Patents

Literature

54results about How to "Realize automatic polishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

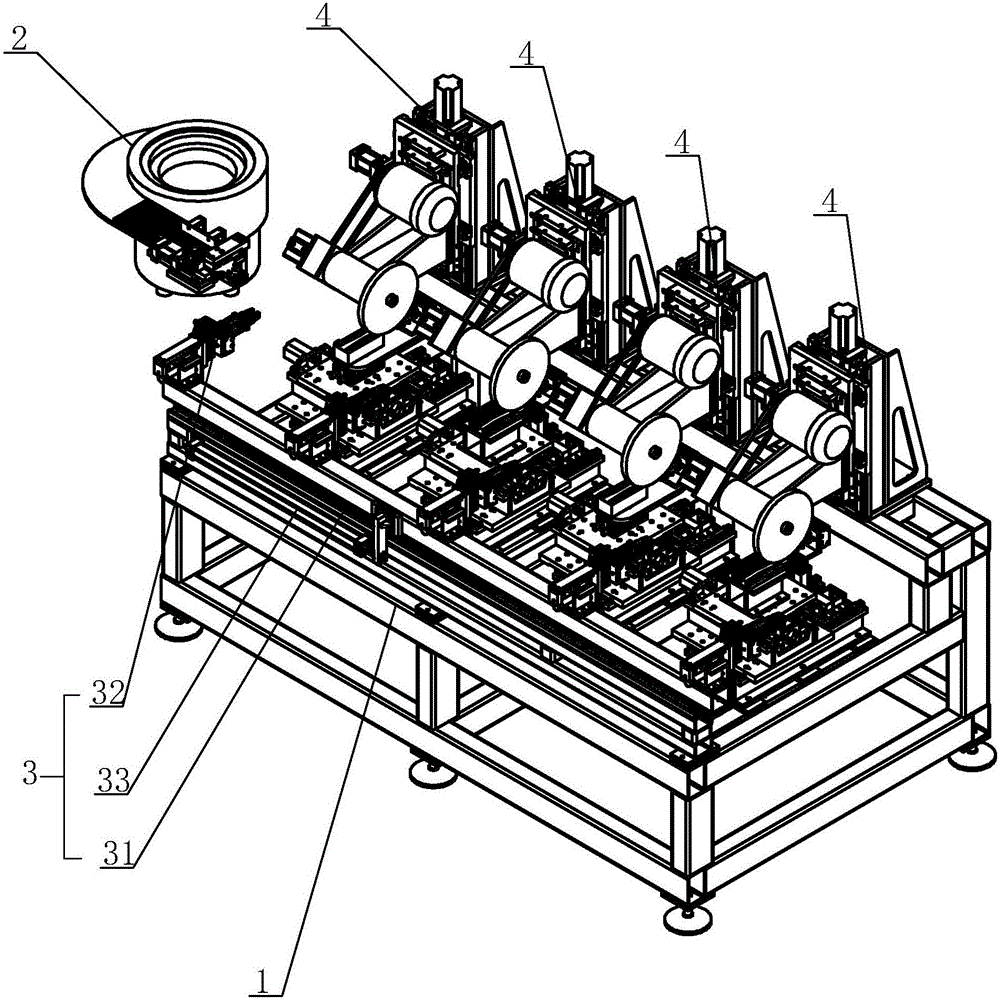

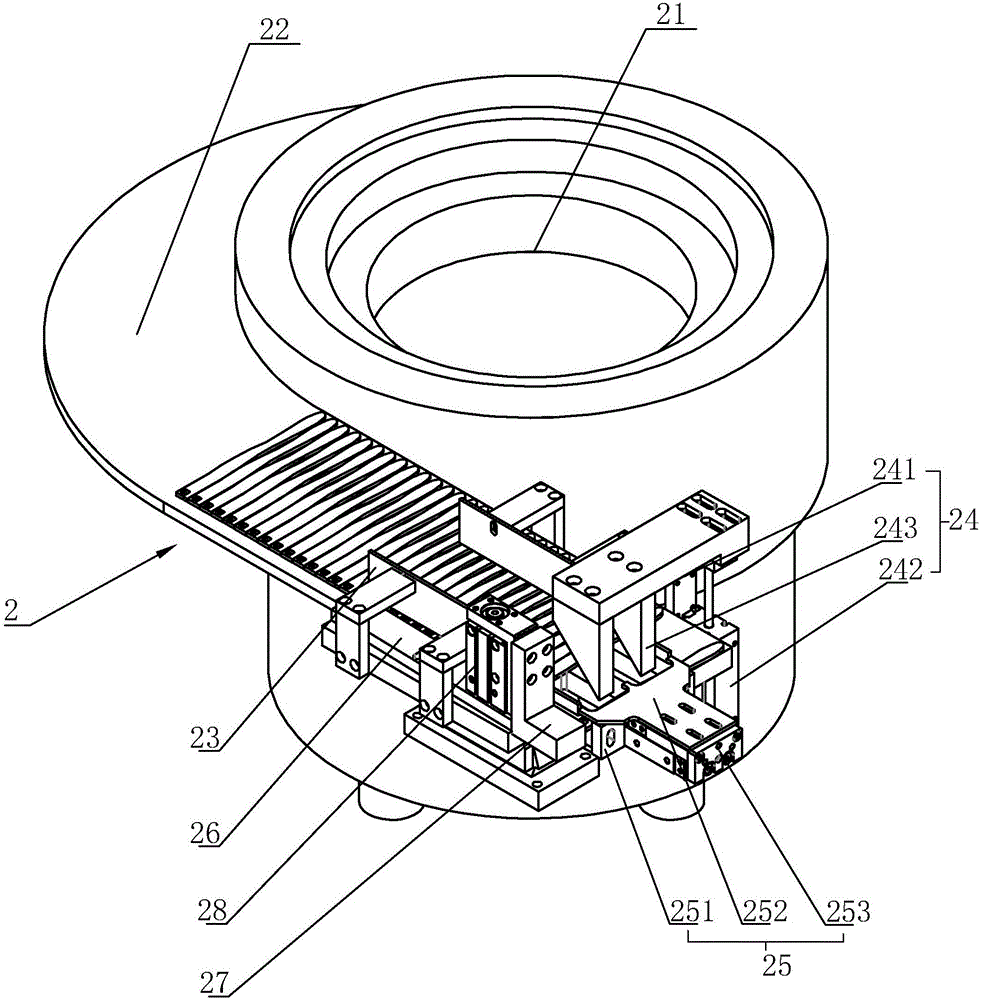

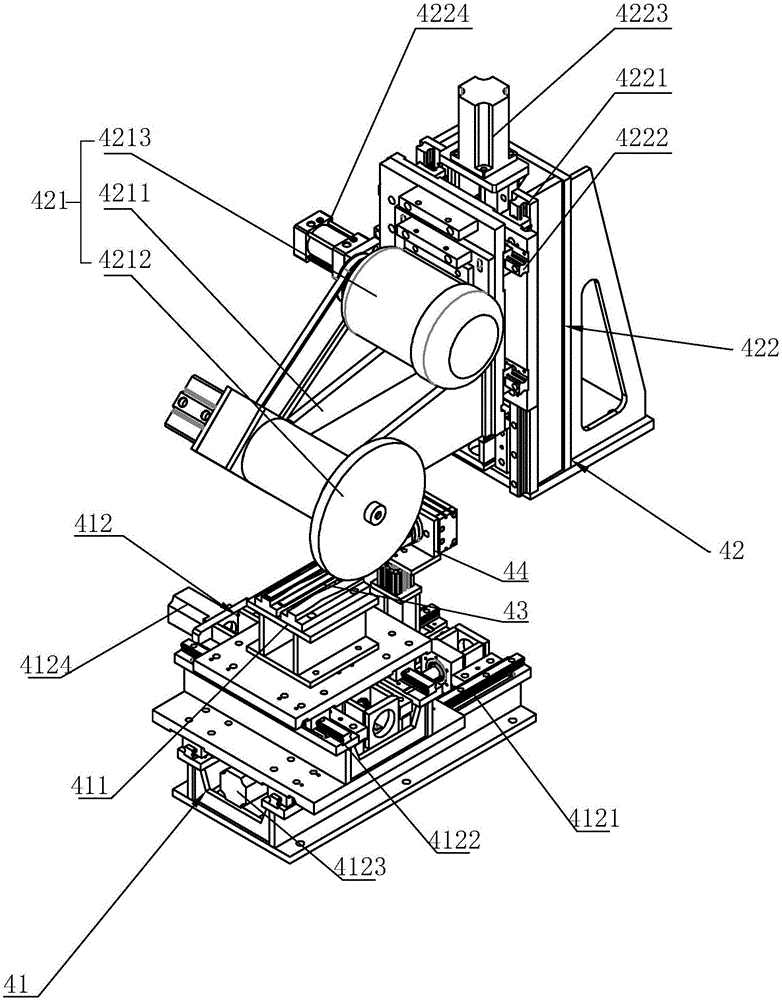

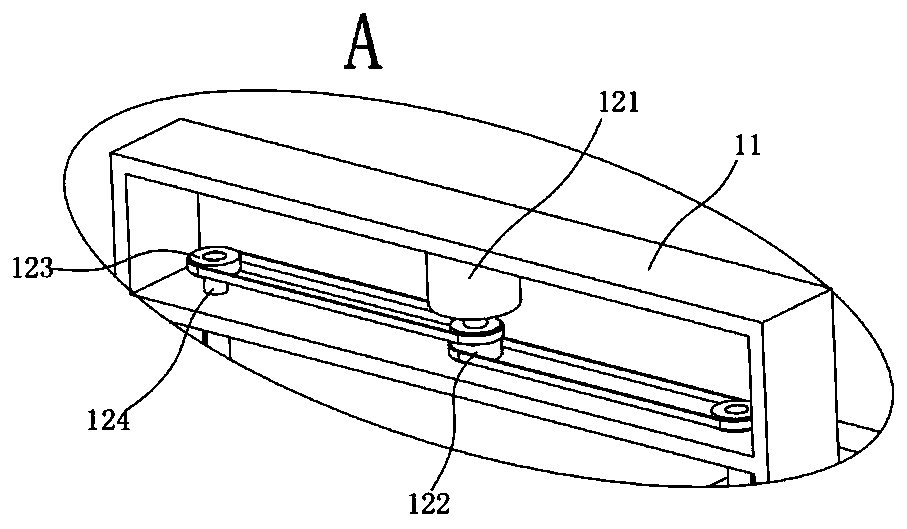

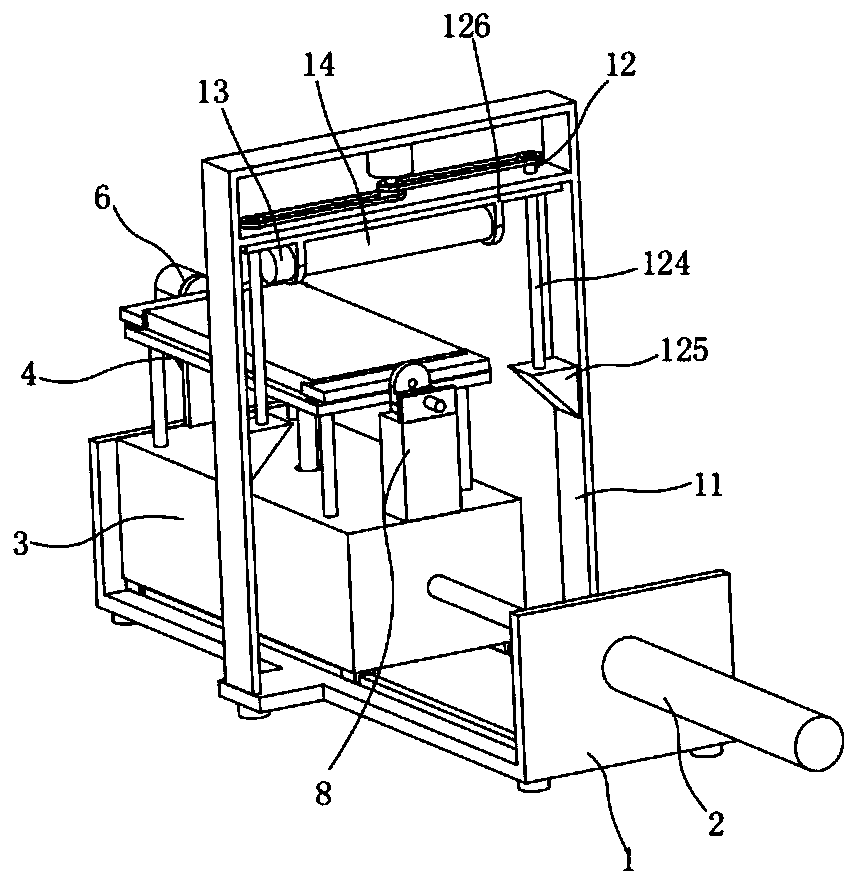

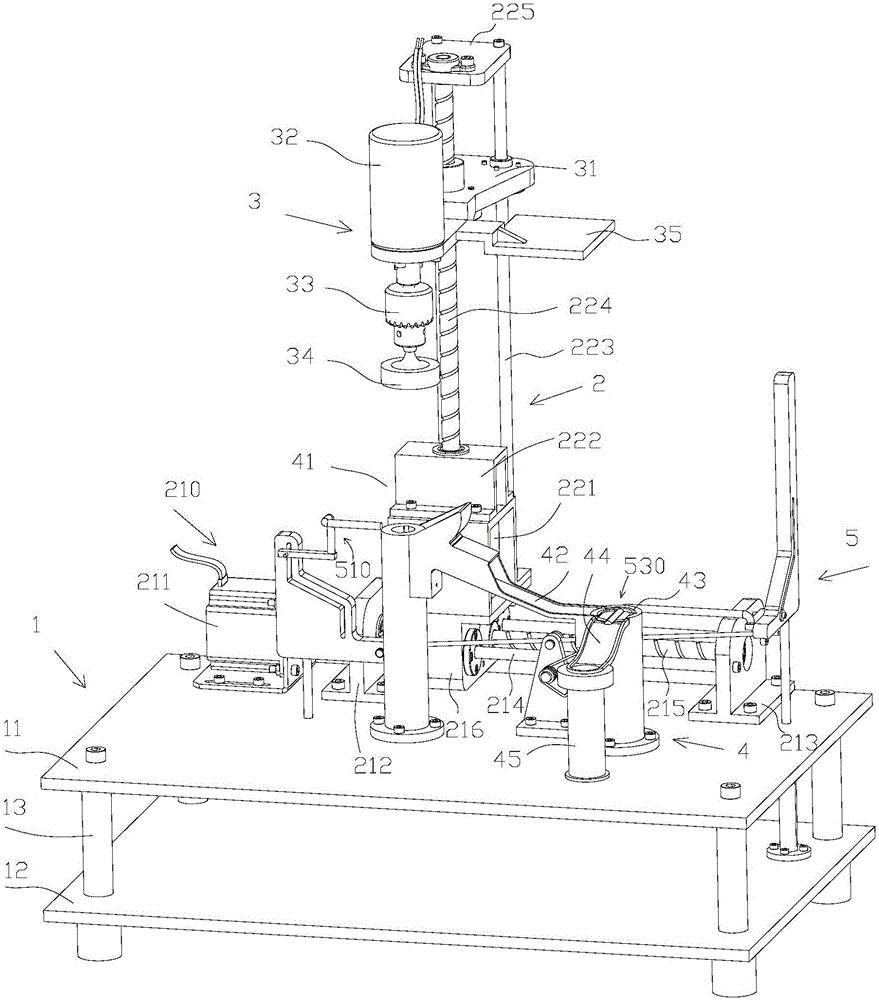

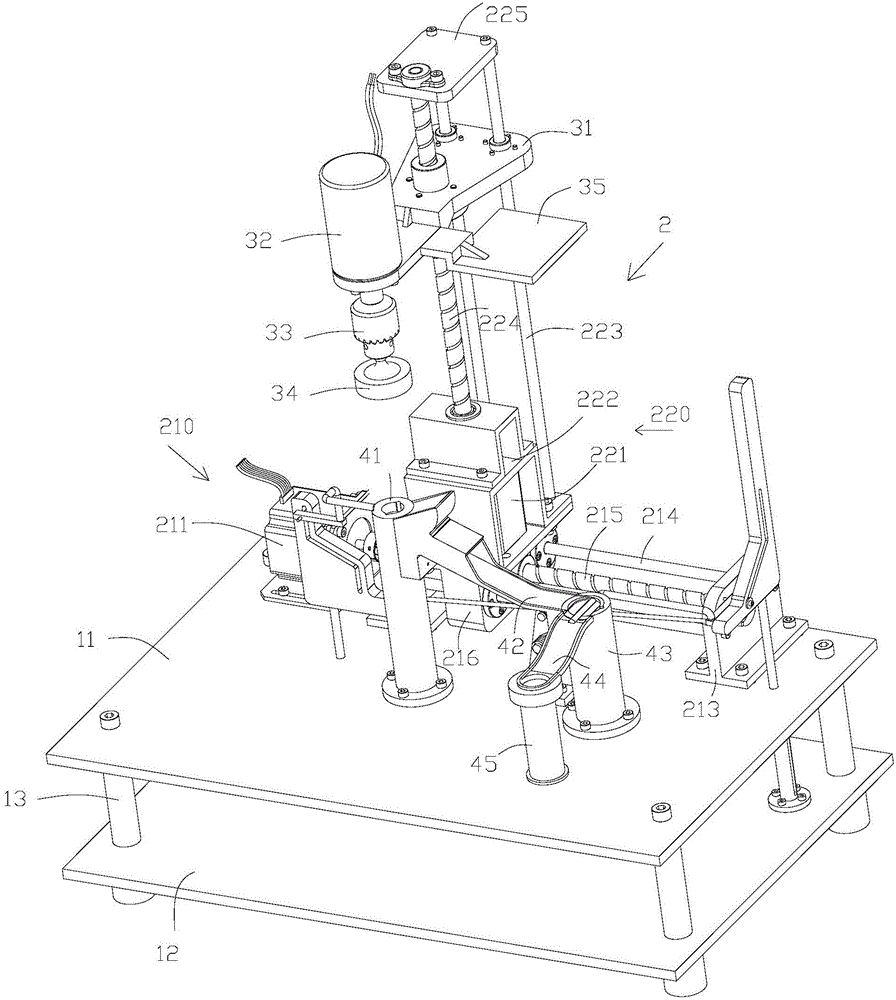

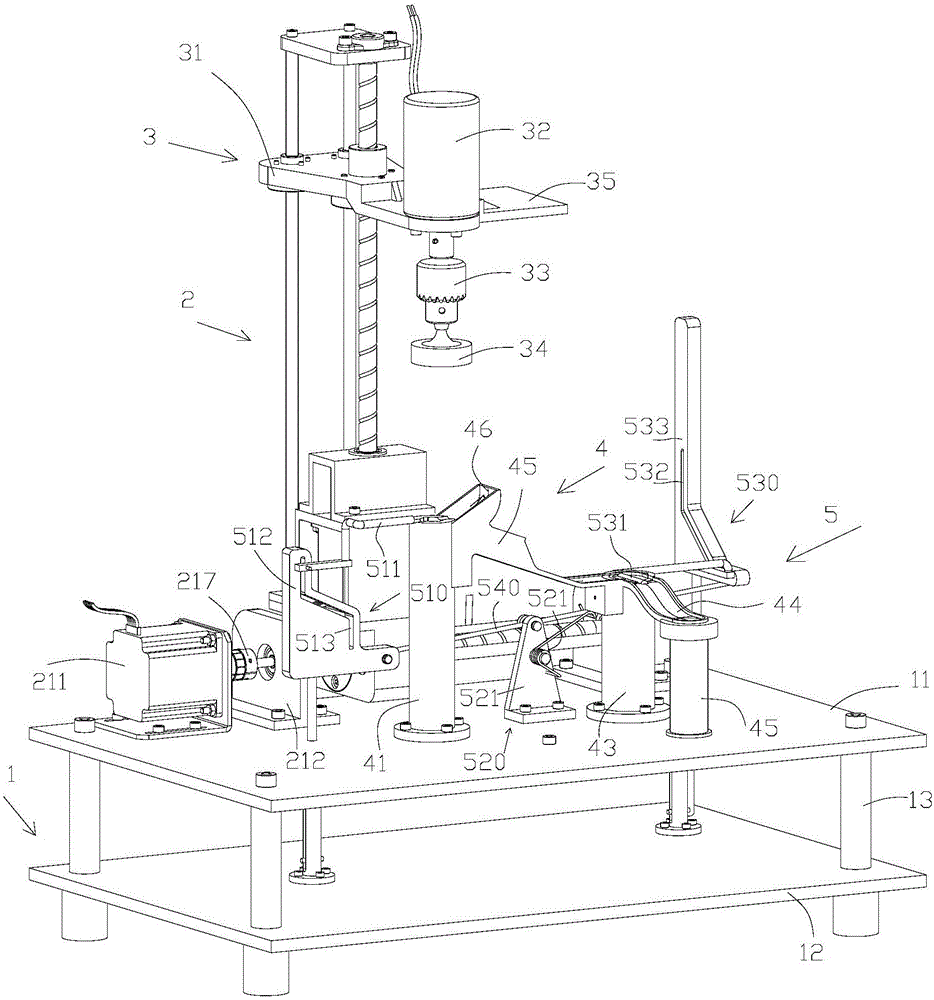

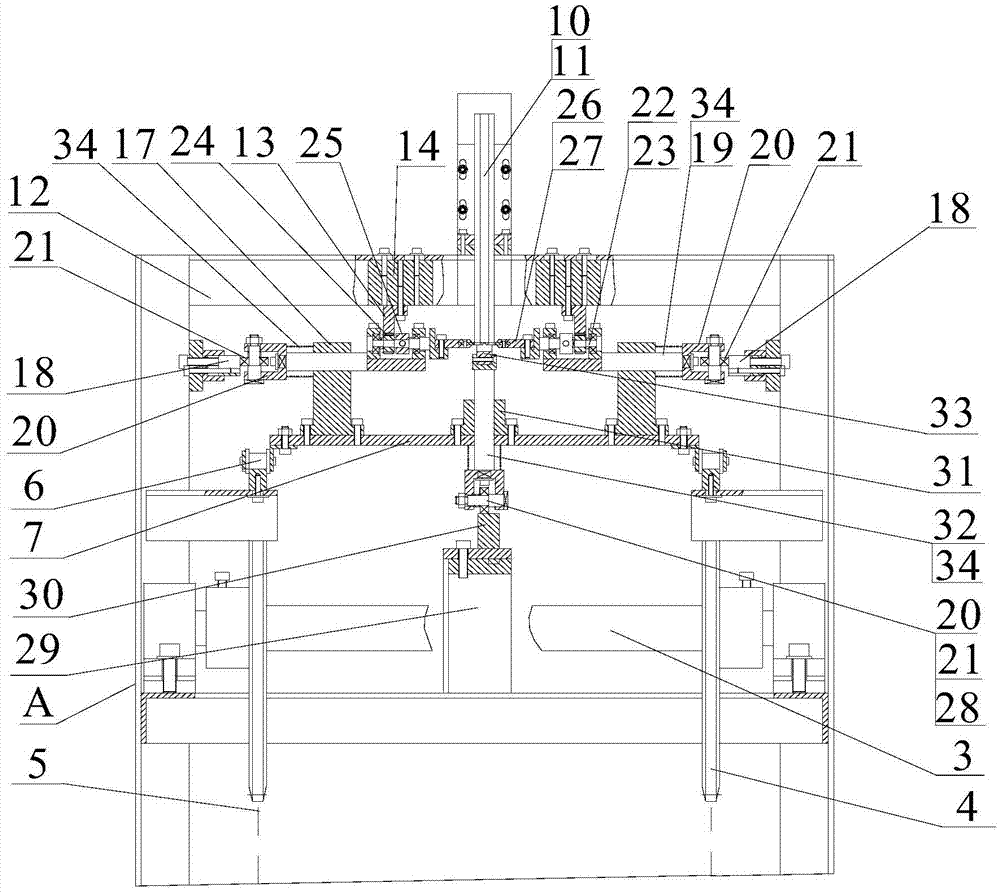

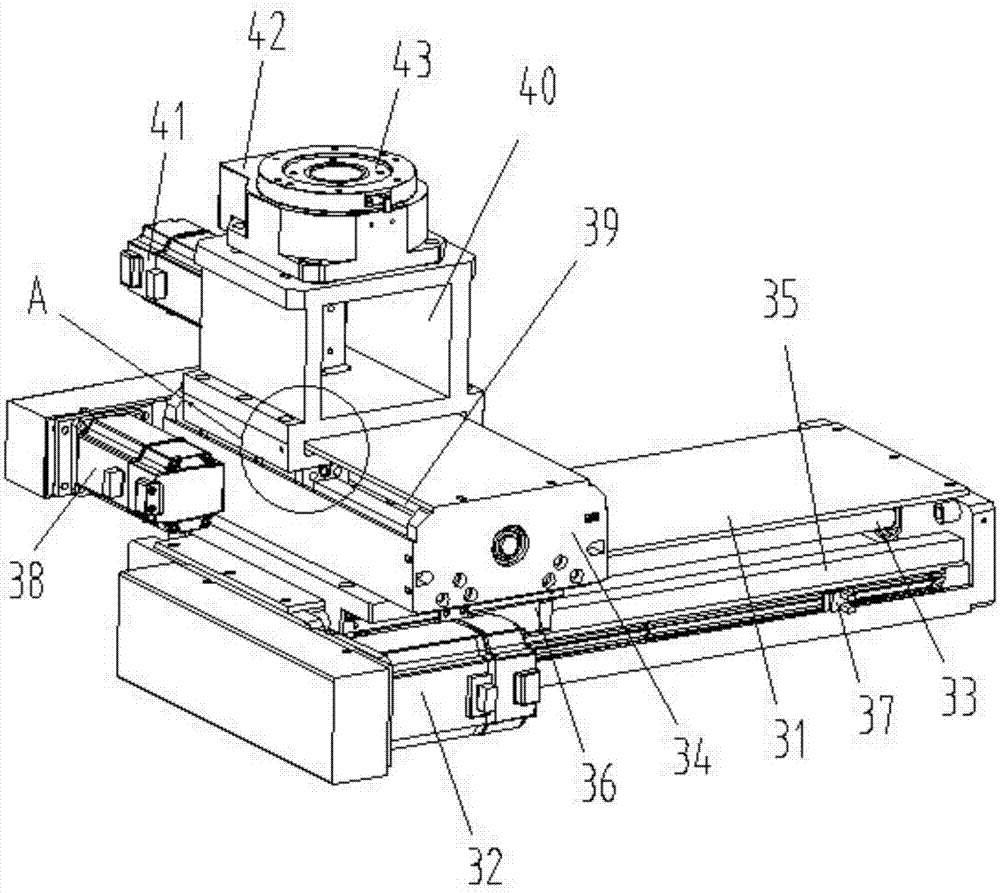

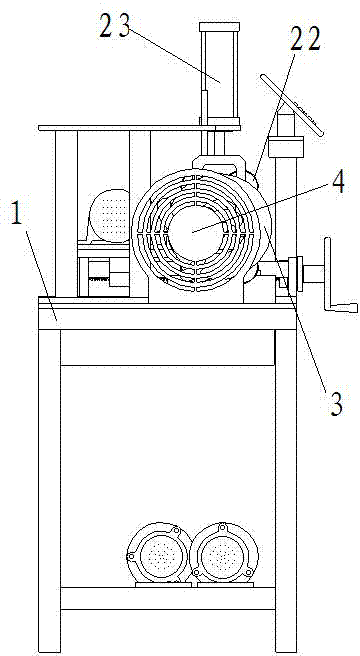

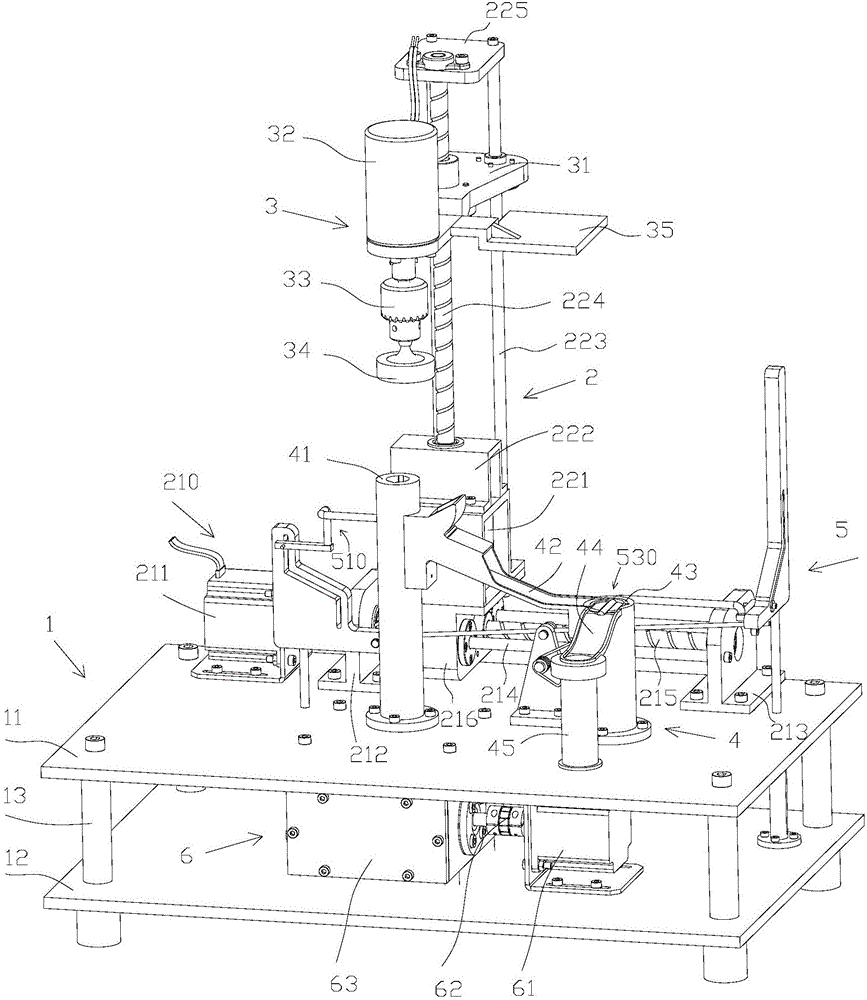

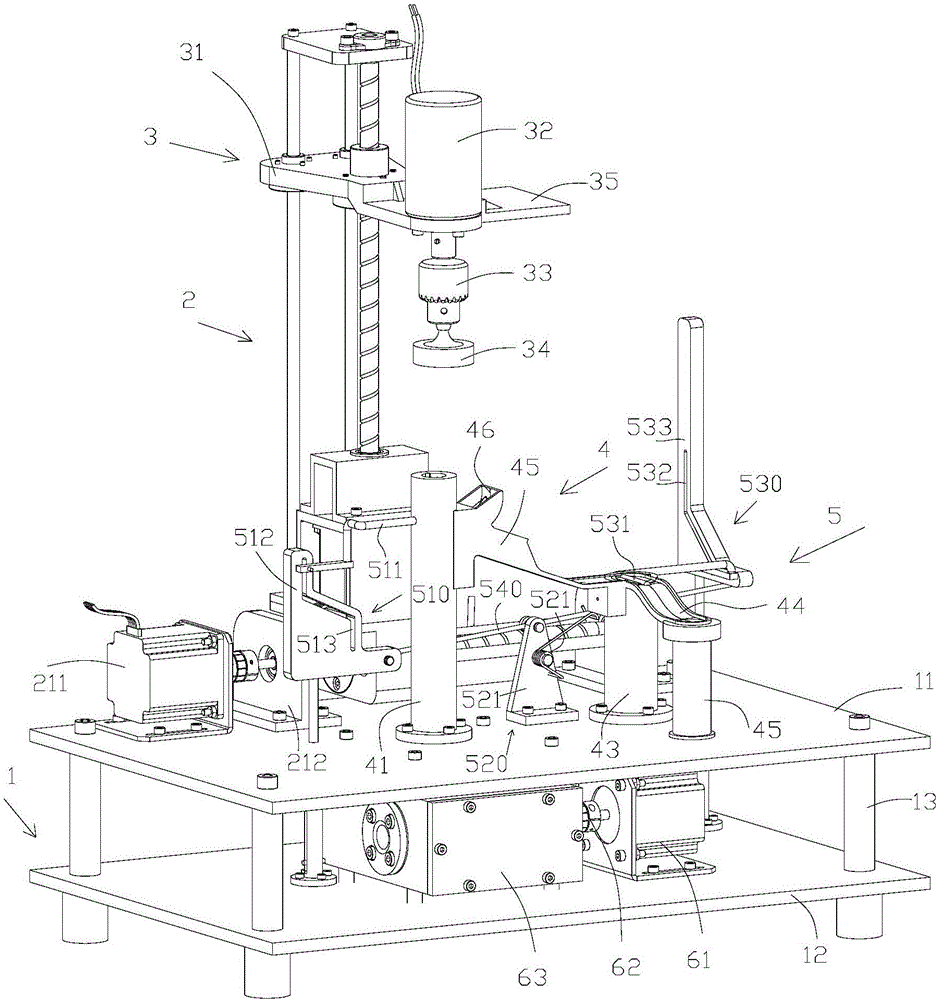

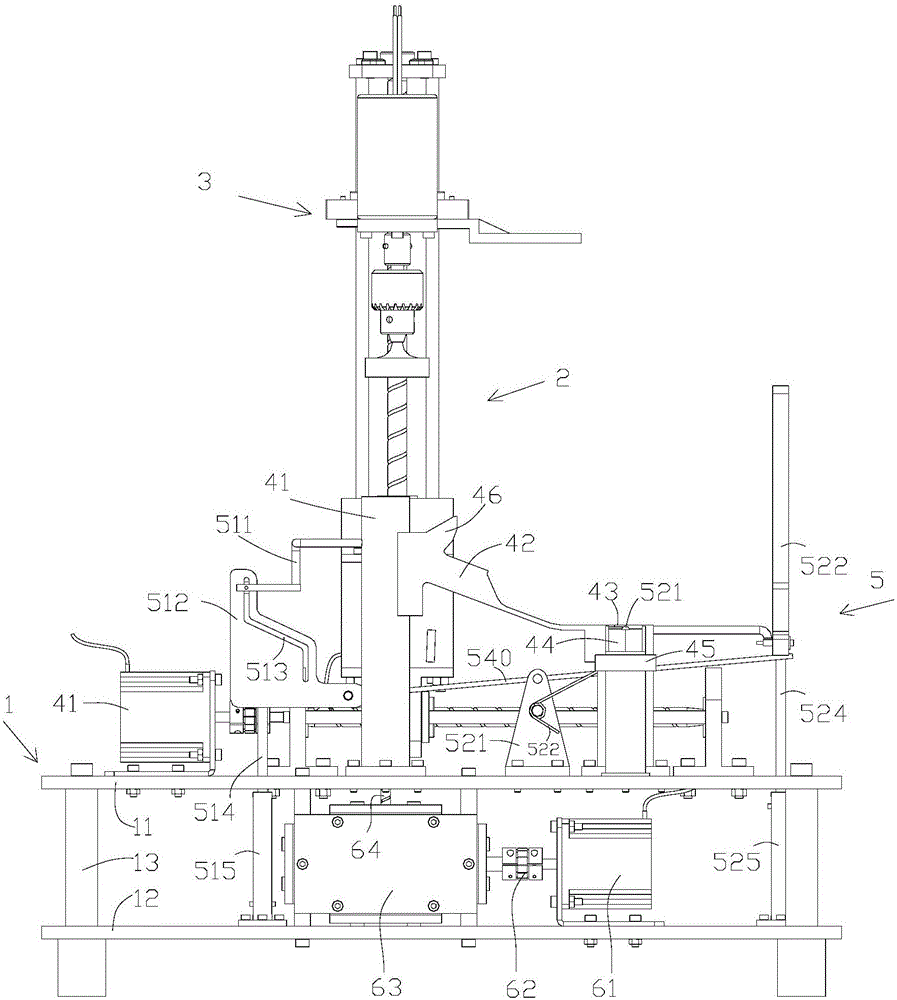

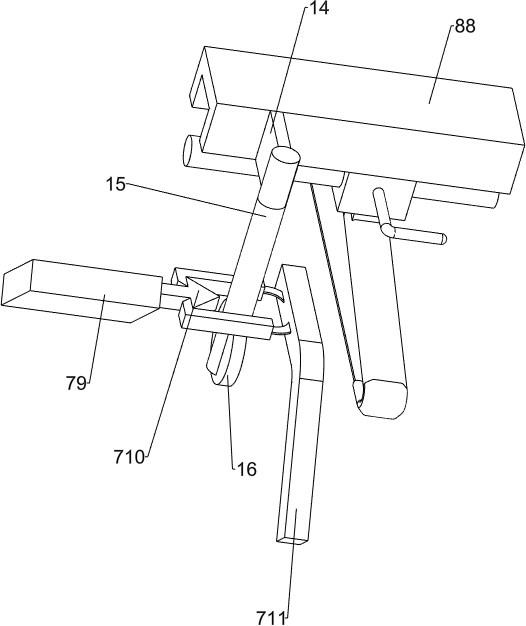

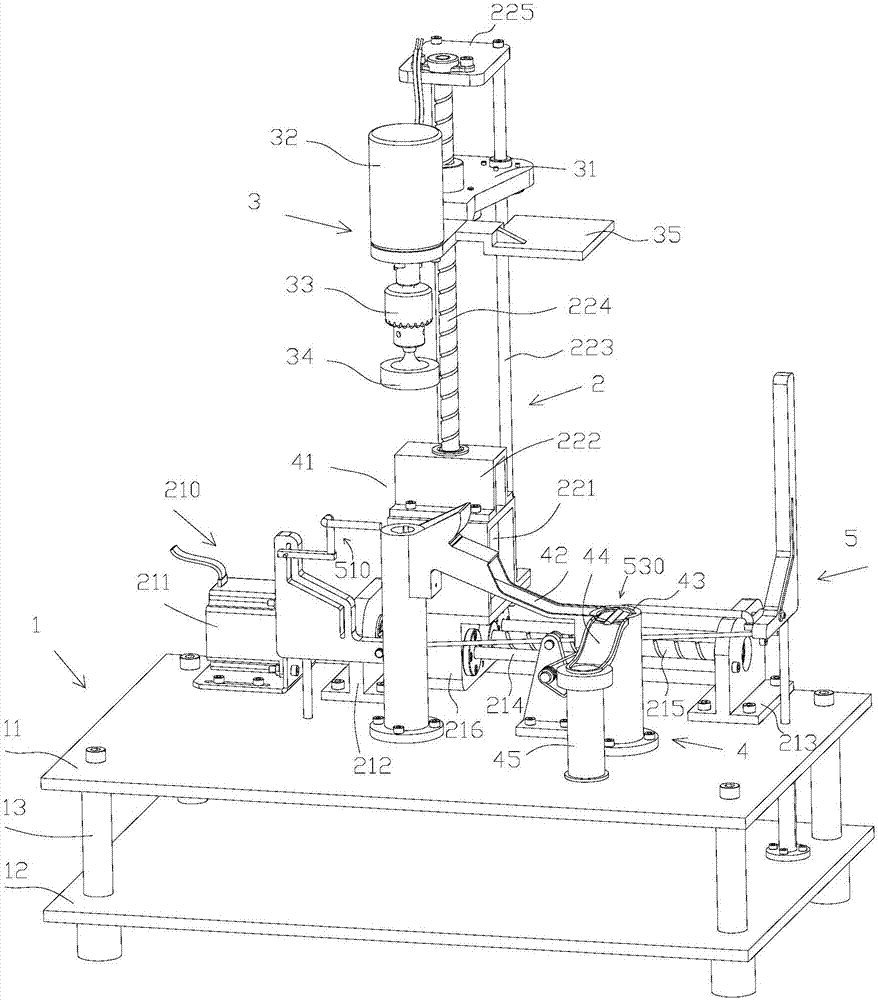

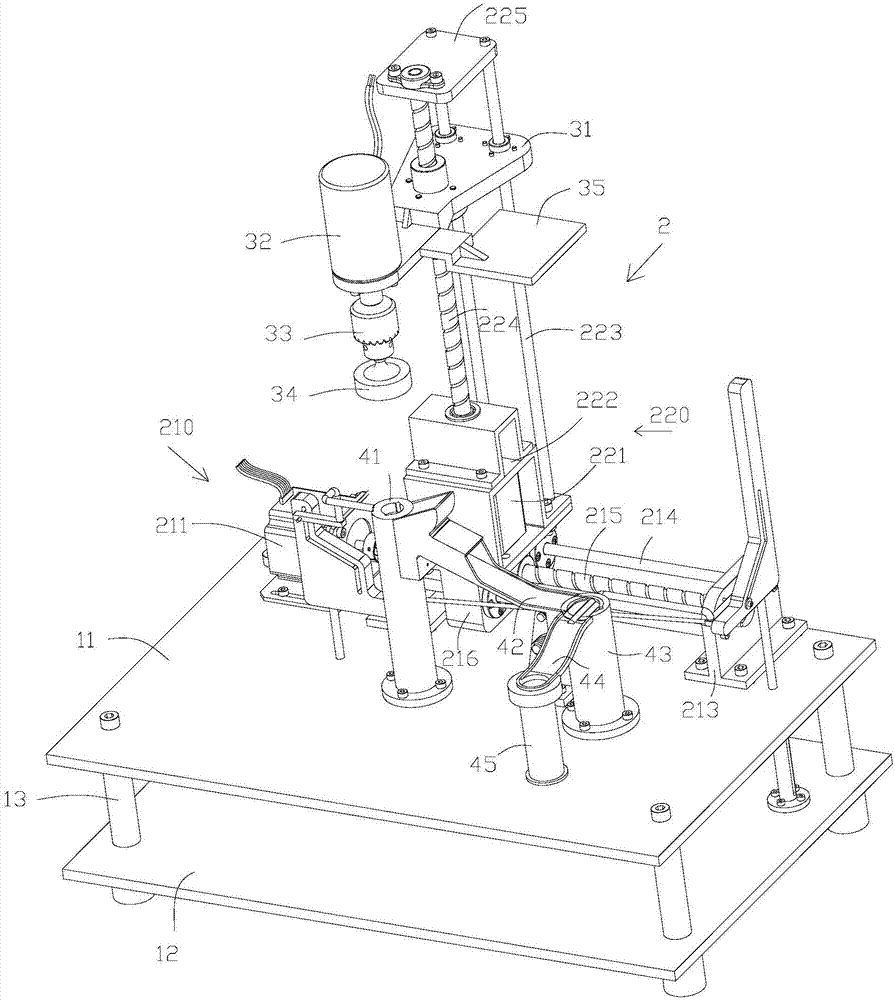

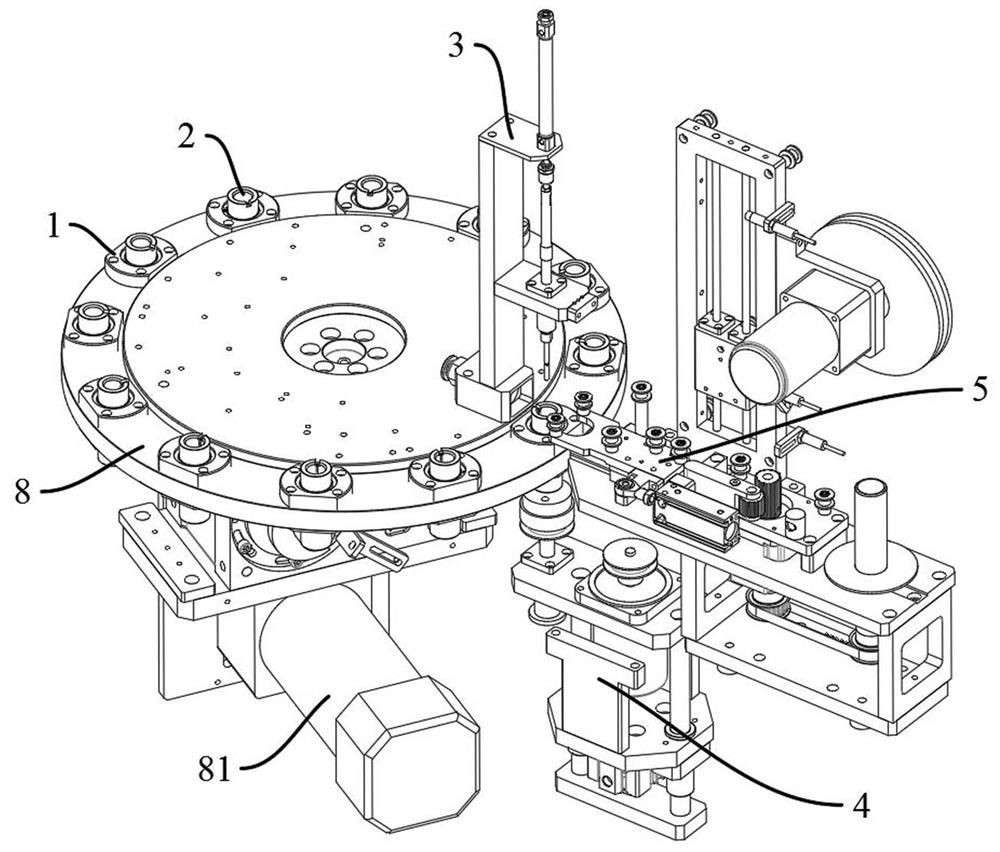

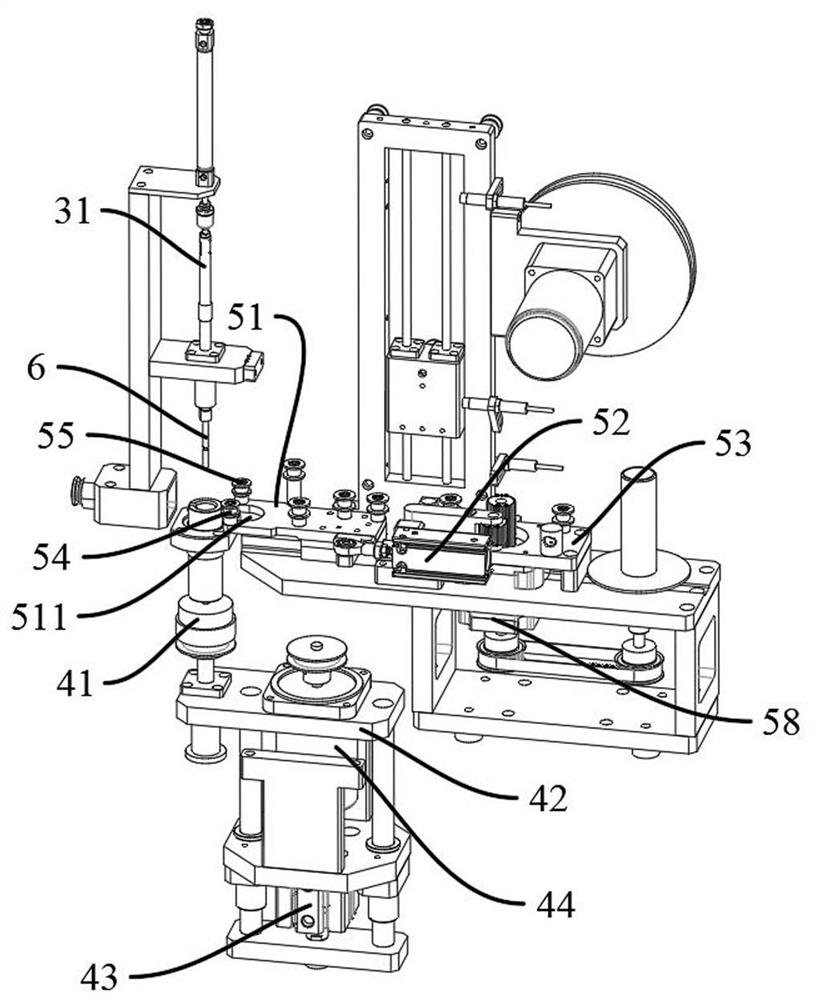

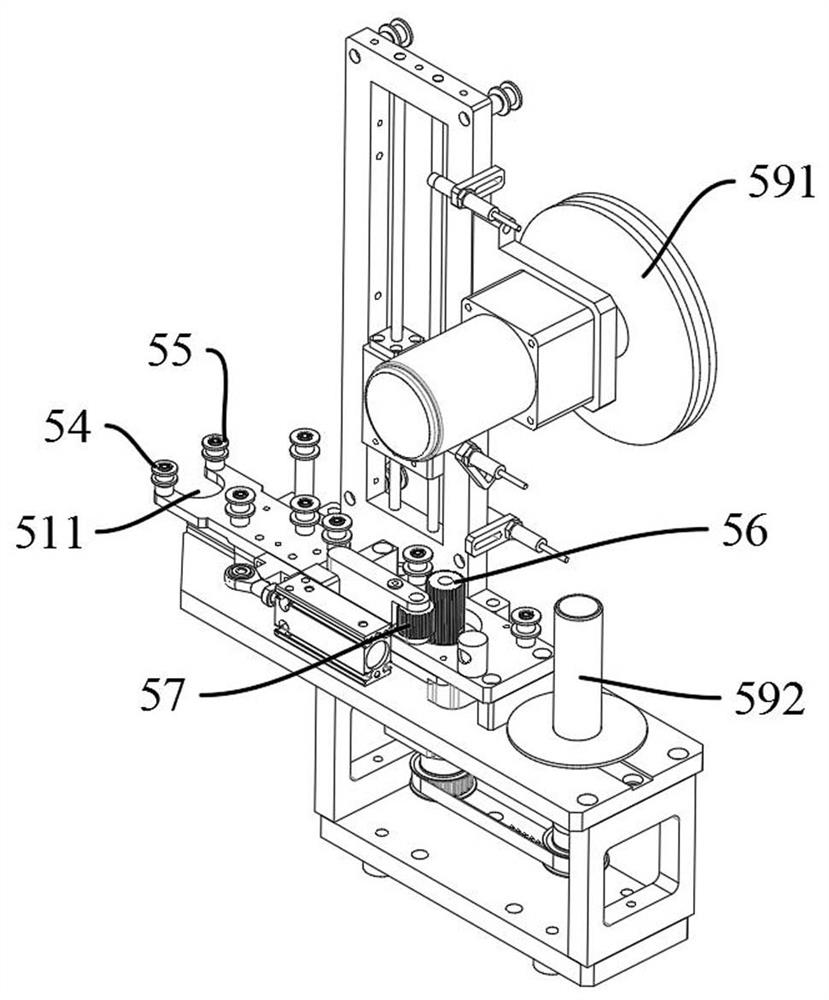

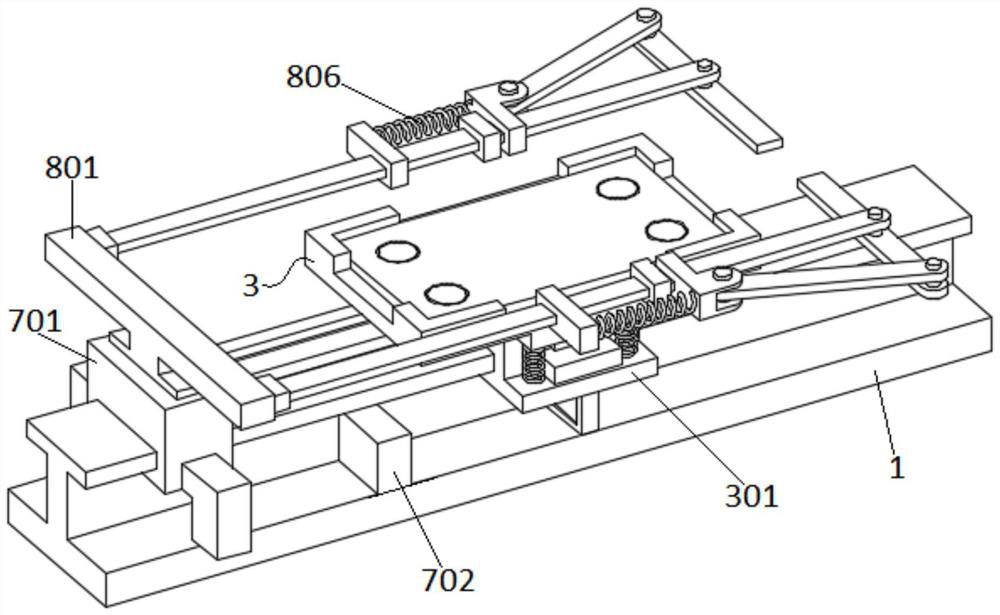

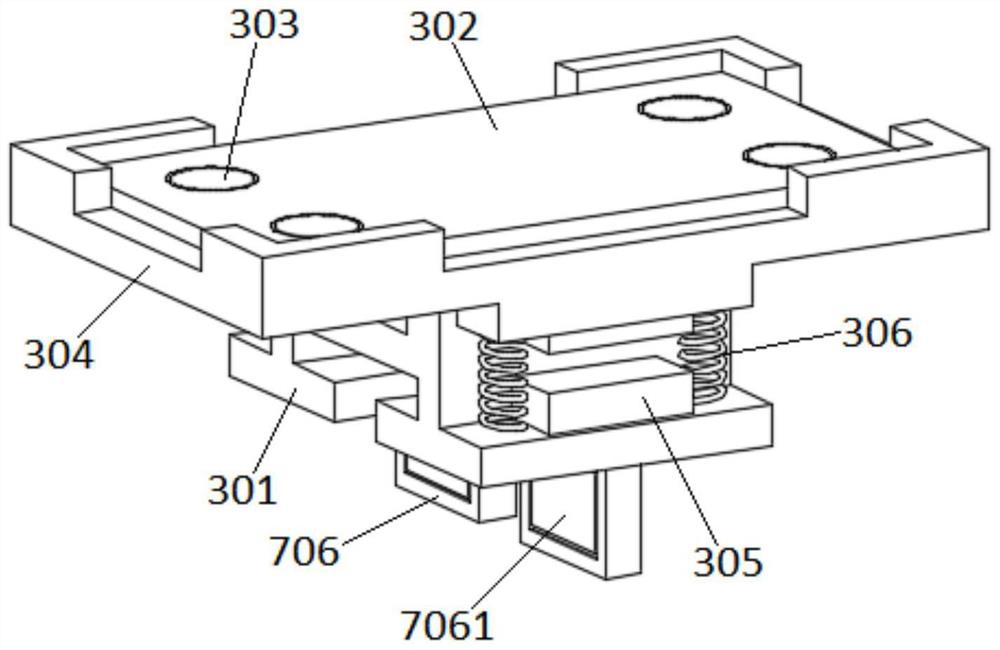

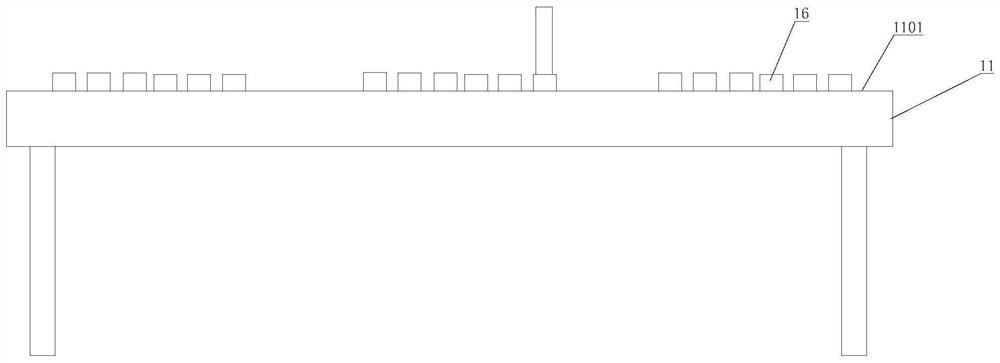

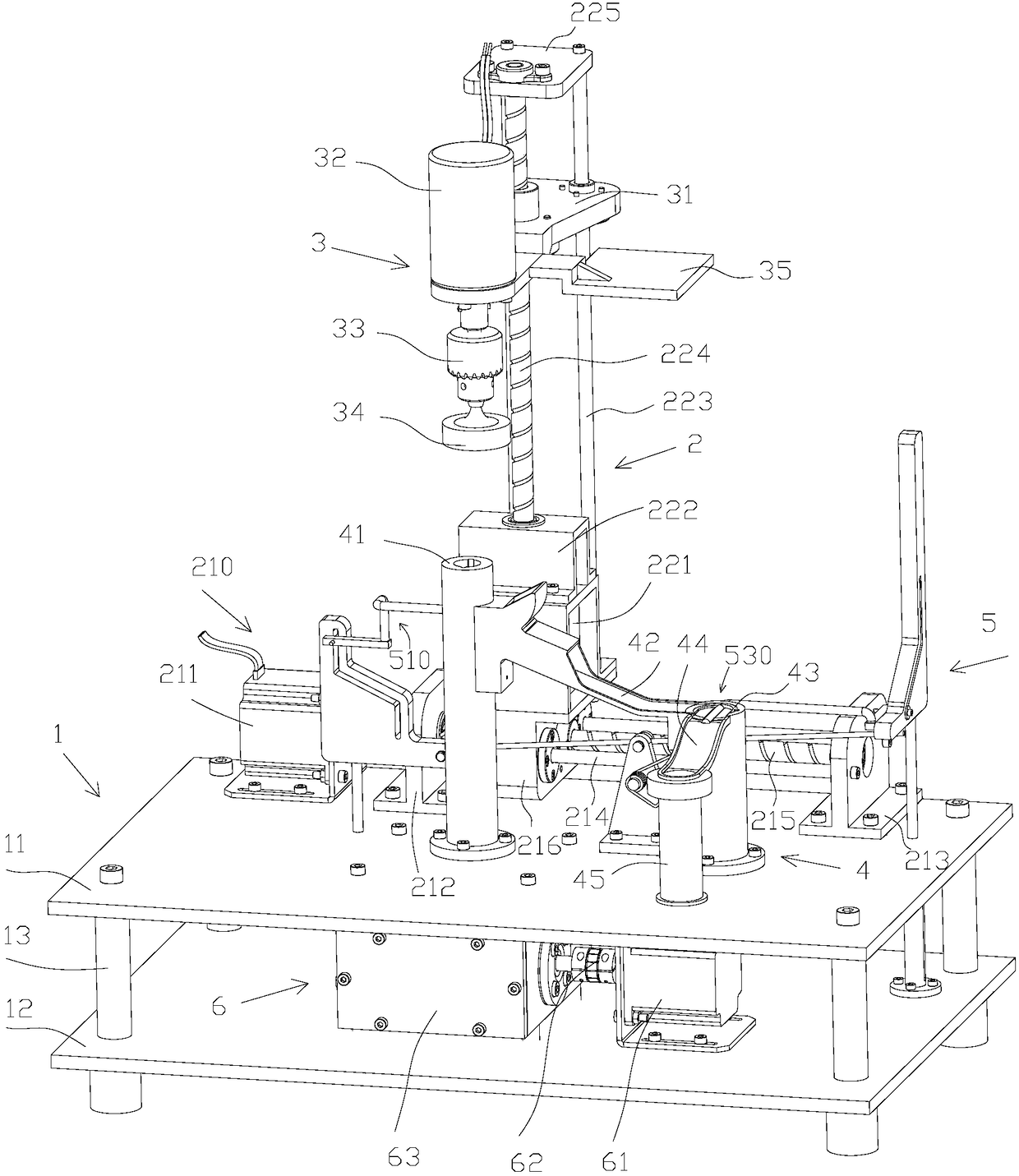

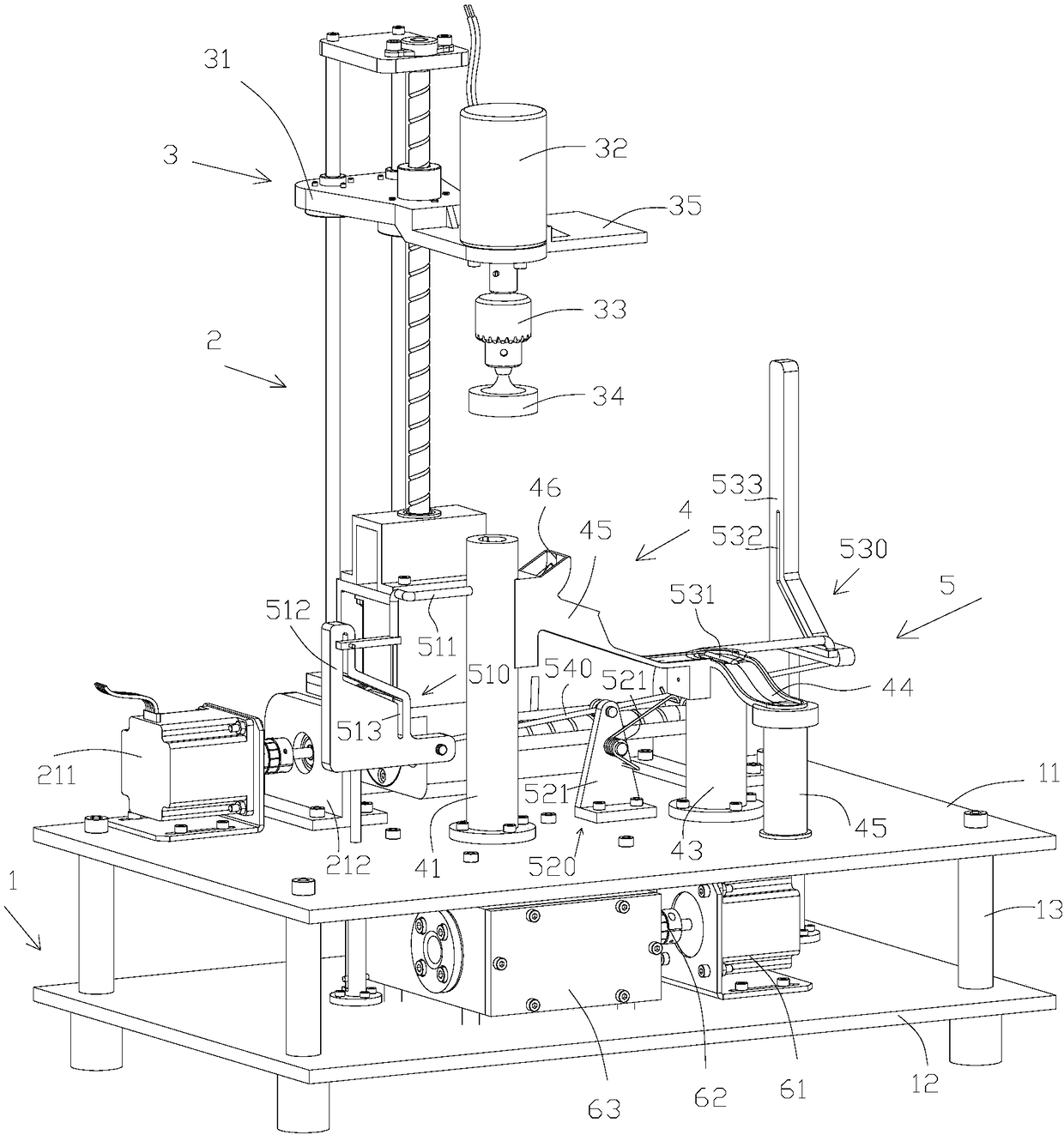

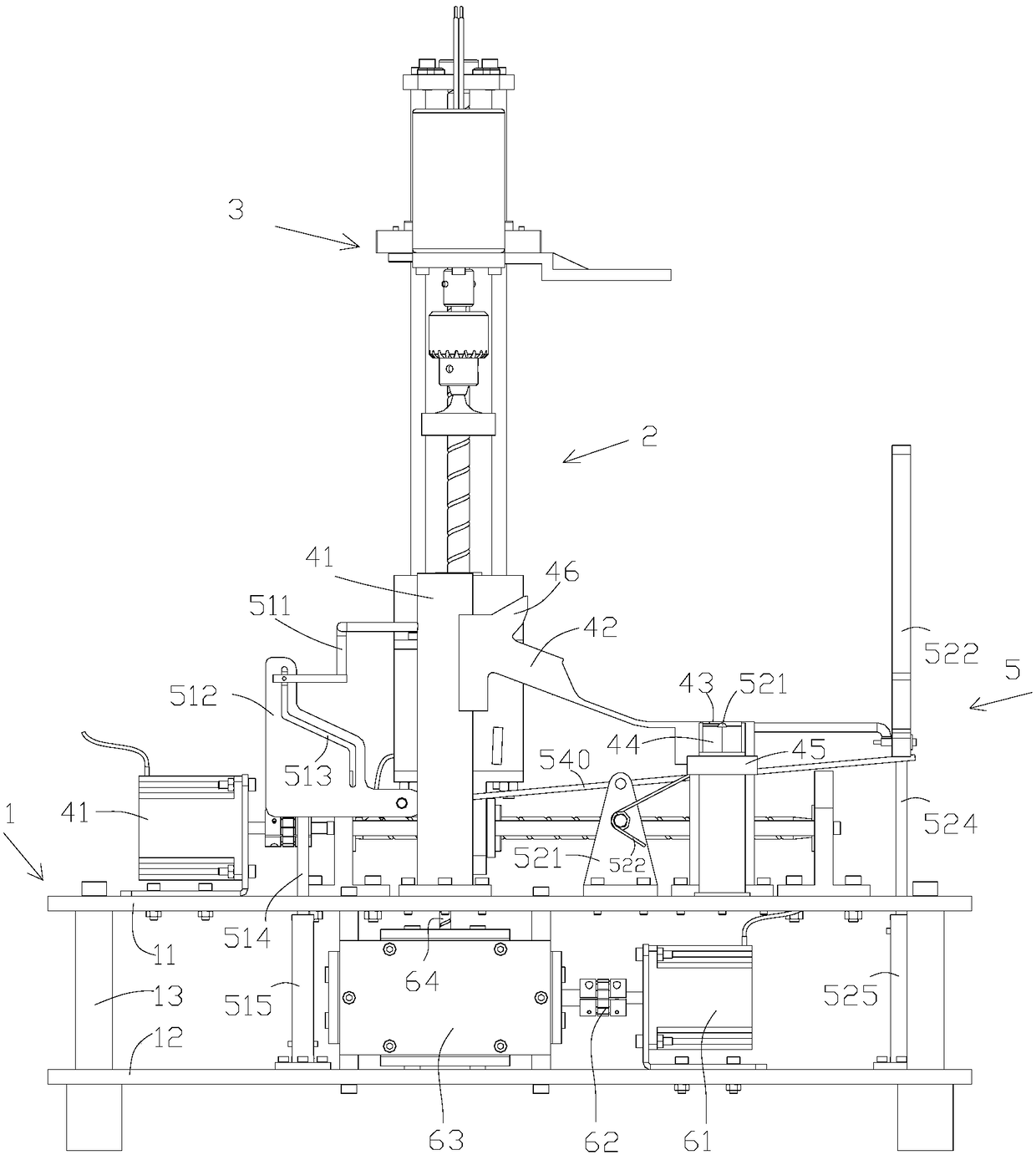

Glasses leg polishing machine

ActiveCN105834881ARealize automatic polishingIncrease productivityProgramme-controlled manipulatorGrinding carriagesManipulatorArm moving

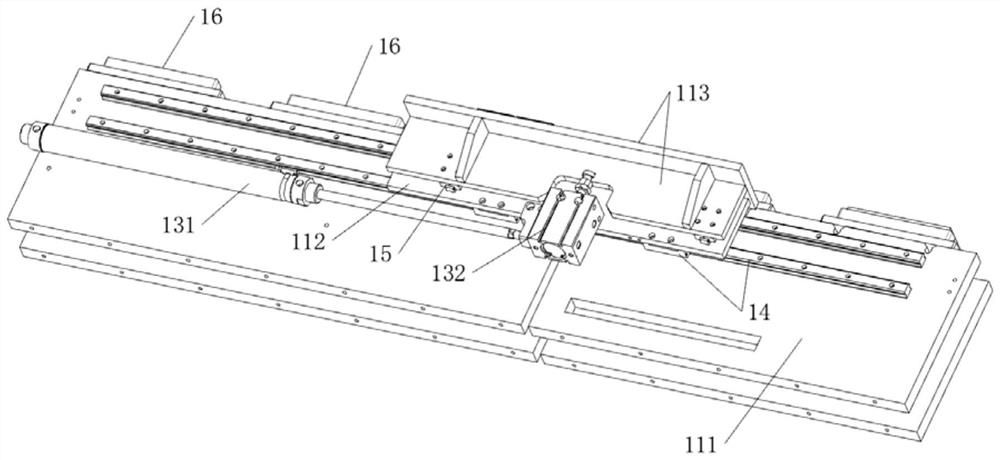

The invention discloses a glasses leg polishing machine. A feeding mechanism, a conveying mechanism and a plurality of polishing mechanisms are arranged on a machine frame. The conveying mechanism comprises a conveying track and a plurality of mechanical arms arranged on the conveying track. A conveying driver for driving the mechanical arms to do reciprocating sliding is arranged on the conveying track. The feeding mechanism is arranged on one side of the conveying track. The polishing mechanisms are distributed at intervals along the conveying track. Each polishing mechanism comprises a clamping device for clamping a glasses leg and a polishing