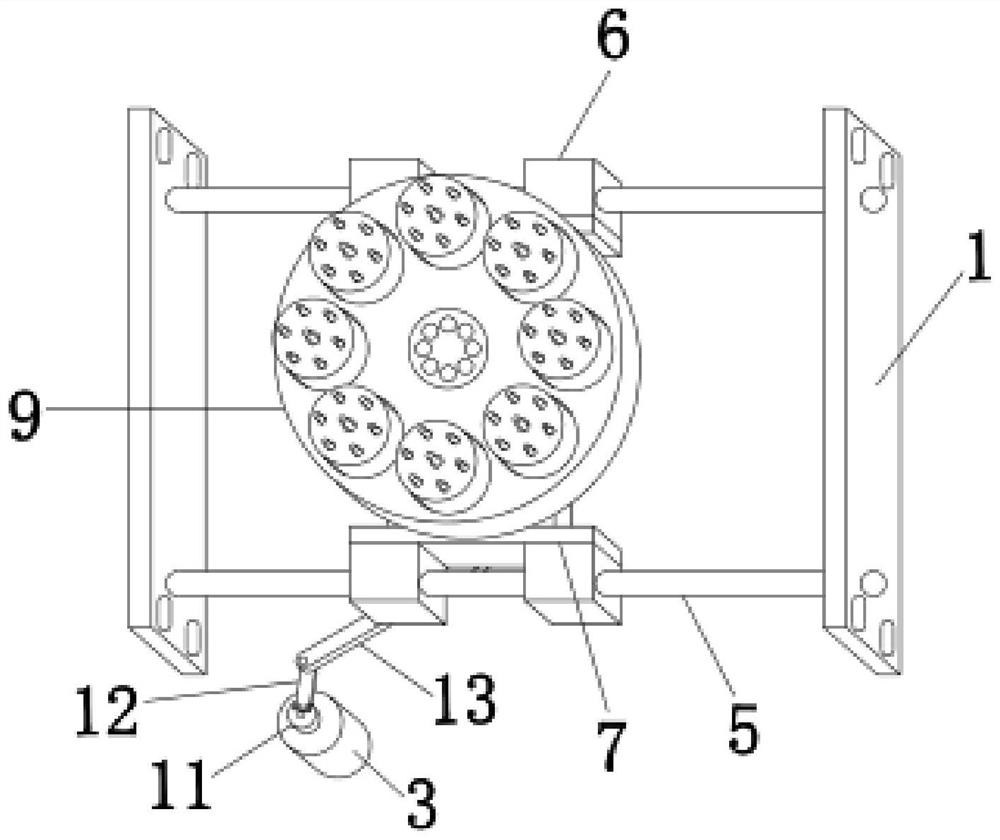

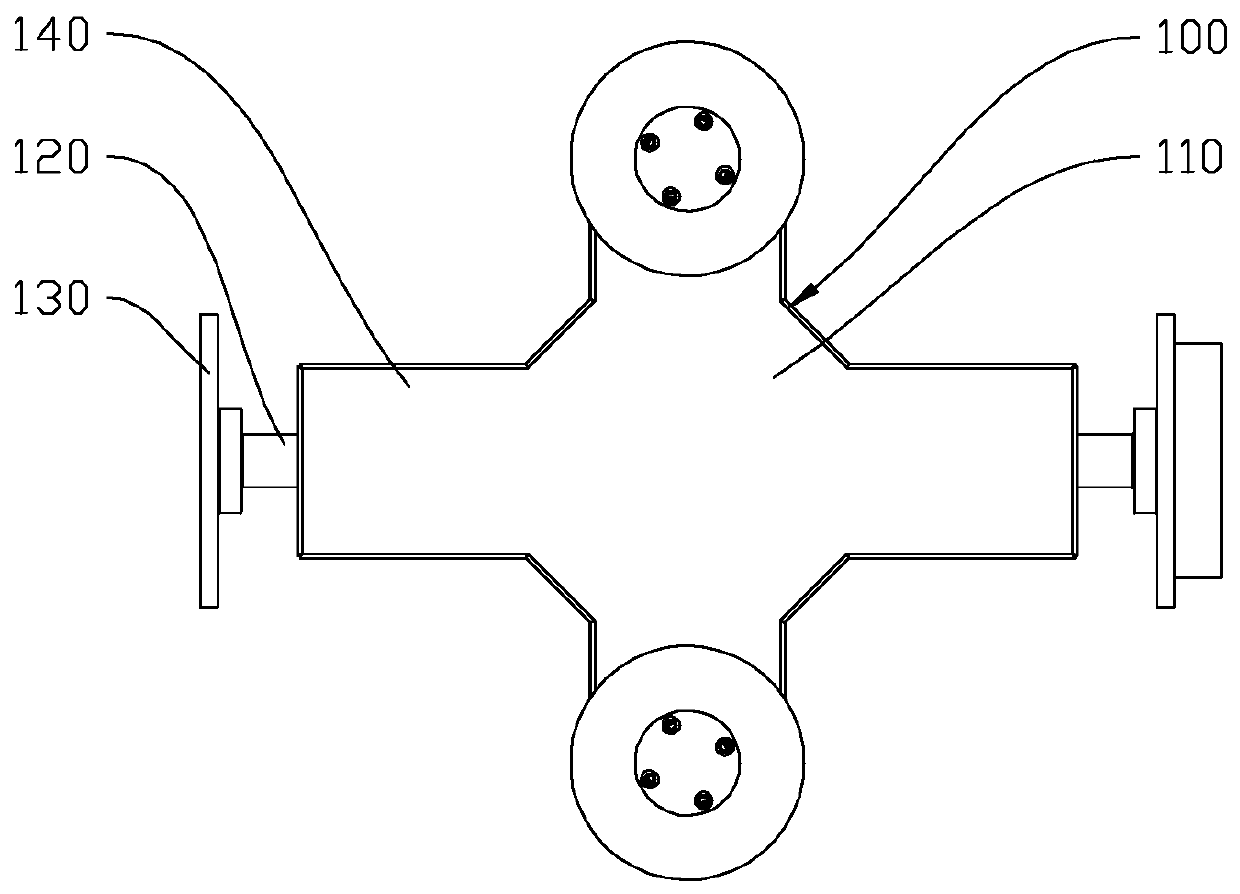

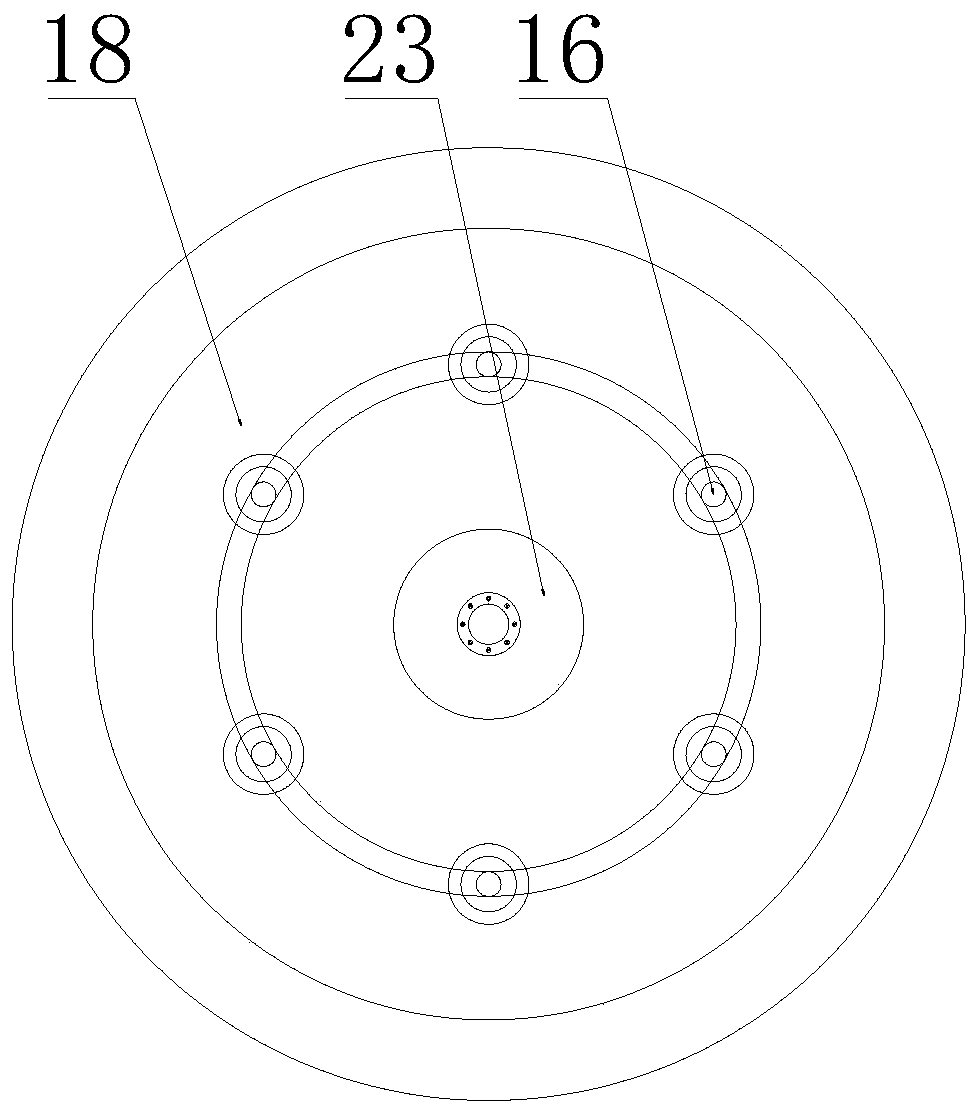

Magnetic polishing assembly

ActiveCN110480423ASatisfy polishing needsRealize automatic polishingGrinding drivesGrinding work supportsFlangeElectrical and Electronics engineering

The invention discloses a magnetic polishing assembly. The magnetic polishing assembly comprises two supporting plates, a first motor, a second motor and a magnetic disk, wherein an output end of thefirst motor is connected with the center of the bottom end of the magnetic disk through a flange; guide rods are arranged at the front end and the rear end of the inner sides of the supporting platesin the left-right direction; the left side and the right side of the outer wall of each guide rod are sleeved with sliders; the inner sides of each of the two sliders which are symmetrical in the front-back direction are in screwed connection with a vertical plate; a transverse plate is arranged at the inner sides of the vertical plates; the first