Patents

Literature

73results about How to "Achieve continuous work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

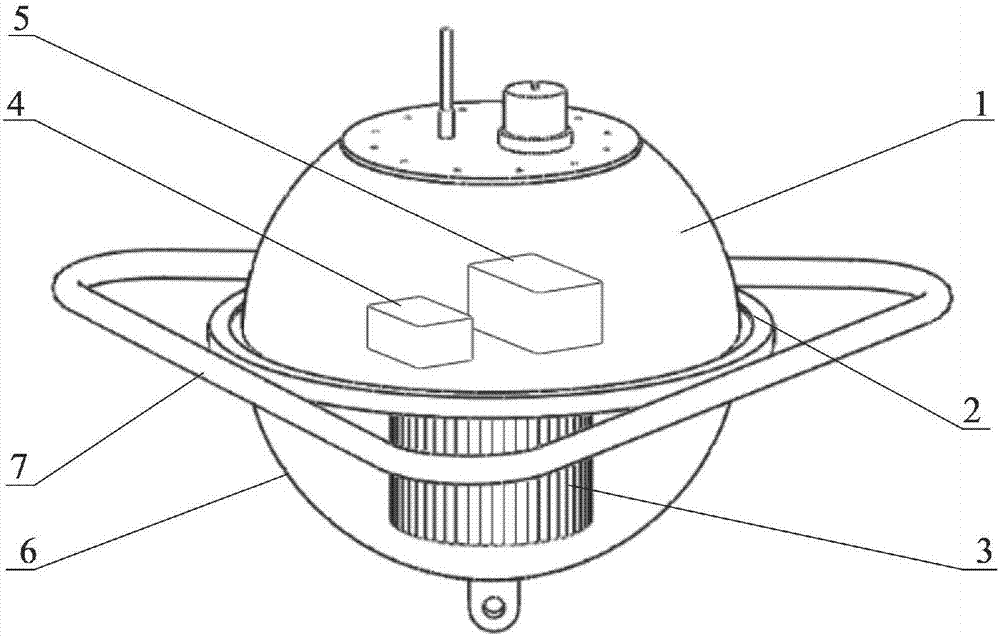

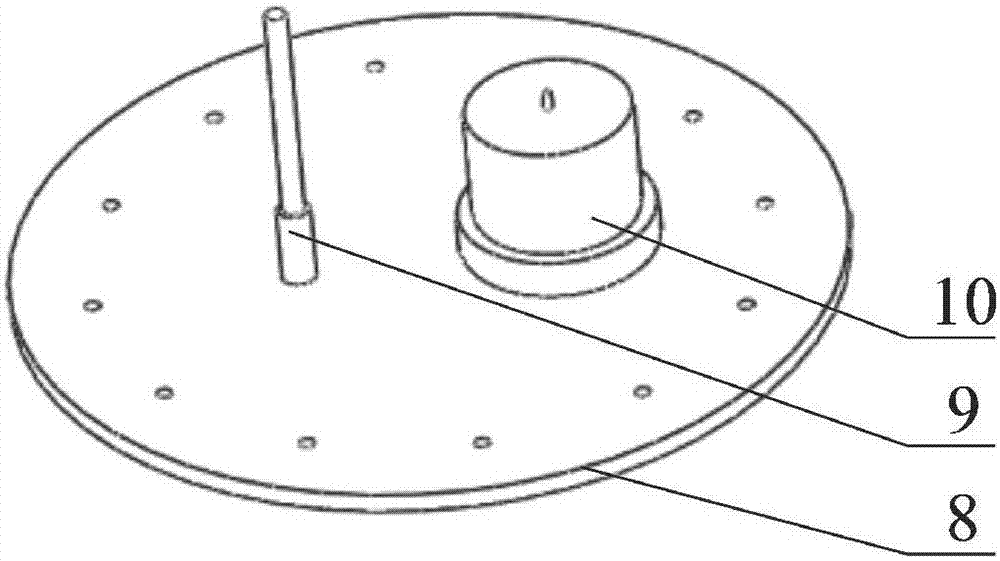

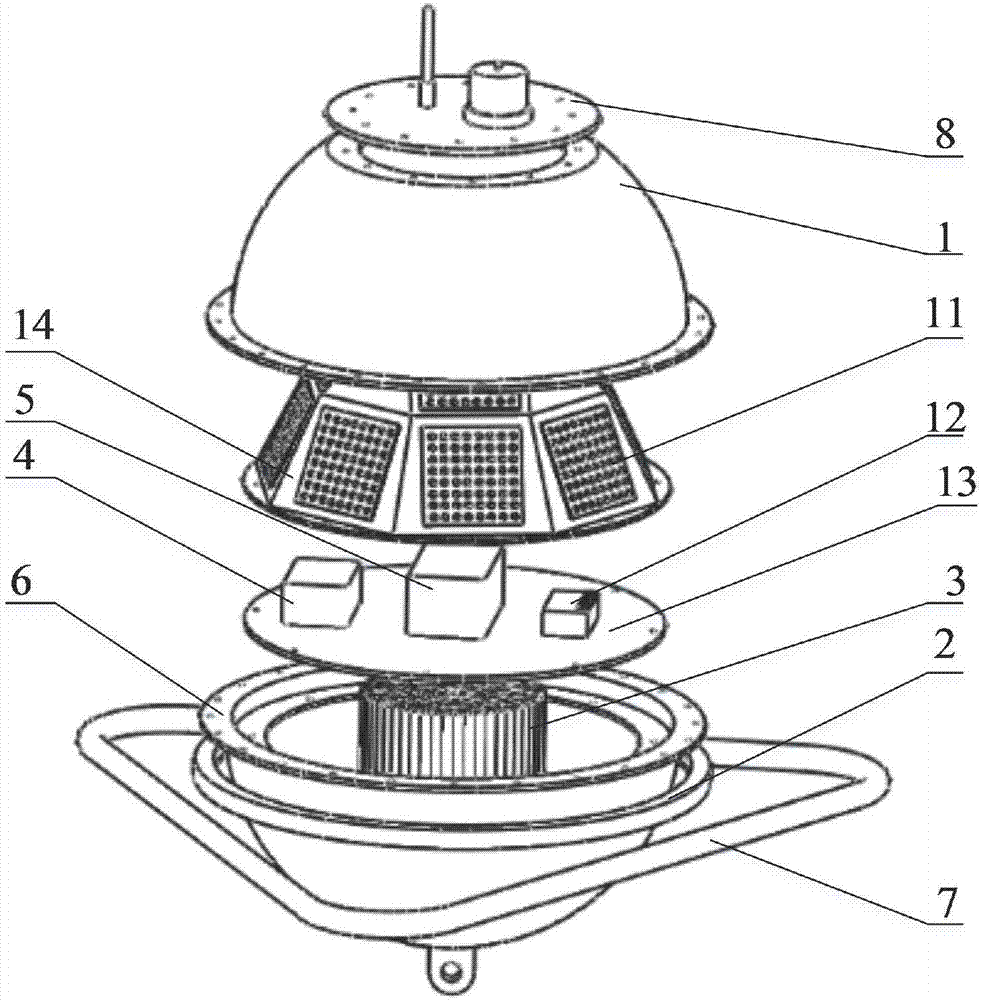

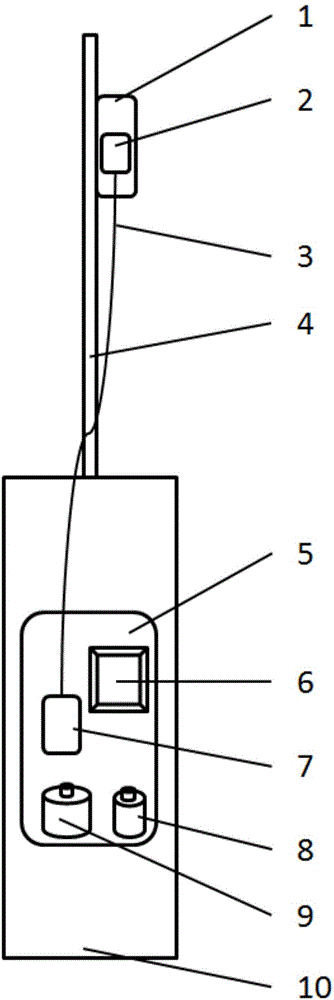

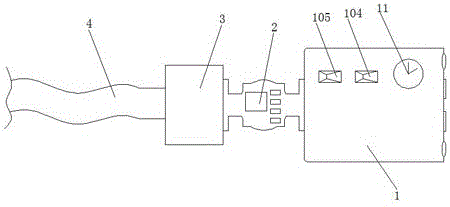

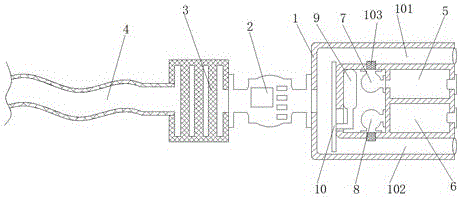

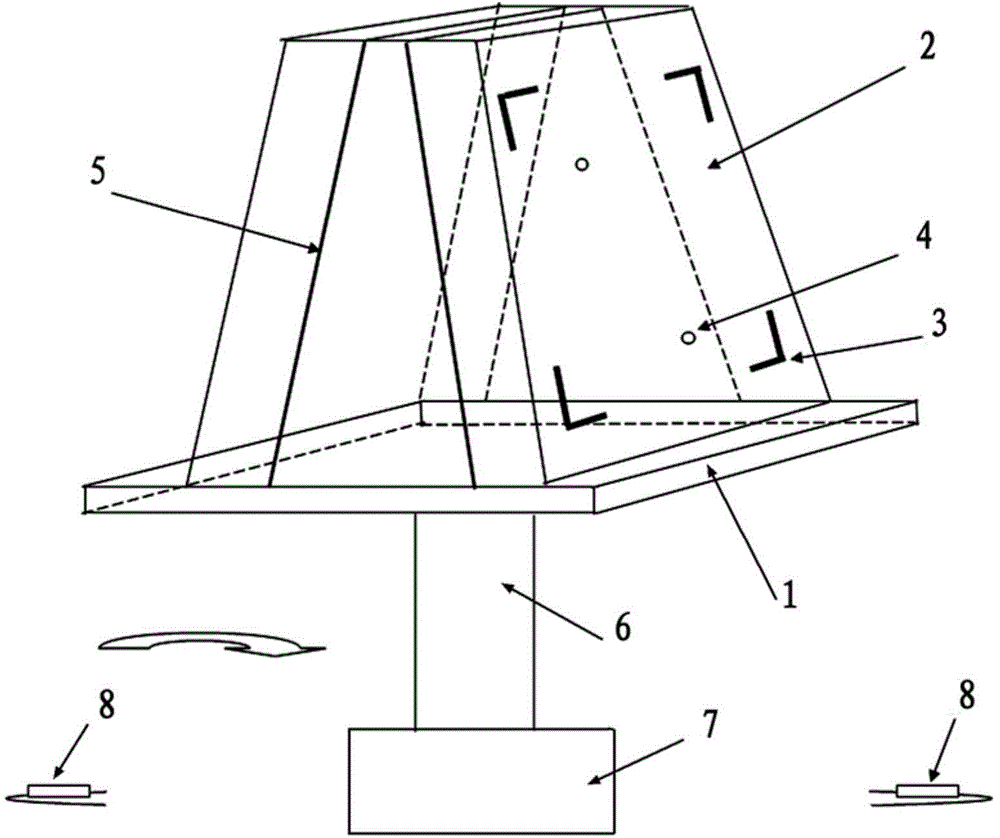

Transparent spherical wave buoy

InactiveCN106882330AAchieve continuous workReduce maintenance frequencyBatteries circuit arrangementsWaterborne vesselsData acquisitionEngineering

The invention discloses a transparent spherical wave buoy. The wave buoy comprises a hollow buoy shell inside, a navigation light and an antenna arranged outside the buoy shell, and a battery pack arranged inside the buoy shell, Data collector, sensor group, solar panel and charge and discharge controller; the data collector is connected to the sensor group and antenna respectively; the buoy housing is made of transparent material; the solar panel is arranged on the The inside of the buoy housing is used to convert the solar energy passing through the buoy housing into electrical energy; the charge and discharge controller is respectively connected with solar panels, battery packs, navigation lights, antennas, data collectors and sensor groups ; used to control the solar panel to charge the battery pack, or control the battery pack to discharge to the beacon light, antenna, data collector and sensor group, so as to realize the continuous operation of the wave buoy by converting solar energy, Reduce maintenance frequency.

Owner:STATE OCEAN TECH CENT

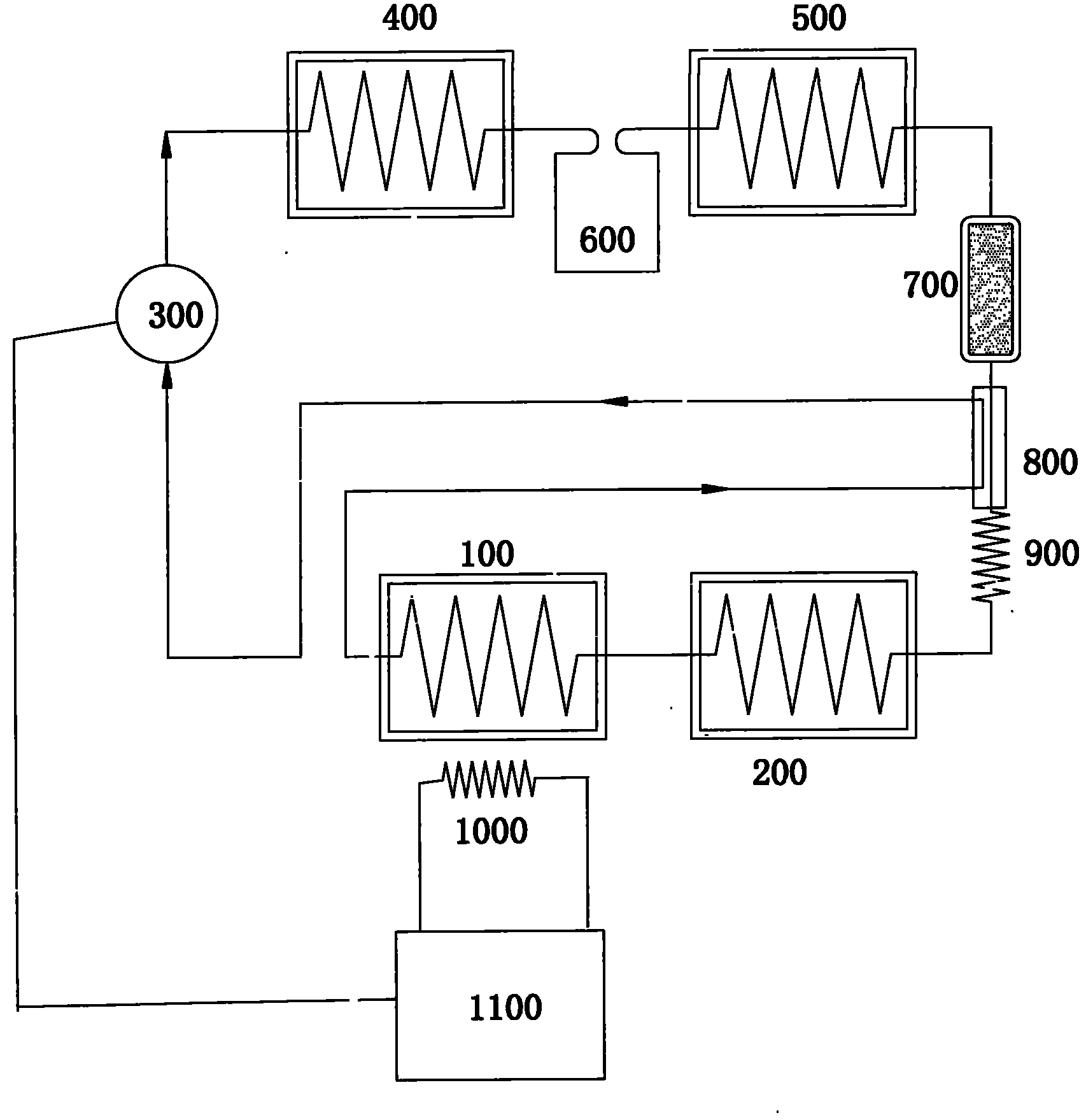

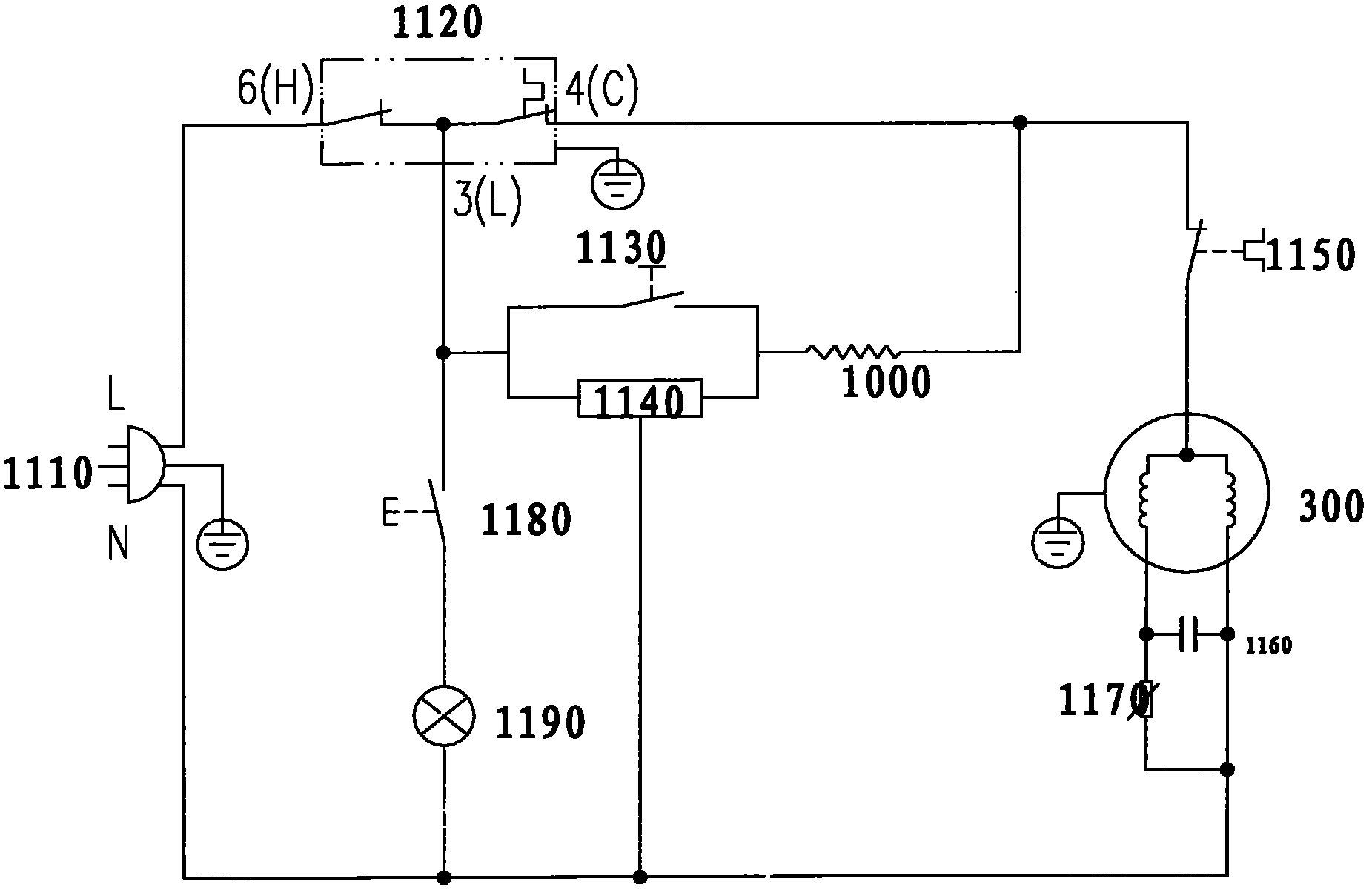

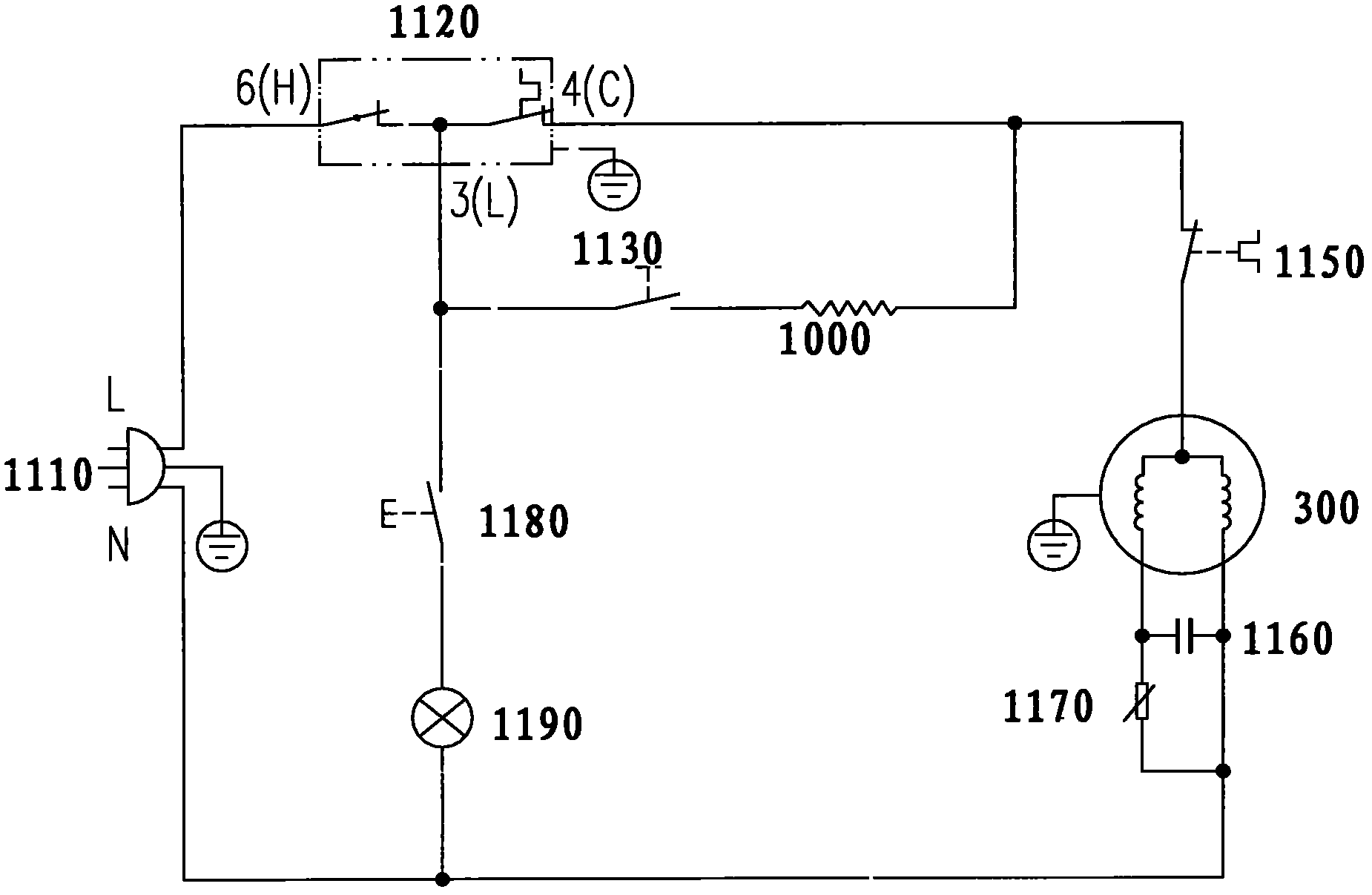

direct cooling refrigerator

ActiveCN102278847AAchieving Low Temperature CompensationAchieve continuous workLighting and heating apparatusDomestic refrigeratorsEngineeringCold store

The invention provides a direct cooling refrigerator comprising a refrigerating chamber evaporator, a freezing chamber evaporator, one or more condensers, a compressor, a compensating heater and a control circuit, wherein the compensating heater is used for heating the refrigerating chamber evaporator and the control circuit is used for controlling the compressor and starting the compensating heater so as to heat the refrigerating chamber evaporator when the compressor starts or the fast refrigeration is carried out by the direct cooling refrigerator. In the embodiment of the invention, the low temperature compensation for the compressor can be realized through the compensating heater; the refrigerating chamber evaporator can be heated through the compensating heater when the fast refrigeration is carried out by the direct cooling refrigerator; and therefore, the temperature of a refrigerating chamber is stabilized.

Owner:HUBEI MIDEA REFRIGERATOR CO LTD

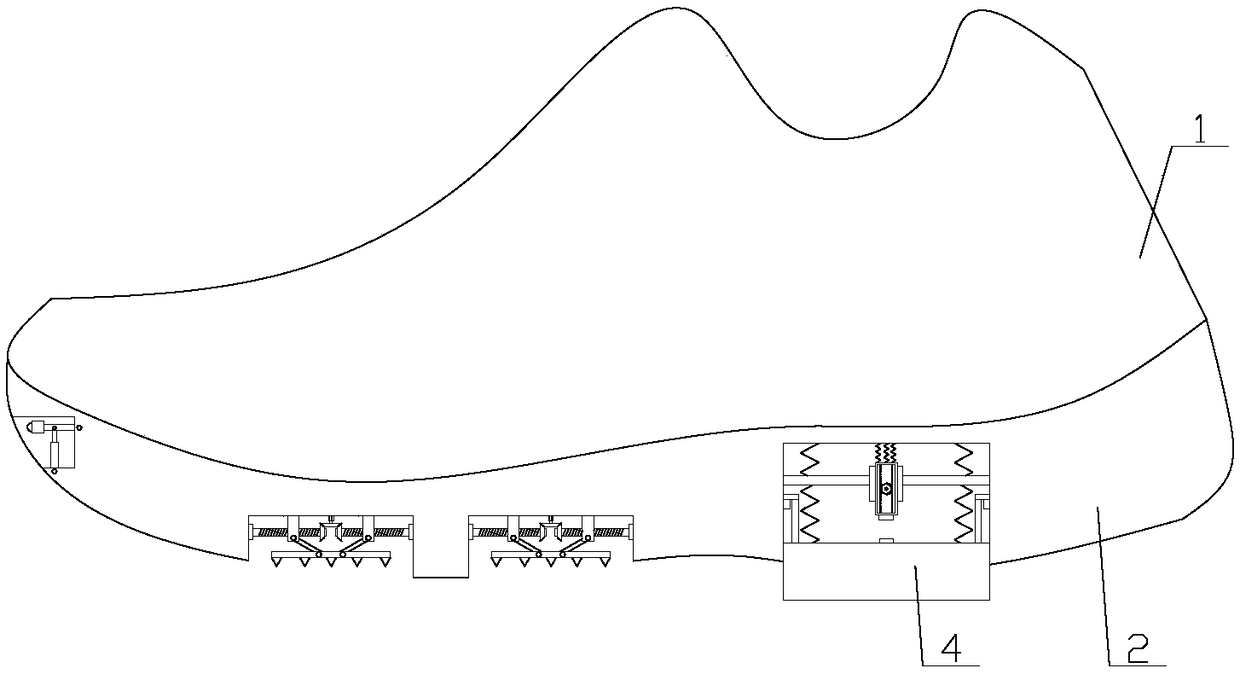

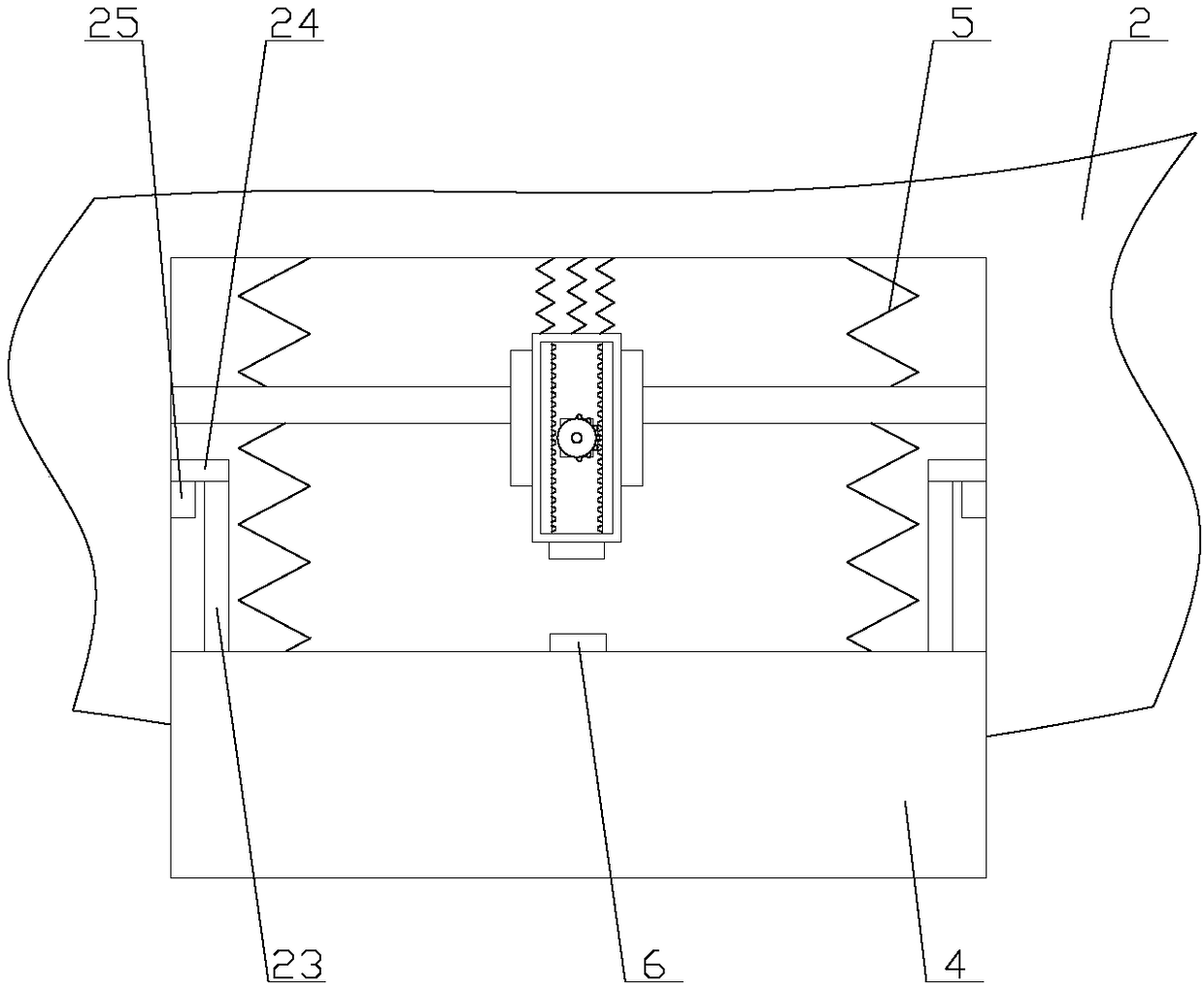

Energy-saving intelligent shoe with antiskid function on basis of internet of things

InactiveCN108391891AImprove practicalityImprove convenienceSolesLighting elementsThe InternetEngineering

The invention relates to an energy-saving intelligent shoe with an antiskid function on the basis of an internet of things. The energy-saving intelligent shoe comprises a shoe, a shoe sole, an illuminating lamp, a power generation mechanism and a plurality of antiskid mechanisms. The power generation mechanism comprises a driving assembly and a power generation assembly, and each antiskid mechanism comprises a driving motor, a first bevel gear, a lifting plate and two lifting units. The energy-saving intelligent shoe with the antiskid function on the basis of the internet of things has the advantages that kinetic energy generated when people walk can be sufficiently utilized, and accordingly power can be continuously generated by the power generation mechanism; electric energy can be stored, accordingly, the illuminating lamp can continuously work, batteries can be omitted and do not need to be changed, the practicality and the convenience of the energy-saving intelligent shoe can be improved, energy consumption can be reduced, and the energy-saving intelligent shoe conforms to energy-saving and environment-friendly concepts; the antiskid mechanisms can be started when a wearer needs to wear the energy-saving intelligent shoe to ascend or walk on icy road surfaces, accordingly, the shoe sole can be prevented from skidding, and the practicality and the safety of the energy-saving intelligent shoe can be improved.