device used for polishing the glasses leg. Each clamping device comprises a carrying platform used for carrying the glasses leg and a carrying platform moving assembly used for driving the carrying platform to move relative to a polishing wheel assembly. One side of each carrying platform is provided with a clamping arm used for clamping the glasses leg and a clamping arm moving assembly used for driving the clamping arm to rotate and move relative to the corresponding carrying platform. Each polishing wheel assembly is arranged above the corresponding carrying platform. The glasses leg polishing machine achieves the effect of automatic polishing and improves the production efficiency.

Owner:温州创宇智能设备有限公司

Panel polishing device for square reading bookshelf production

InactiveCN111098217AAchieve contactAchieve separationGrinding carriagesPolishing machinesHydraulic cylinderPiston rod

The invention discloses a panel polishing device for square reading bookshelf production. The panel polishing device comprises a mounting frame, a hydraulic cylinder is fixed to one side of the mounting frame, a mounting box is fixed to the end of a piston rod of the hydraulic cylinder, the mounting box is slidably connected with the bottom end of the mounting frame through a linear rail, and a supporting mechanism is arranged on the mounting box; a first fixing block is fixed to one side of the top end of the mounting box, a steering mechanism is arranged on the first fixing block, a first clamping plate is arranged on the steering mechanism, and a second fixing block is fixed to the side, away from the first fixing block, of the mounting box; a jacking mechanism is arranged at the upperend of the second fixing block, and a second clamping plate is arranged on the jacking mechanism; and a panel is clamped between the first clamping plate and the second clamping plate, a supporting frame is fixed to the two sides of the middle of the mounting frame, a lifting mechanism is arranged on the supporting frame, a first servo motor is arranged on the lifting mechanism, and a grinding roller is fixed to an output shaft of the first servo motor. The panel polishing device has the advantages that automatic overturning and automatic polishing are achieved, and the working efficiency is high.

