Multifunctional hot melt adhesive production equipment

A kind of production equipment and multi-functional technology, applied in the field of machinery, can solve the problems of low production effect, equipment damage, unfavorable product quality requirements, etc., and achieve the effect of improving production efficiency and reasonable structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

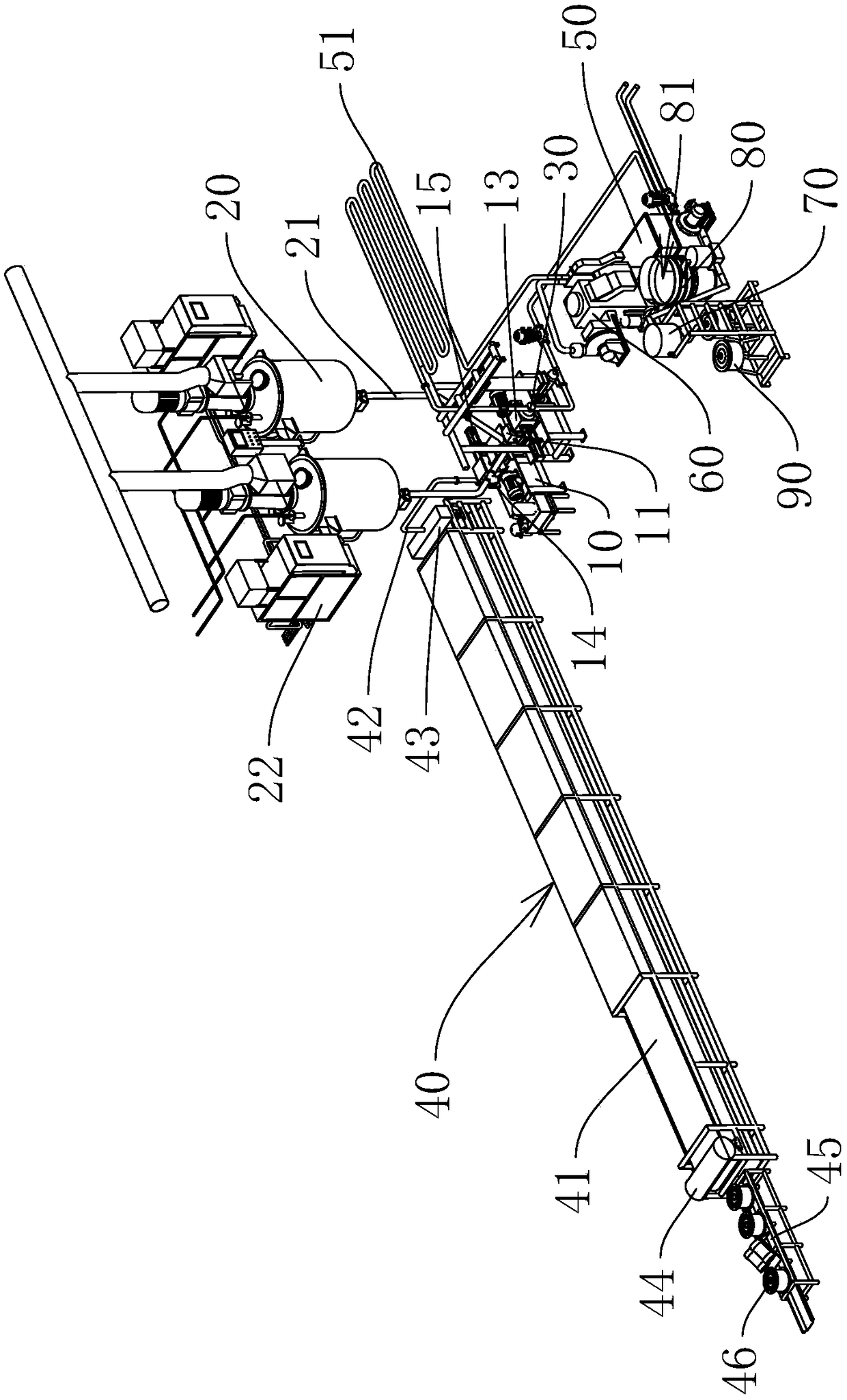

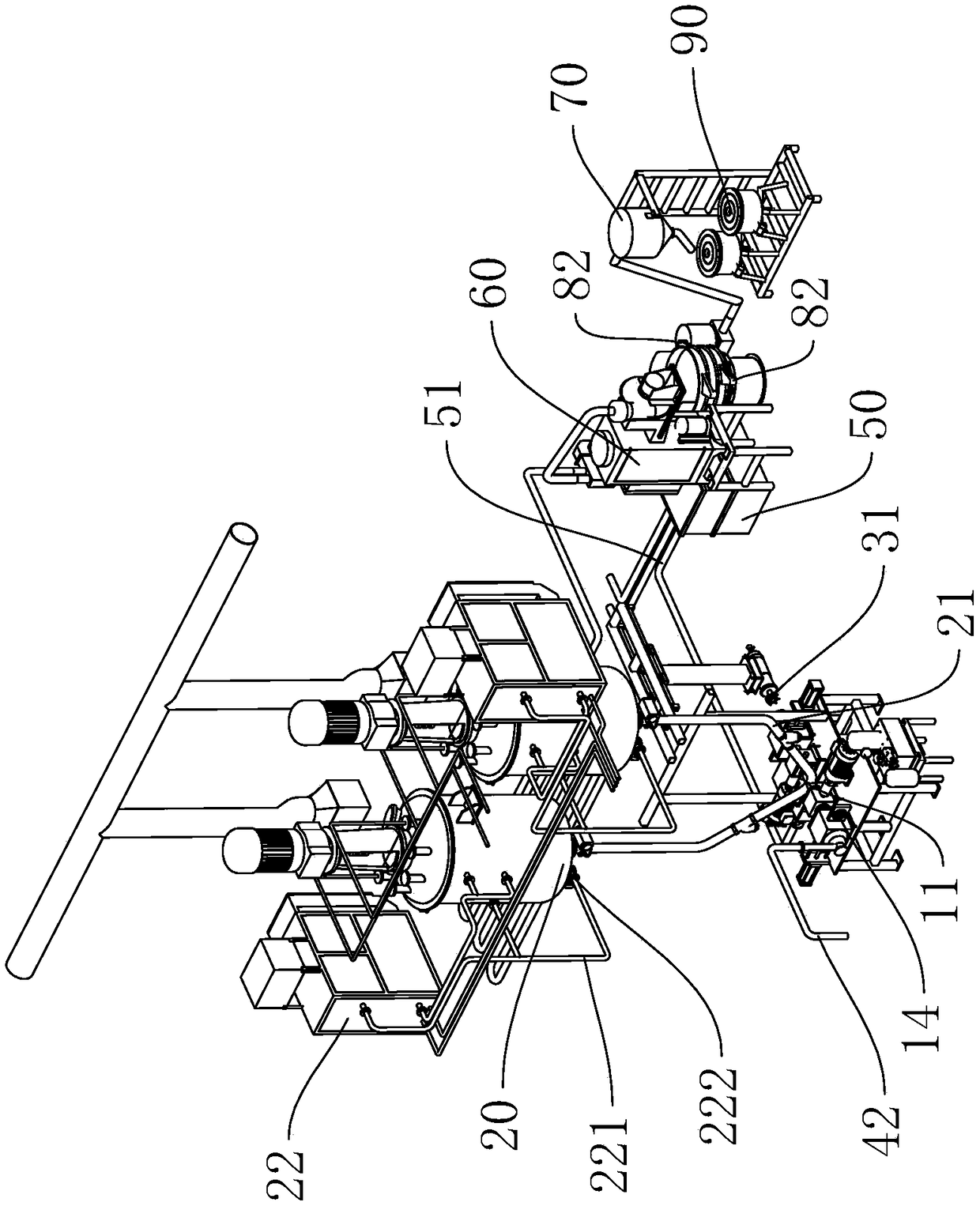

[0030] Such as figure 1 , figure 2 as well as Figure 4 As shown, the hot melt adhesive multifunctional production equipment includes:

