Patents

Literature

68results about How to "Realize automatic drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

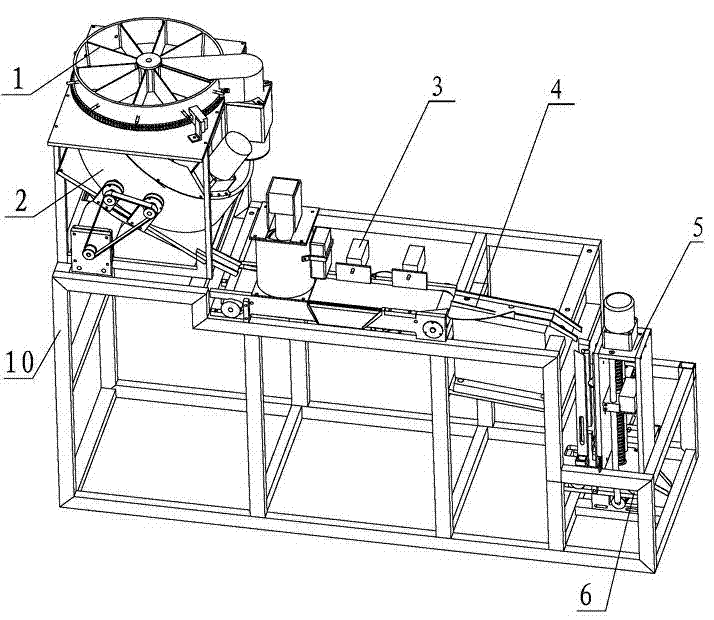

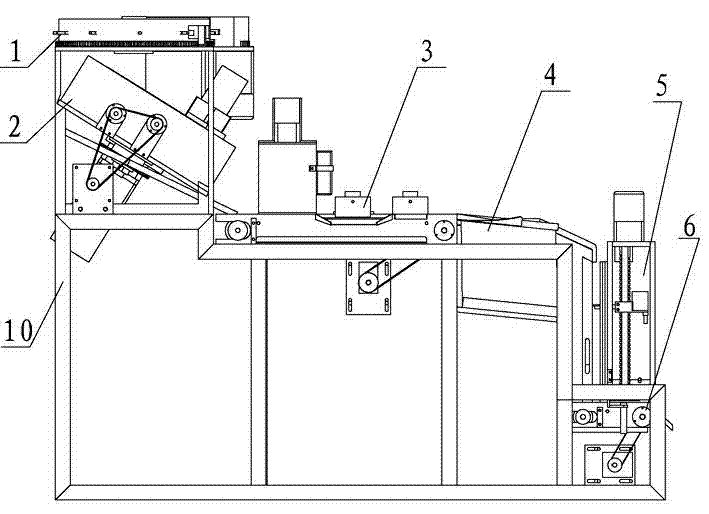

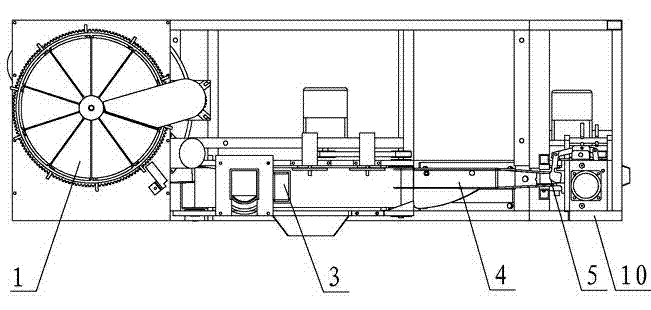

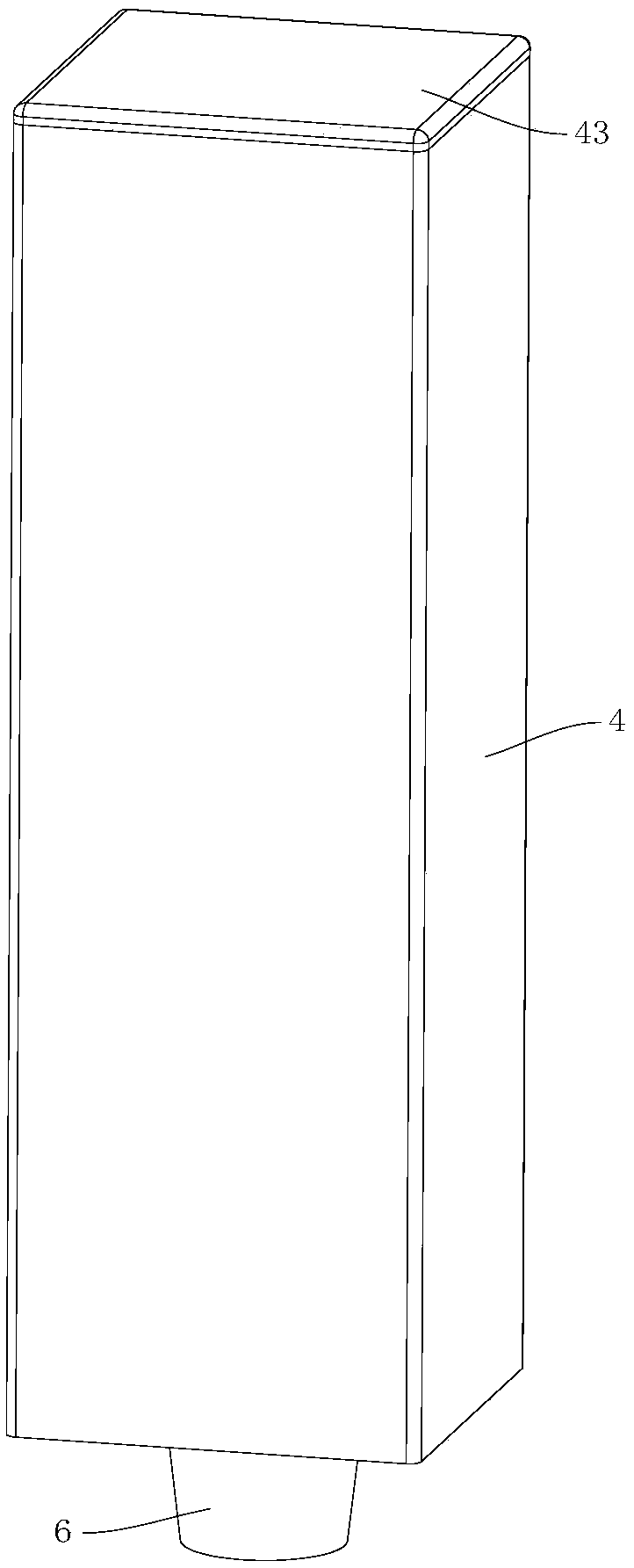

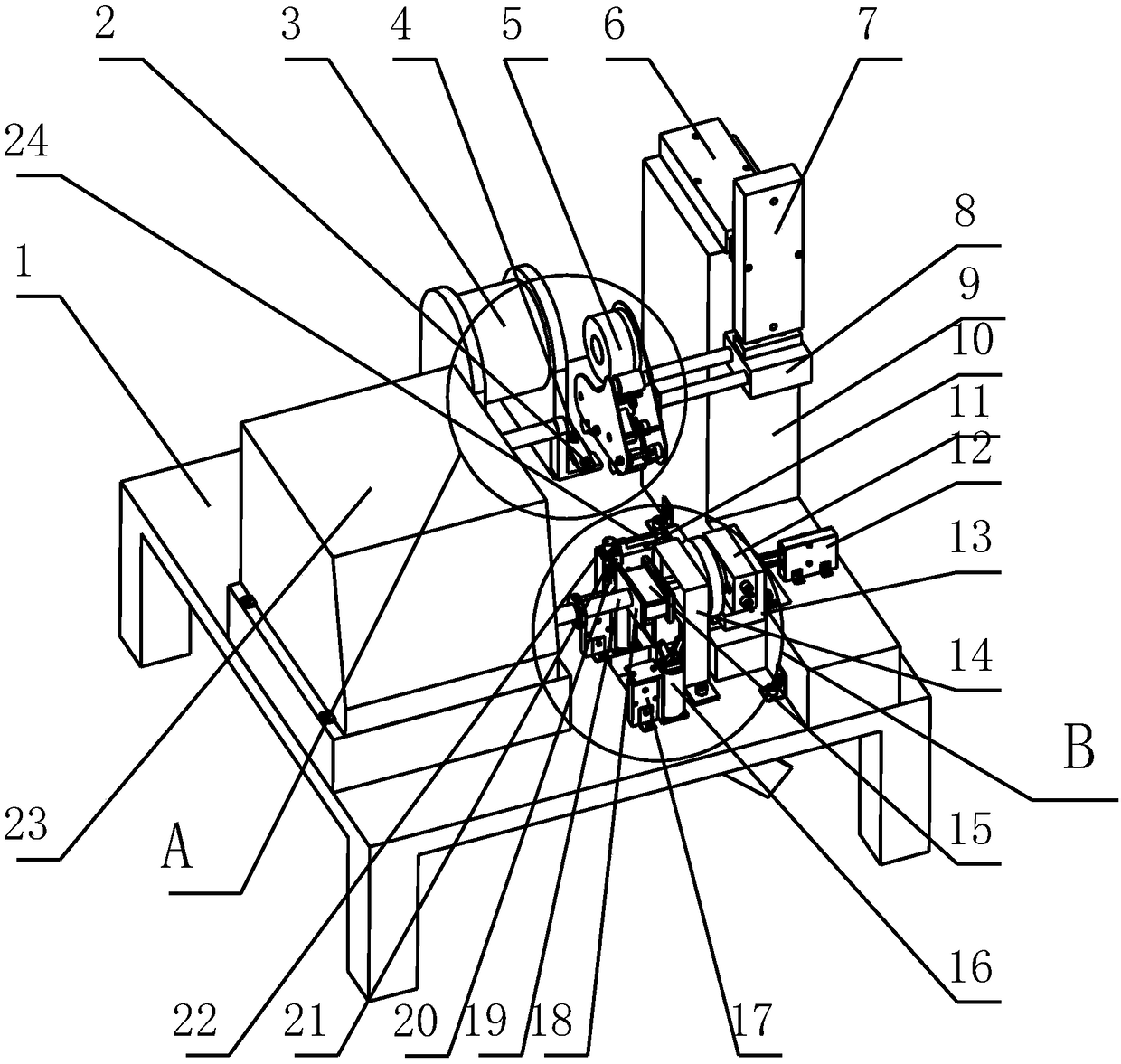

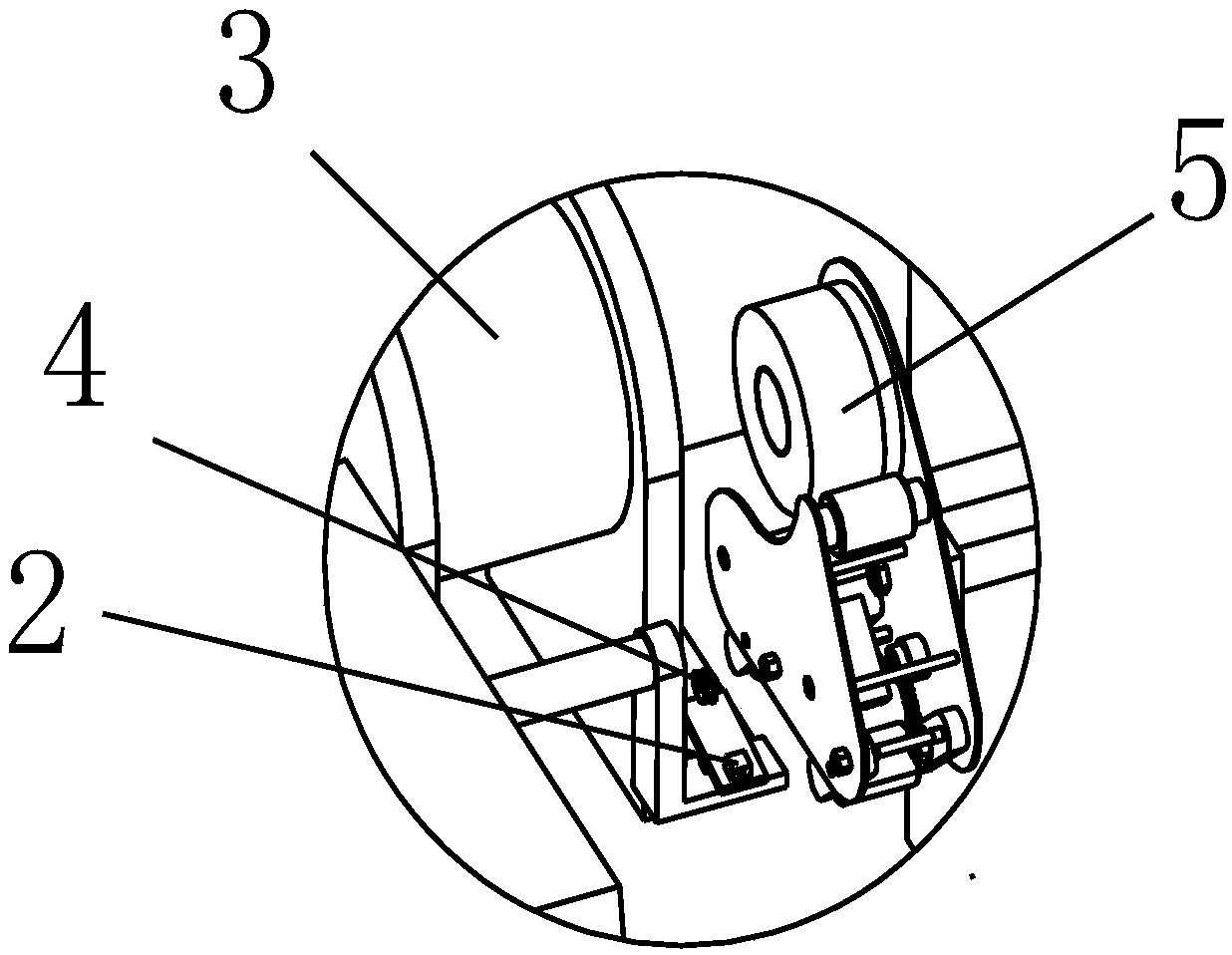

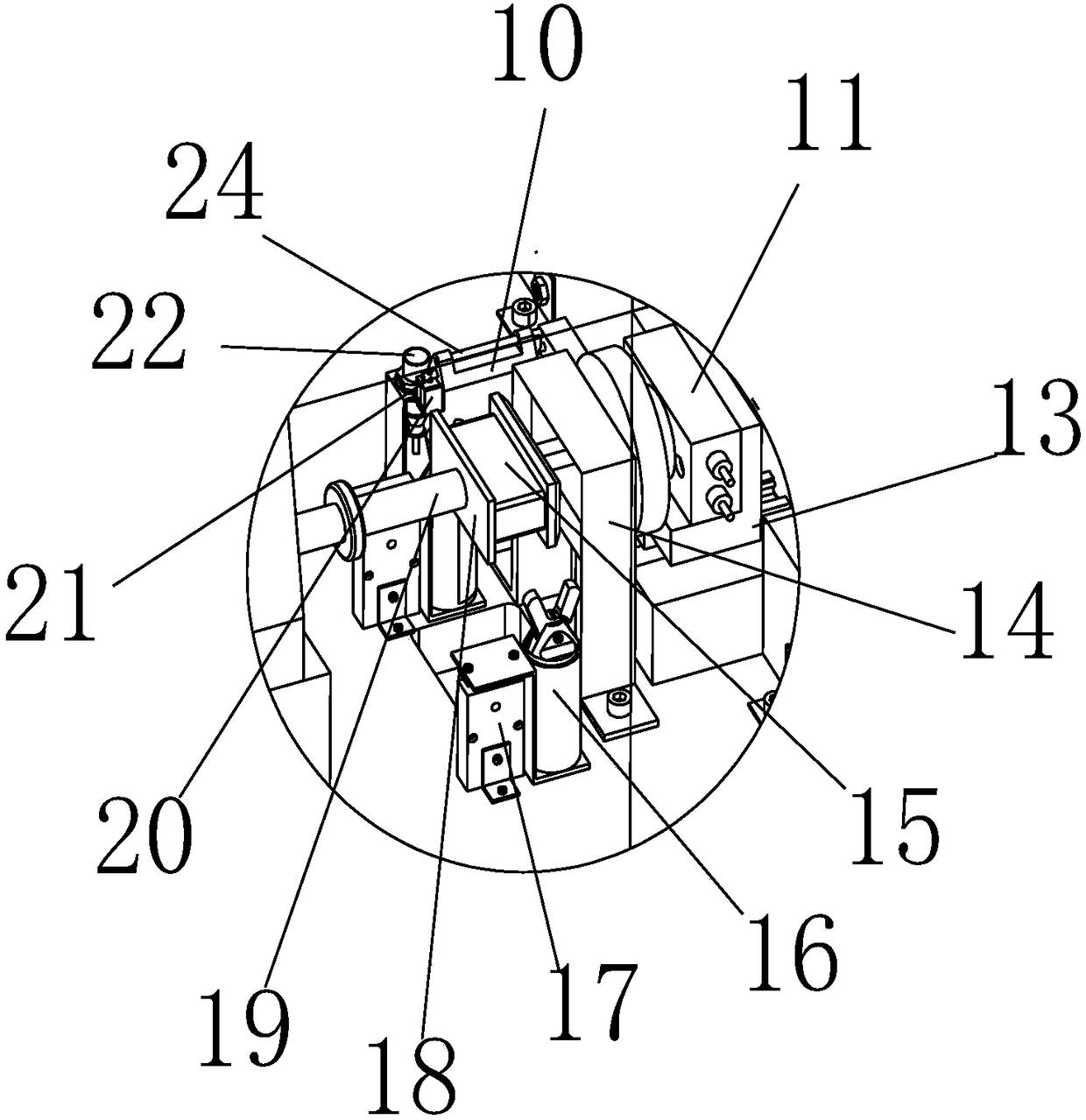

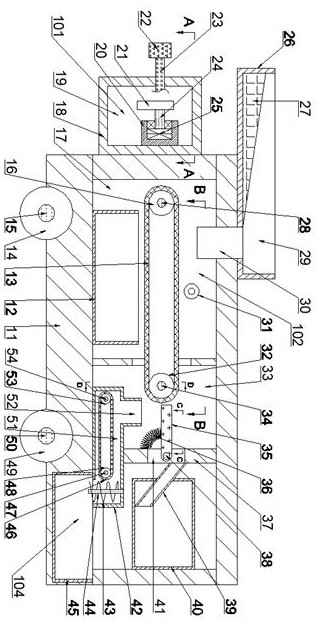

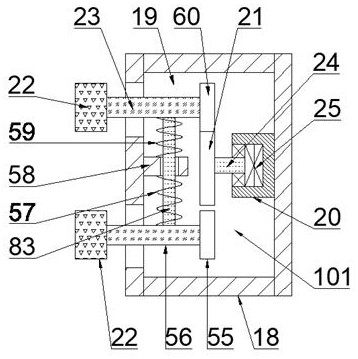

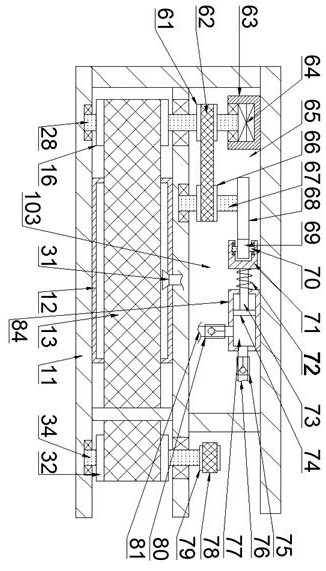

Strip metal auto-screening and integrated feeding device

The invention relates to equipment for processing metals, in particular to a strip metal auto-screening and integrated feeding device which is characterized in that, according to the process flow, a meshed discharging device, a turnplate discharging device, a screening device, an overturn device, an integration device and a feeding device are sequentially arranged on a frame. The strip metal auto-screening and integrated feeding device disclosed by the invention is intelligent and is aimed at solving the disadvantage that strip metal processing equipment in the prior art is insufficient in degree of automation. The strip metal auto-screening and integrated feeding device automatically finishes the operations of single discharging, distinguishing and screening qualified strip metals, revising the front sides and the back sides of the strip metals, collecting qualified strip metals and single feeding.

Owner:XIAOSHAN IND RES INST +1

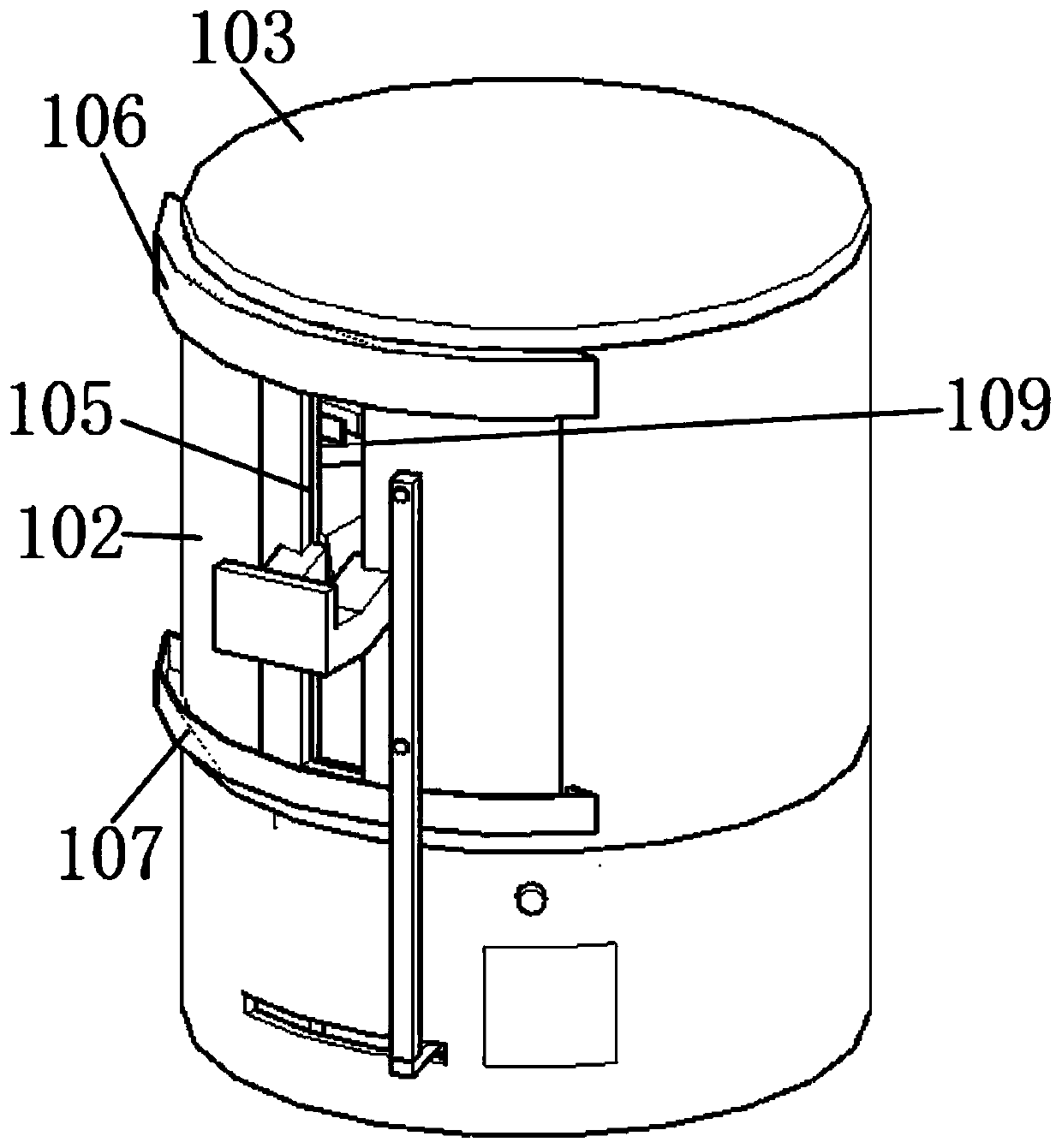

Automatic discharging machine for appliances

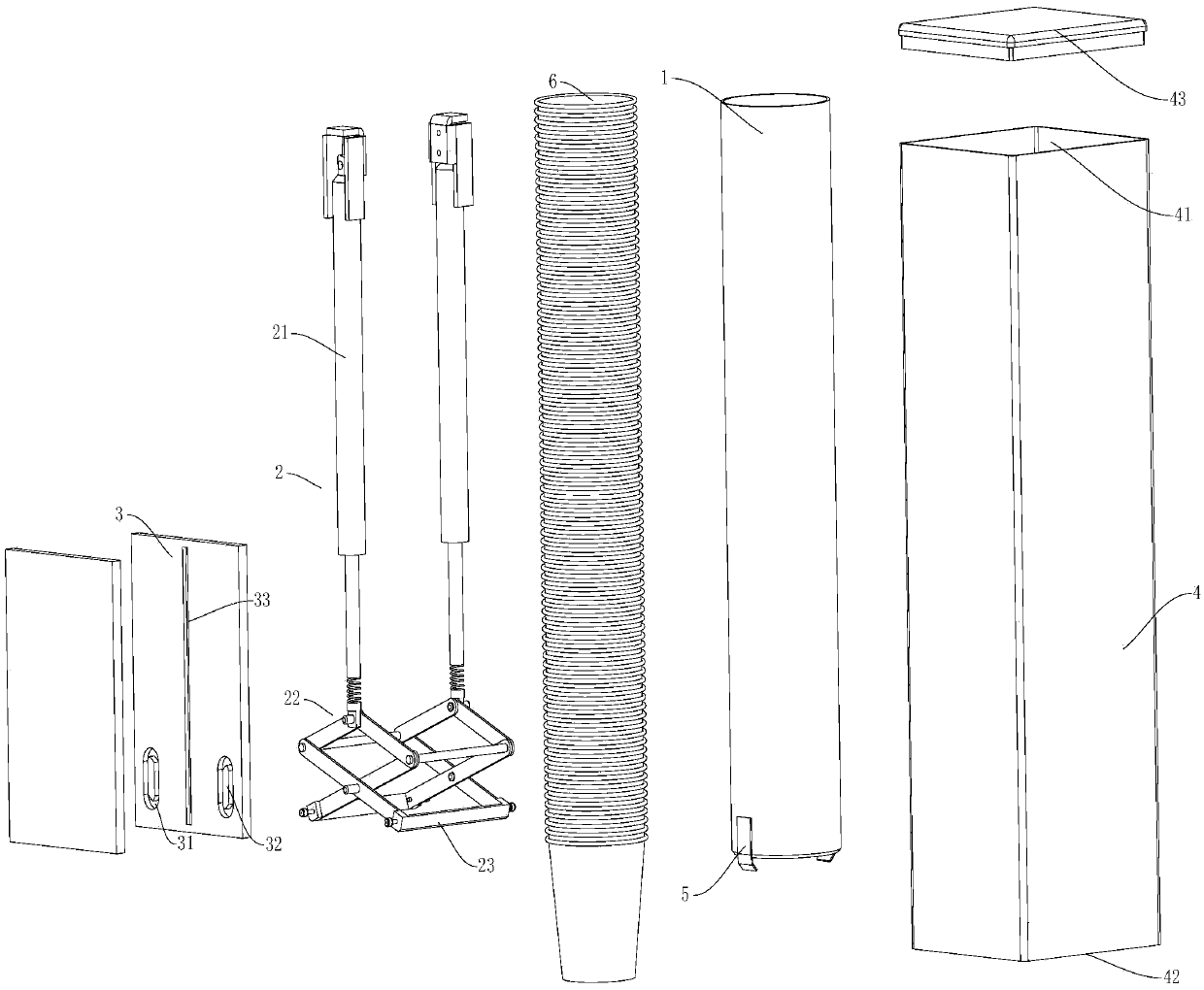

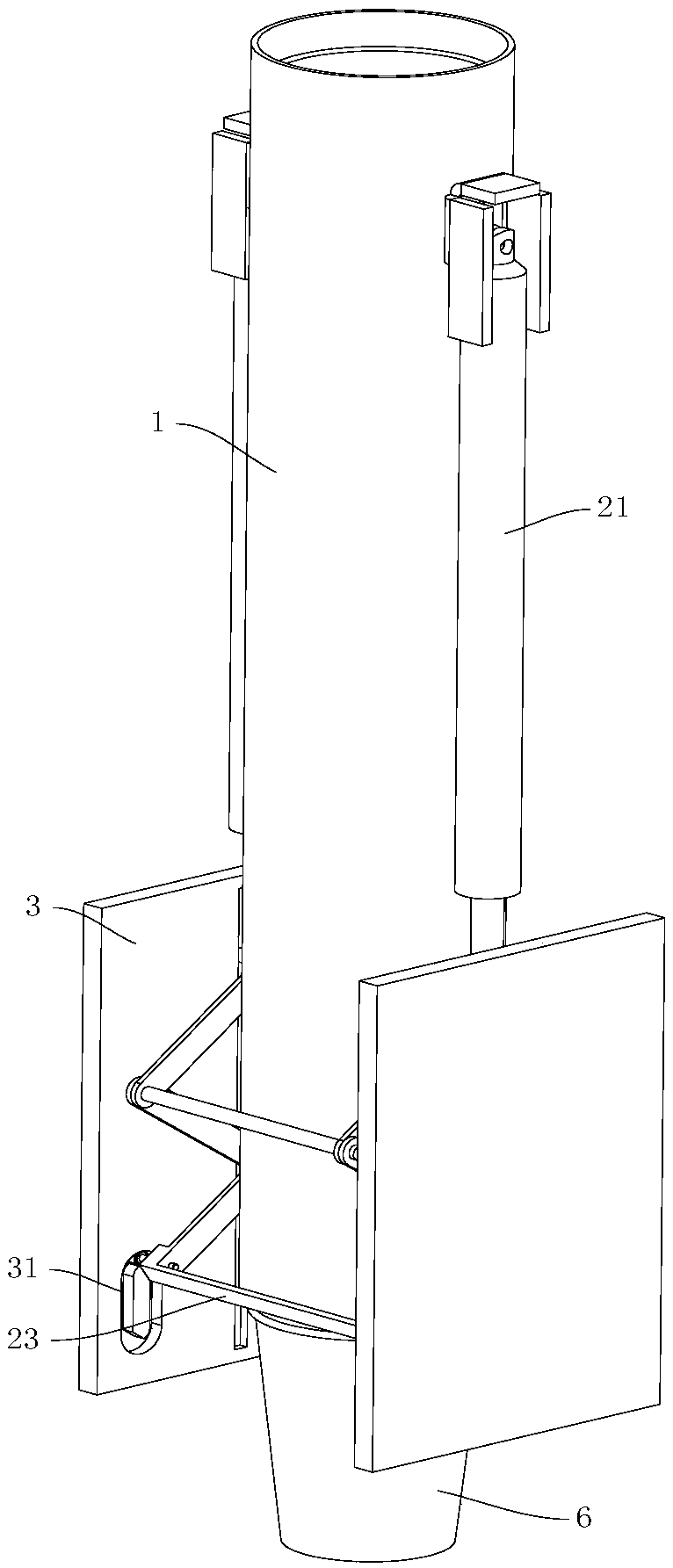

PendingCN109674286AIngenious structural designCompact structureRacksEngineeringMechanical engineering

The invention discloses an automatic discharging machine for appliances. The automatic discharging machine comprises a storage cylinder, a baffle, a positioning plate and a driving assembly, wherein the storage cylinder is used for storing the appliances; the baffle is used for bearing the appliance on the bottommost layer; and the driving assembly comprises a pushing plate, a shear fork mechanismand a driving component, a circulating track is formed in the positioning plate and comprises a and a falling track connected with the clamping track. The driving assembly comprises the pushing plate, the shear fork mechanism and the driving component, and a second end of the pushing plate is connected with the circulating track in a sliding manner; when passing through the clamping track, the pushing plate can be obliquely embedded into a gap between the appliance on the bottommost layer and the appliance sleeved with the appliance on the bottommost layer; and when passing through the falling track, the pushing plate props against the edge of an opening of the appliance on the bottommost layer so as to drive the appliance to be sequentially separated from the baffle and the appliance sleeved with the appliance on the bottommost layer. The automatic discharging machine is low in machining difficulty, compact in structure, relatively skillful in design and relatively high in practicability.

