A kind of water-based magnetorheological polishing fluid and preparation method thereof

A magnetorheological polishing, water-based technology, applied in polishing compositions containing abrasives, etc., can solve the problems of insufficient viscosity stability, low zero magnetic field viscosity, and zero magnetic field viscosity, and achieve long-term effectiveness, zero magnetic field viscosity, etc. Magnetic field viscosity reduction and high viscosity stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] In the preparation step of the above-mentioned composite base carrier liquid provided by the present invention, in step a1), the stirring speed of the mixing is preferably 300-600r / min, specifically 300r / min, 350r / min, 400r / min, 450r / min / min, 500r / min, 550r / min or 600r / min; the mixing temperature is preferably 22 to 25°C, specifically 22°C, 23°C, 24°C or 25°C; the mixing time is preferably 1 ~2h, specifically 1h, 1.1h, 1.2h, 1.3h, 1.4h, 1.5h, 1.6h, 1.7h, 1.8h, 1.9h or 2h.

[0060] In the preparation step of the above-mentioned composite base carrier liquid provided by the present invention, in step a2), the stirring speed of the mixing is preferably 300-600r / min, specifically 300r / min, 350r / min, 400r / min, 450r / min / min, 500r / min, 550r / min or 600r / min; the mixing temperature is preferably 22 to 25°C, specifically 22°C, 23°C, 24°C or 25°C; the mixing time is preferably 0.5 ~1h, specifically 0.5h, 0.6h, 0.7h, 0.8h, 0.9h or 1h.

[0061] In the preparation step of the abo...

Embodiment 1

[0077] 1) Composition design

[0078] The specific components and contents of the water-based magnetorheological polishing fluid provided in this embodiment are as shown in Table 1:

[0079] Table 1 The composition information table of embodiment 1 magnetorheological polishing fluid

[0080]

[0081]

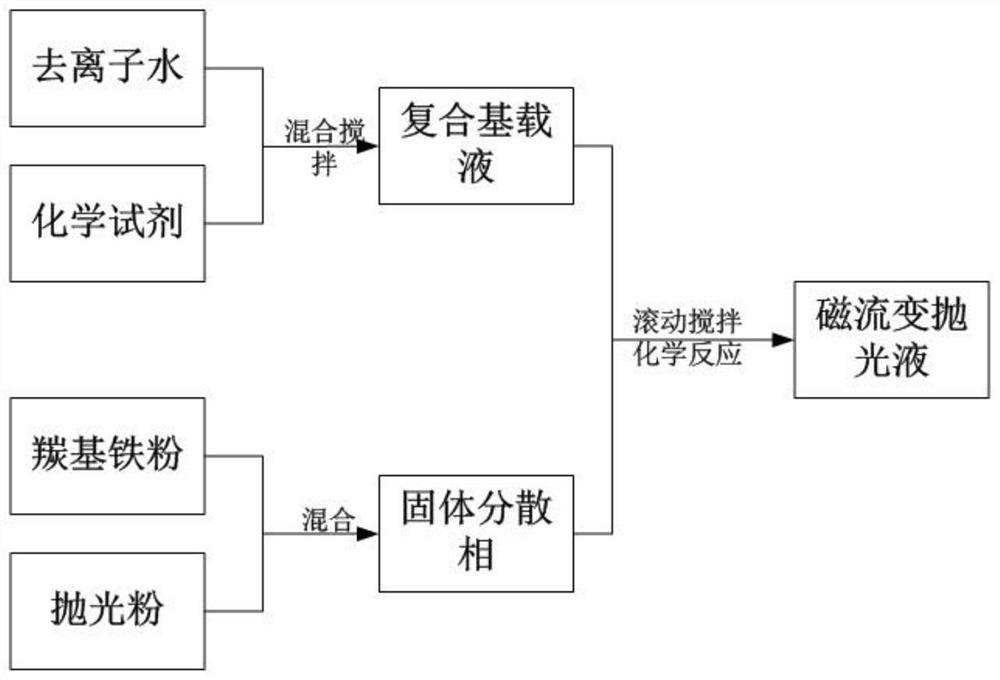

[0082] 2) Compare the composition information in Table 1, according to figure 1 The process shown in the preparation of water-based magnetorheological polishing fluid, the specific steps are as follows:

[0083] Step 1. Add the dispersion stabilizer sodium citrate into 250ml of deionized water and stir for 1 hour. The rotation speed of the stirrer is set at 400r / min, and the temperature is controlled between 22°C and 25°C.

[0084] Step 2. Add the wetting agent propylene glycol into the solution obtained in step 1, and stir for 0.5 hours with a stirrer, the speed of the stirrer is set at 400 r / min, and the temperature is controlled between 22°C and 25°C.

[0085] Step 3...

Embodiment 2

[0092] 1) Composition design

[0093] The specific components and contents of the water-based magnetorheological polishing fluid provided in this embodiment are as shown in Table 1:

[0094] Table 2 The composition information table of embodiment 2 magnetorheological polishing fluid

[0095]

[0096]

[0097] 2) Comparing the composition information in Table 2, according to figure 1 The process shown in the preparation of water-based magnetorheological polishing fluid, the specific steps are as follows:

[0098] Step 1. Add the dispersion stabilizer mixed with sodium tripolyphosphate and sodium hexametaphosphate into 250ml of deionized water and stir. The speed of the stirrer is set at 400r / min, and the temperature is controlled between 22°C and 25°C.

[0099] Step 2. Add the wetting agent sorbitol into the solution obtained in step 1, and stir for 0.5 hours with a stirrer, the speed of the stirrer is set at 400 r / min, and the temperature is controlled between 22°C and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com