Optical free curved surface polishing device and method

A free and curved surface technology, applied in the direction of optical surface grinder, grinding automatic control device, grinding/polishing equipment, etc., can solve the problems of difficult polishing process and difficult surface, and achieve the effect of small size and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

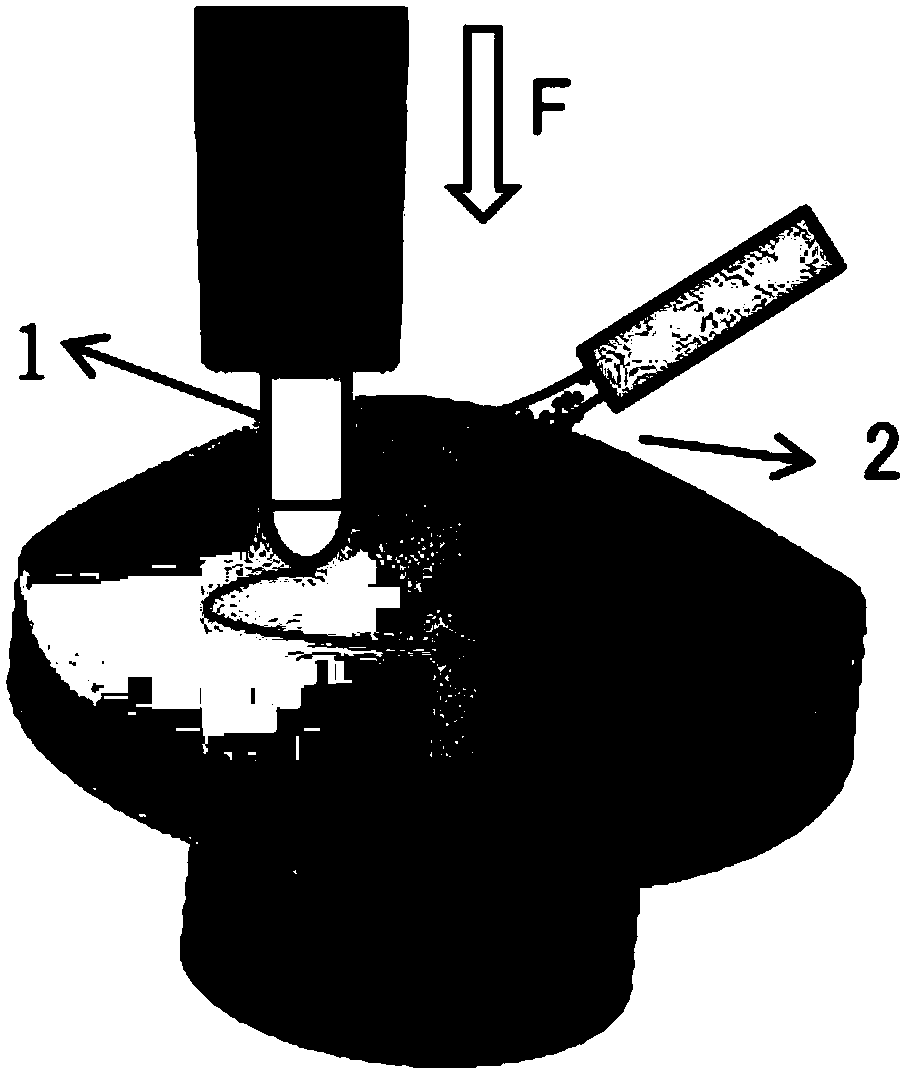

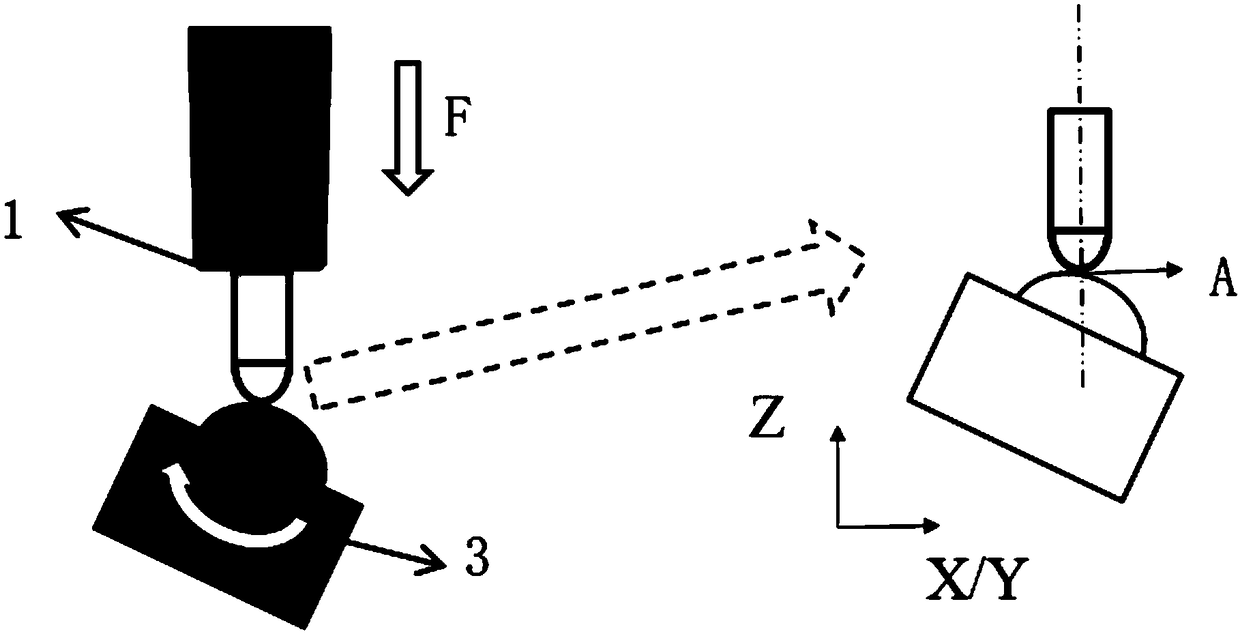

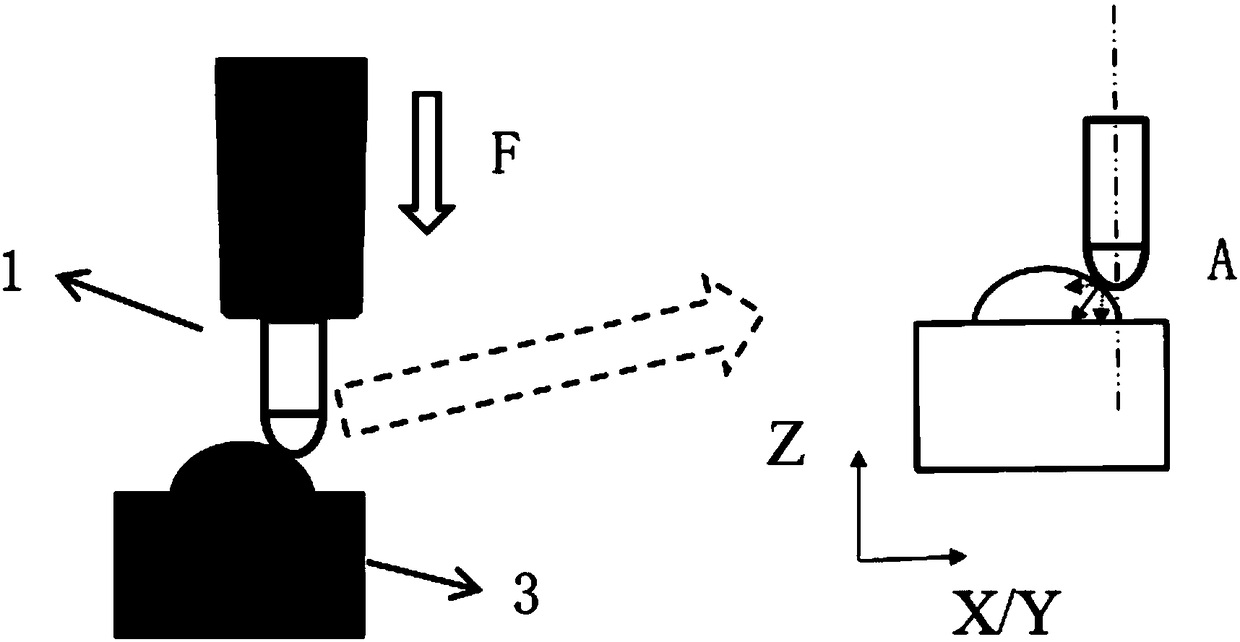

[0032] A vibration polishing device for a micro optical free-form surface, the vibration polishing device comprises a vibration polishing head 1, a micro optical free-form surface 3, a control system 5, a PC 6, a five-axis numerical control platform 7, and a polishing pressure control mechanism 8.

[0033] The control system 5 is located above the movable worktable 4 and includes a driver, a numerical control system, and a controller; the driver is connected to the vibration polishing head 1 , the numerical control system is connected to the five-axis numerical control platform 7 for communication, and the controller is connected to the polishing pressure control mechanism 8 . The PC 6 is located above the movable workbench 4 and is connected to the control system 5. After setting the polishing parameters, the PC 6 transmits them to the control system 5, and then drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com