Owner:GUANGZHOU FUGANG WANJIA INTELLIGENT TECH CO LTD

Medical medicine residue packing equipment

InactiveCN108945541ASpeed up the fallImprove work efficiencySolid materialPackaging machinesMedicineMobile device

The invention relates to packing equipment, in particular to medical medicine residue packing equipment. The technical effect of providing the medical medicine residue packing equipment having advantages that the efficiency of packing medicine residues is high, and clothes of people cannot be polluted in the packing process of the medicine residues is aimed to be achieved. According to the technical scheme, the medical medicine residue packing equipment comprises a bottom plate, a first sliding rail, first sliding blocks, placing frames, a connecting rod, a frame body, a nail, a support, a supporting plate, a material storage frame, a discharging hopper, an L-shaped supporting rod and the like; the first sliding rail is embedded on the right portion of the upper side of the bottom plate, the two first sliding blocks are arranged on the first sliding rail in a sliding mode, the placing frames are arranged on the tops of the first sliding blocks on the left side and the right side, the connecting rod is connected between the placing frames on the left side and the right side. According to the equipment, the effects that the efficiency of packing the medicine residues is high, and theclothes of people cannot be polluted in the packing process of the medicine residues are achieved; and due to the arrangement of a mobile device, a baffle and the frame body can automatically, synchronously and reversely move, then automatic falling and automatic falling pause of the medicine residues can be realized, and the packing efficiency of the medicine residues can be improved.

Owner:李春明

Automatic cocoon picking system, automatic cocoon picking machine and cocoon picking method

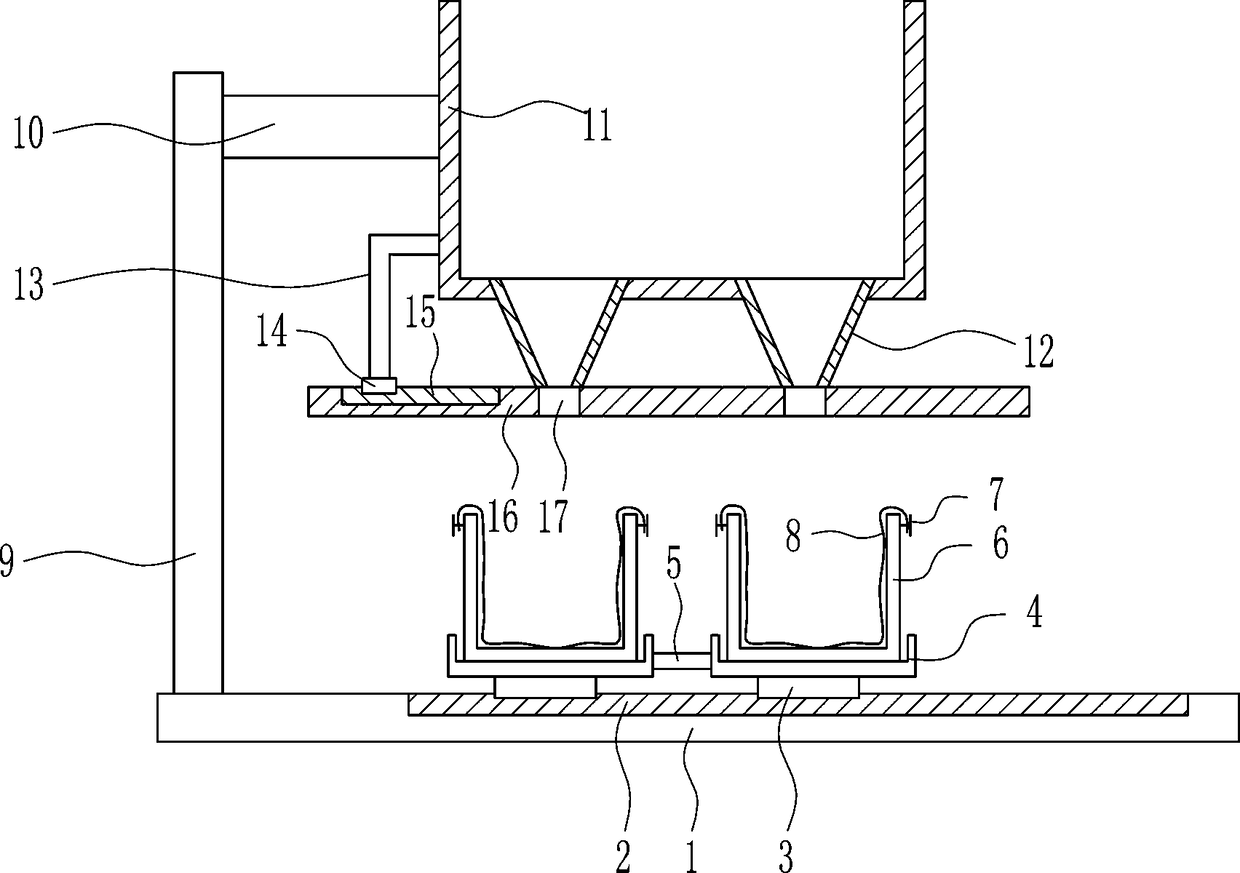

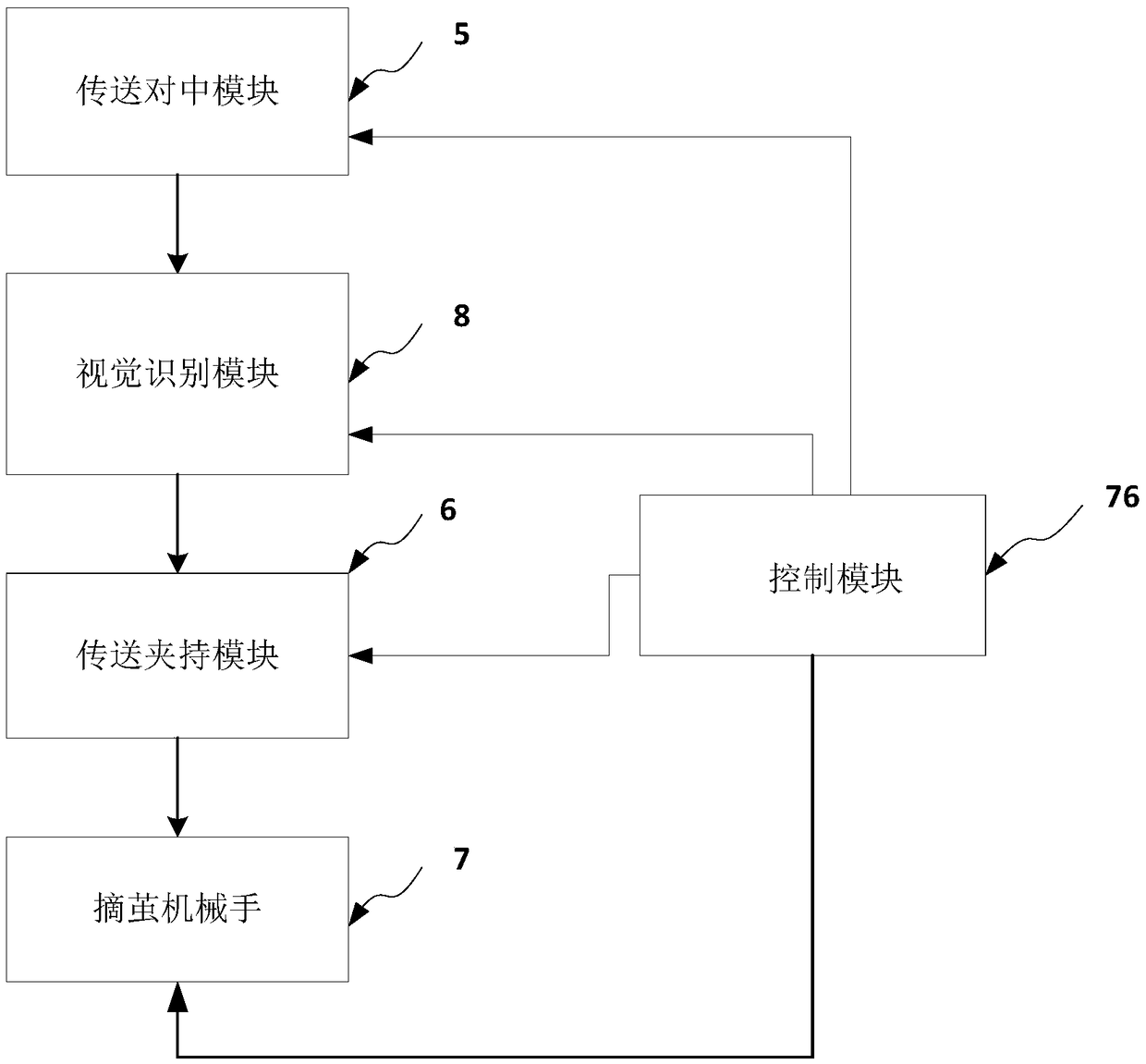

ActiveCN109035244AImprove cocoon picking efficiency and cocoon picking qualityImprove the quality of cocoon pickingImage enhancementImage analysisManipulatorVisual identification

The invention provides an automatic cocoon picking system, an automatic cocoon picking machine and a cocoon picking method. The method comprises a transfer centering module for detecting and transmitting a grid cluster; a visual identification module connected with the transfer centering module, collecting a grid cluster image transmitted by the transfer centering module, and identifying a cocoonand a grid cluster border frame; a transmission clamping module connected with the visual identification module, transmitting, detecting and clamping the grid cluster; a cocoon picking manipulator arranged on a conveying clamping module for picking cocoons from a grid cluster; a control module communicatively connecting and controlling the transfer centering module, the visual identification module, the transfer clamping module and the cocoon picking manipulator respectively. By adopting the technical scheme, the automatic cocoon picking of the grid cluster is realized, and the cocoon pickingefficiency and cocoon picking quality of the mulberry farmer in silkworm rearing based on the grid cluster are improved.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG

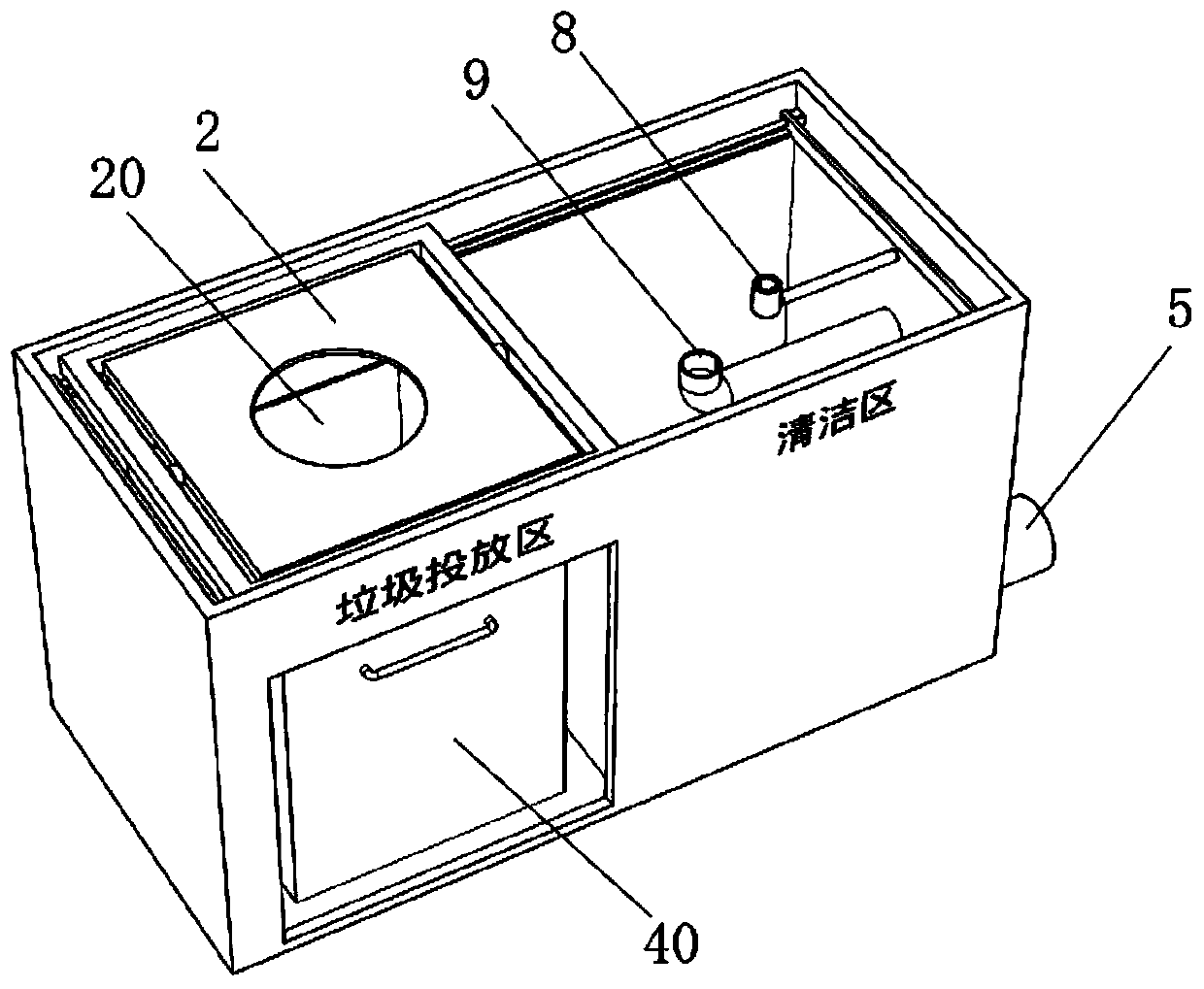

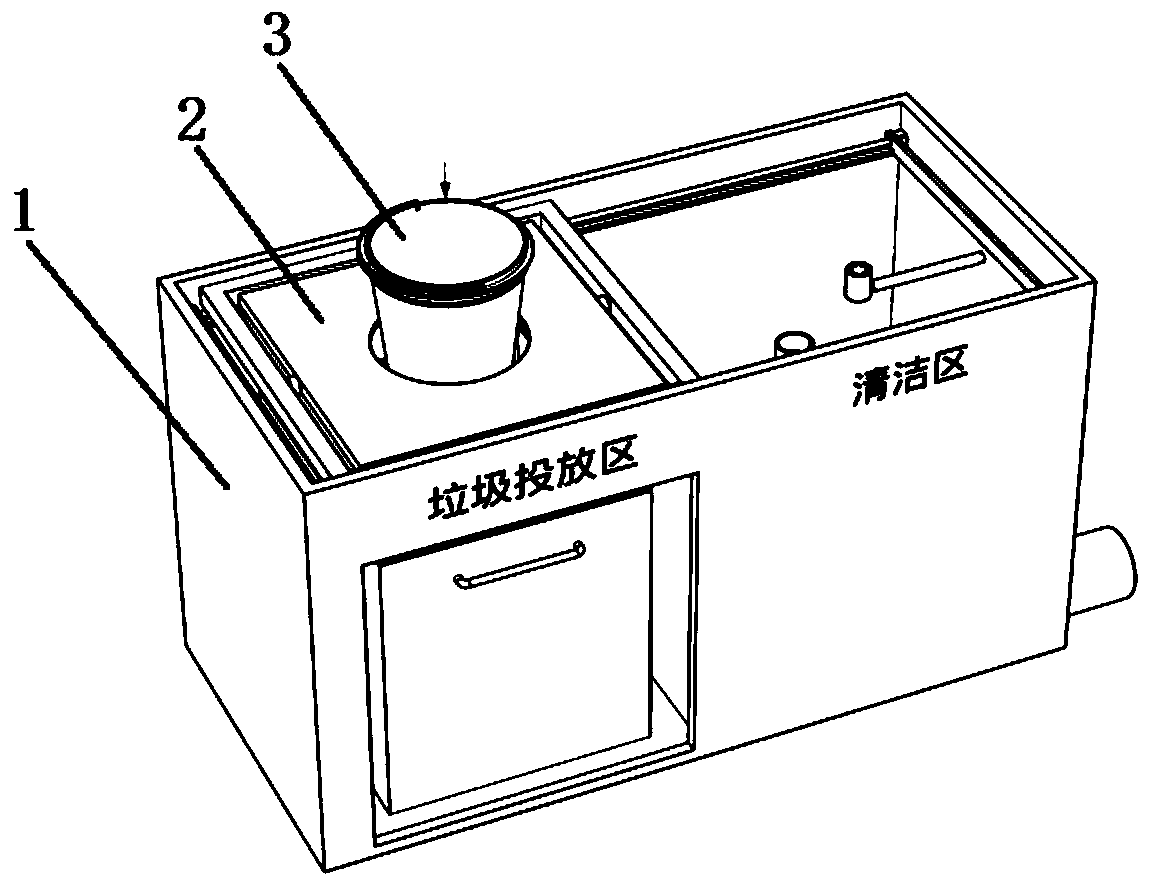

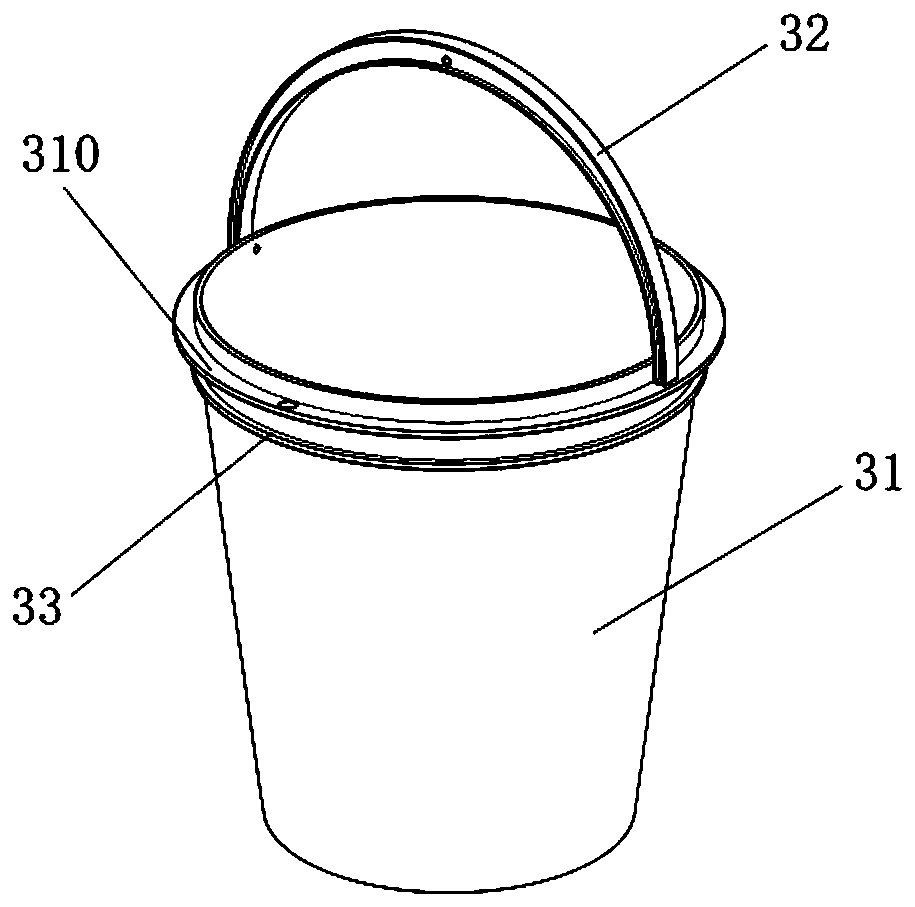

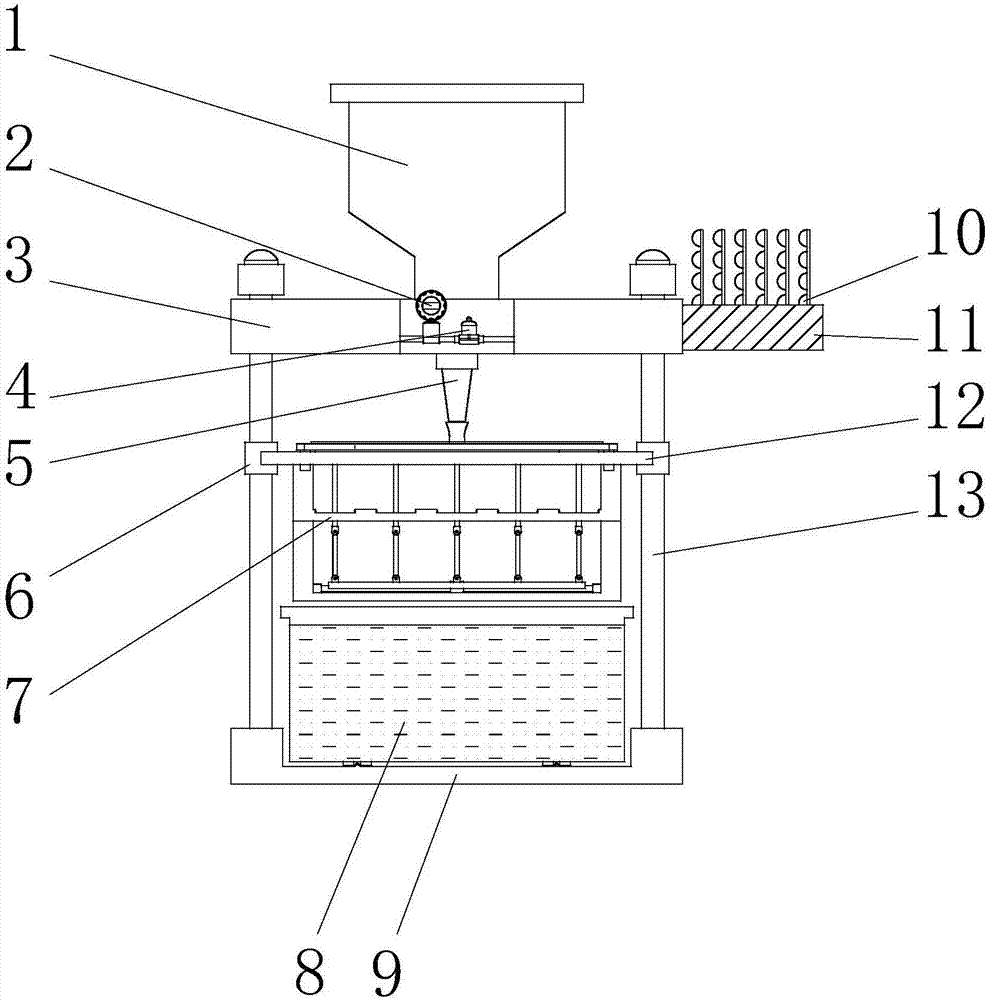

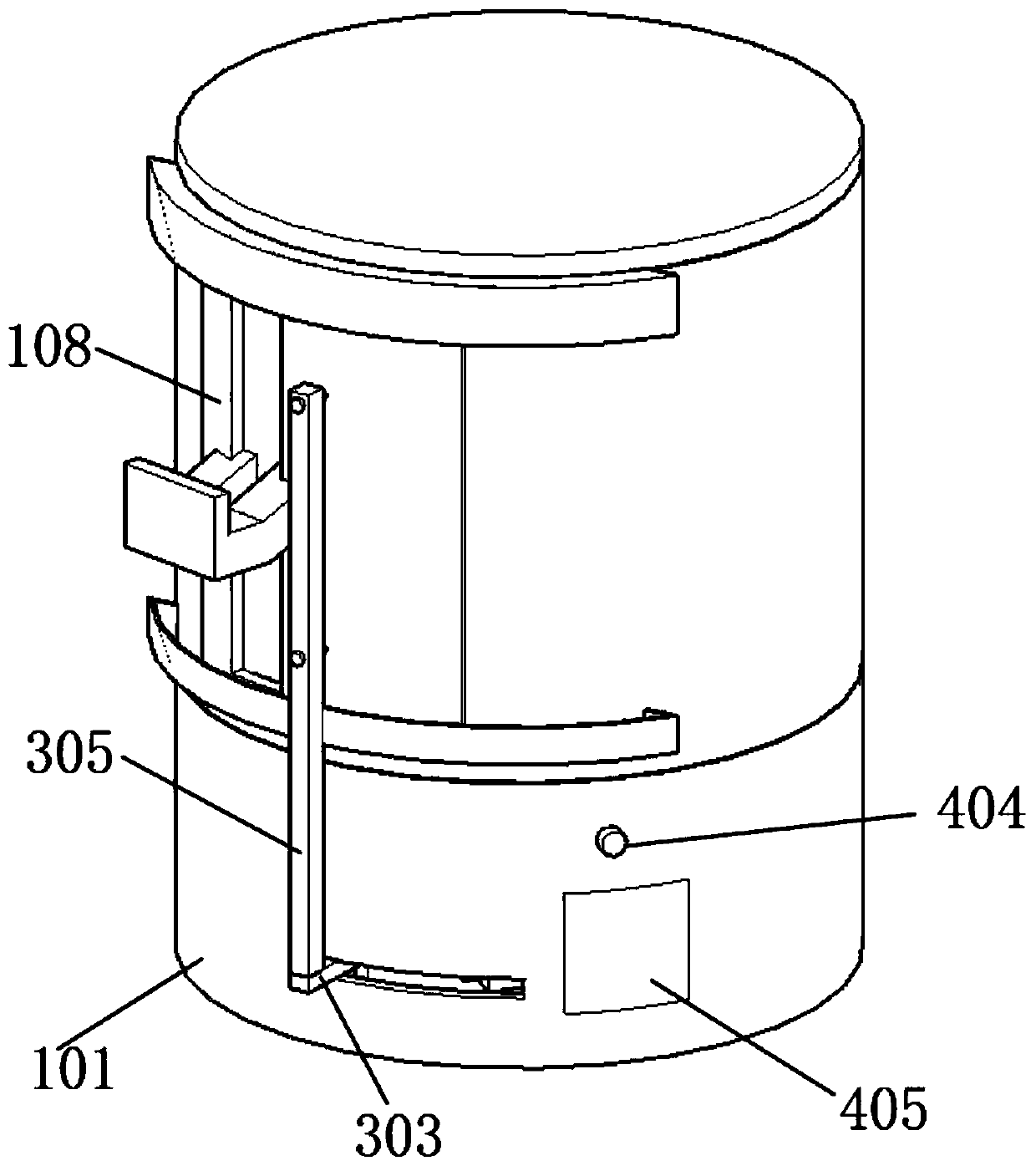

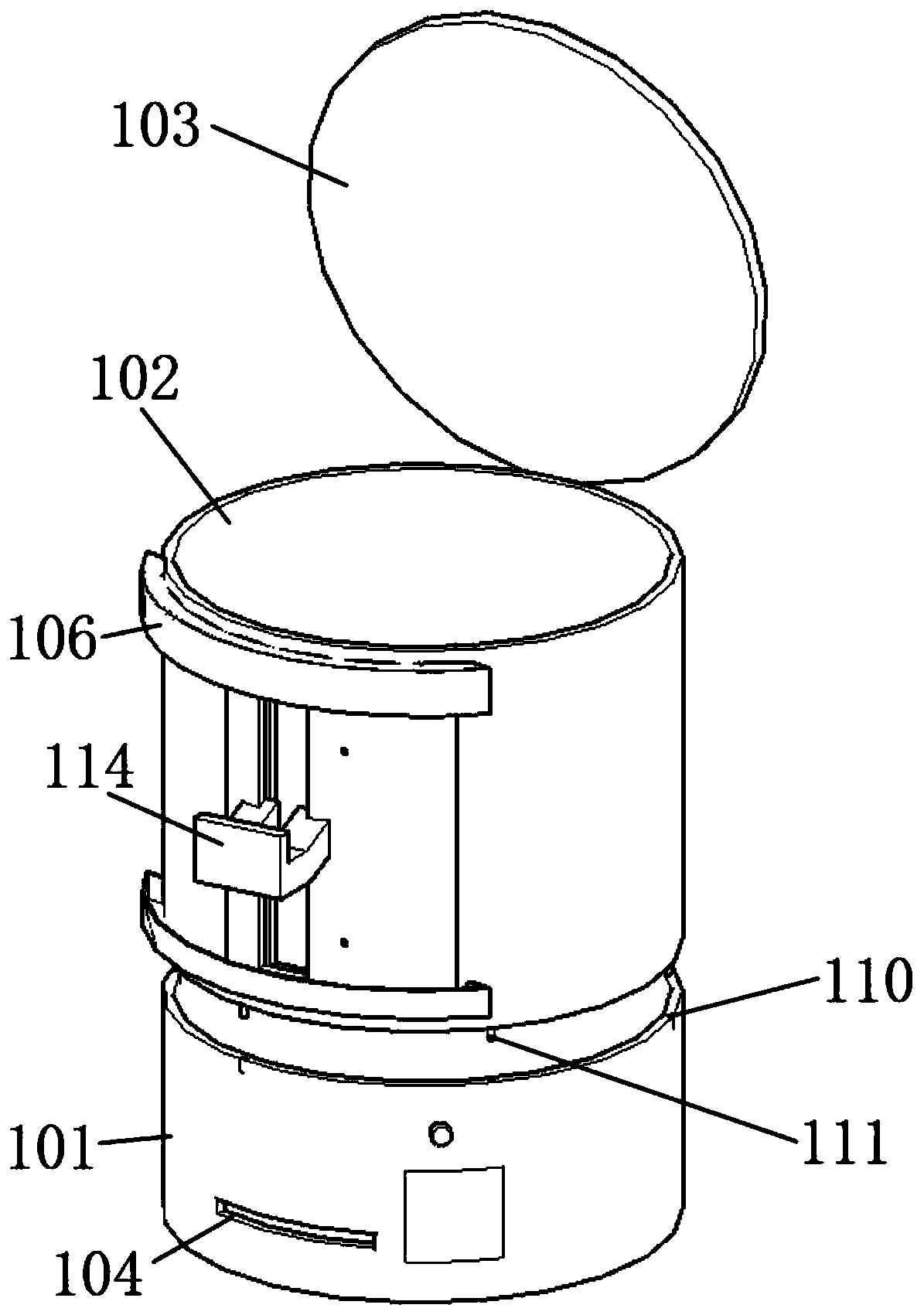

Kitchen garbage can capable of realizing automatic garbage can dumping and cleaning

ActiveCN111003388AAutomatic dumpingRealize automatic dropRefuse receptaclesRefuse cleaningProcess engineeringMechanical engineering

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Forming die for toys

The invention relates to the field of dies for toys, particularly to a forming die for toys. The forming die is mainly used for making the toys with planar bottoms, and comprises a die lifting rack, and a fixed plate is installed above the die lifting rack, and used for installing a storage tank; the front end of the fixed plate is provided with a flowmeter and a solenoid valve, and the storage tank is installed above the fixed plate; a discharge port is formed at the part below the fixed plate, and a die fixture is installed in the middle of the die lifting rack, and used for installing and externally connecting the die; the die fixture is connected to the die lifting rack through a sliding sleeve used for moving the die fixture easily, and the sliding sleeve is installed on the die lifting rack. According to the forming die for the toys, provided by the invention, the problems that the toy casting molding is slow, the toys are uneasy to carry, the models are less, the operation is inconvenient, and different kinds of flat toys can not be manufactured simultaneously in the prior art are solved.

