Rapid almond-hulling equipment

An almond, fast technology, applied in the field of fast almond shelling equipment, can solve the problems of low shelling efficiency and easy damage to nuts, and achieve the effect of improving efficiency and reducing manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

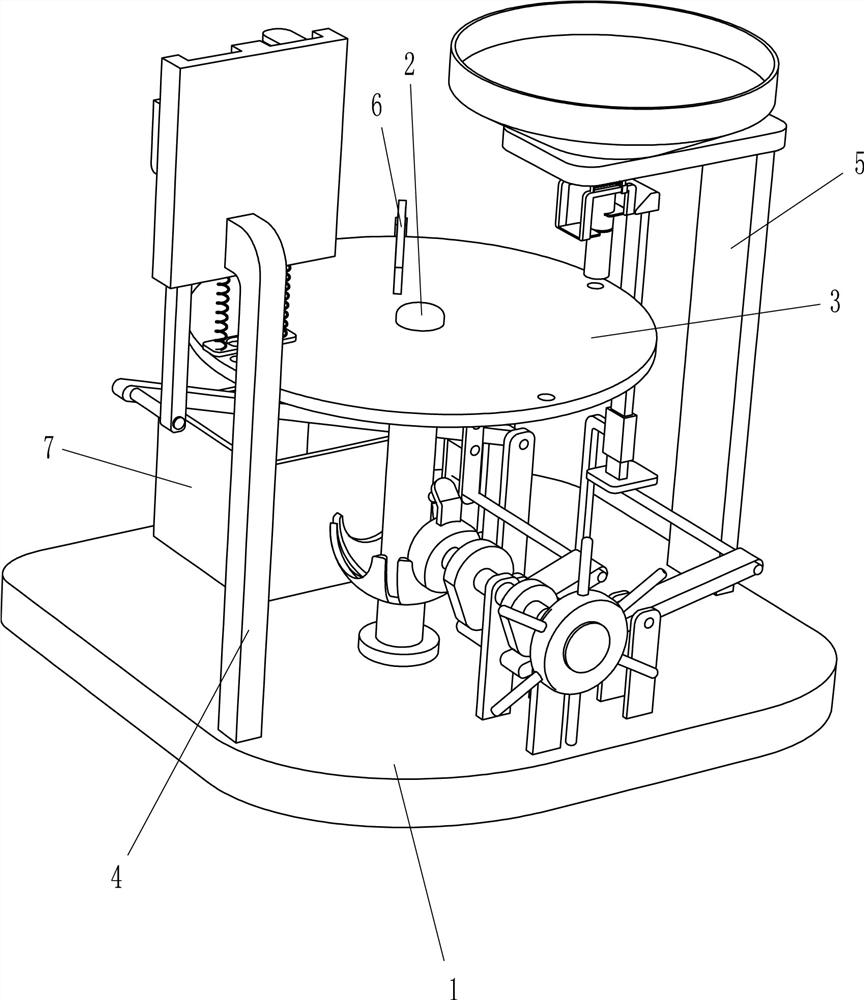

[0043] A kind of fast shelling equipment for almonds, such as figure 1 As shown, it includes a base 1, a first rotating shaft 2, a turntable 3, a knocking mechanism 4, a blanking mechanism 5, a second baffle 6 and a collection frame 7, and the top of the base 1 is provided with a first rotating shaft 2 rotating on the left side. A turntable 3 is installed on the top of the first rotating shaft 2, and four circular holes are evenly opened on the turntable 3. A knocking mechanism 4 is arranged on the base 1. A blanking mechanism 5 is installed on the right side of the top of the base 1. The rear side of the right part of the base 1 is arranged There is a second baffle 6, and the second baffle 6 is located on the turntable 3, and a collection frame 7 is placed on the rear side of the base 1.

[0044] When the almonds need to be shelled, manually place the almonds in the parts of the blanking mechanism 5, manually turn the turntable 3, so that a round hole on the turntable 3 is lo...