Owner:SHENZHEN XIAOKONG COMM TECH CO LTD

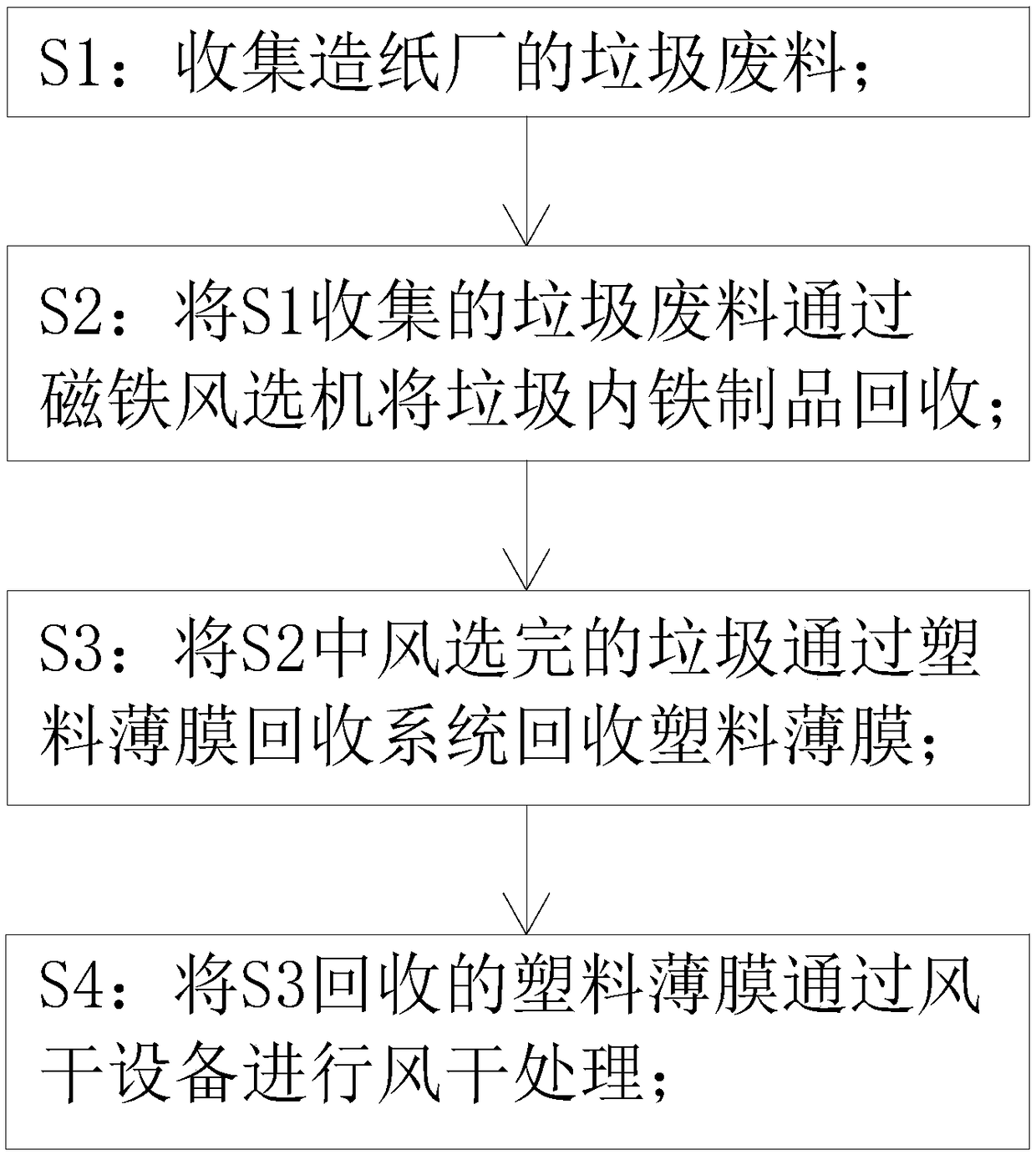

Waste plastic recycling process

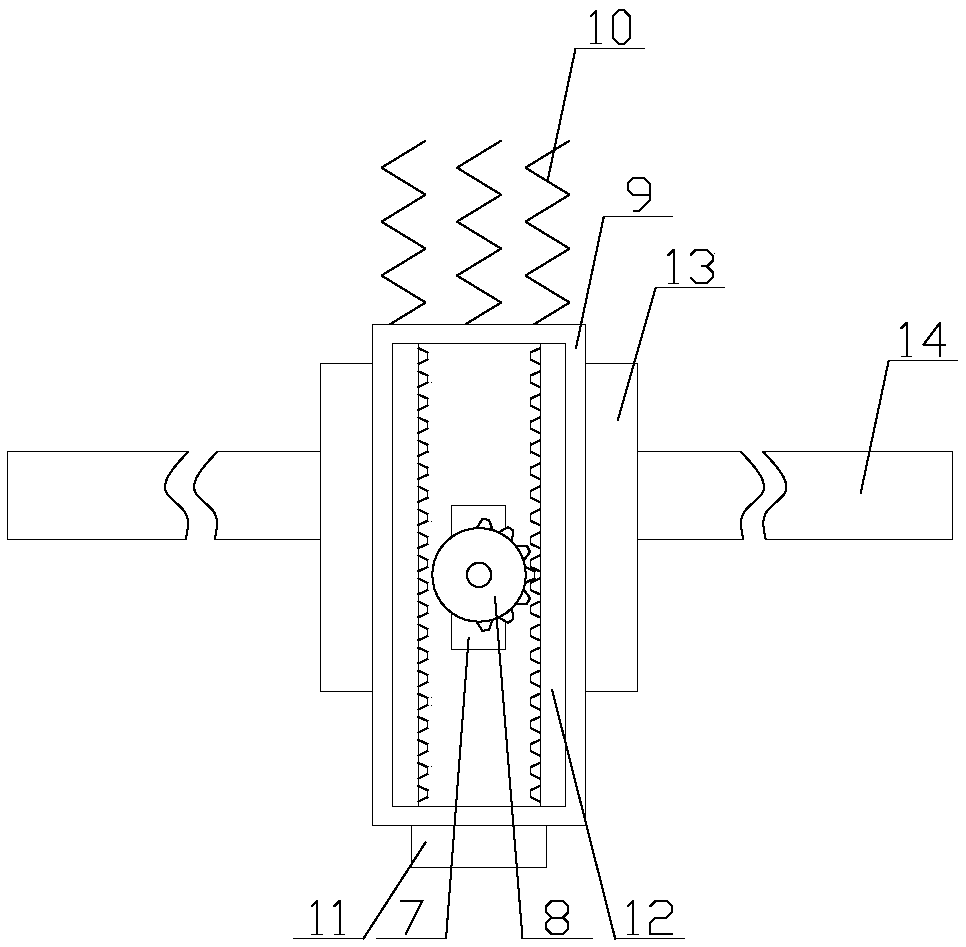

The invention relates to the technical field of resource recycling and particularly relates to a waste plastic recycling process. The waste plastic recycling process comprises a frame body, wherein aplurality of first airbags are arranged in a rubber belt and are sequenced in an equal internal manner; first springs fixedly connected to the upper and lower inner walls of the rubber belt are arranged on two sides of each first airbag; at least three extrusion wheels are arranged between a first driving wheel and a second driving wheel; each extrusion wheel rotates along the upper surface of therubber belt; the arrangement distance of the extrusion wheels is equal to that of the first airbags; suction discs which are in the equal number of the first airbags and in positional correspondencewith the first airbags are fixedly connected to the surface of the rubber belt; at least three cams are arranged in the framework; and the cams rotate to be cooperated with the extrusion wheels to extrude the suction discs so as to extrude the first airbags through the rubber belt, the cams do not extrude the first airbags because the first airbags are in a compression state when the first airbagspass the next cam, and the different suction discs are extruded by extruded parts during the rotation of the cams for one cycle.

Owner:湖北卓安塑业有限公司

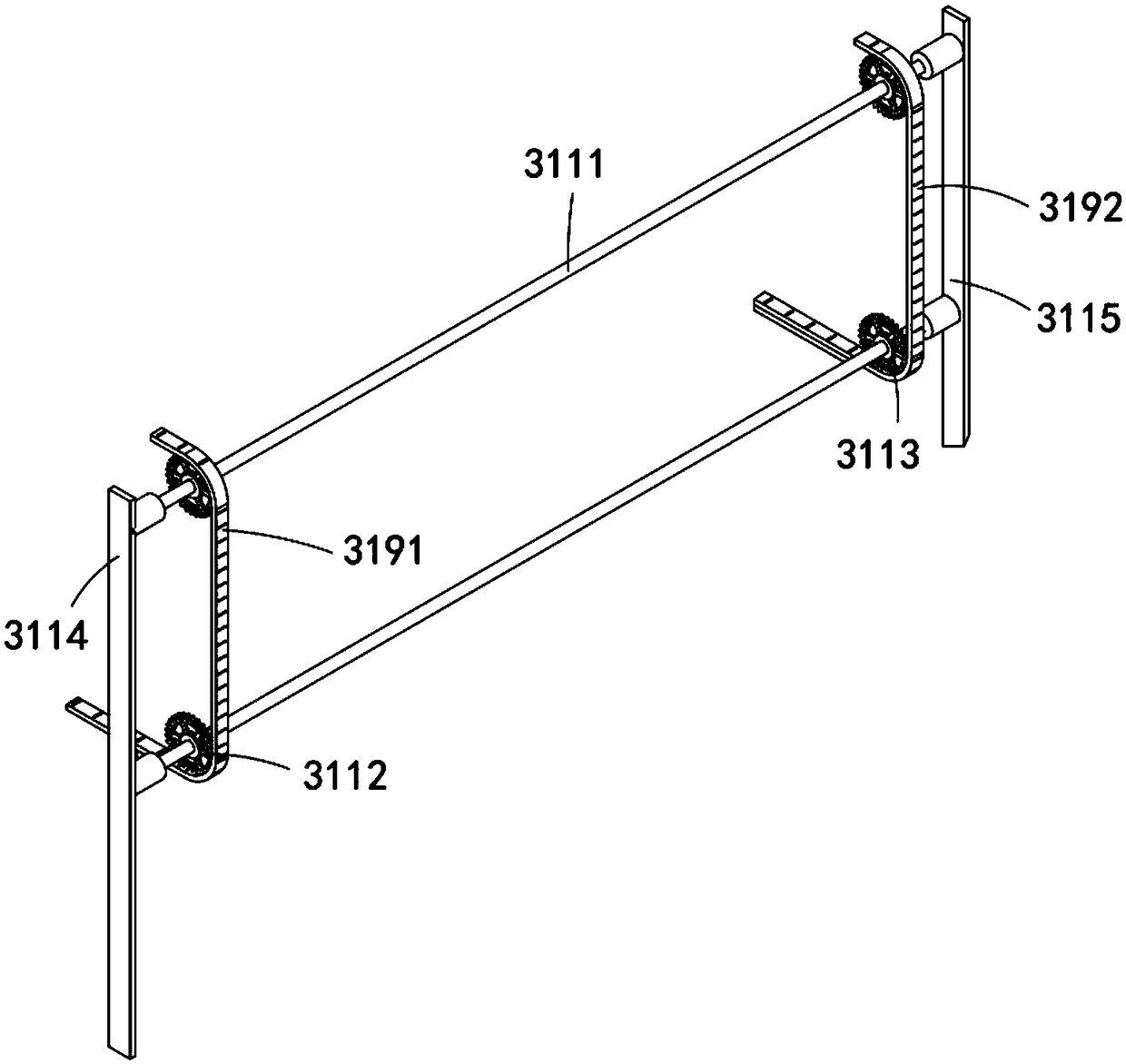

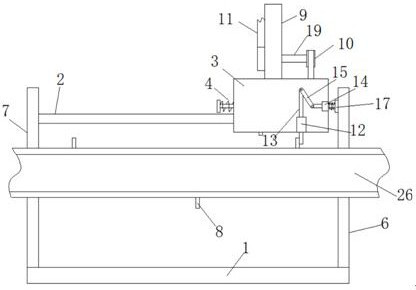

Automatic wire winding device

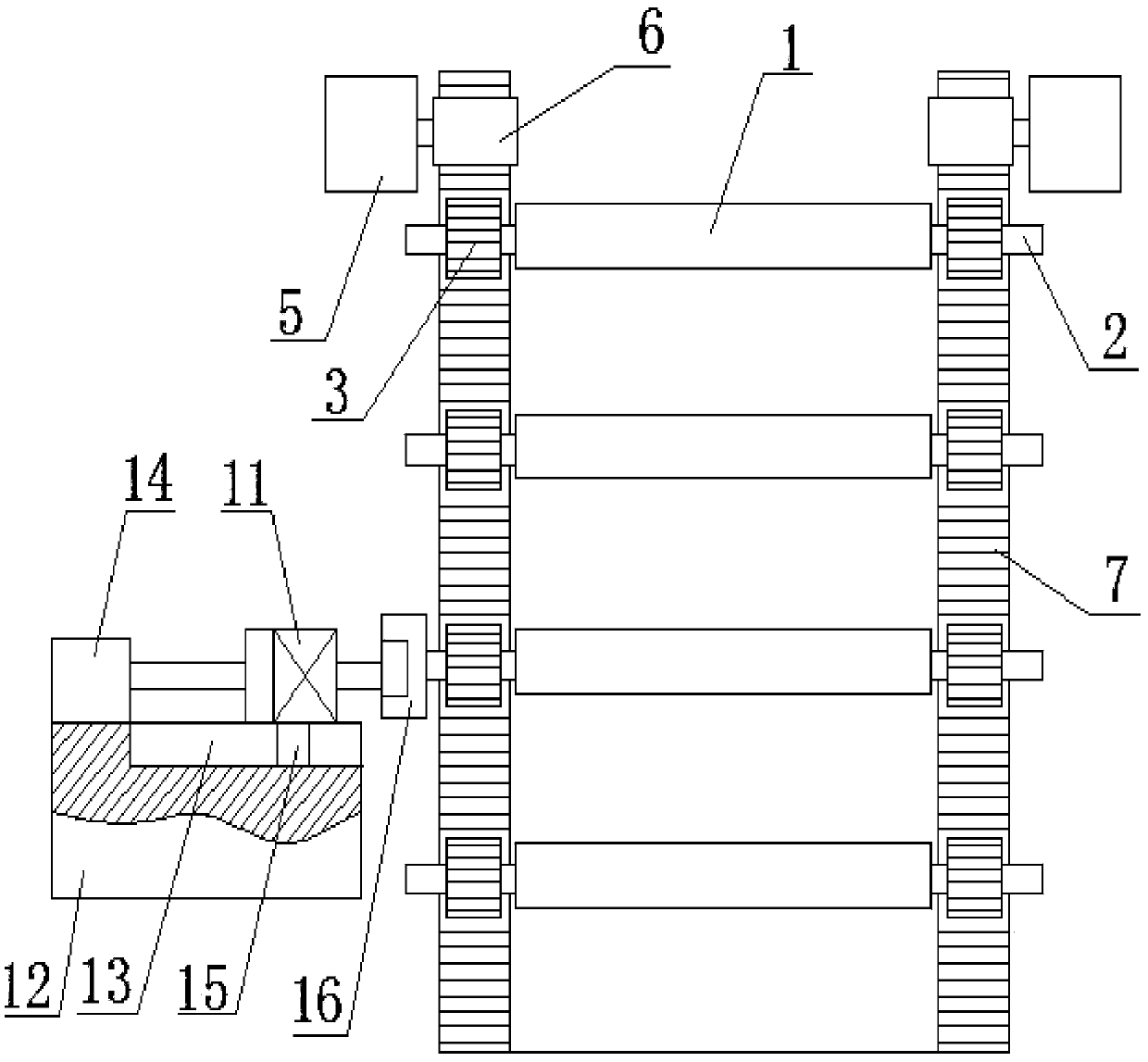

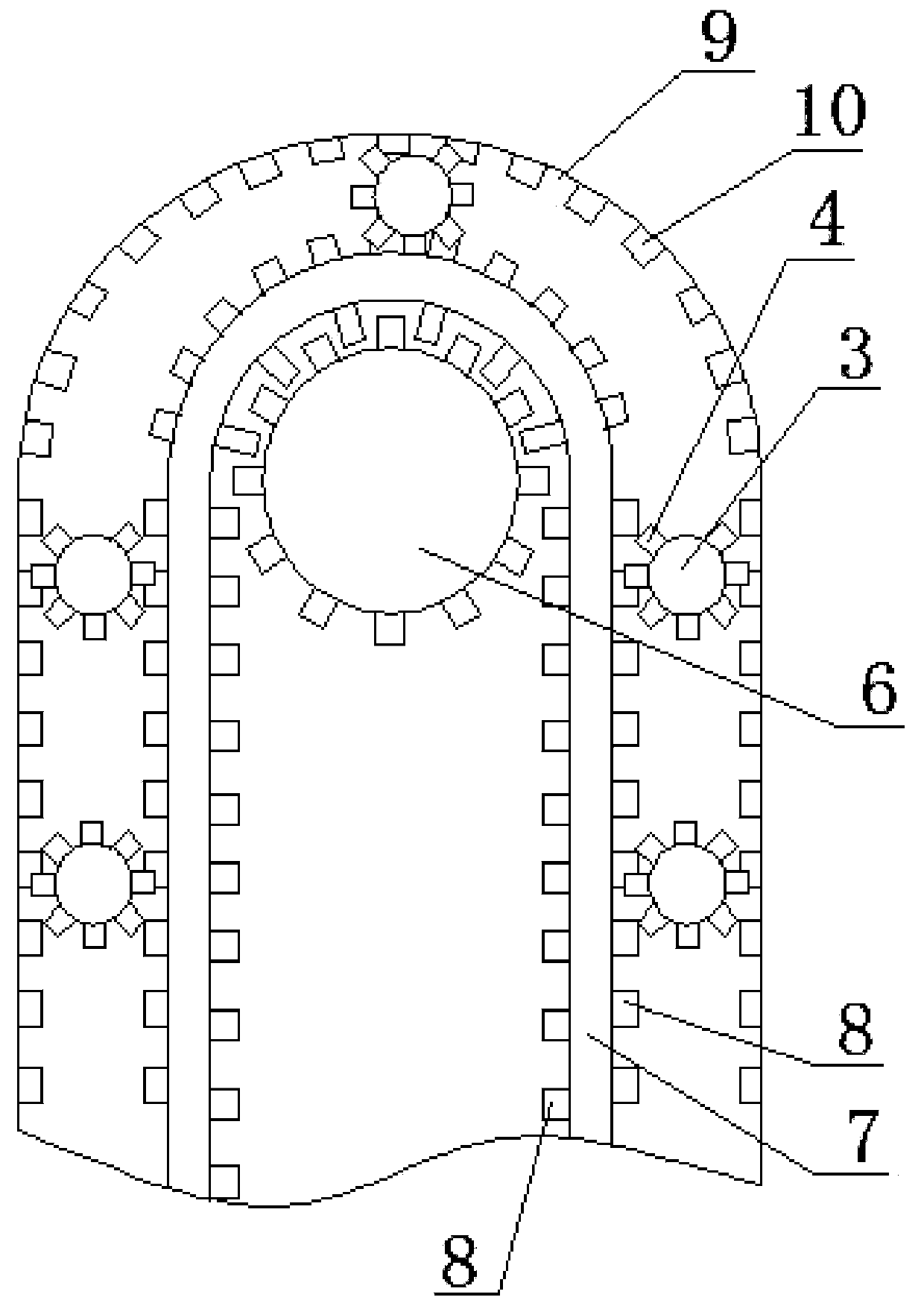

PendingCN107673123AAchieve continuous workHigh degree of automationFilament handlingWinding machineDrive shaft

The invention discloses an automatic wire winding device. Each wire winding roller assembly comprises a wire winding roller. A roller transmission shaft is arranged on each wire winding roller in a penetrating manner. Bearings are arranged at the two ends of each roller transmission shaft and are fixedly arranged in bearing sleeves. First transmission gear teeth are arranged on the outer surface of each bearing sleeve. Each transmission assembly comprises a first motor and two transmission gears located on the same vertical face, wherein the transmission gear located on the upper portion is connected with the first motor, and a transmission belt is wound between the two transmission gears. Second transmission gear teeth are arranged on the two sides of each transmission belt. Transmissionguide rails are arranged on the outer sides of the transmission belts. Third transmission gear teeth are arranged on the surfaces, adjacent to the transmission belts, of the transmission guide rails.The bearing sleeves are arranged between the transmission guide rails and the transmission belts. According to the automatic wire winding device, the work automation degree of a wire winding machine can be greatly increased, and the work efficiency of the wire winding machine is greatly improved.

Owner:宿松天工纺织有限公司

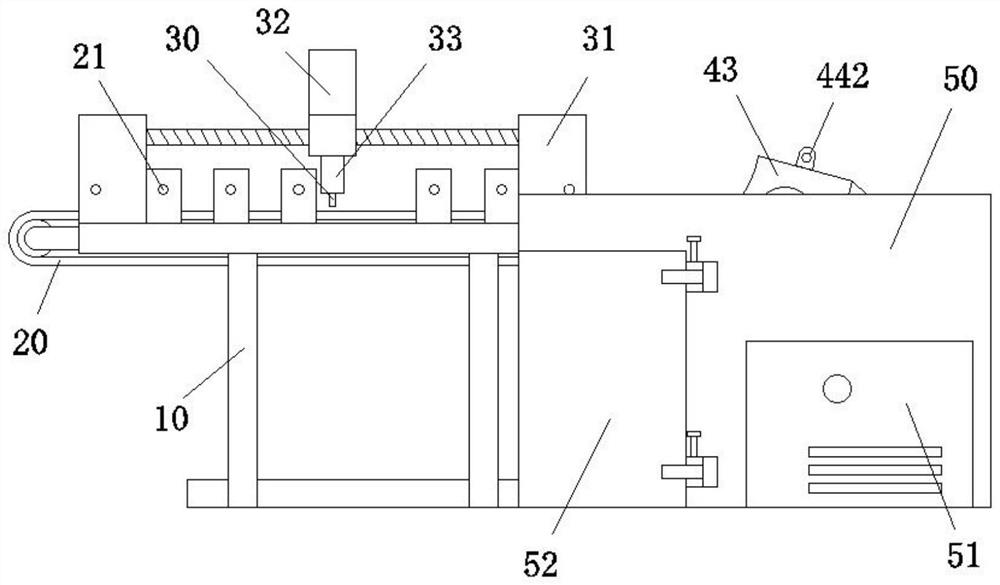

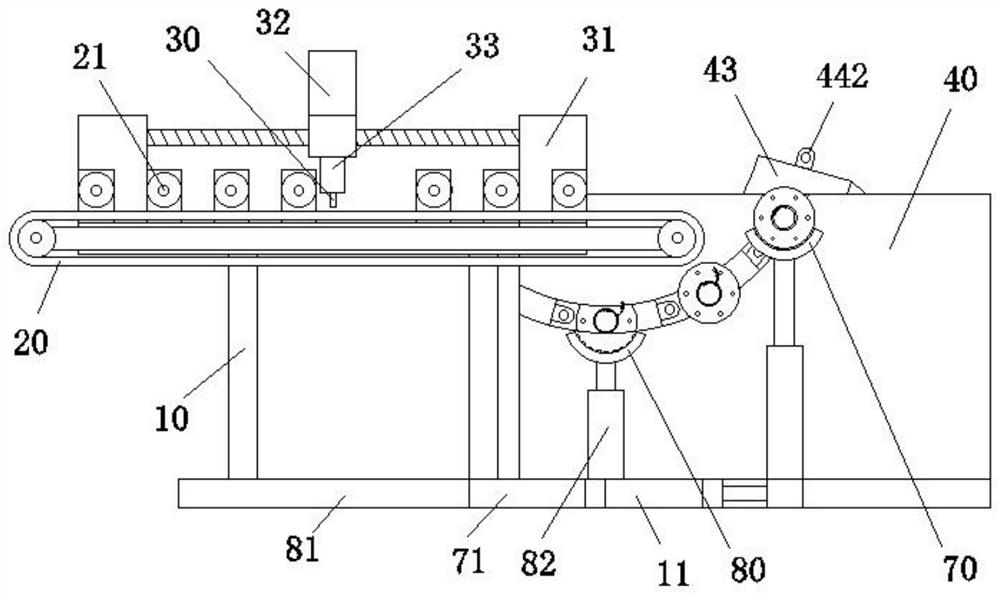

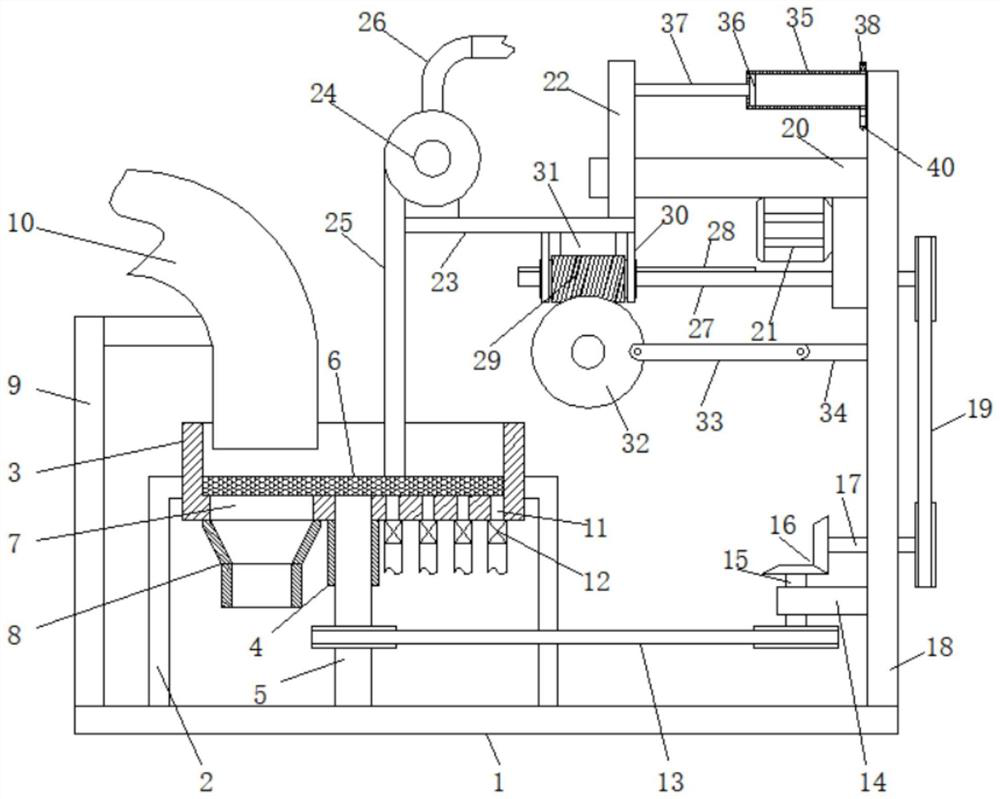

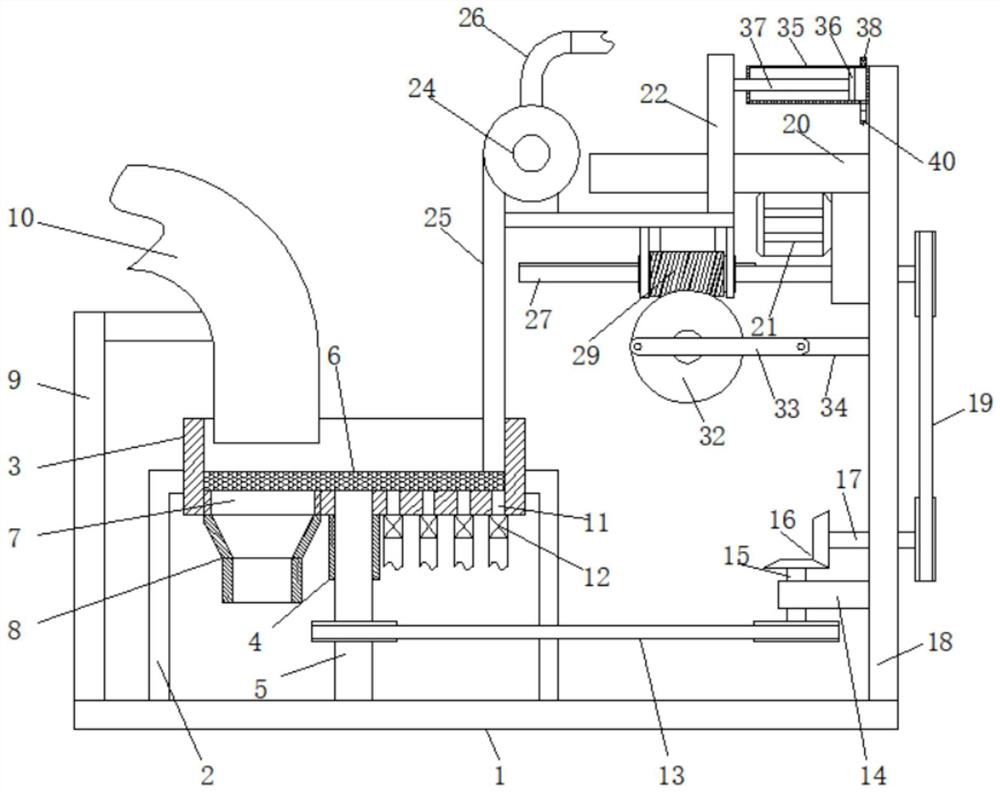

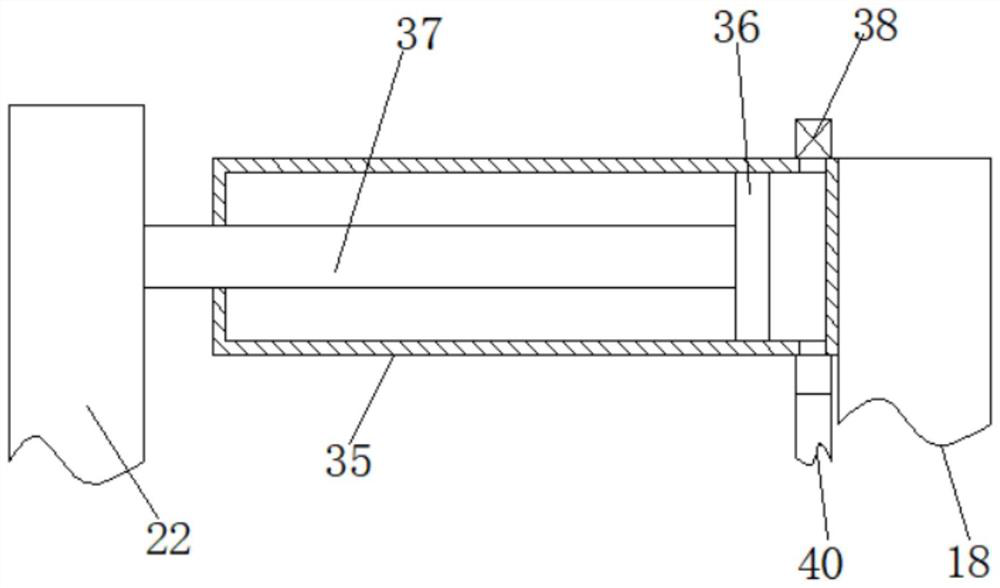

Rapid cooling and drying mechanism of vacuum aluminizing laminating machine and cooling method thereof