Owner:汕头市裕晟塑胶实业有限公司

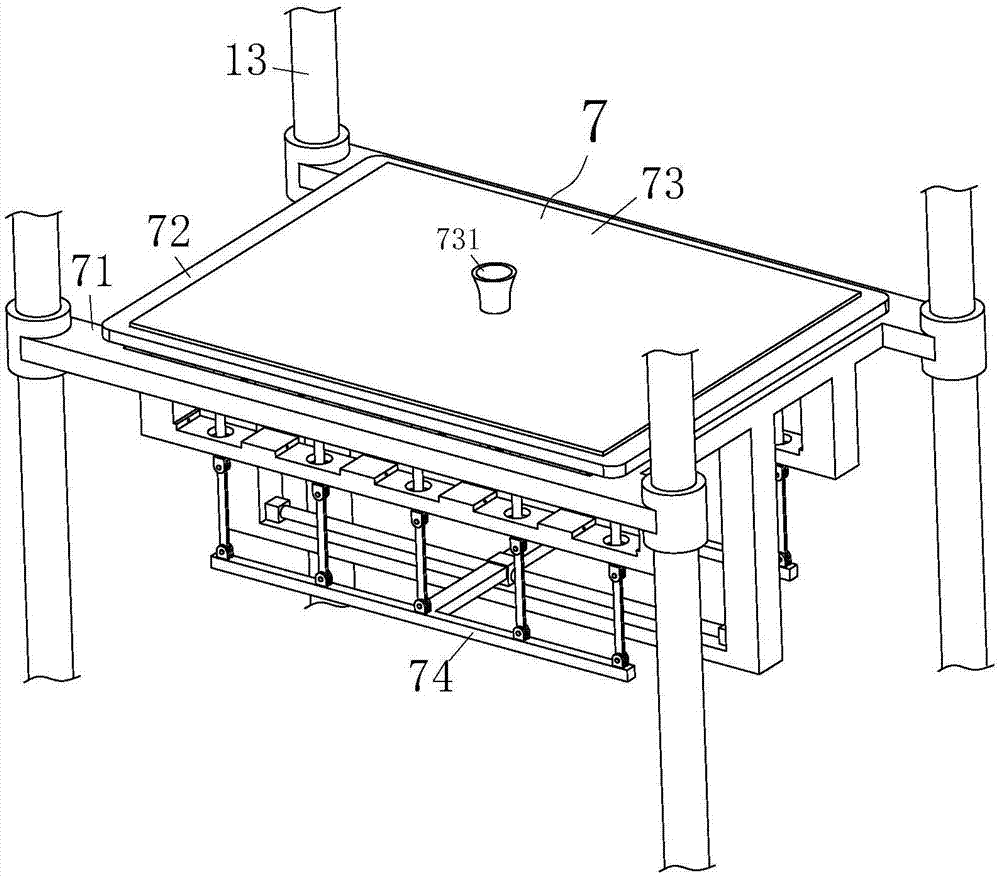

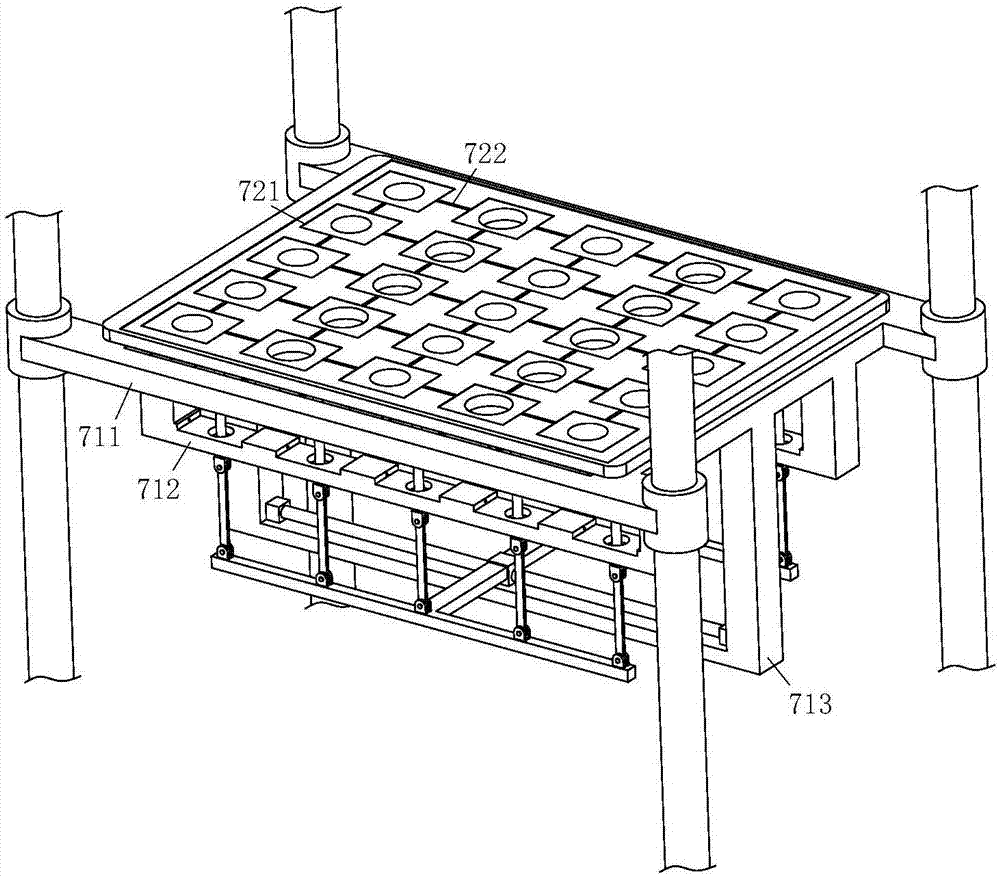

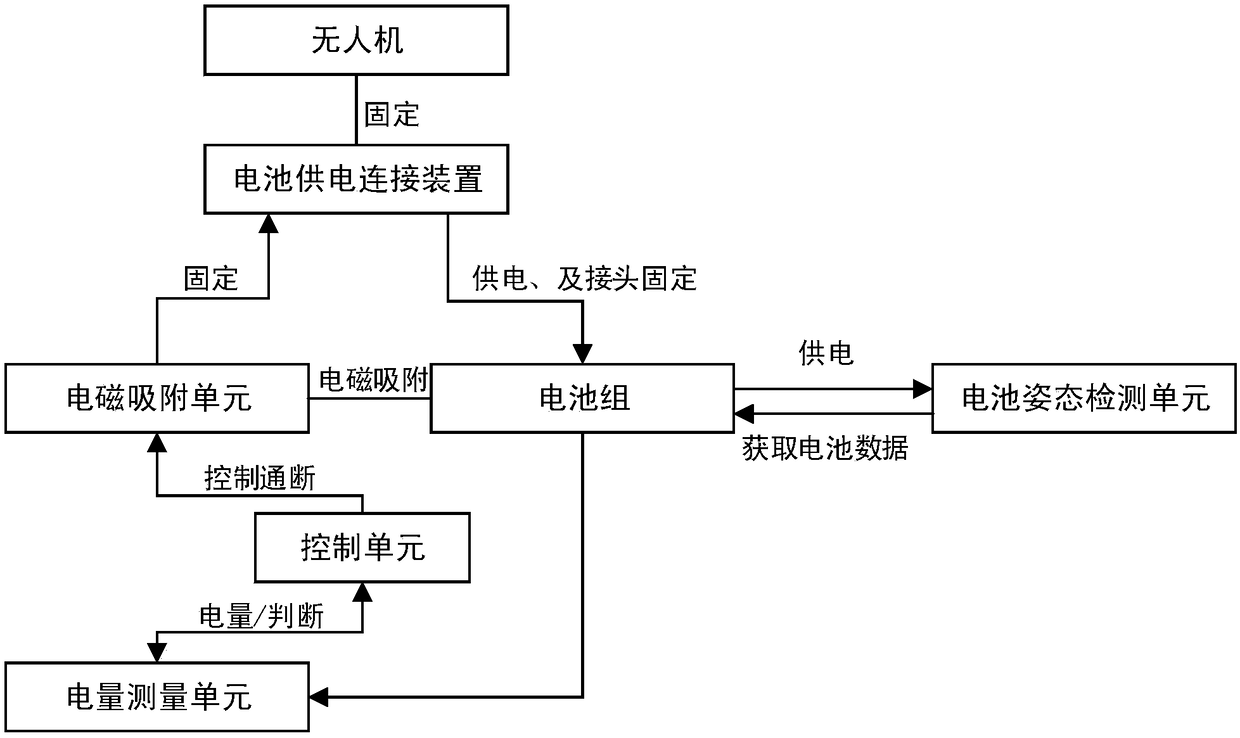

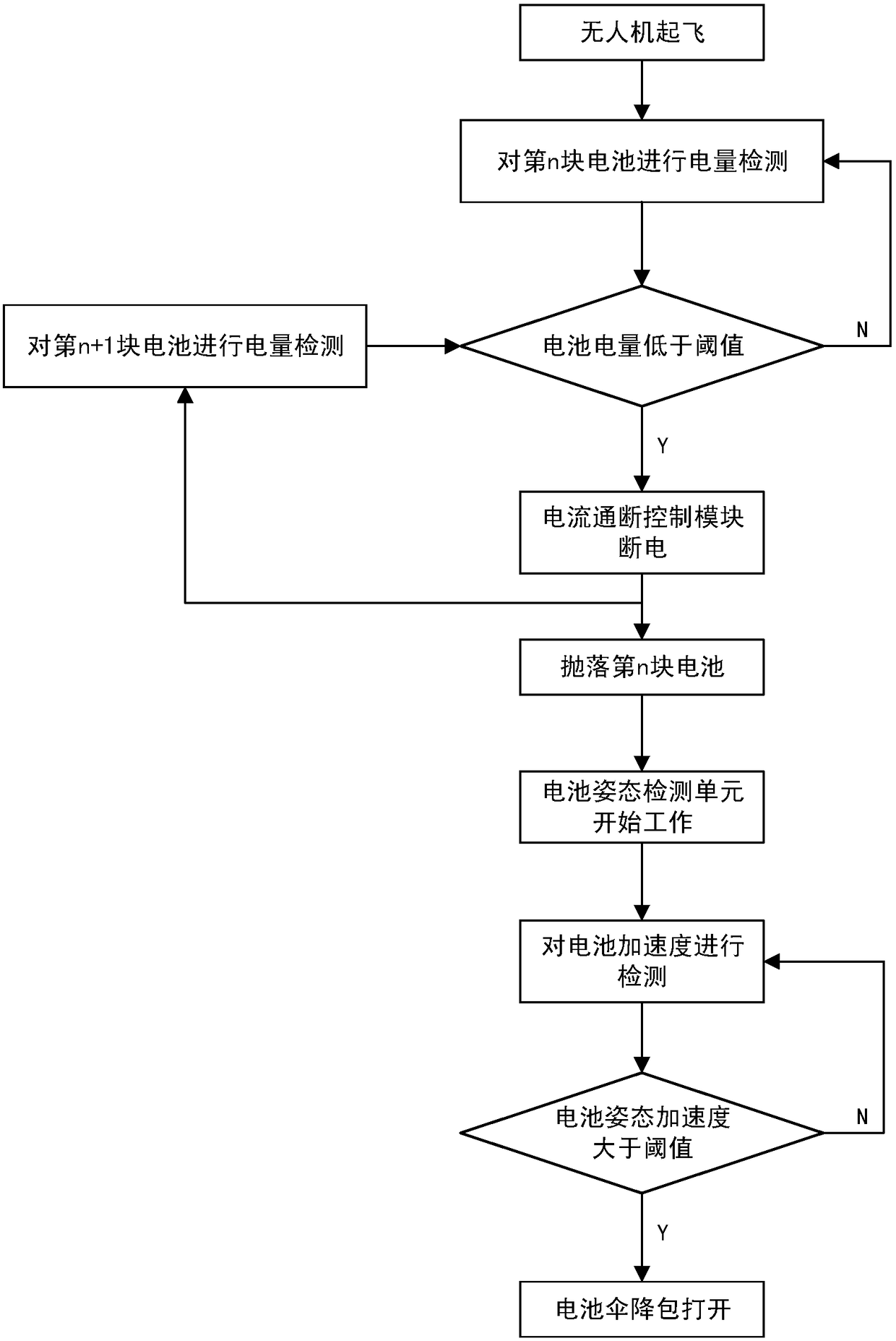

UAV intelligent battery dropping control system

ActiveCN108287496AEasy to findRealize fixed adsorptionProgramme controlComputer controlElectrical batteryEngineering

A UAV intelligent battery dropping control system carries a plurality of batteries in parallel to successively supply power to a UAV one by one, wherein a battery interface is screwed to a power supply connection device through a slip ring; the batteries are attracted to a battery fixing frame by a battery attraction unit; a power measuring unit monitors the power of the batteries; an enable control unit performs short-circuit control on an electromagnetic attraction device, and then automatically drops the batteries and a power supply line connector; when a battery attitude detecting unit detects that the battery falling acceleration is greater than a set threshold by an attitude module, an parachute is opened so that the batteries slowly descend in virtue of the parachute; a positioningmodule transmits the GPS / BD data back to the ground through a transmitter, facilitating the recycle of the dropped batteries.

Owner:中国航天系统科学与工程研究院

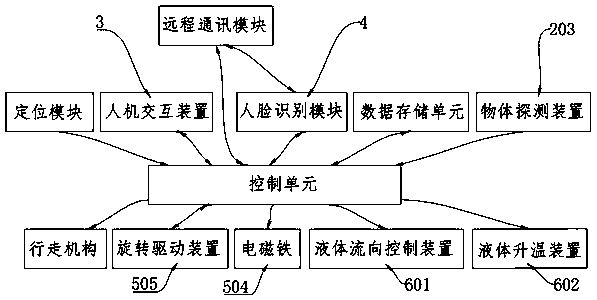

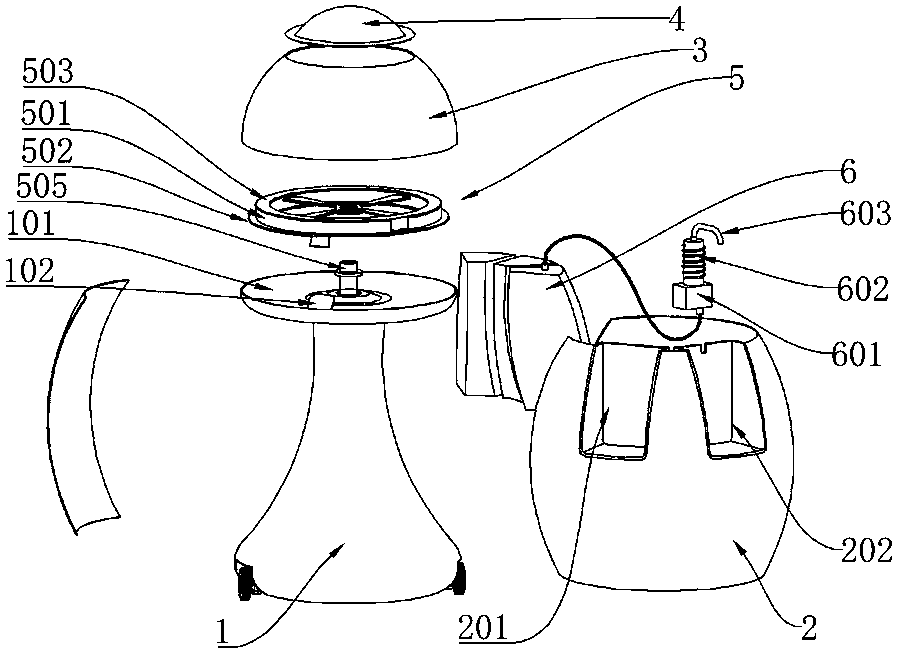

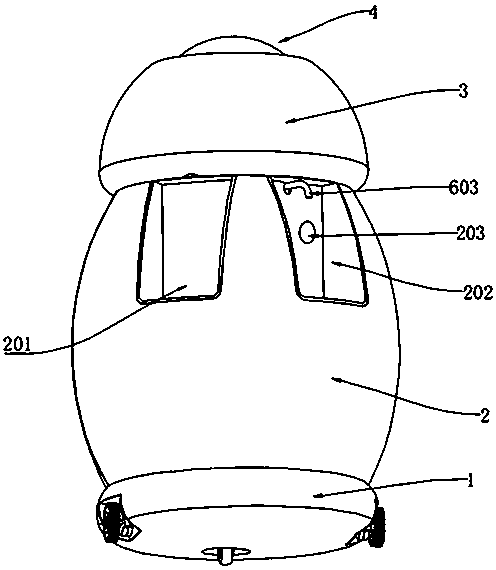

Intelligent medicine supply robot for old men and medicine supply method

PendingCN111113453AImprove drug supply capacityAvoid mistakesManipulatorInteraction deviceMedication taking

The invention relates to the technical field of pension robots, in particular to an intelligent medicine supply robot for the old men and a medicine supply method. A man-machine interaction device, ahuman face recognition module, a positioning module, a medicine storage mechanism, a control unit, a remote communication module, a data storage unit, a walking mechanism arranged at the bottom of thebody and the like are arranged in a walking robot body. The purpose of automatically providing needed medicines for the old men is achieved, the remote communication module is used for providing different medicines for different medicine taken old men or medicine taken old men in different illness states, the purpose of providing medicines emergently for the unattended medicine taken old men is achieved, and work of the medicine supply robot is higher in efficiency and more accurate.

