Petal-shaped corrugated pipe forming method

A corrugated tube and petal-shaped technology, which is applied in the field of petal-shaped corrugated tube forming, can solve problems affecting the performance of corrugated tubes, complex tooling design, and scratches on corrugated tubes, and achieve good product size consistency, reduce surface damage, and process good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

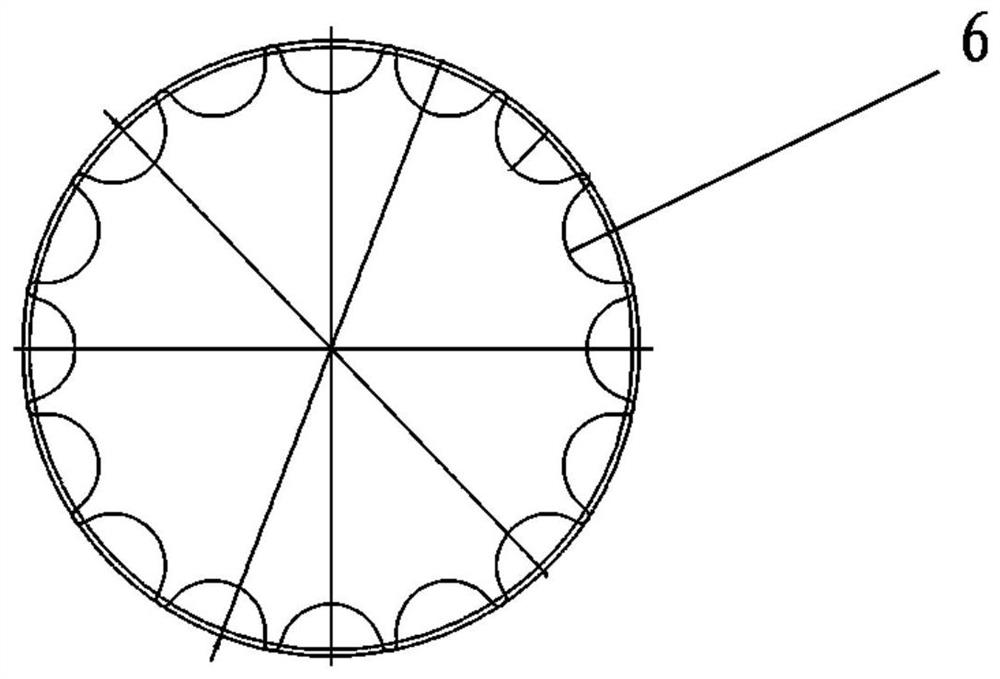

[0024] see Figure 1-4 , a petal-shaped bellows forming method provided by an embodiment of the present invention includes:

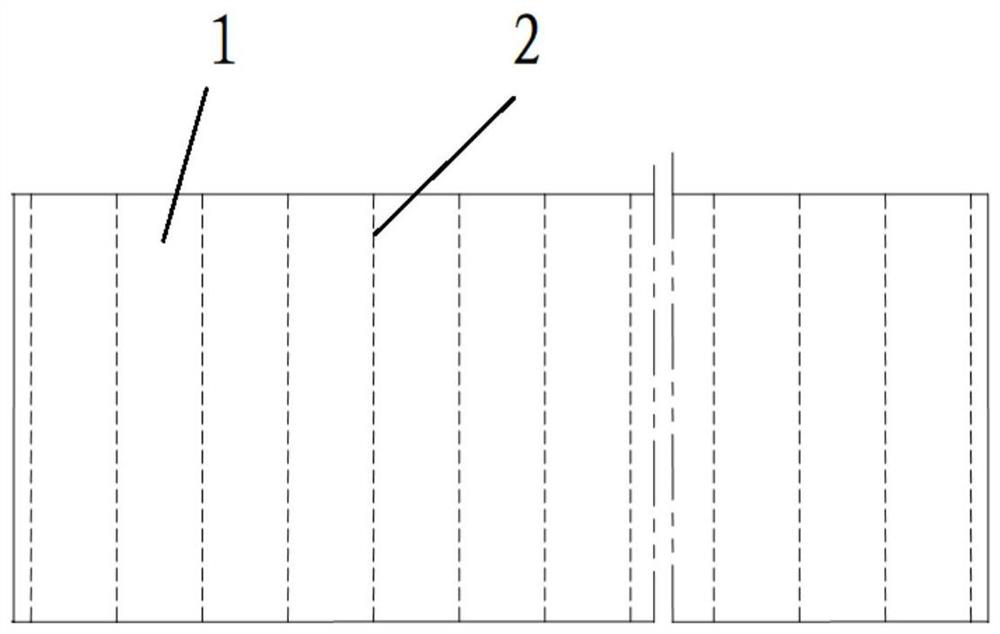

[0025] Obtain the unfolding material 1.

[0026] Set n gate pressure lines 2 on the unfolded material, the distance between every two adjacent gate pressure lines in the n gate pressure lines 2 matches the half-wave expansion length of the bellows, and n is a positive integer.

[0027] The developed material 1 is placed on the two lower die mandrels 3-1 of the lower die forming mold 3, and the developed material is supported by the two lower die mandrels 3-1, wherein the mth gate pressure of the n gate pressure lines 2 The line is aligned with the axis of one of the two die mandrels, and m is an odd number greater than 1.

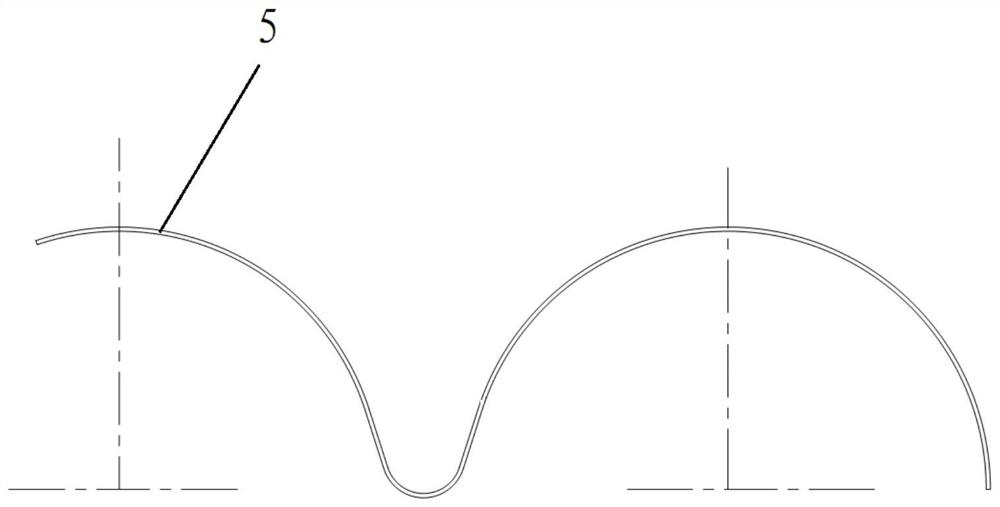

[0028] Operate the upper mold forming die 4 to move between the two lower mold mandrels 3-1, press the gate to expand the material 1, until all the corrugations 5 on the expanded material 1 are formed, and the parts are obtained. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com