Polishing device for intelligently machining workpieces with regular shapes

An intelligent processing and polishing device technology, which is applied in the direction of grinding/polishing safety device, workpiece feed movement control, grinding workpiece support, etc., can solve the problem of high labor intensity, metal dust, workpiece heating cannot be processed in time, and operator health As well as the adverse effects of environmental protection and other issues, to achieve the effect of avoiding loosening of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

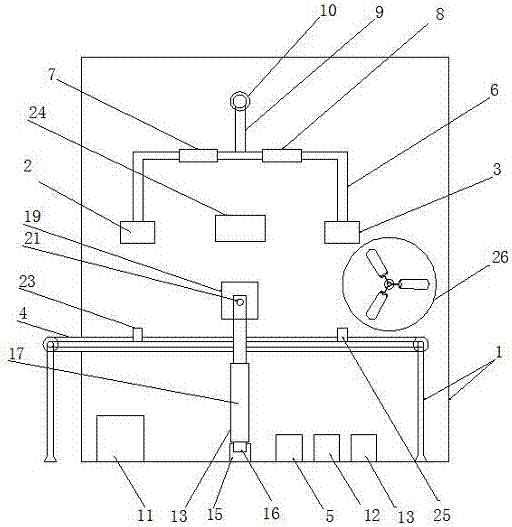

[0021] Such as figure 1 As shown, a polishing device for intelligently processing regular-shaped workpieces includes a frame 1, a first polishing wheel 2, a second polishing wheel 3, a conveyor belt 4 and a processor 5, wherein the first polishing wheel 2 And the second polishing wheel 3 is arranged at the position vertically above the frame 1, the first polishing wheel 2 and the second polishing wheel 3 are connected by a first connecting device 6, and the first connecting device 6 Including the first electro-hydraulic push rod 7 and the second electro-hydraulic push rod 8, the first electro-hydraulic push rod 7 and the second electro-hydraulic push rod 8 are connected to the processor 5, the first electro-hydraulic push rod 7 is used to control the horizontal movement of the first polishing wheel 2, the second electro-hydraulic push rod 8 is used to control the horizontal movement of the second polishing wheel 3, and the first connection device 6 is connected to the second c...

Embodiment 2

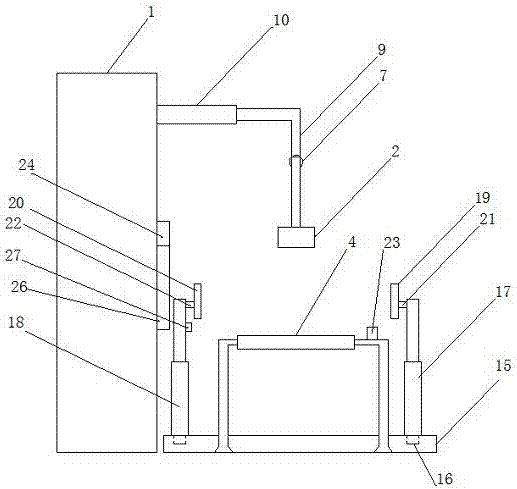

[0024] Such as figure 2 As shown, the material of the first polishing wheel 2 is set as soft sandpaper, and the material of the second polishing wheel 3 is set as hard sandpaper. The frame 1 is provided with a hardness tester 23 which is connected to the processor 5 and is used to test the hardness of the surface of the workpiece to be processed. The third connection device 10 is a hydraulic rod, and the hydraulic pump 11 drives the hydraulic rod to expand and contract.

[0025] Specifically, the operator places the workpiece to be processed on the conveyor belt 4, and the conveyor belt 4 transports the workpiece to be processed to the detection area of the hardness tester. The first hardness interval and the second hardness interval are preset. The first hardness Any hardness value in the interval is greater than the hardness value in the second hardness interval, and the hardness detector 23 is used to detect the hardness value of the surface of the workpiece to be proce...

Embodiment 3

[0029] Such as figure 2 As shown, the frame 1 is also provided with a dust suction device 24 for absorbing metal dust generated during processing. The frame 1 is also provided with a temperature sensor 25, the temperature sensor 25 is an infrared temperature sensor connected with the processor 5 for detecting the surface temperature of the workpiece after processing. The frame 1 is also provided with a fan 26, which is connected to the processor 5 and used to cool the heated workpiece.

[0030] Specifically, the staff engaged in the polishing industry has been in contact with harmful metal dust for a long time, which is likely to cause occupational diseases such as pneumoconiosis. In the working area of the second polishing wheel 3, when the first polishing wheel 2 or the second polishing wheel 3 are working, the dust suction device 24 is opened synchronously to absorb the harmful metal dust produced by the polishing of the polishing wheel in time, reducing the number of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com