Owner:燕京理工学院

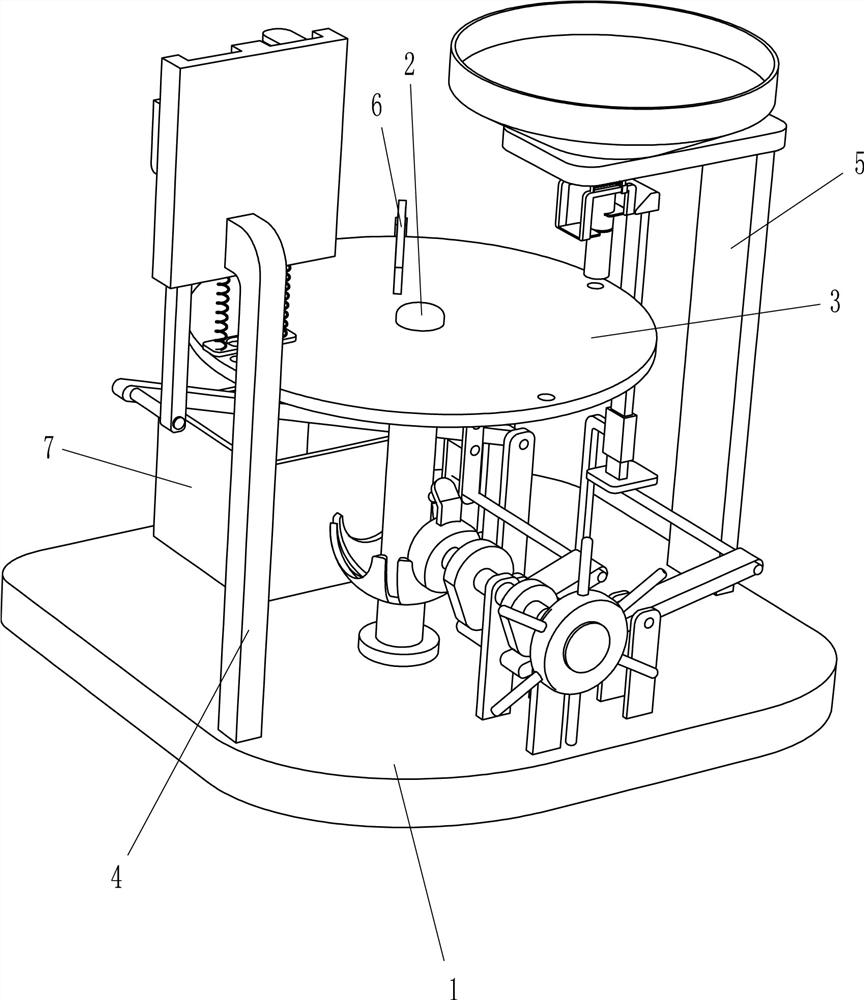

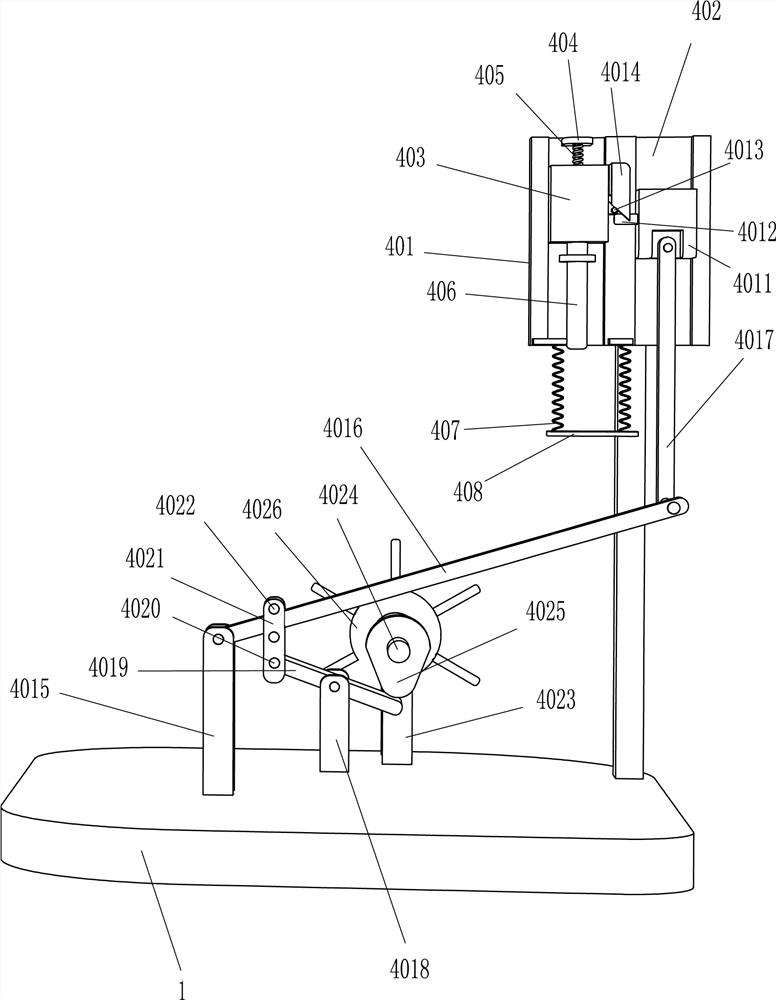

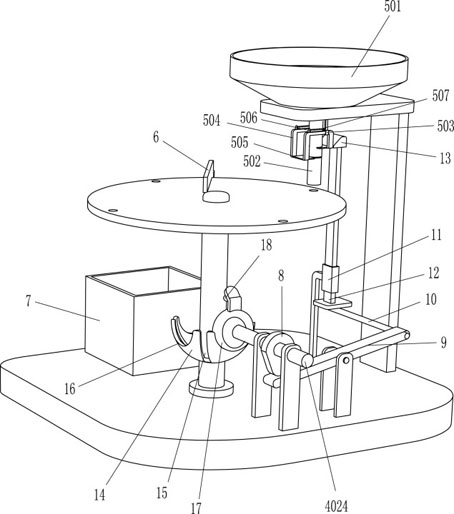

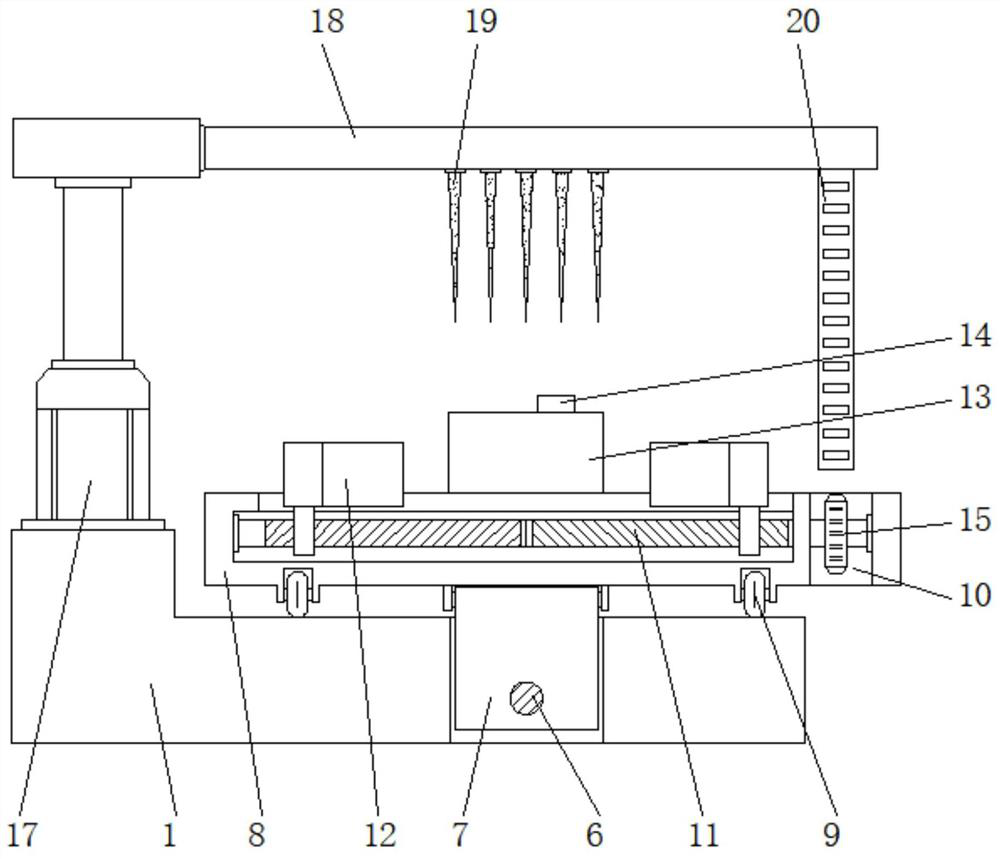

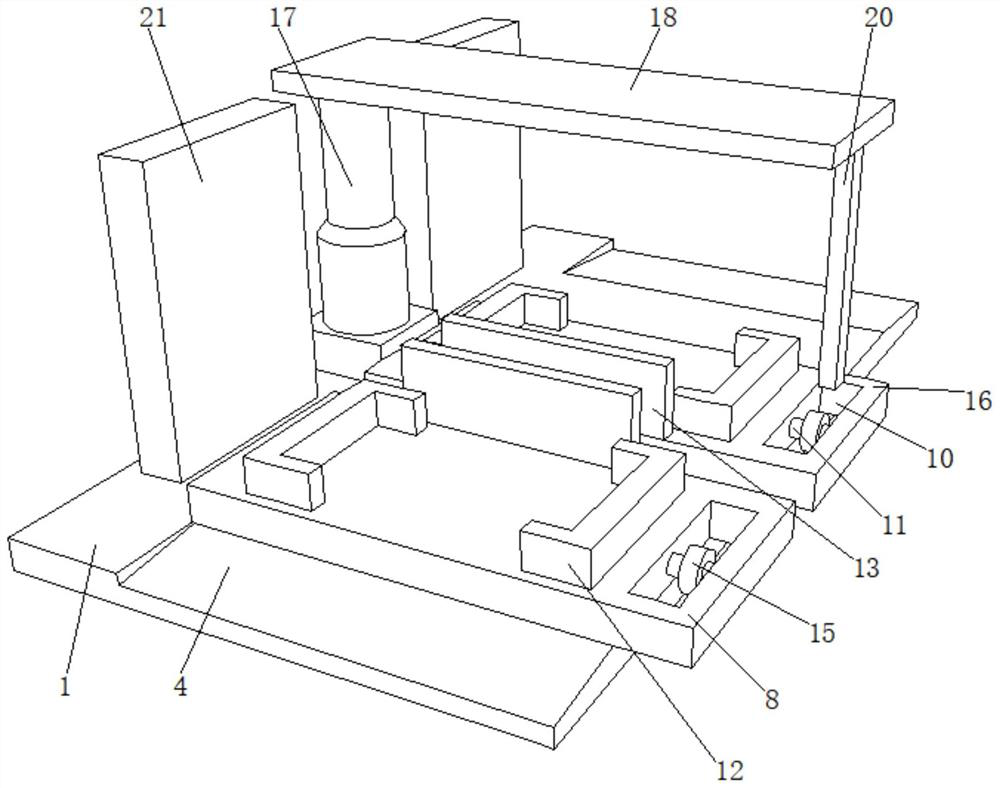

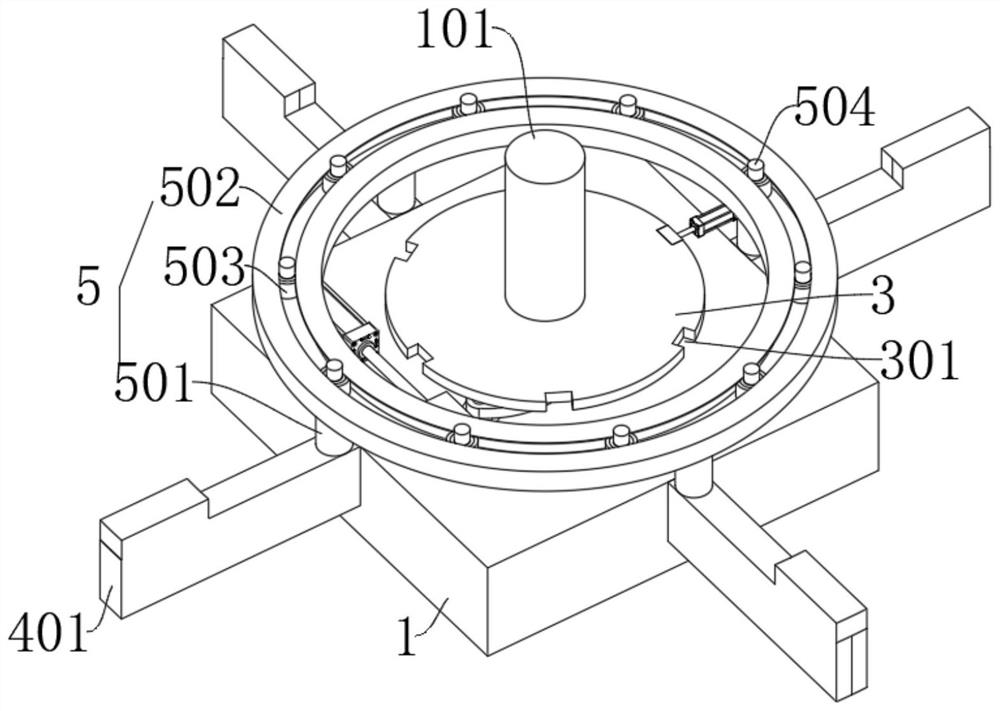

Rapid almond-hulling equipment

InactiveCN111685339AImprove shelling efficiencyEasy to removeHuskingHullingAgricultural engineeringCam

The invention relates to hulling equipment, and particularly relates to rapid almond-hulling equipment. The invention aims at providing the almond-hulling equipment having the advantages that almondscan be automatically loaded, the hulling efficiency can be improved, and meanwhile, the integrity of the almonds can be guaranteed. The technical scheme of the invention is follows: the almond-hullingequipment comprises a base and a knocking mechanism, wherein a first rotating shaft is rotatably arranged at the side part of the base, a rotating disc is mounted at the top of the first rotating shaft, and at least four round holes for placing the almonds are uniformly formed in the rotating disc; and the knocking mechanism is arranged on the base. By utilizing the knocking mechanism, the almonds can be knocked, and almond hulls can be rapidly removed, so that the hulling efficiency of the almonds is improved; by utilizing a blanking mechanism, the almonds can intermittently fall to the rotating disc and do not need to be manually placed on the rotating disc; and by utilizing a second cam and a second wedge-shaped block, the almonds can automatically fall down during rotation of a hand wheel, and a first baffle does not need to be manually moved.

Owner:黄应辉

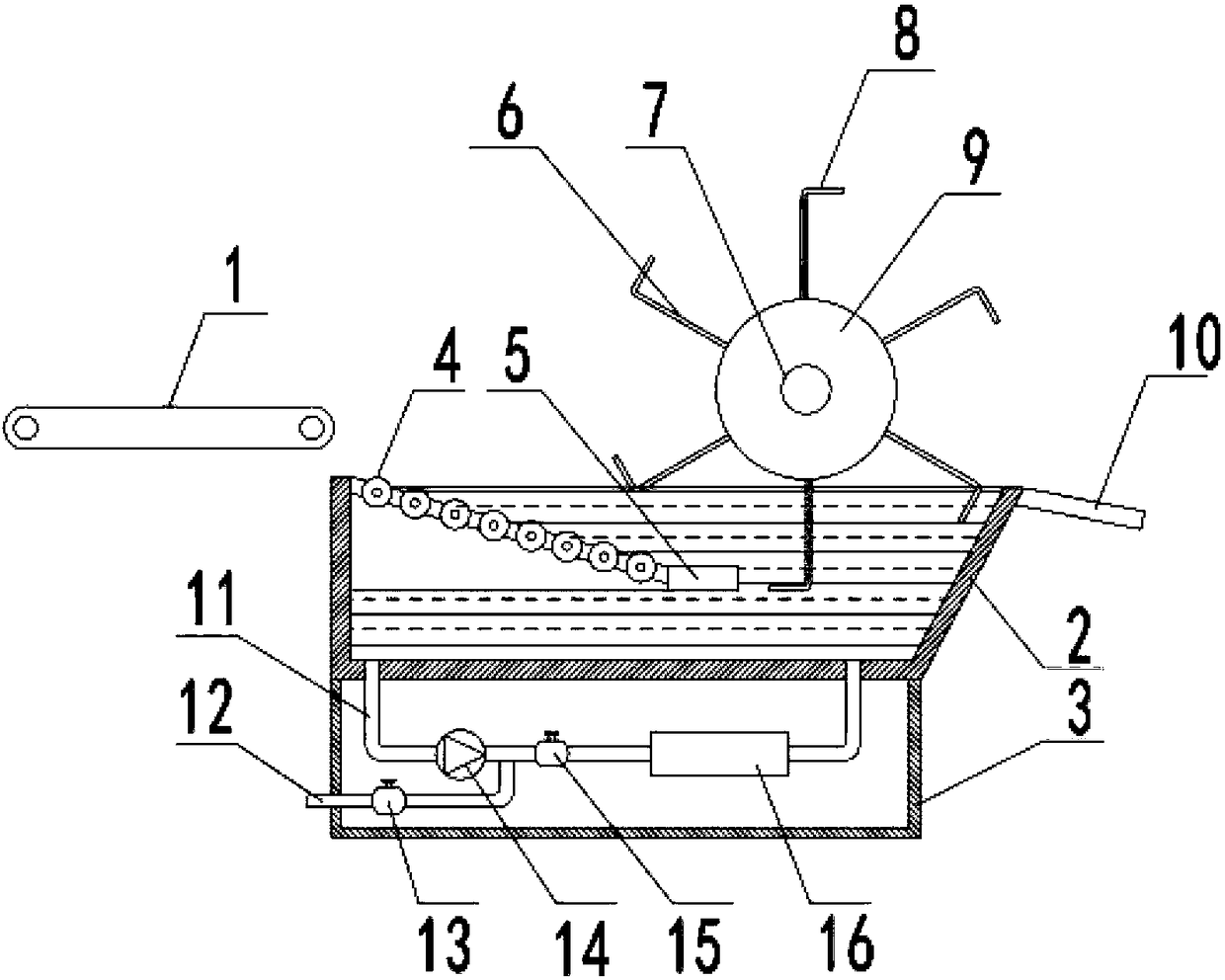

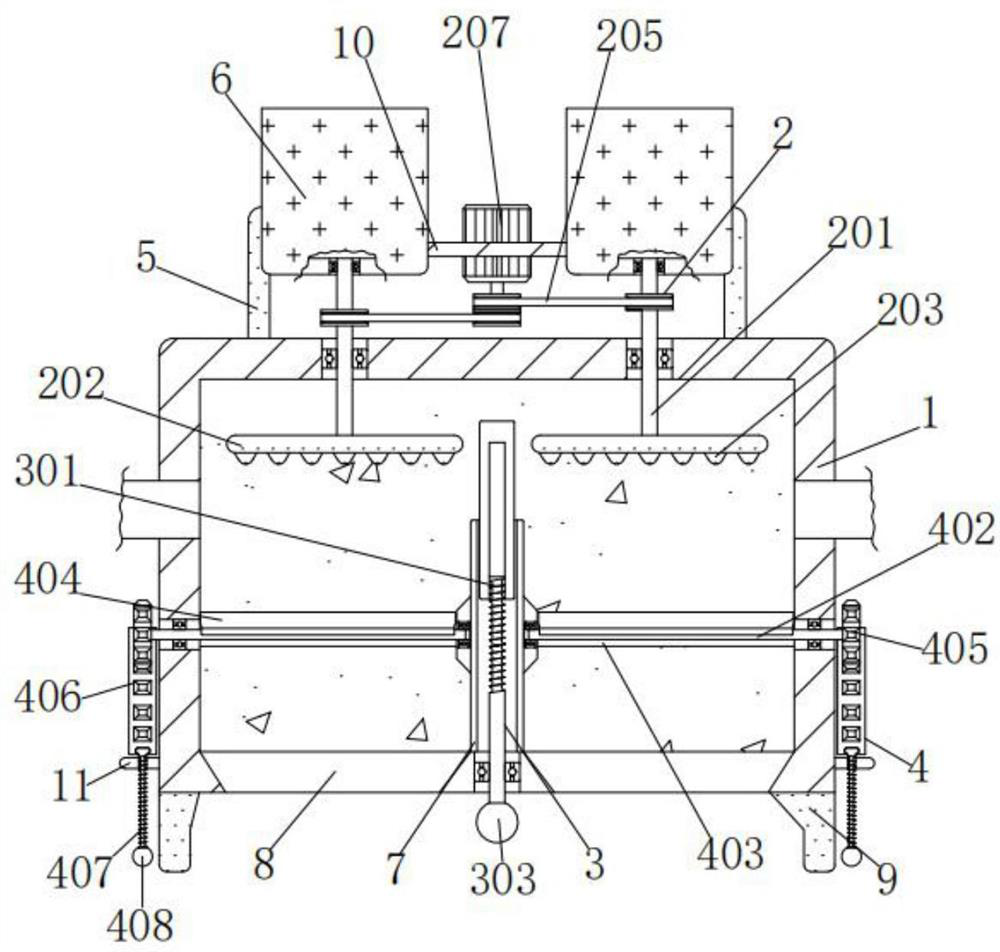

Automatic quenching device of hardware metal parts

InactiveCN108588363ARealize automatic dropIncrease productivityQuenching devicesConveyor beltQuenching

The invention discloses an automatic quenching device of hardware metal parts. The automatic quenching device comprises a feeding conveyor belt, a quenching tank, a base, a switching mechanism, material carrying plates and a discharging plate, wherein a feeding conveying belt used for feeding is arranged at one side of the quenching tank, a sliding roller way which is obliquely arranged is arranged in the quenching tank, the position of the highest point of the sliding roller way corresponds to the end of the feeding conveying belt, the switching mechanism is connected to the position of the bottom end of the sliding roller way, the sliding roller way and the switching mechanism are arranged below liquid level in the quenching tank, a rotating shaft is further installed at the position above the quenching tank, a rotating cylinder is fixed outside the rotating shaft, and the plurality of material carrying plates are uniformly fixed on the outer circumference of the rotating cylinder. The automatic quenching device has the beneficial effects that the sliding roller way, the switching mechanism and the material carrying plates are arranged, so that automatic falling, transferring, quenching and discharging actions of metal parts can be realized, the manual participation is basically not needed, the production efficiency is greatly improved, the overall structure is relatively simple, and the operation is convenient.

