Water drill bit polishing device

A technology of polishing device and drill bit, applied in grinding drive device, grinding/polishing equipment, drilling tool accessories, etc., can solve the problems of reduced efficiency, uneven polishing of water drill bit, hand fatigue, etc. The effect of easy collection and simplified reset process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

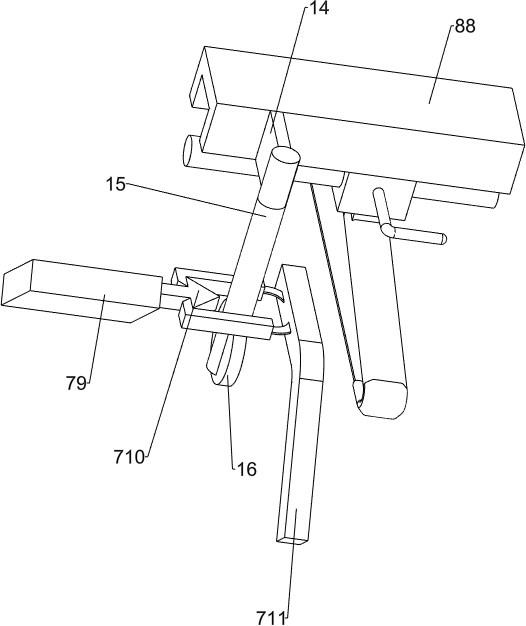

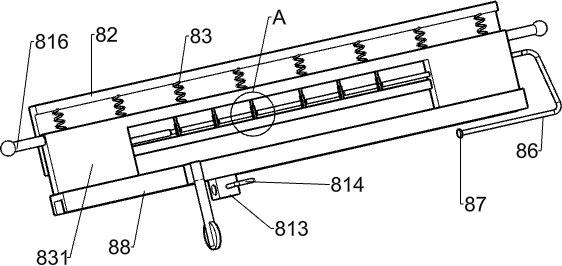

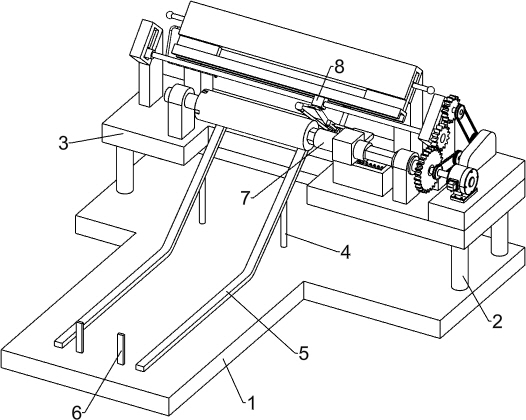

[0026] like Figure 1-8 As shown, a water drill bit polishing device includes a base 1, a first support column 2, a workbench 3, a second support column 4, a track 5, a baffle plate 6, a rotating mechanism 7 and a polishing mechanism 8, and the left and right sides of the base 1 top Two first support columns 2 are symmetrically arranged on both sides, a workbench 3 is fixedly connected between the tops of the first support columns 2, and a second support column 4 is fixedly connected symmetrically to the left and right in the middle of the top of the base 1. There is a track 5, the front side of the track 5 is connected with the base 1, the left and right baffles 6 are arranged symmetrically on the front side of the top of the base 1, the rotating mechanism 7 is arranged on the front side of the top of the workbench 3, and the polishing mechanism 8 is arranged on the rear side of the top of the workbench 3 .

[0027] When people use this device, at first the water drill bit t...

Embodiment 2

[0033] like Figure 5 and Figure 8 As shown, on the basis of Embodiment 1, a water drill bit polishing device also includes a speed control box 9, a rotating shaft 10, a third circular gear 11, a first belt transmission device 12 and a second belt transmission device 13, and a pad The rear side of the 717 top is provided with a speed regulating box 9, and the second slide box 810 top on the right side is provided with a rotating shaft 10 in a rotating manner, and the rotating shaft 10 is fixedly connected with a third round gear 11, and the third round gear 11 is connected to the second round gear. Gear 815 meshes, and the first belt transmission device 12 is connected between the right end of rotating shaft 10 and the output shaft of the speed regulating box 9, and the second belt transmission device 13 is arranged between the output shaft of the servo motor 718 and the input shaft of the speed regulating box 9.

[0034] When the water drill bit is polished, the second roun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com