Owner:JIANGXI EQUIP INDAL GROUP GREAT INSURANCENT

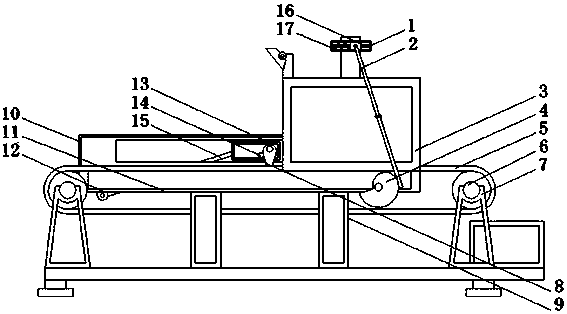

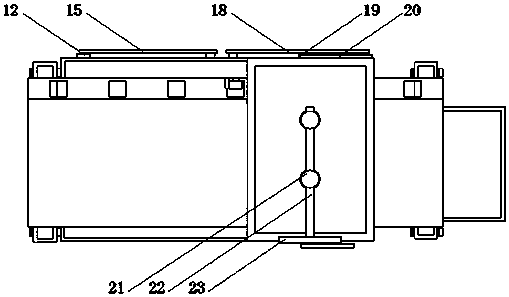

Polishing device for intelligently machining workpieces with regular shapes

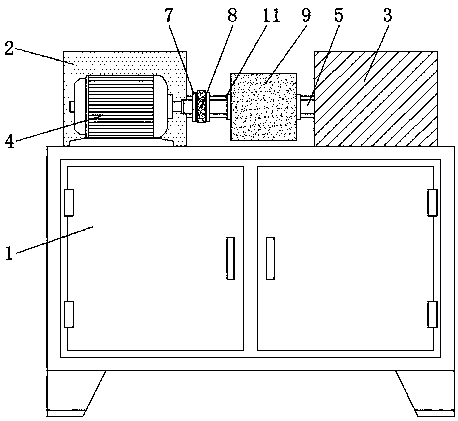

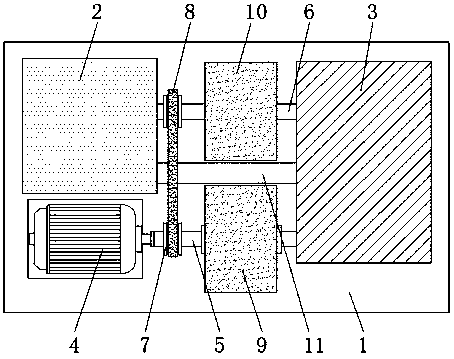

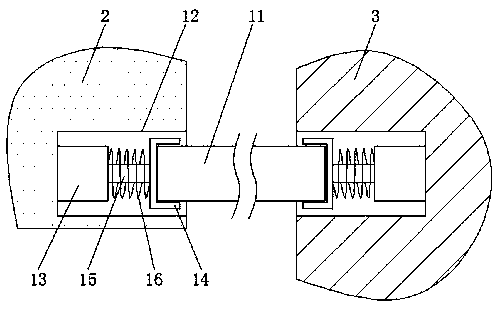

ActiveCN107030586APrevent looseningRealize automatic polishingGrinding carriagesPolishing machinesReciprocating motionHydraulic pump

The invention discloses a polishing device for intelligently machining workpieces with regular shapes. The polishing device comprises a frame, a first polishing wheel, a second polishing wheel, a conveying belt and a processor; the first polishing wheel and the second polishing wheel are connected through a first connecting device; the first connecting device comprises a first electric-hydraulic push rod and a second electric-hydraulic push rod; the first electric-hydraulic push rod controls the first polishing wheel to horizontally move; the second electric-hydraulic push rod controls the second polishing wheel to horizontally move; the first connecting device is connected with a second connecting device; the second connecting device is connected with a third connecting device; the third connecting device is connected with the frame; and the conveying belt is arranged above the frame. The polishing device further comprises a hydraulic pump, a control device, a driving device, clamping devices and linear guide rails; the clamping devices are arranged on two sides of the frame; the linear guide rails are arranged below the frame; the clamping devices are connected with slide blocks to move in the linear guide rails back and forth; and the clamping devices include first hydraulic rods, second hydraulic rods, first clamping plates and second clamping plates.