Owner:李冰雪

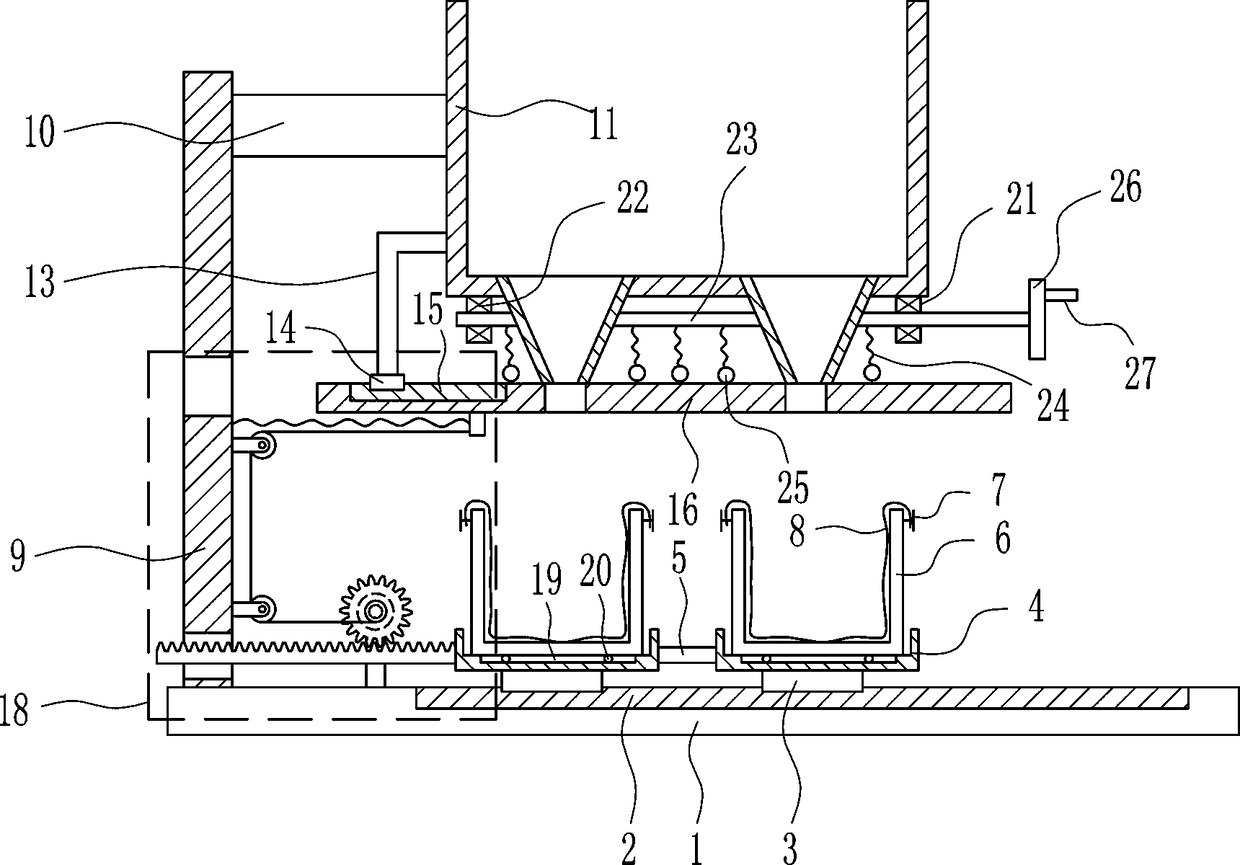

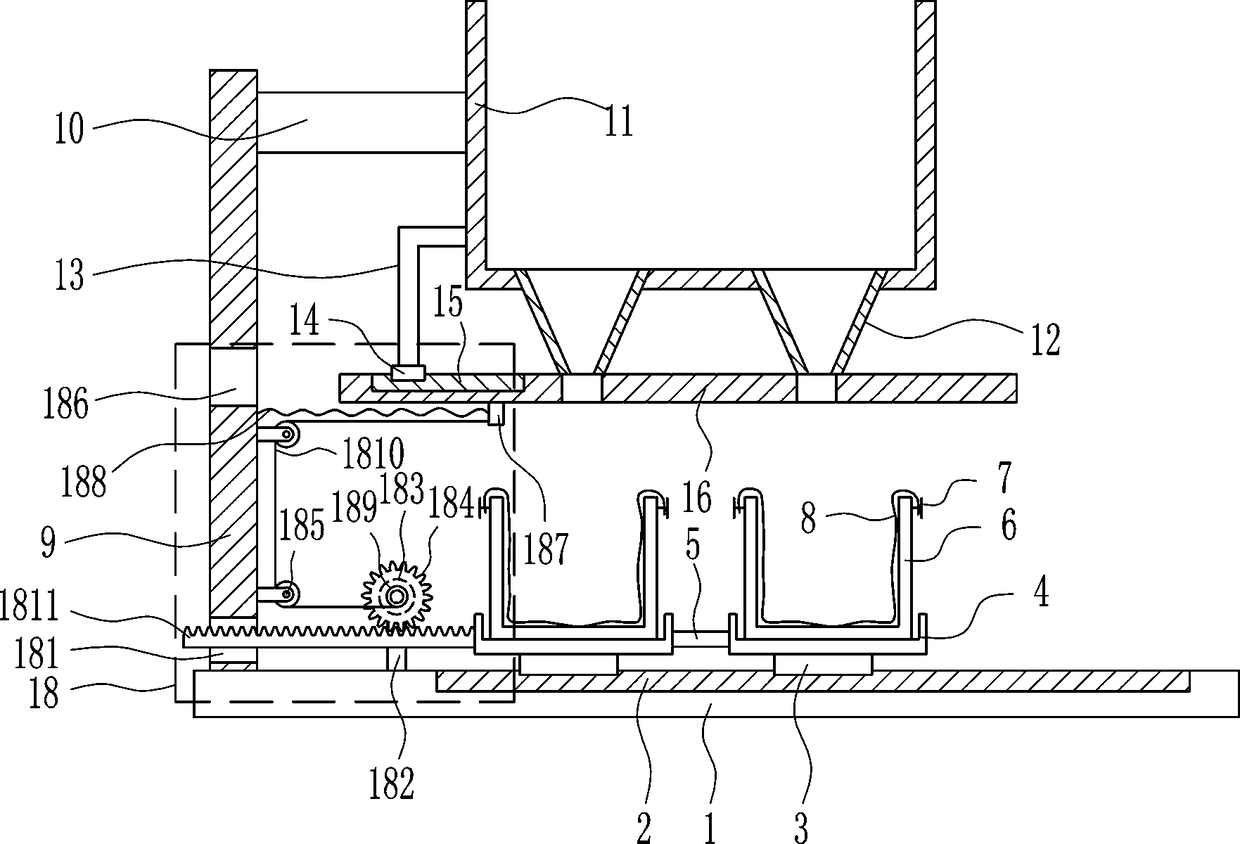

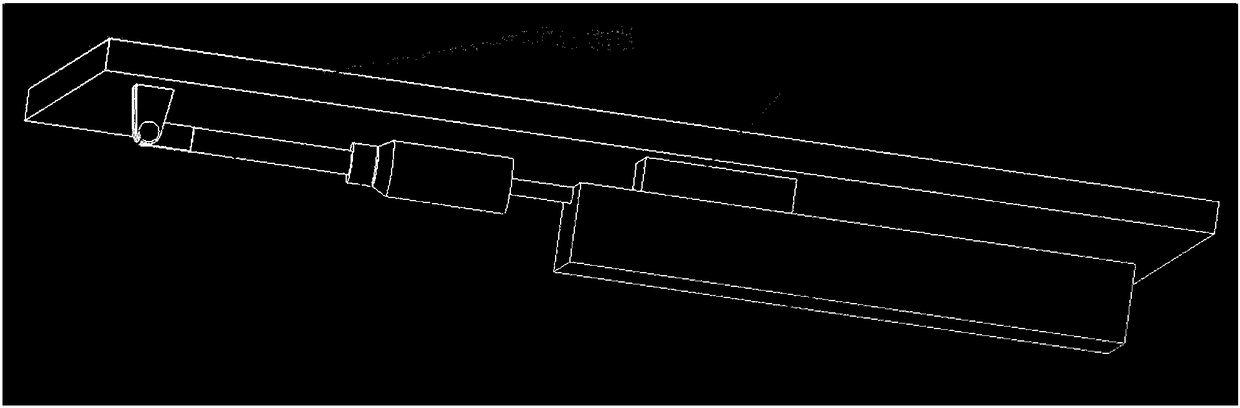

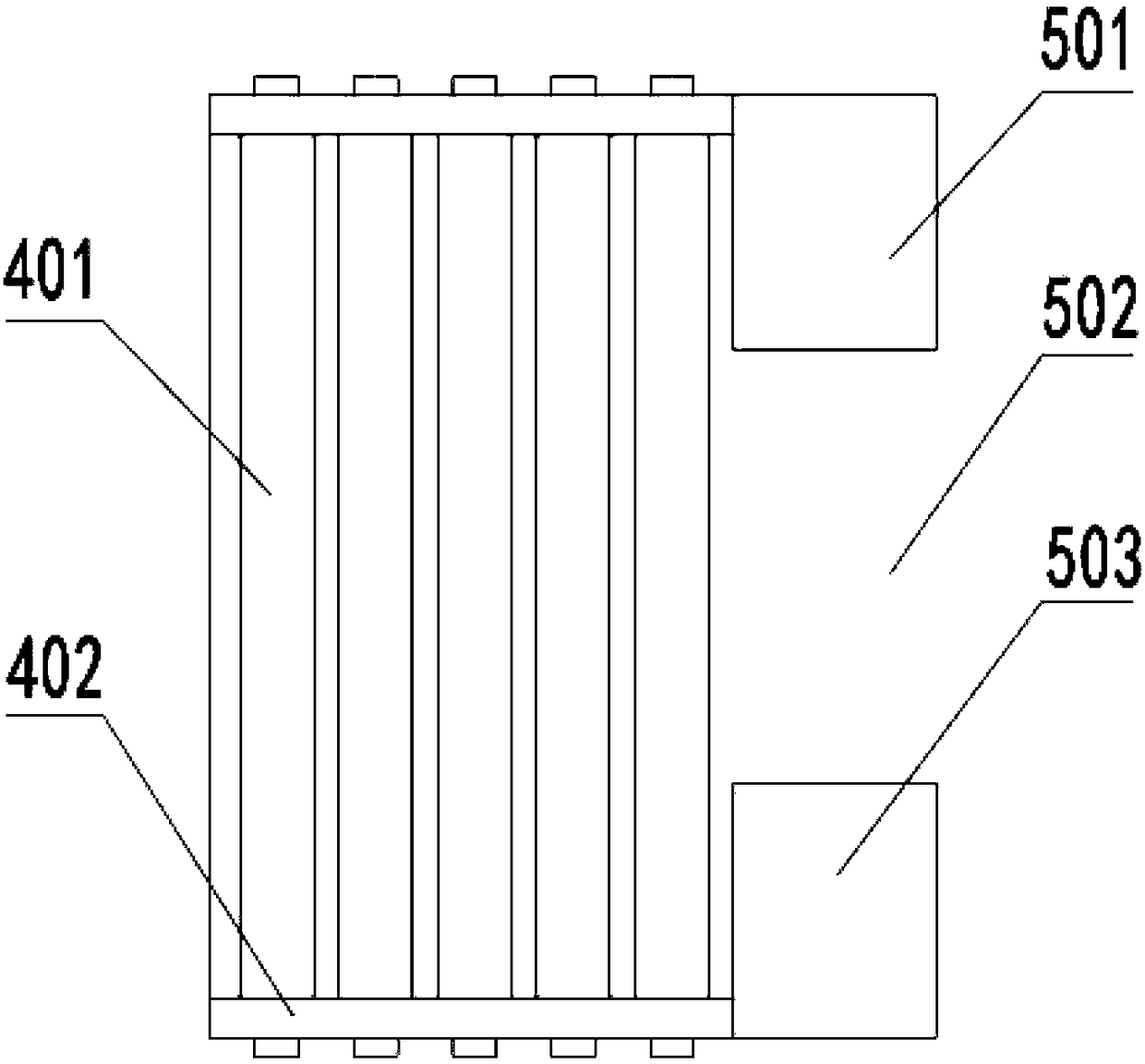

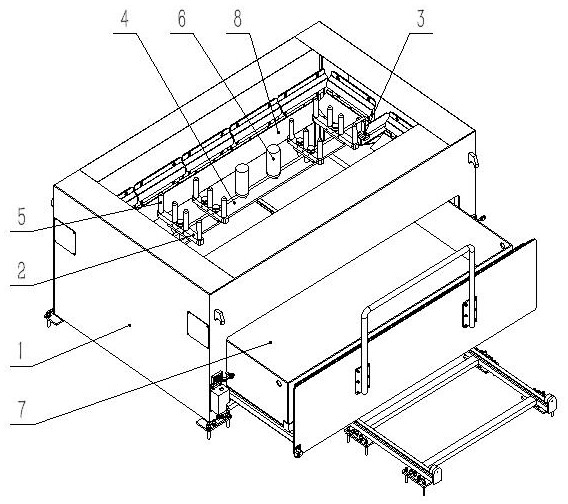

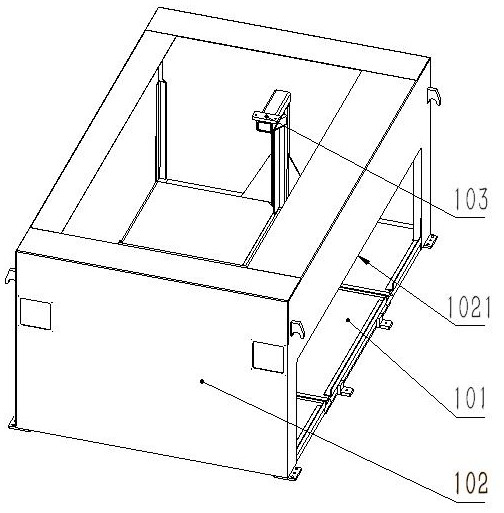

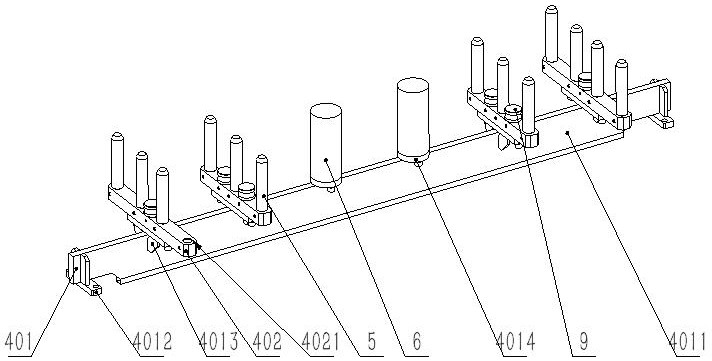

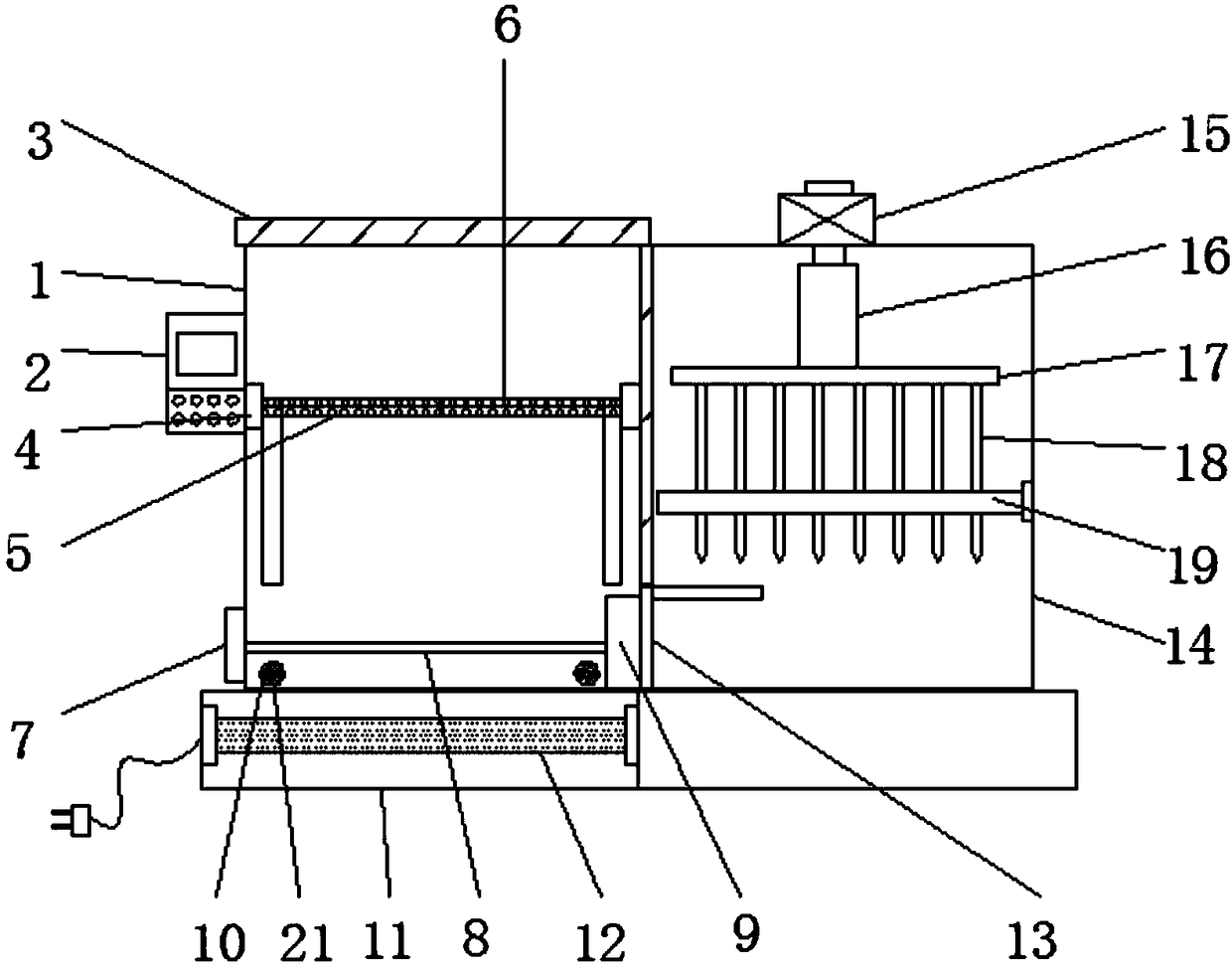

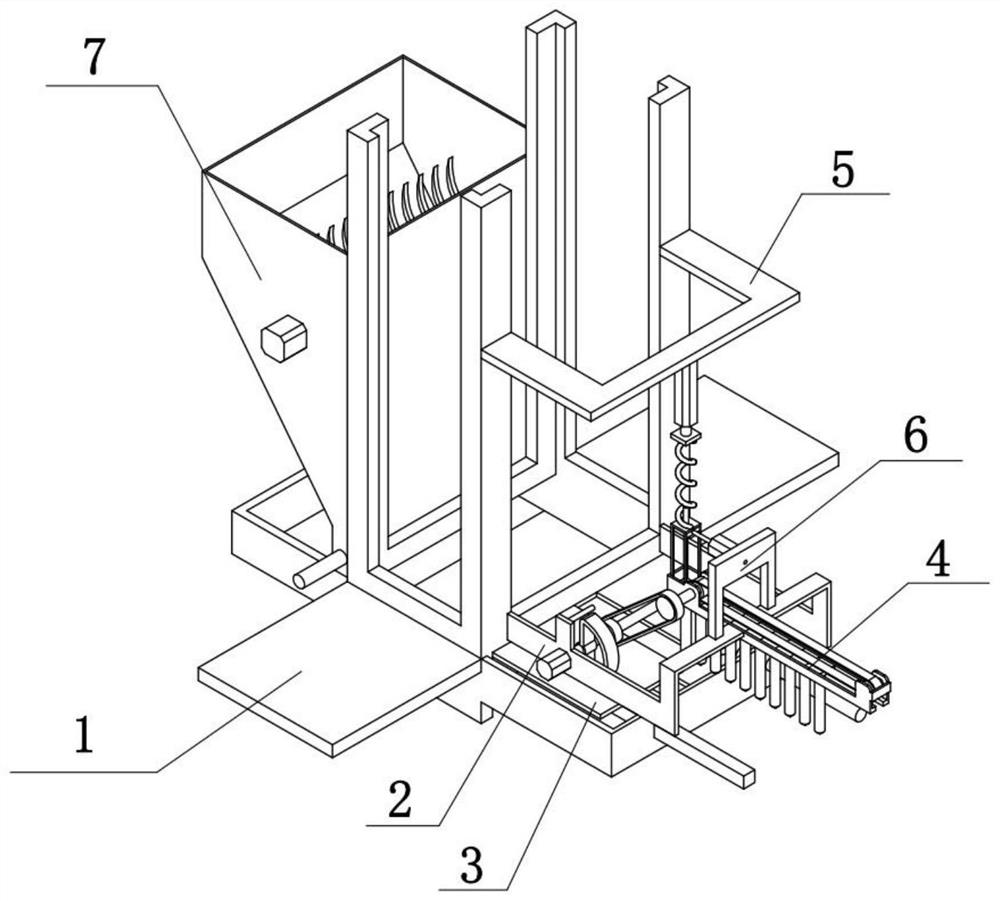

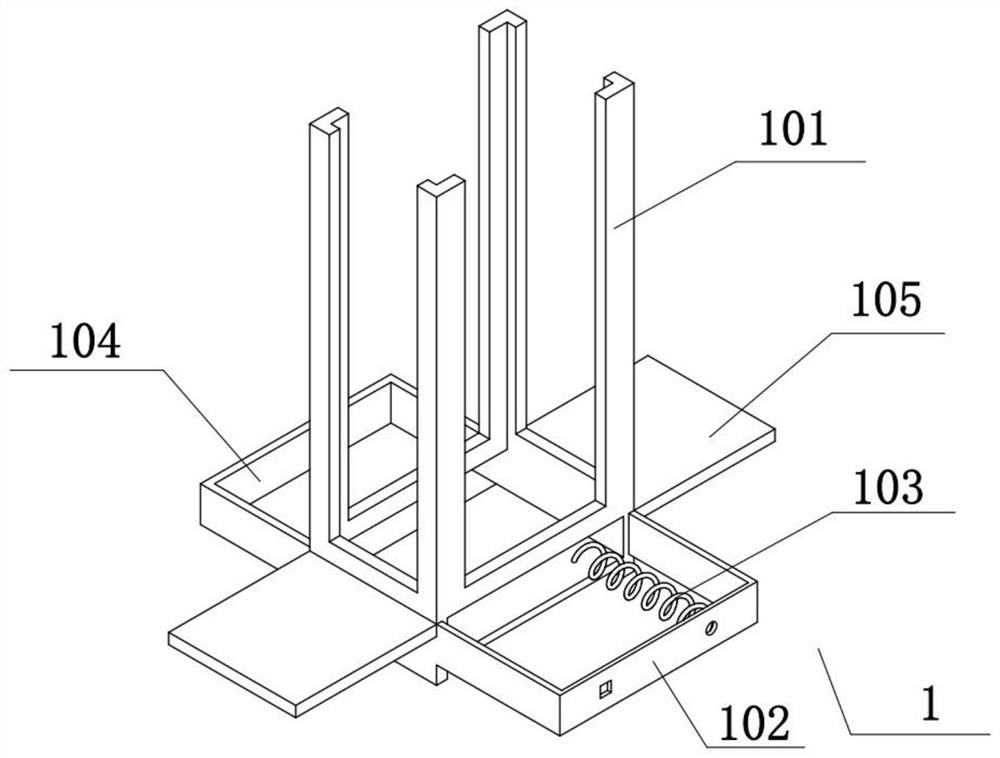

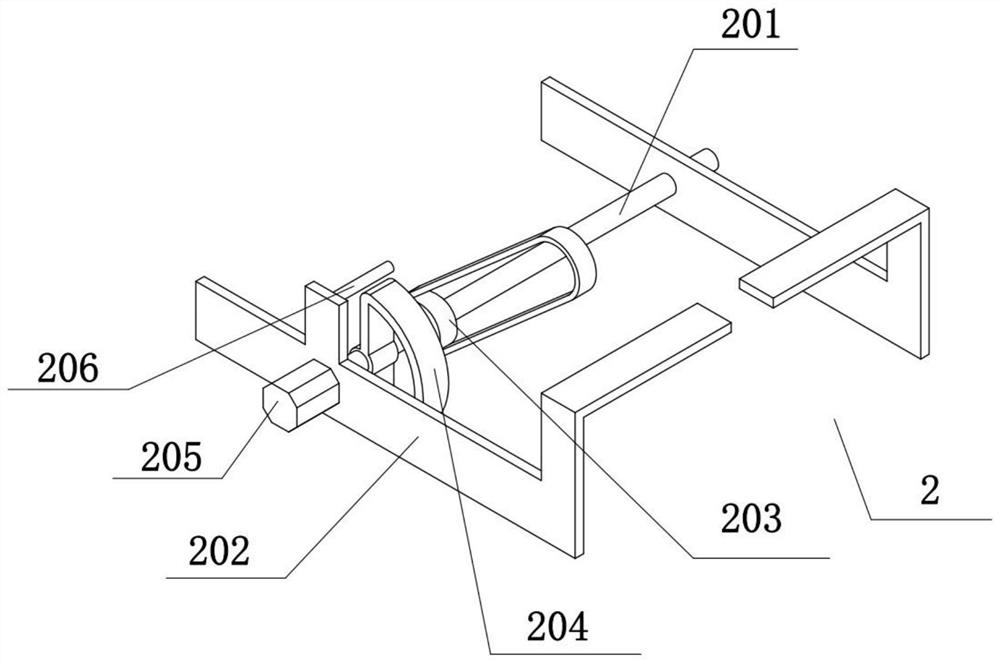

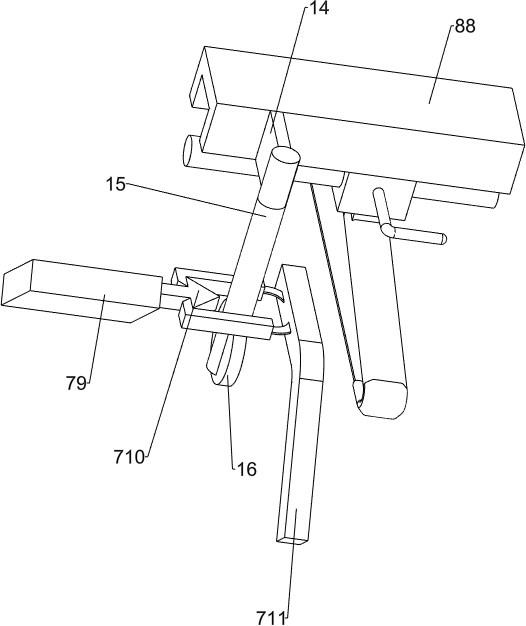

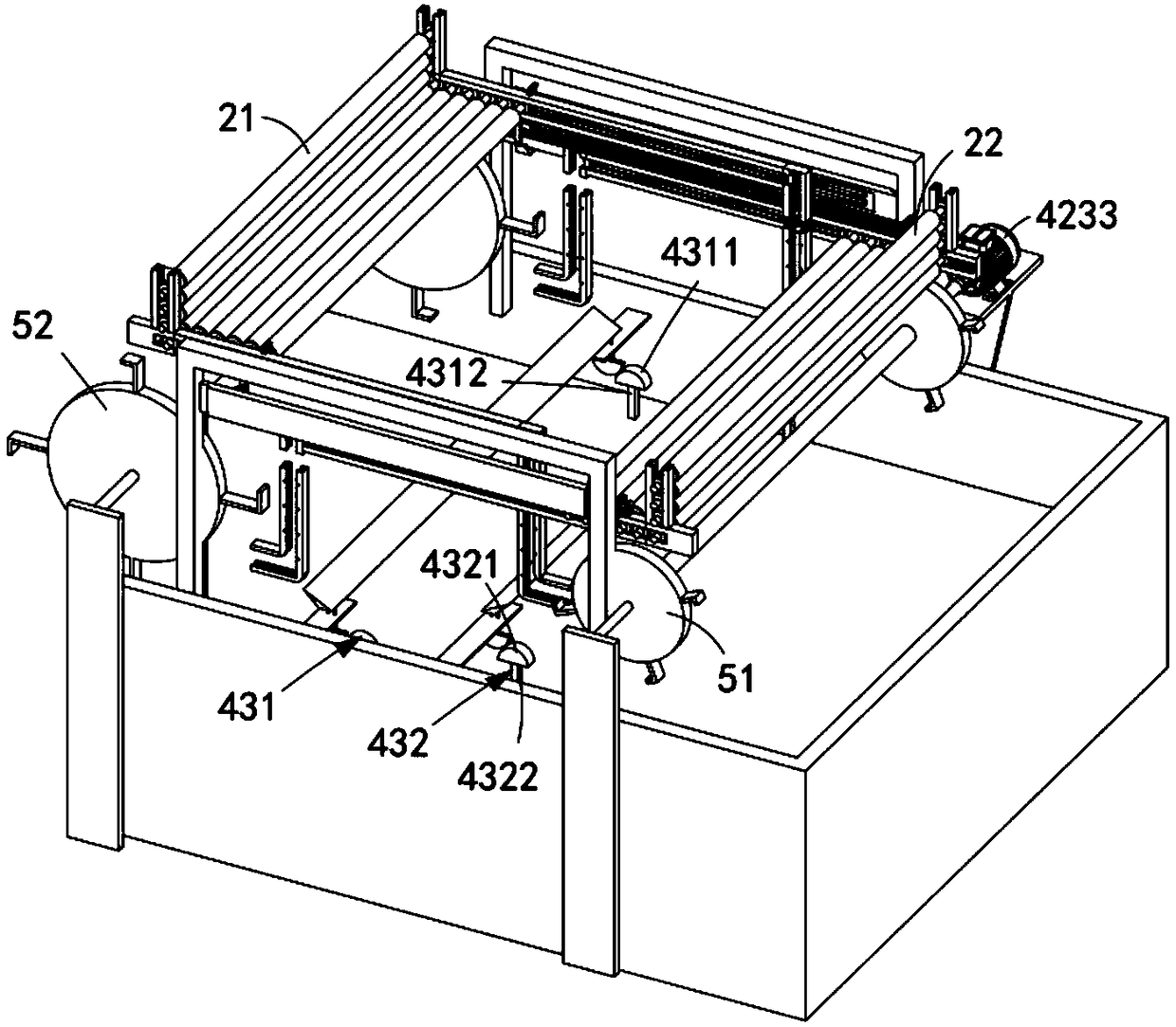

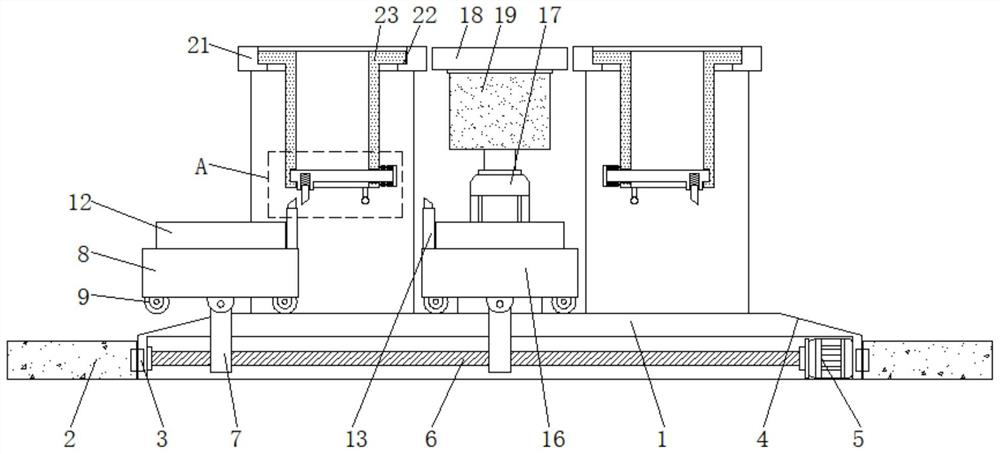

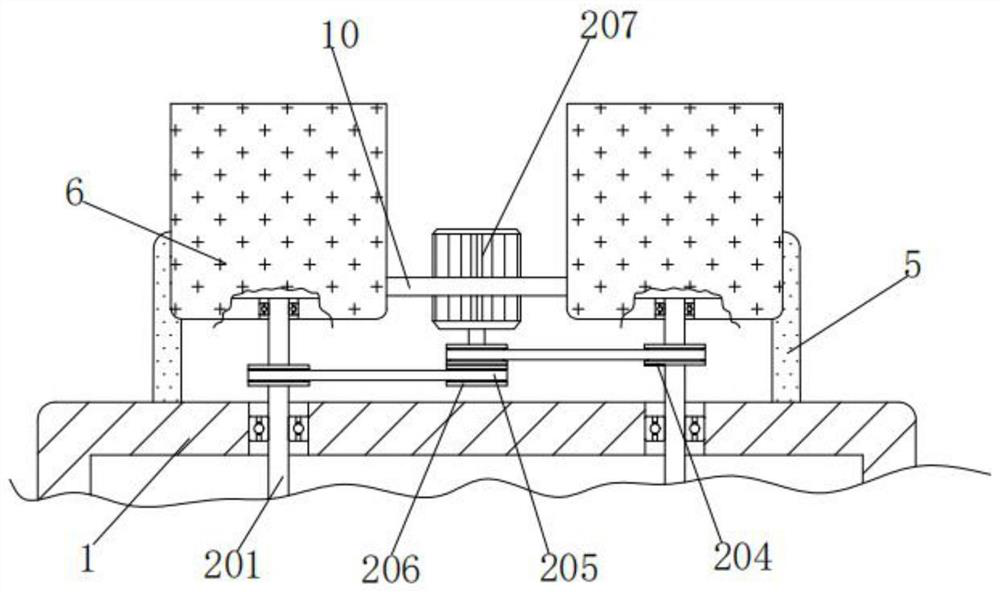

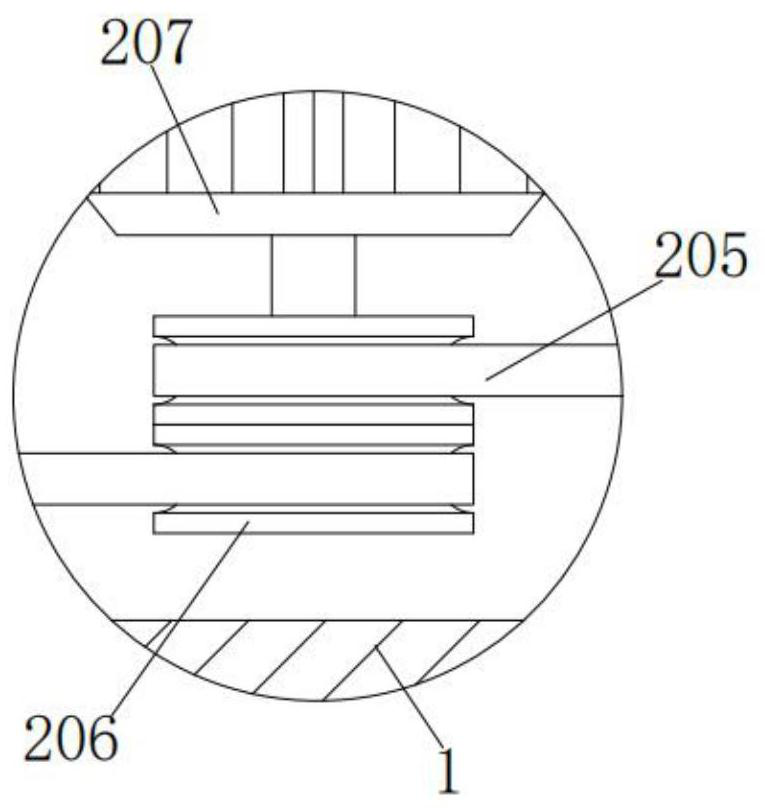

Flat plate groove cutting workbench with open table top

PendingCN113290397AImprove cut qualityRealize automatic dropLarge fixed membersPositioning apparatusEngineeringIron oxide

The invention relates to a cutting workbench, in particular to a flat plate groove cutting workbench with an open table top. The flat plate groove cutting workbench comprises a workbench body and a supporting frame assembly; the workbench body is of a box type structure with the open upper part; the supporting frame assembly is arranged in the workbench body, the two ends of the supporting frame assembly are connected with the two ends of the workbench body through fasteners, and the other parts of the supporting frame assembly are suspended; the supporting frame assembly comprises a supporting frame, a supporting column and a magnetic attraction column; the supporting column and the magnetic attraction column are both arranged on the supporting frame; the bottom of the workbench body is provided with a waste collecting tank which can be moved out of the workbench body; an inclined guide plate is arranged above the waste collecting tank; and the guide plate is fixedly connected with the inner wall of the workbench body. According to the cutting workbench, the stability and reliability of workpiece supporting can be achieved, the workpiece is prevented from moving and sliding off, automatic falling, collecting and cleaning of cutting waste and iron oxide slag are facilitated, the flatness of the supporting face of the cutting workbench is guaranteed, manpower is saved, and the groove cutting quality and the production efficiency are improved.

Owner:芜湖行健智能机器人有限公司 +1

Garbage recycling process equipment

InactiveCN108380317AEfficient crushingEasy to cleanSolid waste disposalTransportation and packagingProcess equipmentPulp and paper industry

The invention discloses garbage recycling process equipment. The garbage recycling process equipment comprises a collecting chamber, a push plate and a cleaning plate. A control panel is arranged at the left end of the collecting chamber, and a first sieve plate and a second sieve plate are installed inside the collecting chamber. A controller is connected between the first sieve plate and the collection chamber, and a push rod is connected to the right end of the push plate. A drainage exit is formed in the bottom of the outer surface of the collecting chamber, and a sieve is mounted on the outer surface of the drainage exit. A heating tube is installed inside a base, and a baffle is arranged at the bottom end of the joint between the collection chamber and a crushing chamber. A hydraulicpress is installed at the upper end of the crushing chamber, and a hydraulic rod is connected to the lower end of the hydraulic press. A cross bar is connected to the lower end of the hydraulic rod,and blades are mounted at the lower end of the cross bar. The cleaning plate is installed on the right wall of the crushing chamber. The garbage recycling process equipment can clean garbage adheringto the blades without affecting the use of the next time.

Owner:湖南钜晟环保科技股份有限公司

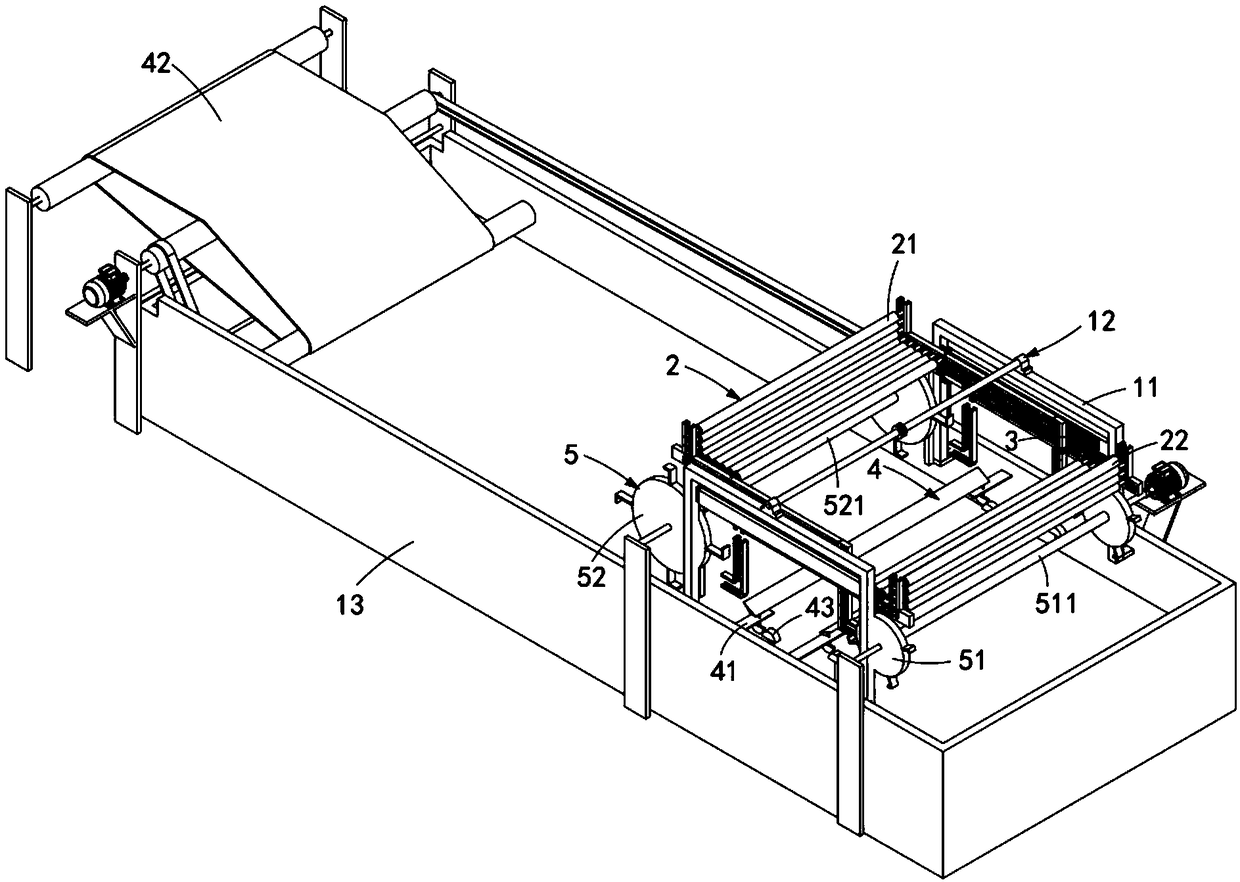

Continuous automatic output vermicelli cooking device

The invention relates to a continuous automatic output vermicelli cooking device. The device comprises a sheet jelly conveying belt which is erected at the top of a machine frame, a cooking box is arranged at the bottom of the sheet jelly conveying belt, the cooking box comprises a material holding mechanism, a driving mechanism and a transmission mechanism, the material holding mechanism is fixedly arranged below the sheet jelly conveying belt and is arranged on the machine frame, the material holding mechanism is used for supporting the sheet jelly which is vertically output by the sheet jelly conveying belt and outputting the sheet jelly in an S shape, the material holding mechanism comprises a first material holding assembly and a second material holding assembly, the first holding assembly and the second holding assembly are arranged in parallel in a staggered mode; the driving mechanism are symmetrically arranged below the sheet jelly conveying belt and is arranged between the first holding assembly and the second holding assembly, the transmission mechanism is arranged below the material holding mechanism and is arranged in a circuitous manner along the length direction of the cooking box, the transmission mechanism comprises a transmission component, a material receiving component and a discharging component. According to the continuous automatic output vermicelli cooking device, the technical problem that the sheet jelly cannot be transmitted out in time is solved.

Owner:赵长春

Building fire alarm device

ActiveCN114377326ARealize automatic recyclingRealize automatic dropFire rescueFire alarm smoke/gas actuationStructural engineeringElectrical and Electronics engineering

The invention is applicable to the technical field of alarm equipment, and provides a building fire alarm device which comprises a shell, a smoke sensing alarm module and a storage mechanism, the smoke sensing alarm module is fixedly connected to the shell, the storage mechanism is fixedly connected to the interior of the shell, and the smoke sensing alarm module controls the storage mechanism; the storage mechanism is used for lifting a fire extinguishing tool; a plurality of hanging ports are formed in the upper part and the periphery of the shell; the storage mechanism comprises a winding wheel, a guide column and a storage frame, the winding wheel is rotationally connected with the shell, and a volute spiral spring is arranged between the winding wheel and the shell. Therefore, the device is small in size, easy to carry, convenient to use in a construction site and rapid to install, when a fire disaster occurs, an alarm signal is sent out, meanwhile, a fire extinguishing tool in the alarm device is released, a constructor is reminded of the position of the fire extinguishing tool through sent alarm sound, and the fire extinguishing time is brought forward.

