Non-contact intelligent card manufacturing equipment

A non-contact smart card and manufacturing equipment technology, which is applied to record carriers, instruments, and computer parts used in machines. It can solve the problems of chip welding, open circuit, and inaccurate placement of chips, so as to improve work efficiency and improve welding accuracy. , the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

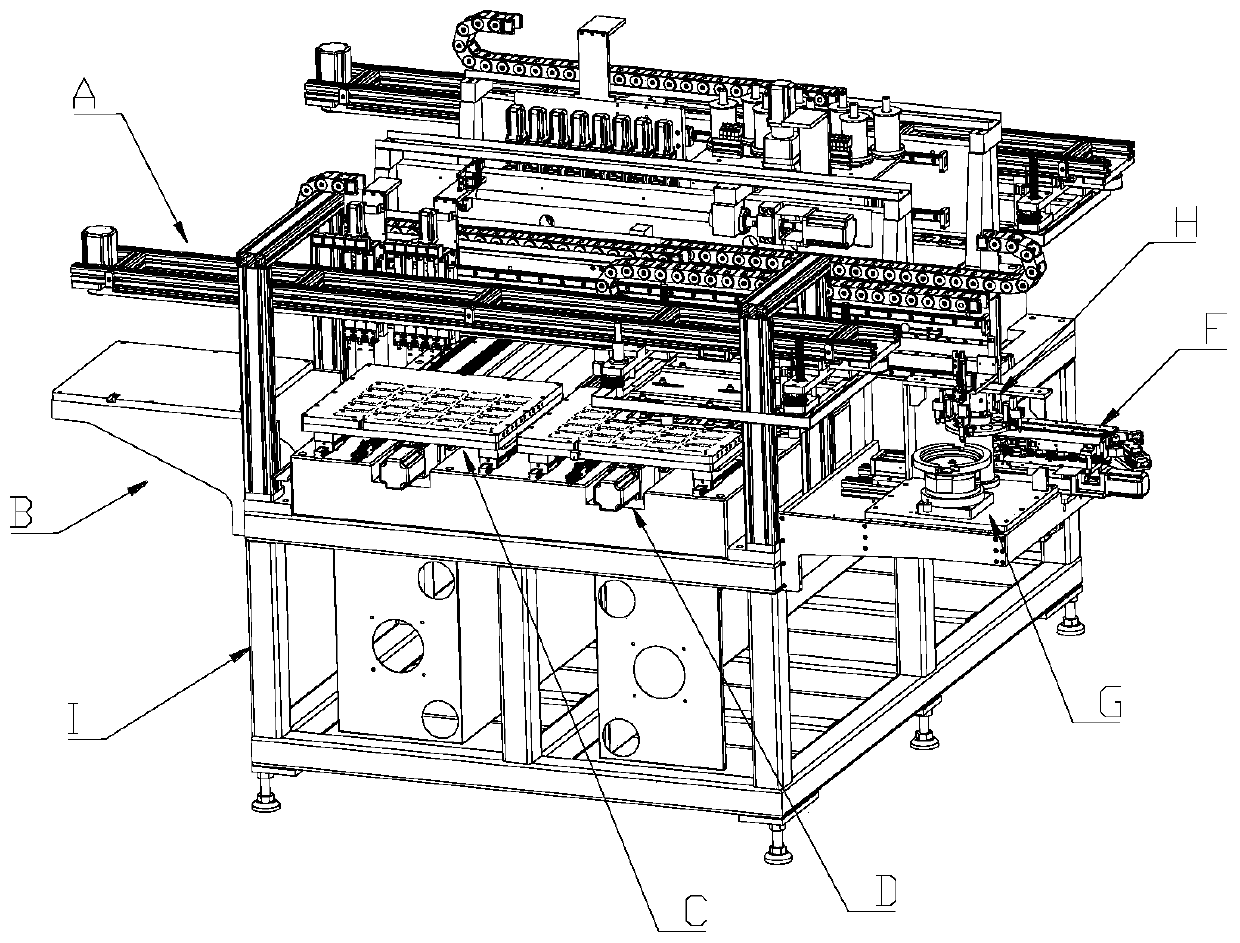

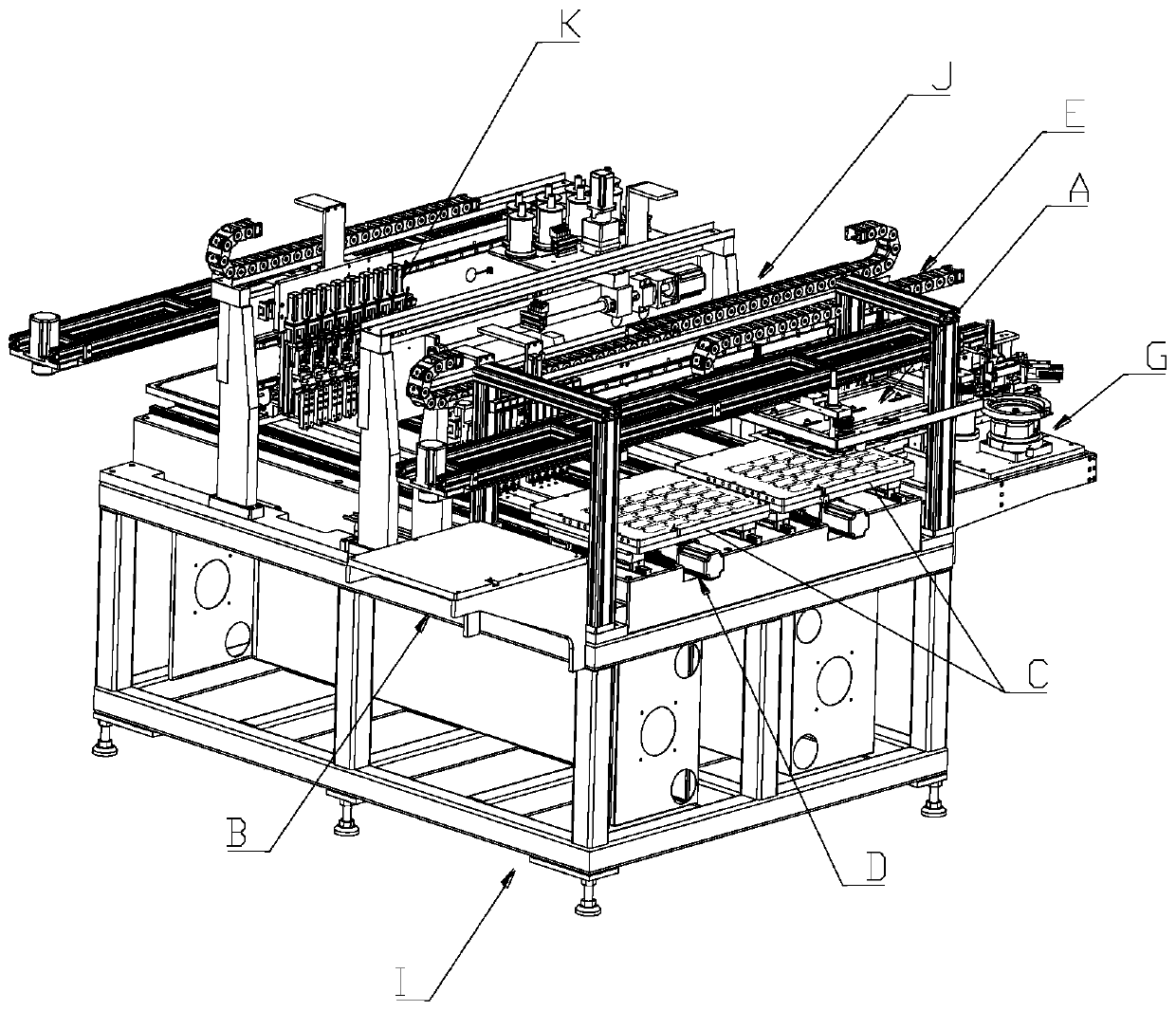

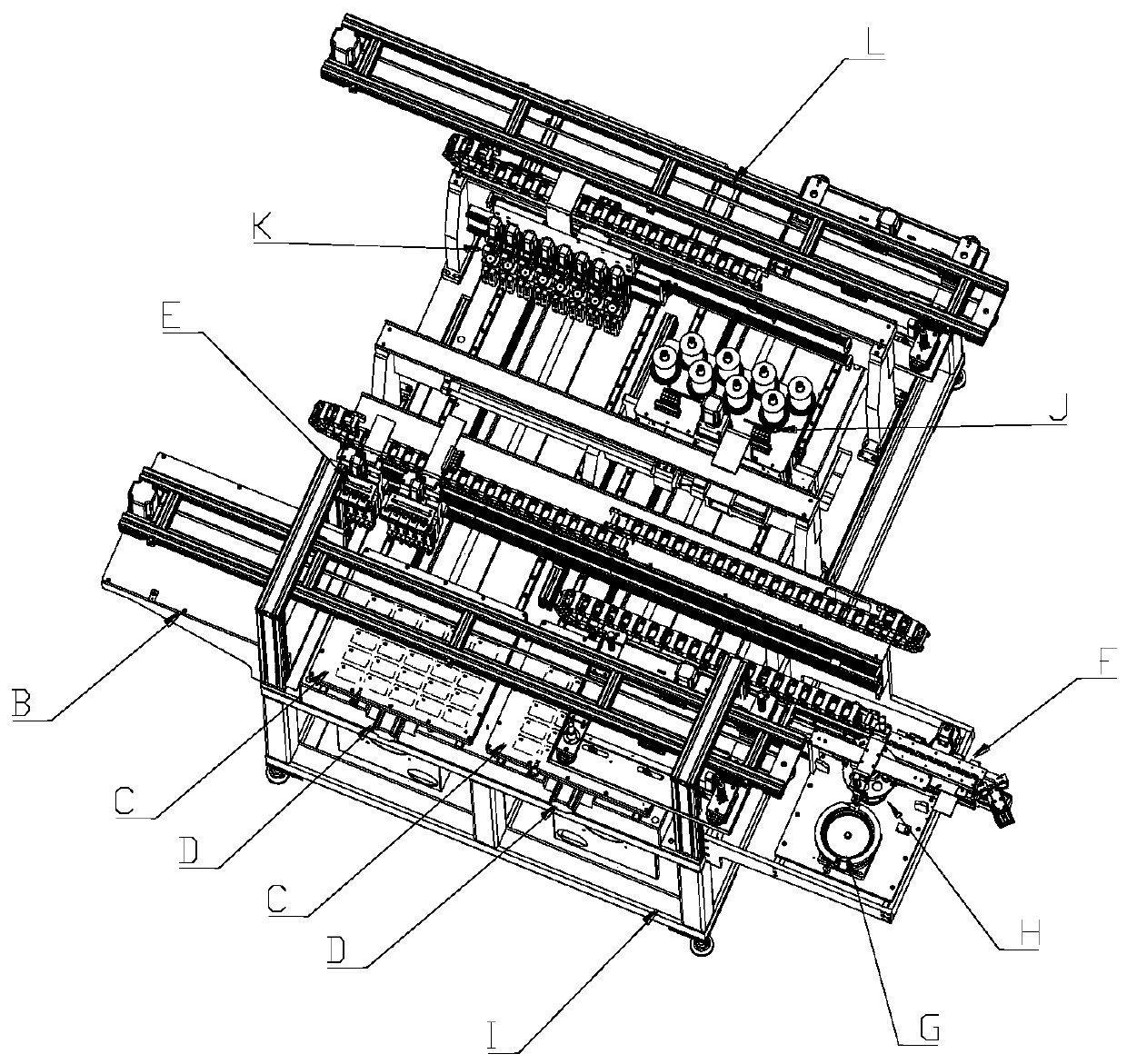

[0051] see Figure 1-Figure 42 , the non-contact smart card manufacturing equipment of the present invention comprises a rack I, a sheet feeding device arranged on the rack I, a chip feeding device, a winding device J, a chip welding device K, and a sheet feeding device in the sheet feeding device. The sheet material 7a and the chips in the chip feeding device are sequentially conveyed to the conveying devices in the winding device J and the chip bonding device K, wherein,