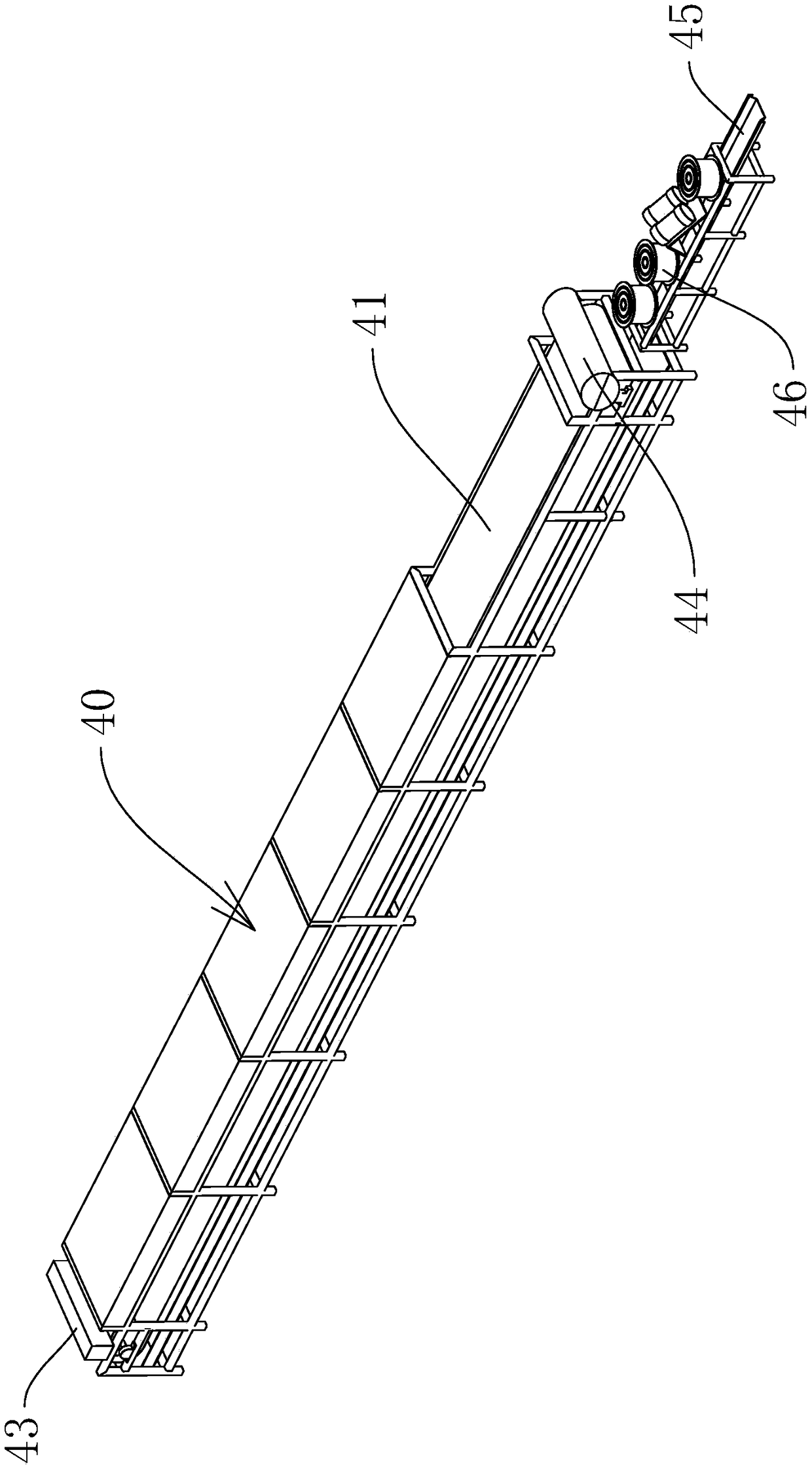

[0031] The frame 10 is symmetrically provided with two material pumps 11, and the two material pumps 11 are connected through a connecting pipe 12. One of the material pumps 11 is connected to the material cutting chamber 30, and the other material pump 11 is connected to the granulation frame 40. And the material pump 11 is respectively connected to the corresponding cutting chamber 30 or granulation frame 40 through the plate filter 13, the material cutting chamber 30 is used for forming round rubber particles, and the granulation frame 40 is used for forming sheet-shaped rubber particles;

[0032] Stirrer 20 is arranged as two and two stirrers 20 are positioned at the top of frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com