Flat plate groove cutting workbench with open table top

A bevel cutting and workbench technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of falling into the workbench, reducing the flatness of the cutting platform, consuming manpower and time, and achieving Avoid moving or falling, improve cutting quality, and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

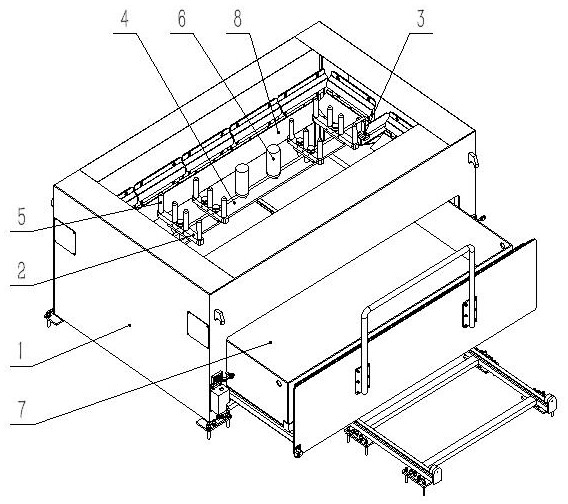

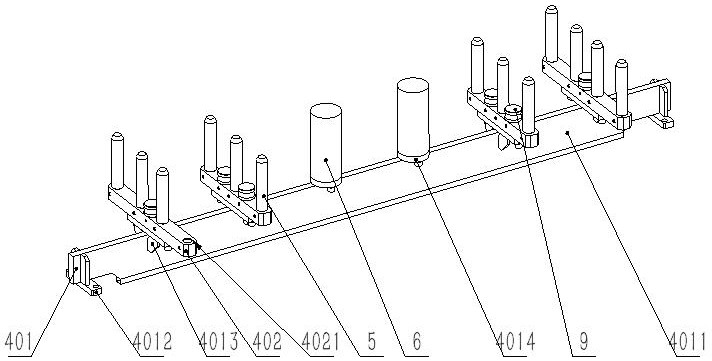

[0041] Such as figure 1As shown, a kind of steel plate part bevel plasma cutting workbench designed by the present invention includes a workbench main body 1 and a support frame assembly 2; the workbench main body 1 is a box structure with an open top; the support frame assembly 2 It is arranged inside the main body 1 of the workbench, and the two ends are connected with the two ends of the main body 1 of the workbench by fasteners 3, and the rest is suspended in the air, which is beneficial to the automatic fall of cutting waste and iron oxide slag, without hanging the table; The support frame assembly 2 includes a support frame 4, a support column 5 and a magnetic suction column 6; the support column 5 and the magnetic suction column 6 are all arranged on the support frame 4 for better fixing the workpiece and preventing the workpiece from escaping during cutting. move or fall; the bottom of the workbench main body 1 is provided with a waste collection tank 7 that can move i...

Embodiment 2

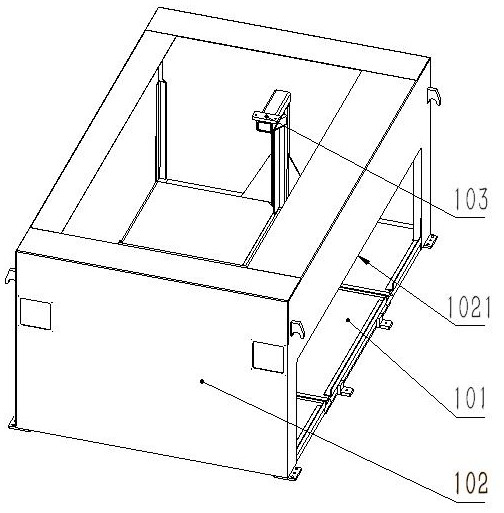

[0061] Such as Figure 8 , Figure 9 As shown, due to the limitation of the installation site and other reasons, the waste material collection tank 7 cannot be moved in and out from the side of the workbench main body 1. At this time, the waste material collection tank 7 can be directly placed on the adjustable support seat 19 at the inner bottom of the workbench main body 1. Above, the support frame assembly 2 is connected with the workbench main body 1 by positioning pins that can realize quick separation and fastening; after a shift or the waste collection tank 7 is filled with waste materials, the support frame assembly 2 is manually lifted from the working table by a crane. The top of the table main body 1 is hoisted out; then the waste collection tank 7 full of cutting waste and iron oxide slag is lifted out from the top of the workbench main body 1 with a crane, replaced with an empty waste collection tank 7, and the next shift is continued. cutting work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com