[0052] The conveying device includes two positioning platforms C arranged on the frame I for precise positioning of the sheet material 7a and the chips, and a conveying mechanism D for driving the two positioning platforms C to move independently, wherein the The two positioning platforms C are arranged in parallel, and each positioning platform C is driven by a single conveying mechanism D;

[0053] The chip feeding device includes a chip placing table G and a second conveying device E for transferring t...

Embodiment 2

[0142] see Figure 43 The difference between this embodiment and Embodiment 1 is that the vertical drive assembly of the positioning assembly 5a in the first conveying device A in this embodiment can also be in another form, and the vertical drive assembly includes a slider sliding rail mechanism and the spring 5-4a; wherein the slider rail mechanism includes a positioning guide rail 5-5a and a positioning slider 5-6a matching with the positioning guide rail 5-5a; the guide rail The upper end of the slide rail is connected with the mounting frame 2a, the positioning member 5-1a is fixed on the lower end of the positioning slider 5-6a through the connecting member 5-7a, and the lower part of the positioning guide slide rail 5-5a is also provided with a At the limiting portion 5-21a that defines the position of the positioning slider 5-6a, the spring 5-4a is arranged between the mounting frame 2a and the positioning slider 5-6a, and one end of the spring 5-4a is It acts on the ...

Embodiment 3

[0144] see Figure 44 , the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the first vertical driving mechanism 6a in the first conveying device A in this embodiment may be in another form, and the screw rod 6- 3a The transmission assembly is a group, the first driven driving wheel 6-6a is arranged on the vertical fixing seat 6-2a, and a guide is provided between the mounting frame 2a and the vertical fixing seat 6-2a. A guide post and guide sleeve mechanism for the mounting frame 2a to move up and down, wherein the guide post and guide sleeve mechanisms are in multiple groups, and the multiple groups of guide post and guide sleeve mechanisms are distributed around the mounting frame 2a; The mechanism includes a guide post 6-9a and a guide sleeve 6-10a matched with the guide post 6-9a. One end of the guide sleeve 6-10a is fixed on the vertical fixing seat 6-2a. One end of -9a is fixed on the mounting frame 2a, and the other end extends vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com