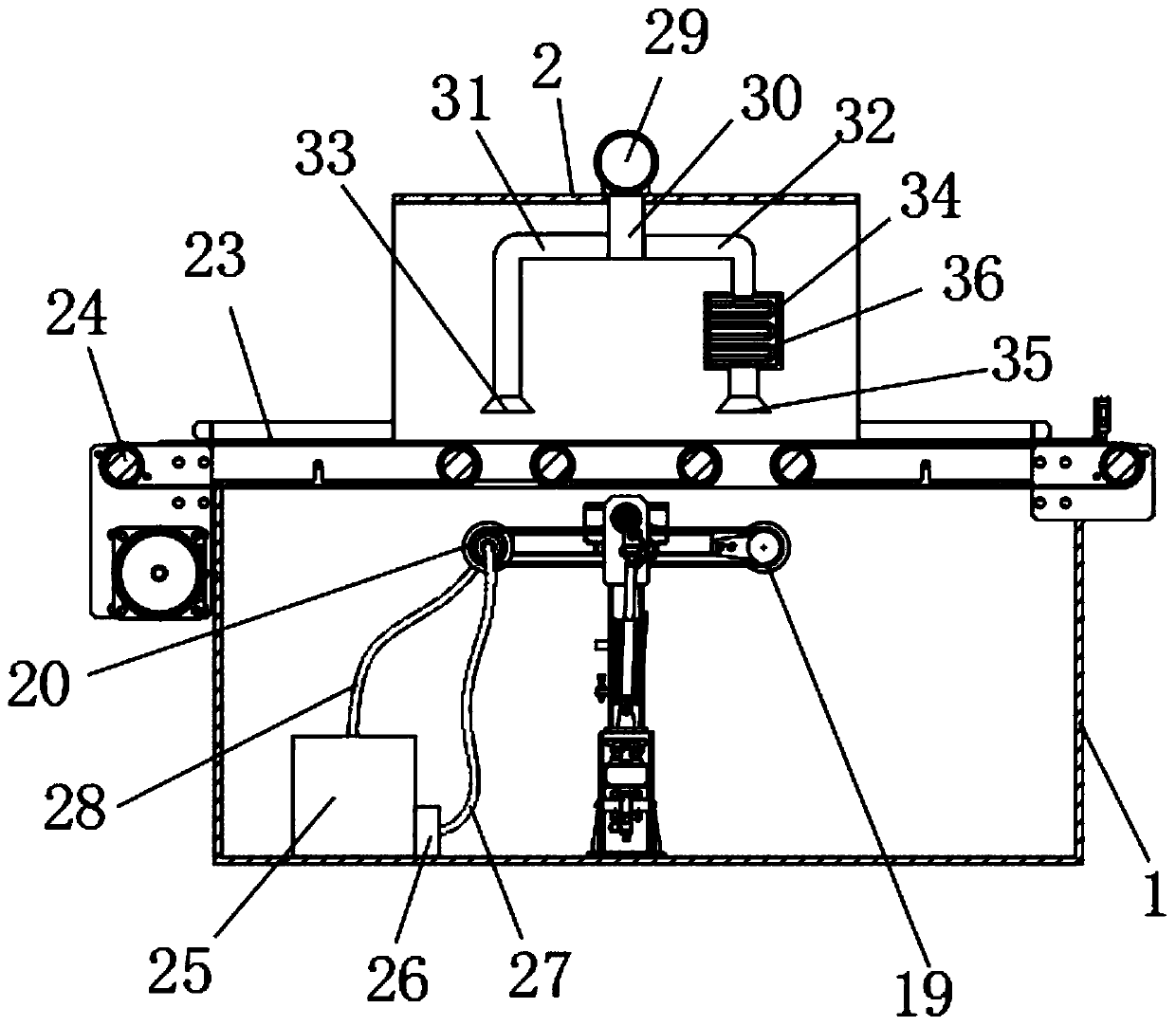

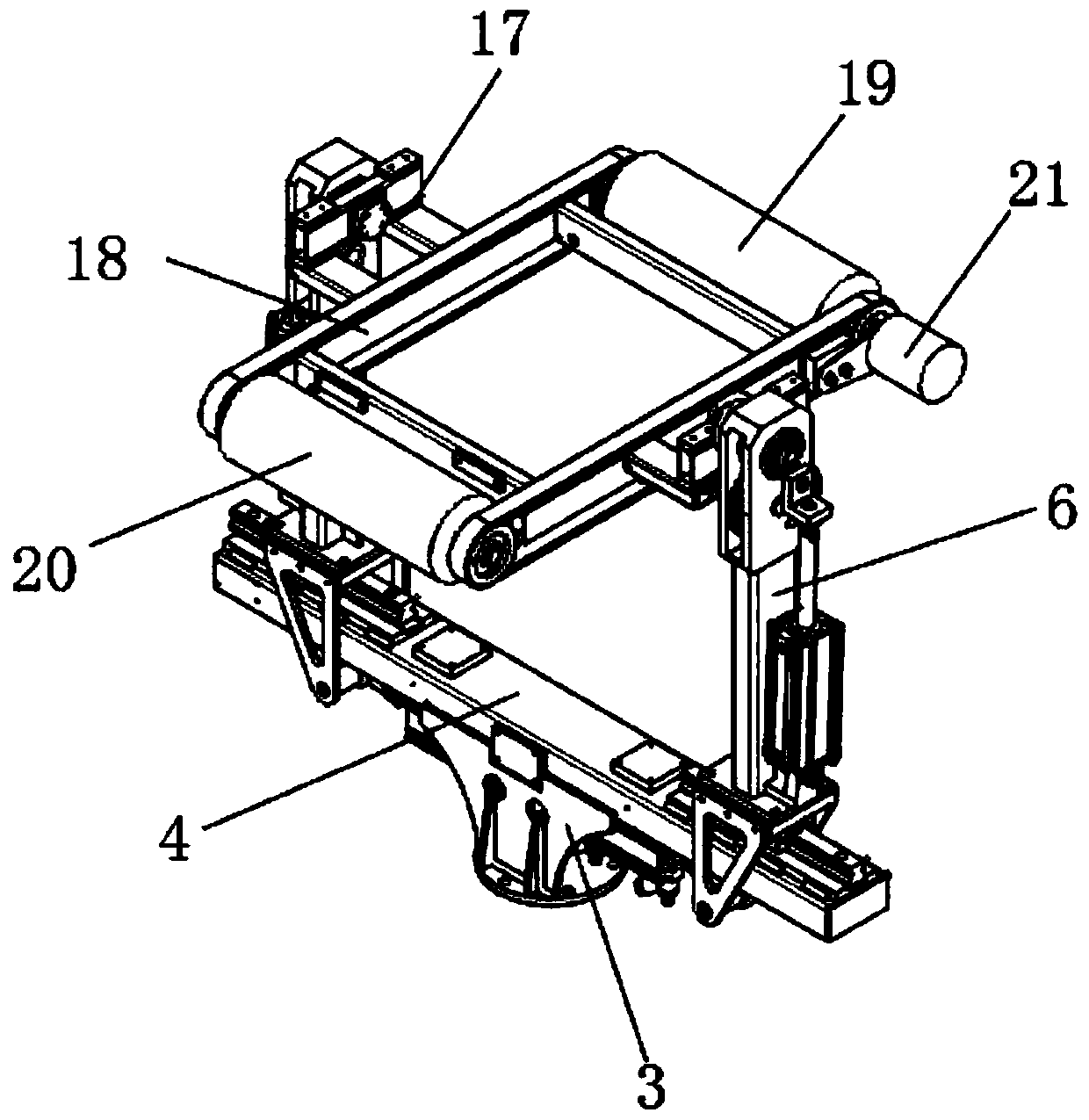

PendingCN111546746AFlexible operationReasonable designLamination ancillary operationsLaminationCooling effectWorkbench

The invention discloses a rapid cooling and drying mechanism of a vacuum aluminizing laminating machine and a cooling method thereof. The mechanism comprises a workbench, two sliding seats are movablymounted on the upper surface of a fixed supporting rod; supporting arms are fixedly mounted on the upper surfaces of the sliding seats; mounting chucks are fixed at the top ends of the supporting arms; a heating roller and a cooling roller are arranged between installation side plates, three conveying belts are arranged at the top of the workbench, a draught fan is fixedly installed at the top ofan installation housing, a first nozzle is fixedly installed at the bottom end of a first guide pipe, a heating box is fixedly installed at the bottom end of a second guide pipe, and a second spray head is fixedly installed at the bottom of the heating box. The cooling and drying mechanism is flexible, rapid and convenient to operate, capable of being switched back and forth between a drying modeand a cooling mode and reasonable in design; an aluminized product is dried and cooled at the same time in an air blowing mode and a roller contact mode, the drying and cooling effects are good, thedrying efficiency is improved, and continuous work of a cooling roller is achieved.

Owner:ANHUI SHUNTONG PACKAGING MATERIAL

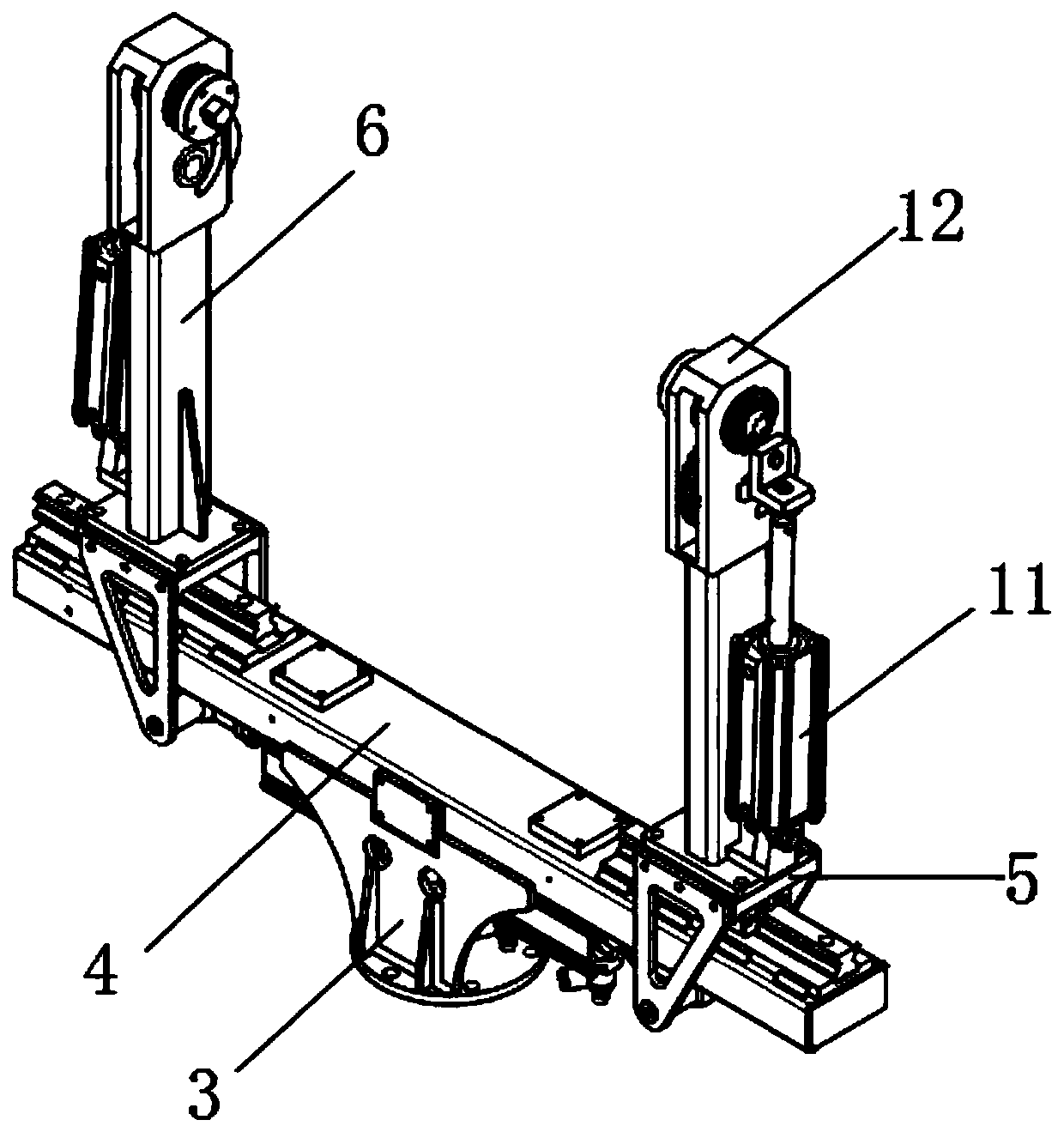

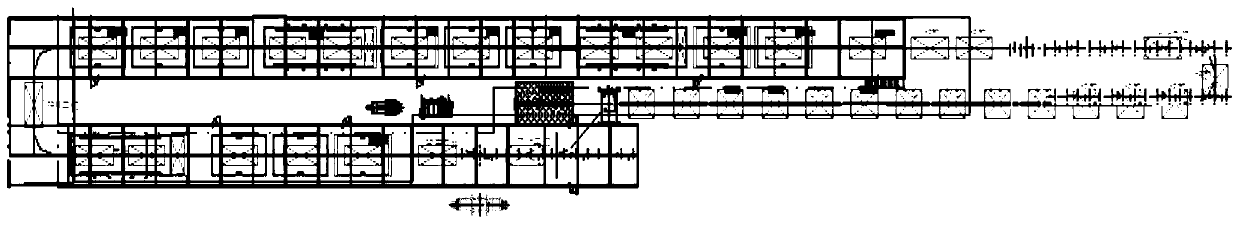

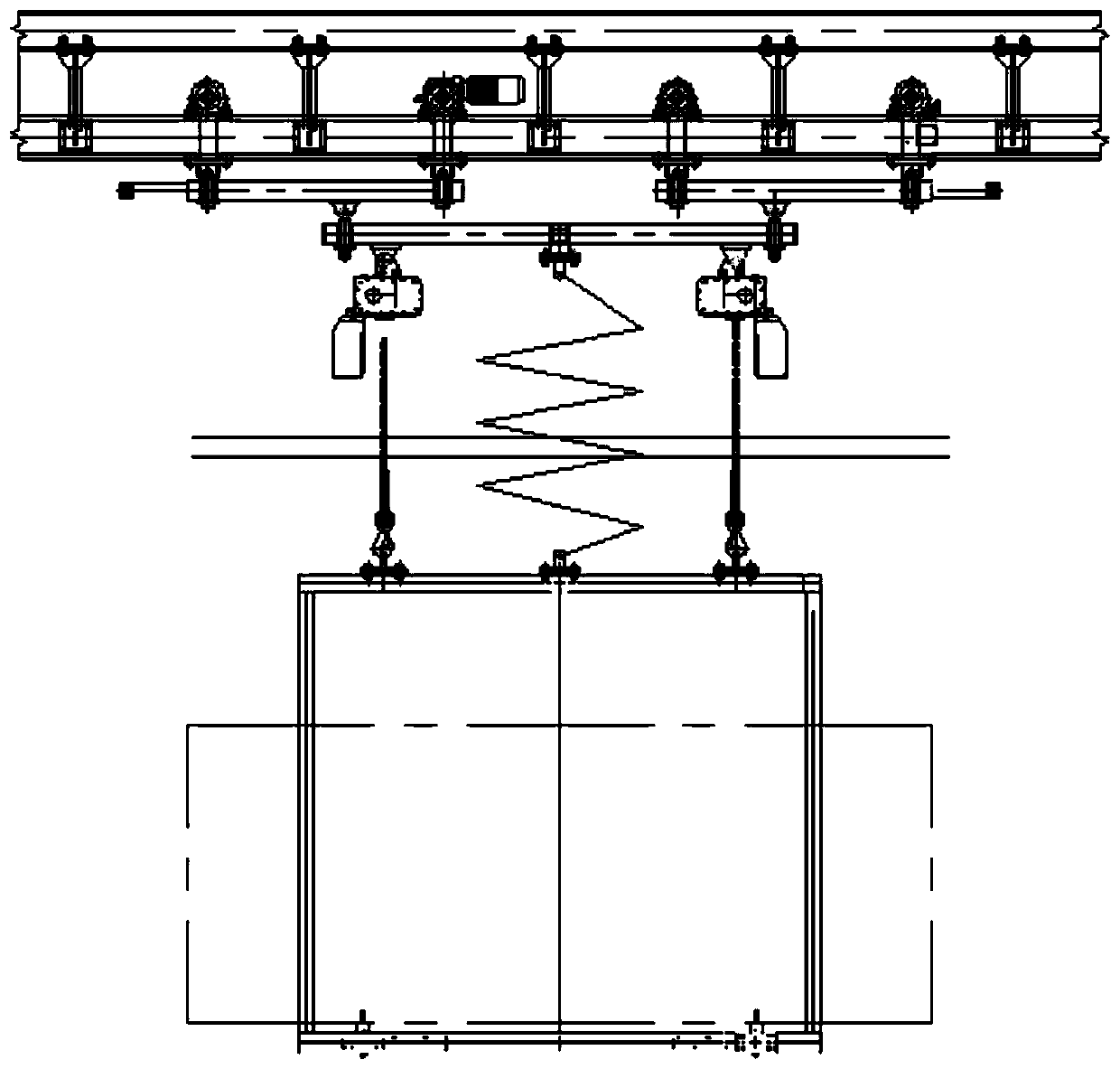

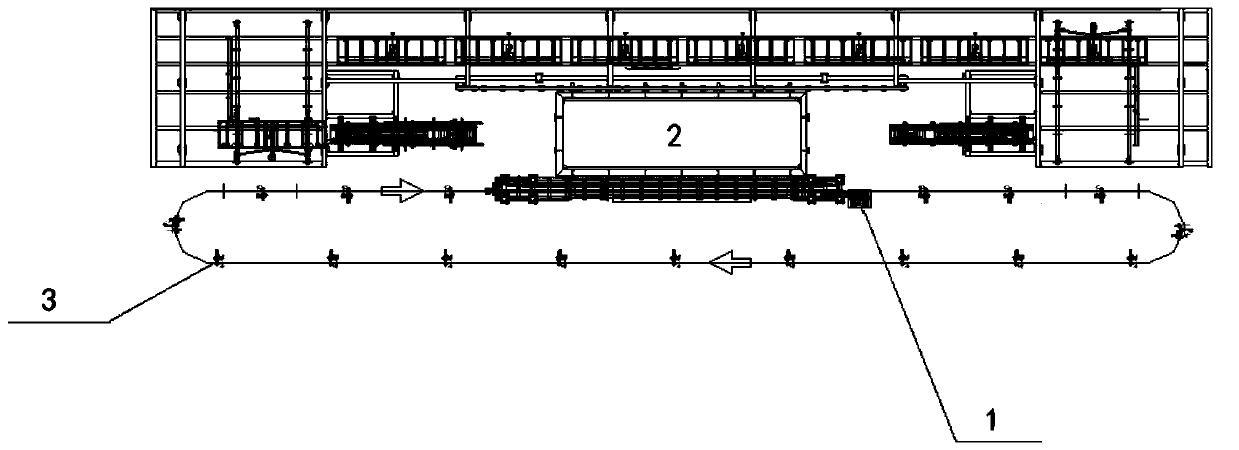

Automobile coating pretreatment and electrophoresis conveying device and conveying mode

InactiveCN110834955AReduce pollutionAutomatic transfer is easyCharge manipulationConveyor partsProcess engineeringElectrophoreses

The invention provides an automobile coating pretreatment and electrophoresis conveying device and conveying mode. The device comprises a vertical conveying chain and a friction conveying system, wherein the vertical conveying chain is arranged on one side of a tank body, and the vertical conveying chain can rotate while walking above one side of the tank body; and the friction conveying system isarranged on the other side of the vertical conveying chain, and the friction conveying system can convey a trolley through friction driving. The conveying device and the conveying mode enable the device to automatically rotate and hang safely and reliably, a return line process is flexible in adjustment, the process section eliminates the potential safety hazard of a pollution tank, a multi-vehicle type shared hanger does not need to replace the process section, and the automation degree and the degree of flexibility of a production line are truly improved.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD +1

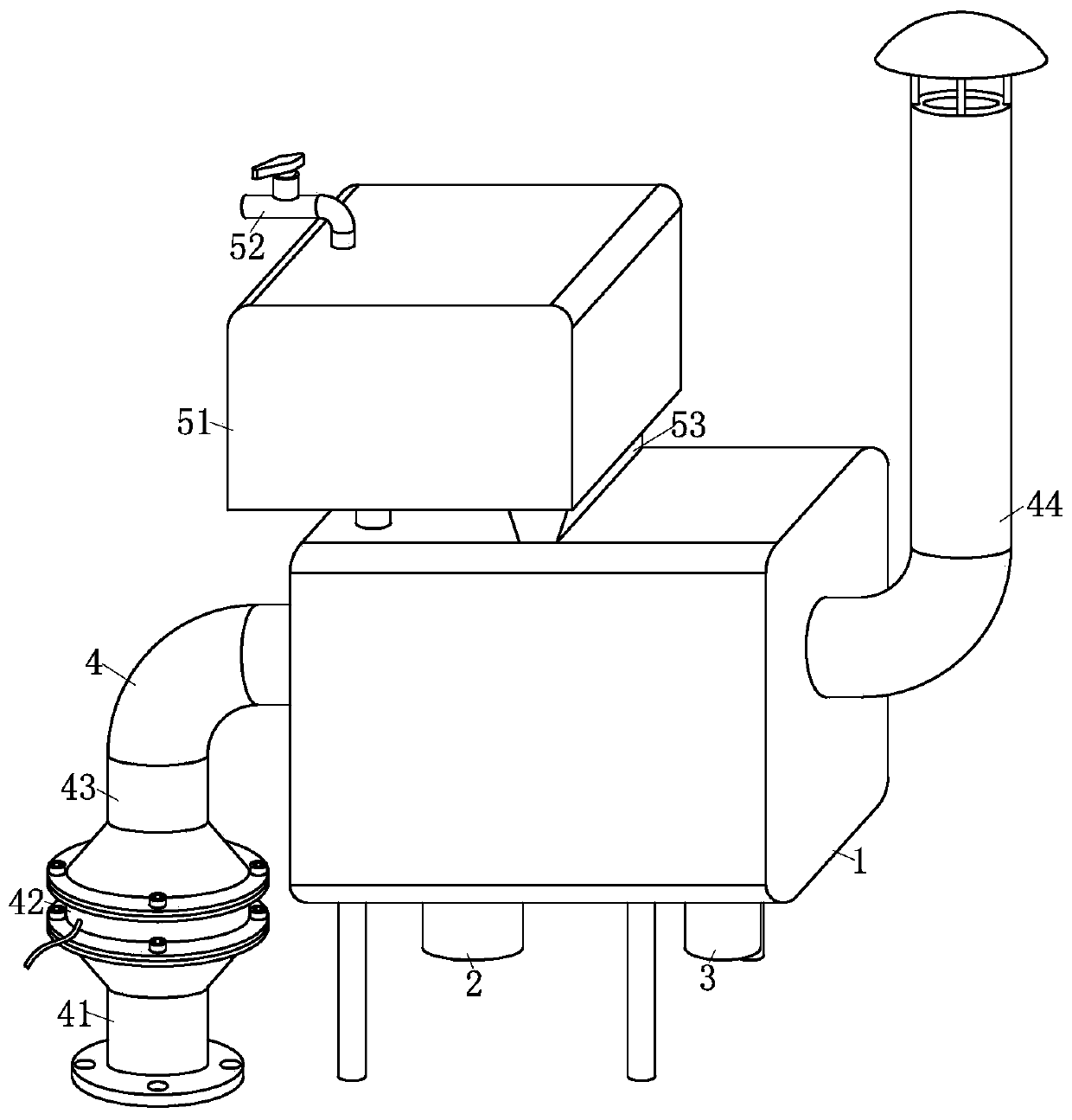

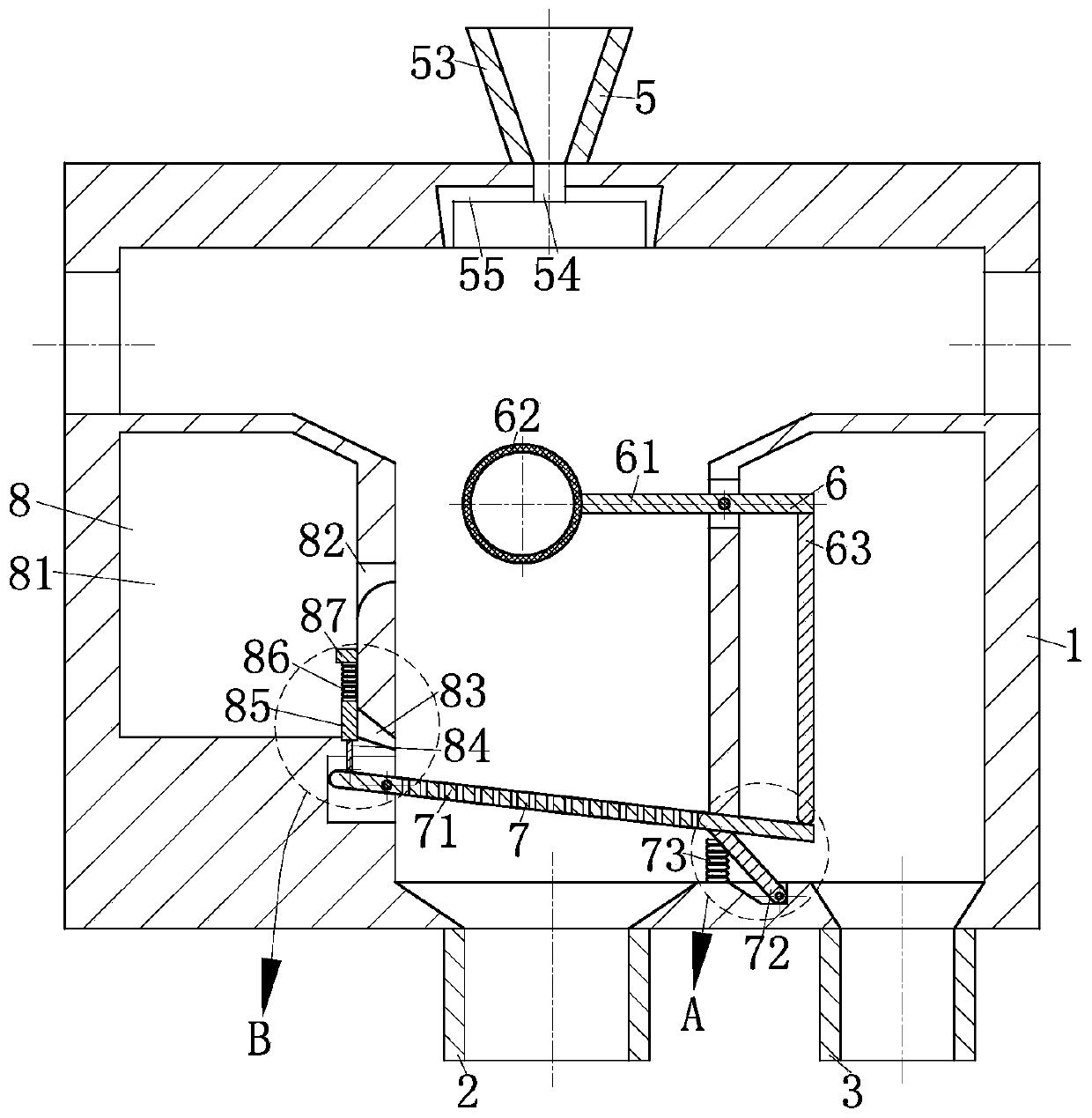

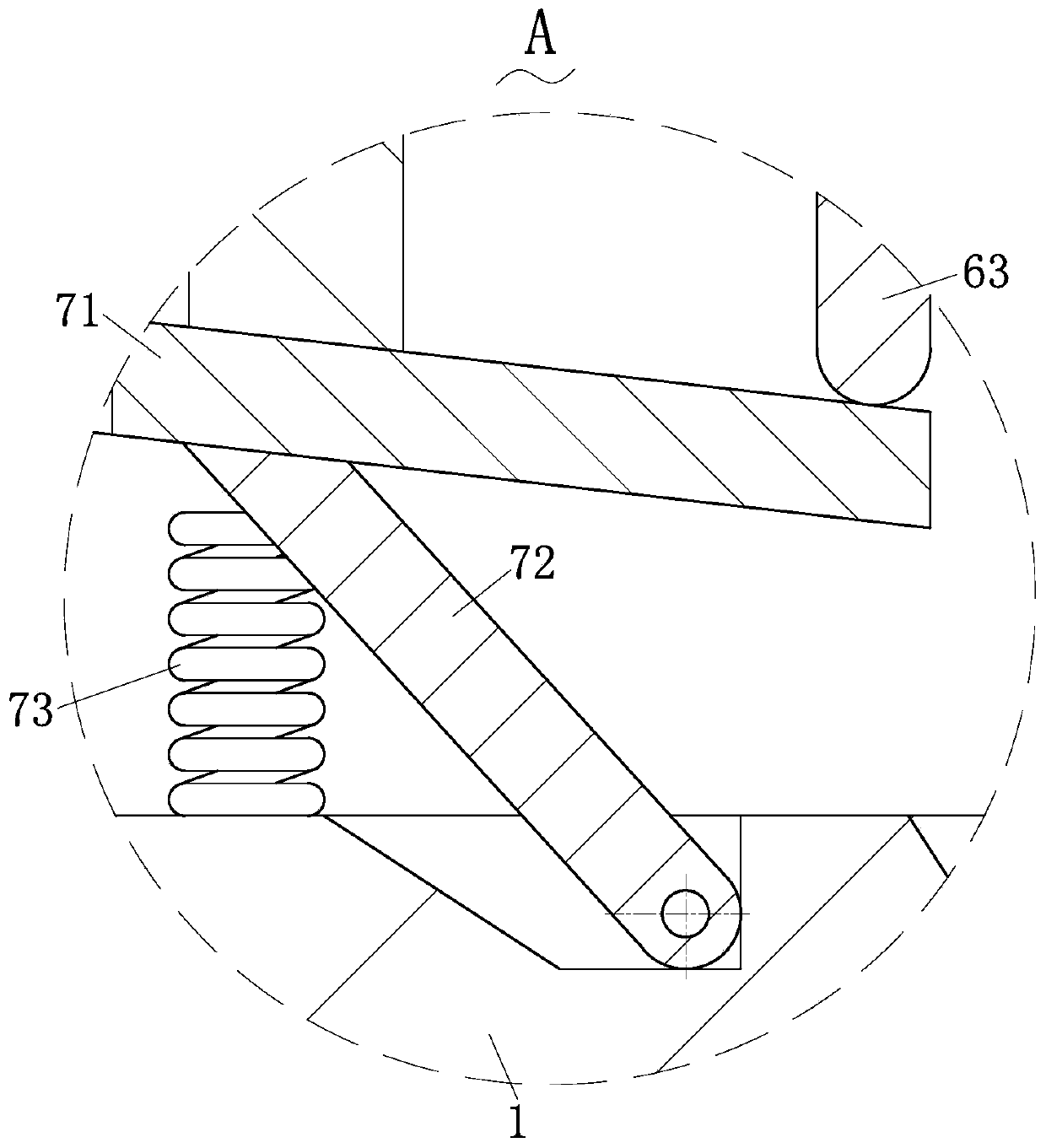

High-efficiency horizontal dust collector

ActiveCN110302619AConvenience to workEasy to useUsing liquid separation agentSeparation devicesWater dischargeWater level rise

The invention relates to the field of dust collectors, in particular to a high-efficiency horizontal dust collector. The dust collector comprises a box body, a water discharge pipe, a sewage dischargepipe, a suctioning structure, a dust removal structure, a pressing structure, a filtering structure and a rinsing structure. When shelled peanut skins adhere to the filtering structure too much, blockage of the filtering structure can be caused, the blockage of the filtering structure can prevent water inside the box body from being discharged in time, a water level inside the box body can be raised, when the water level rises to a certain position, the pressing structure can be pressed, the pressing structure can make the filtering structure rotate, water and the shelled peanut skins on thefiltering structure can be discharged from the sewage discharge pipe, the filtering structure can work normally, the normal work of the filtering structure can ensure that the dust removal structure can work better, when the filtering structure occurs rotation, the rinsing structure can be driven to perform working, the working of the rinsing structure can rinse the shelled peanut skins on the filtering structure, and thereby the normal use of the filtering structure can be further ensured.