Owner:温州神一轴业股份有限公司

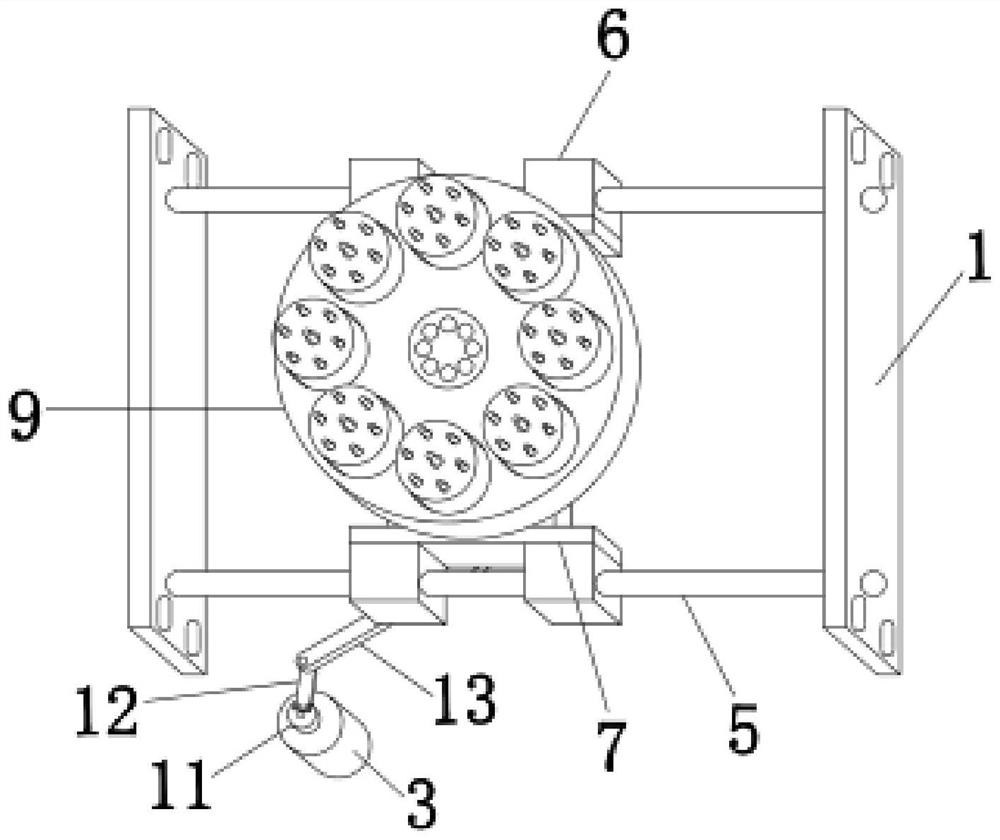

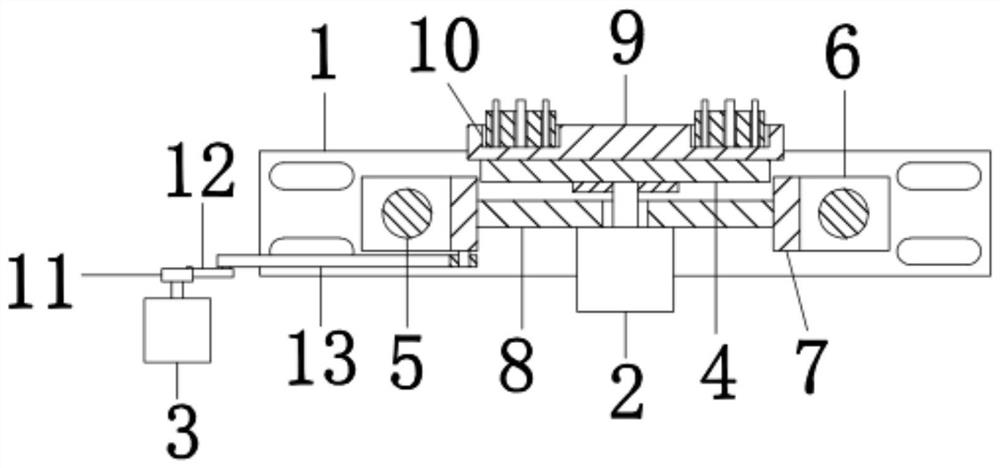

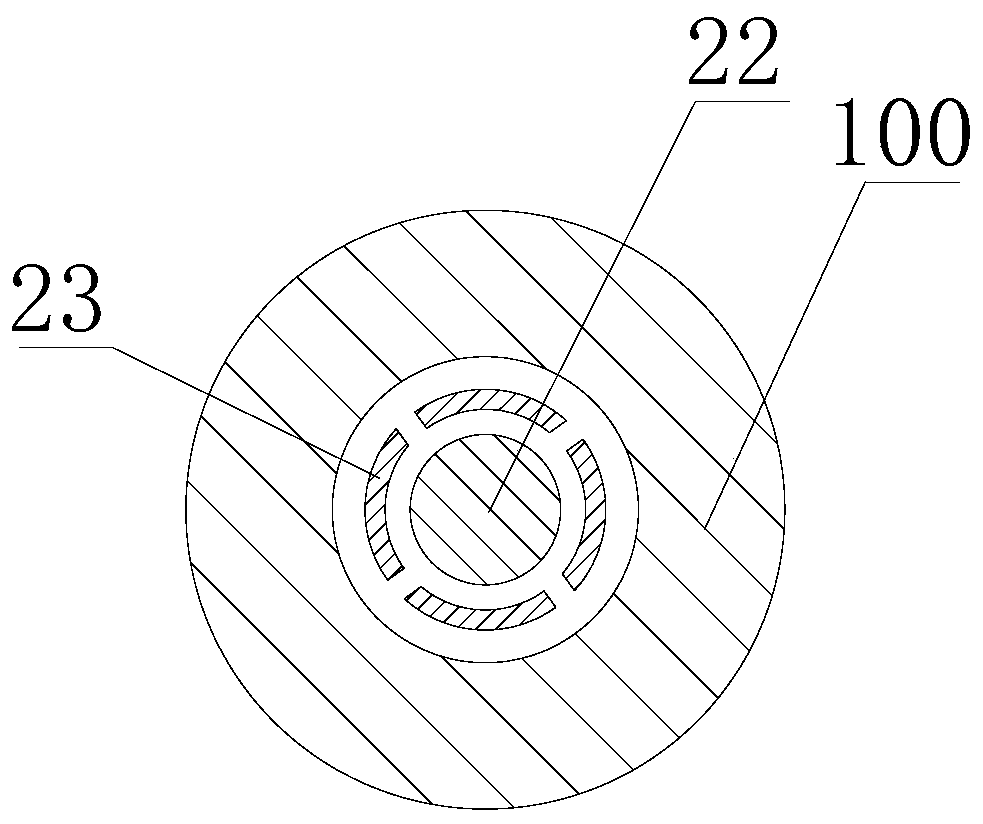

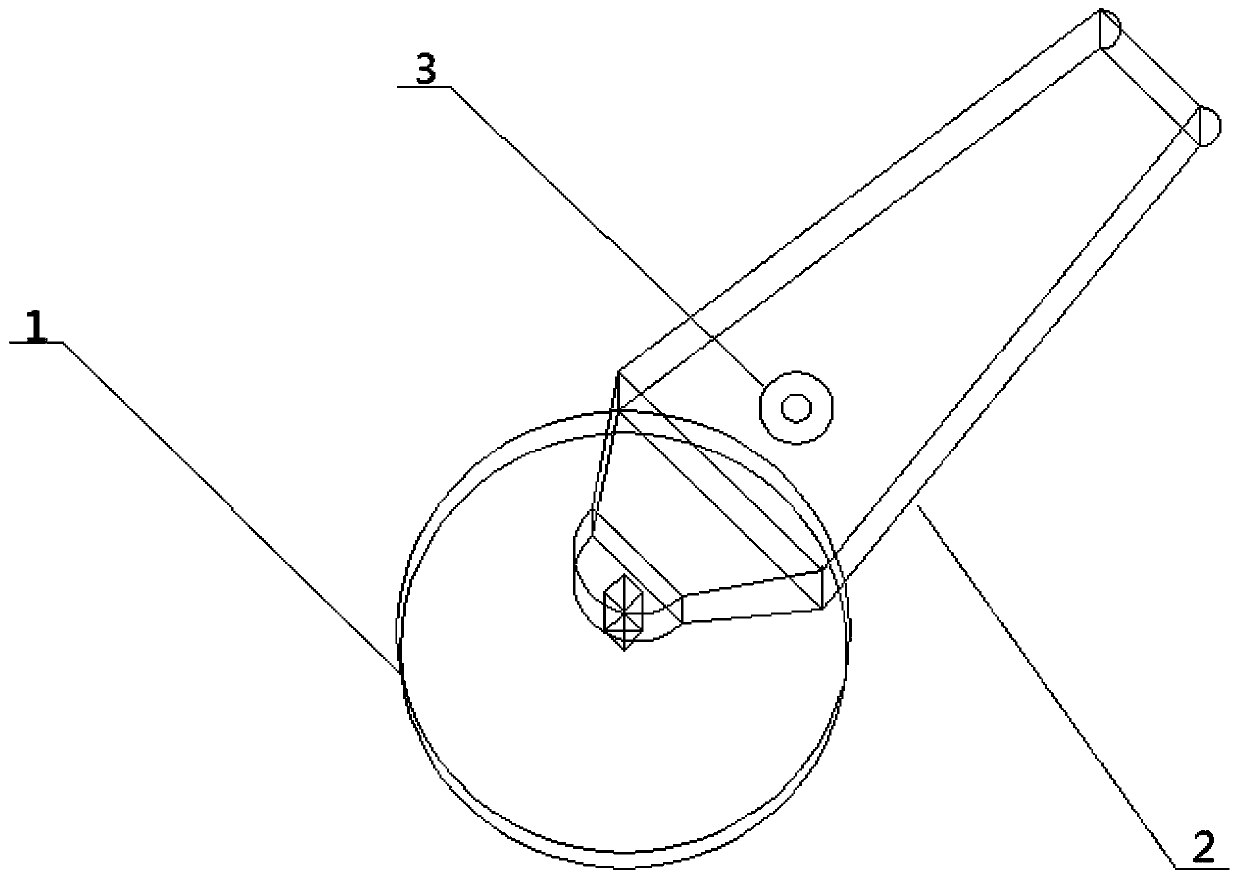

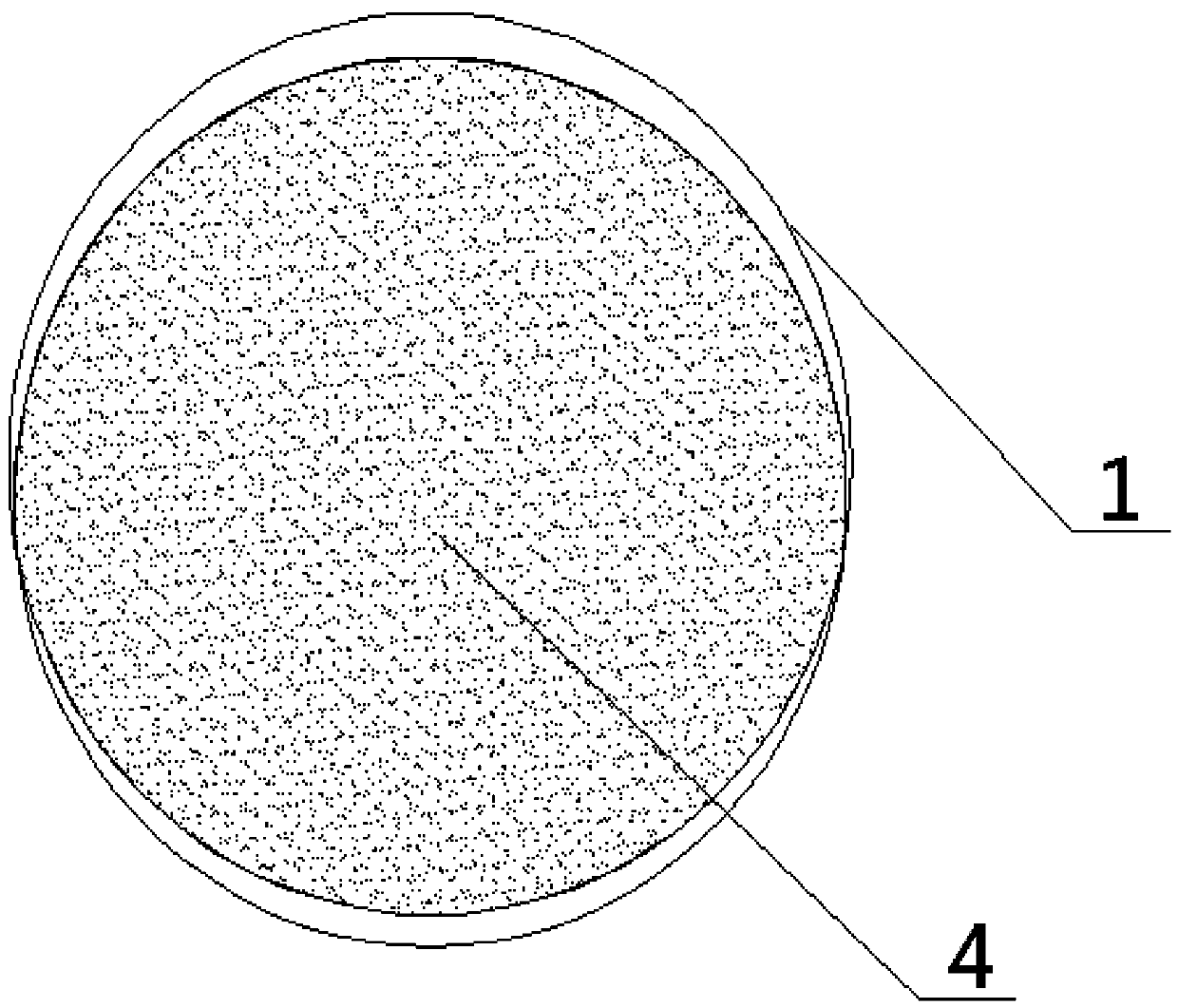

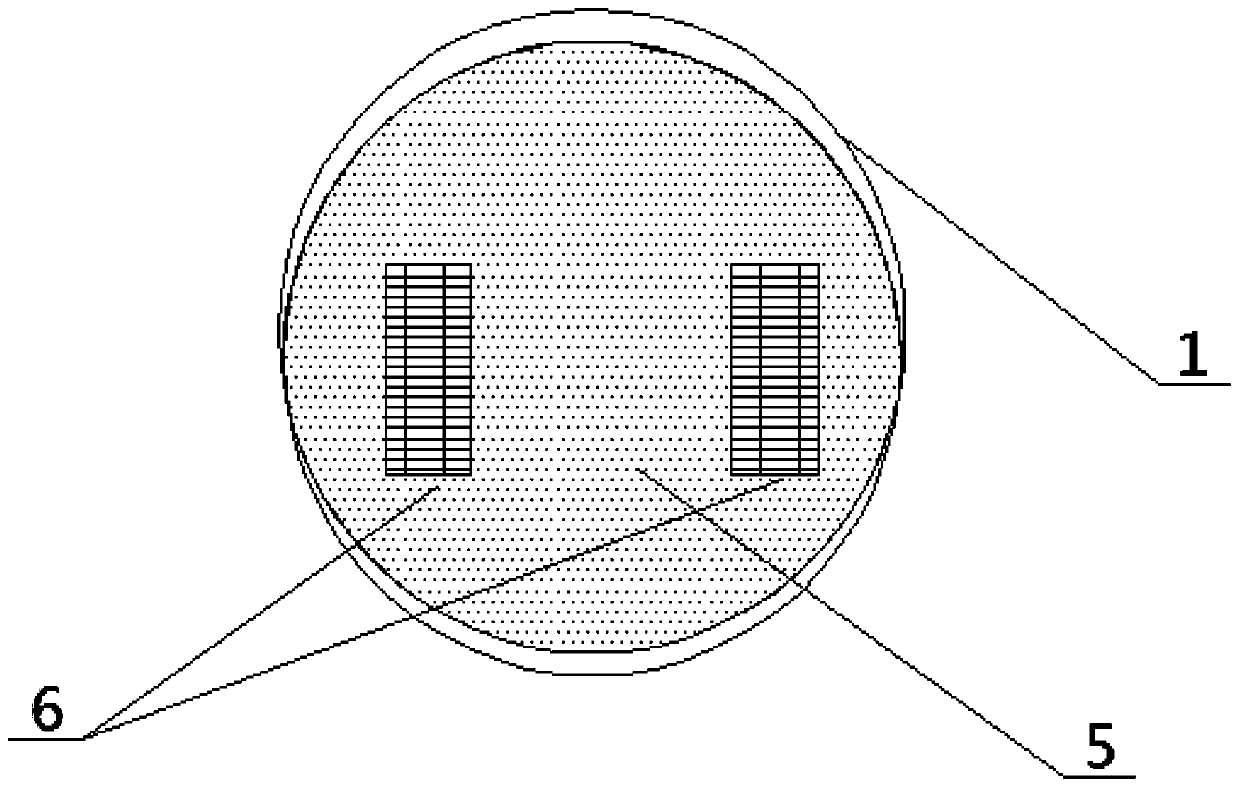

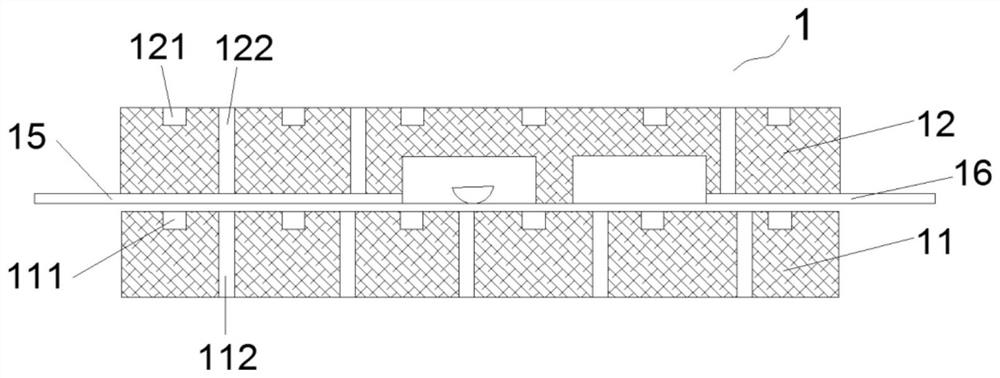

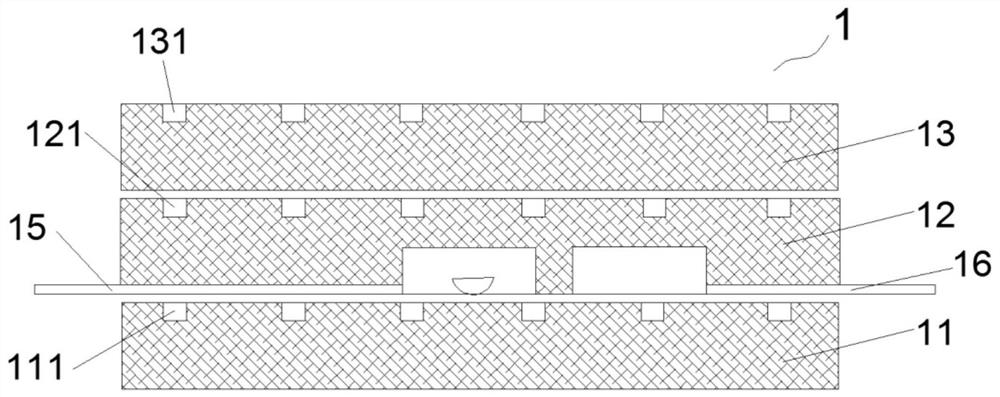

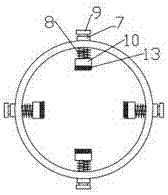

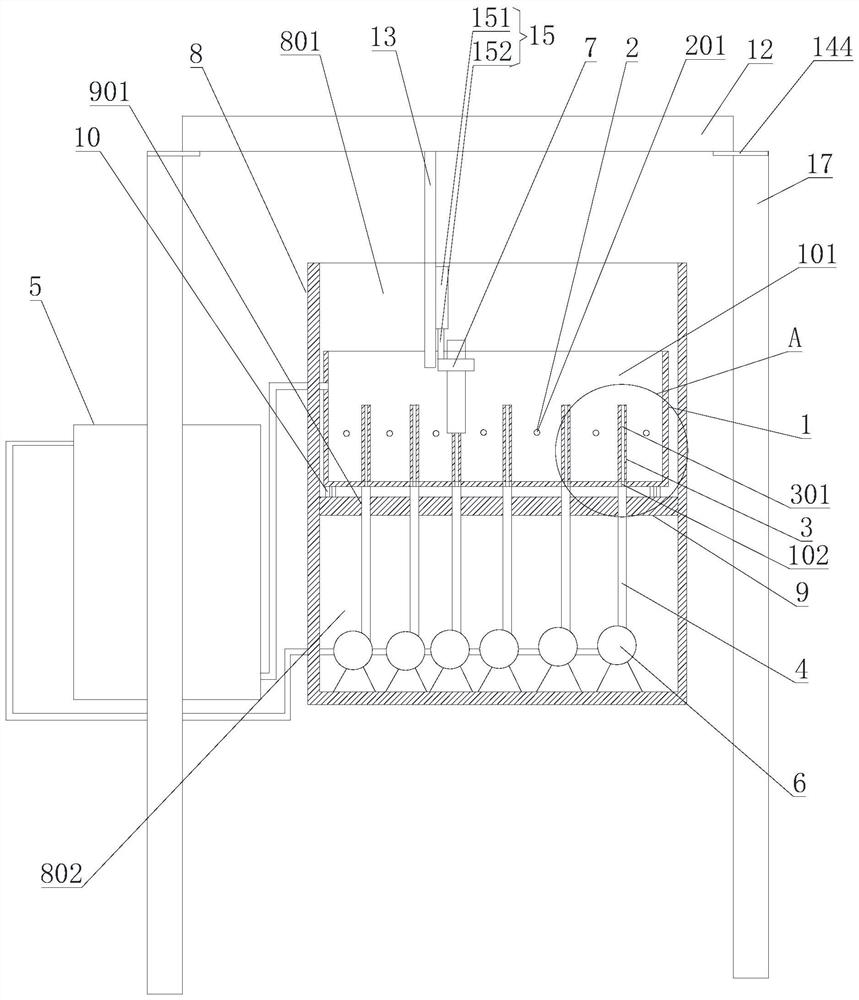

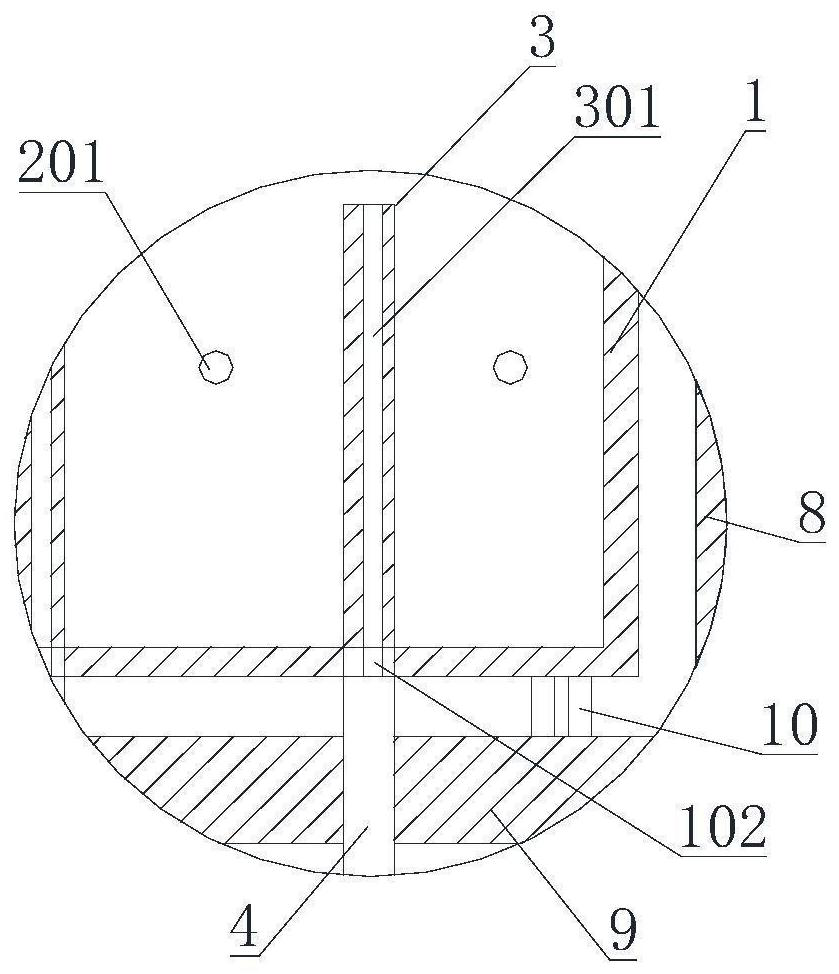

A magnetic polishing component

ActiveCN110480423BSatisfy polishing needsRealize automatic polishingGrinding drivesGrinding work supportsCircular discElectric machine

Owner:WUHAN SUNSHINE LASER & TECH

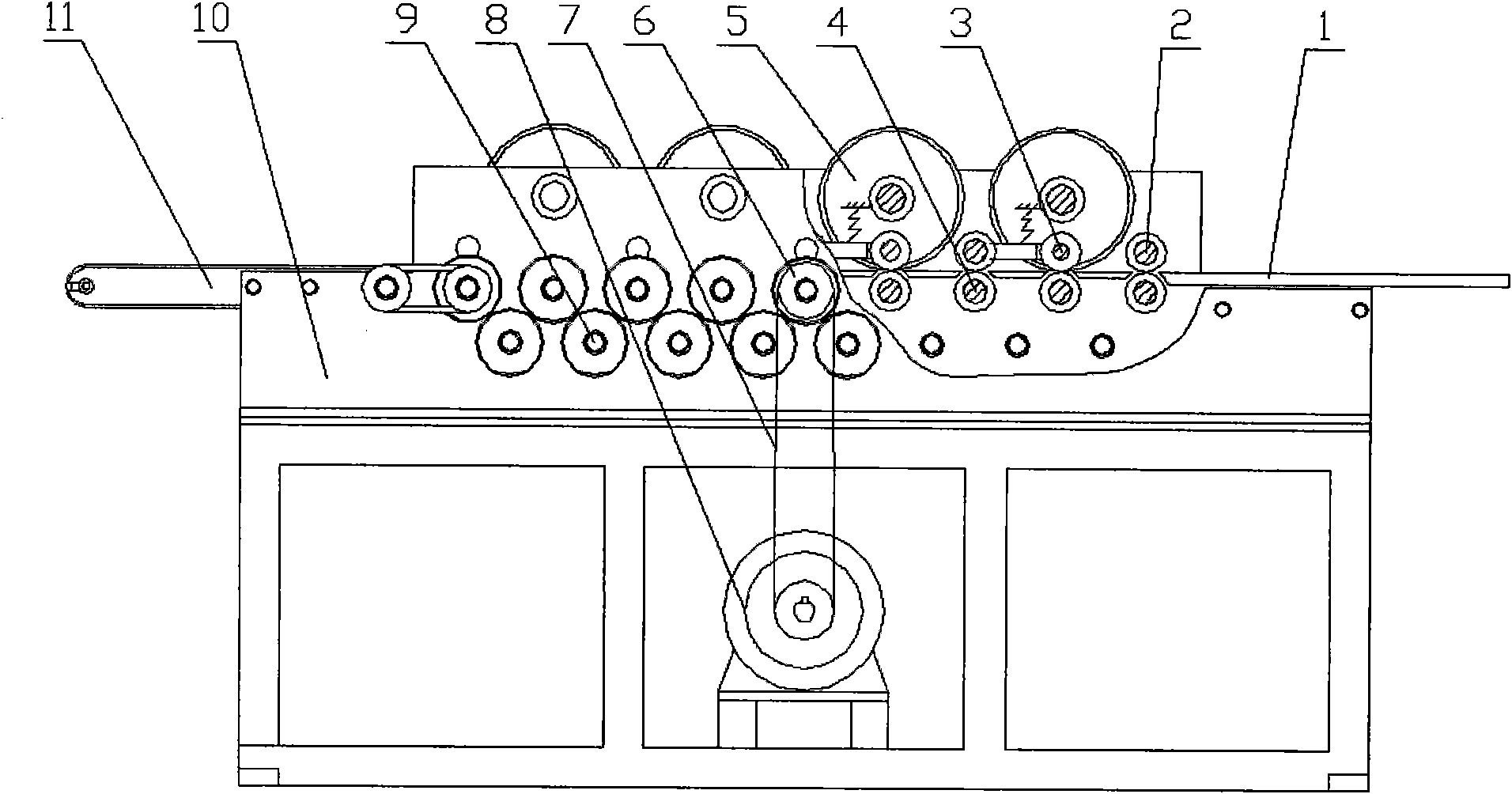

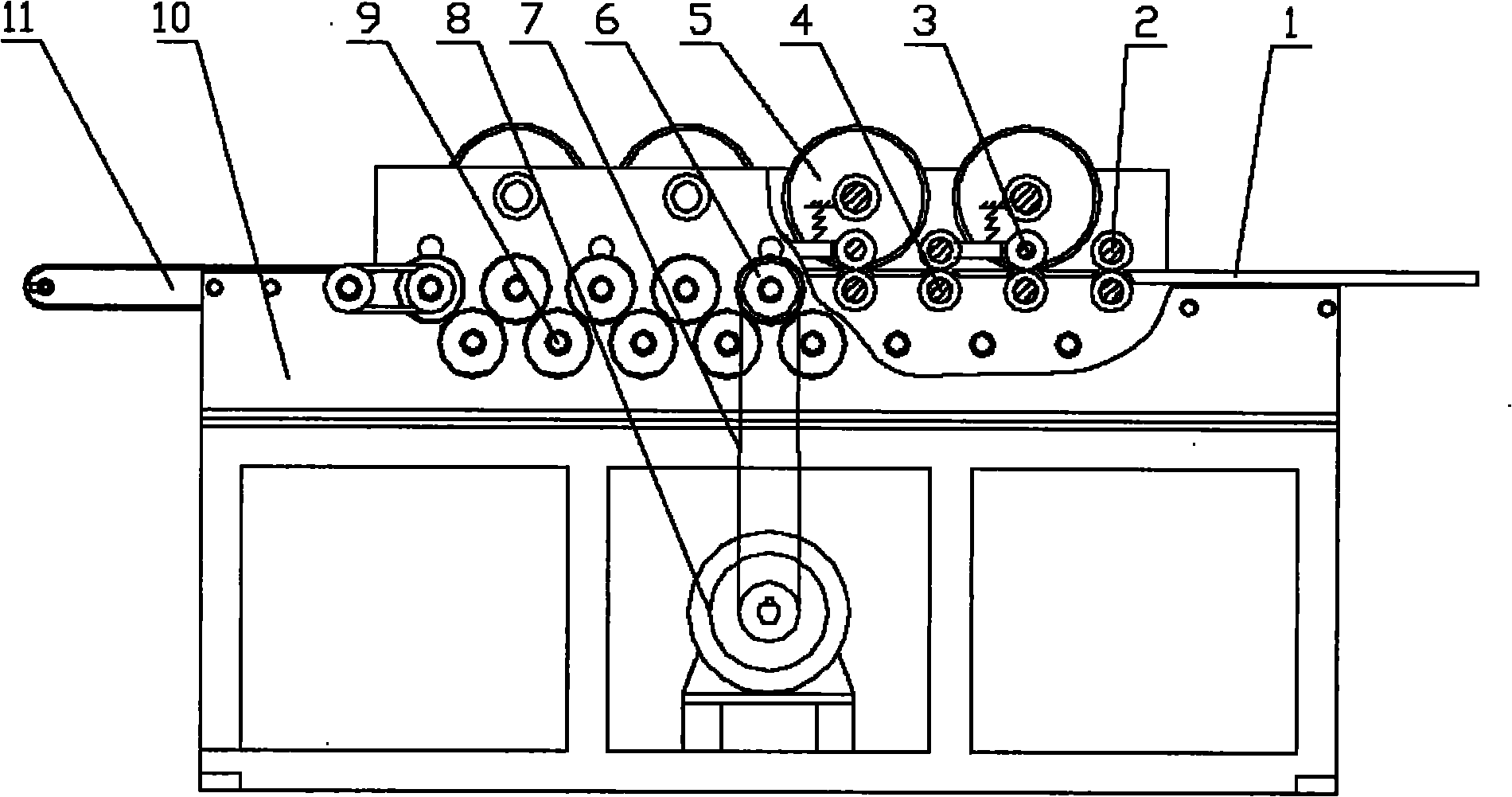

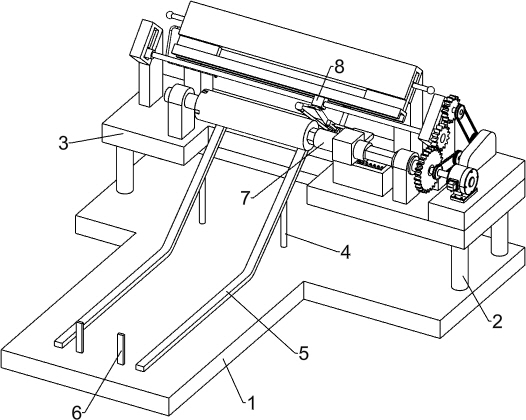

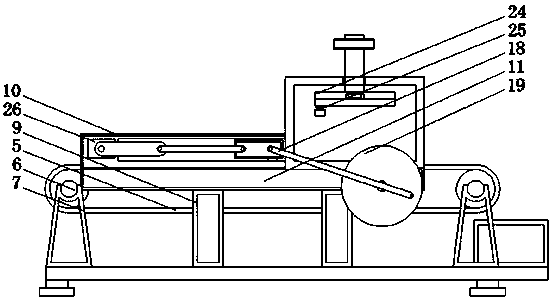

Automatic plane polishing device

The invention discloses an automatic plane polishing device. The automatic plane polishing device comprises a feed platform, compression rollers, point compression rollers, driving rollers, polishing wheels, a chain wheel, a transmission chain, a feed motor, reversing gears, a rack, a discharging device, a transmission device and a polishing motor; the feed platform and the feed motor are arranged on the rack, the compression roller and the driving rollers are compacted and arranged on the rack, the feed motor is connected with the driving rollers through the transmission chain and the chain wheel, the driving rollers are connected with the reversing gears through gears, the polishing wheels are connected with the polishing motor through the transmission device, and the discharging device is arranged on the feed platform, and the point compression rollers are hinged on shafts of the polishing wheels through connecting rods which are arranged on the rack through a compressed spring, the polishing wheels are sequentially distributed in a staggered way in a feed direction, and the point compression rollers are sequentially distributed in a staggered way in the feed direction. The automatic plane polishing device has a good polishing effect, and is simple in a principle and a structure, and high in production efficiency and convenient to manufacture and use; and the process cost is far lower than that of the conventional manual polishing mode.

