Winding device for non-woven fabric production

A winding device and non-woven fabric technology, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of high labor intensity for workers, low efficiency of replacing winding rollers, low winding efficiency, etc. , to achieve the effect of shortening the processing time, ensuring the quality of the field products, and improving the winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

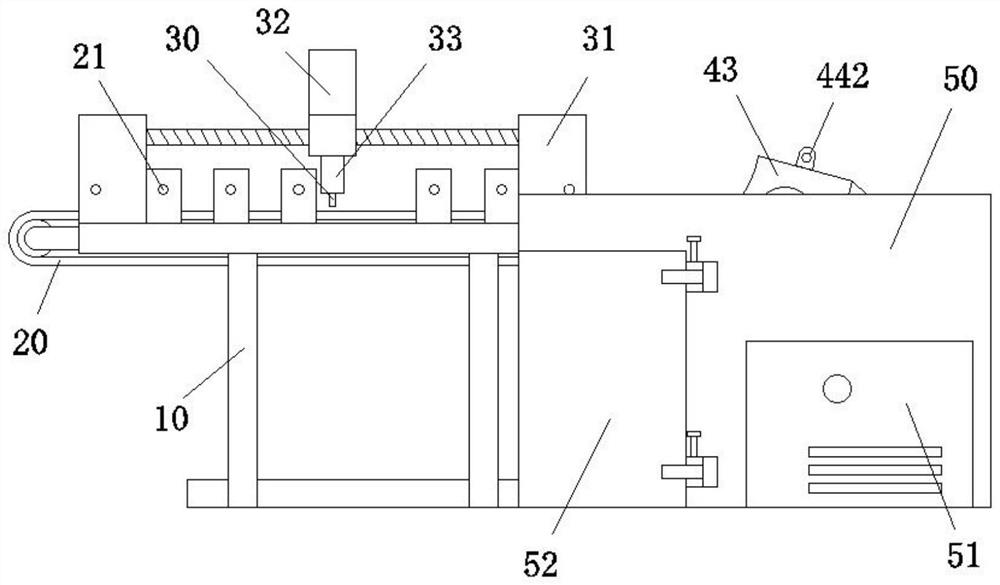

[0037] refer to Figure 1-6, a winding device for non-woven fabric production, comprising a truss 10, a conveyor belt 20 mounted on the truss 10, a cutter 30 positioned at the top of the conveyor belt 20, a lifting platform 70 located obliquely below the conveyor belt 20, the two sides of the lifting platform 70 are connected The components are identical and arranged symmetrically; the side of the truss 10 away from the lift platform 70 is fixed with a side plate 40, and the side wall of the side plate 40 close to the truss 10 is provided with a storage slot 41 with an arc-shaped vertical section, and an opening at one end of the storage slot 41 Located at the top of the side plate 40, the other end opening of the storage tank 41 is located on the side wall of the side plate 40, and the other end opening of the storage tank 41 is located on the side wall of the side plate 40, and the storage tank 41 is slidingly connected to three structures with the same structure. And the sl...

