Full-automatic polishing machine of profiled component

A fully automatic, polishing machine technology, applied in the field of polishing machinery, can solve problems such as unstable processing quality, serious dust pollution, and high labor intensity, and achieve great promotion and application value, low environmental pollution, and low operational pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

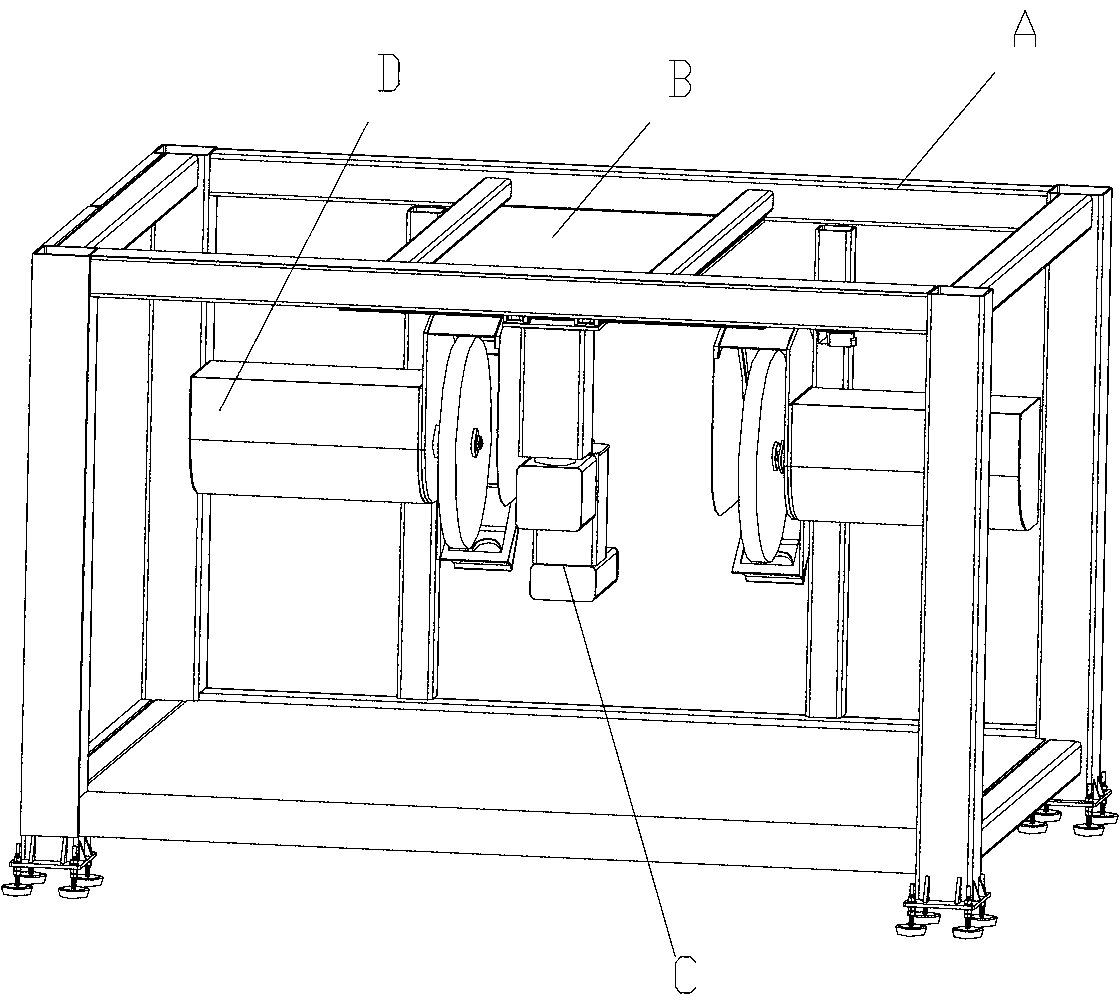

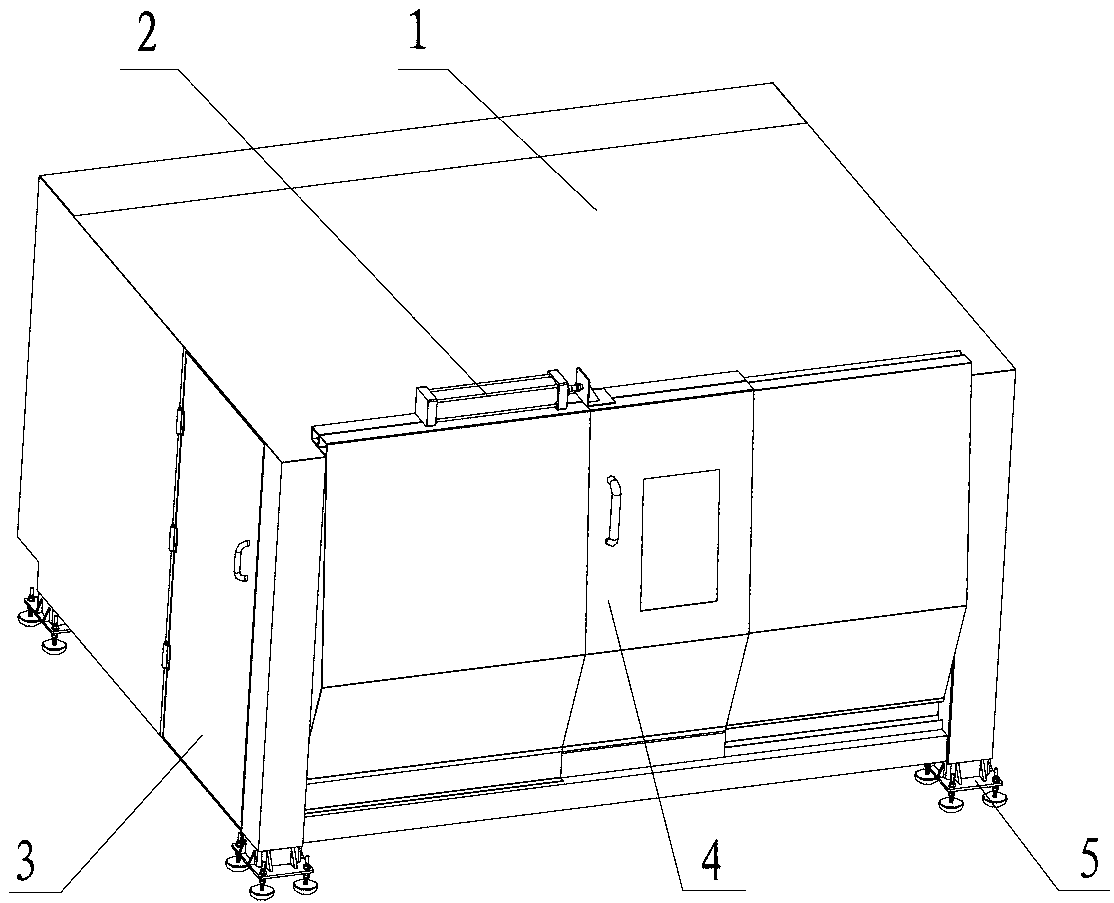