Owner:SHENYANG LIGONG UNIV

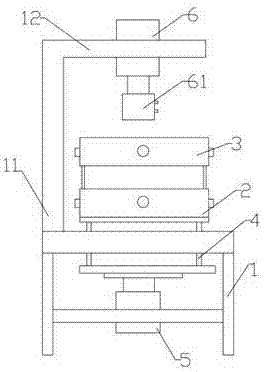

Double-surface ceramic plate polisher

ActiveCN106475888ARealize double-sided small batch processingSimple structureGrinding carriagesPolishing machinesWorking environmentDrive motor

The invention discloses a double-surface ceramic plate polisher, and belongs to the field of polishing equipment. The double-surface ceramic plate polisher comprises a base, a movable platform, a polishing assembly, a workpiece placing table assembly and a controller, wherein the movable platform is mounted on the upper end surface of the base; the polishing assembly is mounted on the movable platform; the workpiece placing table assembly is mounted on the upper end surface of the base and corresponds to the polishing assembly; the workpiece placing table assembly comprises a first placing table, a first slide and a second placing table; a turnover part is positioned at an entrance of the first slide and is opposite to one side of the first placing table; a push rod mechanism is further arranged and corresponds to the first placing table; a pressure sensor is correspondingly arranged below workpiece placing positions of upper end surfaces of the first placing table and the second placing table; the controller is connected with the pressure sensor; and the controller controls a first moving mechanism, a second moving mechanism and a driving motor in a connection manner. The double-surface ceramic plate polisher is small in size, double surfaces of a ceramic plate can be polished, a working environment of experimental persons can be improved effectively, and experiment efficiency can also be improved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

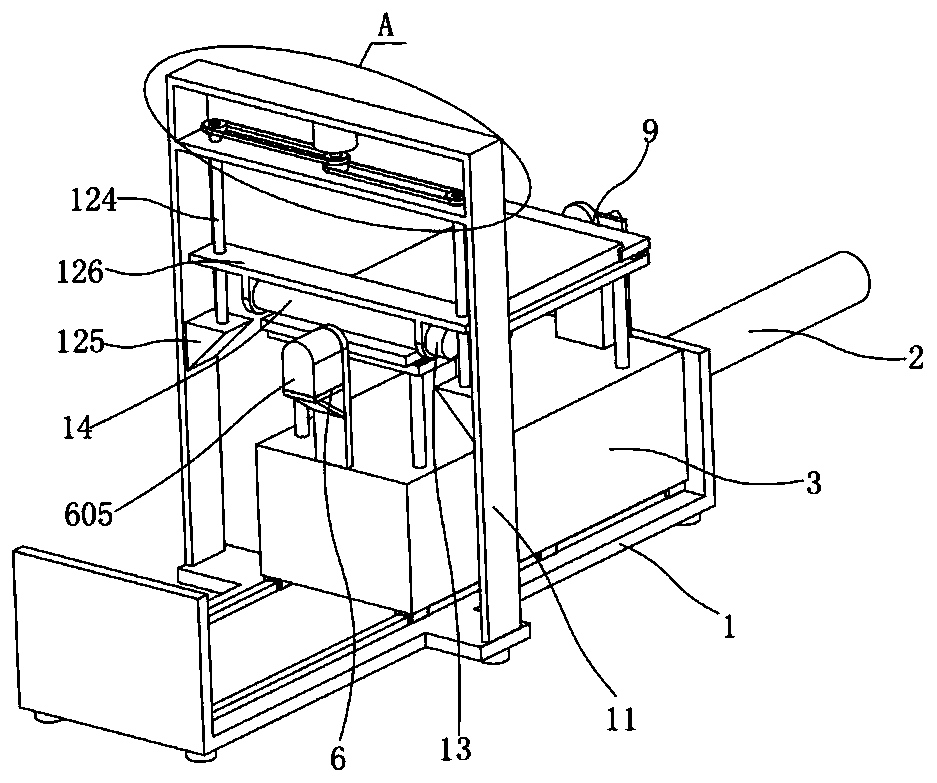

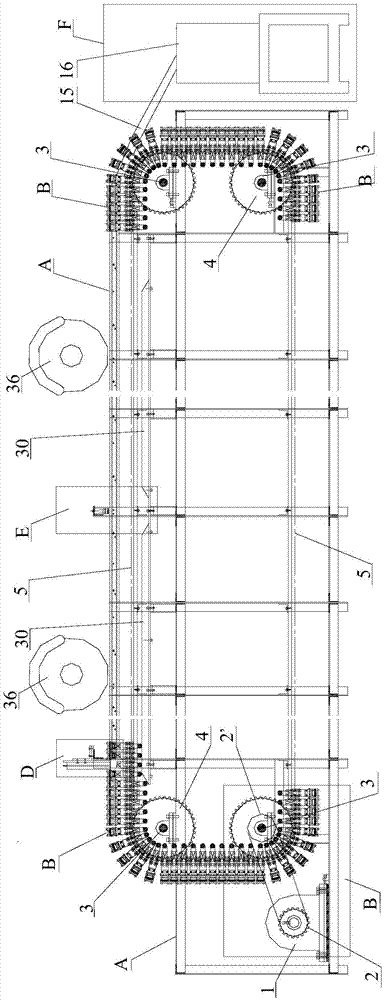

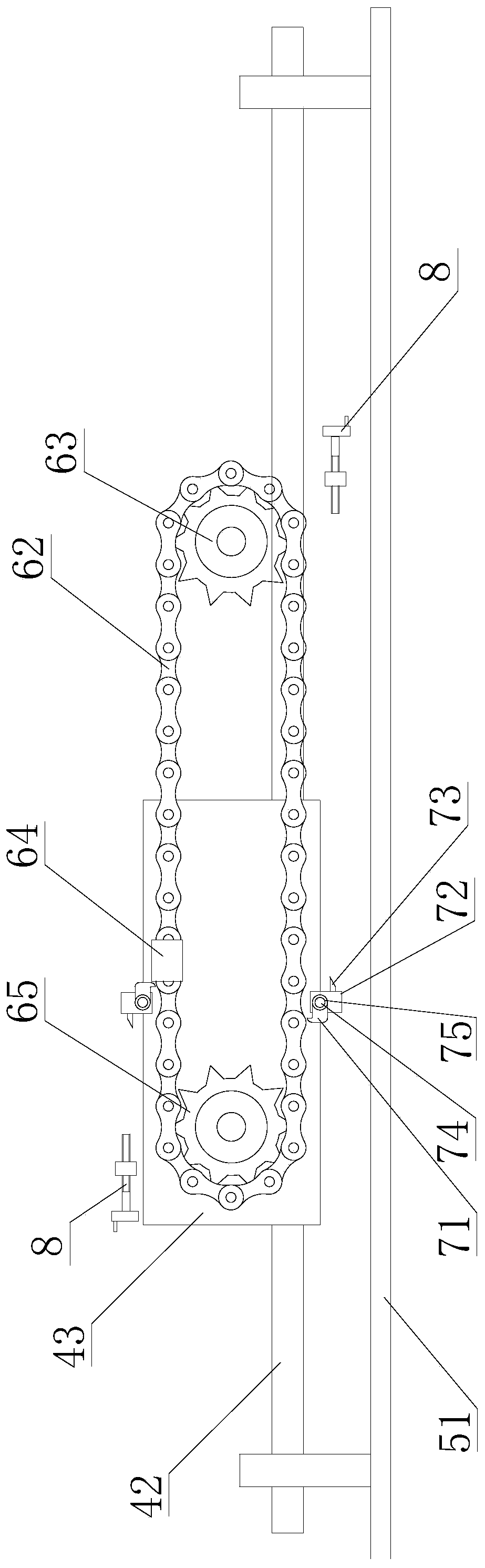

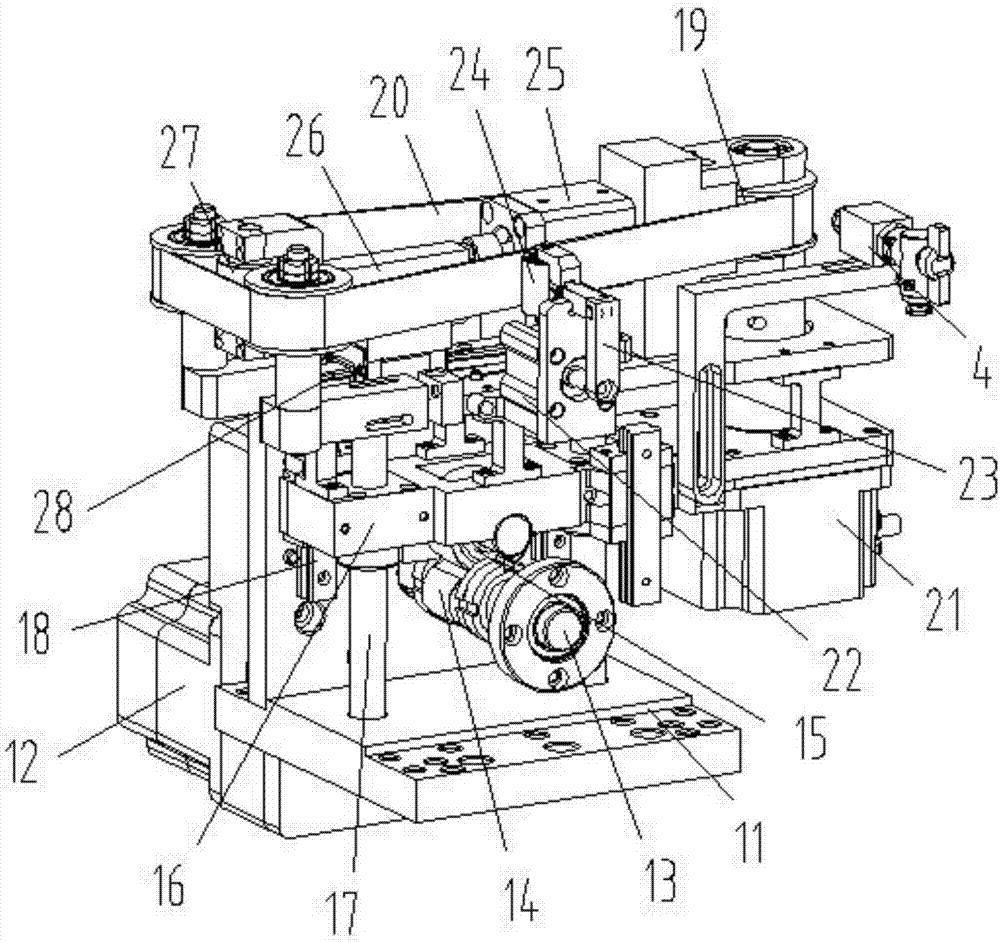

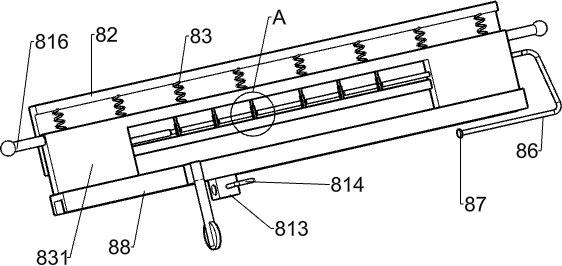

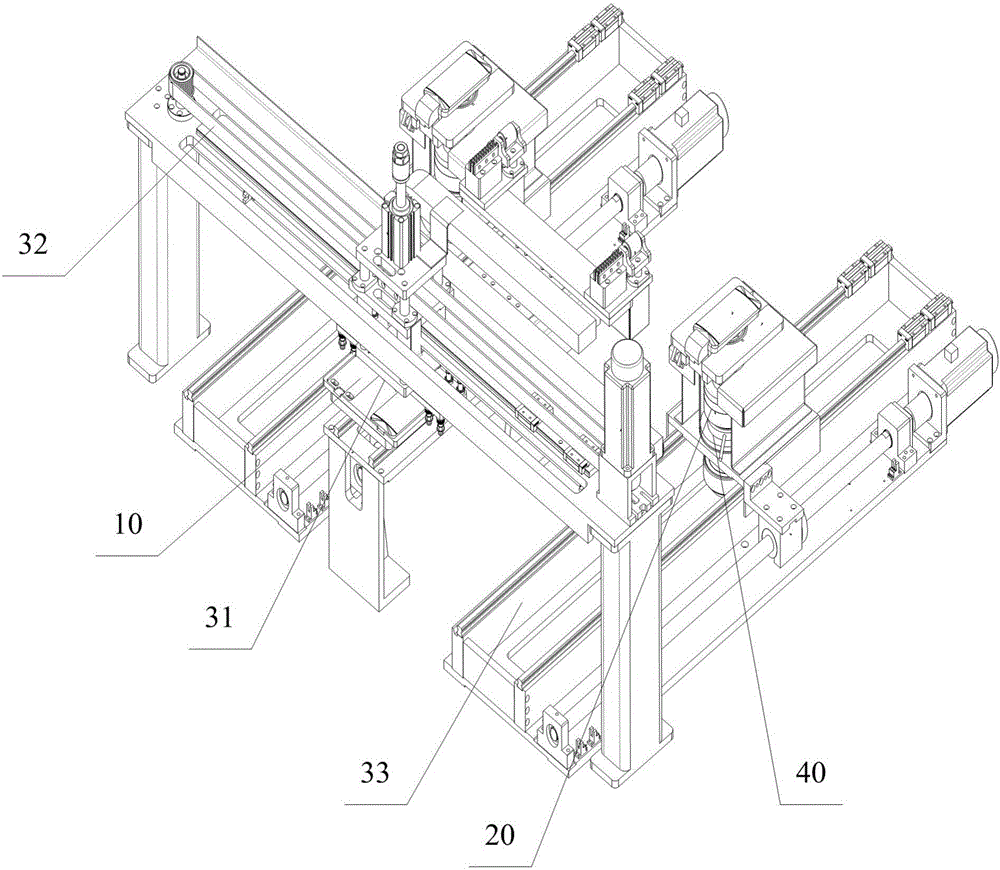

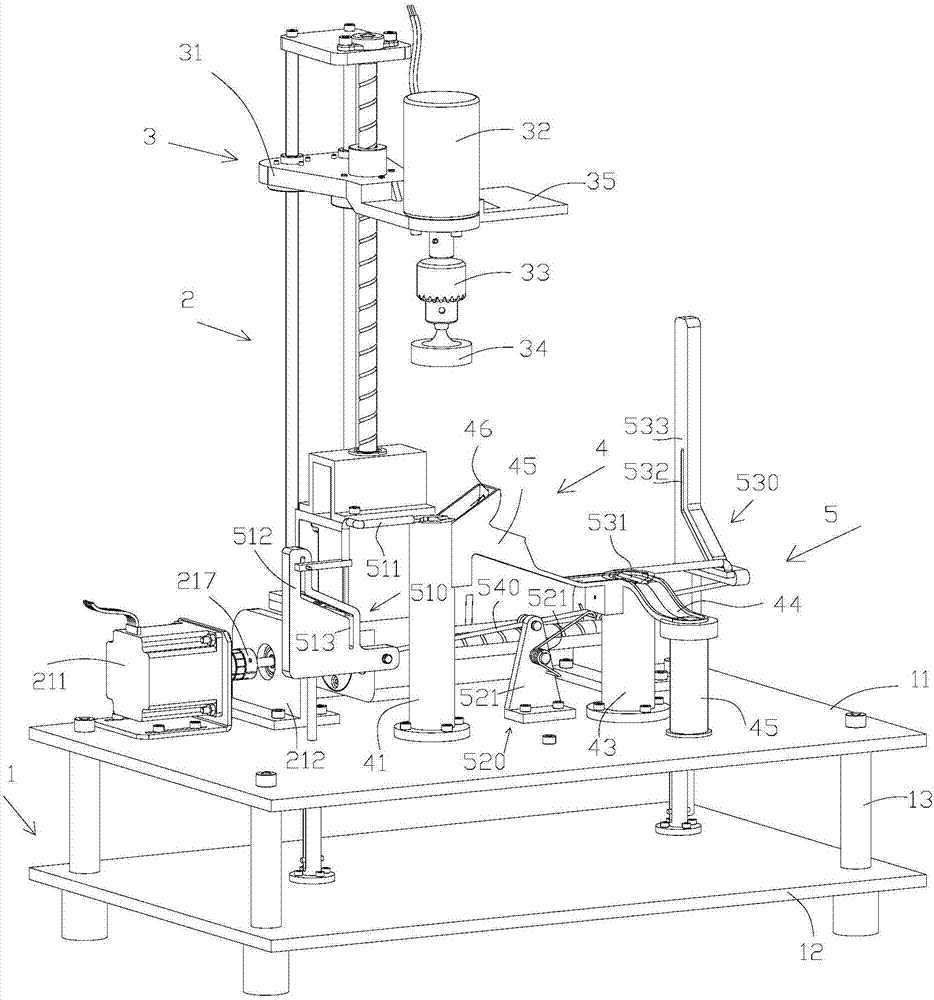

Automatic polishing and feeding device for watch band grains

InactiveCN105437048ARealize clamping transferRealize automatic blankingPolishing machinesGrinding machinesSprocketDrive motor

The invention discloses an automatic polishing and feeding device for watch band grains. Power is transmitted to a driven sprocket by a driving motor mounted on a rack, a main drive sprocket and a drive chain, the driven sprocket drives a sprocket shaft to rotate so as to drive the drive chain to rotate, and thus a follow-up clamping mechanism is driven to run forwards; when the follow-up clamping mechanism runs to a feeding position, the watch band grains are automatically fed to a workpiece positioning block of a longitudinal clamping component from a feeding mechanism, and are clamped by a workpiece clamping block of a transverse clamping component, so that clamped conveyance of the watch band grains is implemented; while the watch band grains continue running forwards, upper surfaces of the watch band grains are polished by a left polishing wheel; when the follow-up clamping mechanism runs to a steering mechanism, the longitudinal clamping component retracts, the steering mechanism drives the watch band grains clamped by the transverse clamping component to rotate at an angle of 180 degrees, and then the longitudinal clamping component upwards supports workpieces; when the watch band grains continue moving forwards, the other surfaces of the watch band grains are polished by a right polishing wheel; and when forwards moving to a discharging mechanism, the watch band grains are discharged automatically, and automatic polishing of the watch band grains is finished.

Owner:SOUTH CHINA UNIV OF TECH

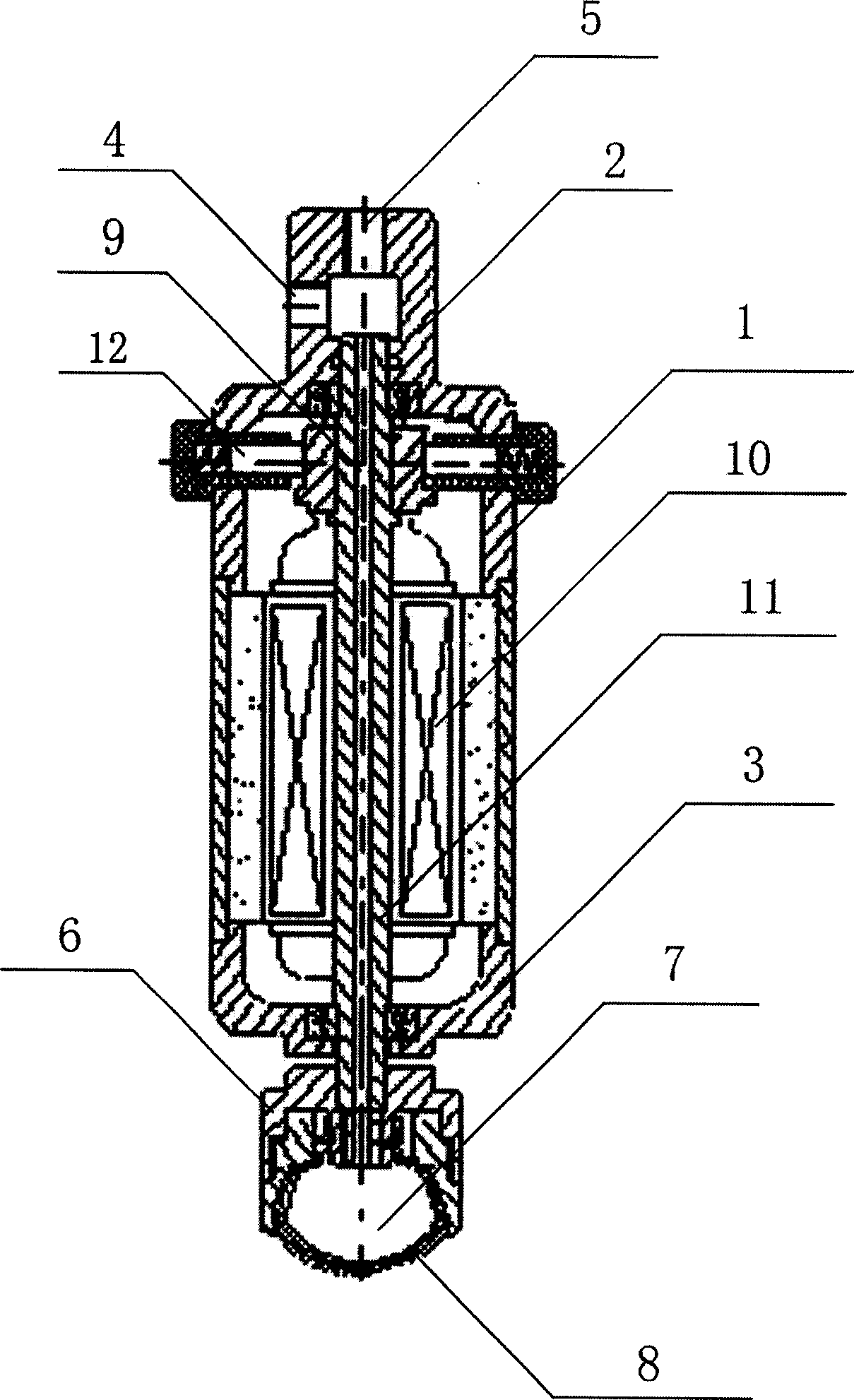

Precision machining device for spherical surface of orthopedic implant

PendingCN110340744ARealize automatic polishingHigh polishing precisionGrinding drivesSpherical surface grinding machinesLiquid stateEngineering

The invention discloses a precision machining device for the spherical surface of an orthopedic implant. A polishing body is arranged on a base through a horizontal movement mechanism, a coil is fixedto the polishing body, a polishing groove is formed in the polishing body, magneto-rheological polishing fluid is located in the polishing groove, and a rotating mechanism for clamping and rotating apolished part is arranged above the polishing groove. The horizontal movement direction of the polishing body is consistent with the length direction of the polishing groove. The precision machiningdevice has the beneficial effects that the magneto-rheological polishing fluid is converted into a solid-like form through a magnetic field, the horizontal movement mechanism and the rotating mechanism are simultaneously started, the polished part can relatively move in the horizontal direction while rotating, omni-bearing polishing is carried out, automatic polishing is achieved, as the magneto-rheological polishing fluid is in a liquid state when not collected in the magnetic field, the portion between the side wall of the polishing groove and the polished part can be well filled with the magneto-rheological polishing fluid, after the magneto-rheological polishing fluid is converted into the solid-like state due to the magnetic field change, the magneto-rheological polishing fluid can polish each fine position of the polished part, the polishing precision is greatly improved, and automatic polishing is achieved.