motor is in screwed connection with the center ofthe bottom end of the transverse plate; a disk is arranged at the top end of the magnetic disk; station grooves are formed in the outer side of the upper surface of the disk along the circumferentialdirection; an output end of second motor is in key connection with a supporting seat; and the inner cavity of the supporting seat is in threaded connection with the one end of a first connecting rod.According to the magnetic polishing assembly, automatic polishing is achieved, time and labor are saved, polishing efficiency is high, polishing is uniform, and polishing requirements of small aperture on workpieces are greatly met.

Owner:WUHAN SUNSHINE LASER & TECH

Rectangular glass segmented polishing method

ActiveCN109834574AGuaranteed uniformityDo not avoid enteringPolishing machinesGrinding machinesClockwiseComputer programming

The invention discloses a rectangular glass segmented polishing method. The rectangular glass segmented polishing method comprises the steps that S1, a workpiece is placed into a station and fixed; S2, initial positions of two polishing wheels and the workpiece are set; S3, program parameters are input into a host computer of a polishing machine; S4, the two polishing wheels move towards the workpiece; S5, the workpiece rotates counterclockwise; S6, the workpiece rotates clockwise to return to the initial position; S7, the workpiece rotates clockwise; S8, the workpiece rotates counterclockwiseto return to the initial position; and S9, the steps S5 to S8 are repeated. The process steps of the rectangular glass segmented polishing method are simple and reasonable in design, and the uniformity of polishing of the workpiece can be ensured; the segment polishing can avoid corners of the glass workpiece entering the polishing wheels, thereby protecting the corners of the glass workpiece from being polished, and meeting the polishing requirements of certain glass workpieces of which arc corners cannot be polished; and automatic computer programming is highly automated, and the polishinguniformity can be ensured.