Owner:嘉善百伟锌业有限公司

Multifunctional hot melt adhesive production equipment

The invention provides multifunctional hot melt adhesive production equipment, belongs to the technical field of machinery and solves the problem that existing products produced by a hot melt adhesiveare single. The multifunctional hot melt adhesive production equipment comprises a rack and stirrers. Two material pumps are arranged symmetrically on the rack, the two material pumps communicate through a connecting pipe, one of the material pumps is connected to a material cutting room, the other one of the material pumps is connected to a granulating rack, the material pumps are separately connected to the corresponding material cutting room or the granulating rack through plate type filters, separately, the material cutting room is used for forming round colloidal particles and the granulating rack is used for forming sheet colloidal particles; the two stirrers are located above the rack, a material conveying pipe extends downward at the bottom of each stirrer, the two material conveying pipes are close to each other till communicating to the connecting pipe, the stirrers are used for mixing raw materials to form a sizing material and conveys the sizing material downward to the two material pumps to further convey the sizing material to the material cutting room or the granulating rack for forming the colloidal particles. The multifunctional hot melt adhesive production equipment provided by the invention has the characteristic of diversified production.

Owner:嘉兴正野新材料有限公司

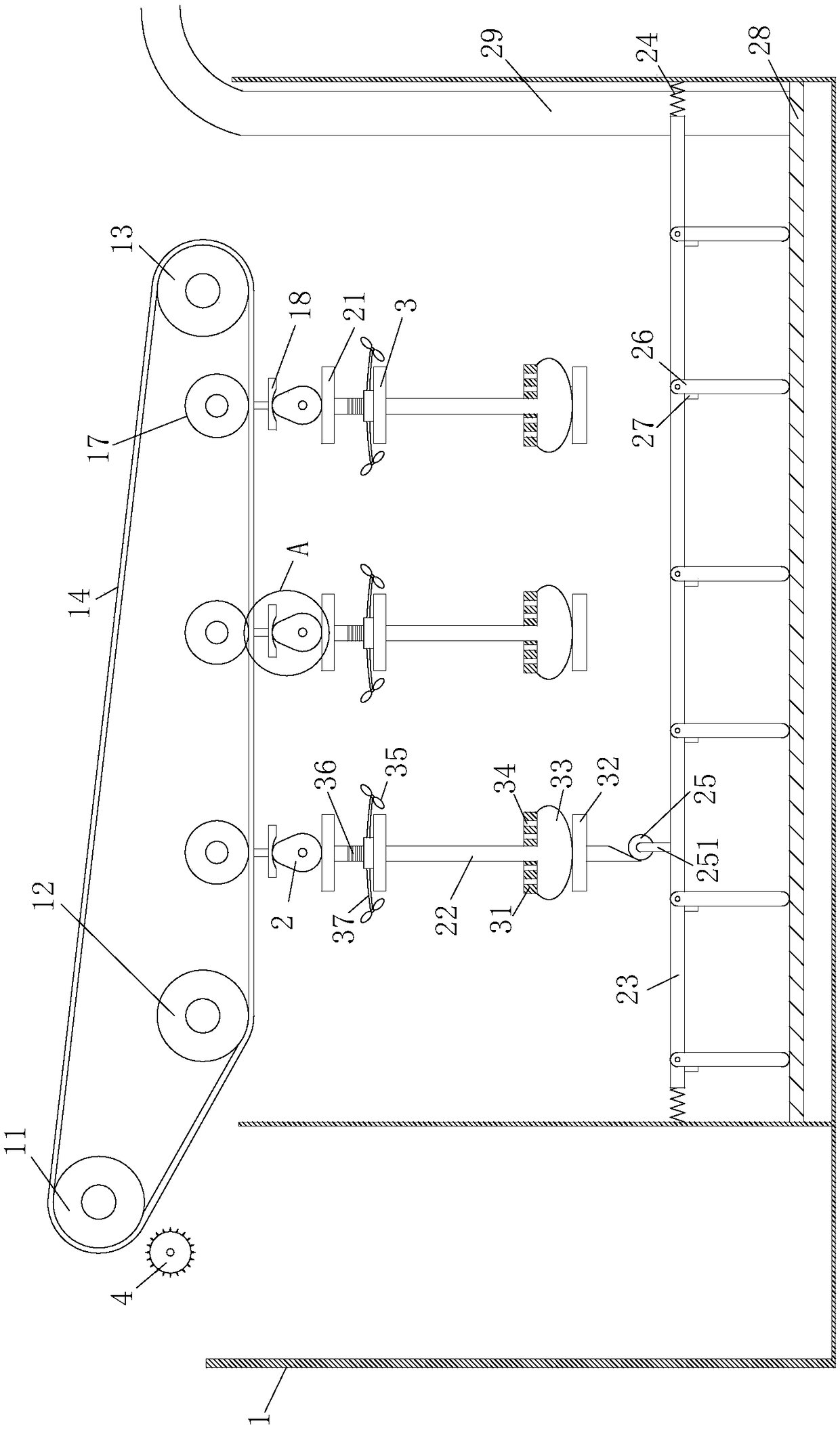

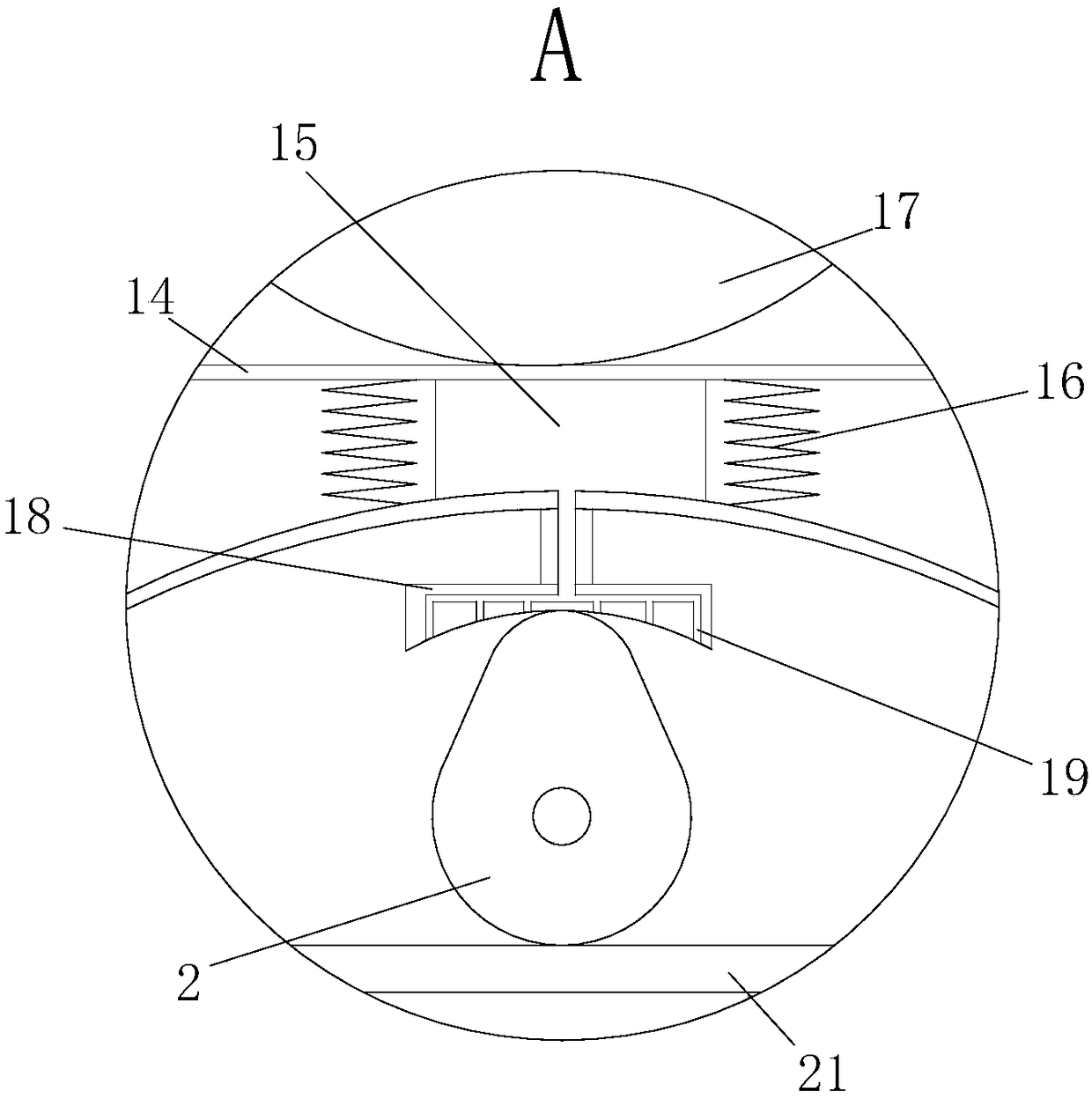

Continuous automatic output vermicelli cooking device

The invention relates to a continuous automatic output vermicelli cooking device. The device comprises a sheet jelly conveying belt which is erected at the top of a machine frame, a cooking box is arranged at the bottom of the sheet jelly conveying belt, the cooking box comprises a material holding mechanism, a driving mechanism and a transmission mechanism, the material holding mechanism is fixedly arranged below the sheet jelly conveying belt and is arranged on the machine frame, the material holding mechanism is used for supporting the sheet jelly which is vertically output by the sheet jelly conveying belt and outputting the sheet jelly in an S shape, the material holding mechanism comprises a first material holding assembly and a second material holding assembly, the first holding assembly and the second holding assembly are arranged in parallel in a staggered mode; the driving mechanism are symmetrically arranged below the sheet jelly conveying belt and is arranged between the first holding assembly and the second holding assembly, the transmission mechanism is arranged below the material holding mechanism and is arranged in a circuitous manner along the length direction of the cooking box, the transmission mechanism comprises a transmission component, a material receiving component and a discharging component. According to the continuous automatic output vermicelli cooking device, the technical problem that the sheet jelly cannot be transmitted out in time is solved.

Owner:赵长春

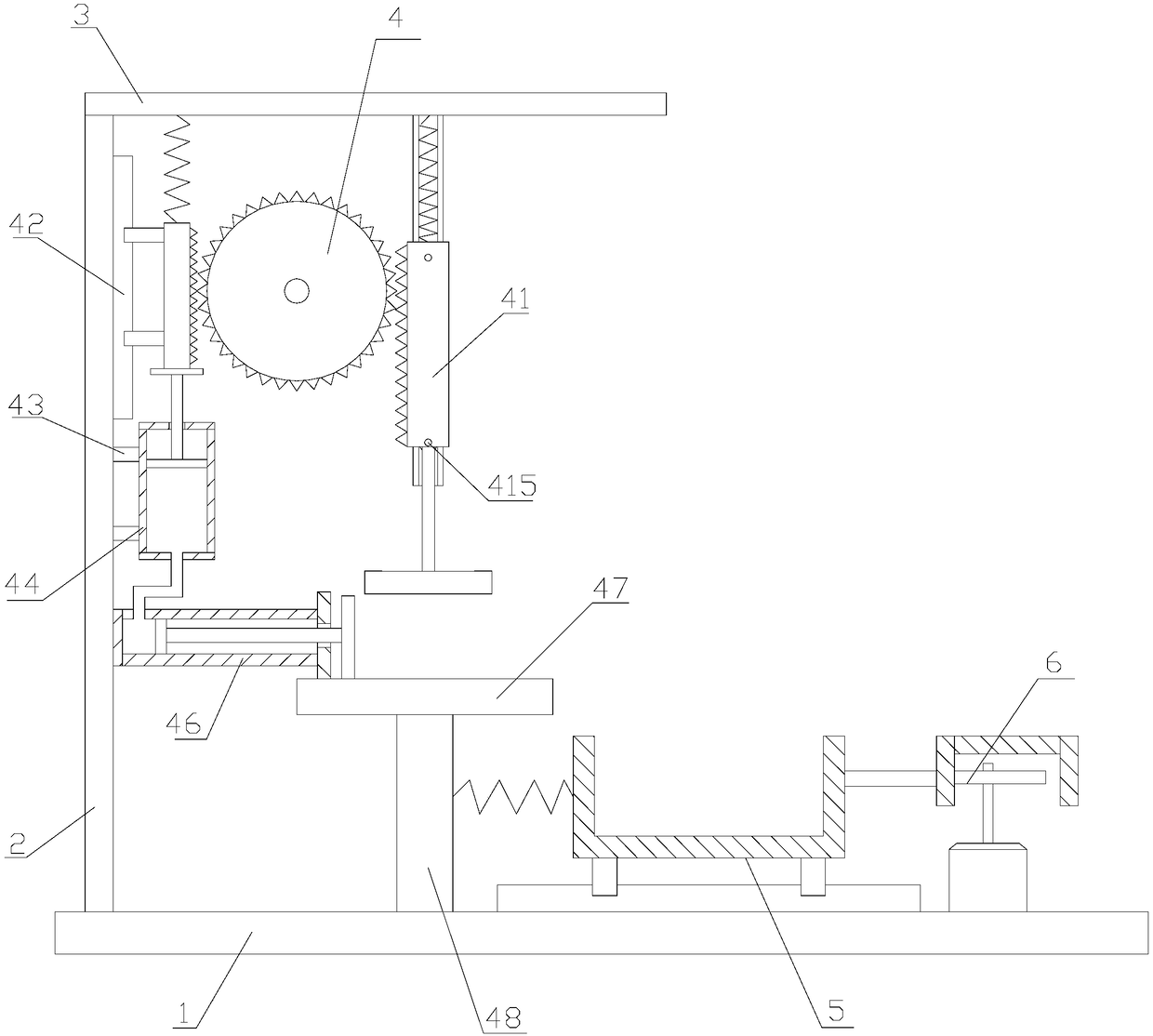

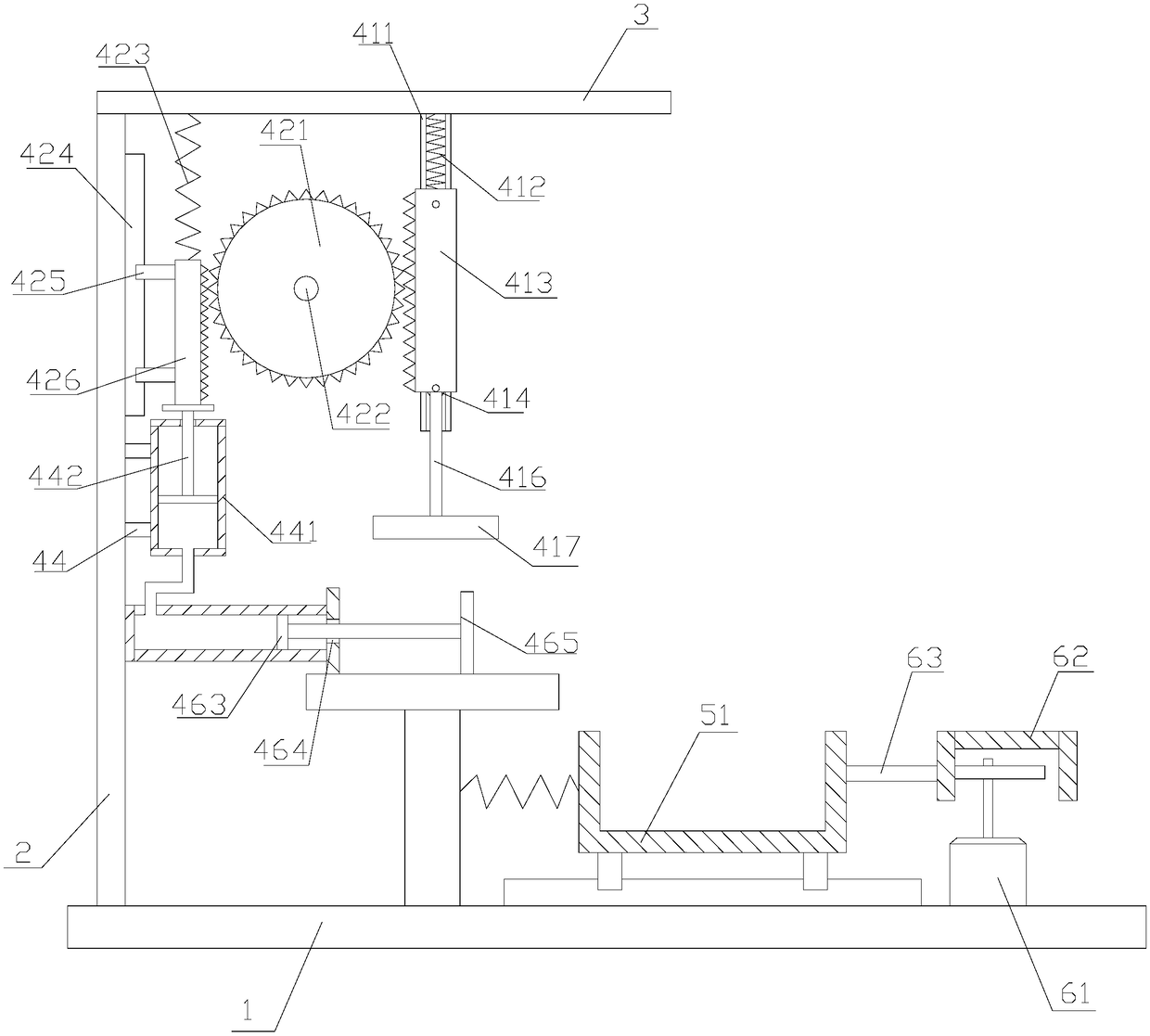

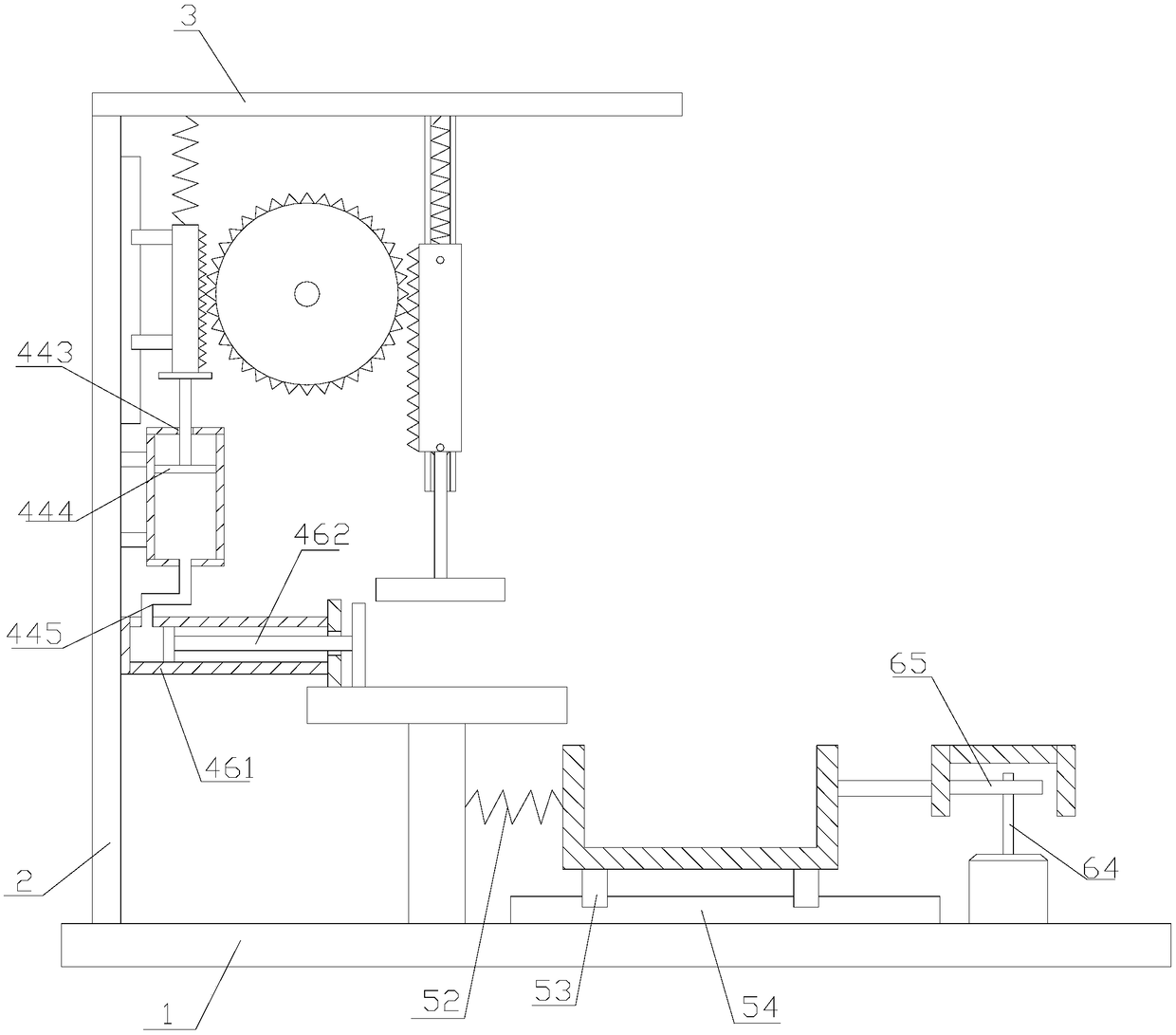

Leatherware laminating device for leatherware production and processing

ActiveCN108707698AEvenly distributedAchieve continuous workLeather manufacturingSkins/hides/leather/fur manufacturing apparatusEngineering

The invention discloses a leatherware laminating device for leatherware production and processing. The leatherware laminating device for leatherware production and processing structurally comprises abottom plate, a left side plate, a top plate, a leatherware laminating mechanism, a leatherware storing device and a shaking device. The left side plate, the leatherware storing device and the shakingdevice are sequentially arranged on the top part of the bottom plate from left to right; the left side plate is vertically arranged; and the bottom part of the left side plate is perpendicularly arranged at the left end of the top part of the bottom plate in a welding connection manner. A pushing device is arranged on a working table and is matched with the laminating device, and when a pressingblock on the laminating device presses leatherware and then lifts up, a pushing rod on the pushing device stretches to push the pressed leatherware into the leatherware storing device from the workingtable, so that through the 'press-and-push' action, the leatherware has no need to be taken down by hand manuually, the continuous work can be realized, and the production efficiency is improved.

Owner:天辰兰德(山东)科技服务有限公司

Winding device for non-woven fabric production

The invention relates to the field of non-woven fabric production, discloses a winding device for non-woven fabric production. The device aims to solve the problems that after non-woven fabric is wound, the efficiency of replacing a material collecting roller is low, the labor intensity of workers is high, and the winding efficiency is low due to the fact that a machine needs to be stopped when the material collecting roller is replaced. The device comprises a truss, a conveying belt installed on the truss, a cutter located at the top of the conveying belt and a lifting table located below the conveying belt, a side plate is fixed to one side, away from the lifting table, of the truss, a storage groove with an arc-shaped vertical section is formed in the side wall, close to the truss, of the side plate, an opening in one end of the storage groove is located in the top of the side plate, three sliding plates which are of the same structure and are sequentially connected are connected into the storage groove in a sliding mode, and a gear for driving the sliding plates to rotate is fixed into the storage groove. The device is simple in structure, reasonable in design and small in occupied space, reduces the probability of defective products after non-woven fabric winding, saves energy, is environmentally friendly, is particularly suitable for non-woven fabric production winding in an unmanned workshop, and has a high application prospect.

Owner:厦门谷岩纺织有限公司

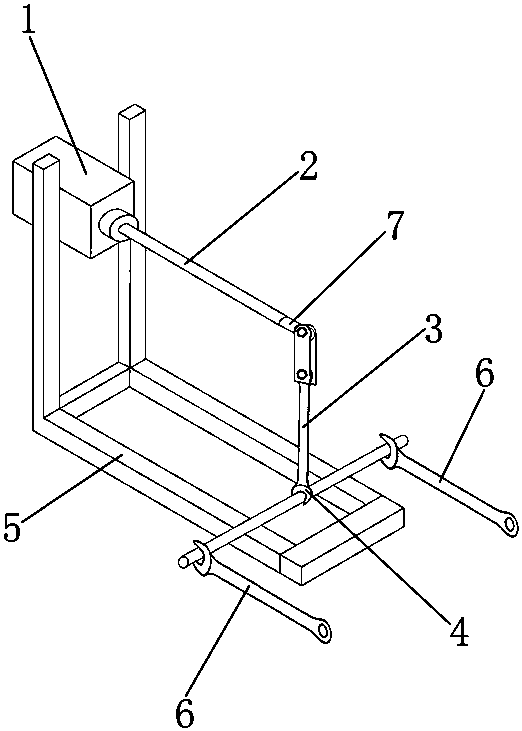

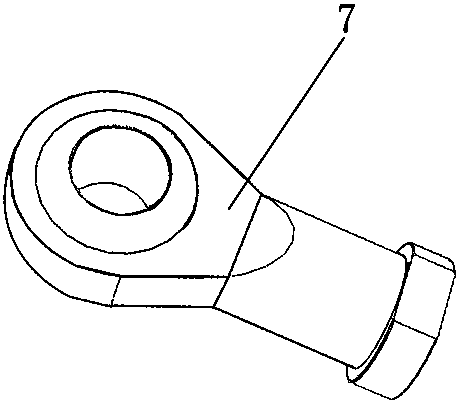

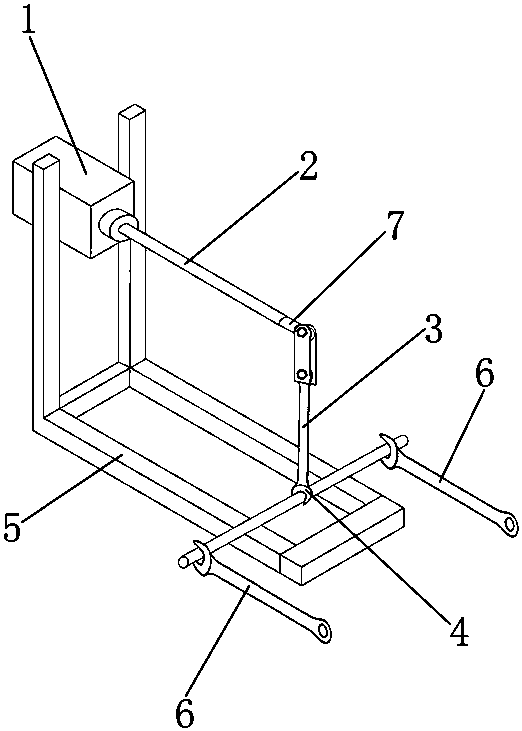

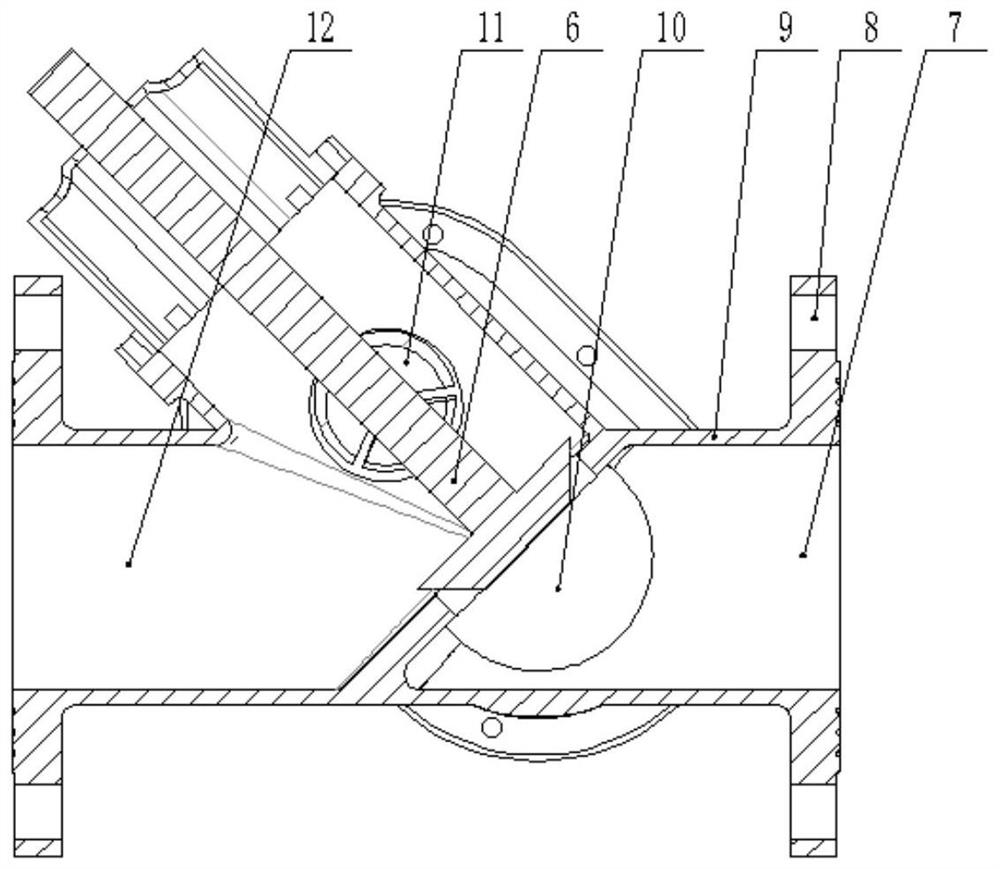

Straight thread sleeve connection device and method

PendingCN110029823AImprove connection efficiencyAchieve continuous workBuilding reinforcementsBuilding material handlingReciprocating motionControl valves

The invention discloses a straight thread sleeve connection device and method, and belongs to the field of building construction devices. The straight thread sleeve connection device and method are characterized in that the straight thread sleeve connection device comprises a reciprocating motion device and a rebar sleeve wrench; a piston rod is arranged in the reciprocating motion device; a sleeve clamp is arranged at the lower end of the rebar sleeve wrench; and the piston rod is movably connected with the steel wrench. The straight thread sleeve is sleeved a rebar end socket which needs tobe connected, a rebar is fixed by fixing clamps; the sleeve clamp of the rebar sleeve wrench is sleeved the straight thread sleeve; and the reciprocating motion device is started, the piston rod reciprocates forward and backward in the horizontal direction, the upper end of the rebar sleeve wrench moves forward and backward driven by the reciprocating motion device through movable connection, andreciprocating motion of the sleeve clamp at the lower end of the rebar sleeve wrench realizes connection of the straight thread sleeve. Force is added through machinery, thus torque meets the design requirements, the qualification rate is increased, thus the construction speed is accelerated, the construction period is effectively shortened, the speed can be increased by adjusting a speed controlvalve, and the work efficiency is improved.