Owner:ZHEJIANG CANWELL MEDICAL DEVICES CO LTD

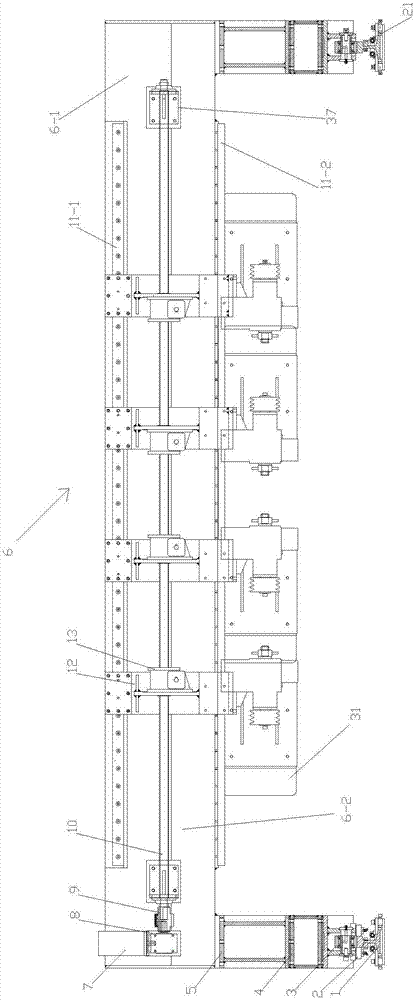

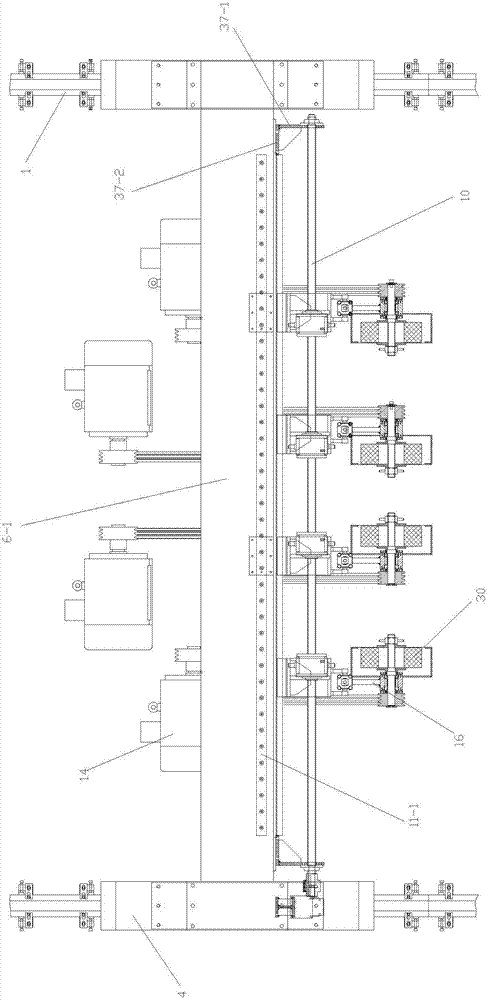

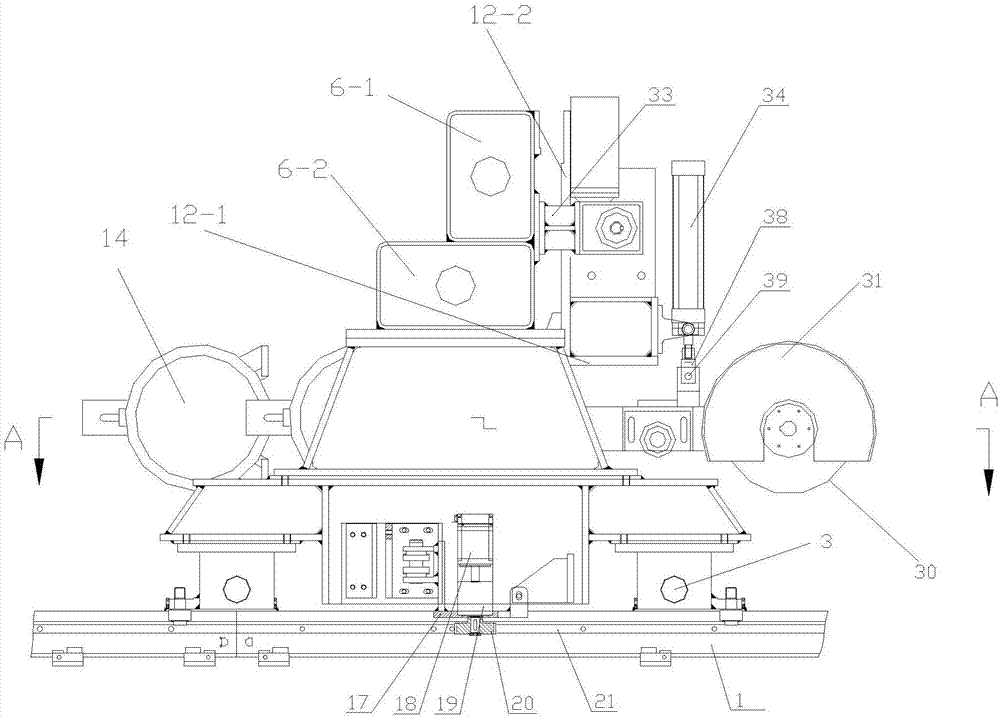

Multi-head metal composite plate polishing machine

ActiveCN107953229ASimple structureReasonable designGrinding carriagesPolishing machinesEngineeringComposite plate

The invention discloses a multi-head metal composite plate polishing machine which comprises a guide rail device, a vehicle body device, a polishing device and a monitoring device. The vehicle body device comprises a crossbeam, travelling mechanisms and travelling driving mechanisms. The polishing device comprises a lead screw, a plurality of polishing mechanisms, a plurality of polishing drivingmechanisms and a rocker arm mechanism, wherein the polishing mechanisms, the polishing driving mechanisms and swing mechanisms are the same in number. The multiple polishing mechanisms are arranged inthe length direction of the lead screw. The crossbeam is provided with sliding mechanisms and synchronous regulating mechanisms. The sliding mechanisms are provided with polishing regulating mechanisms. The monitoring device comprises a control device, a space measuring module, a first displacement detection module and a second displacement detection module. The structure is simple, metal composite plates are simultaneously polished through the multiple polishing mechanisms, the multi-head metal composite plate polishing machine is suitable for the metal composite plates of different thicknesses, moving is reliable and safe, the automation degree is high, and the production efficiency is improved.

Owner:THE NORTHWEST MACHINE

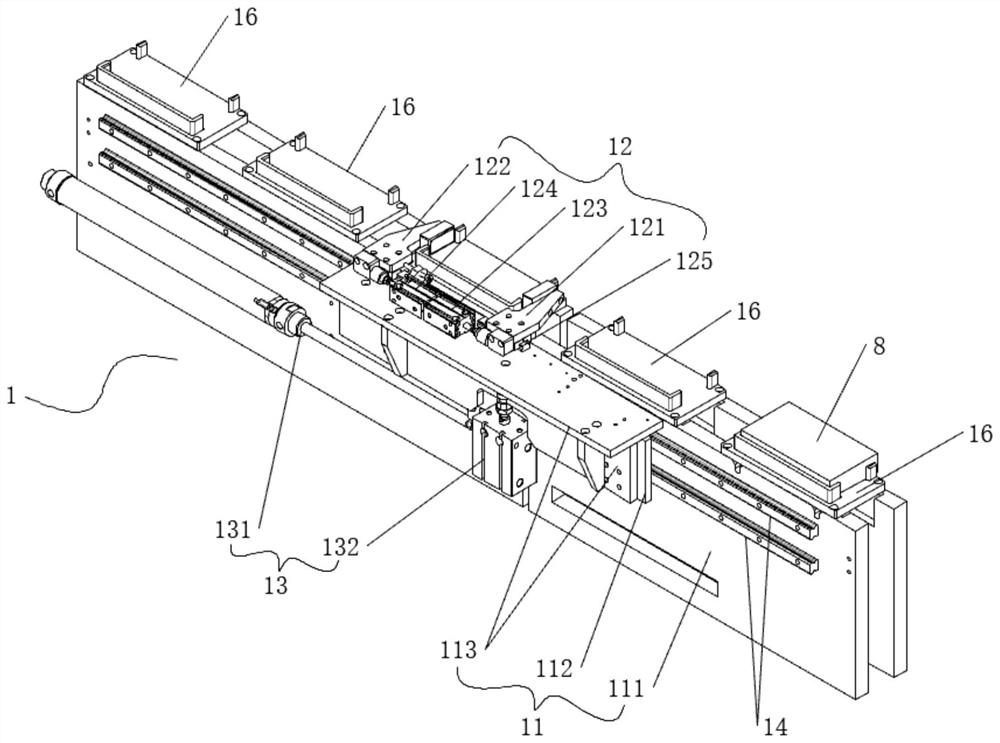

Abrasive belt full-automatic external circle polishing mechanism

InactiveCN106863081AEliminate potential safety hazardsHigh precisionGrinding carriagesBelt grinding machinesLevel lineEngineering

The invention relates to an abrasive belt type fully automatic outer circle polishing mechanism. The polishing seat on the polishing seat is provided with a triangular distribution of installation cylinders, and the two installation cylinders on the front side are on the same horizontal horizontal line, and the outer surface of the installation cylinder is equipped with a polishing abrasive belt that matches the product on the loading device. One of the mounting cylinders is connected to the polishing motor, and the polishing motor and the loading device are connected to the controller; the purpose of the present invention is to provide an abrasive belt-type fully automatic cylindrical polishing mechanism, which uses a rotating abrasive belt as the polishing part, and can be matched front and rear The loading device that moves left and right can realize automatic polishing of the outer circle of the product. Compared with grinding wheel polishing, it basically eliminates potential safety hazards, improves the accuracy of polishing, and will not affect the outer circle size of the product due to polishing. , also simplifies the structure of the polished part.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

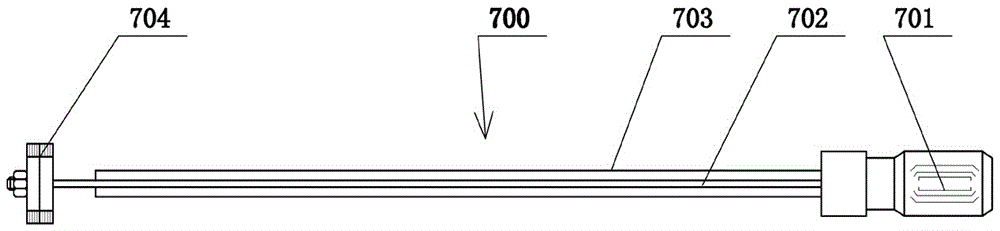

Composite pipe inner polishing device and inner polishing method

InactiveCN106826526ASolving Polishing ProblemsSimple structureGrinding carriagesPolishing machinesEngineering

A composite pipe internal polishing device and an internal polishing method belong to the technical field of mechanical polishing equipment and polishing methods, including a girder, a moving trolley, a moving motor, a moving horizontal plate, an adjusting support plate mechanism, an axial rotation mechanism and a bearing roller mechanism; the girder is installed There are left beam racks arranged horizontally front and back; the moving motor is fixedly installed on the mobile trolley, and the output end of the moving motor is equipped with a moving gear meshing with the left beam rack; the moving horizontal plate is horizontally arranged, and the right end It is fixedly installed on the mobile trolley, and the left end is fixedly equipped with an adjusting pallet mechanism; the axial rotation mechanism includes a polishing motor, a rotating inner shaft, a sleeve, and a polishing wheel; the polishing motor is fixedly installed on the adjusting pallet mechanism. The device realizes the self-rotation of the composite pipe, the self-propagation of the polishing wheel, and the axial feeding of the polishing wheel; the above three movements are combined to realize the automatic polishing of the inner wall of the ultra-long pipe.

Owner:ZHEJIANG JIULI HI TECH METALS

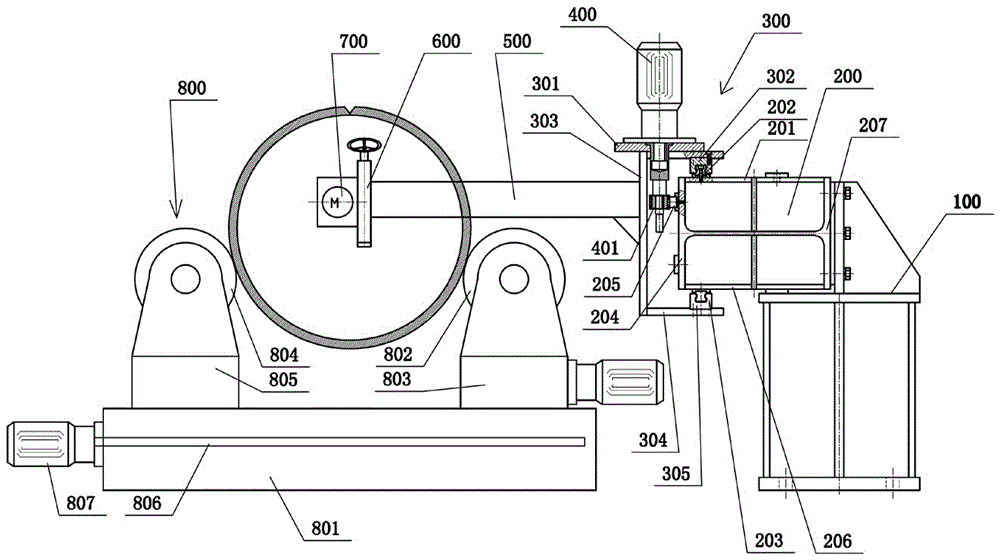

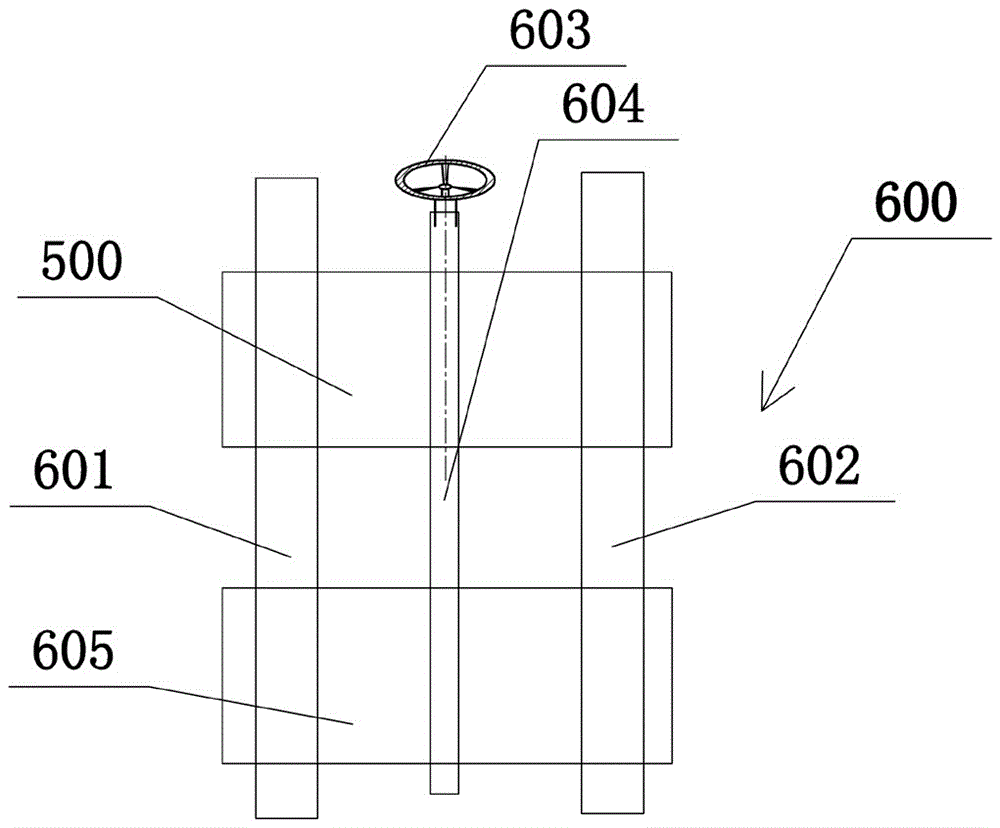

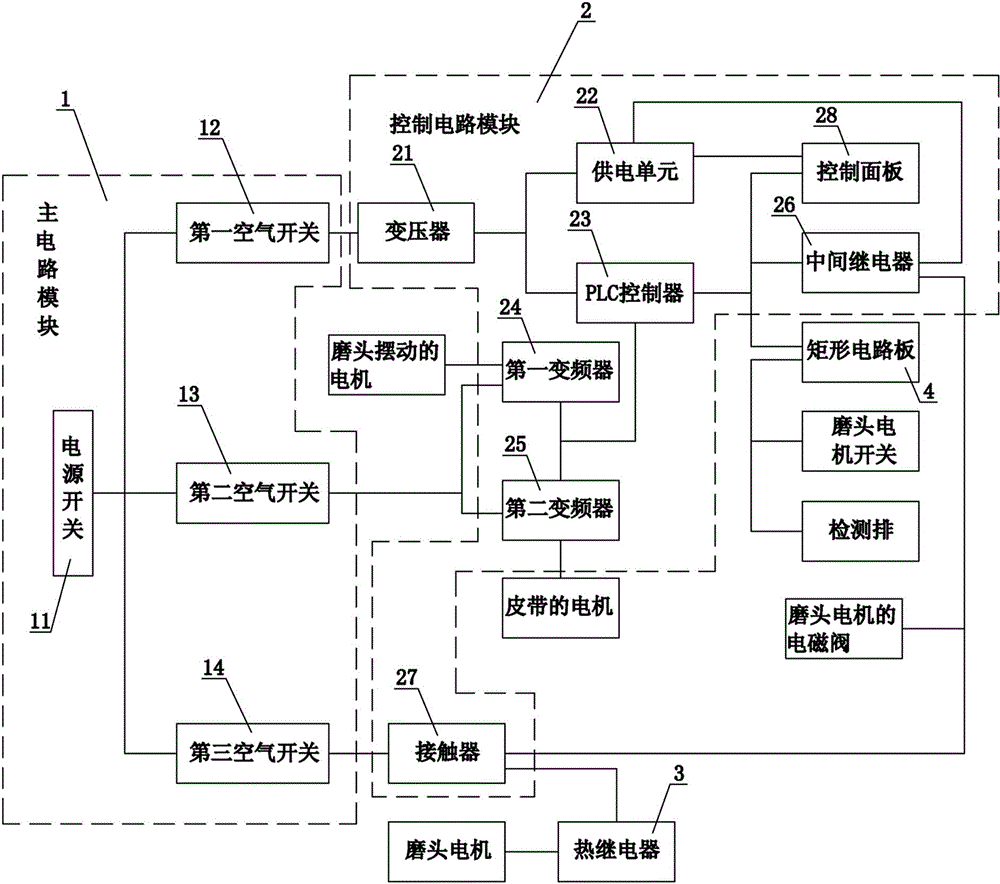

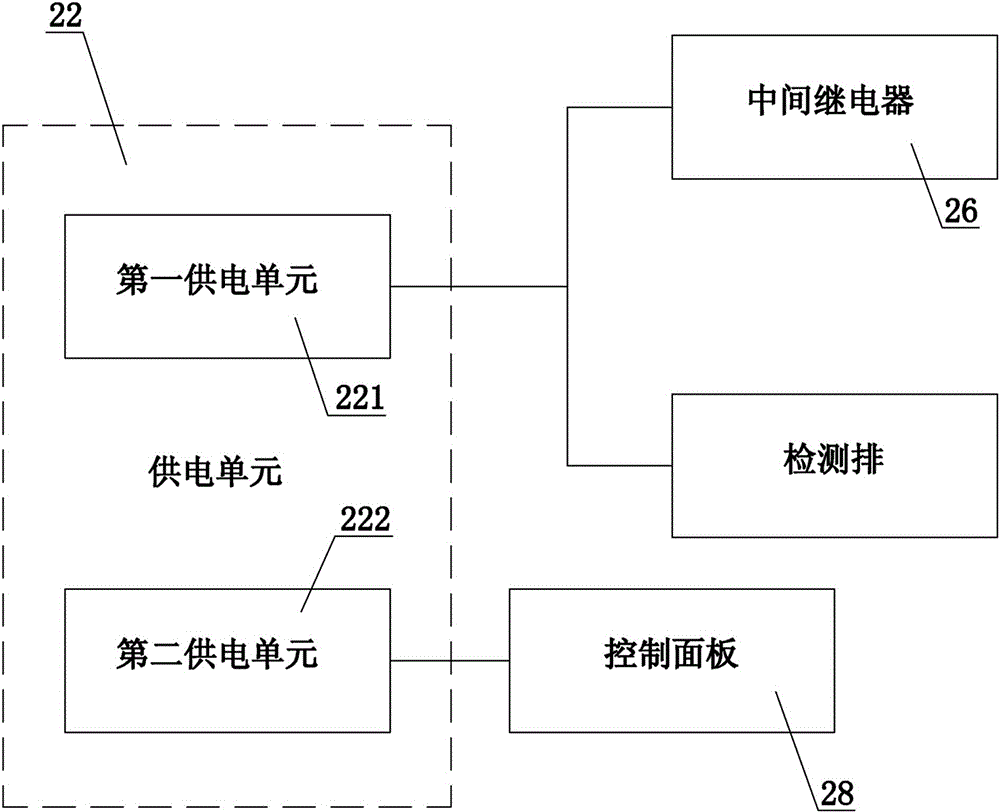

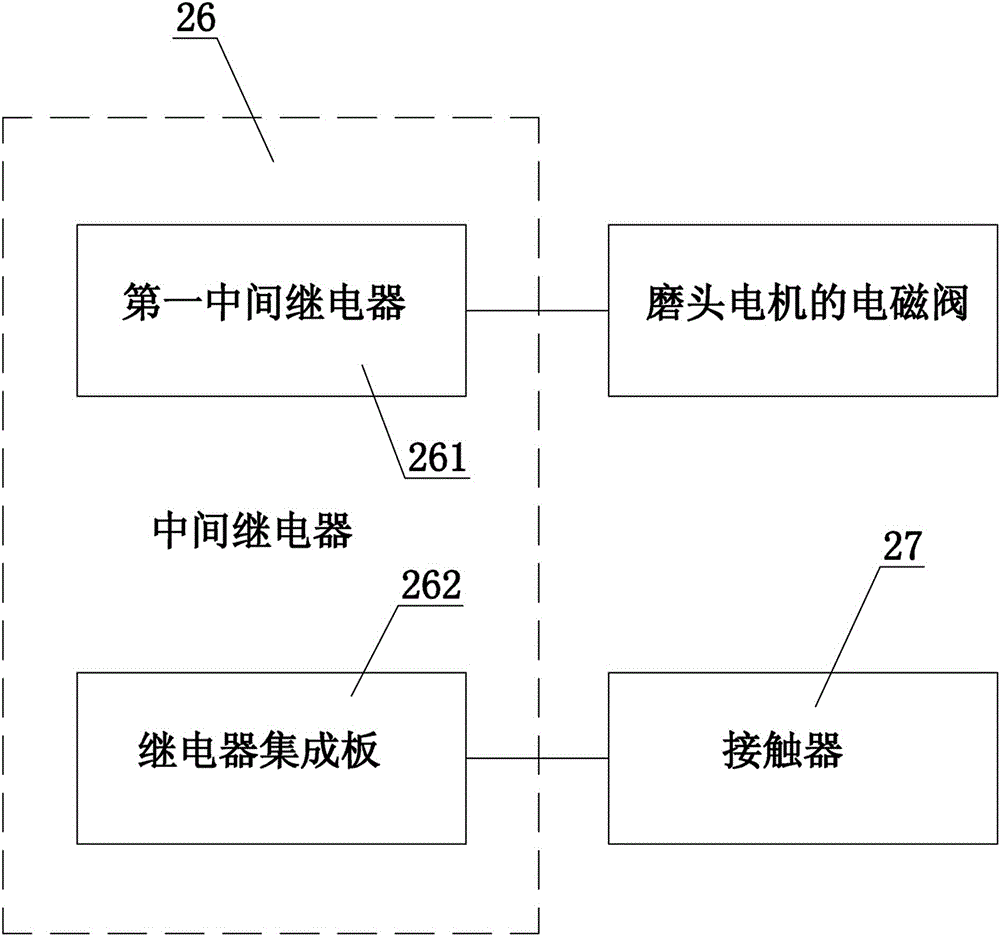

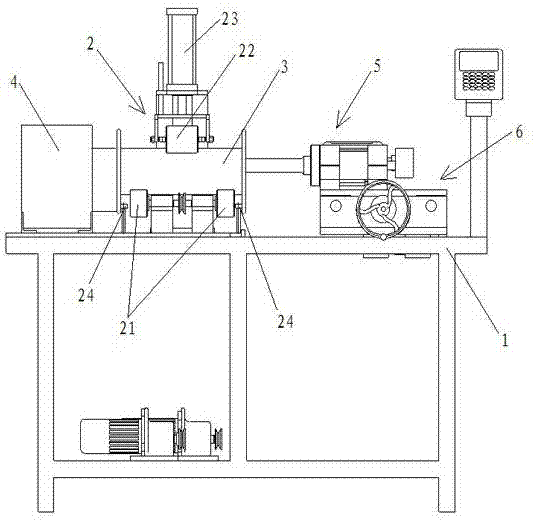

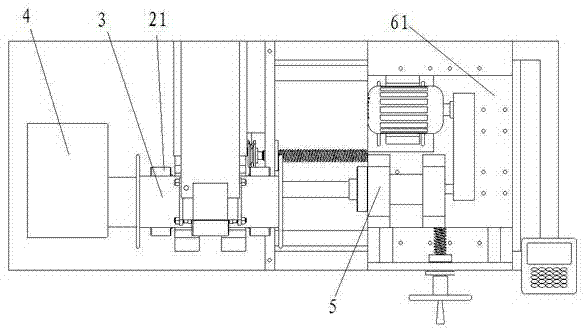

Control system for stone polishing machine

InactiveCN104669115AIncrease profitRealize automatic polishingAutomatic grinding controlTransformerControl system

The invention provides a control system for a stone polishing machine. The control system comprises a master circuit module, and a control circuit module connected with the master circuit module, wherein the master circuit module comprises a power switch, a first air switch, a second air switch and a third air switch; and the control circuit module comprises a transformer, a power supply unit, a PLC, a first frequency converter, a second frequency converter, an intermediate relay, a contactor and a control panel. According to the control system disclosed by the invention, the automatic stone polishing can be realized, the polishing efficiency is high, the system is stable to operate, high in degree of automation, and easy and convenient to operate, and the human resource cost of enterprises is greatly reduced.