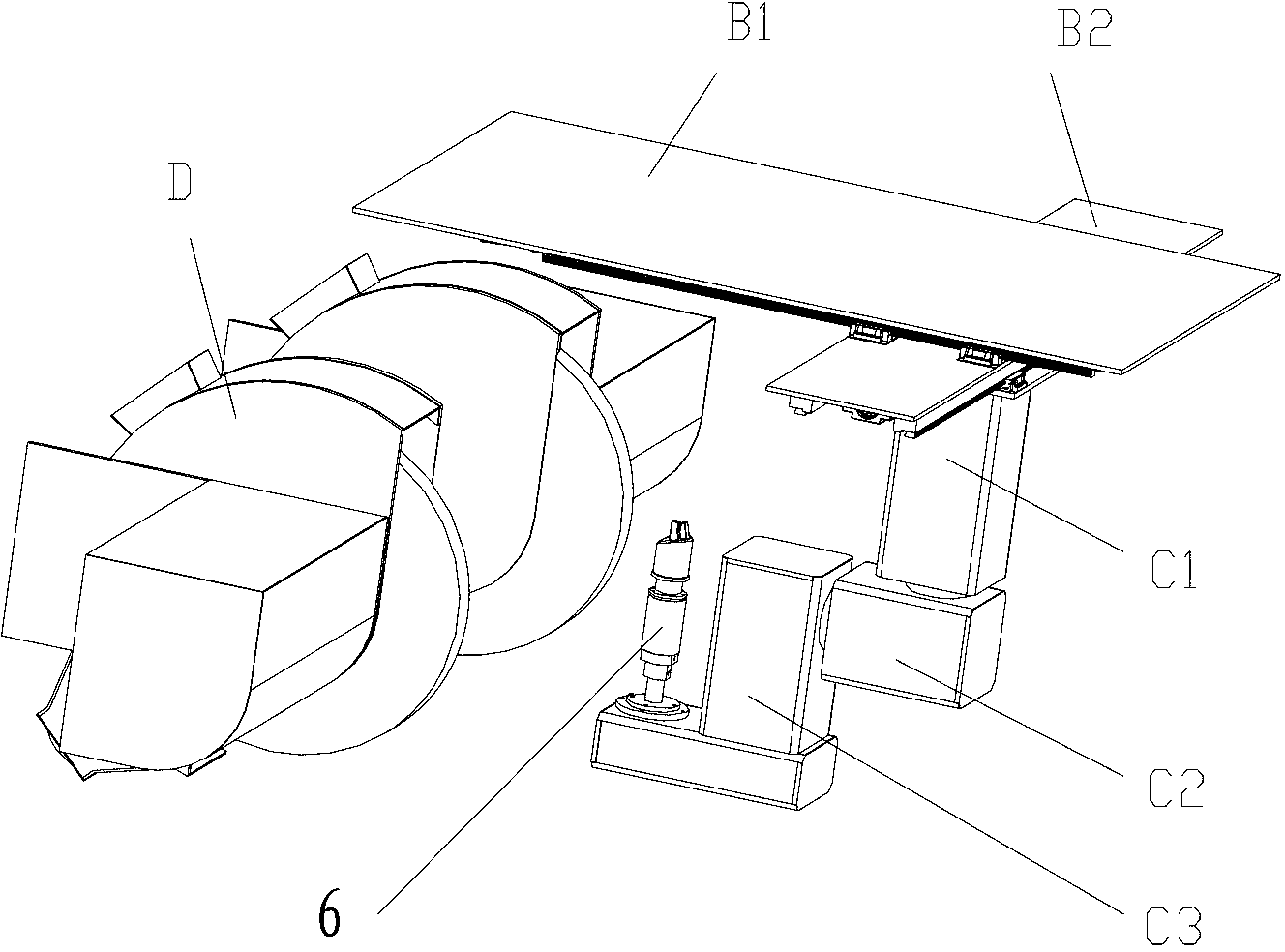

[0028] see Figure 1-9 , the embodiment of the present invention is provided with a peripheral sheet metal protection module A, an XY axis module B, a robot arm module C and a polishing wheel module D.

[0029] The peripheral sheet metal protection module A is provided with a sheet metal protective cover 1, a cylinder 2, a side door 3, a pneumatic protective door 4 and a base 5; The switching action of the protective door 4; the side door 3 is located on the left side of the sheet metal protective cover 1; the base 5 is installed on the lower part of the sheet metal protective cover 1;

[0030] The XY-axis module B is provided with an X-axis sub-module B1 and a Y-axis sub-module B2; both the X-axis sub-module B1 and the Y-axis sub-module B2 are provided with a bottom plate 8, a screw nut 9, a screw rod 10, and a screw seat 11 , the line rail 12 and the servo motor 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com