Owner:蒙马科技(深圳)有限公司

a cable device

ActiveCN109015262BExtended service lifePolished meetGrinding drivesBelt grinding machinesAutomatic controlPolishing

Owner:FUJIAN SOUTHERN NEW CABLE

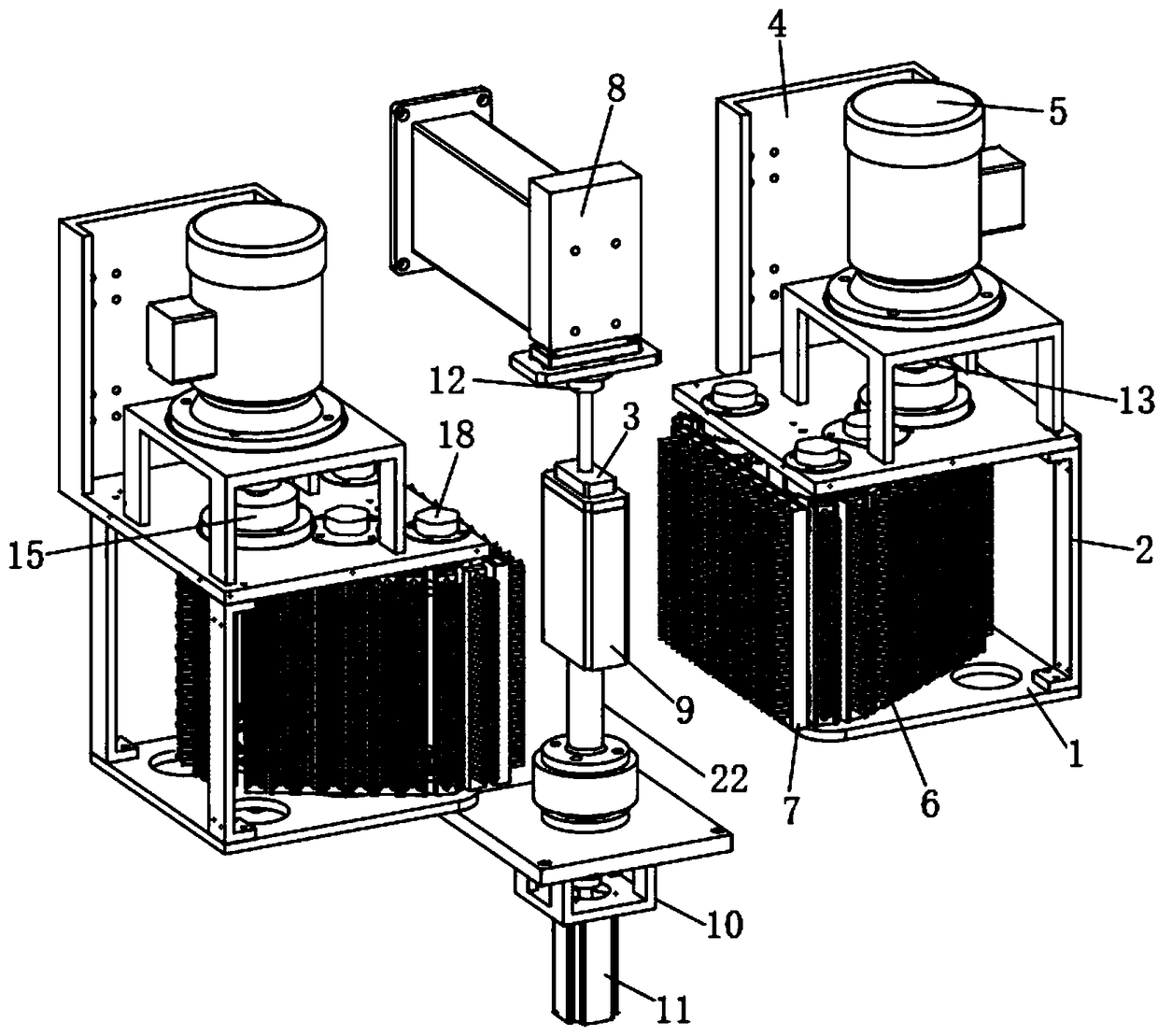

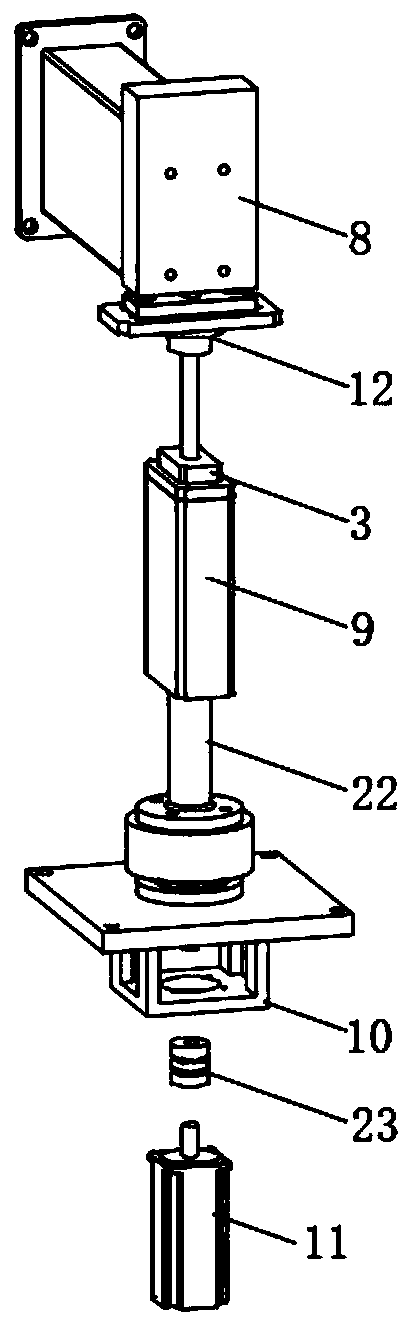

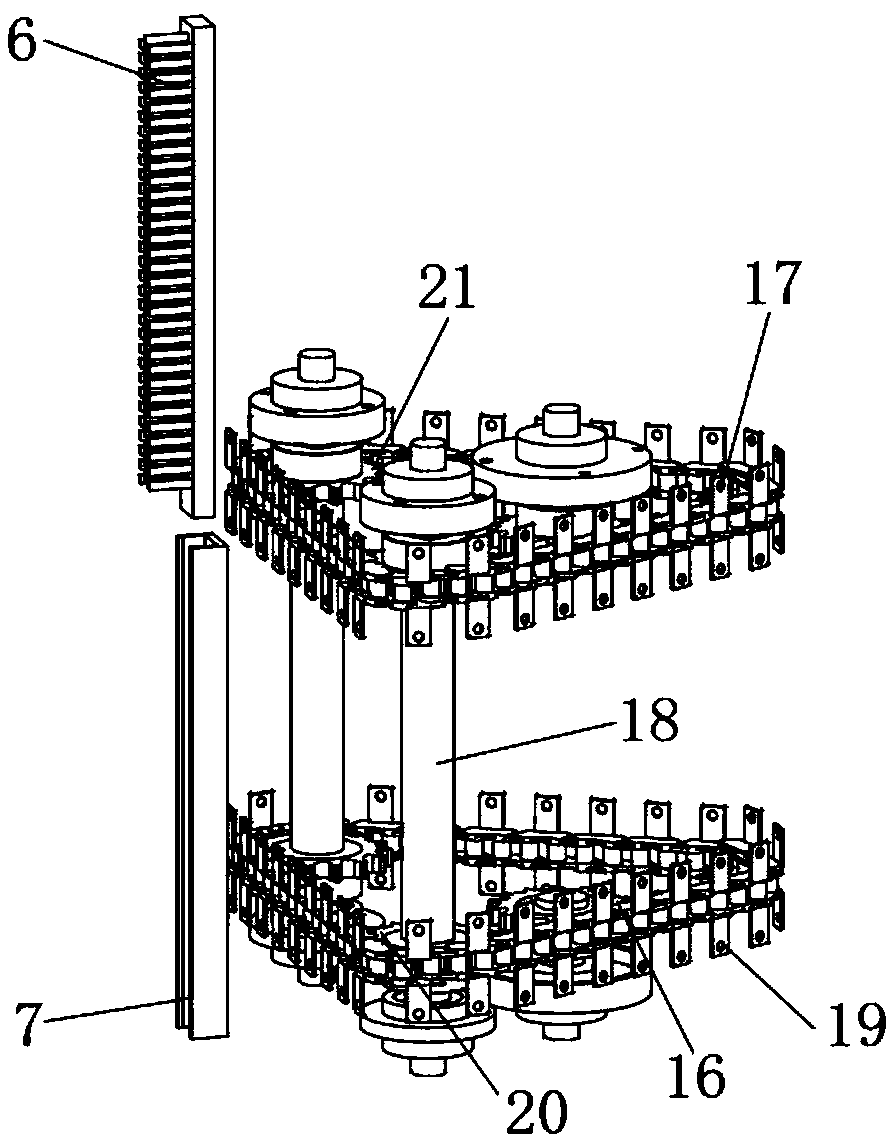

Tank chain type edge polishing machine

PendingCN109108820ADifferent speedSatisfy polishing needsPolishing machinesGrinding drivesDrive shaftCoupling

The invention discloses a tank chain type edge polishing machine. The tank chain type edge polishing machine comprises two transmission shaft fixed bases; motor fixed bases are arranged above the twotransmission shaft fixed bases; multiple support frames are connected between the two motor fixed bases and the corresponding transmission shaft fixed bases; high-speed rotating motors are arranged onthe motor fixed bases; the upper ends of the transmission shaft fixed bases are rotationally connected with a transmission main shaft and two rotating auxiliary shafts; the transmission main shaft and the two rotating auxiliary