Owner:QUANZHOU XINHAI ENERGY TECH

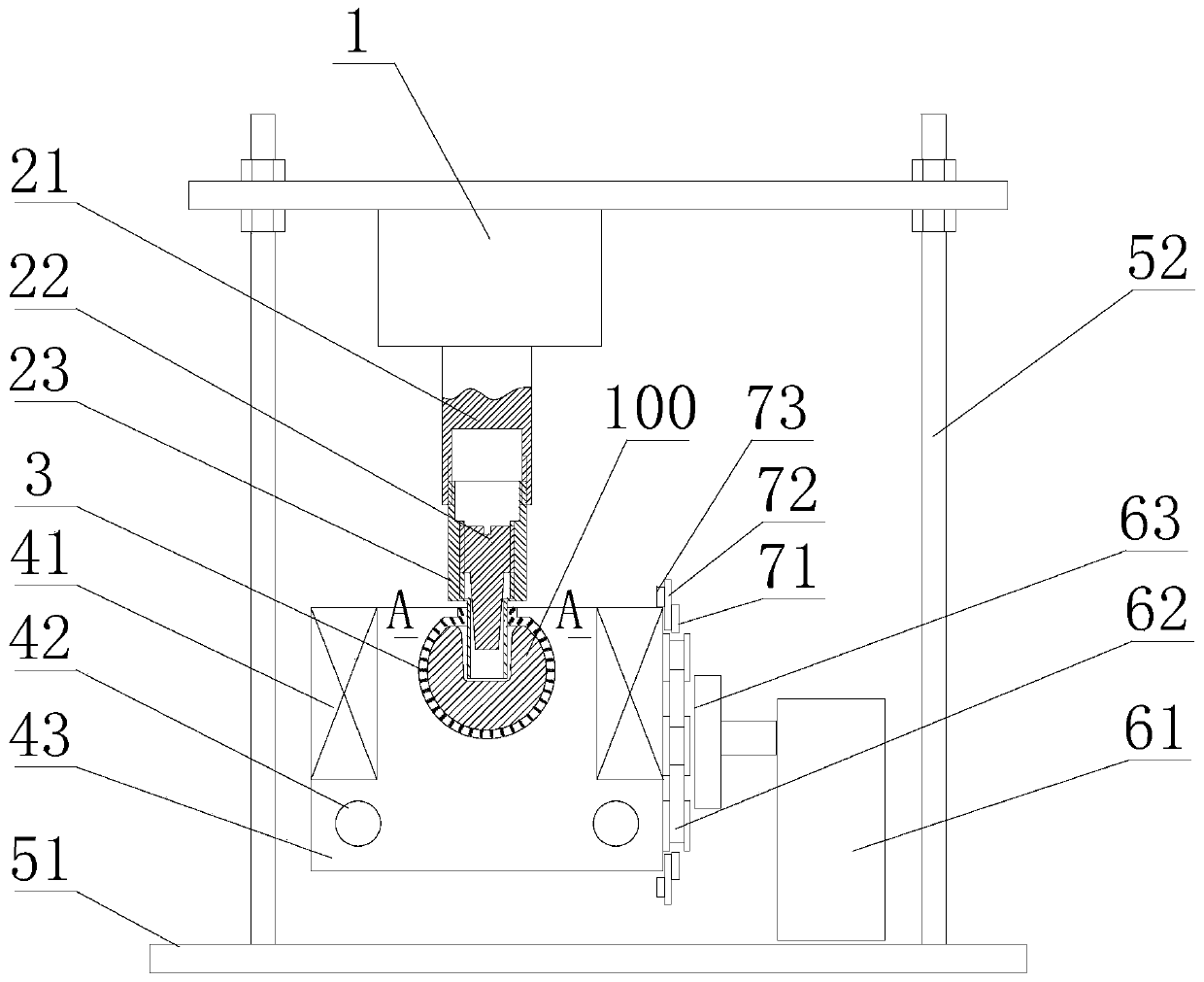

Inner circle polisher for bobbins

InactiveCN103203680ARealize automatic polishingImprove polishing efficiencyPolishing machinesImpellerBobbin

The invention discloses an inner circle polisher for bobbins. The inner circle polisher for bobbins comprises a bed. A bobbin clamping driving mechanism is arranged on the bed, and a bobbin is transversely clamped and fixed on the bed by the bobbin clamping driving mechanism. A dust extraction axial flow fan and a grinding head component which respectively correspond to the inner circle of the bobbin are arranged on two sides of the bobbin clamping driving mechanism. The bobbin clamping driving mechanism comprises an upper fixing rubber roller set and a lower clamping rubber roller set. The grinding head component comprises a spindle. An impeller is fixed at one end of the spindle, corresponding to the bobbin. The grinding head component is arranged on a transversely moving feed mechanism. Compared with the prior art, the polisher allows the inner circle of the bobbin to be automatically polished, and polishing efficiency and effect are greatly improved.

Owner:王守志 +2

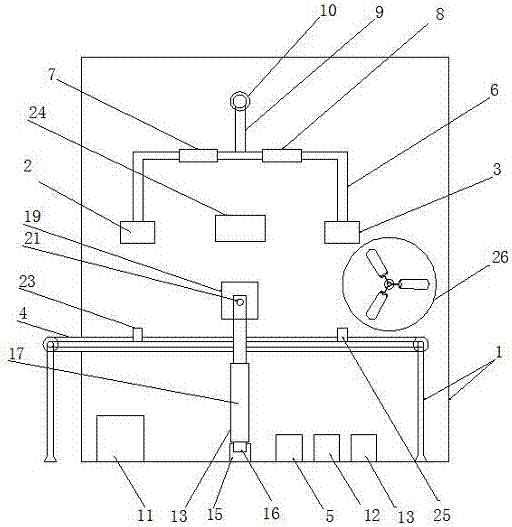

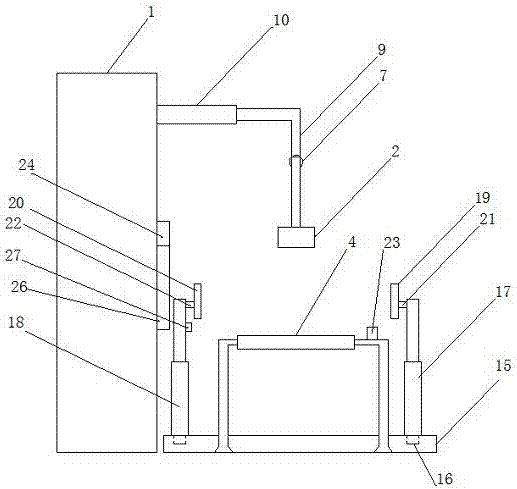

Double-sided polishing equipment

ActiveCN106514477ARealize double-sided small batch processingSimple structureGrinding carriagesPolishing machinesPolishingWorking environment

The invention discloses double-sided polishing equipment, and belongs to the field of surface polishing equipment. The double-sided polishing equipment comprises a base, a movable platform installed on the upper end surface of the base, a polishing assembly installed on the movable platform, and a workpiece placement table assembly installed on the upper end surface of the base and corresponding to the polishing assembly, wherein the workpiece placement table assembly comprises a first placement table, a first slide, a second placement table, a second slide and a storage barrel; a turnover part is arranged at the inlet of the first slide and opposite to one side of the first placement table; and a push rod mechanism is further arranged in a manner of corresponding to the first placement table and the second placement table, and a feeding mechanism is arranged in the first placement table. The double-sided polishing equipment disclosed by the invention is small in size, capable of realizing double-sided polishing for a ceramic wafer, and capable of effectively improving the working environment of experimenters and increasing the experiment efficiency.

Owner:广西日瑞智能科技有限公司

Water drill bit polishing device

InactiveCN112157491ARealize automatic polishingEase of workGrinding carriagesGrinding drivesPolishingEngineering

The invention relates to a polishing device, in particular to a water drill bit polishing device. The water drill bit polishing device is automatic in polishing, easy to operate and capable of reducing the working difficulty of people. The water drill bit polishing device comprises a base, wherein a plurality of first supporting columns are arranged on the base; a workbench arranged between the tops of the first supporting columns; second supporting columns symmetrically arranged at the top of the base; rails arranged on the second supporting columns and connected with the base; baffles arranged on the side, close to the rails, of the top of the base; and a rotating mechanism arranged on one side of the top of the workbench. Through the cooperation of the rotating mechanism and a polishingmechanism, after a servo motor is started, the rotating mechanism clamps a water drill bit and drives the water drill bit to rotate, meanwhile, the polishing mechanism moves leftwards to polish the water drill bit, thus, automatic polishing can be achieved, and then the working difficulty of people is reduced.

Owner:邓贵龙

Stiffness-adjustable grinding device and using method

ActiveCN111168503AReduce the effect of grinding hardnessAdjust stiffnessBelt grinding machinesLeather surface mechanical treatmentRubber materialConvex structure

The invention provides a stiffness-adjustable grinding device and a using method. The stiffness-adjustable grinding device comprises a motor for providing power; a switch used for controlling the motor to start is mounted on the motor; a grinding wheel or a grinding belt used for grinding is mounted on an output shaft of the motor; a grinding area on the grinding wheel or the grinding belt is divided into a plurality of layers by adopting a rubber material; the intermediate layer adopts a hydraulic layer or a pulse layer which can produce instantaneous acting force; the remaining layers are the stiffness layers that can provide different grinding stiffness; the hydraulic layer or the pulse layer are respectively connected with a hydraulic device or a pulse device correspondingly; a convexstructure used for enhancing a grinding effect is arranged on the surface of the grinding wheel and the grinding belt; the outer surface of the convex structure is wrapped with a flexile material layer; and by changing the grinding material of the stiffness layer in real time, the object can be polished by fine adjustment of appropriate stiffness. Compared with a common grinding device, the stiffness-adjustable grinding device has wider practicality and economic benefits, and better meets the grinding requirements required by production and living.

Owner:CHINA THREE GORGES UNIV

Metalware polishing device

InactiveCN107838798ARealize automatic polishingEnable mobilityGrinding carriagesPolishing machinesProduction rateEngineering

The invention discloses a metal product polishing device, which comprises a base. The four corners of the upper end of the base are provided with brackets, and two brackets on the same side form a group, and a rotating shaft is arranged between the two brackets of the same group. The rotating shafts are rotatably connected by a conveyor belt, and a limit hole is provided on one side of the conveyor belt. Four support blocks are fixed on the upper end of the base, and a partition is fixed on the upper ends of the four support blocks, and the bottom surface of the partition and the conveyor belt In case of conflict, a bearing plate is fixed on one side of the upper end of the partition. The invention realizes the automatic polishing and moving of the product, solves the problem that the general polishing device still needs manual assistance, the product is placed on the polishing device, the machine is shut down after the polishing is completed and the product is removed, and the product automation is realized Polishing speeds up work efficiency, improves productivity, has a simple structure, is convenient to operate, and is suitable for popularization.

Owner:常熟国球包装材料有限公司

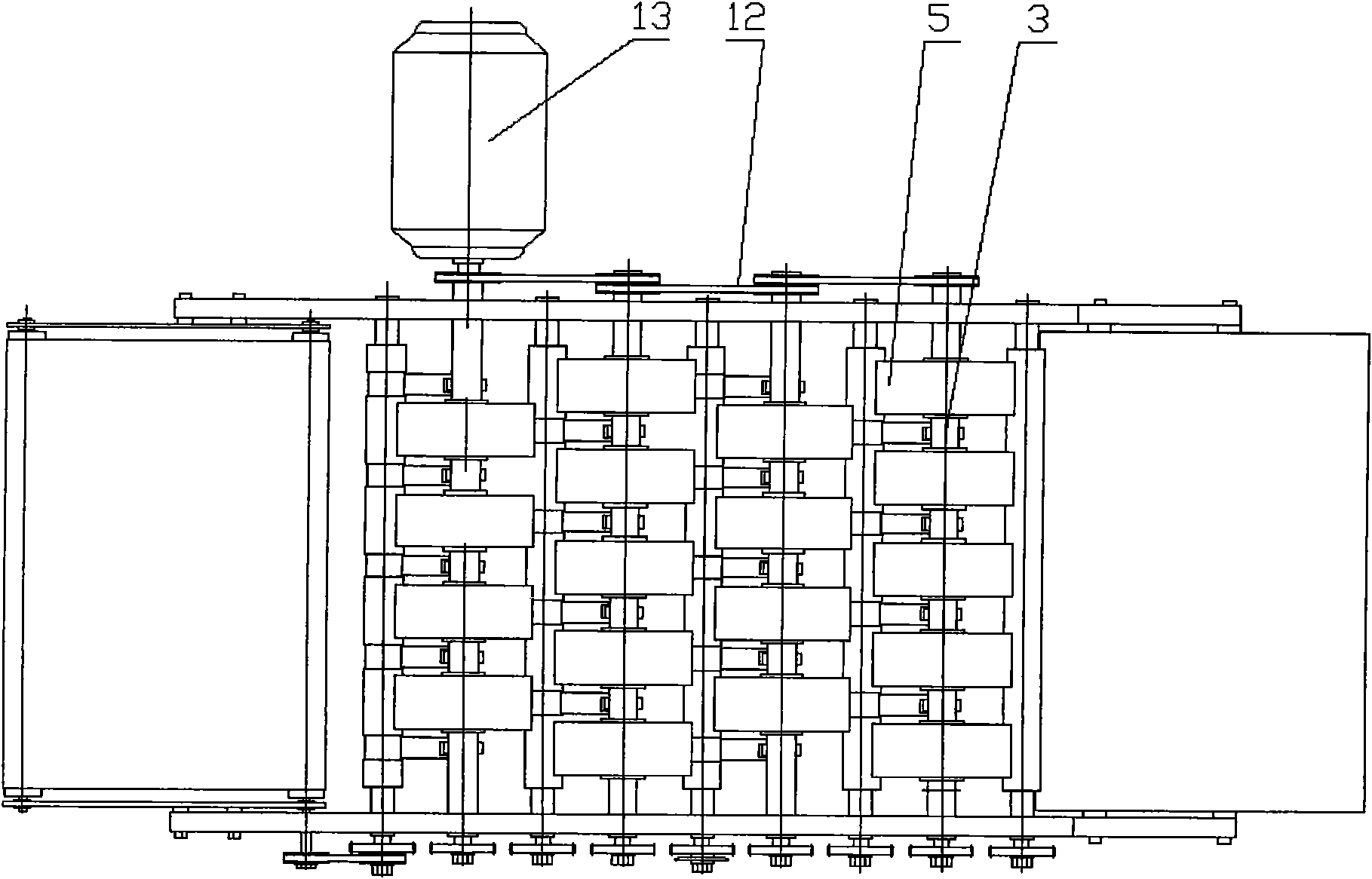

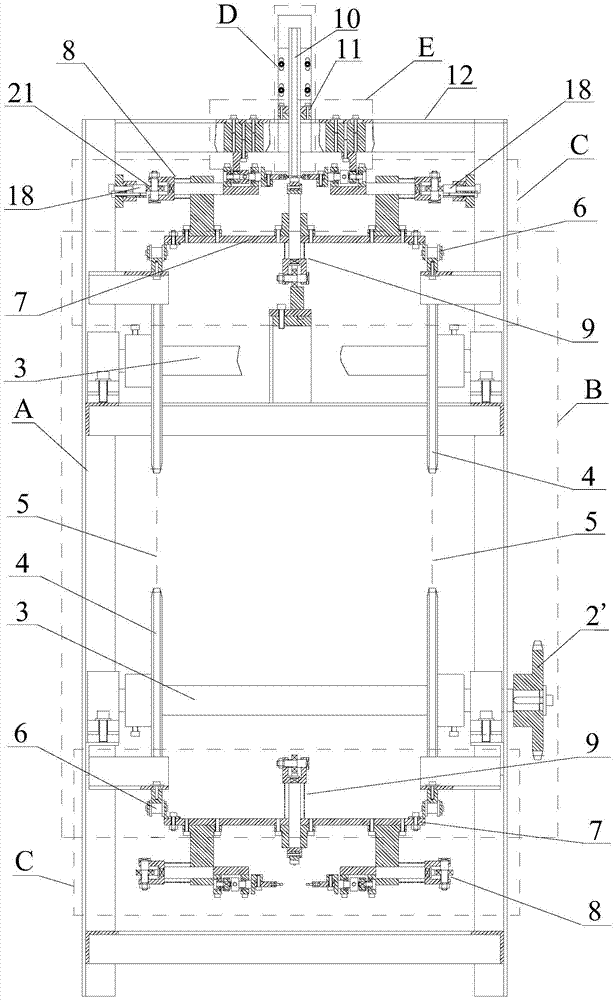

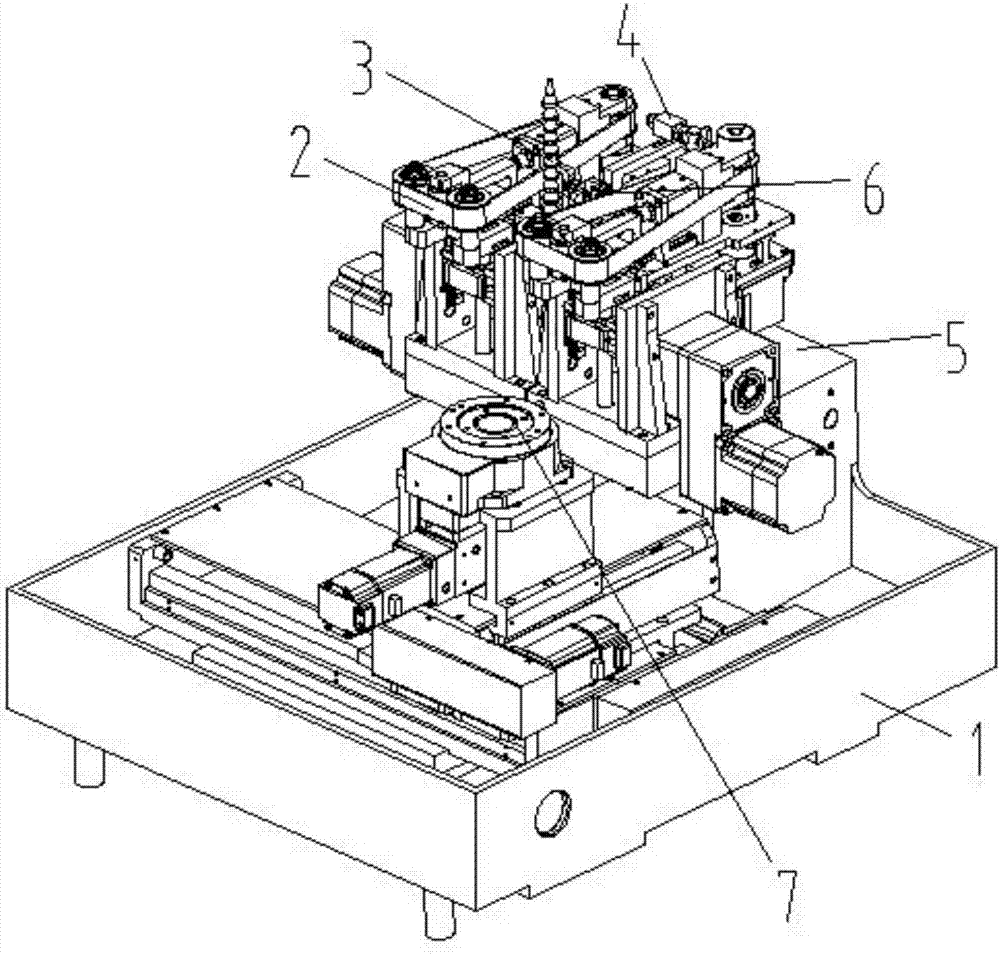

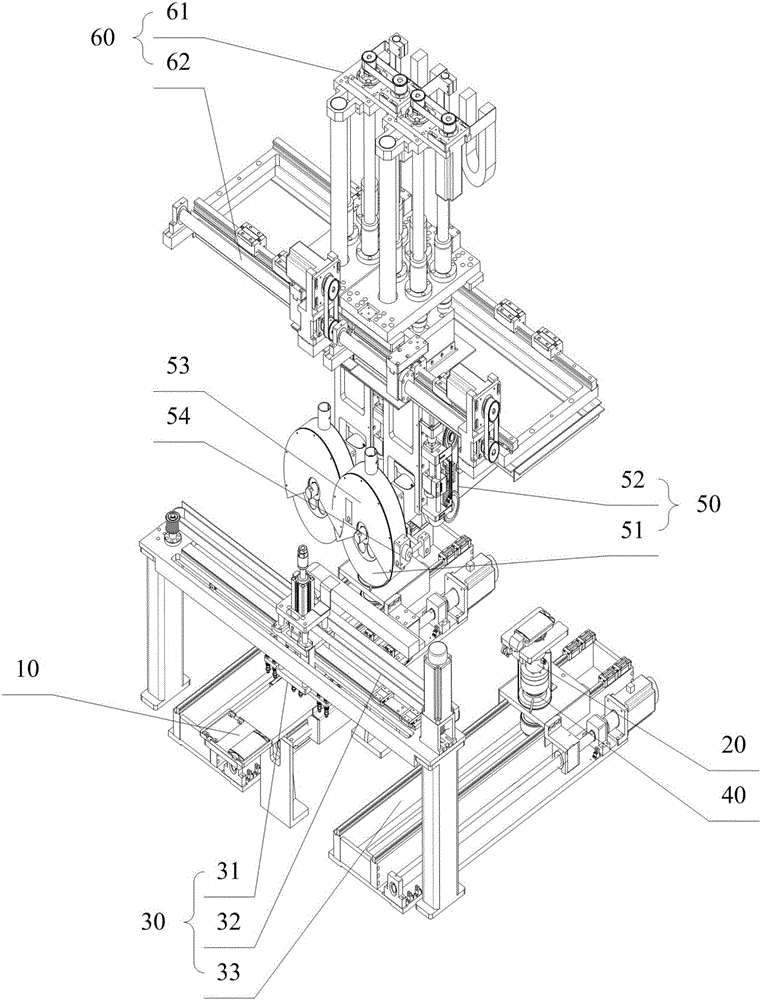

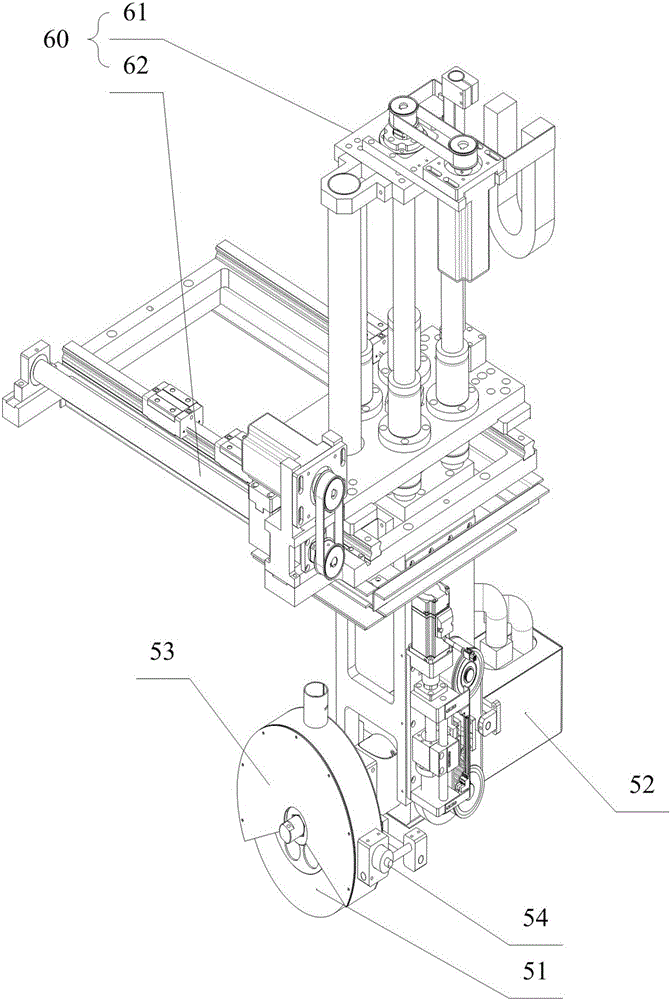

Polyhedron shell multi-shaft polisher

InactiveCN105922128ARealize automatic polishingImprove pass rateBurnishing machinesGrinding work supportsMachiningEngineering

The invention discloses a polyhedron shell multi-shaft polisher. The polyhedron shell multi-shaft polisher comprises at least one polishing device; the polishing device includes a loading bracket for placing a fixture for fixing a polyhedron shell, a machining station fixing module for fixing the fixture, a conveying module for conveying the fixture on the loading bracket to the machining station fixing module, a rotating module positioned below the machining station fixing module and connected with the machining station fixing module for driving the machining station fixing module to rotate so as to rotate the polyhedron shell on the machining station fixing module, a polishing module positioned above the machining station fixing module for polishing the polyhedron shell, and a moving module connected with the polishing module for driving position movement of the polishing module; and when the polishing module moves to a preset position, the polishing module is in butt joint with the machining station fixing module for polishing the polyhedron shell.

Owner:SHENZHEN CITY POSONWONE TECH

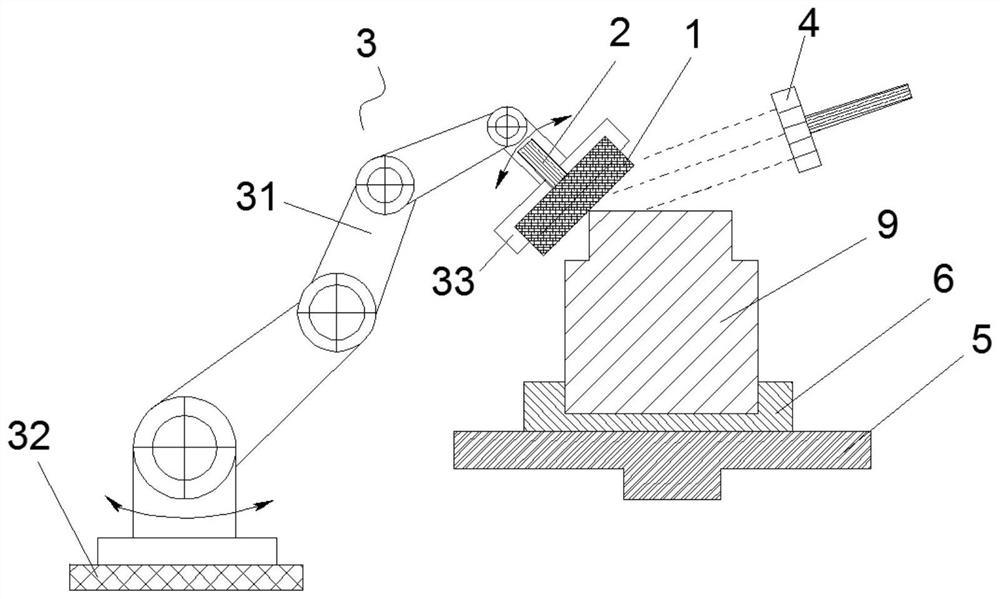

Special-shaped surface polishing device and method

ActiveCN112935994AEasy to replaceImprove liquidityOptical surface grinding machinesGrinding drivesPolishingStress sensors

The invention relates to a special-shaped surface polishing device and method.The special-shaped surface polishing device comprises a polishing medium, a six-axis mechanical arm, polishing liquid jetting equipment, polishing liquid sprinkling equipment and a workpiece clamping and rotating platform, the polishing medium comprises an imbedding layer and a polishing layer which are arranged in a stacked mode, and a first groove is formed in the upper surface of the imbedding layer; a second groove is formed in the face, making contact with the imbedding layer, of the polishing layer, a pressure sensor and a temperature sensor are arranged in the imbedding layer, and a polishing structure of the polishing layer is matched with a to-be-polished face; and the polishing medium is made of microporous polyurethane. The polishing medium made of the microporous polyurethane material is selected, foaming holes of the microporous polyurethane facilitate the fluidity of polishing powder, the polishing medium comprises the imbedding layer and the polishing layer which are arranged in a stacked mode, grooves are formed in each layer, the fluidity of polishing liquid is improved, the polishing efficiency is improved, the polishing medium is grabbed through the six-axis mechanical arm, and the polishing medium is convenient to replace.

