Inner circle polisher for bobbins

A technology of an I-shaped wheel and a polishing machine is applied in the field of polishing machines, which can solve the problems of difficulty in ensuring polishing effect and low efficiency, and achieve the effect of improving polishing efficiency and polishing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical contents not mentioned below can adopt or learn from the prior art.

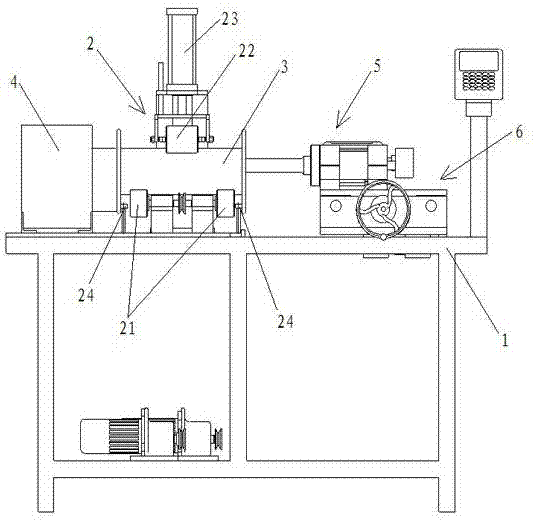

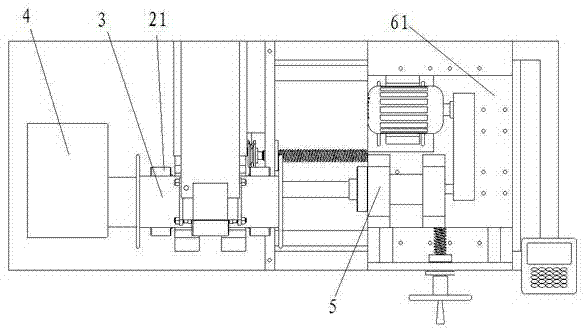

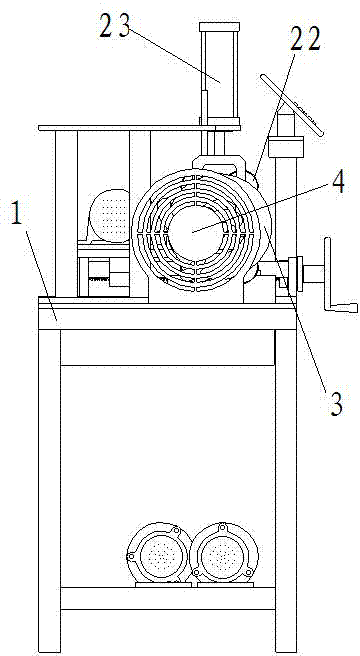

[0018] As shown in Figures 1, 2, and 3, the present invention includes a bed 1, which is provided with an I-shaped wheel clamping drive mechanism 2, and the I-shaped wheel 3 is laterally clamped and fixed by the I-shaped wheel clamping drive mechanism 2. On the bed 1, the two sides of the I-wheel clamping drive mechanism 2 are respectively provided with a dust-removing axial flow fan 4 and a grinding head assembly 5 corresponding to the inner circle of the I-wheel.

[0019] The above-mentioned I-wheel clamping drive mechanism 2 includes a lower set of fixed rubber rollers 21 and an upper clamped rubber roller set 22 . The clamping rubber roller group 22 is driven to move up and down by the cylinder 23, and one group of the fixed rubber roller group 21 below is a driving roller, which can drive the I-shaped wheel and the main shaft of the grinding head assembly to rotate in the same direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com