shafts are rotationally connected with the motor fixed bases; and the tail ends of output shafts of the high-speed rotating motors and the transmission main shaft are connected through first couplings. The tank chain type edge polishing machine is reasonable in structural design, can obtain different polishing speeds in different areas of workpieces to be machined, canfreely adjust the friction force between brush bars and the workpieces to be machined according to the shapes of the workpieces to be machined, and is more uniform in polishing to prevent the problemof product deformation.

Owner:SHENZHEN XIKEO IND CO LTD

Intelligent polishing equipment for building and polishing method

PendingCN114193311ASatisfy polishing needsImprove polishing efficiencyGrinding carriagesPolishing machinesPolishingStructural engineering

The invention discloses intelligent polishing equipment for a building and a polishing method, and relates to the technical field of building material processing. The intelligent polishing equipment for the building comprises a supporting table, a top face polishing mechanism and a side face polishing mechanism, the top face polishing mechanism and the side face polishing mechanism are installed on the supporting table, the top face polishing mechanism is used for polishing the top faces of materials with different heights, and the side face polishing mechanism is used for polishing the two sides of the materials with different widths. Through the structural design, the top faces of materials with different heights can be polished, the applicability is more excellent, through the structural design of the side face polishing mechanism, adaptive adjustment machining can be conducted according to the width of the materials, and multi-face simultaneous machining of the materials is achieved in cooperation with application of the top face machining mechanism; therefore, the overall processing efficiency is improved.

Owner:CHINA MCC17 GRP

a cable device

ActiveCN109015322BExtended service lifePolished meetGrinding carriagesPolishing machinesAutomatic controlPolishing

Owner:安徽天盛新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com