Owner:潍坊中维美瑞机械有限公司

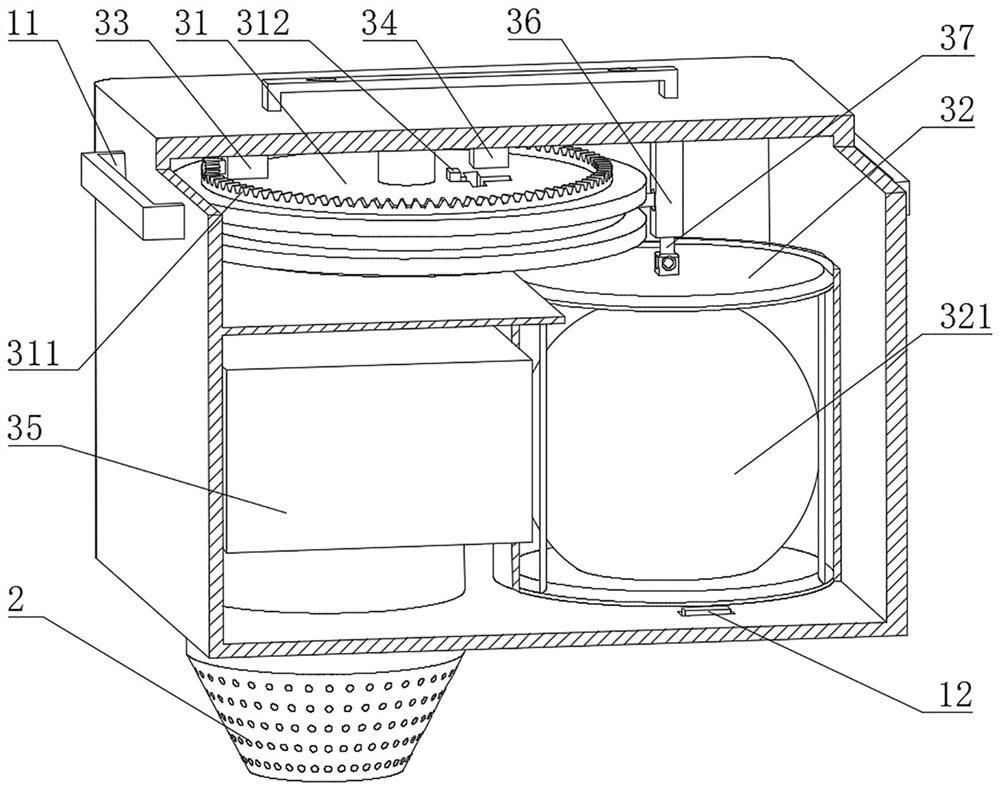

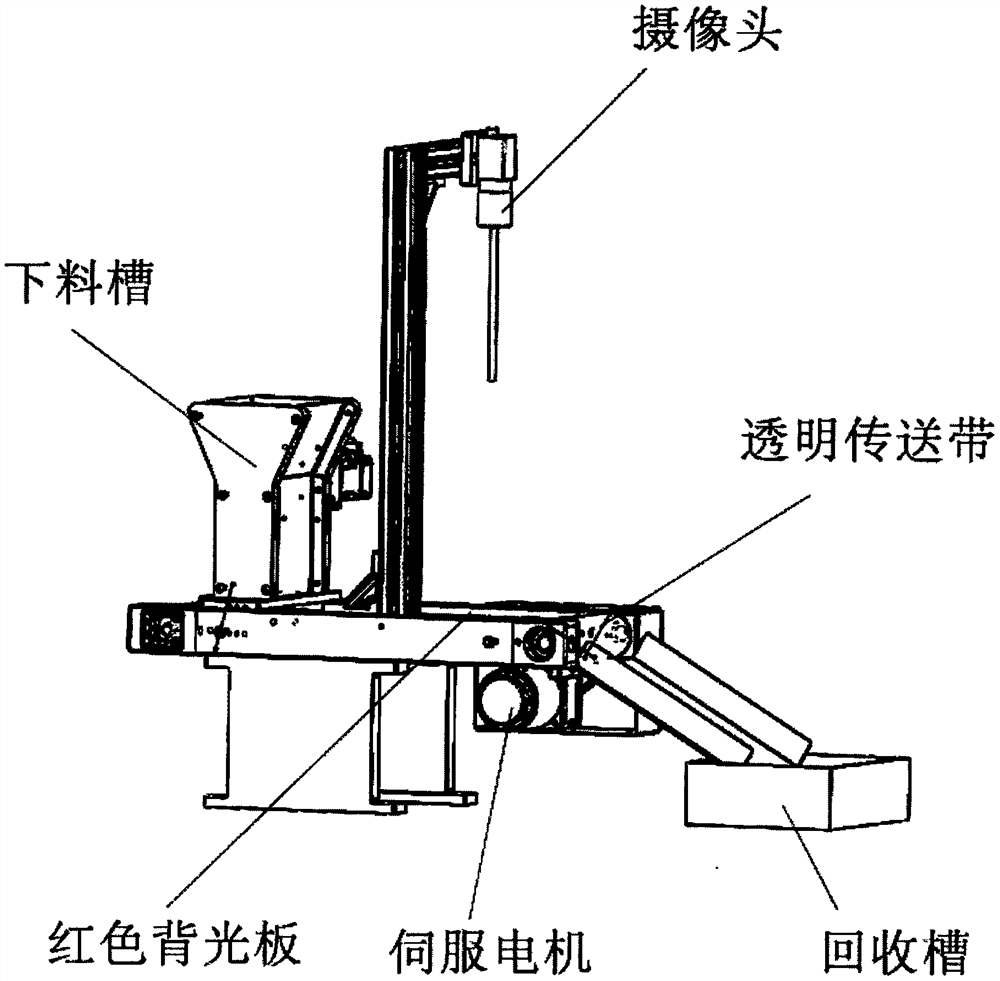

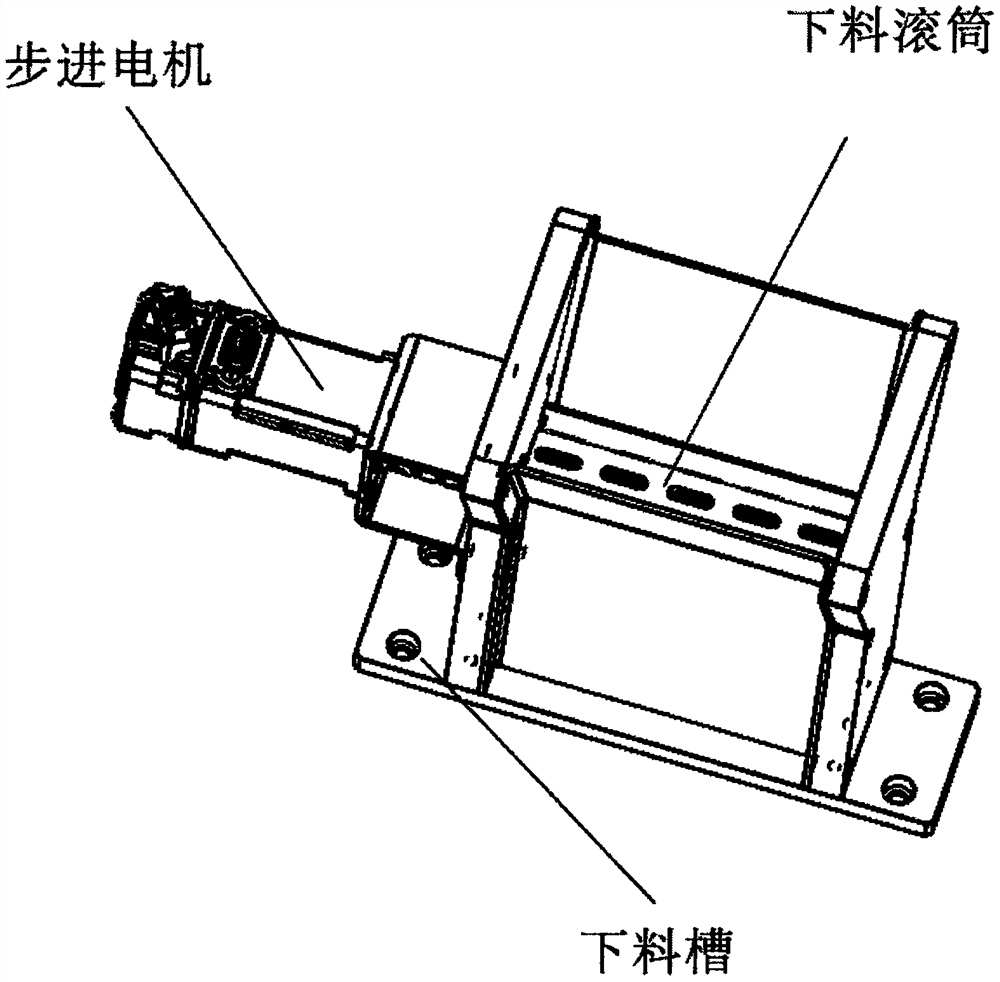

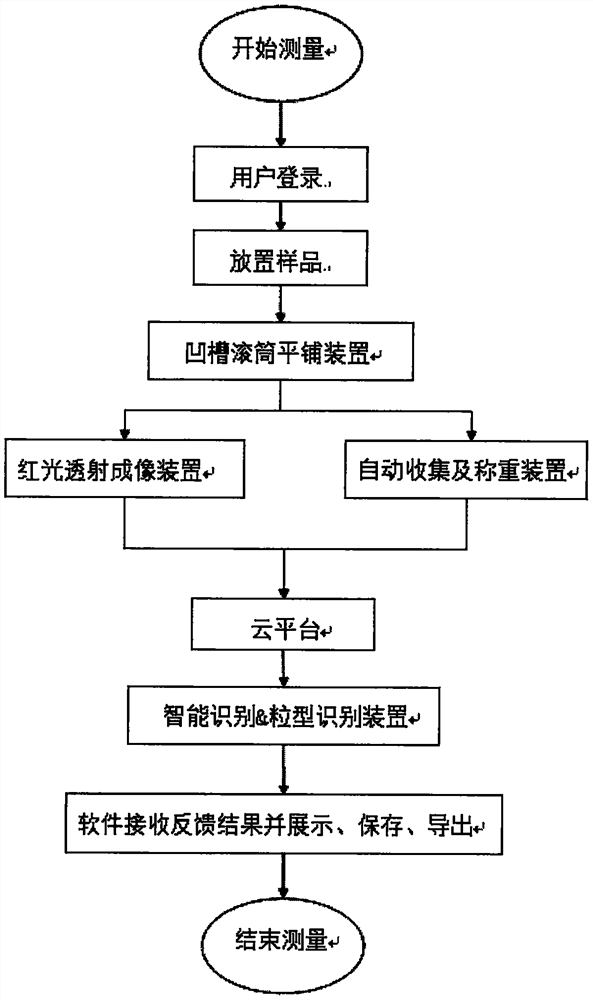

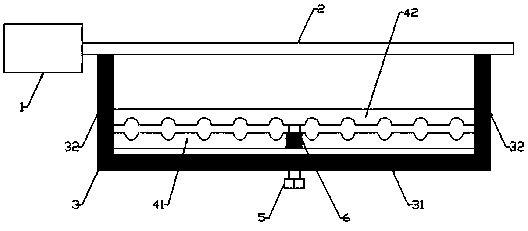

Small intelligent rice seed detecting instrument

InactiveCN112042313ARealize automatic dropAchieve recyclingGerminating apparatusSoftware systemAgricultural engineering

The invention designs a small intelligent rice seed detecting instrument. A full-automatic seed flat-laying and recycling device is additionally mounted on a detection platform, and the detection platform is improved, so that the detection platform can complete detection and identification of flat and bad seeds by utilizing red light image transmission imaging on the basis of general character detection, and counting and calculation are completed by utilizing a software system. A deep learning algorithm is utilized, so that adverse factors such as impurity mixing, awned rice and adhesion can be overcome, and the anti-interference capability of the system is improved. Full-automatic seed detection is realized, the working efficiency is improved, the manual labor intensity is greatly reduced, the functions are increased, the application range is expanded, and great significance to the development of intelligent detection of plant seeds in China is achieved.

Owner:HUAZHONG AGRI UNIV

Building construction device and construction method

ActiveCN112854781ARealize automatic dropPrevent coagulationBuilding material handlingBrickArchitectural engineering

The invention relates to the technical field of equipment, and particularly relates to a building construction device and a construction method. The building construction device and the construction method have the advantage that a brick wall laid on a building can be nailed and fixed. The construction method of the building construction device comprises the following steps that S1, bricks are placed in a walking assembly, and concrete is added into a coating assembly; S2, the walking assembly is started to move at a fixed length, a driving assembly is started to periodically mesh with and drive a pushing assembly to push the bricks to be laid, and pushed rotating blocks are coated with the concrete; S3, after a force storage assembly stores force, nails provided by an impact nail supply assembly are released to fixedly connect the laid rotating blocks; and S4, the walking assembly is started again to walk, and the next brick is laid.

Owner:湖南天禹建设有限公司

Water drill bit polishing device

InactiveCN112157491ARealize automatic polishingEase of workGrinding carriagesGrinding drivesPolishingEngineering

The invention relates to a polishing device, in particular to a water drill bit polishing device. The water drill bit polishing device is automatic in polishing, easy to operate and capable of reducing the working difficulty of people. The water drill bit polishing device comprises a base, wherein a plurality of first supporting columns are arranged on the base; a workbench arranged between the tops of the first supporting columns; second supporting columns symmetrically arranged at the top of the base; rails arranged on the second supporting columns and connected with the base; baffles arranged on the side, close to the rails, of the top of the base; and a rotating mechanism arranged on one side of the top of the workbench. Through the cooperation of the rotating mechanism and a polishingmechanism, after a servo motor is started, the rotating mechanism clamps a water drill bit and drives the water drill bit to rotate, meanwhile, the polishing mechanism moves leftwards to polish the water drill bit, thus, automatic polishing can be achieved, and then the working difficulty of people is reduced.