Owner:CHINA BUILDING MATERIALS ACAD

Self-driving air sac pressure controlled flexible furbisher

InactiveCN1754660AFlexible adjustment of removal volumeImprove polishing efficiencyMetal working apparatusEngineeringGas chamber

This invention relates to automatic gas pressure control flexible polishing tool, which comprises the following parts: one gas chamber with polishing cloth as work surface in front end installed in one sustaining rack; one rotation drive structure connected to the sustaining rack; the said gas chamber is connected to the outer gas source entrance through gas channel with overflow valve. The invention provides one mode curve polishing tool with high efficiency and quality.

Owner:ZHEJIANG UNIV OF TECH

Polishing device for refrigerator injection mold guide columns

InactiveCN110524379AReduce workloadImprove production efficiencyPolishing machinesGrinding drivesDrive shaftEngineering

The invention relates to the technical field of mold machining, and further discloses a polishing device for a refrigerator injection mold guide column. The device comprises a workbench, a base block,a fixed block, a motor, a driving shaft and a transmission shaft, the base block and the fixed block are fixedly installed at the two sides of the top of the workbench correspondingly, and the motoris fixedly installed at the top of the workbench and is located in front of the base block; one end of the driving shaft is fixedly connected with an output shaft of the motor, the other end of the driving shaft is rotationally connected with the inner side face of the fixed block, and the transmission shaft is located behind the driving shaft and is parallel to the driving shaft. According to thepresent invention, the motor drives the driving shaft and the transmission shaft to rotate, so that a first polishing wheel and a second polishing wheel rotate to conduct friction polishing on the surface of a guide column body, the automatic polishing is achieved, the workload of the workers is reduced, and the working efficiency and the polishing quality can be improved, and accordingly the enterprise production benefits are improved, and the polishing device is convenient to apply and popularize.

Owner:泰州市朗拓塑料有限公司

A double-sided ceramic sheet polishing machine

ActiveCN106475888BRealize double-sided small batch processingSimple structureGrinding carriagesPolishing machinesPolishingElectric machinery

The invention discloses a double-sided ceramic sheet polishing machine, which belongs to the field of polishing equipment. It includes a base, a mobile platform installed on the upper end surface of the base, a polishing assembly installed on the mobile platform, a workpiece placement table assembly and a controller installed on the upper end surface of the base and corresponding to the polishing assembly; the workpiece placement table assembly includes a first placement table , the first slide and the second placement platform; located at the entrance of the first slide and opposite to the side of the first placement platform, an overturning part is provided; corresponding to the first placement platform, a push rod mechanism is also provided; corresponding to the first placement platform and the second placement platform A pressure sensor is arranged below the place where the workpiece is placed on the upper end surface of the workpiece, and the controller is connected to the pressure sensor; the controller is connected to control the first moving mechanism, the second moving mechanism and the driving motor. The invention is compact in volume, can realize double-sided polishing of ceramic sheets, can effectively improve the working environment of experimenters and improve experiment efficiency.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

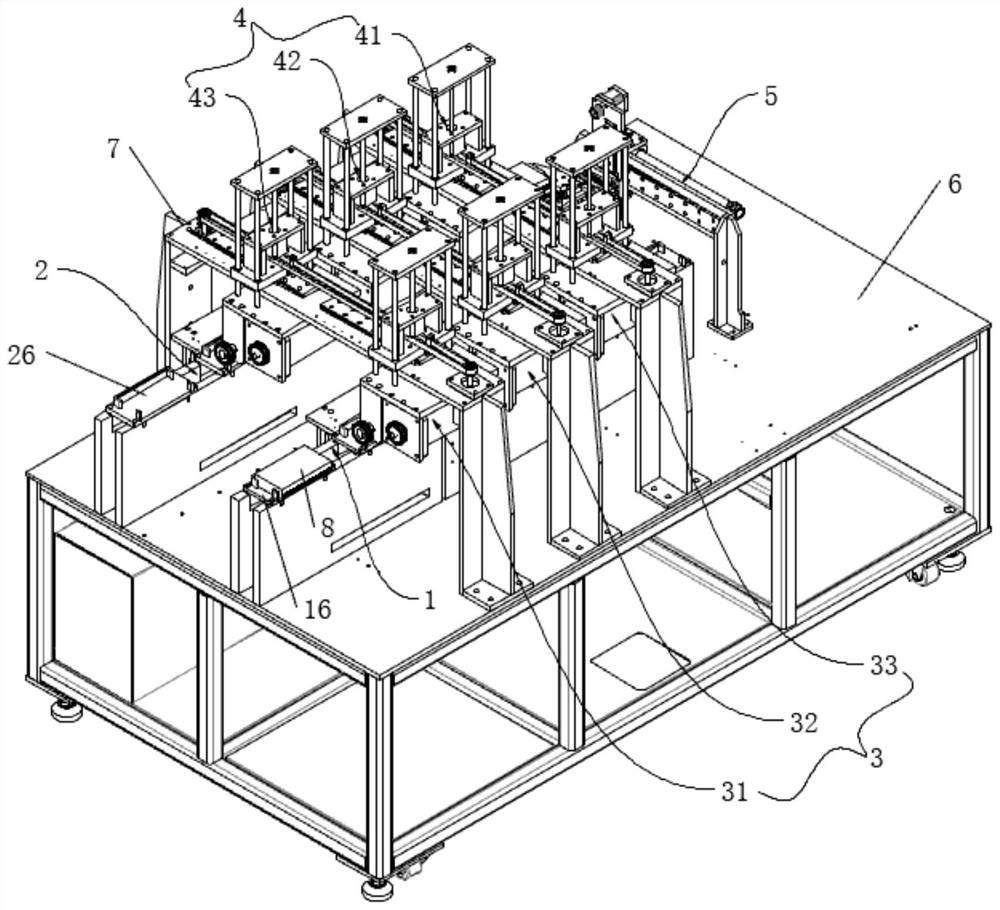

Part polishing machine

PendingCN112828751ARealize automatic polishingImprove polishing efficiencyGrinding carriagesPolishing machinesPolishingMachine

The invention discloses a part polishing machine. The part polishing machine comprises a first part conveying mechanism, a second part conveying mechanism, a first polishing mechanism, a second polishing mechanism and a part turn-over transferring mechanism, the first part conveying mechanism and the second part conveying mechanism are arranged in a spaced mode, the first part conveying mechanism is provided with a first polishing station, the second part conveying mechanism is provided with a second polishing station, the first polishing mechanism corresponds to the first polishing station, the second polishing mechanism corresponds to the second polishing station, and the part turn-over transferring mechanism corresponds to the output end of the first part conveying mechanism and the input end of the second part conveying mechanism. According to the part polishing machine, automatic polishing of parts can be realized, and therefore the polishing efficiency of the parts is improved.

Owner:TCL KING ELECTRICAL APPLIANCES HUIZHOU

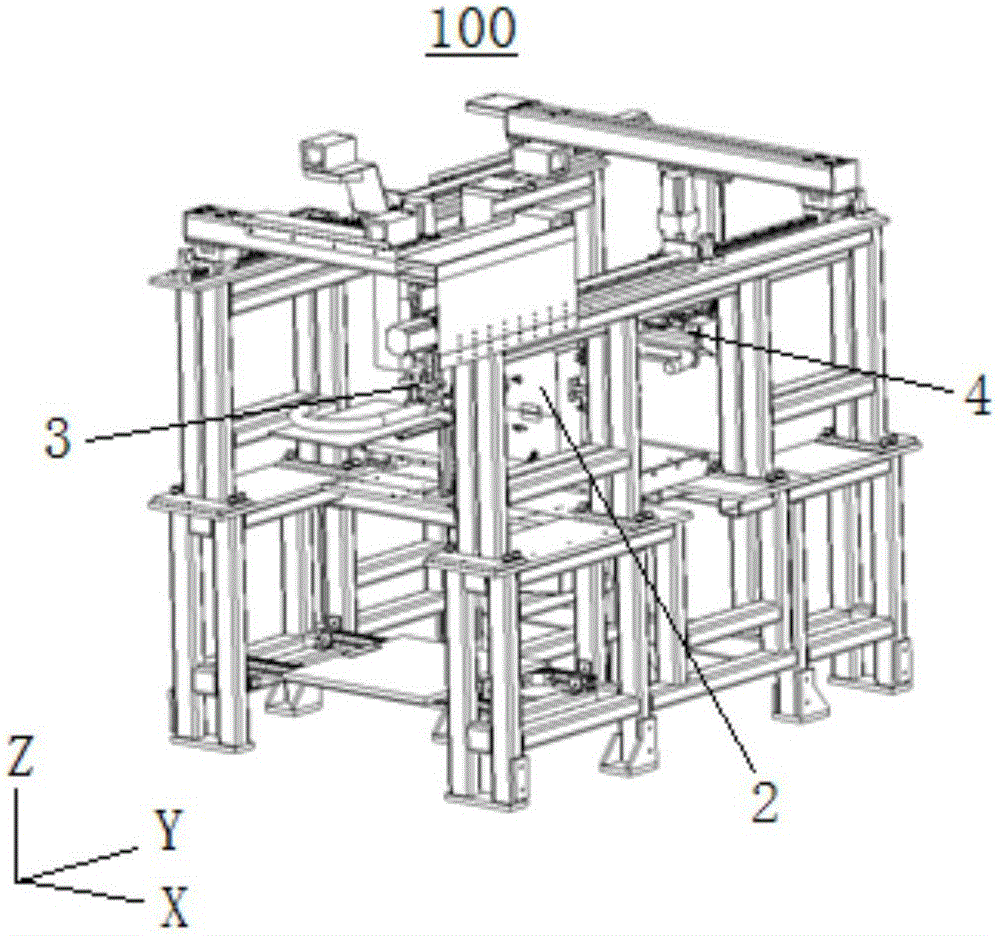

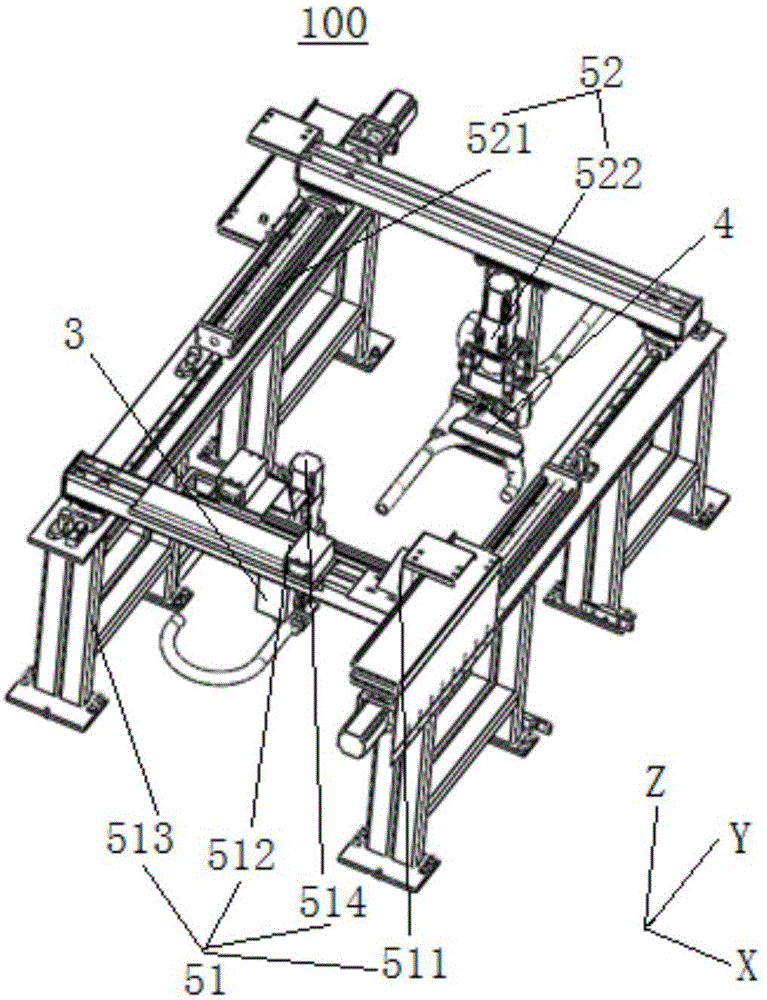

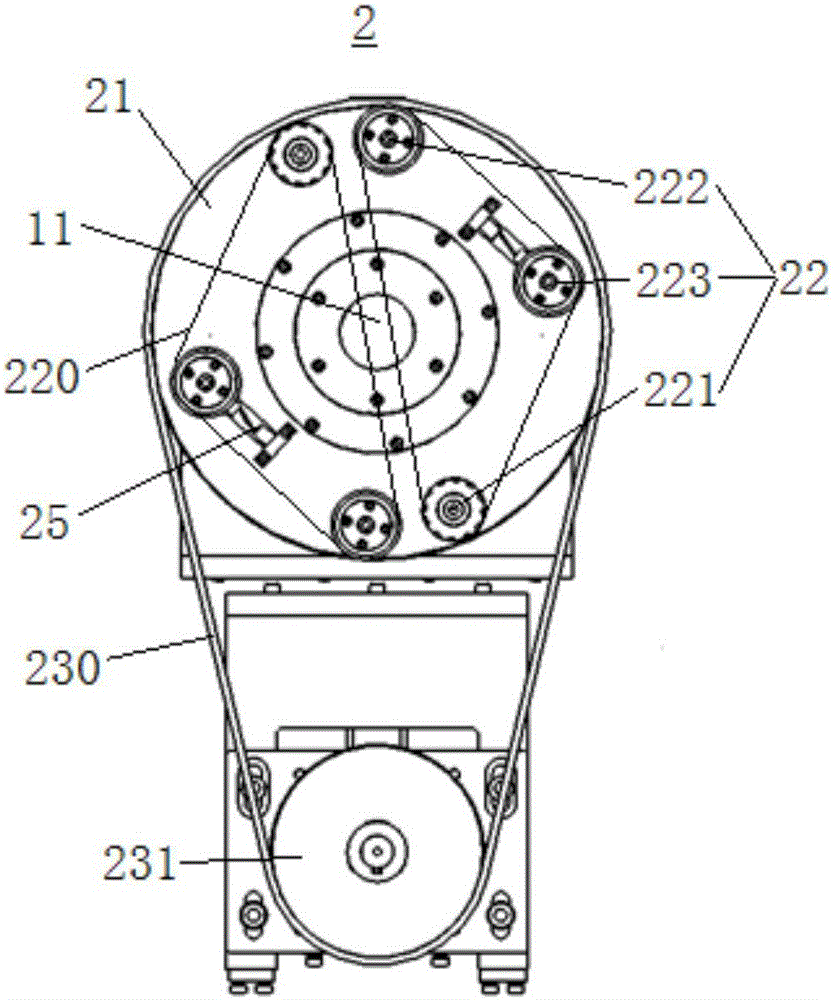

Dual-mechanical-arm polishing mechanism and polishing equipment with dual-mechanical-arm polishing mechanism

InactiveCN106239321ARealize automatic polishingImprove polishing efficiencyGrinding carriagesGrinding drivesEngineeringManipulator

The invention discloses a dual-mechanical-arm polishing mechanism and polishing mechanism with the dual-mechanical-arm polishing mechanism. The dual-mechanical-arm polishing mechanism comprises a rack, a polishing head device, a main mechanical arm, an auxiliary mechanical arm and a drive device. The polishing head device is mounted on the rack. The main mechanical arm is movably arranged on the rack and located on one side of the polishing head device and is provided with a main clamping part used for clamping a bent pipe. The auxiliary mechanical arm is movably arranged on the rack and located on the other side of the polishing head device and is provided with an auxiliary clamping part used for clamping the bent pipe. The drive device drives the main mechanical arm and the auxiliary mechanical arm to move, so that the main clamping part clamps one end of the bent pipe to enable the end of the bent pipe to stretch into the polishing head device from one side, and the auxiliary clamping part clamps the other end of the bent pipe to enable the end of the bent pipe to stretch out from the other side. According to the dual-mechanical-arm polishing mechanism, automatic polishing can be achieved, the polishing efficiency is high, and cost is low.

Owner:TSINGHUA UNIV

A feeder hole polishing device and method

ActiveCN112975719BReasonable and ingenious structural designRealize automatic polishingPolishing machinesGrinding drivesCouplingEngineering

The invention discloses a feeder hole polishing device and method, wherein the feeder hole polishing device includes: a base, which has an accommodating space; Place the antenna vibrator; the polishing rod supply assembly, which is used to supply the polishing rod to the vibrator fixture; the jig drive assembly, which is located under the vibrator fixture, has a magnet drive block, and the magnet drive block is provided with a rotation positioning groove; Wherein, the lower end of the vibrator jig is extended with a magnet coupling part protruding from the lower end surface of the base, and the jig drive assembly drives the magnet coupling part to rotate through the magnet drive block; the polishing rod passes through the feeder hole of the antenna vibrator and is inserted into the rotation positioning slot to determine The center of rotation of the magnet joint. The automatic polishing of the feeder hole is realized, which solves the problem that the prior art does not have a good solution for the polishing that needs to be shifted from the center of rotation, and the problem of the drop in polishing accuracy caused by the vibration of the end of the polishing rod during processing.

Owner:东莞市振亮精密科技有限公司

Mobile phone rear shell polishing and grinding device

ActiveCN114083393ARealize automatic polishingImprove polishing efficiencyGrinding drivesGrinding machinesEngineeringMechanical engineering

The invention discloses a mobile phone rear shell polishing and grinding device, and relates to the technical field of mobile phone production. The device comprises a supporting rail which is horizontally arranged, wherein a mounting frame is fixed above the supporting rail; a bearing assembly is arranged on the supporting rail; a conveying assembly is arranged above the bearing assembly; a feeding assembly and a polishing and grinding assembly are arranged on the two opposite sides of the conveying assembly correspondingly; and the conveying assembly, the feeding assembly and the polishing and grinding assembly are all arranged on the mounting frame. According to the invention, a mobile phone rear shell is conveyed to the conveying assembly through the feeding assembly, then the mobile phone rear shell is conveyed to the bearing assembly through the conveying assembly, and finally the mobile phone rear shell is polished and ground through the polishing and grinding assembly, so that automatic polishing and grinding of the mobile phone rear shell are achieved, the polishing and grinding efficiency of the mobile phone rear shell is effectively improved, and the device has high market application value.

Owner:江苏中昇电子科技有限公司

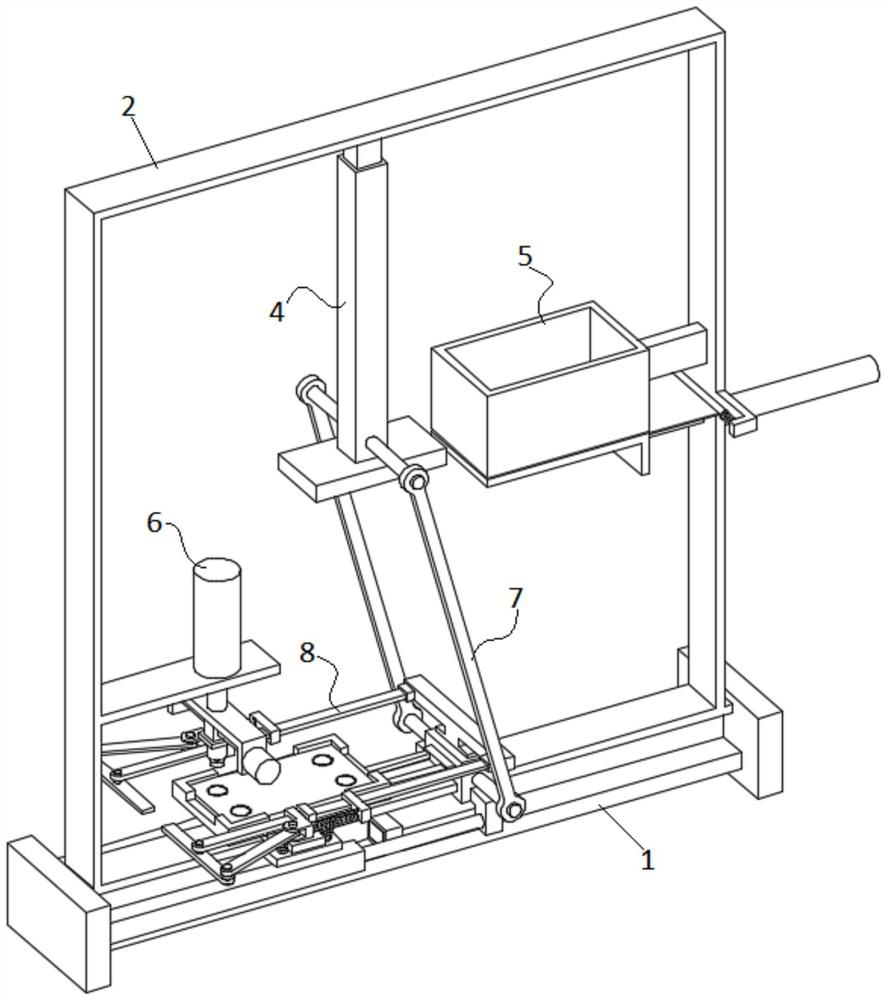

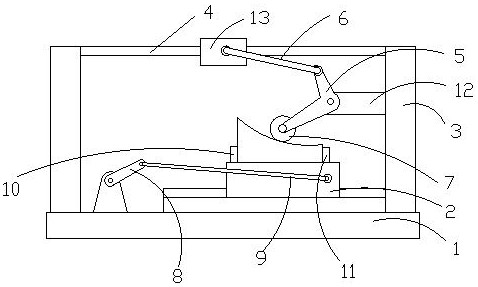

surface polishing machine

ActiveCN110877280BRealize automatic polishingImprove polishing effectGrinding carriagesPolishing machinesPolishingElectric machinery

The invention discloses a polishing machine for curved surfaces. The polishing machine comprises a base, a workpiece installing frame slidably arranged on the base, stand columns vertically and fixedly arranged on two sides of the base, and a guide column laterally and fixedly arranged between the stand columns on two sides, the sliding direction of the workpiece installing frame is parallel to the length direction of the guide column, and the workpiece installing frame is provided with a locking mechanism for locking a workpiece; a sliding member is slidably arranged on the guide column, thesliding member is rotatably provided with one end of a driving rod, one stand column on one side is rotatably provided with the middle part of an L-shaped swing arm, the other end of the driving rod is rotatably connected with the upper end part of the swing arm, the lower end part of the swing arm is rotatably provided with a polishing wheel, and the lower end part of the swing arm is provided with a polishing motor for driving the polishing wheel to rotate; and an installation plate is fixedly arranged on the base, the installation plate is rotatably provided with one end of a rotating arm,the other end of the rotating arm is rotatably connected to one end of a pull rod, the other end of the pull rod is rotatably connected to the workpiece installing frame, and a rotating motor for driving the rotating arm to rotate is arranged on the installation plate.

Owner:宜兴市安达信封头有限公司

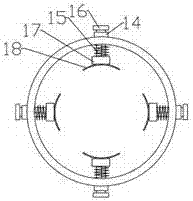

Two-stage polishing device for cylinder outer circle

PendingCN107322454ARealize automatic polishingImprove the quality of workPolishing machinesQuality of workDrive motor

The invention discloses a two-stage polishing device for a cylinder outer circle. The two-stage polishing device comprises a bottom support and a vertical support. An inward-bent horizontal support is arranged at the top end of the vertical support. The vertical support is arranged on the bottom support. The two-stage polishing device is characterized in that a first rotating ring and a second rotating ring are sequentially arranged above the bottom support; a transition casing pipe is arranged at the bottom of the first rotating ring; a drive motor located on the bottom support is arranged at the lower end of the transition casing pipe; multiple connecting rods are evenly distributed at the top end of the first rotating ring; the top ends of the connecting rods stretch into the bottom end of the second rotating ring; and a telescopic device located on the horizontal support is arranged above the second rotating ring. According to the two-stage polishing device for the cylinder outer circle, a polishing steel wire brush and abrasive paper are utilized for carrying out two-stage grinding and polishing on the cylinder outer circle, cylinder automatic polishing is achieved, the work quality is excellent, and the efficiency is high.

Owner:SUZHOU FUSHIMAN PRECISION MACHINERY CO LTD

Plasma nano-polishing device and automatic polishing equipment for semi-closed inner hole metal workpieces

ActiveCN111152073BWon't happenWill not corrodeGrinding feedersGrinding work supportsPolishingLiquid storage tank

The invention relates to the technical field of polishing, in particular to a plasma nano-polishing device and an automatic polishing device for a metal workpiece with a semi-closed inner hole; it includes a polishing conductive groove, a liquid storage chamber is arranged in the polishing conductive groove, and a heating mechanism is arranged inside the liquid storage chamber , the bottom of the liquid storage chamber is arranged at intervals with a plurality of conductive columns vertically connected to the bottom of the liquid storage chamber, each conductive column is provided with a drainage cavity, and each drainage cavity penetrates upwards through the top of the conductive column, and the bottom of the polished conductive groove is provided with a Each drainage chamber has a one-to-one corresponding lead-out hole, the lead-out hole is connected with the liquid inlet of the plasma liquid storage tank through the return line, the liquid outlet of the plasma liquid storage tank is connected with the liquid inlet of the polished conductive groove, and the plasma liquid storage tank is connected with the liquid inlet of the polished conductive groove. The return pipeline between the polishing conductive grooves is also connected with a liquid pump; it also includes a polishing workpiece conductive fixture, the polishing workpiece conductive fixture is electrically connected to the positive electrode of the power supply, and the polished conductive groove is electrically connected to the negative electrode of the power supply.

Owner:中唯精密工业有限公司

A double-sided polishing equipment

ActiveCN106514477BRealize double-sided small batch processingSimple structureGrinding carriagesPolishing machinesPolishingWorking environment

The invention discloses double-sided polishing equipment, and belongs to the field of surface polishing equipment. The double-sided polishing equipment comprises a base, a movable platform installed on the upper end surface of the base, a polishing assembly installed on the movable platform, and a workpiece placement table assembly installed on the upper end surface of the base and corresponding to the polishing assembly, wherein the workpiece placement table assembly comprises a first placement table, a first slide, a second placement table, a second slide and a storage barrel; a turnover part is arranged at the inlet of the first slide and opposite to one side of the first placement table; and a push rod mechanism is further arranged in a manner of corresponding to the first placement table and the second placement table, and a feeding mechanism is arranged in the first placement table. The double-sided polishing equipment disclosed by the invention is small in size, capable of realizing double-sided polishing for a ceramic wafer, and capable of effectively improving the working environment of experimenters and increasing the experiment efficiency.

Owner:广西日瑞智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com