Continuous automatic output vermicelli cooking device

An automatic output and cooking device technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of boiled vermicelli and unable to transfer the vermicelli, and achieve the effect of avoiding boiled, simple structure and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

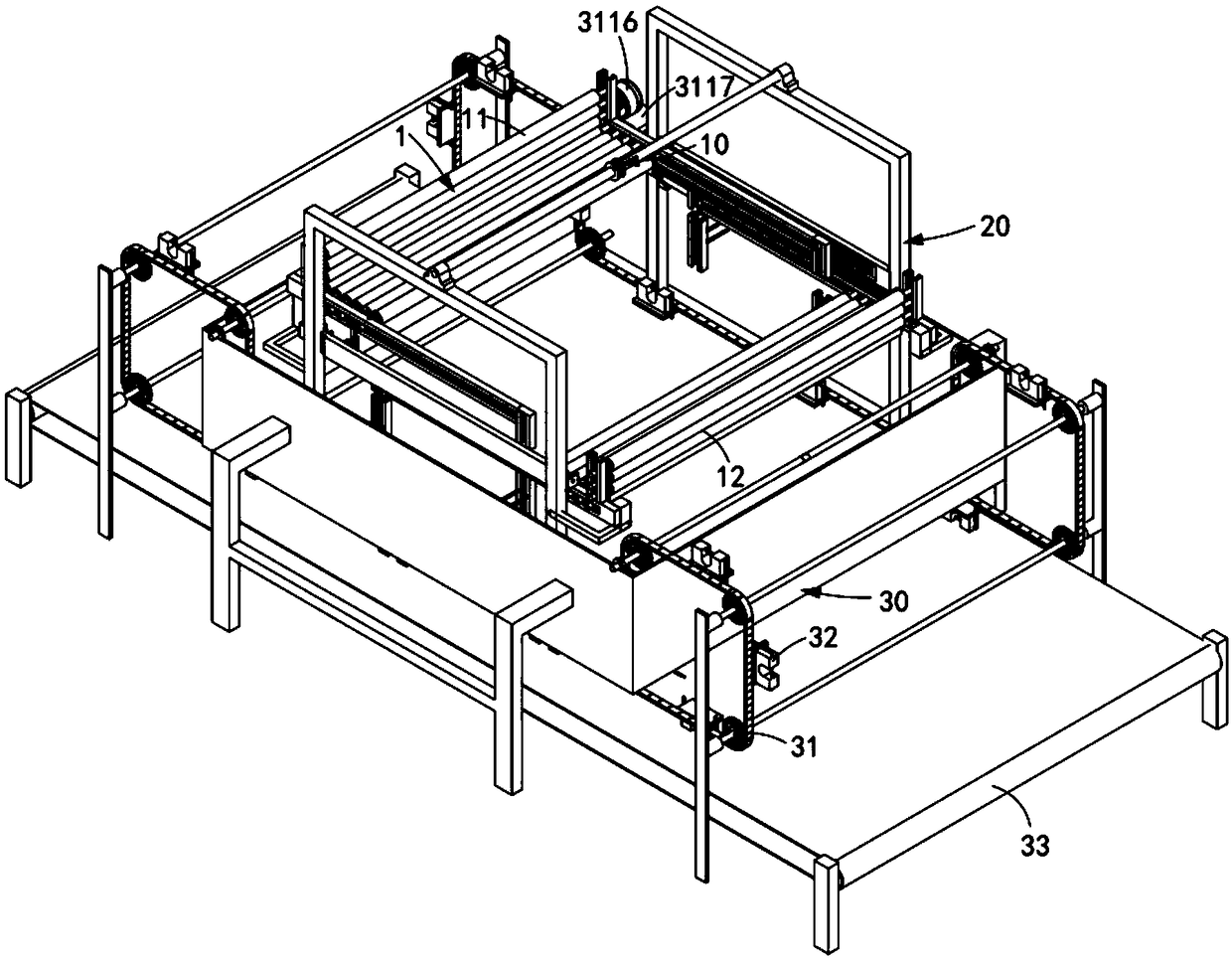

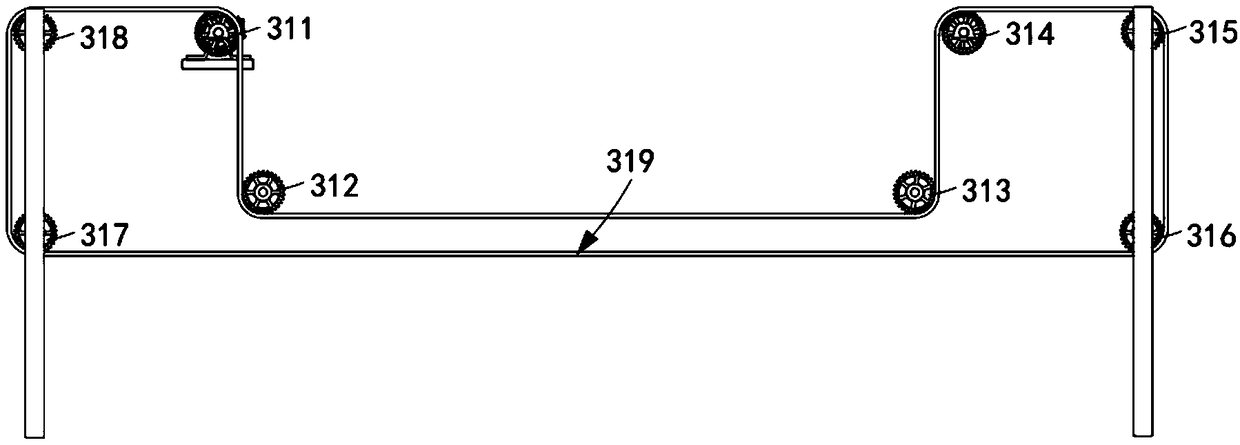

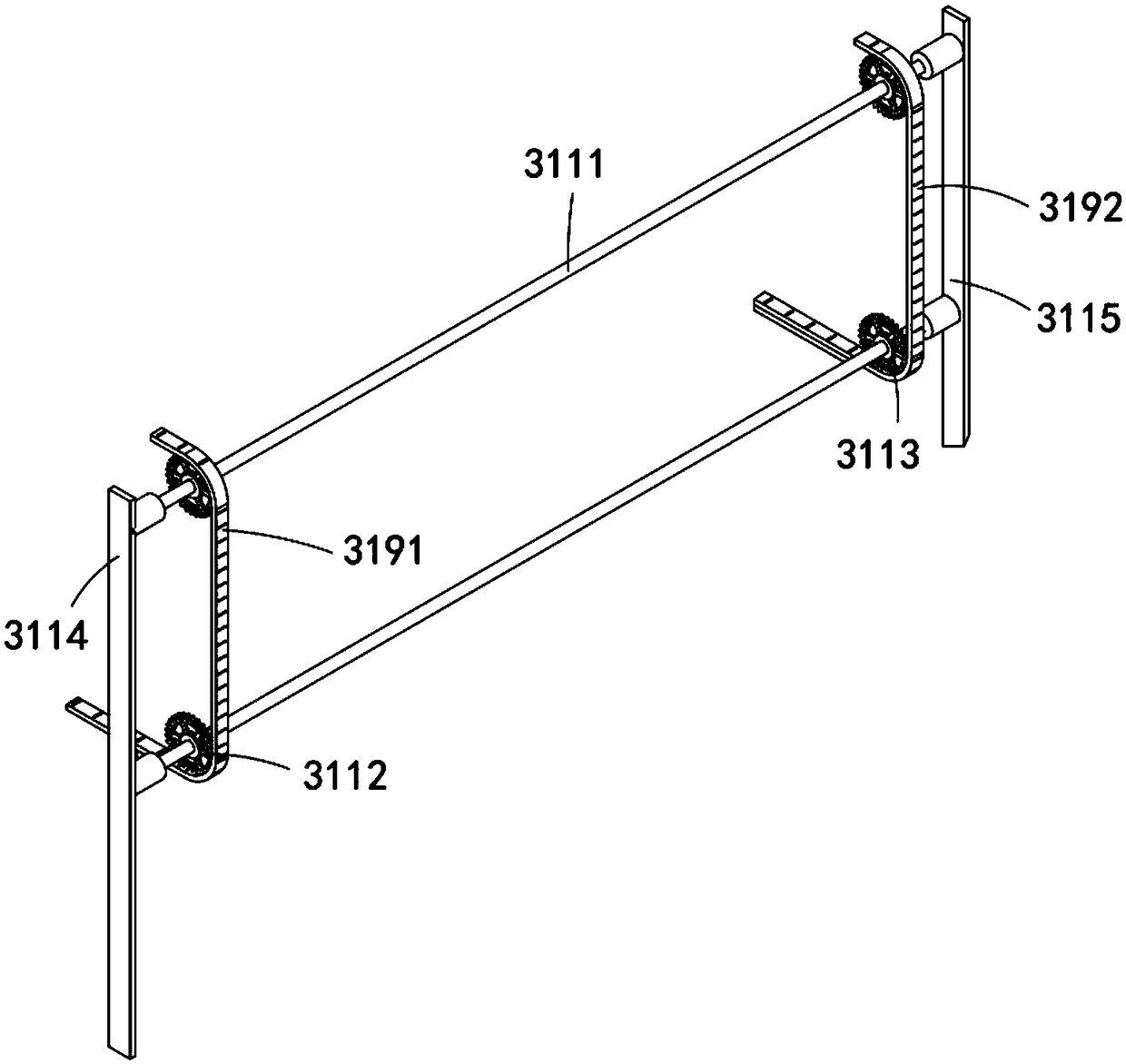

[0072] Such as figure 1 As shown, a continuous automatic output vermicelli cooking device includes a vermicelli conveyor belt 10, which is erected on the top of a frame 20, and a cooking box 30 is provided at the bottom thereof, and the frame 20 is installed on the cooking box 30 within, including:

[0073] Material holding mechanism 1, the material holding mechanism 1 is fixedly arranged below the vermicelli conveyor belt 10 and installed on the frame 20, the material holding mechanism 1 is used to support the vermicelli that is vertically output by the vermicelli conveyor belt 10 And it is output in an S shape, which includes a first material holding assembly 11 located on one side of the cooking box 30 and a second material holding assembly 11 located on the other side of the cooking box 30 and arranged below the first material holding assembly 11. Material holding component 12, the first material holding component 11 and the second material holding component 12 are arrang...

Embodiment 2

[0125] Such as Figure 9 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0126] Further, the position where the guide block 27 and the chute 23 penetrate and cooperate is arranged in a square shape, and it fits closely with the chute 23, so as to ensure that the guide block 27 is always in a vertical state during the movement process, and no deflection, and the guide block 27 can only move vertically along the chute 23.

[0127] work process:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com