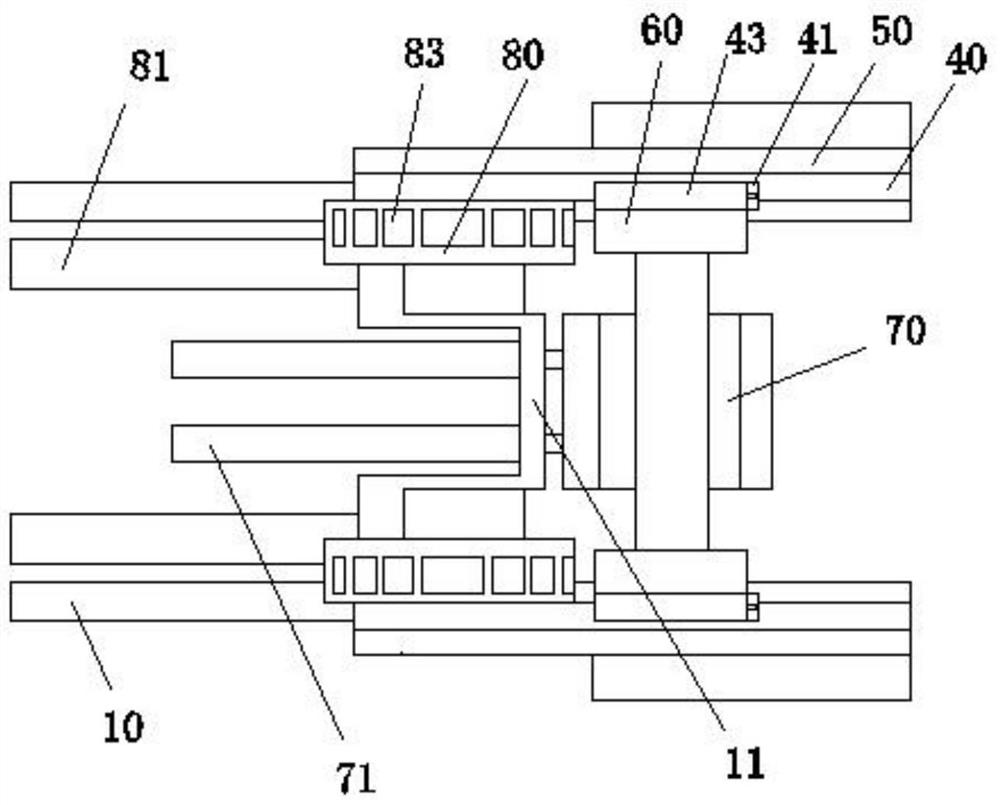

Embodiment 2

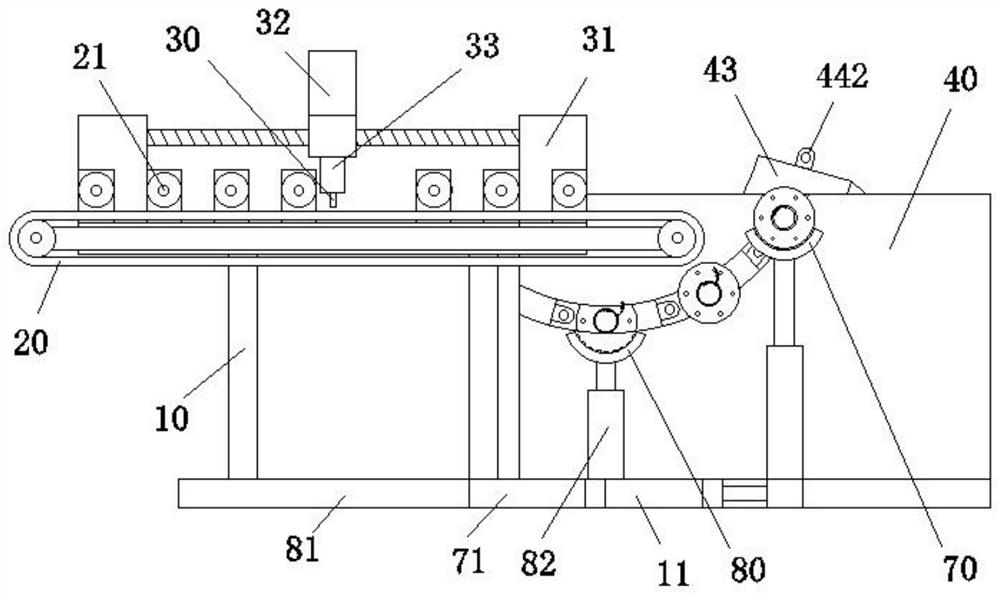

[0044] refer to Figure 1-6 , a winding device for non-woven fabric production, the same as Embodiment 1, the difference between this embodiment and Embodiment 1 is that the bottom of the side wall of the truss 10 is fixed with a horizontally arranged mounting plate 11, and the top of the mounting plate 11 is horizontal. The cross-section is a few-shaped structure, and the middle part of one side of the mounting plate 11 is fixed with two hydraulic cylinders 71 arranged horizontally. Both are provided with a hydraulic cylinder 2 81 fixed on the end of the mounting plate 11, the output end of the hydraulic cylinder 2 81 is fixed with a base plate, and the top of the base plate is fixed with a loading platform 80 through a vertical hydraulic cylinder 3 82, and the loading platform 80 Located below the end of the conveyor belt 20.

[0045] Working principle: the hydraulic cylinder 1 71 works to move the lifting platform 70 in the horizontal direction, and the lifting platform 70...

Embodiment 3

[0048] refer to Figure 1-6 , a winding device for the production of non-woven fabrics, the same as the second embodiment, the difference between this embodiment and the second embodiment is that a connecting groove 441 is provided on the vertical side wall of the slide plate 43, and the other vertical wall of the slide plate 43 A connecting plate 442 is arranged on one side wall, and two adjacent slide plates 43 are fixed by connecting grooves 441 and connecting plates 442. The side wall of the slide plate 43 is provided with a convex tooth 45, the convex tooth 45 meshes with the gear 42, and the drive wheel 433 and the turntable 432 are one of meshing connection and belt connection. 43 interiors are embedded with a storage battery that drives the drive wheel 433 to rotate, and the side wall of the drive wheel 433 is provided with a pin hole 46, and the drive wheel 433 is pinned to the receiving roller 60 by a fixed pin, which is convenient for the disassembly and assembly of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com