Owner:RAILWAY TENTH GROUP NORTHWEST ENG

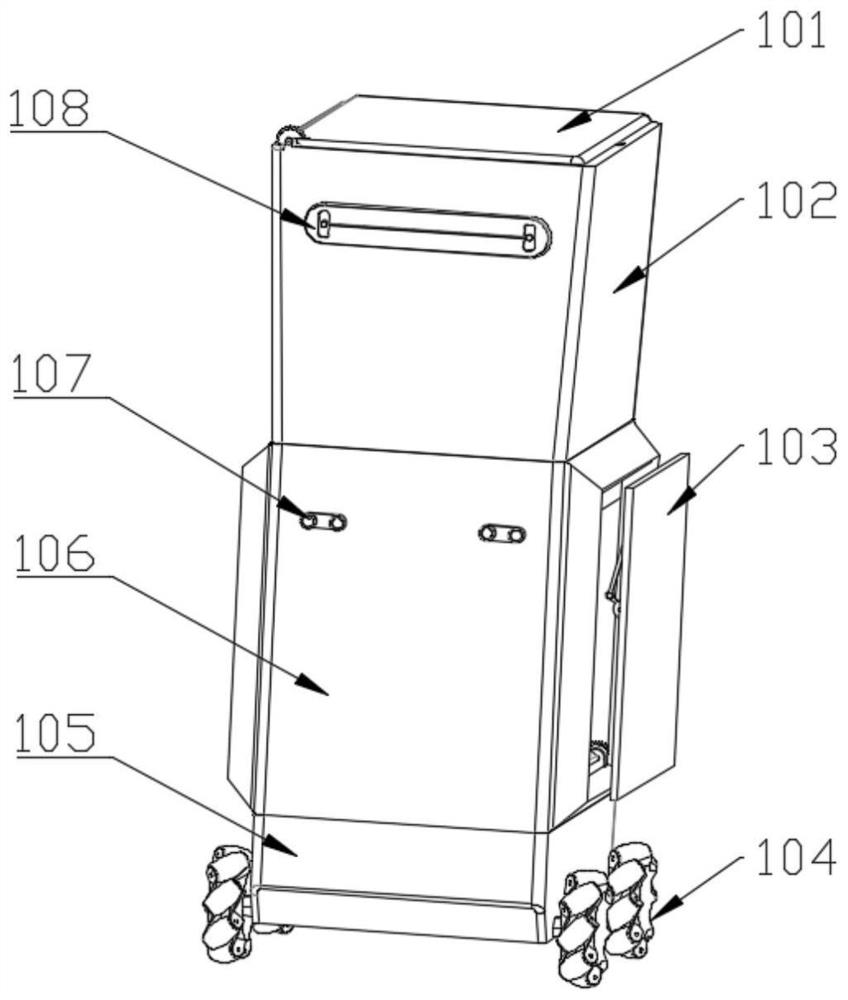

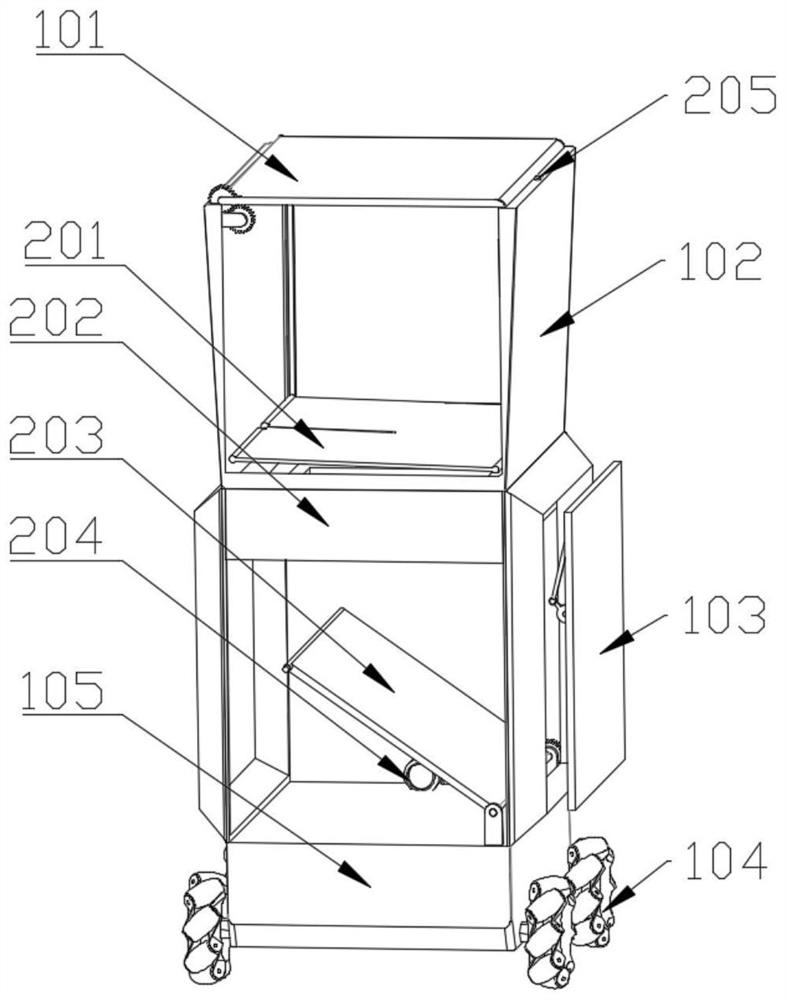

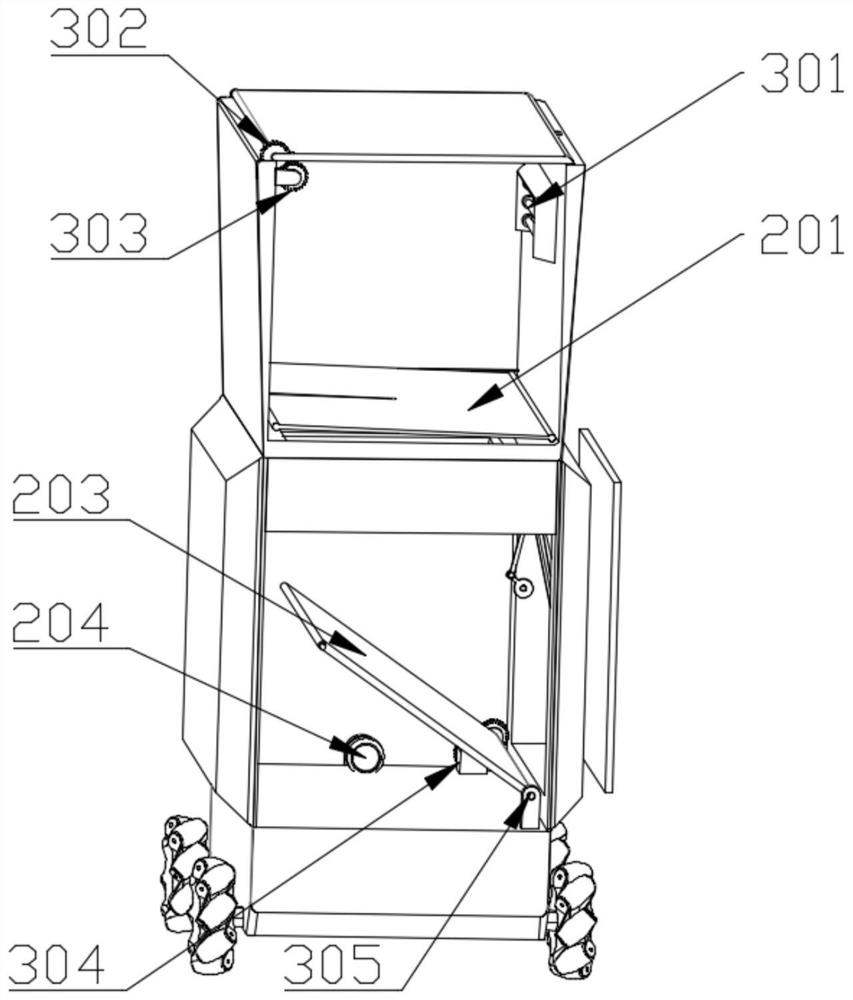

Isolation area garbage treatment robot based on automatic following

PendingCN114348501AAvoid exposureIncrease transmission rateRefuse receptaclesRefuse cleaningMechanical equipmentOmni directional

The invention provides an isolation area garbage treatment robot based on automatic following. The isolation area garbage treatment robot comprises a first-stage treatment bin, and a second-stage treatment bin communicating with the first-stage treatment bin is arranged on the lower side of the first-stage treatment bin; a movable chassis is arranged on the lower side of the secondary treatment bin, a plurality of omnidirectional wheels are arranged on the movable chassis, and a stepping motor for driving the omnidirectional wheels is arranged on the top surface of the movable chassis; a top cover for opening and closing the top surface of the primary treatment bin is arranged on the upper side of the primary treatment bin, an infrared temperature measurement sensor is arranged on the top cover, a UWB following module is arranged on the front side wall of the primary treatment bin, two ultrasonic modules are arranged on the front side wall of the secondary treatment bin, and a side door is arranged on the right side of the secondary treatment bin. The problems that existing mechanical equipment is single in function, mostly adopts autonomous movement, virus spreading risks exist in the garbage transferring process, cost is high and the like are solved.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

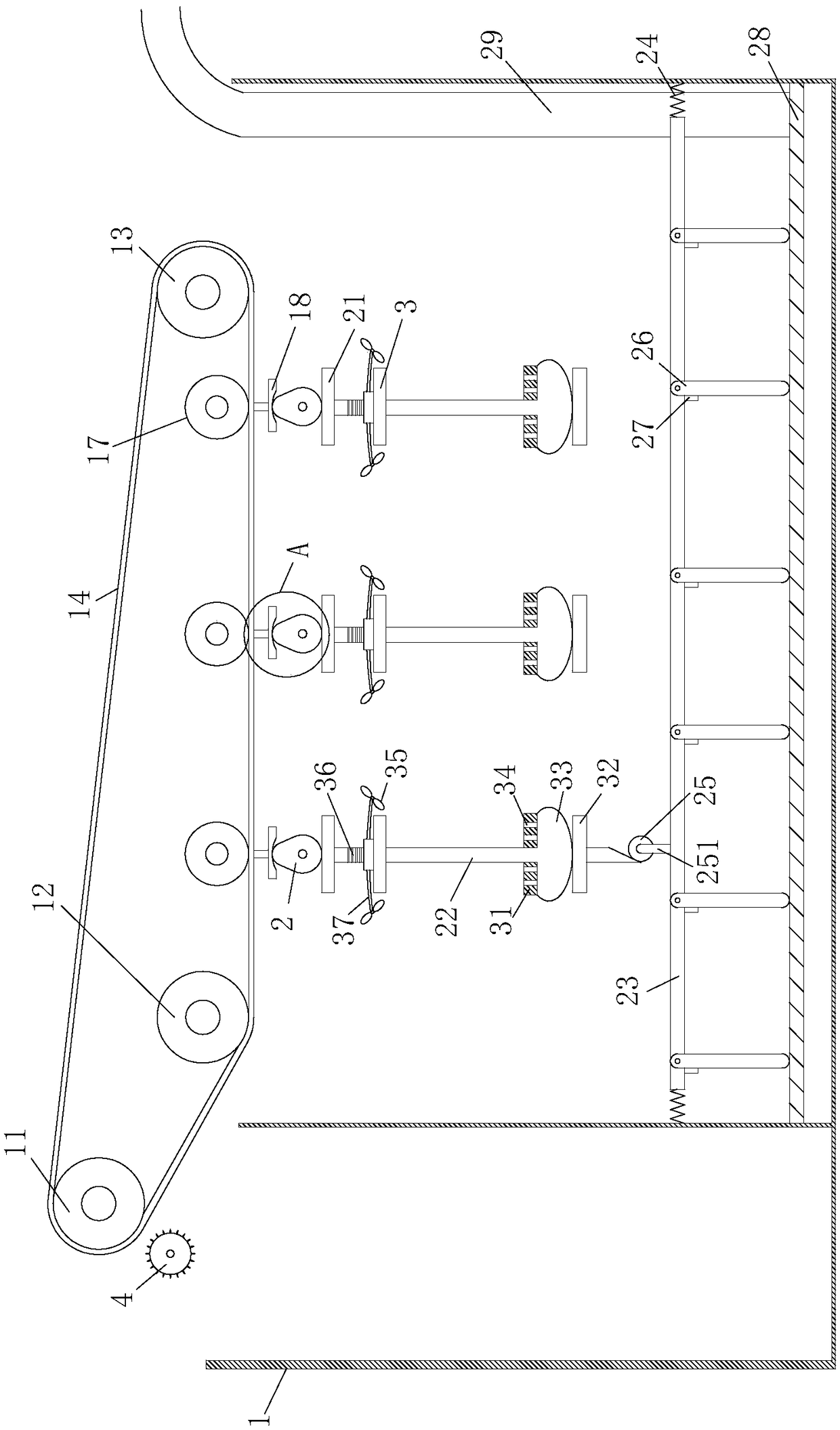

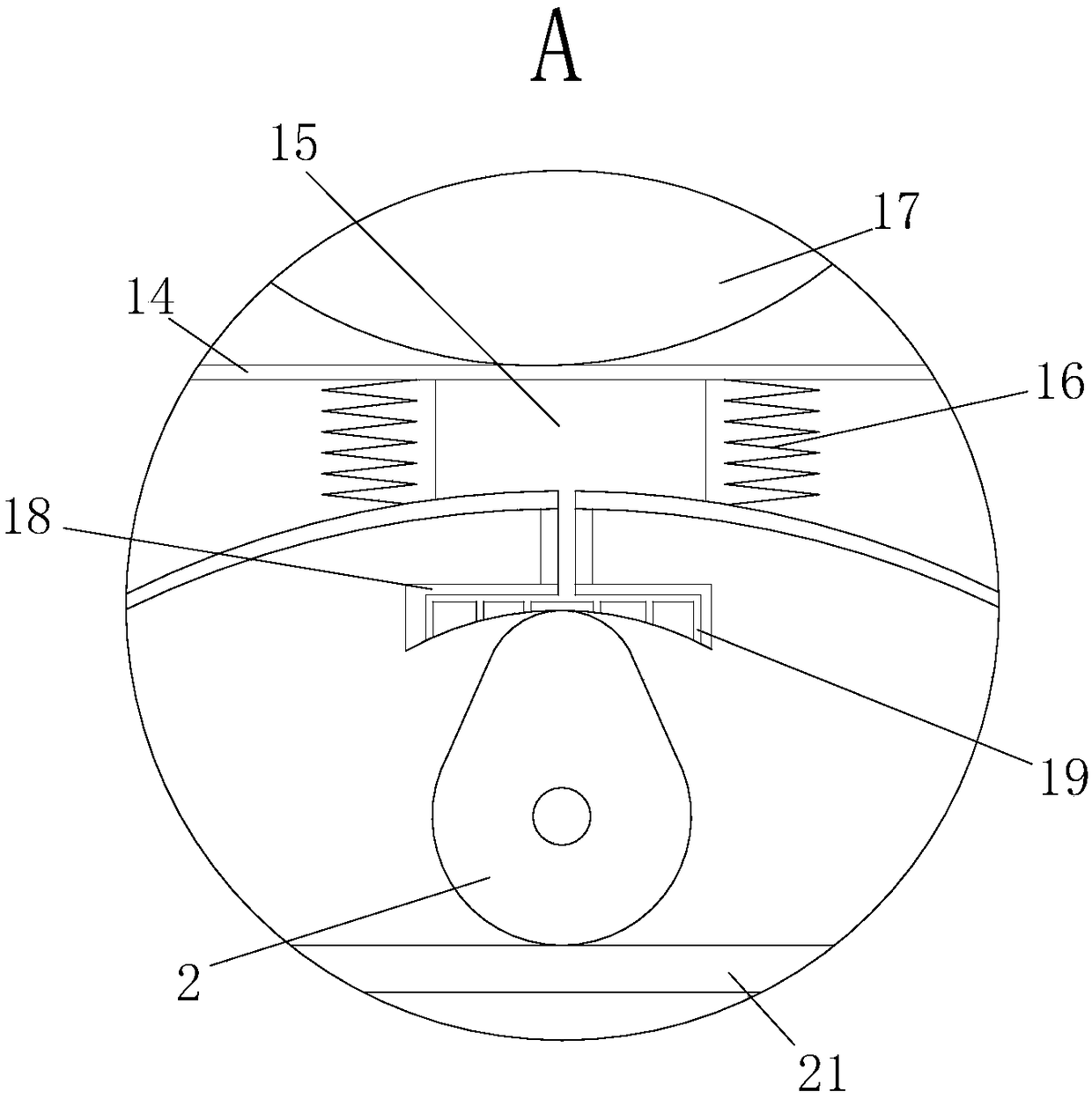

Plastic film recovery system for paper mill

The invention relates to material sorting equipment, in particular to a plastic film recovery system for a paper mill. The plastic film recovery system comprises a frame body, wherein a plurality of first air bags are arranged in a rubber belt; the first air bags are arranged at equal intervals; two sides of each first air bag are provided with first springs fixedly connected to an upper inner wall and a lower inner wall of the rubber belt; at least three extruding wheels are arranged between a first driven wheel and a second driven wheel; each extruding wheel rotates by clinging to an upper surface of the rubber belt; an arrangement distance of the extruding wheels is equal to an arrangement distance of the first air bags; suckers with the number the same as that of the first air bags andpositions corresponding to those of the first air bags are fixedly connected to a surface of the rubber belt; at least three cams are arranged in the frame body; and the cams rotate to be matched with the extruding wheels to extrude the suckers, so that the first air bags are extruded by the rubber belt, and when the first air bags pass by the next cam, as the first air bags are in a compressed state, the first air bags cannot be extruded by the cam, and different suckers can be extruded by a convex position during every revolution of the cam.

Owner:李露青

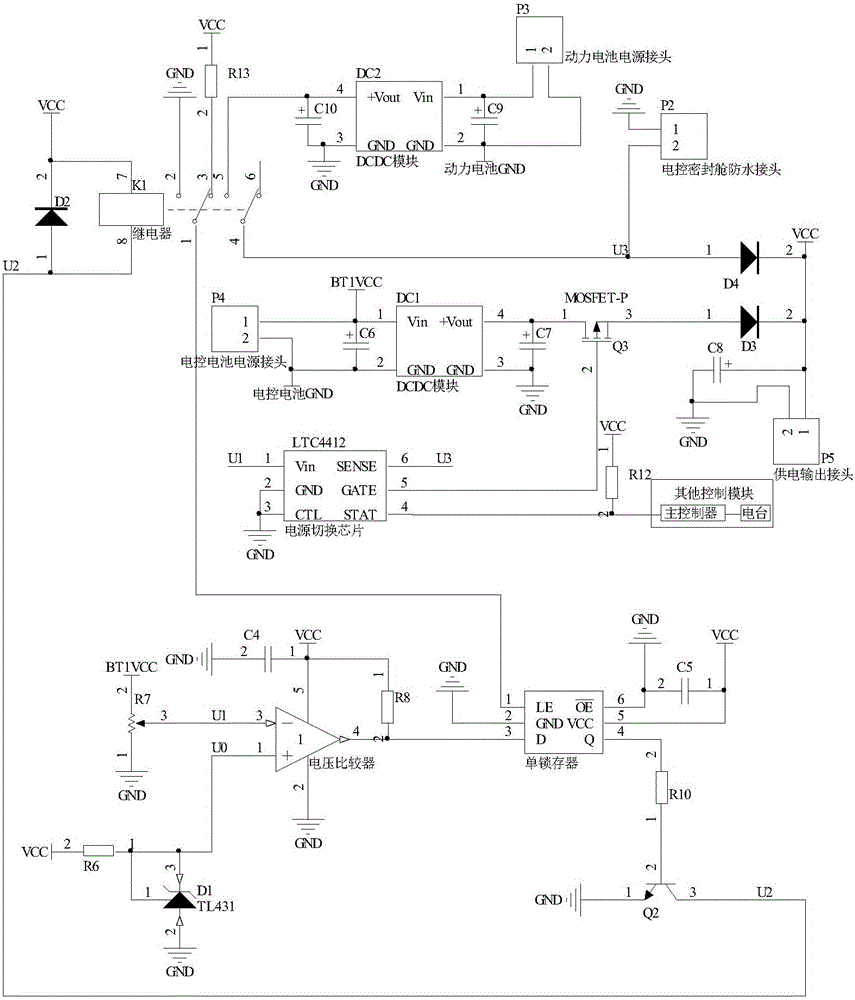

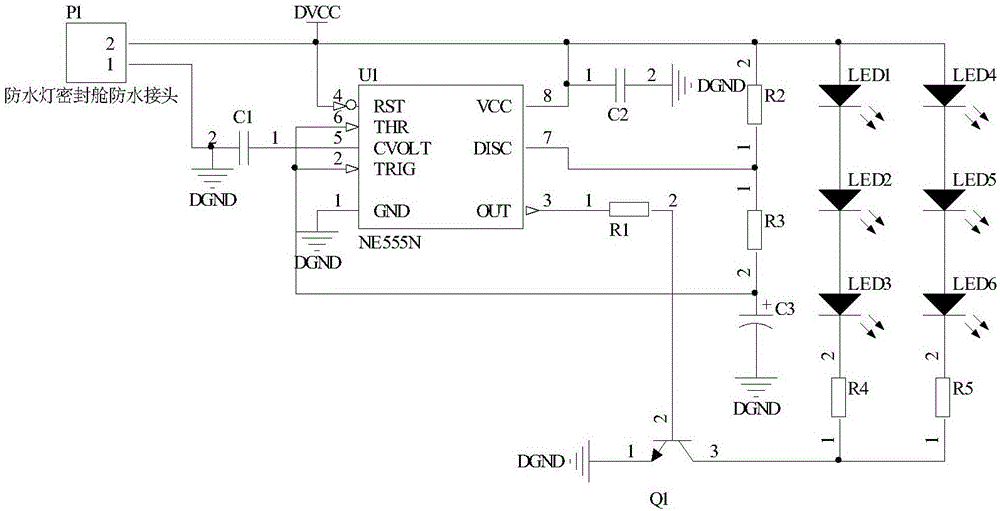

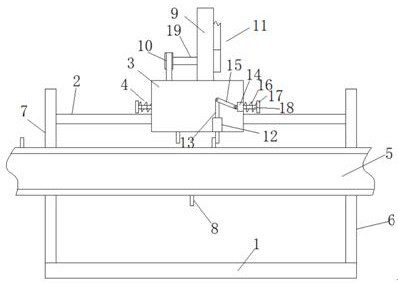

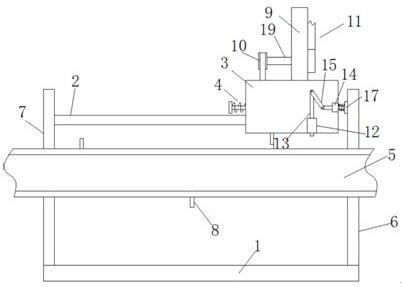

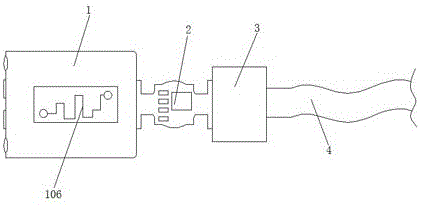

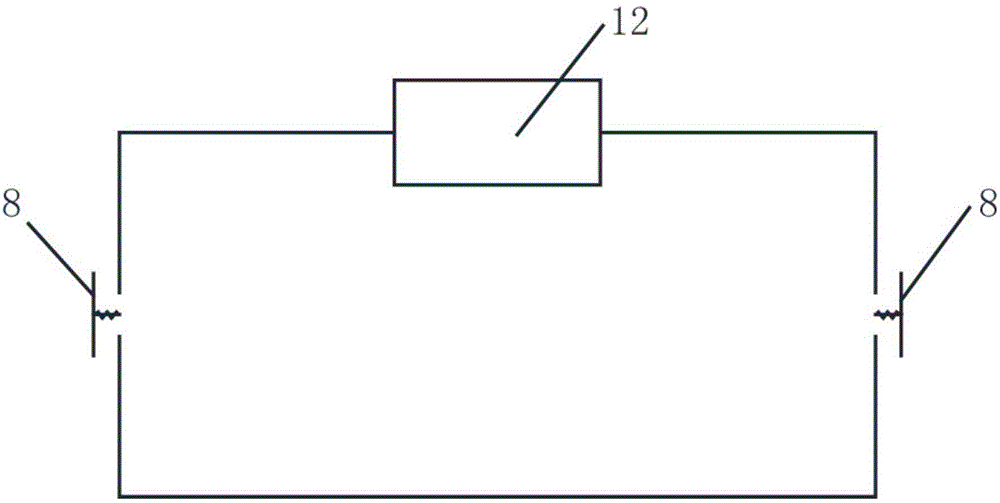

Power-battery-power-supply-to-electric-control-power-supply automatic emergency switching and alarm device for power buoy and control method thereof

ActiveCN106130174AAchieve continuous workTake advantage ofEmergency power supply arrangementsPower batteryElectrical battery

The invention provides a power-battery-power-supply-to-electric-control-power-supply automatic emergency switching and alarm device for a power buoy and a control method thereof. The automatic emergency switching and alarm device comprises an electric control sealed cabin and a waterproof lamp sealed cabin. The electric control sealed cabin is internally provided with a power battery, an electric control battery, a power supply switching module and a control module; the waterproof lamp sealed cabin is internally provided with a light alarm module; a power battery power connector of the power supply switching module is connected with the output end of the power battery; an electric control battery power connector of the power supply switching module is connected with the output end of the electric control battery; a power supply switching signal output end of the power supply switching module is connected with a power supply switching signal input end of the control module; and the power supply switching module is connected with the light alarm module through a waterproof cable. The device does not need an extra high-capacity stand-by power supply; and when the power battery has a large amount of residual electric quantity, an electronic device is automatically switched to the power battery for power when the electric control battery is in the undervoltage state, thereby realizing uninterrupted work and automatic alarm of the electronic device.