Embodiment 2

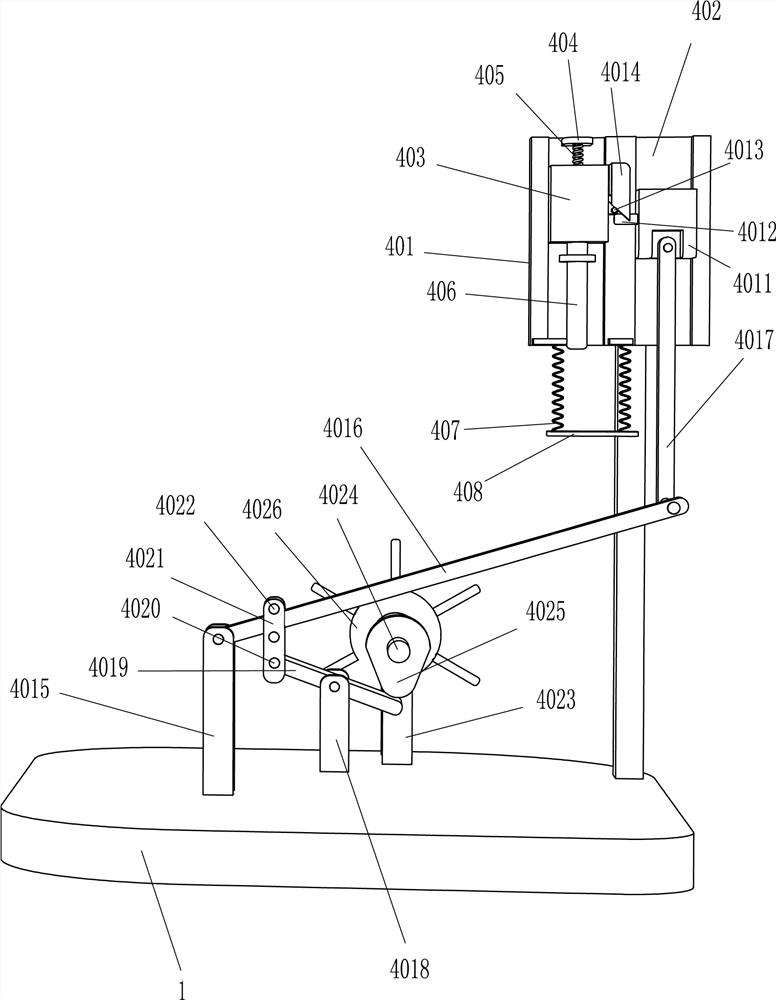

[0046] Specifically, as Figure 2-4 As shown, the knocking mechanism 4 includes a first mounting plate 401, a first slide block 403, a first fixed block 404, a first elastic member 405, a pressing rod 406, a second elastic member 407, a crushing plate 408, a first wedge block 409, the third elastic member 4010, the second slider 4011, the ejector rod 4012, the ejector shaft 4013, the wedge-shaped ejector block 4014, the first mounting block 4015, the first swinging plate 4016, the second swinging plate 4017, and the second mounting plate 4018 , the third swing plate 4019, the connecting shaft 4020, the second fixed block 4021, the card shaft 4022, the bearing seat 4023, the rotating shaft 4024, the first cam 4025 and the hand wheel 4026, and the first mounting plate is provided on the left front side of the base 1 401, two sliding slots 402 are provided on the rear side of the first mounting plate 401, the first sliding block 403 is slidably installed in the sliding slot 402 o...

Embodiment 3

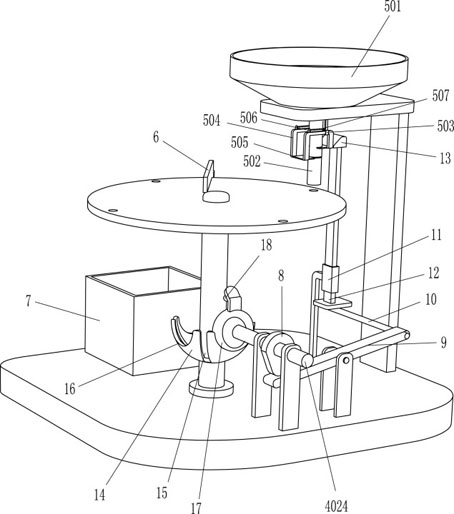

[0051] according to Figure 4 As shown, it also includes a second cam 8, a fourth swing plate 9, a cross bar 10, a second sliding sleeve 11, a T-shaped bar 12 and a second wedge block 13, the second cam 8 is installed in the middle of the rotating shaft 4024, and the base 1 The front side swing type is provided with a fourth swing plate 9, the left side of the fourth swing plate 9 is in contact with the second cam 8, the right side of the fourth swing plate 9 is provided with a cross bar 10, and the rear side of the right part of the base 1 is equipped with a second slide. Sleeve 11, the sliding type in the second sliding sleeve 11 is provided with T-shaped bar 12, and the bottom of T-shaped bar 12 is in contact with the rear part of cross bar 10, and the top of T-shaped bar 12 is equipped with second wedge-shaped block 13, and second wedge-shaped block 13 and The upper first baffle 505 is accessible.

[0052] Manually turn the handwheel 4026 clockwise, when the protruding pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com