Production method of carbon-pultrued-plate single-lap tensile shearing specimen

A technology of tensile shearing and manufacturing method, applied in the preparation of test samples, etc., can solve the problems of low work efficiency, low fluid viscosity, difficulty and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

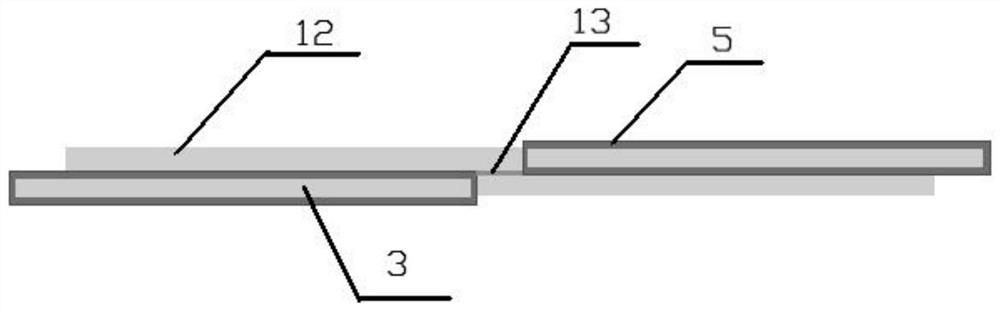

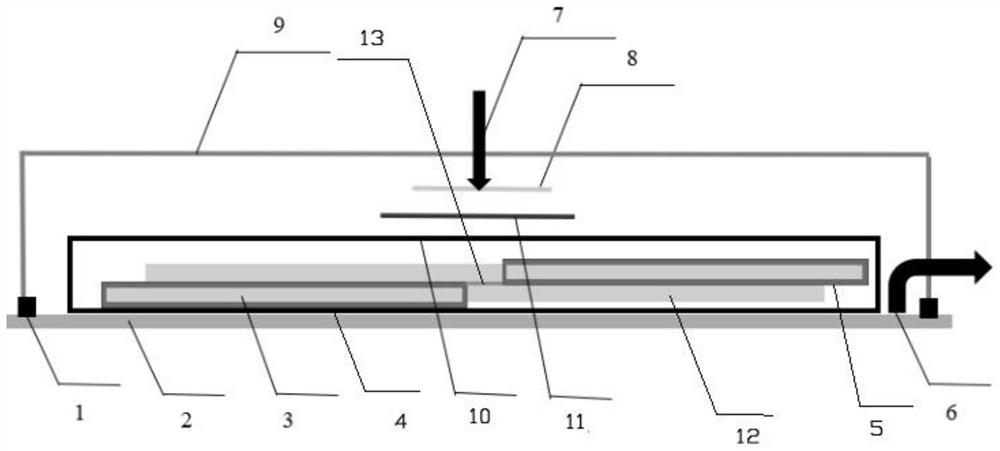

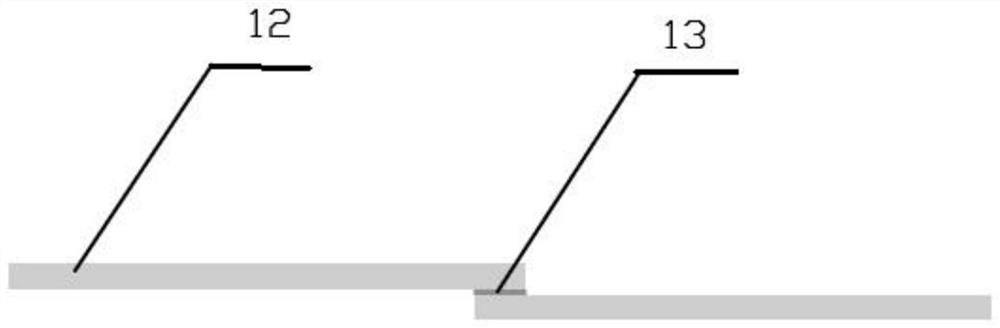

[0051] The staff cut the carbon pultrusion plate 12 into four pieces 3 with a length of 15cm, and wrapped two of the pieces 3 with a single-layer No. 1 isolation film 5 with holes. During the wrapping process, the No. 1 isolation film 5 interface Use blade strong spray glue for bonding, and then follow the figure 1 Lay the sample block 3 in the same way, lay the corresponding diversion medium in the area of the glue joint surface 13, the size of the glue joint surface 13 is 12.5mm, the sample block 3 wrapped by the No. Each sample block 3 is glued together, and can be separated separately later, and the laid sample block 3 is used figure 2 The upper and lower surfaces of the sample block 3 are wrapped with the first layer of release cloth 4 and the second layer of release cloth 10, placed on the electric heating mold 2, and the upper surface of the adhesive surface 13 area is laid with a hole 1 No. 5 isolating film 5 and No. 1 isolating film 5 are laid with diversion net 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com