Owner:HARBIN ENG UNIV

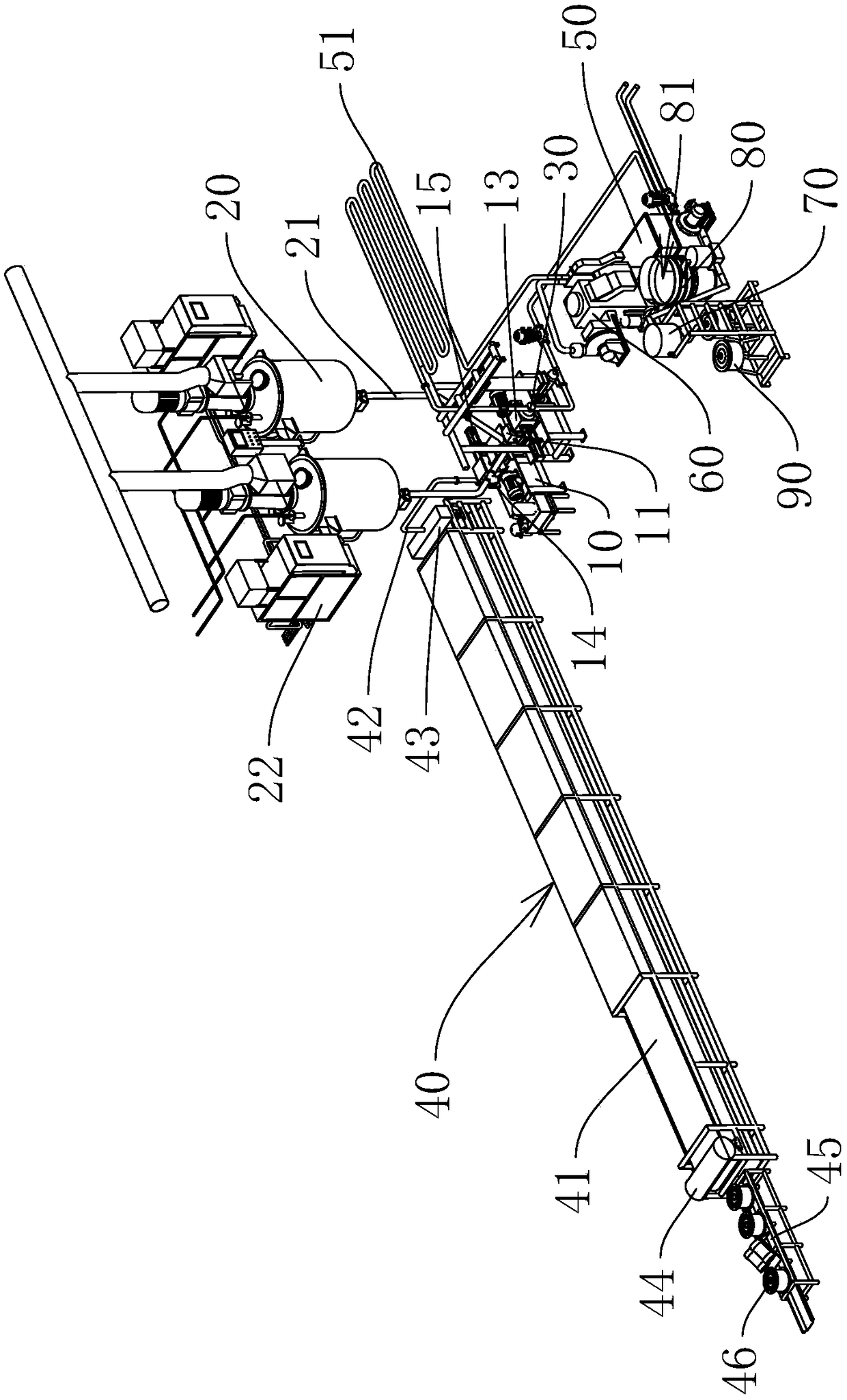

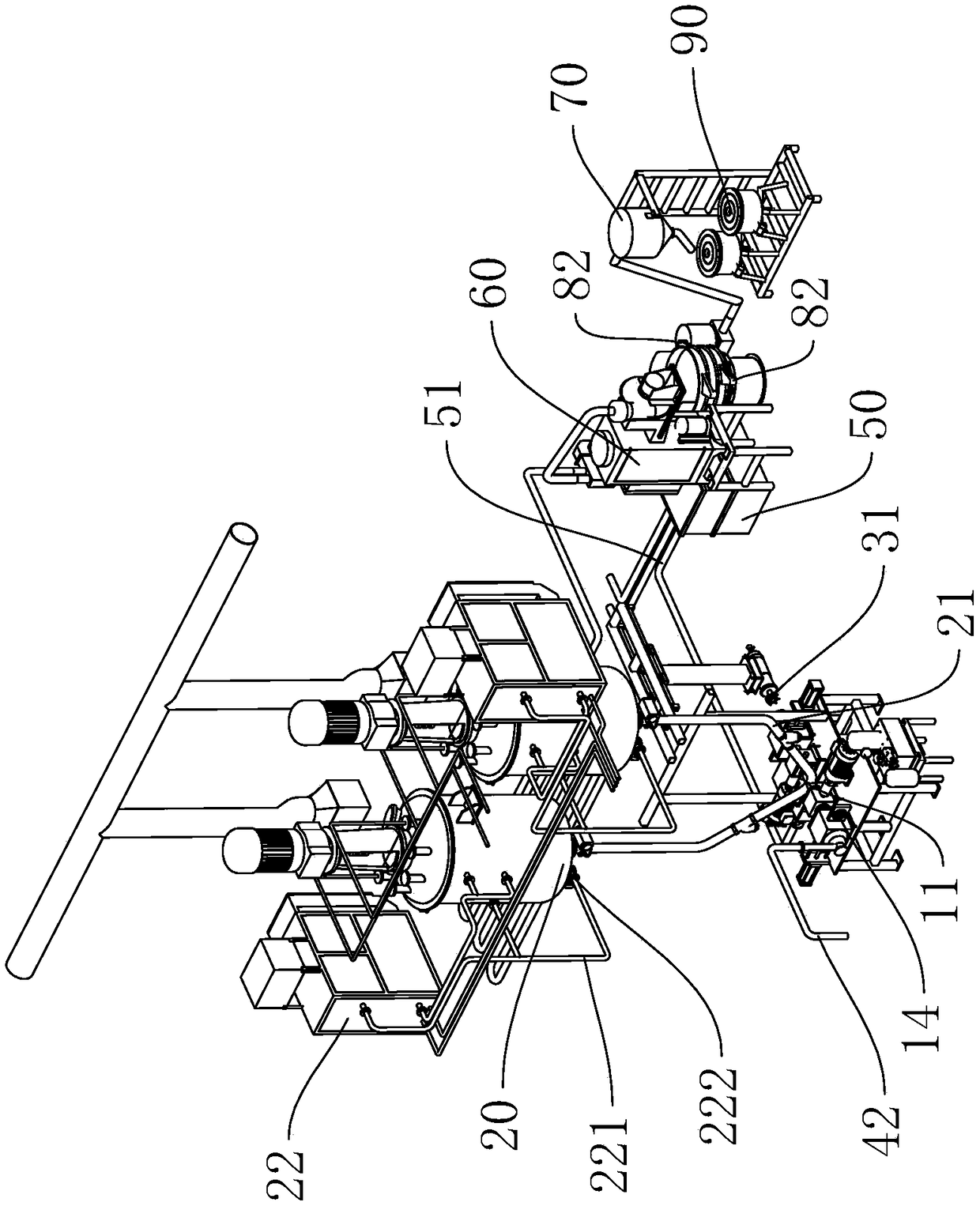

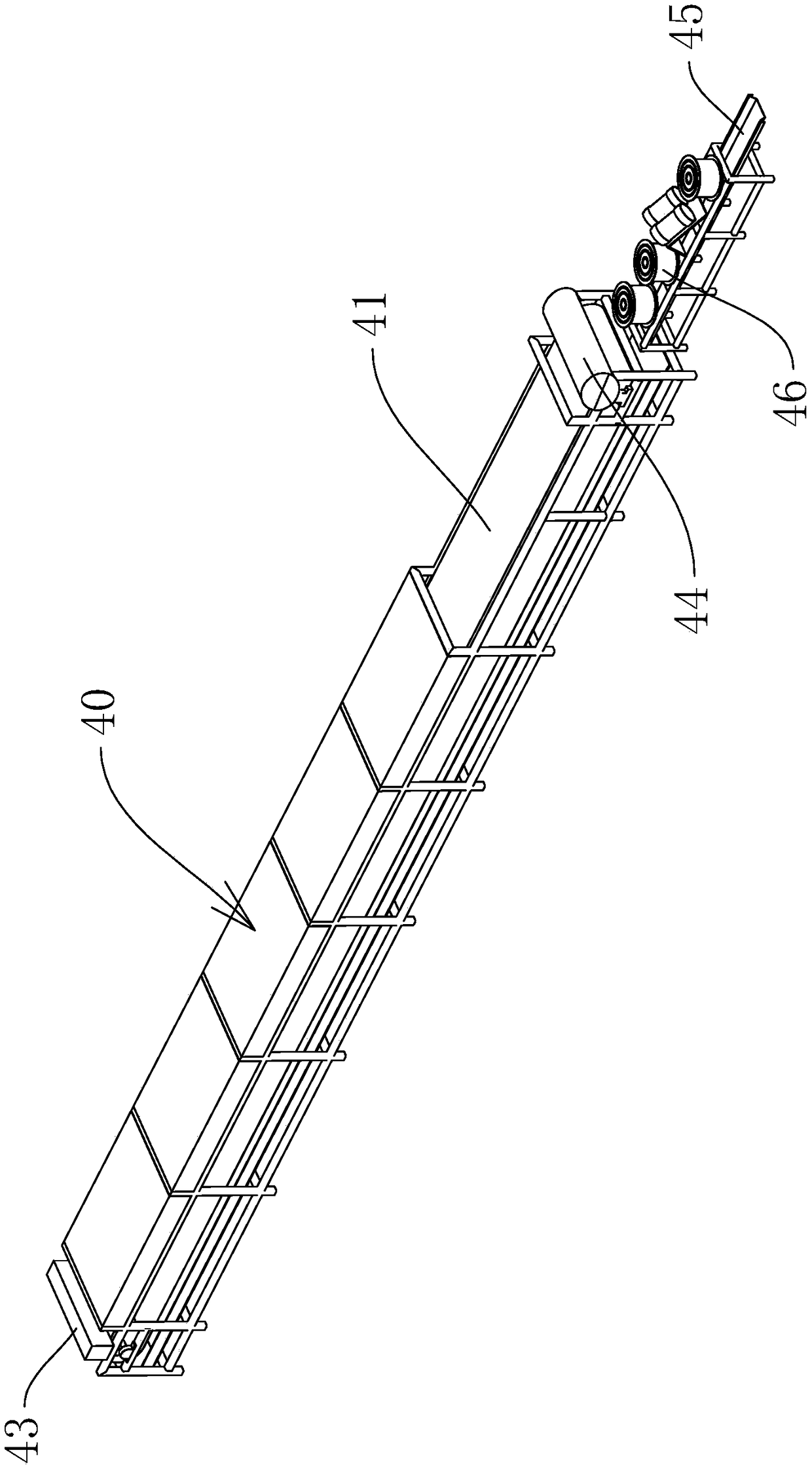

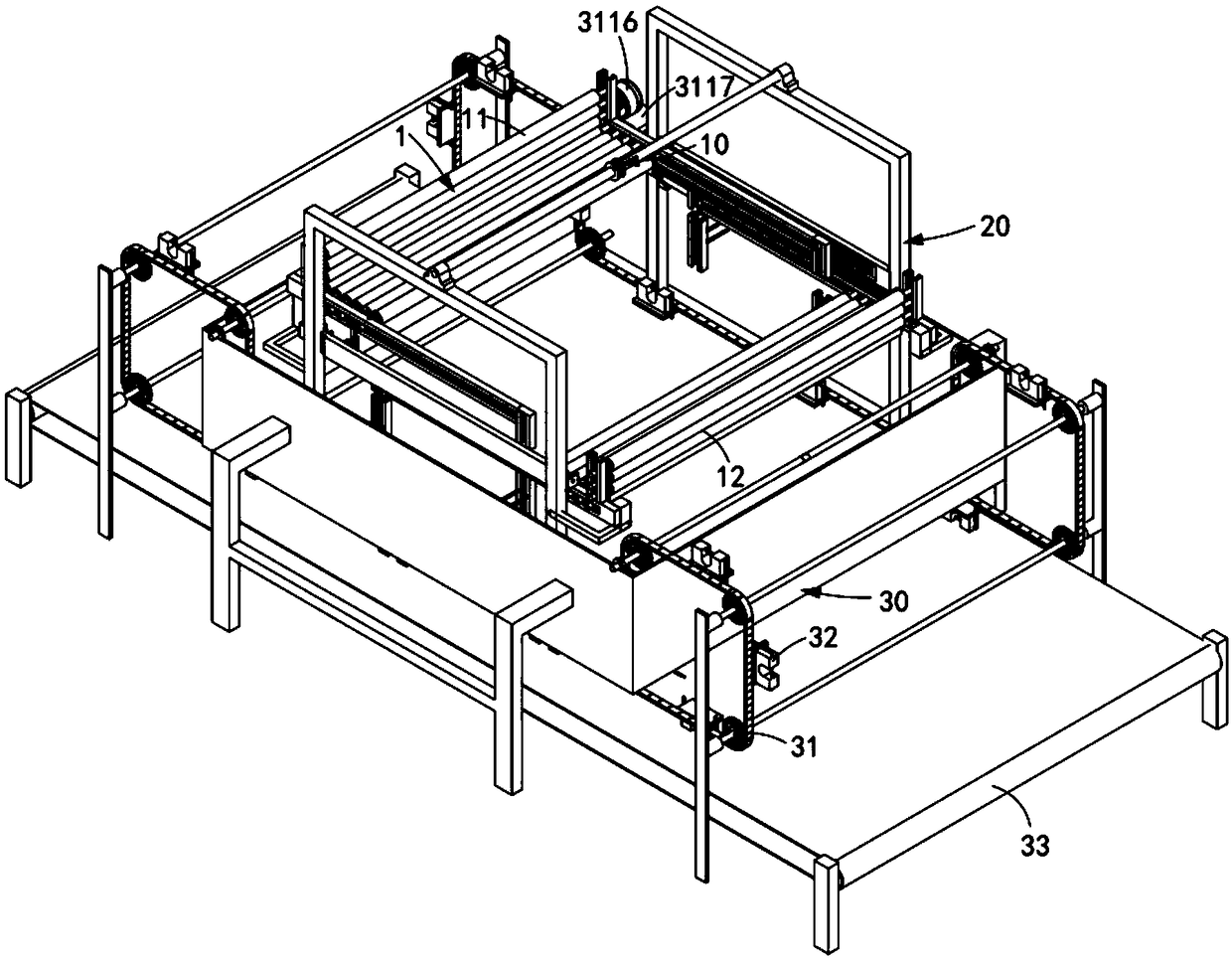

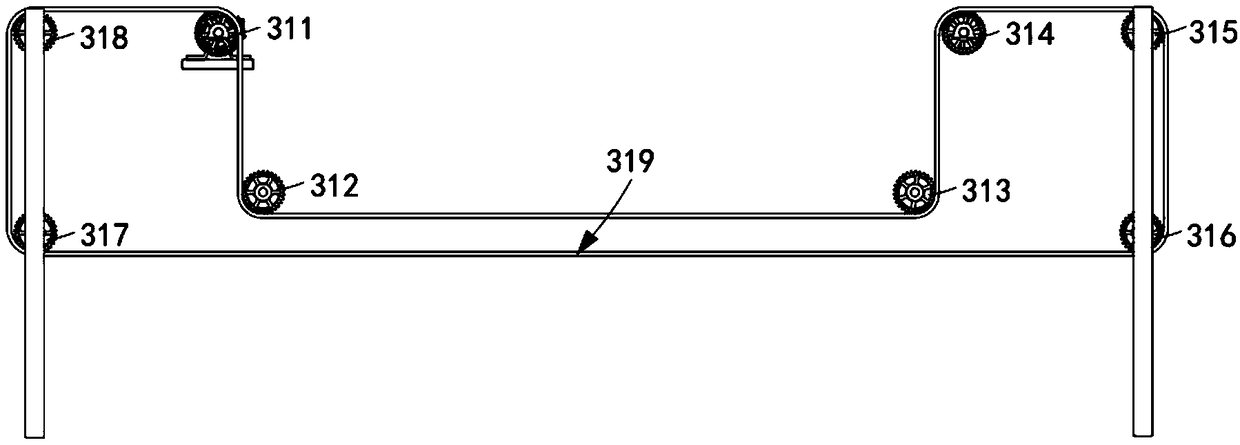

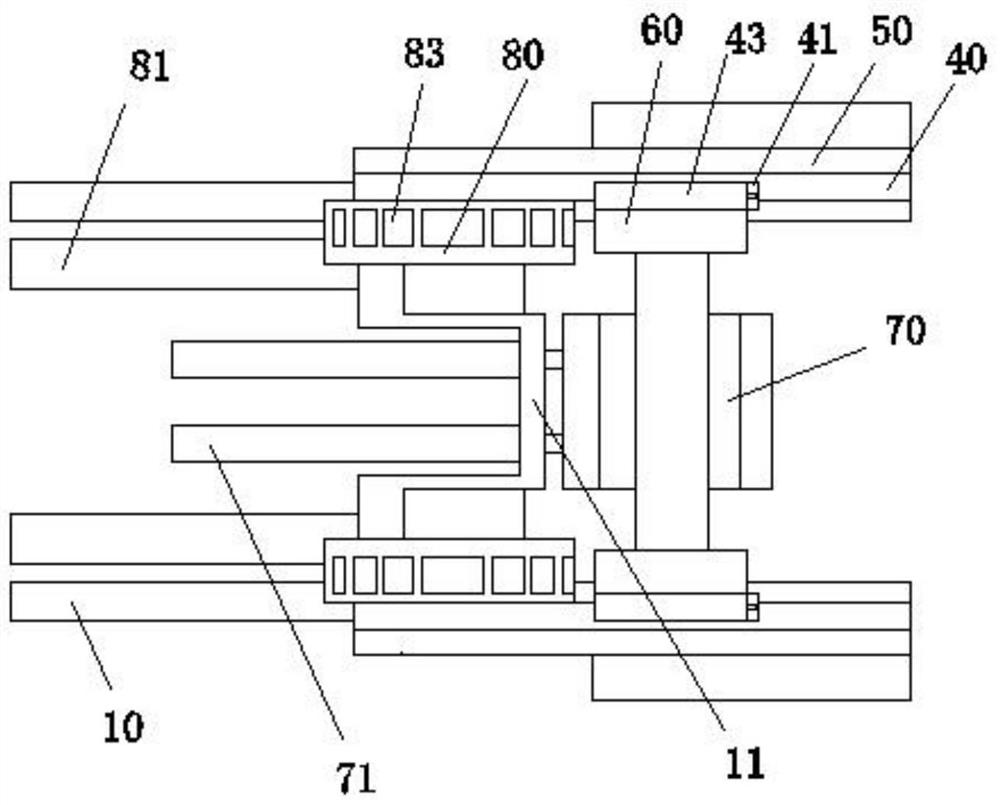

A flat ceramic membrane production and transportation equipment and its use method

ActiveCN112678422BAchieve continuous workImprove delivery efficiencyConveyorsConveyor partsEngineeringCeramic membrane

Owner:江苏新时膜科技有限公司

Filtering device for industrial wastewater purification and use method thereof

ActiveCN112973243AImprove processing efficiency and effectivenessImprove processing efficiencySpecific water treatment objectivesTreatment involving filtrationProcess engineeringSewage

The invention relates to the field of industrial wastewater purification equipment, in particular to a filtering device for industrial wastewater purification and a using method thereof. The filtering device comprises a base, wherein a filtering mechanism used for filtering flocculate in wastewater is arranged on the base, a sewage disposal mechanism is arranged on the base, is used for sucking and discharging the flocculate filtered on the filtering mechanism, and is in transmission connection with the filtering mechanism, an air pumping mechanism is arranged on the sewage disposal mechanism, and is used for cleaning and dredging the filtering mechanism in an air blowing mode, and the sewage disposal mechanism is in transmission connection with the air pumping mechanism. According to the filtering device for industrial wastewater purification and the use method thereof, the sewage disposal mechanism drives the filtering mechanism to filter wastewater subjected to flocculation treatment, so that efficient filtration of the wastewater is maintained, the wastewater treatment efficiency and effect are improved, shutdown is not needed, continuous work of the whole device is achieved, the wastewater treatment efficiency is improved, and the cleaning difficulty and the labor intensity of the flocculate are reduced.

Owner:浙江环森环境科技有限公司

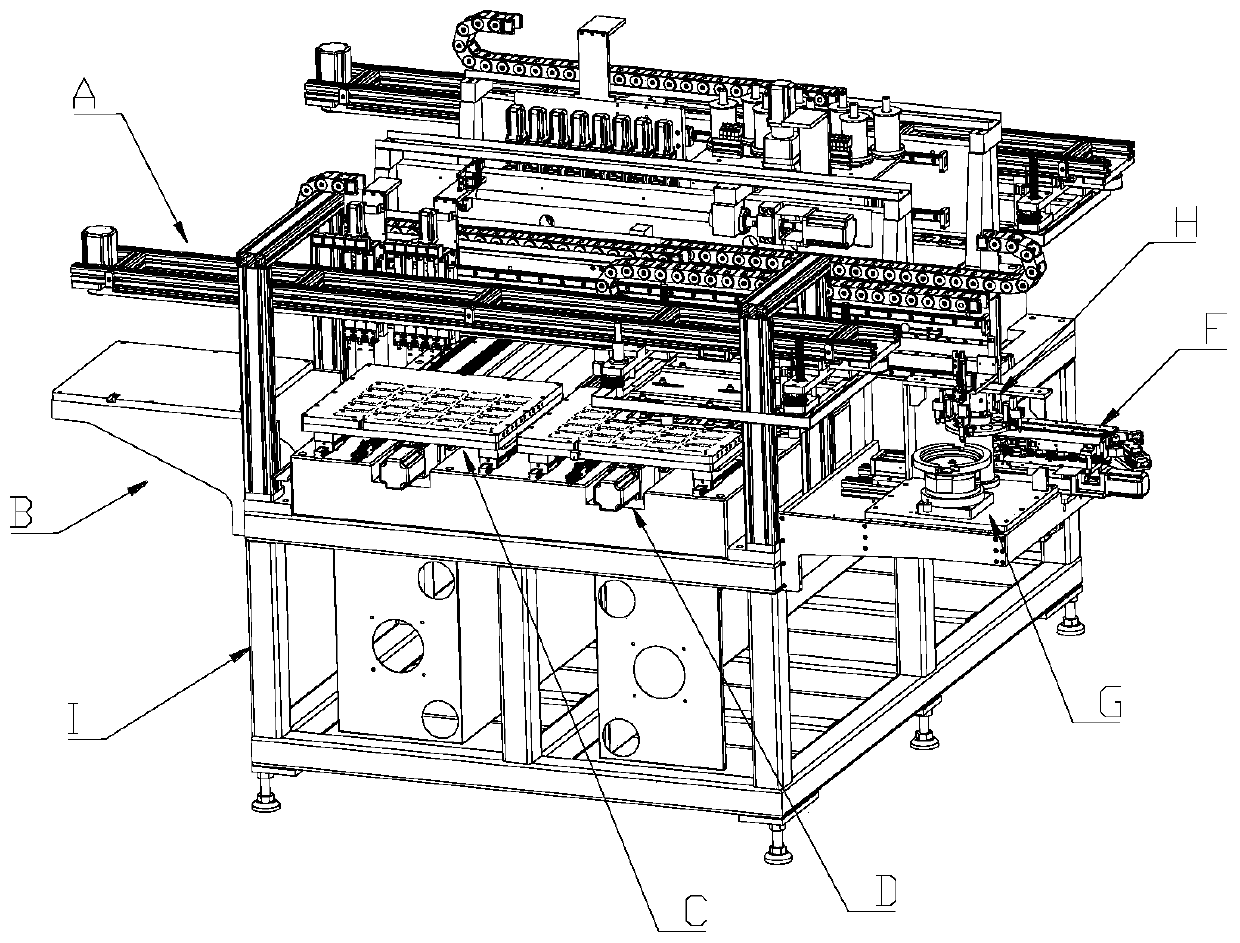

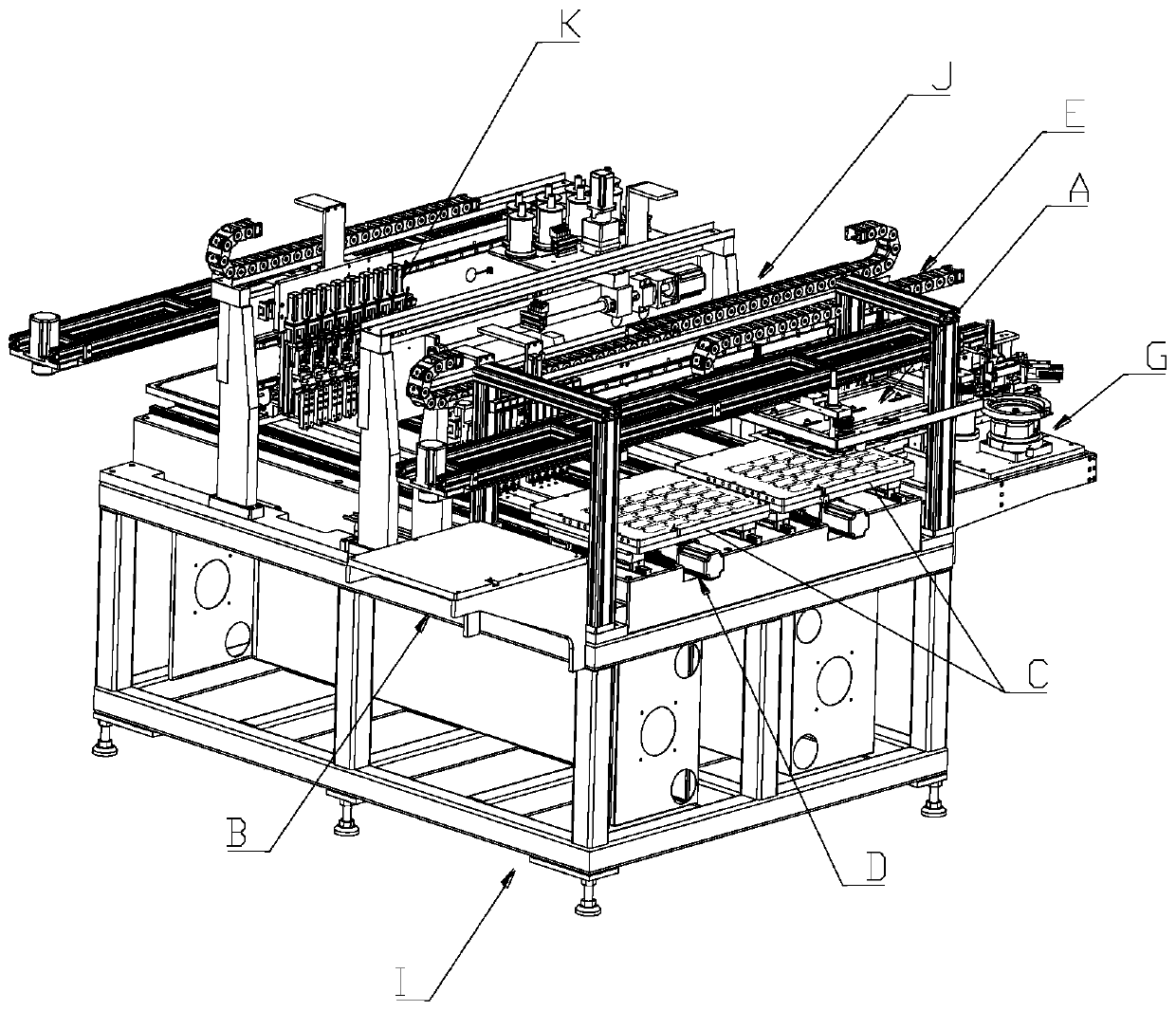

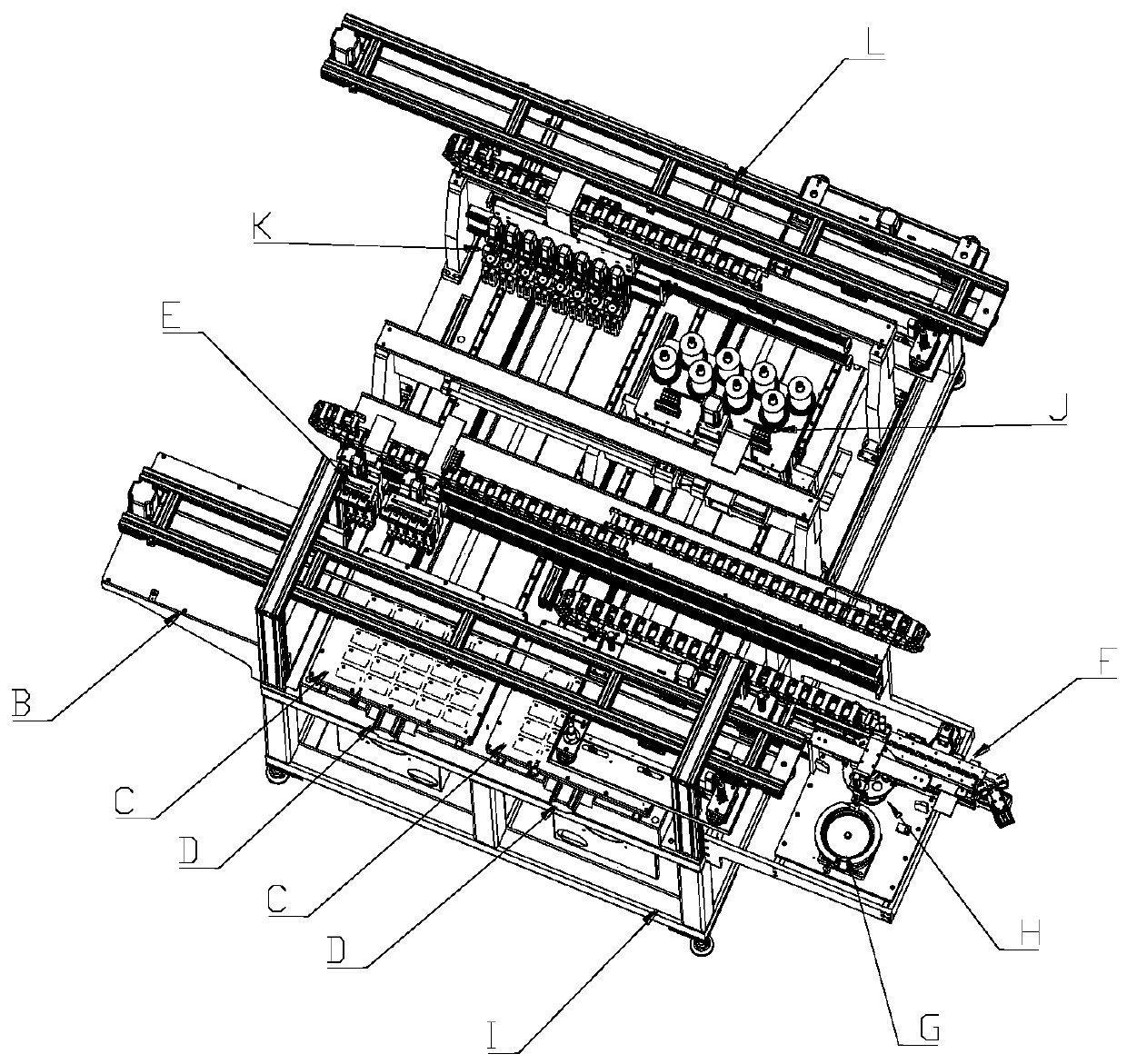

Non-contact intelligent card manufacturing equipment

PendingCN110524888AImprove work efficiencyImprove welding precisionRecord carriers used with machinesEngineeringWire wrap

The invention discloses non-contact intelligent card manufacturing equipment. The non-contact intelligent card manufacturing equipment comprises a rack, and comprises a plate feeding device, a chip feeding device, a winding device, a chip welding device and a conveying device which are arranged on the rack. The conveying device comprises a positioning platform and a conveying mechanism. The positioning platform comprises a base plate and a plurality of wire wrap card positions arranged on the base plate. The wire wrap card positions are in one-to-one correspondence with the wire wrap card units on the plate; each wire wrap card position is provided with a chip storage groove, and the chip storage grooves are in one-to-one correspondence with chip placement positions in the wire wrap card units. The plate feeding device comprises a plate containing table and a first carrying device. The chip feeding device comprises a chip placing table and a second carrying device. According to the non-contact intelligent card manufacturing equipment, accurate positioning of the plate and the chip in the production process of a non-contact intelligent card can be achieved, and therefore the production quality and the production efficiency of the non-contact intelligent card are improved.