Owner:邓贵龙

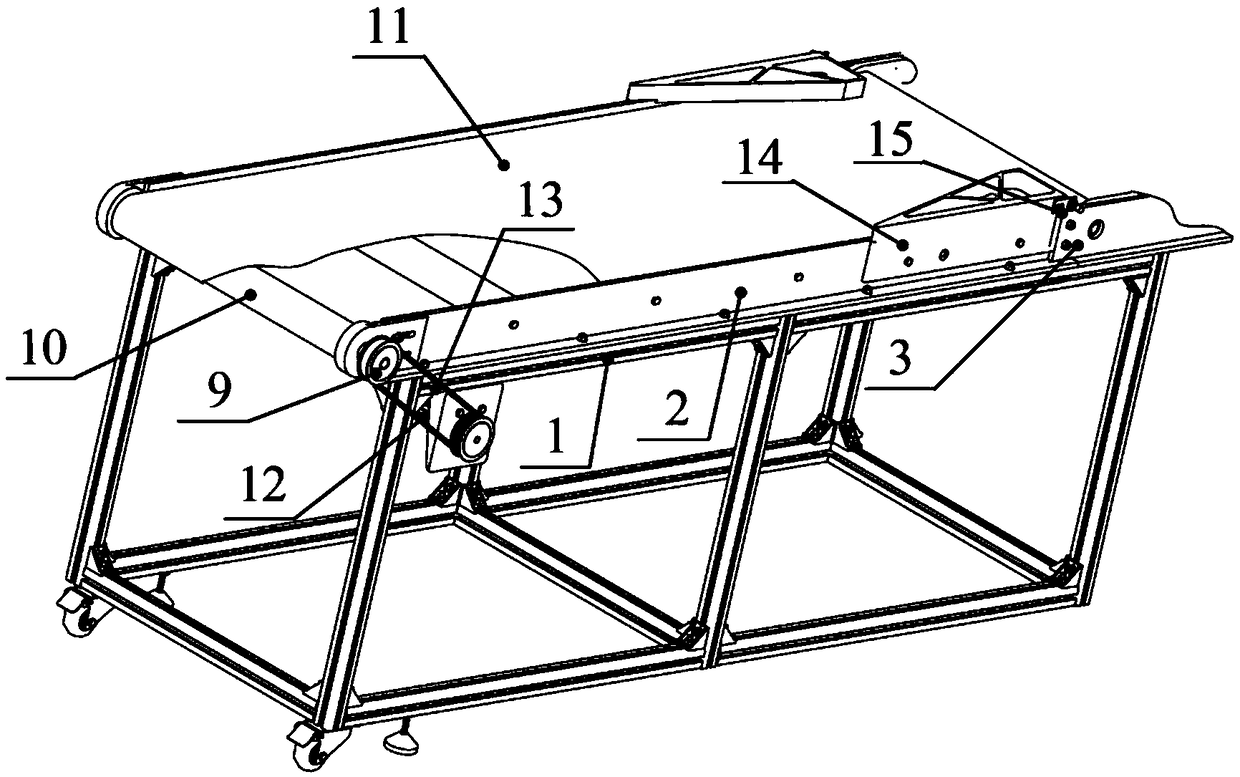

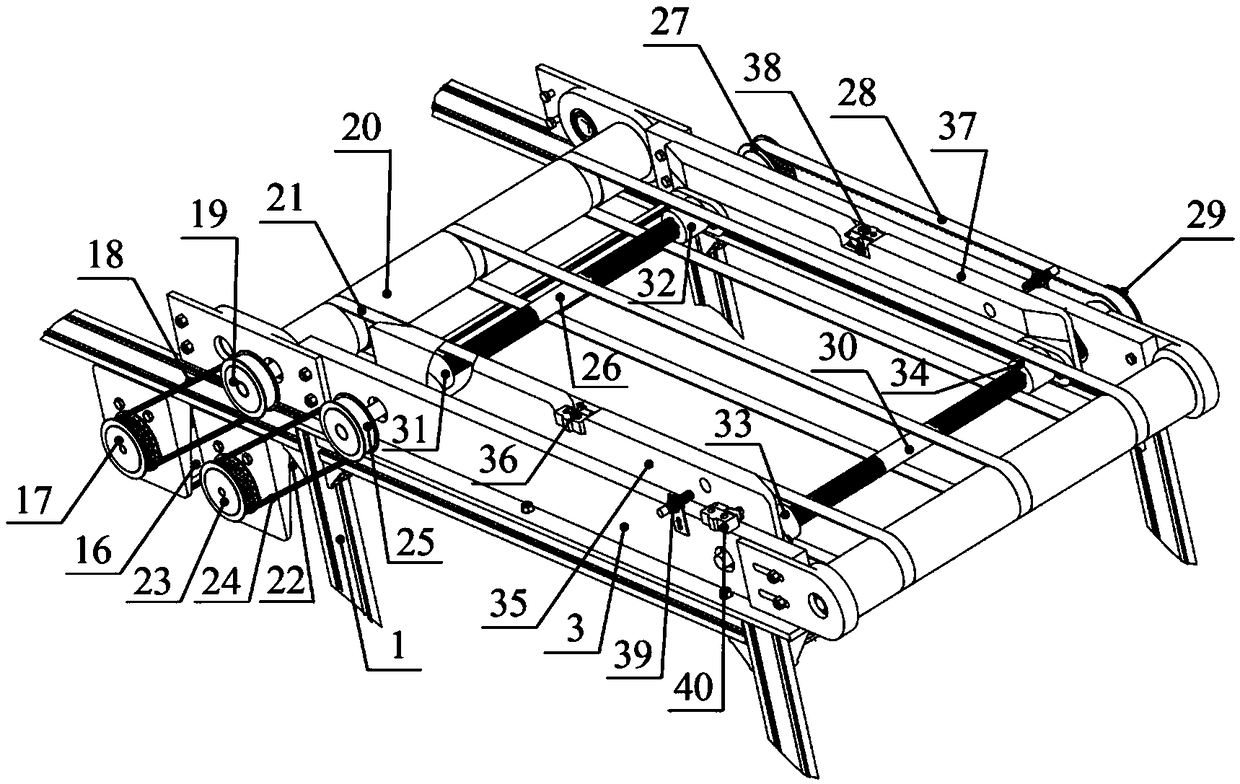

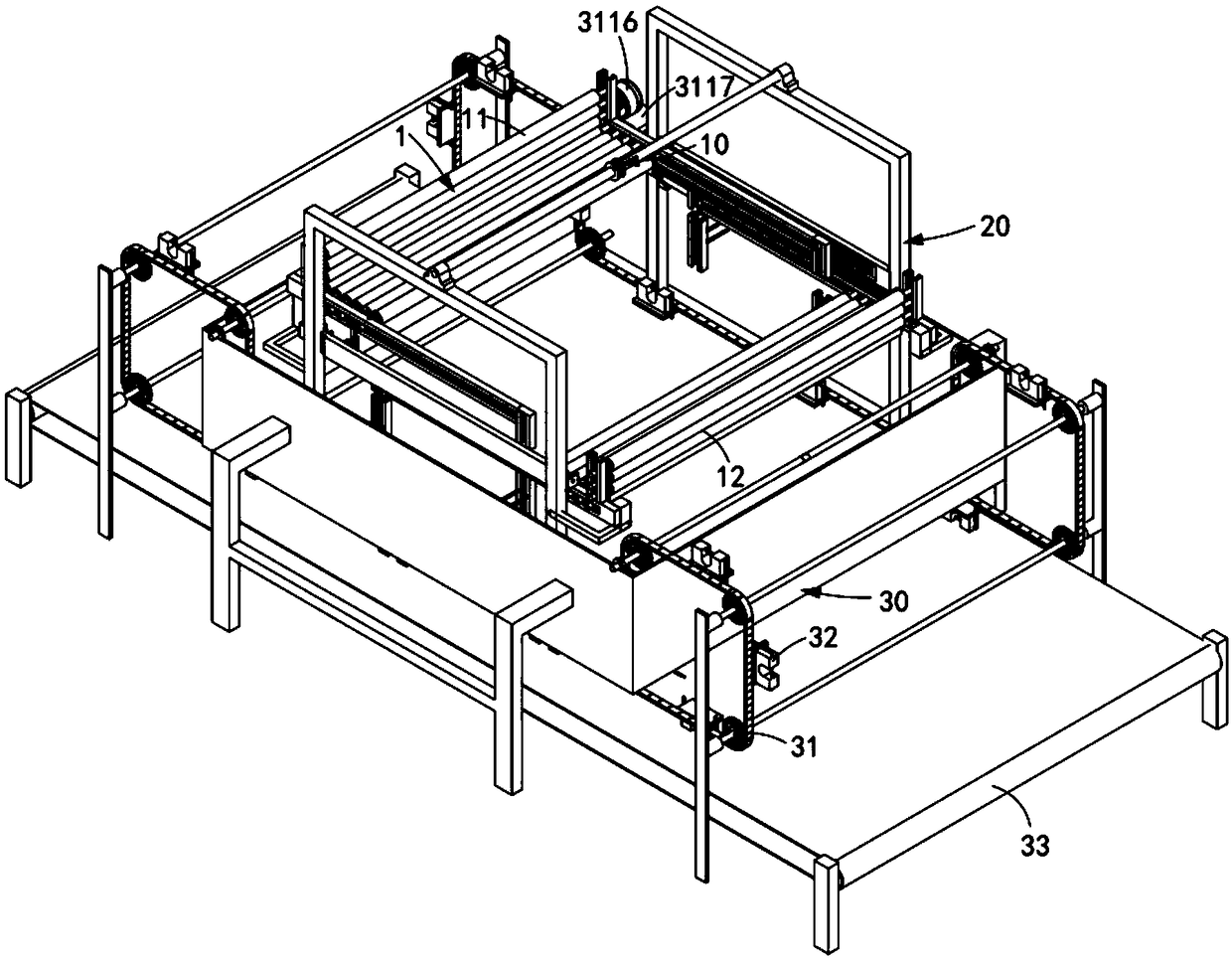

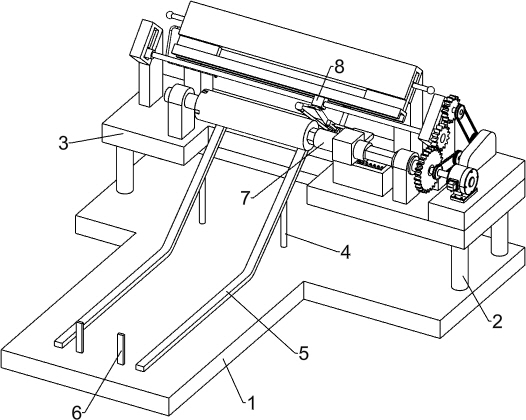

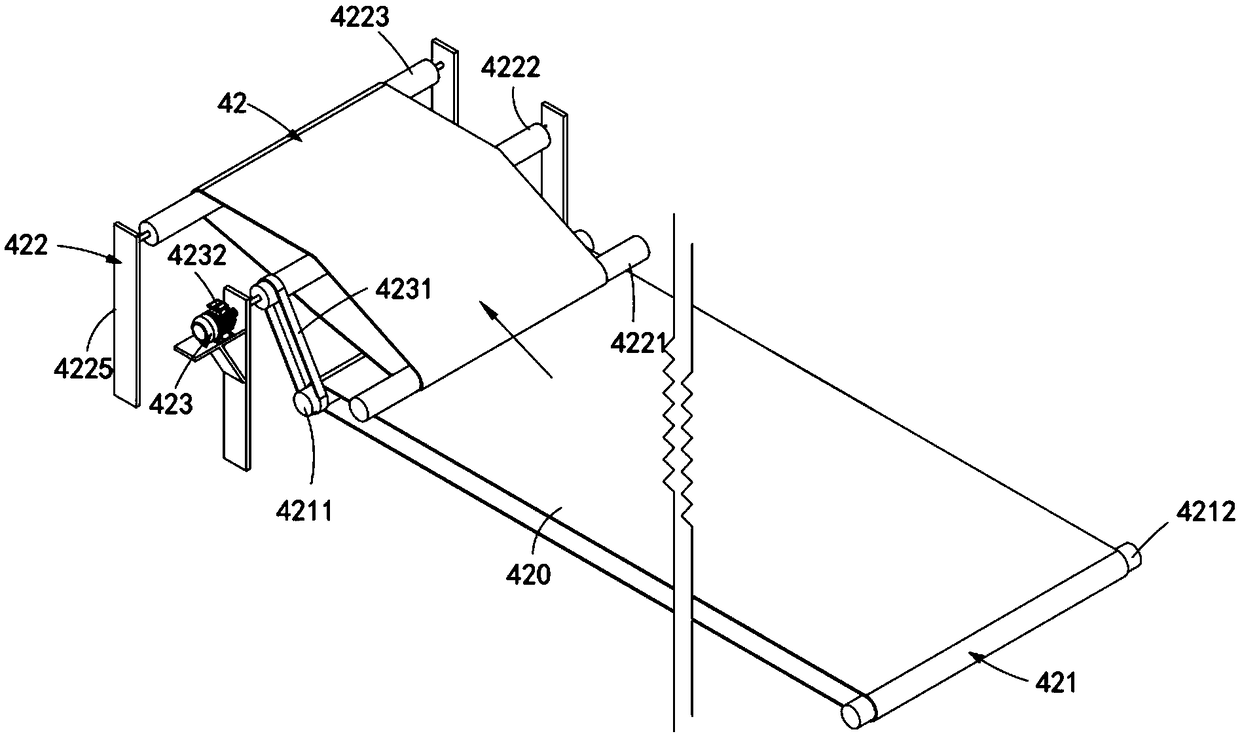

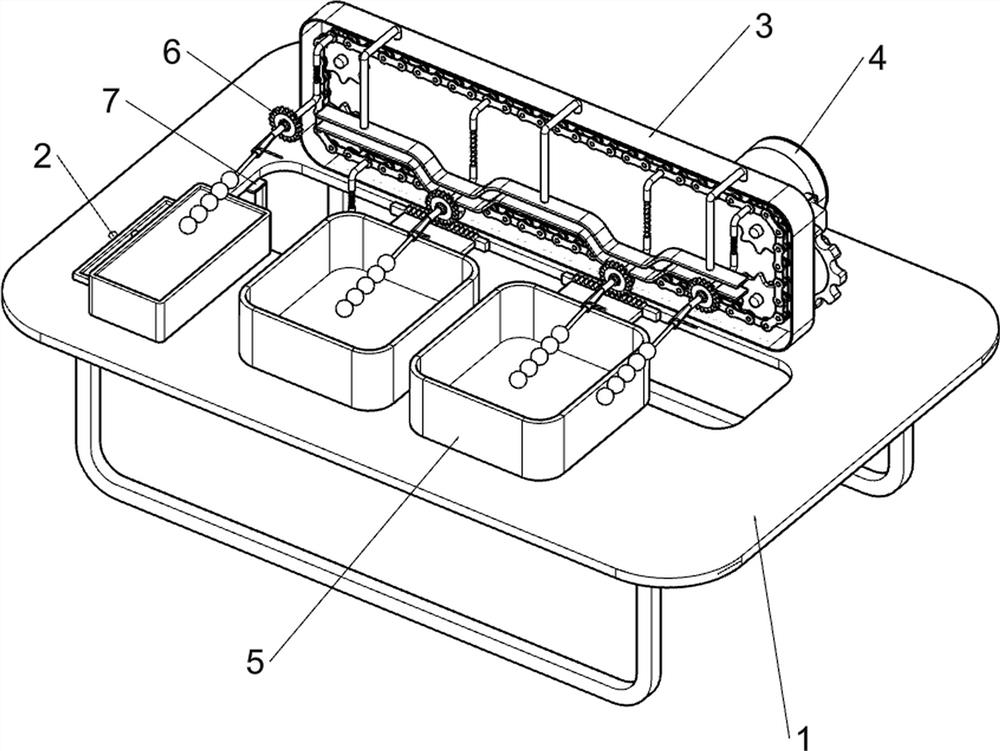

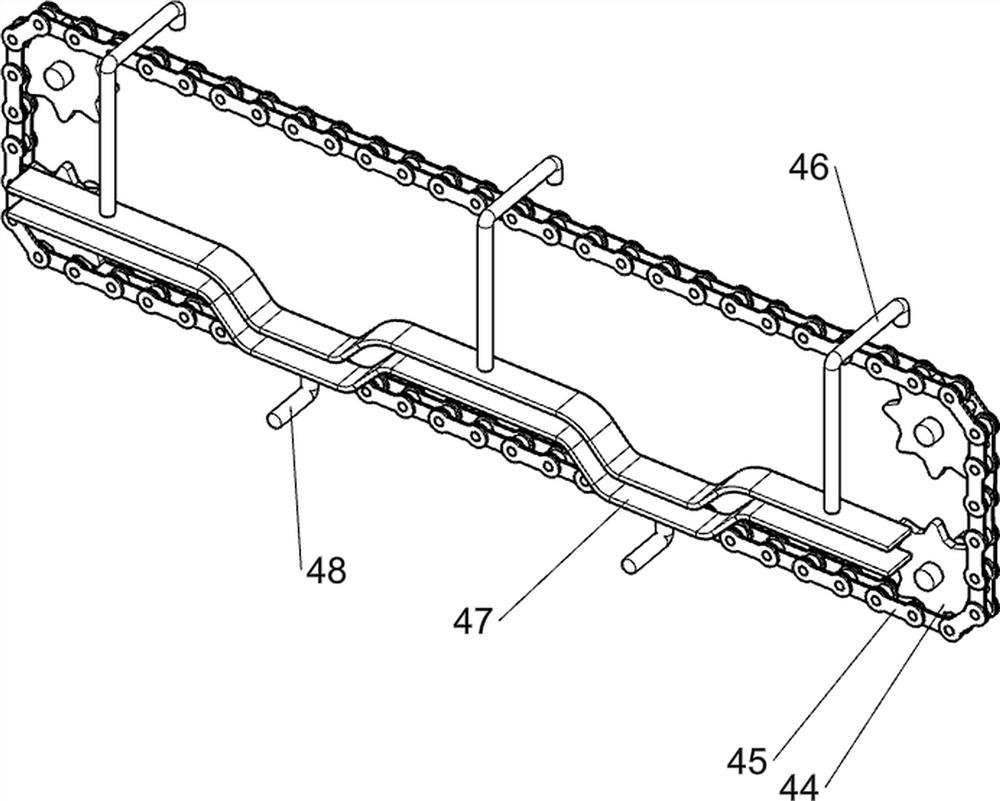

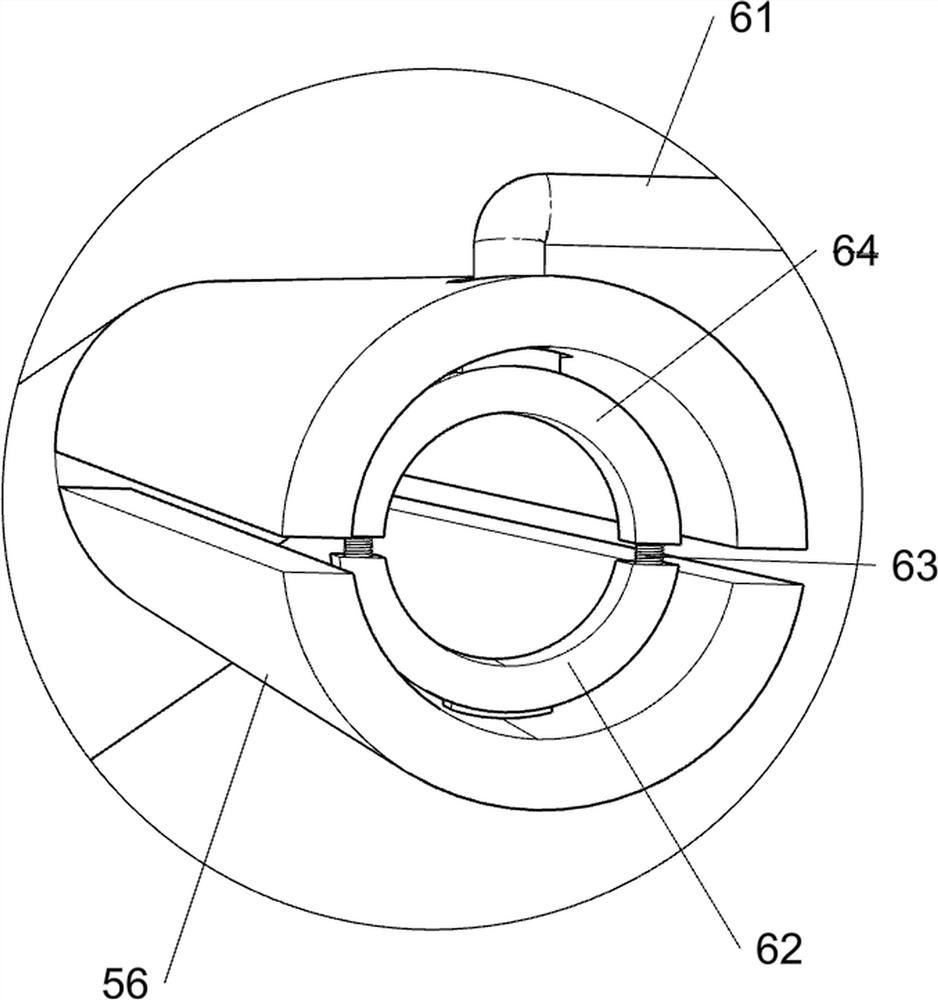

Bean vermicelli cooking device with slitting function

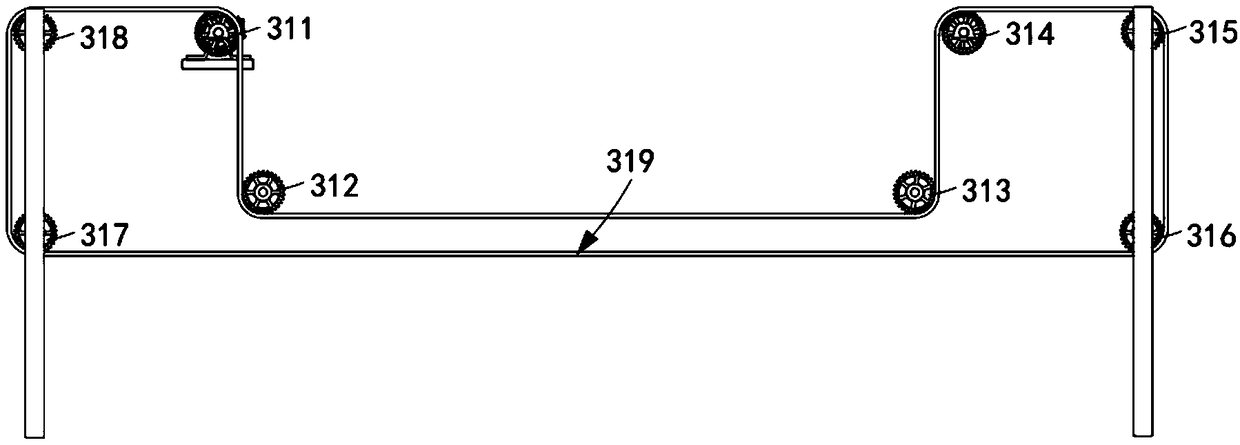

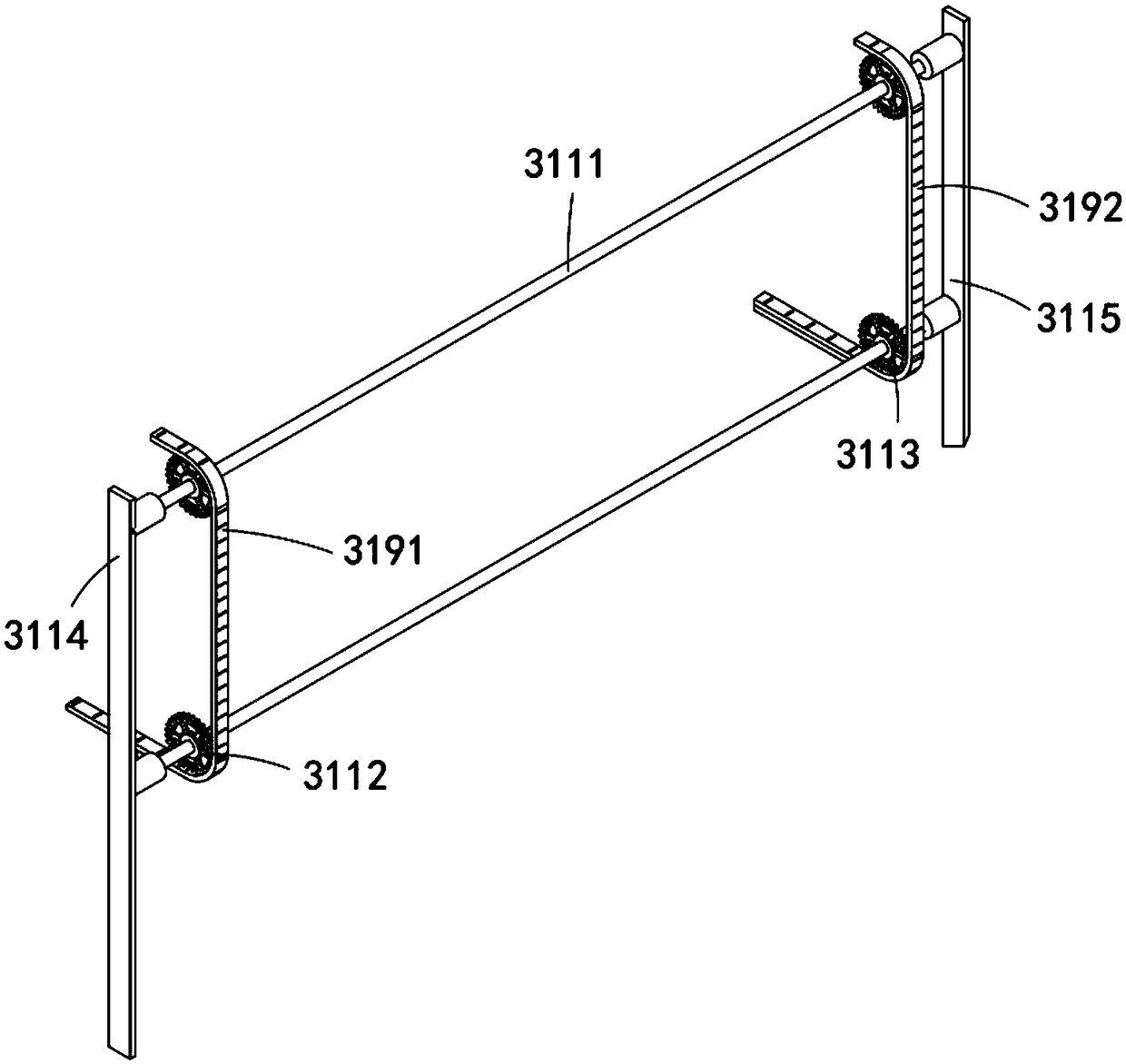

ActiveCN109176624AHigh linkageHigh degree of automationMetal working apparatusFood scienceEngineeringMechanical engineering

The invention relates to a bean vermicelli cooking device with a slitting function. The device comprises a bean starch sheet conveying belt which is erected on the top of a rack, a boiling tank is arranged on the bottom of the bean starch sheet conveying belt, the rack is arranged in the boiling tank, and the rack comprises a material supporting mechanism, driving mechanisms, a shearing mechanismand circular mechanisms. The material supporting mechanism is fixedly arranged below the bean starch sheet conveying belt and arranged on the rack, the material supporting mechanism is used for supporting the bean starch sheet conveying belt to vertically output bean starch sheets and enabling the bean starch sheets to be output in an S shape, and the material supporting mechanism comprises a first paving assembly and a second paving assembly. The driving mechanisms are symmetrically arranged below the bean starch sheet conveying belt and are arranged between the first paving assembly and thesecond paving assembly; the shearing mechanism is arranged below the driving mechanisms and comprises a sheet forming assembly, a conveying-out assembly and a control assembly; and the circular mechanisms are located on the two sides of the shearing assembly, are rotatably arranged on the rack and each comprise a first returning assembly and a second returning assembly. The device solves the technical problems that the shearing structure is complex, and after shearing is finished, the bean starch sheets cannot be transmitted out in time.

Owner:赵长春

Sugar-coated haw rolling device

PendingCN111955586AImprove work efficiencyReduce workloadConfectioneryCharge manipulationSugarWorkbench

The invention relates to a rolling device, in particular to a sugar-coated haw rolling device. The invention provides the sugar-coated haw rolling device which can automatically fix and convey sugar-coated haws, roll the sugar-coated haws and automatically take down the sugar-coated haws. The sugar-coated haw rolling device comprises: a fixed workbench and a containing box, wherein the containingbox used for containing the sugar-coated haws is arranged on one side of the top of the fixed workbench; a fixed plate which is arranged at the top of the fixed workbench; a conveying mechanism whichis arranged on the side, close to the fixed plate, of the top of the fixed workbench, wherein the fixed plate is connected to the conveying mechanism; and a stirring mechanisms which are arranged on the two sides of the top of the fixed workbench correspondingly, wherein the stirring mechanisms are connected to the conveying mechanism. Under the cooperation of the conveying mechanism, the stirringmechanisms, a haw stick fixing mechanism and a baffle, the process of fixing and conveying the sugar-coated haws, completing rolling and automatically falling onto the placement box can be realized.

Owner:邓颖

Shaping and alternating auxiliary cutting device for food detection

ActiveCN113492425AImprove cutting efficiencyAvoid loose and broken phenomenaMetal working apparatusElectric machineryStructural engineering

The invention discloses a shaping and alternating auxiliary cutting device for food detection. The shaping and alternating auxiliary cutting device comprises a base, a motor and an air cylinder, wherein material receiving discs are arranged on the two sides of the base, and the motor is arranged in the base; a guide block is arranged on the upper surface of the base in an embedded mode; rolling wheels are arranged on the lower surface of a first bearing plate, and a vertical plate is fixed to the upper surface of the first bearing plate; a second bearing plate is arranged on one side of the first bearing plate, and the air cylinder is arranged on the upper portion of one side of the base; and a discharging box is arranged in a clamping groove. According to the shaping and alternating auxiliary cutting device for food detection, the first bearing plate and the second bearing plate are arranged, a threaded rod is driven to rotate through the motor, and the relative positions of the first bearing plate and the second bearing plate and the upper portion of the base can be switched through threaded connection between the threaded rod and the guide block, so that a to-be-detected sample can be conveniently and continuously cut in unit time, and the food cutting efficiency is greatly improved.

Owner:深圳信测标准技术服务有限公司

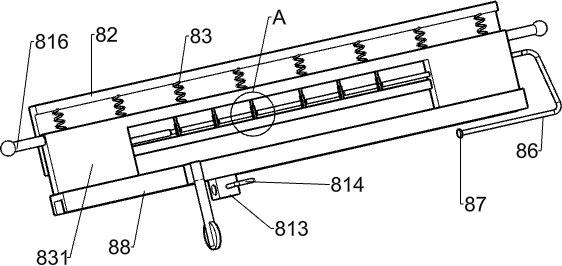

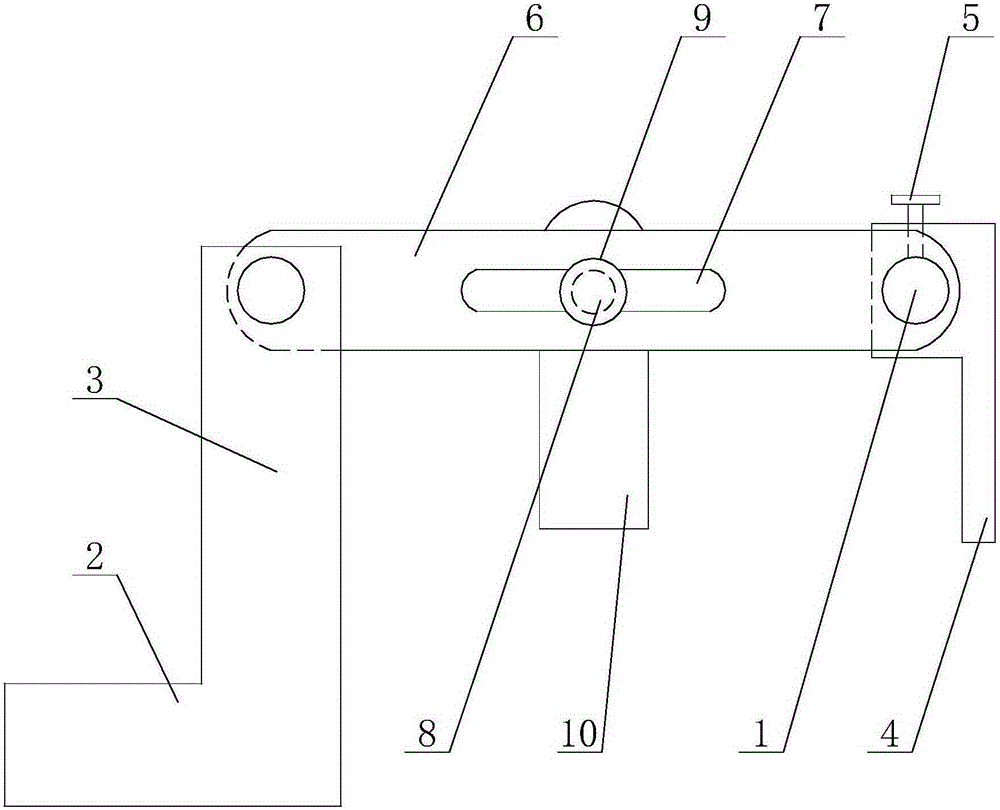

Scrap discharging device of bill die cutting machine

ActiveCN105171824ASimple structureReduce labor intensityMetal working apparatusBiochemical engineeringUltimate tensile strength

The invention discloses a scrap discharging device of a bill die cutting machine. The scrap discharging device comprises a fixing rod, and multiple discharging rods are fixedly connected to the positions, corresponding to bill locating holes, of the fixing rod; the end of the fixing rod is fixedly connected to one end of a transmission rod, the other end of the transmission rod is rotatably mounted on a driving rod, and the driving rod is in transmission connection with an upward-pressing type punch of the die cutting machine; a kidney-shaped hole is formed in the middle of the transmission rod, and a supporting pin shaft is arranged in the kidney-shaped hole; a limiting block with a limiting function is arranged at one end of the supporting pin shaft, and the other end of the supporting pin shaft is fixed to a supporting rod. The scrap discharging device of the bill die cutting machine is simple in structure and easy to realize; by means of the scrap discharging device, scraps at the bill locating holes can automatically fall down, later cleaning is not needed, the labor intensity of workers is greatly lowered, and the production efficiency is improved.

Owner:WUXI DOUBLE DRAGON INFORMATION PAPER

A coil automatic winding device

ActiveCN106653352BRealize automatic binding and fixingInhibit sheddingCoils manufactureEngineeringConductor Coil

The present invention relates to a winding device, in particular to a coil automatic winding device, which includes a frame, a winding main shaft and a winding frame fixed on the winding main shaft, and a wire barrel for supplying wire is provided on one side of the winding main shaft And the wire lead mechanism, the wire lead mechanism includes a fixing mechanism that fixes the thread ends extracted from the bobbin and a first driving mechanism that drives the fixing mechanism to rotate from one side of the main shaft to the other side, and the other side of the main shaft is provided with a clamping and fixing device The clamping mechanism of the wire end on the winding device also includes a tape sealing mechanism for fixing the wire on the winding skeleton, and the winding device also includes a controller for controlling the lead wire mechanism and the clamping mechanism. The present invention The coil automatic winding device does not require manual participation in the entire winding process, with a high degree of automation and high production efficiency.