Owner:广州明森合兴科技有限公司

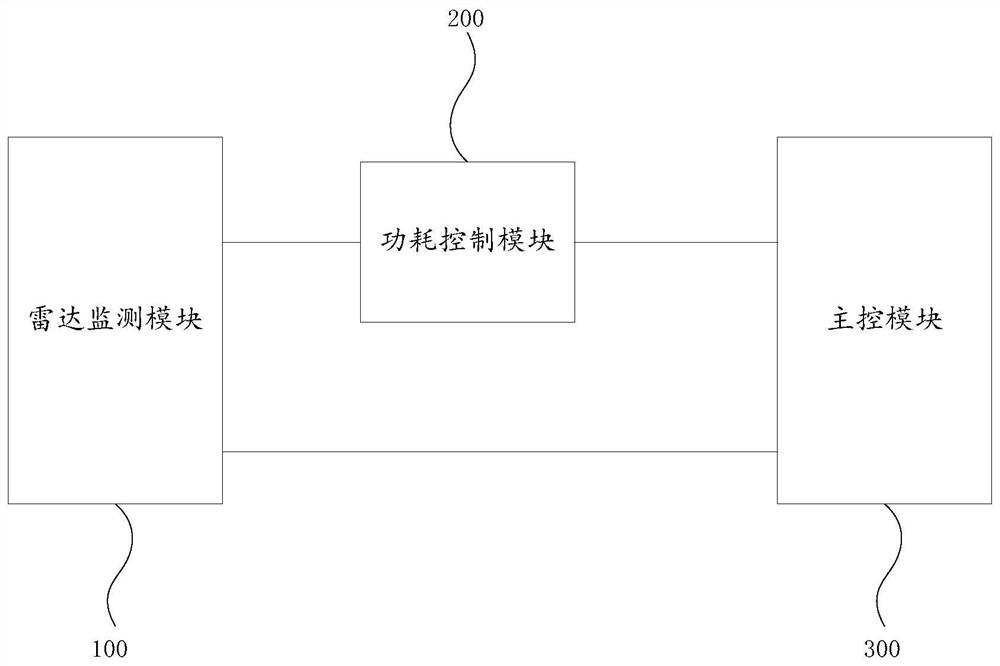

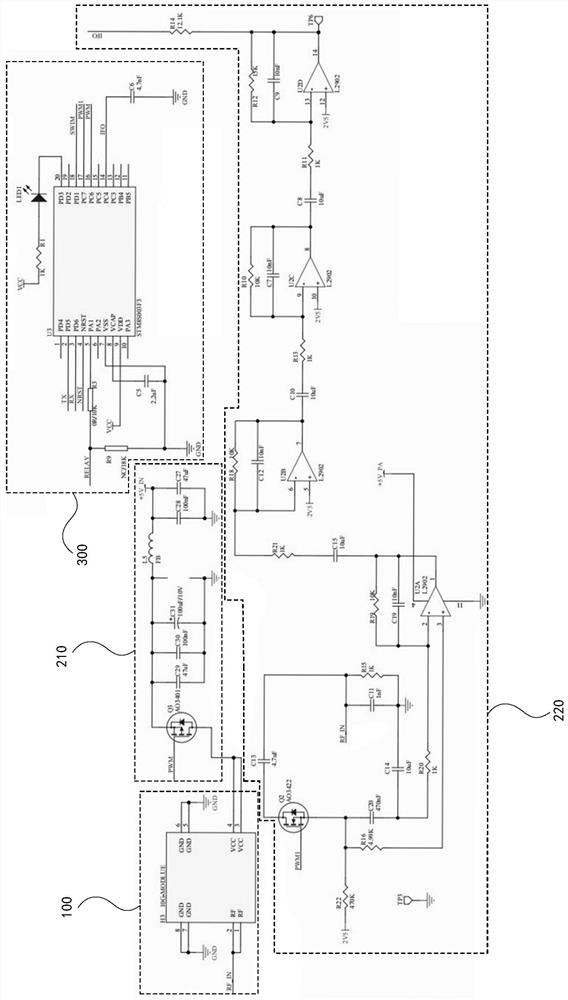

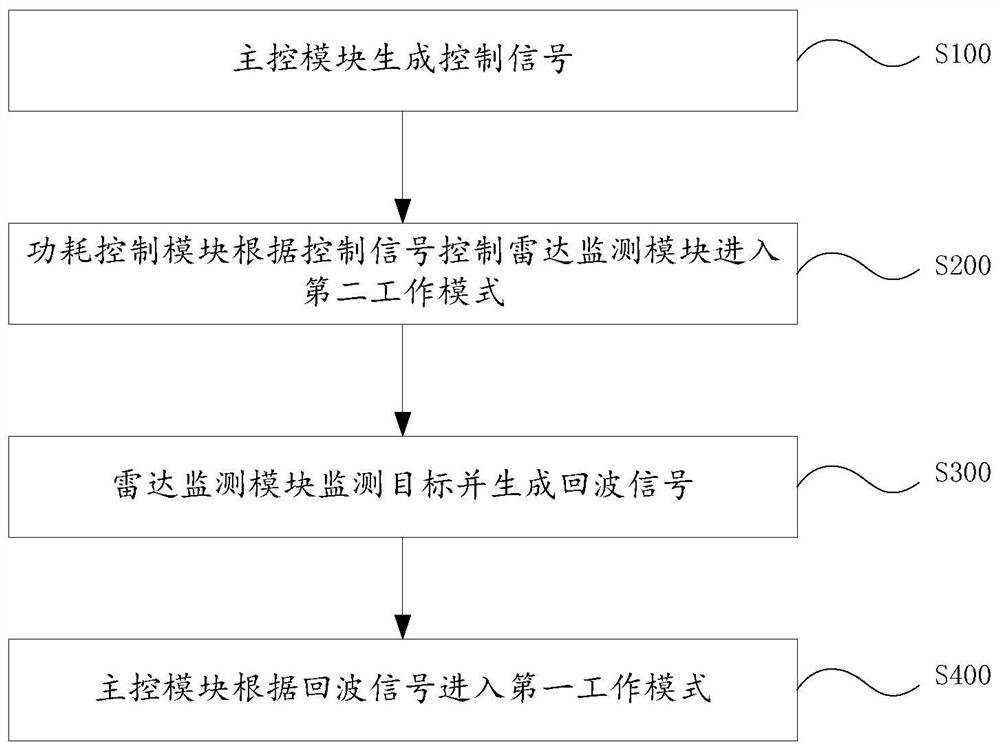

Radar power consumption control system and radar power consumption control method

InactiveCN112394329ALow costReduce power consumptionRadio wave reradiation/reflectionControl signalRadar

The invention discloses a radar power consumption control system and a radar power consumption control method. The radar power consumption control system comprises a radar monitoring module used for monitoring a target and generating an echo signal; a power consumption control module electrically connected with the radar monitoring module; and a main control module of which one end is electricallyconnected with the radar monitoring module and the other end is electrically connected with the power consumption control module and which is used for entering a first working mode according to the echo signal and generating a control signal; The power consumption control module is used for controlling the radar monitoring module to enter a second working mode according to the control signal. Thepower consumption control module controls the radar monitoring module to maintain a low power consumption mode so as to reduce the power consumption of the radar monitoring module. The echo signal isjudged through the main control module, so that the main control module enters a deep sleep mode according to the echo signal, and the power consumption of the main control module is reduced.

Owner:SHENZHEN TIANDING MW TECH CO LTD

Intelligent automobile ventilation device

The invention discloses an intelligent automobile ventilation device which comprises a housing, an air converter, a filter, an outer pipeline, a deodorizing bottle, a disinfection bottle, a first water pump, a second water pump, an electric push rod, a sliding board and a timer. In the use process, a driver can start the air converter for conducting ventilation and air exchange on an automobile; meanwhile, the driver can set the timer, so that the interior of the automobile is ventilated to exchange air in a timing manner; the driver can turn on a second switch, so that the interior of the automobile is effectively disinfected; and the driver can turn on a first switch, so that the interior of the automobile is effectively deodorized. The intelligent automobile ventilation device is ingenious in structure and powerful in function, the interior of the automobile can be effectively ventilated to exchange air and can be automatically ventilated to exchange air in the timing manner, disinfection and deodorization can be conducted on the interior of the automobile as well, the comfort of the driver is improved, and meanwhile the safety of the driver is greatly protected.

Owner:YANCHENG BUGAO AUTO PARTS MFG CO LTD

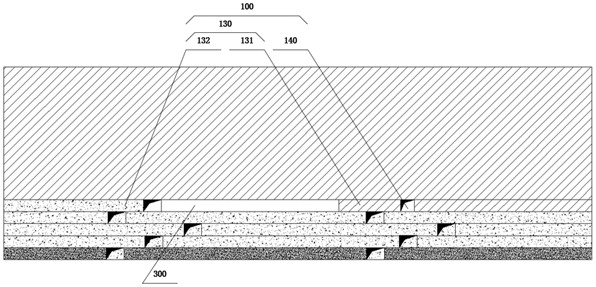

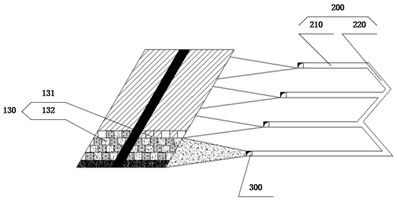

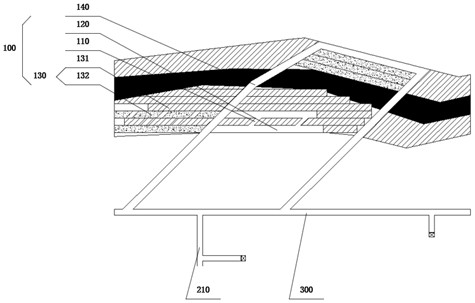

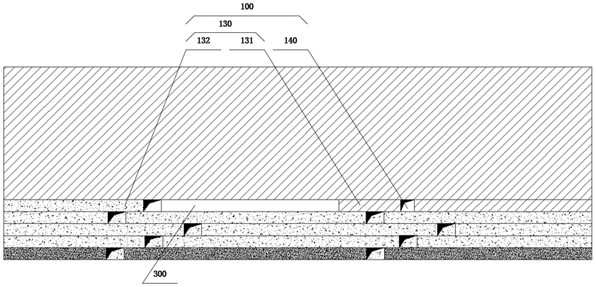

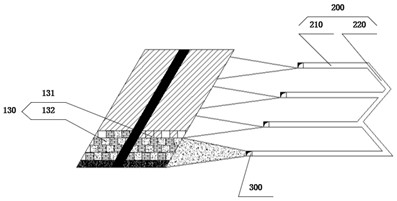

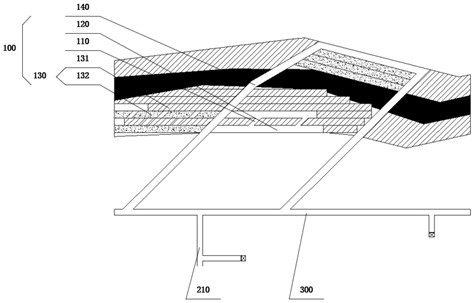

Mechanical continuous mining stope structure of heading machine and mining method of mechanical continuous mining stope structure

ActiveCN114526071ASolve mining inefficienciesImprove mining efficiencyUnderground miningSurface miningMining engineeringWater pipe

The invention provides a mechanical continuous mining stope structure of a heading machine and a mining method of the mechanical continuous mining stope structure, and relates to the technical field of mining. The stoping layer is communicated with the outside-vein roadway, and the stoping layer comprises an access connection channel, a stoped access and a supporting column; one supporting column is arranged between every two adjacent mined access roads, the access road connection channel is arranged on the supporting columns, and the two ends of the access road connection channel are communicated with the two adjacent mined access roads respectively, so that the heading machine can enter the adjacent mined access road from one mined access road, and the heading machine can enter the adjacent mined access road from the other mined access road. When the heading machine is tunneled to a specified position in the first mined drift, the heading machine directly enters the adjacent second mined drift through the drift connection channel to continue to tunnel, and the first mined drift is supported and the wind-water pipe is erected, so that the heading machine does not stop during the supporting and wind-water pipe erecting operation, and the heading machine is not stopped during the supporting and wind-water pipe erecting operation. The problem that an existing heading machine is low in mining efficiency is solved, and the technical effects that the heading machine works continuously and is high in mining efficiency are achieved.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

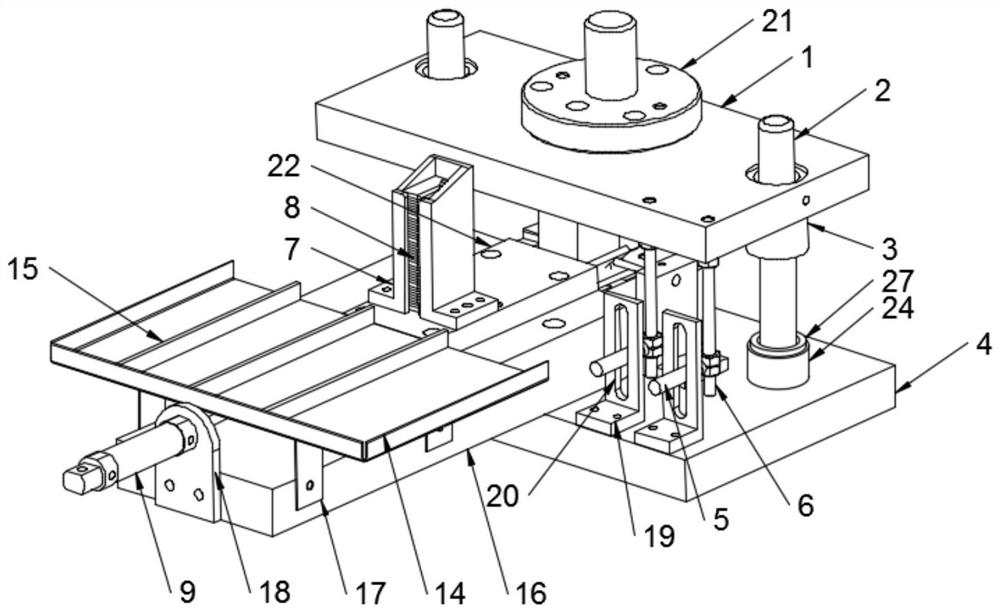

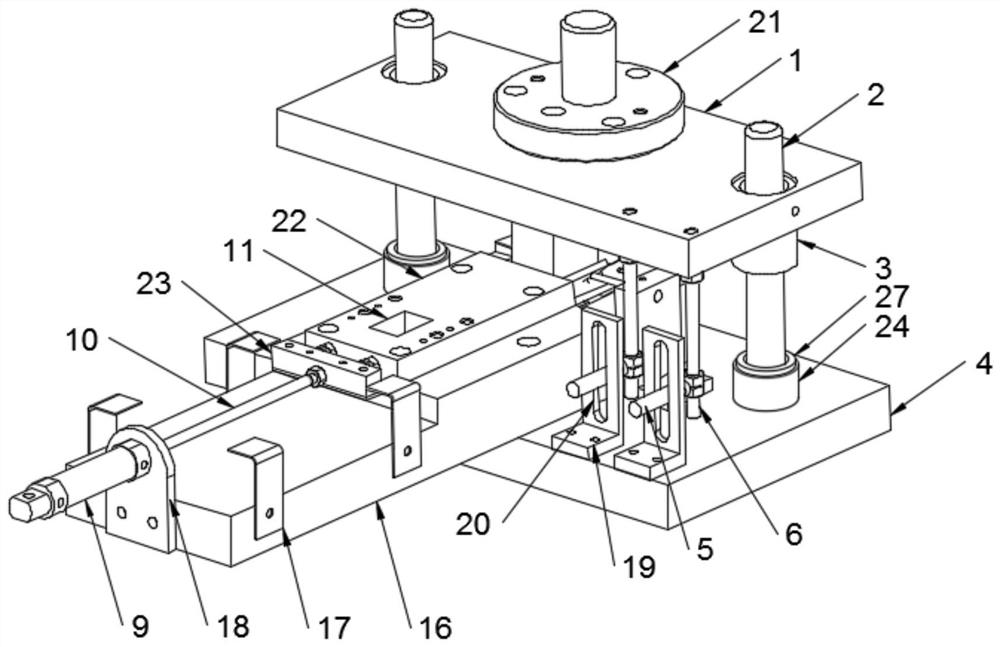

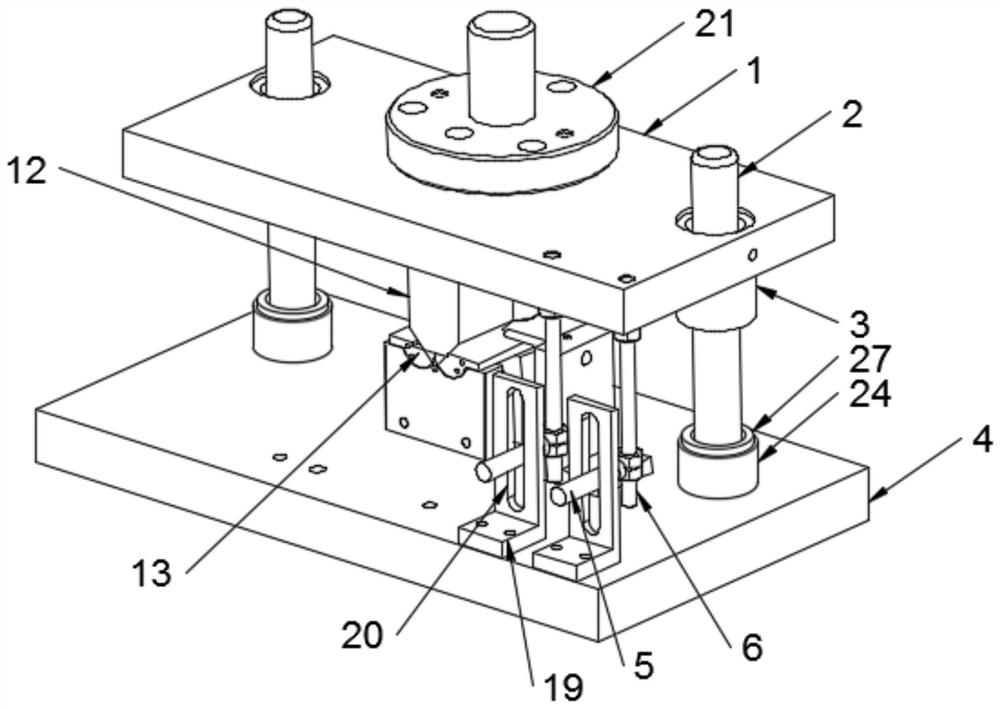

Automatic pushing and bending die of common punch press

InactiveCN112692112AEasy to transportAvoid human contactMetal-working feeding devicesMetal working apparatusPunch pressEngineering

The invention discloses an automatic pushing and bending die of a common punch press. The die comprises an upper die holder and a lower die holder, wherein a fixed base is fixedly arranged at the top end of the lower die holder, and an automatic conveying mechanism is arranged at the top end of the fixed base; the automatic conveying mechanism comprises a fixing plate, a linear air cylinder is fixedly arranged at the front end of the fixing plate, an air cylinder telescopic rod is fixedly arranged at the movable end of the linear air cylinder, a protection plate is fixedly arranged at the top end of the fixed base, a machining station is arranged on the protection plate, a product clamping bin is fixedly arranged at the top end of the protection plate, and a product placing groove is formed in the product clamping bin. According to the die, a workpiece is conveniently conveyed to the top end of a lower-die V-shaped groove through the automatic conveying mechanism, manual contact with an upper die and the lower-die V-shaped groove is avoided, higher safety is achieved, continuous work can be achieved, the working efficiency is improved, a good buffering effect can be achieved through a buffering mechanism when the workpiece is machined, and damage to the upper die and a lower die is avoided.

Owner:苏州市富通精密机械有限公司

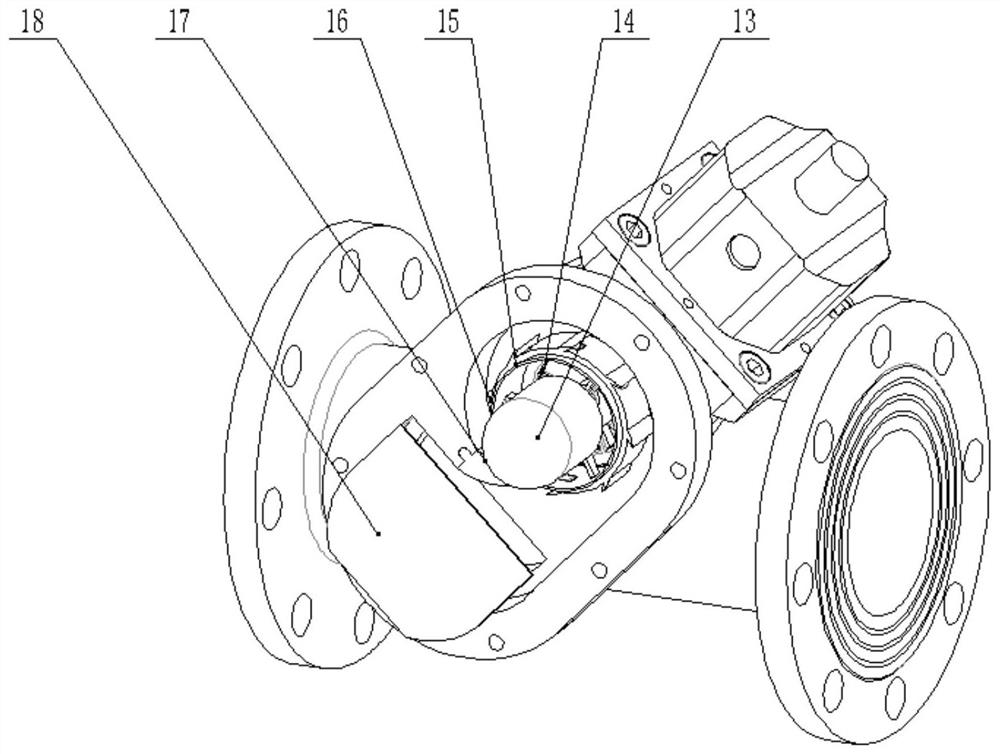

Small impeller power generation device

InactiveCN112360668APlay a protective effectEasy to installHydro energy generationReaction enginesImpellerStream flow

The invention discloses a small impeller power generation device. The small impeller power generation device comprises a device body, the device body comprises a first pipeline and a second pipeline communicated with the side wall of the first pipeline and arranged at a certain inclination angle, and a partition plate dividing a cavity of the first pipeline into a flow-in cavity and a flow-out cavity is arranged in the first pipeline; the flow-out cavity is communicated with the second pipeline, an adjusting opening through which water flow can flow into the flow-out cavity is formed in the partition plate, a circulating opening through which the water flow can flow into the second pipeline is further formed in the flow-in cavity at the front end of the partition plate, and the diameter ofthe adjusting opening is larger than that of the circulating opening; and an adjusting rod for adjusting the water flow rate of the adjusting opening is arranged in the second pipeline in a penetrating manner, the top end of the second pipeline is covered with an adjusting outer cover, and the outer end of the adjusting rod extends out of the adjusting outer cover. According to the small impellerpower generation device, the kinetic energy of the water in the pipeline is converted into electric energy, the water flow rate is changed through the adjusting rod, and the power of the power generation device is controlled.

Owner:YANSHAN UNIV

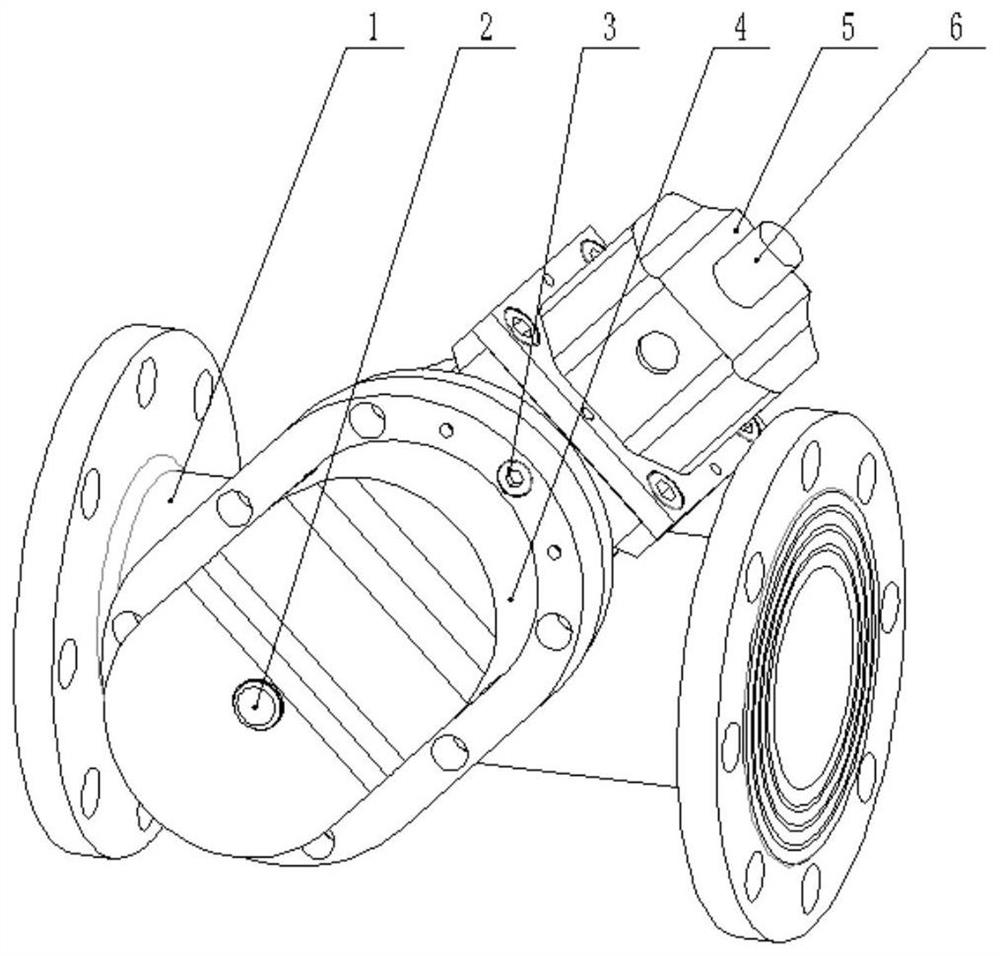

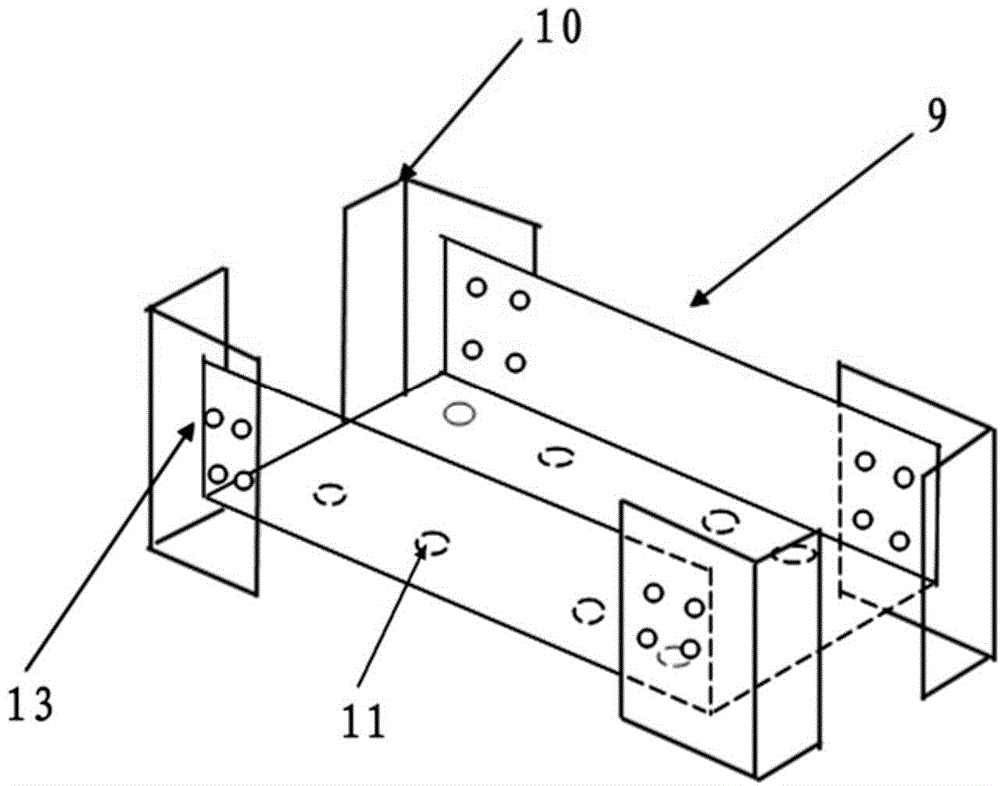

Cross beam riveting clamp

The invention relates to the technical field of vehicle assembly, in particular to a cross beam riveting clamp, and particularly discloses a heavy truck cross beam riveting clamp capable of rotating to switch a station. The cross beam riveting clamp comprises a rotatable platform, wherein the platform is provided with riveting tools; the riveting tools comprise positioning notches and positioning pins; the positioning notches and cross beam connecting plates are correspondingly arranged; the positioning pins are arranged corresponding to the positioning holes in cross beams. Through the clamp, fixed relative positions of the cross beams and the cross beam connecting plates are guaranteed during riveting of the cross beams; the riveting assembly size is accurate, the product quality is guaranteed, the operation is convenient, the two riveting tools are divided into a preassembly station and a riveting station, the two riveting stations are mutually switched through rotation, the degree of automation is high, and continuous work is realized, so that the working efficiency is improved.

Owner:BEIQI FOTON MOTOR CO LTD

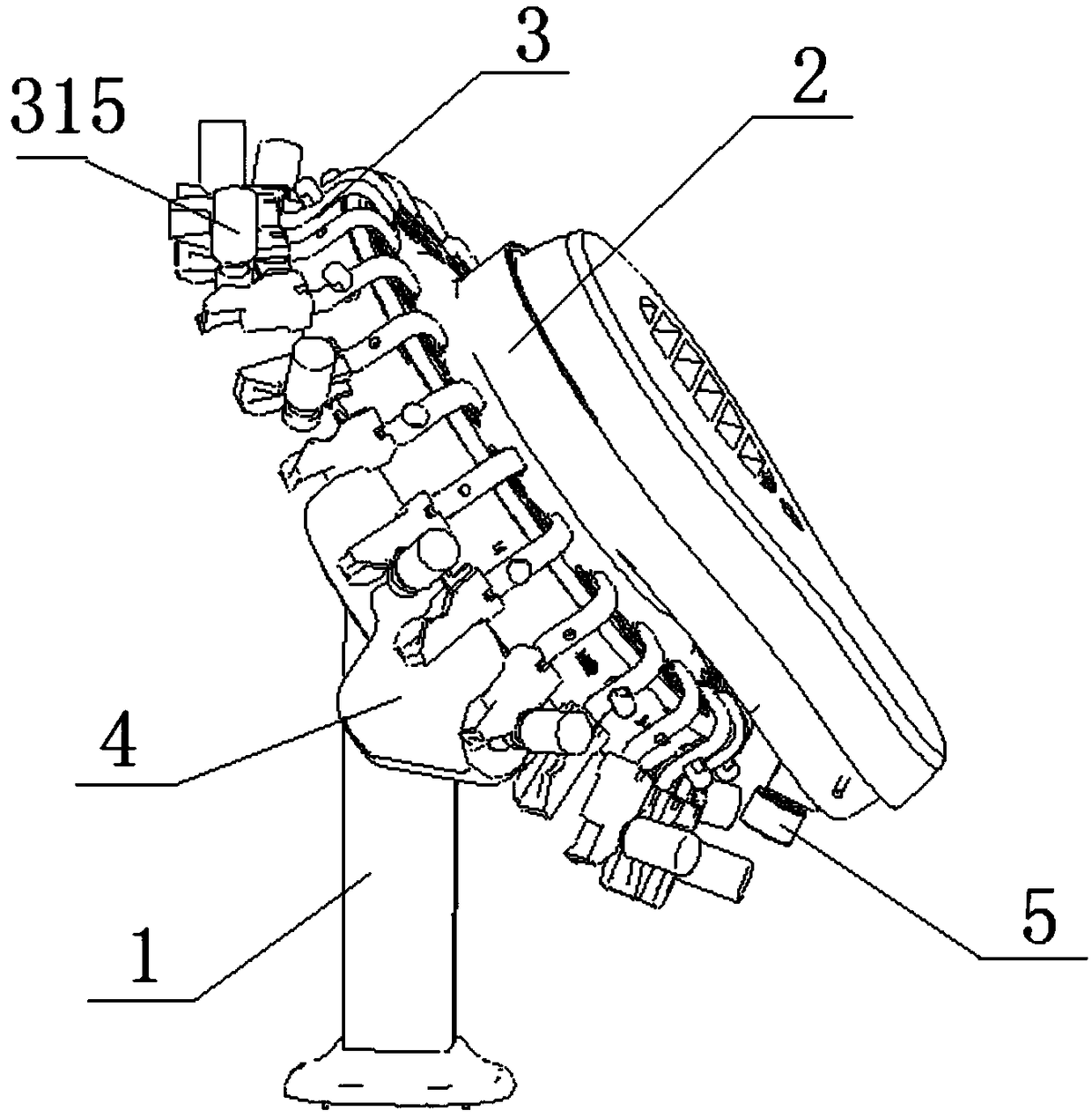

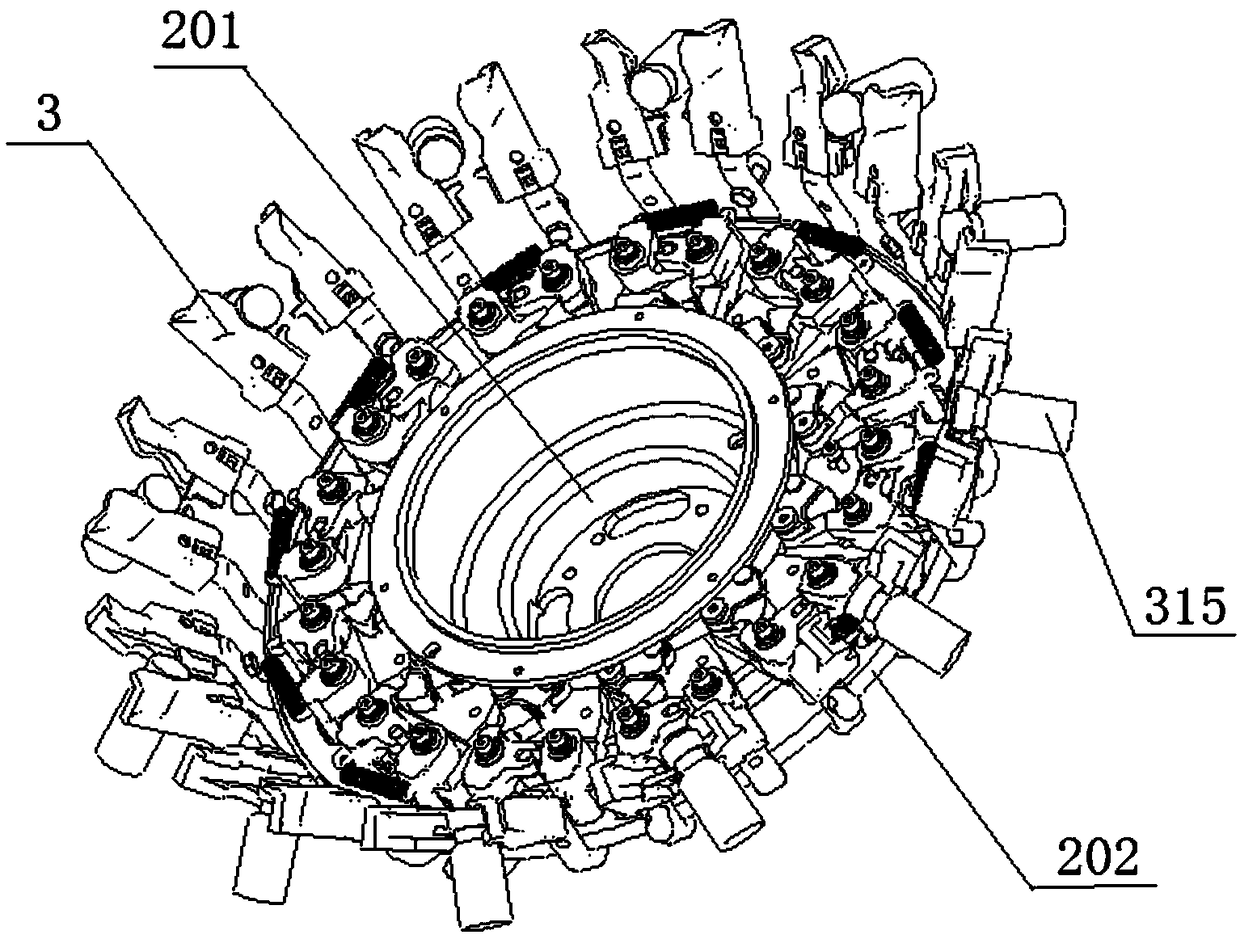

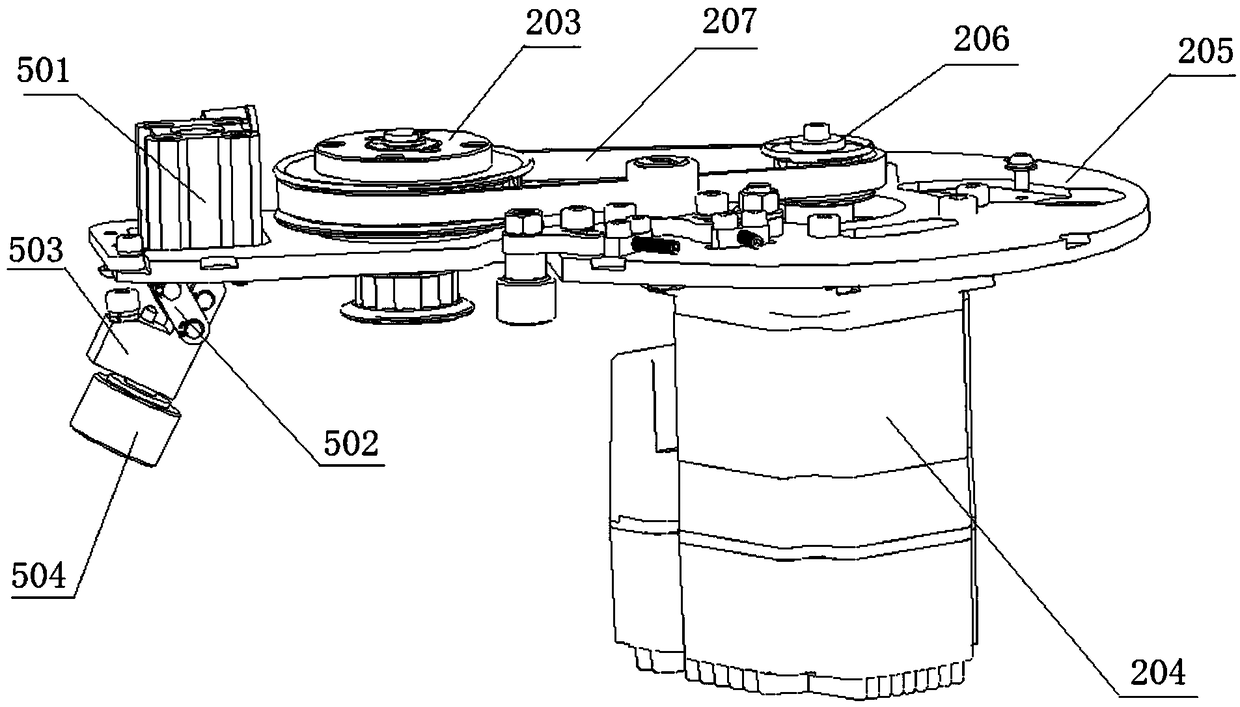

Rotating disc type penicillin bottle conveying device

The invention discloses a rotating disc type penicillin bottle conveying device. The rotating disc type penicillin bottle conveying device comprises a supporting vertical column, a disc rotating assembly is installed at the top of the supporting vertical column, a penicillin bottle clamping assembly is installed on the periphery of the disc rotating assembly, and a bottle unloading device is installed at one end of the disc rotating assembly. According to the rotating disc type penicillin bottle conveying device, penicillin bottles are manually put on clamping devices of the penicillin bottleclamping assembly through workers, the clamping devices act on left clamping jaws and right clamping jaws through elastic force of connection rod limiting springs so that the penicillin bottles can beclamped; a power device of the disc rotating assembly can drive the penicillin bottle clamping assembly to rotate, when the clamping devices clamping the penicillin bottles move to the bottle unloading device, an air cylinder of the bottle unloading device drives a bottle unloading block to open bottle unloading stop blocks on the clamping devices, accordingly, the penicillin bottles are unloaded, and after the penicillin bottles are taken down, under action of elastic force of the connection rod limiting springs, the left clamping jaws and the right clamping jaws are driven to reset by driving the left clamping jaw connection rods and the right clamping jaw connection rods.

Owner:WUXI ANZHIZHUO MEDICAL ROBOT CO LTD

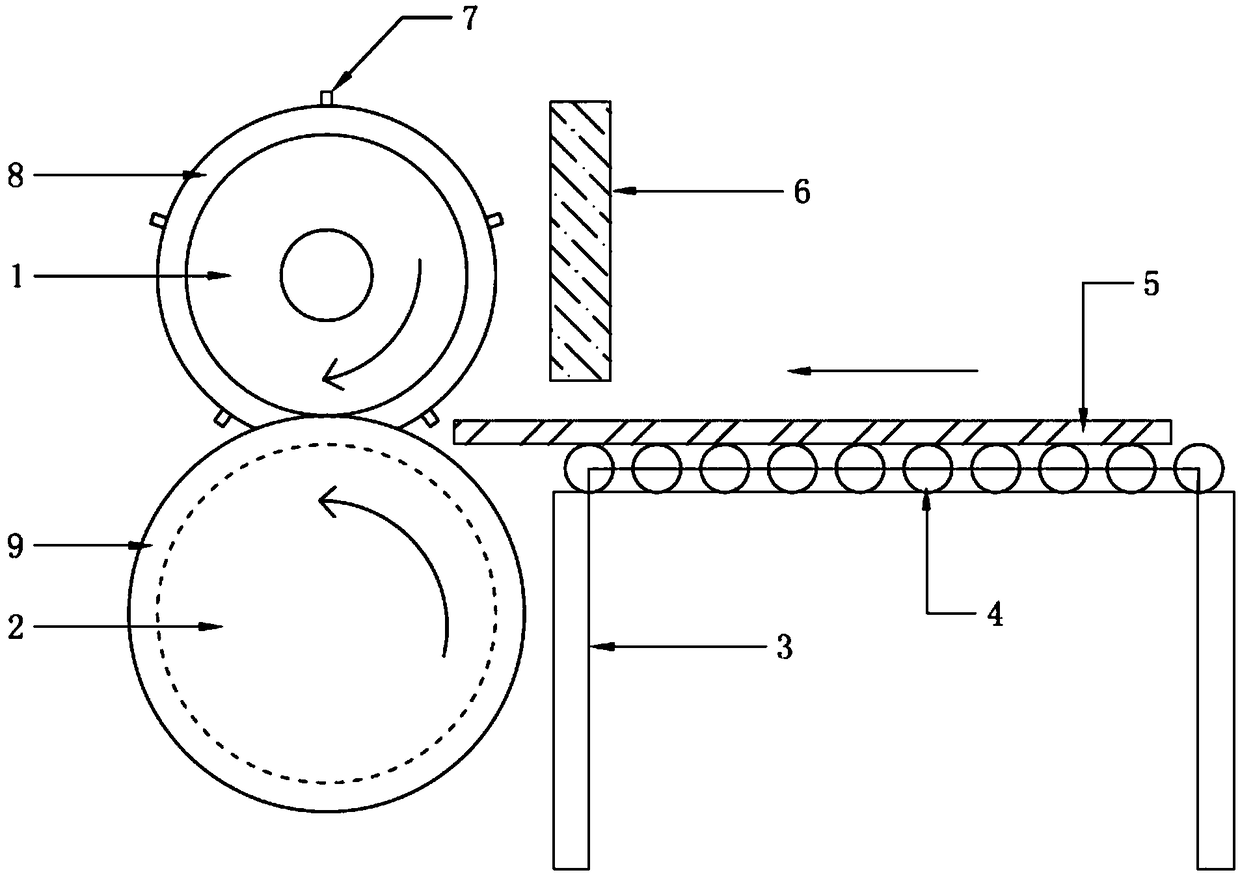

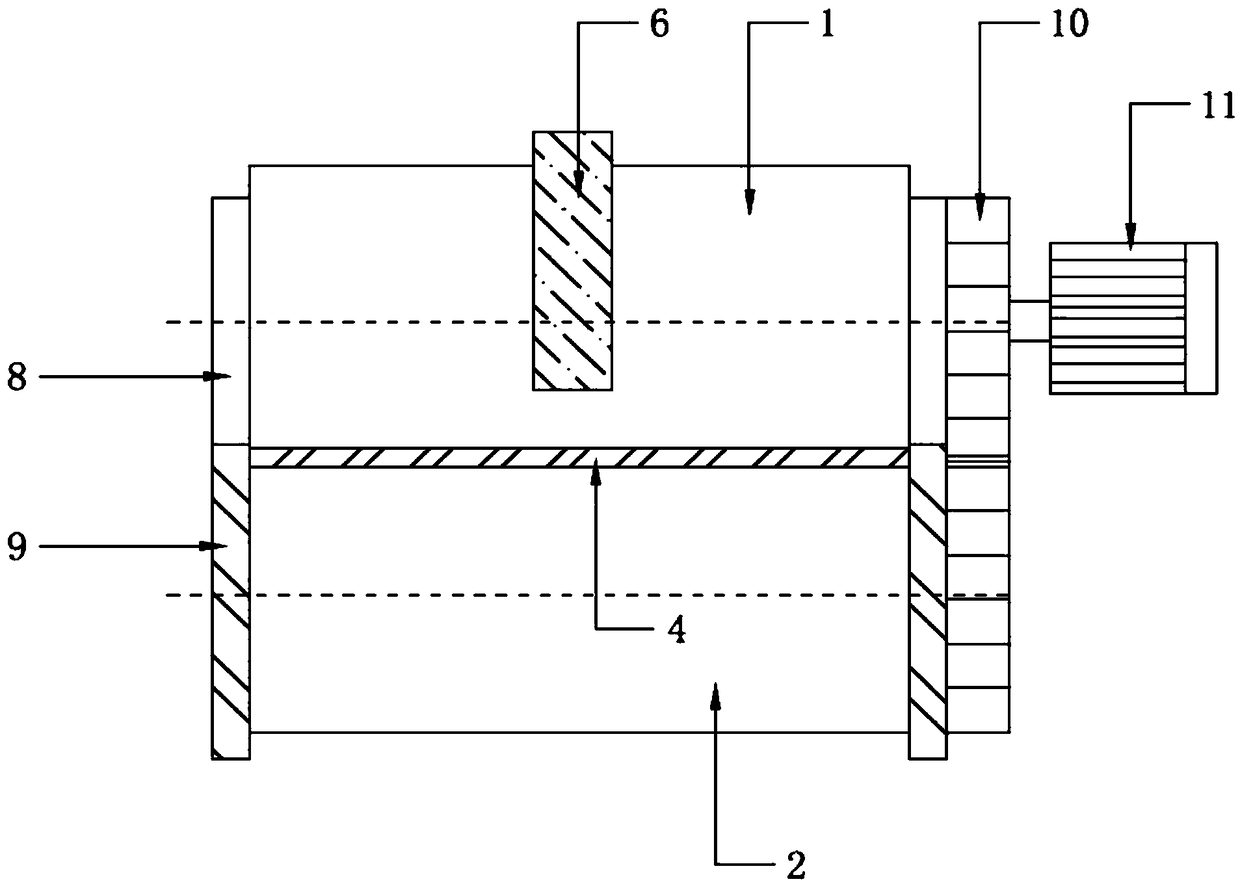

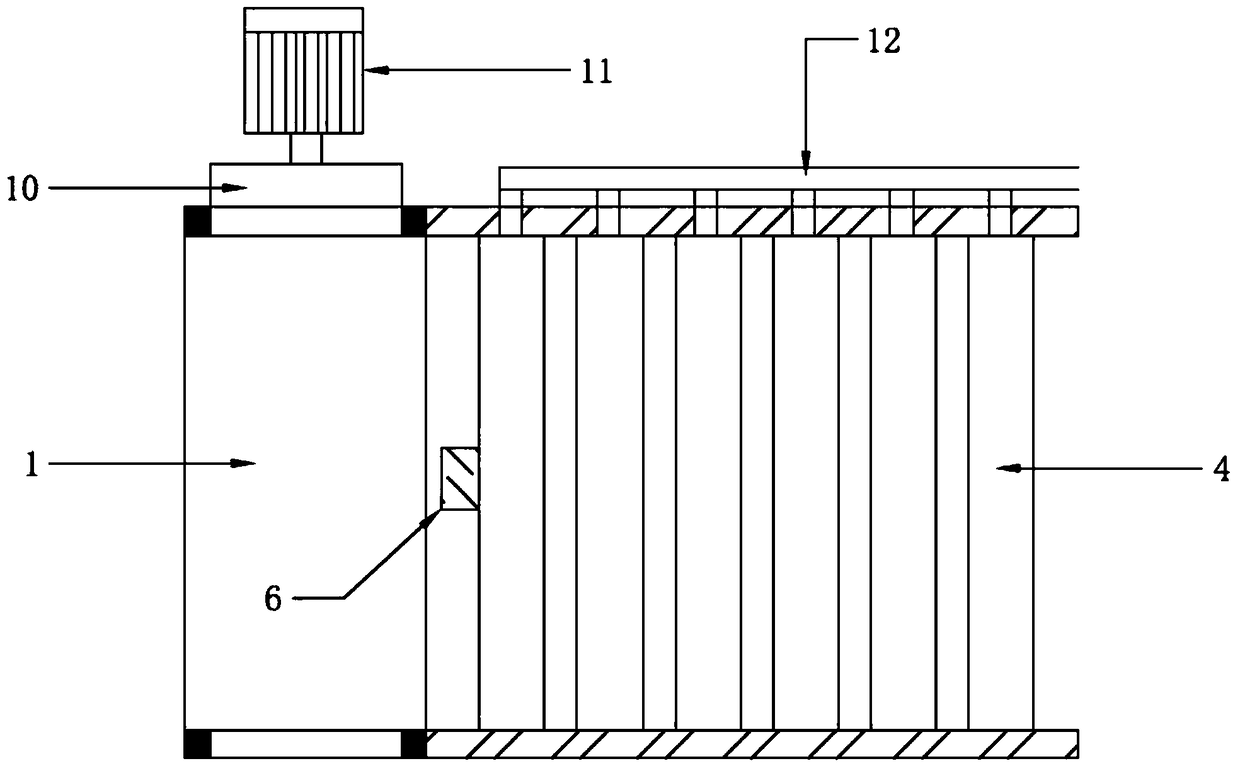

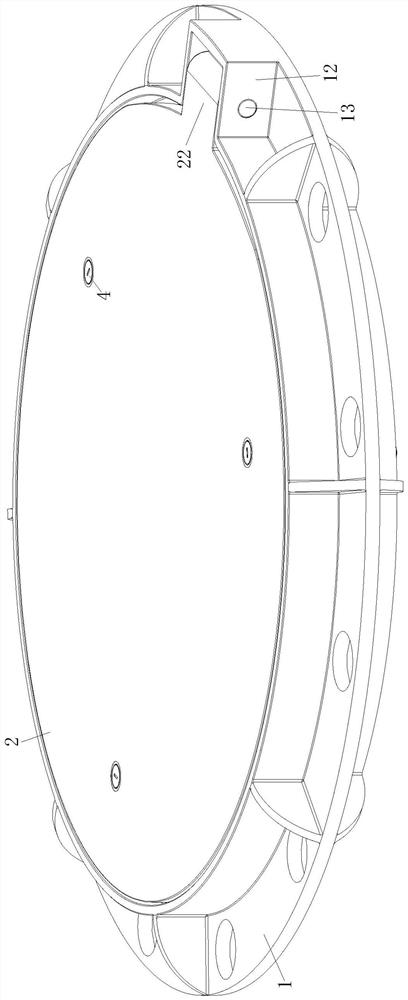

A continuous double-roll die punching device for circuit boards

ActiveCN105916307BRealize direct stampingAchieve continuous workPrinted circuit manufactureDiffuse reflectionEngineering

The invention relates to the technical field of PCB stamping, and provides a continuous pair-roller-type die stamping forming device of an ultra-long circuit board. The continuous pair-roller-type die stamping forming device is characterized in that the device comprises an upper roller body and a lower roller body, convex dies are arranged on the upper roller body, concave dies corresponding to the convex dies are arranged on the lower roller body, a row of feeding rollers are arranged at one side of an engaged plane of the upper roller body and the lower roller body. The feeding rollers are arranged on a feeding working frame and are uniformly connected with a feeding conveying motor through a conveying belt. A sensor is arranged above one end, close to the upper roller body, of the feeding working frame. The sensor is connected with a PLC. The PLC is connected with and controls a pair roller motor. The pair roller motor is connected with the upper roller body. The upper roller body and the lower roller body are engaged with each other through a transmission gear. According to the invention, the pair-roller-type stamping structure is adopted, the ultra-long circuit board is directly punched, the cost and time for pattern transferring are saved; in addition, the infrared diffuse reflection sensor and the PLC are adopted for controlling and completing the die stamping forming of the circuit board, continuous work is realized, and the effect is greatly improved.

Owner:QIMAO ELECTRONICS DINGNAN CO LTD

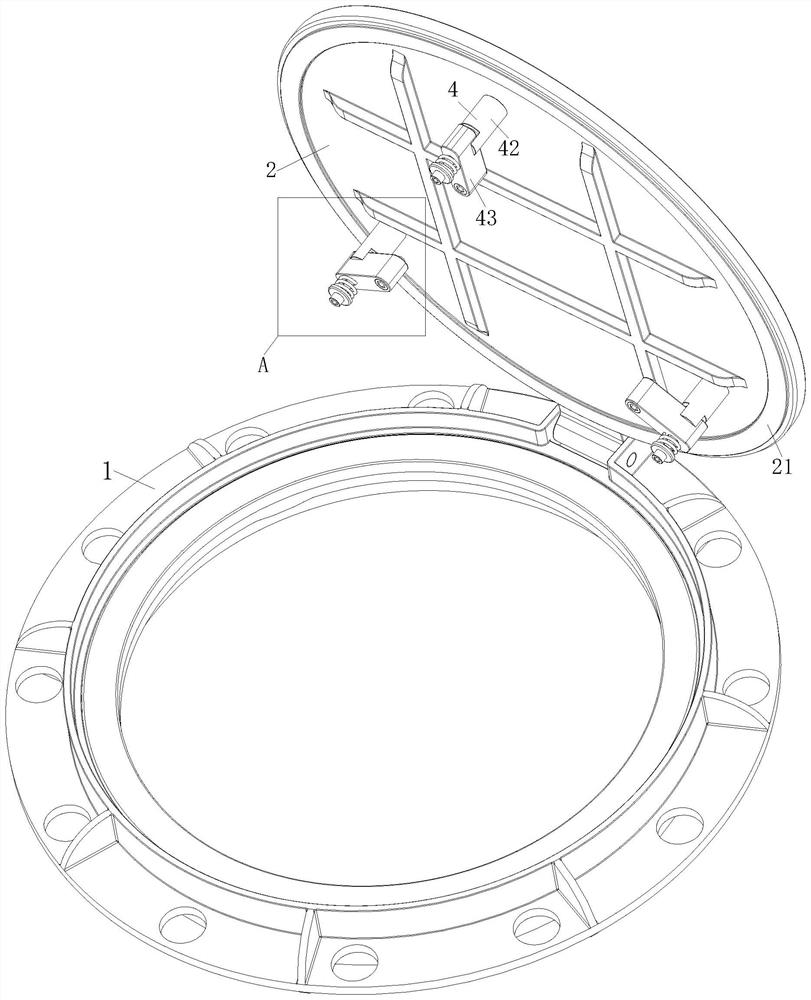

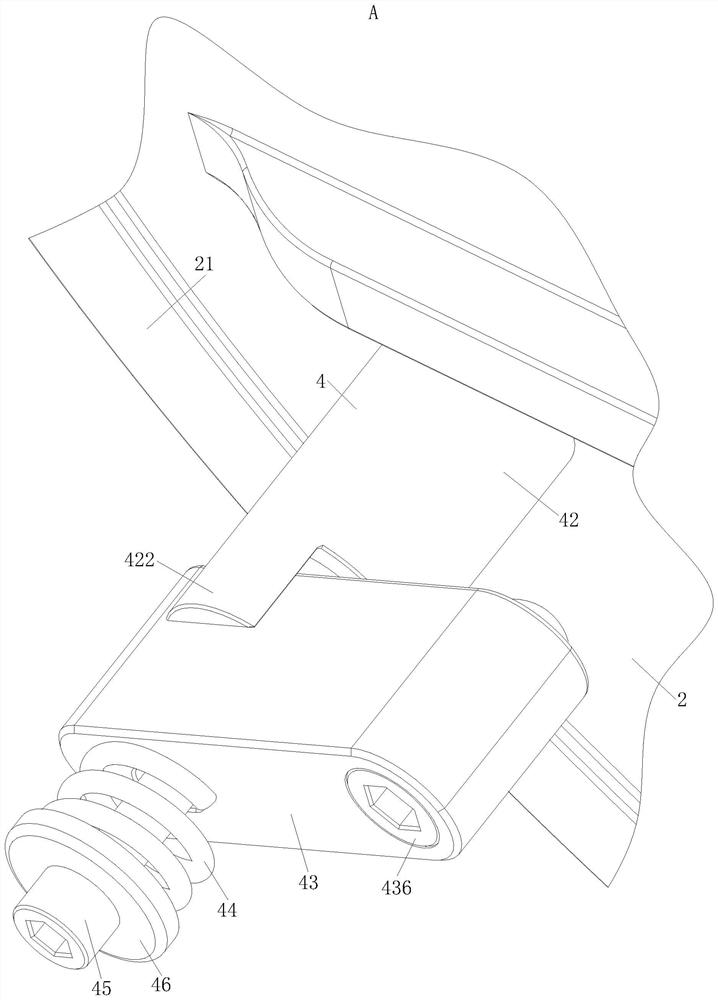

Municipal anti-noise well lid assembly

PendingCN114016548AReduce vibrationAvoid harmArtificial islandsUnderwater structuresStructural engineeringMechanical engineering

The invention belongs to the technical field of well lids, and particularly relates to a municipal anti-noise well lid assembly which comprises a base and a cover plate. The cover plate and the base are connected together through the locking structure, then the hoistway is isolated from the external space, when a vehicle or a pedestrian passes through the upper portion of the cover plate, the cover plate drives the first protruding structure to move downwards, then the first protruding structure extrudes the elastic piece, then the elastic piece generates elastic force, the cover plate is prevented from moving downwards, so the cover plate and the base are prevented from colliding with each other, the damage probability of the cover plate is reduced, the service life of the cover plate is prolonged, noise caused by collision of the cover plate and the base is avoided, noise is reduced, and harm of noise to residents or pedestrians is reduced. Meanwhile, the locking mechanism limits the vertical displacement of the cover plate, so that the vibration amplitude of the cover plate is reduced, the damage of the cover plate to the vehicle and the pedestrian is reduced, and the safety of the vehicle and the pedestrian is protected.

Owner:骆军

Roadheader Machinery Continuous Mining Method

ActiveCN114526071BSolve mining inefficienciesImprove mining efficiencyUnderground miningSurface miningArchitectural engineeringRoadheader

The invention provides a mechanical continuous mining method for a roadheader, which relates to the technical field of mining, including: a mining layer and an extra-vein roadway; the mining layer and the extra-vein roadway are connected; Road and support column; a support column is set between each adjacent two mined access roads, the access road communication channel is set on the support column, and the two ends of the access road communication channel are respectively connected with the adjacent two mined access roads. The road is connected, so that the roadheader can enter the adjacent mining road from one mined road. When the roadheader drives to the specified position in the first mined road, it can directly enter the adjacent road through the road connection channel. The second mined road continues to be excavated, and the support and feng shui pipe erection operations are performed on the first mined road, so that the roadheader does not stop during the support and feng shui pipe erection operations, which solves the problem of low mining efficiency of the current roadheader. The technical effect of continuous work of the roadheader and high mining efficiency is realized.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

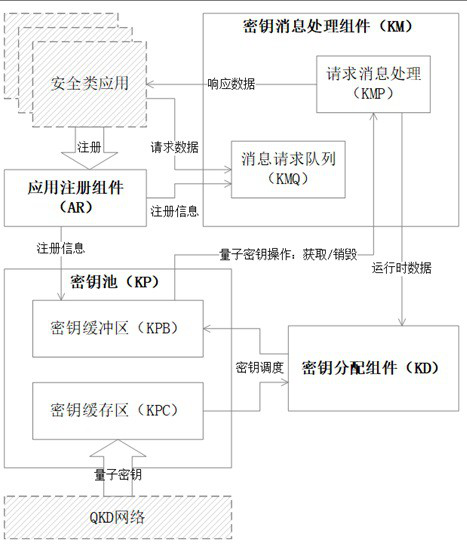

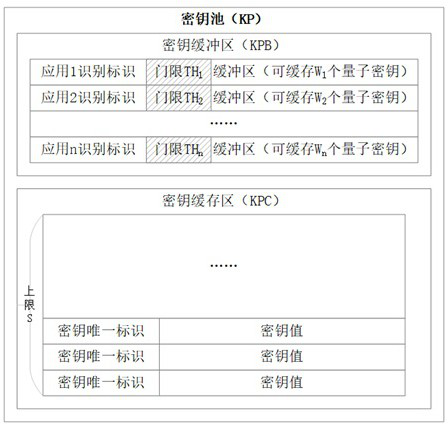

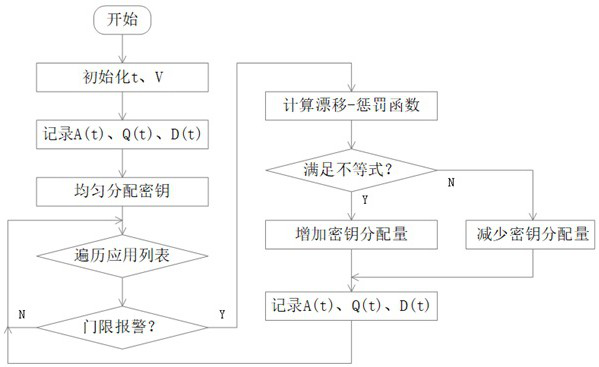

Quantum key scheduling method for cloud computing platform

ActiveCN114499864AAchieve continuous workFix security issuesKey distribution for secure communicationHigh level techniquesLyapunov optimizationMessage processing

A quantum key scheduling method oriented to a cloud computing platform comprises the steps that an operation environment is established, and the operation environment comprises a key pool KP, an application registration component AR, a key message processing component KM and a key distribution component KD. Compared with the prior art, the method solves the problem of matching with an over-low key generation rate of a quantum key distribution system under the condition of relatively high key consumption of a security application of a cloud computing platform. By using the key pool, continuous work of the quantum key distribution process is realized, and the problem that precious quantum key resources are wasted due to the fact that the key pool is not used in time is solved. By using the security application hierarchical design, the problem that the low-level security application and the high-level security application compete for the key when the quantum key supply is insufficient is solved. By using a Lyapunov optimization algorithm in a key distribution process, fair distribution of quantum keys between security applications of the same level is realized, and limited quantum key resources are ensured to be utilized to the maximum extent.

Owner:ZHEJIANG QUANTUM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com