Owner:JIANGSU UNIV OF TECH

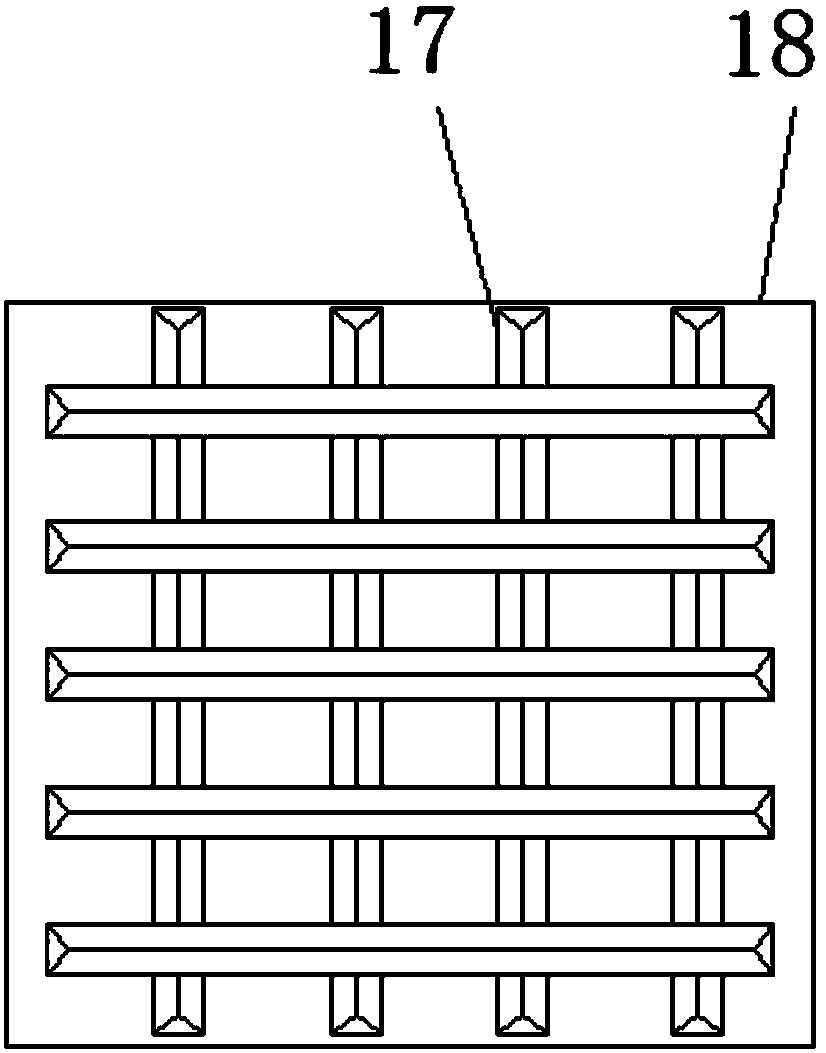

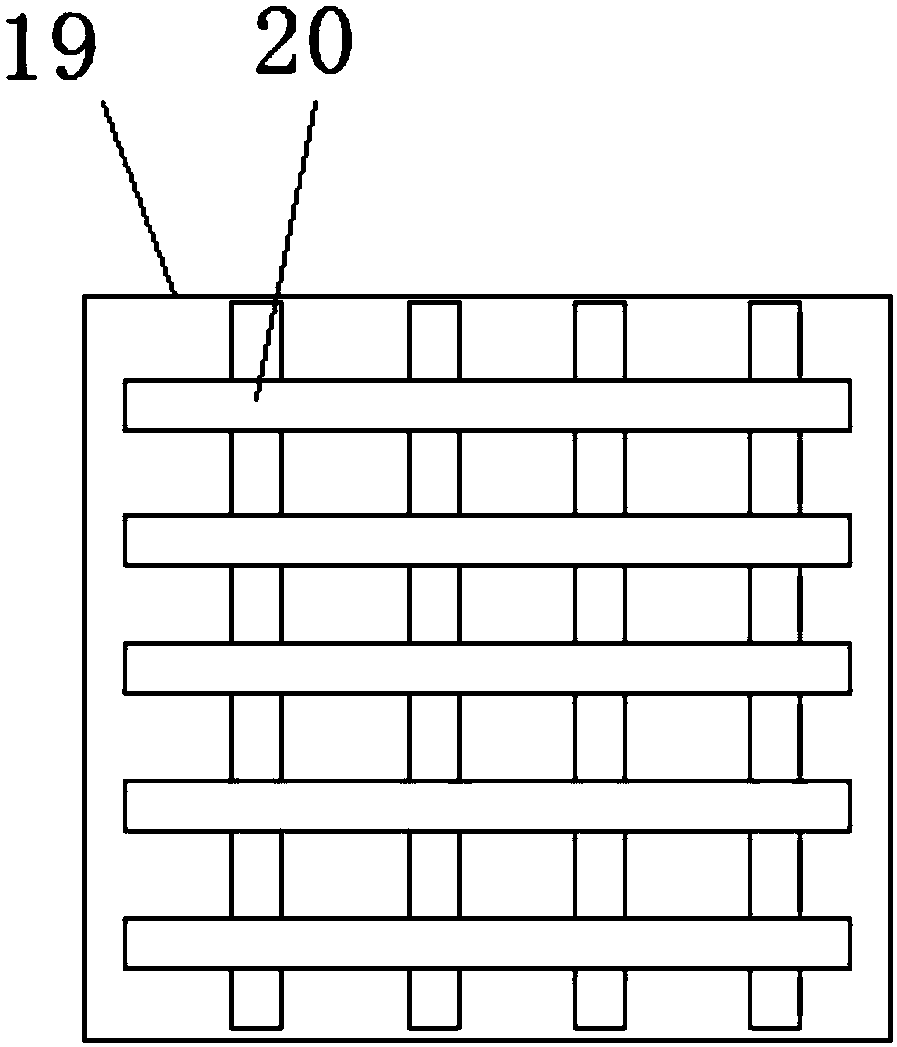

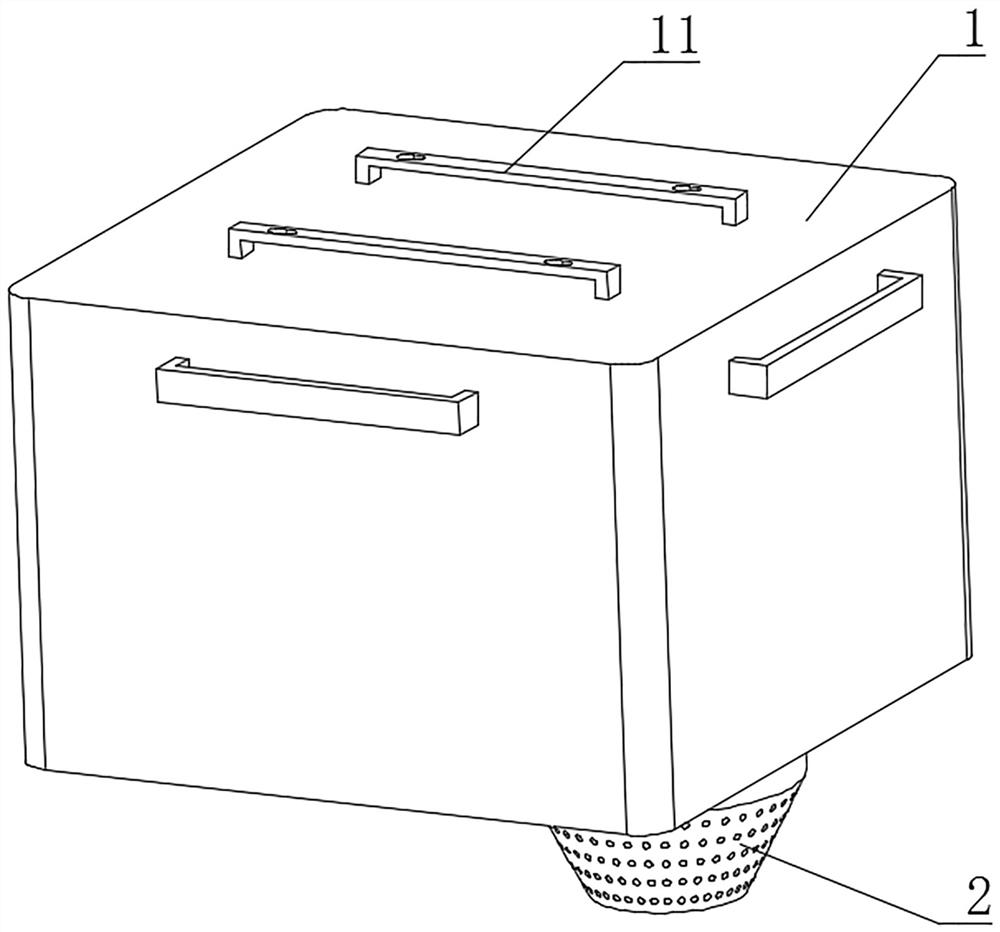

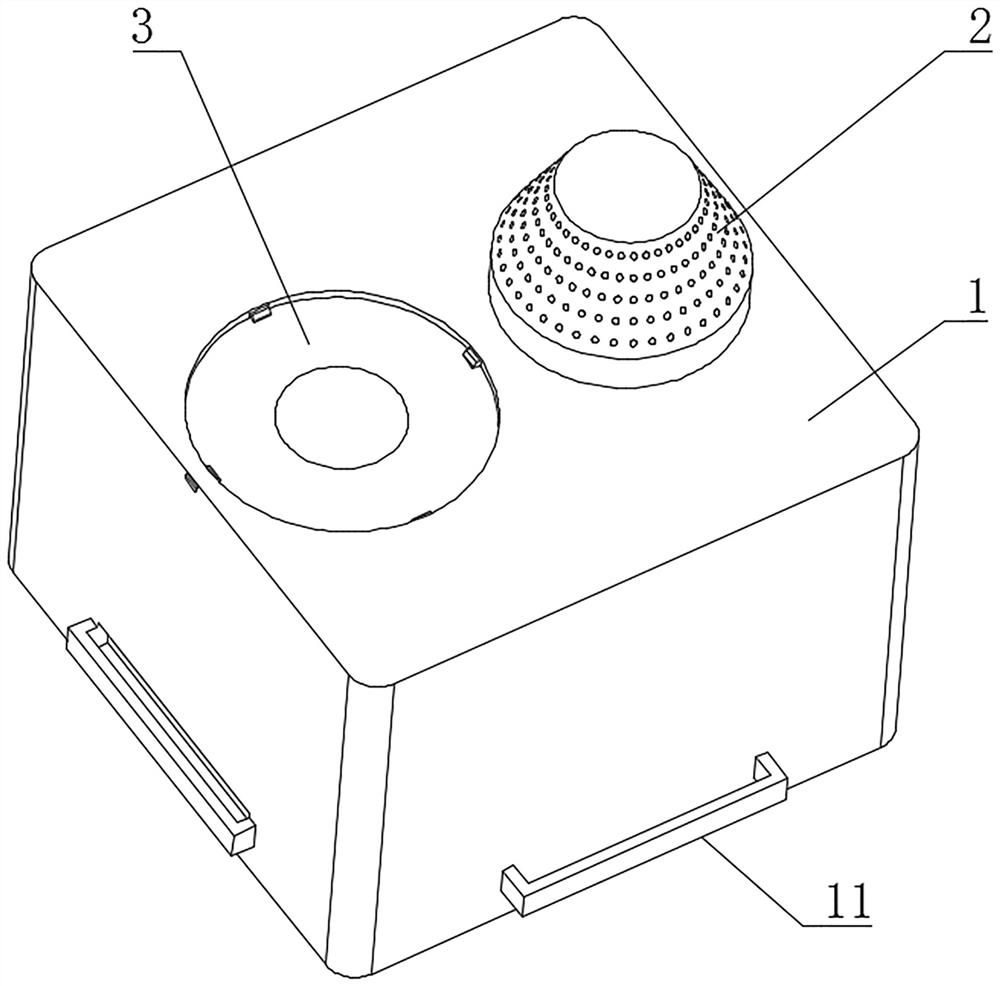

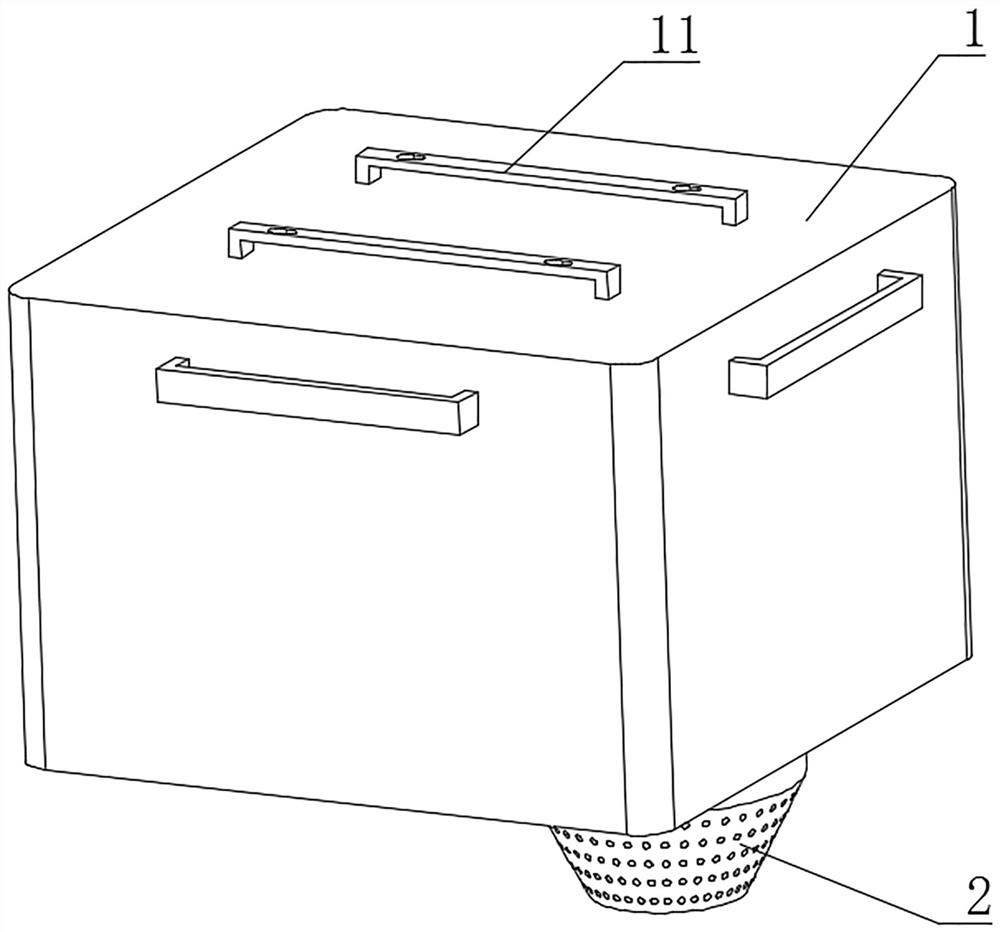

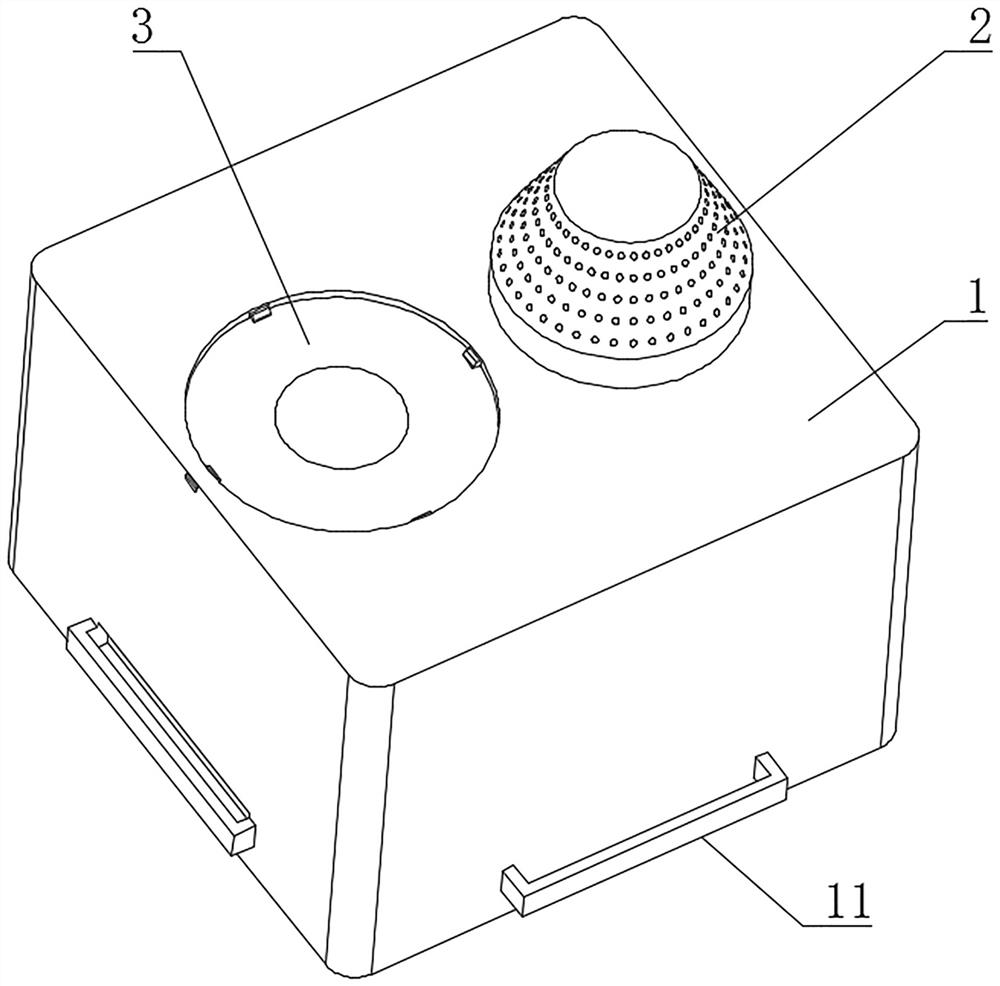

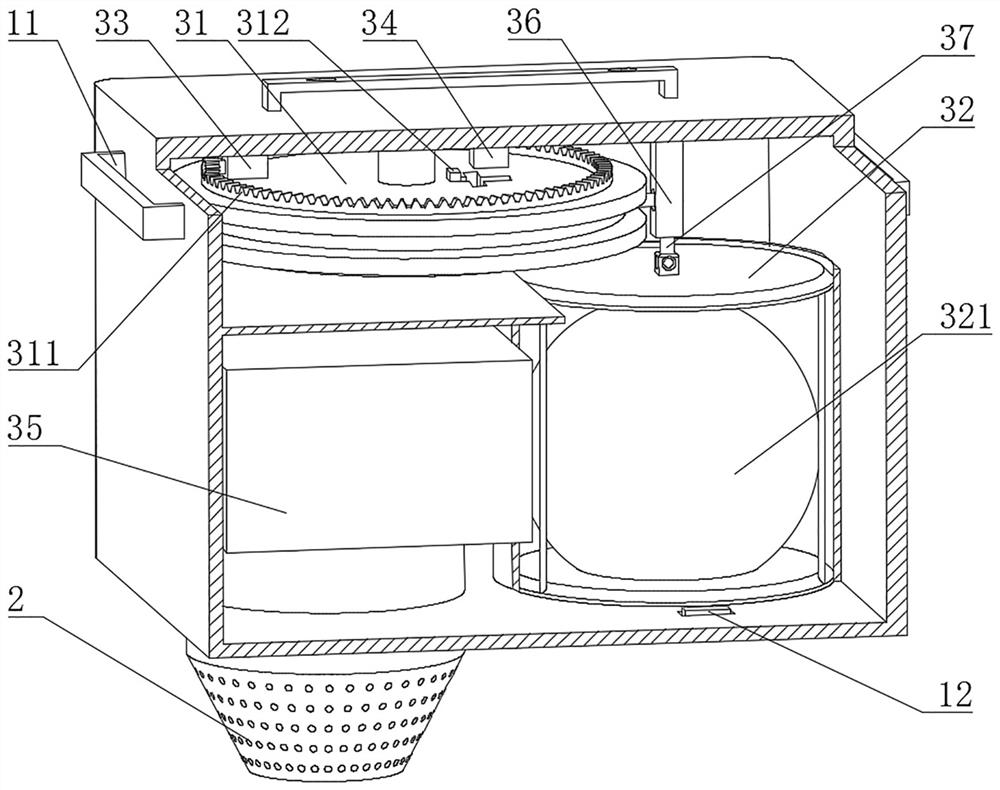

Full-automatic pipette tip box

PendingCN111151321AAvoid the problem of substandard sterilization qualitySteady fallBurette/pipette supportsRatchetPipette

The invention belongs to the technical field of biomedical equipment, and particularly relates to a full-automatic pipette tip box. The full-automatic pipette tip box comprises a box body, a conveyingmechanism, a ratchet mechanism and a control mechanism. According to the invention, tips are vertically inserted into a storage disc, and storage grooves and spiral tracks respectively on the storagedisc and a guide disc correspond to each other, so that the tips can be scattered, and the problem that the sterilization quality does not reach the standard due to accumulation of the tips is avoided. The tips on the storage disc are guided by the guide disc to move along the spiral tracks and finally vertically fall down from an opening along a bearing table, so that the phenomenon of circlingis avoided, and the stable falling of the tips is ensured. An infrared sensor is used for sensing a human hand, and after a hand is sensed, a motor drives a swing rod to perform a reciprocating action, and a tip falls down, so that automatic falling of the tip is realized, and an experiment is facilitated.

Owner:SHANXI MEDICAL UNIV

Clamping device for cigarette inspection

InactiveCN107748222AReduce the amount of manual laborImprove detection efficiencyChemical analysis using combustionEngineeringDrive motor

The invention discloses a clamping device for detecting cigarettes, which comprises a drive motor mounted on a frame, the drive motor is connected with a rotating shaft, a U-shaped frame is arranged on the rotating shaft, and the U-shaped frame It includes a beam and legs fixed at both ends of the beam, the two legs are fixedly connected to the rotating shaft, a lower splint is installed on the beam, and an upper splint is slidably connected between the two legs, the upper splint and the lower splint When in contact with each other, more than five cigarette installation holes can be formed. A threaded through hole with the same diameter and axis is opened in the middle of the beam and the lower splint, and an adjusting bolt is threaded in the two threaded through holes. The screw rod can pass through the two threaded through holes. The invention can realize the automatic drop of the cigarette butt, effectively avoids manual removal, not only reduces the manual labor in the cigarette detection, but also improves the cigarette detection efficiency.

Owner:贵州瀚天科技有限公司

Industrial flue gas desulfurization and dust removal device and implementation method thereof

ActiveCN112628782AAchieve regulationReduce usageHuman health protectionEmission preventionElectric machineDust control

The invention discloses an industrial flue gas desulfurization and dust removal device. The industrial flue gas desulfurization and dust removal device comprises a shell, power mechanisms are arranged on the left side and the right side of the top of the front surface of the shell correspondingly, each power mechanism comprises a long pipe, a transverse pipe, a spray head, a first grooved wheel, a belt, a second grooved wheel and a motor, and the outer walls of the two long pipes are connected to the left side and the right side of the top of the front surface of the shell in a rotating mode correspondingly. According to the industrial flue gas desulfurization and dust removal device, the motors of the power mechanisms drive the second grooved wheels to rotate to be coordinated with the belts to drive the first grooved wheels to rotate to enable the long pipes to rotate, so that spraying work is realized through cooperation of the transverse pipes and the spray heads, power source use is reduced, the work cost is lowered, and the practicability is improved; a water pump does not need to be adopted for pumping spraying liquid for work, so that the cleaning trouble is removed, and later use is facilitated; the size of the space at the top of the inner wall of the shell is adjusted, the gas throughput is guaranteed, backflow of gas is prevented, and normal work is guaranteed; and impurities on the surfaces of transverse plates fall off, cleaning is facilitated, the operation workload is reduced, use is facilitated, and popularization is facilitated.

Owner:LIAONING INST OF SCI & TECH

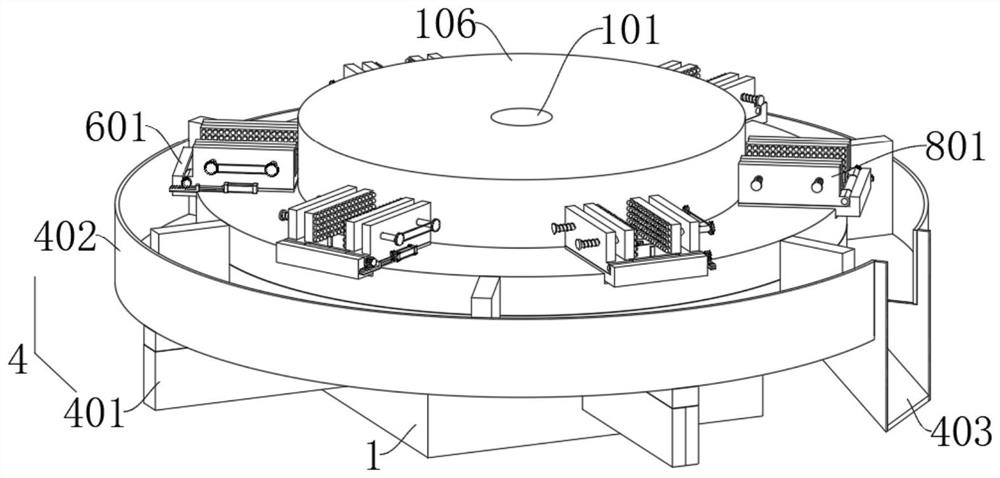

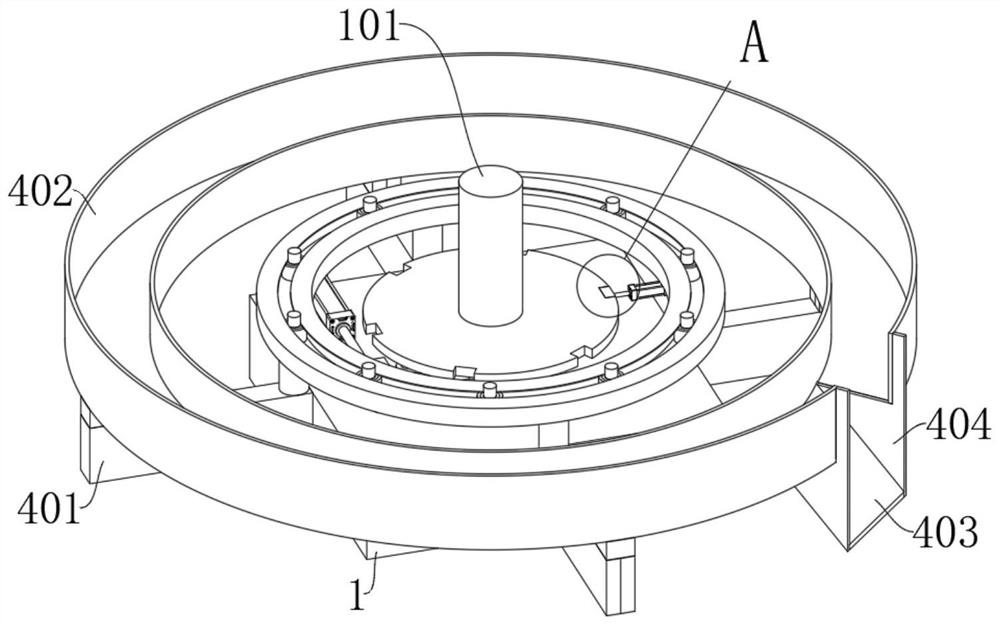

Multi-station fixing device for workpiece machining based on numerical control lathe

PendingCN114850910AEasy angle adjustmentEasy intermittent adjustmentMetal working apparatusPositioning apparatusPhysicsEngineering

The invention provides a multi-station fixing device for workpiece machining based on a numerically controlled lathe, and relates to the technical field of numerically controlled lathes. A supporting shaft is installed in the base, and a positioning disc is fixedly arranged on the outer side of the supporting shaft. A machining table is fixedly arranged on the outer side of the supporting shaft. A driving mechanism is mounted at the top of the base, and a collecting device is fixedly arranged on the outer side of the base; an auxiliary mechanism is mounted at the top of the machining table, and a control mechanism is mounted at the top of the machining table. A fixing mechanism is mounted at the top of the auxiliary mechanism, so that the fixing device can be intermittently adjusted more simply and conveniently according to different machining stations, and multi-process machining of workpieces is facilitated; the problems that intermittent adjustment is inconvenient to conduct on a fixing device according to different machining stations, and angle adjustment is inconvenient to conduct on workpieces according to machining requirements through an existing fixing device are solved.

Owner:施复员

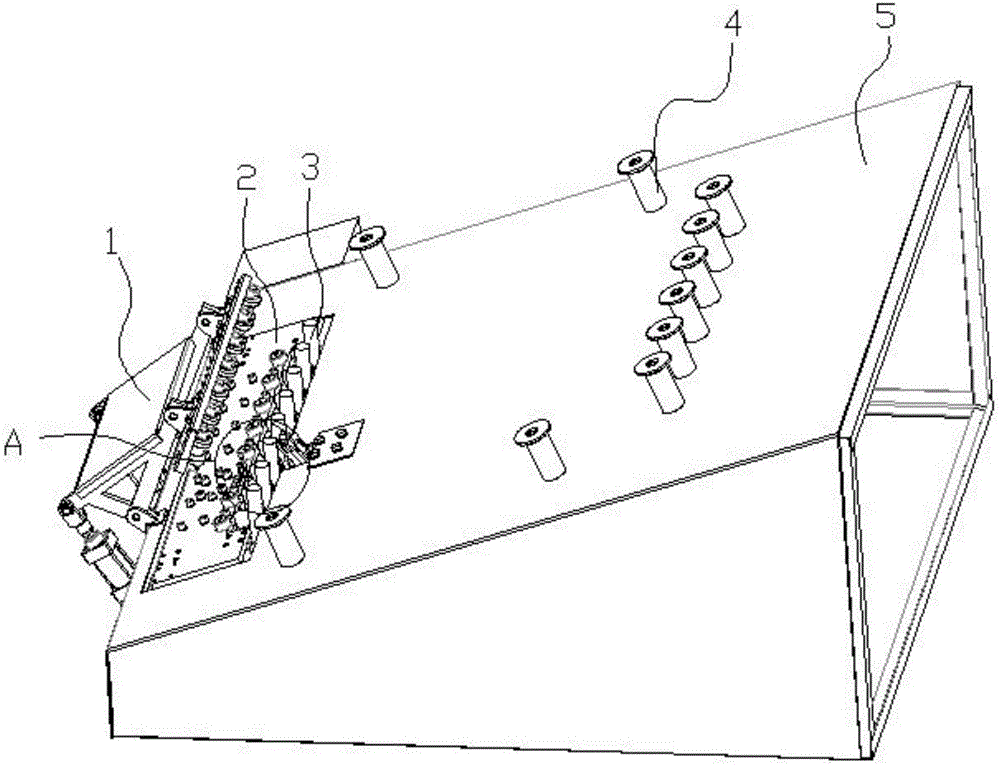

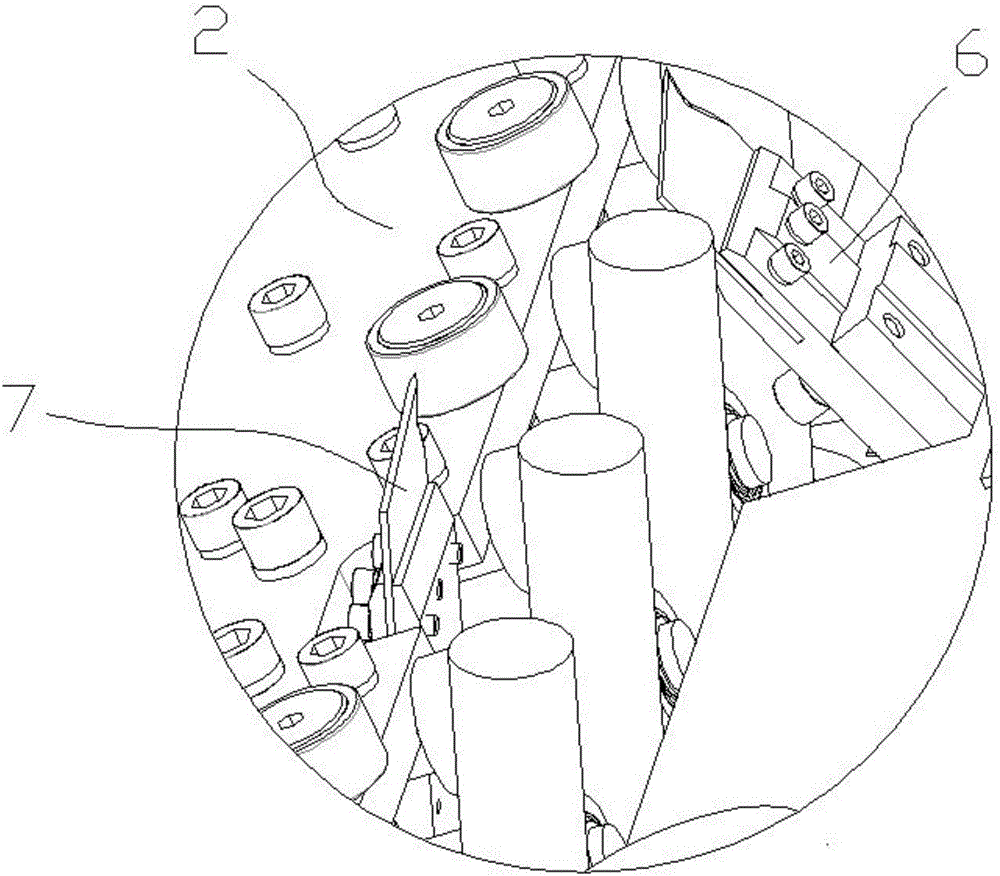

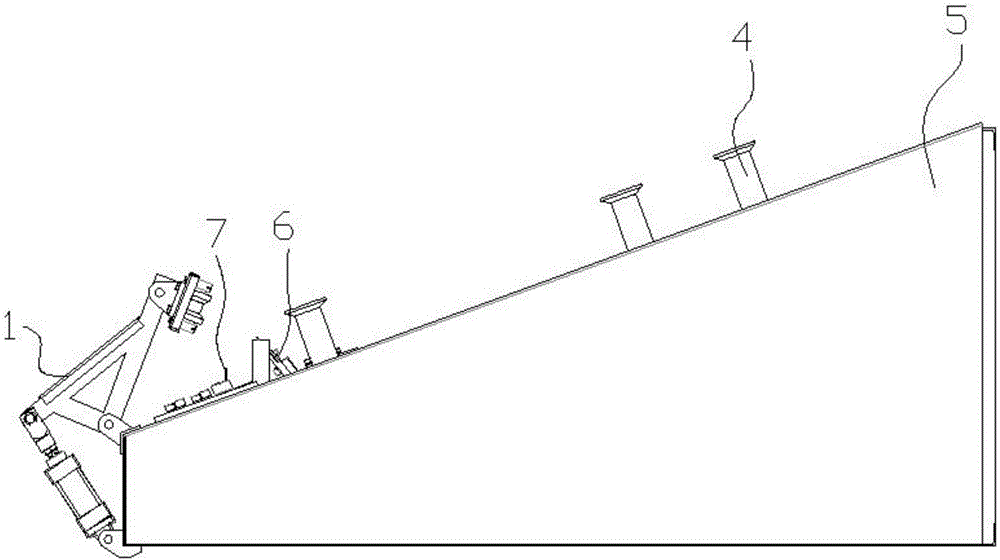

Automatic nozzle cutting device for producing and machining T-shaped rubber seal rings

ActiveCN106182527AIncrease the level of automationRealize automatic dropDomestic articlesMetal working apparatusEngineeringFully automatic

The invention discloses an automatic nozzle cutting device for producing and machining T-shaped rubber seal rings and belongs to the field of seal ring nozzle cutting. The device comprises a rack, an outer side-wheel assembly for cutting and positioning outer side nozzles of the T-shaped rubber seal ring workpieces, and an inner sliding wheel transmission assembly for achieving automatic rotation when the T-shaped rubber seal ring workpieces are cut; supporting wheels for positioning the T-shaped rubber seal ring workpieces are installed on the rack; an upper cutter assembly and a lower cutter assembly used for nozzle cutting of the inner surfaces and the outer surfaces of the T-shaped rubber seal ring workpieces are installed on the rack; a motor assembly is installed in the rack; and the inner sliding wheel assembly is connected with the motor assembly. According to the automatic nozzle cutting device for producing and machining the T-shaped rubber seal rings, the structure is simple; the operation is convenient; fully automatic cutting of the nozzles of the T-shaped rubber seal rings is achieved; the cutting effect is good; off-tracking of the T-shaped rubber seal ring workpieces in the nozzle cutting process can be prevented; the uniformity of the nozzle cutting of the T-shaped rubber seal rings is ensured; and the producing quality of the T-shaped rubber seal rings is improved.

Owner:JIHUA 3517 RUBBER PROD

Conveying equipment capable of picking, cleaning and classifying

InactiveCN111919596ARealize automatic dropShorter picking timeConveyorsFood treatmentStructural engineeringMechanical engineering

Owner:福州市连江县利凯科技有限公司

A building fire alarm device

ActiveCN114377326BRealize automatic recyclingRealize automatic dropFire rescueFire alarm smoke/gas actuationArchitectural engineeringAlarm device

The present invention is applicable to the technical field of alarm equipment, and provides a building fire alarm device, comprising: a housing, a smoke alarm module and a storage mechanism, the smoke alarm module is fixedly connected to the housing, and the storage mechanism is fixedly connected to Inside the casing, the smoke alarm module controls the storage mechanism; the storage mechanism is used for lifting and lowering fire extinguishing tools; several hanging interfaces are provided on the top and around the casing; the storage mechanism includes: a winding wheel , a guide column and a storage frame, the winding wheel is rotatably connected to the casing, and a scroll spring is arranged between the winding wheel and the casing. In this way, the present invention is small in size, easy to carry, convenient to use at the construction site, and can be installed quickly. When a fire occurs, an alarm signal will be sent out, and the fire extinguishing tool inside the alarm device will be released at the same time, and the construction personnel will be reminded of the fire extinguishing tool through the alarm sound. The location of the fire will advance the timing of fire extinguishing.

Owner:潍坊中维美瑞机械有限公司

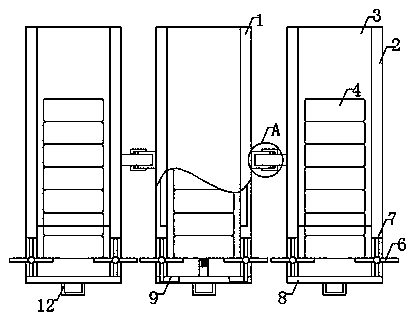

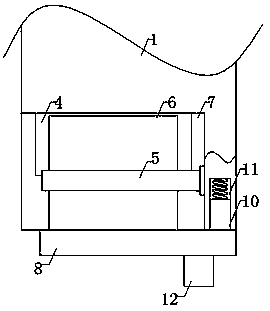

Combined-type storage box capable of providing convenience for taking bags

The invention discloses a combined-type storage box capable of providing convenience for taking bags. The storage box includes a first storage box body and two second storage box bodies, vertical passages are formed in the front surfaces of the first storage box body and second storage box bodies respectively, multiple supplies are vertically placed in the three vertical passages, and openings runthrough the two sides of the lower end of each vertical passage; discharging mechanisms are arranged in the six openings respectively and are convenient to use; when it is needed to fetch the supplies, only a handle needs to be pulled down, and then automatic discharging of the supplies is achieved. The left and right sides of the first storage box body 1 are connected to the two second storage box bodies 2 through combination mechanisms respectively. The combination mechanisms are convenient to use, correspondingly the storage capacity of the storage box is large, the supplies are stacked and placed in the vertical passages, and therefore the internal spaces of the vertical passages are fully utilized.

Owner:SUZHOU MUSHAN CLOUD INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com