Straight thread sleeve connection device and method

A technology of straight threaded sleeves and connecting devices, which is applied to structural elements, building components, building reinforcements, etc., can solve the problems of high per capita labor costs, large input costs, and high costs, and achieve the effect of improving connection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

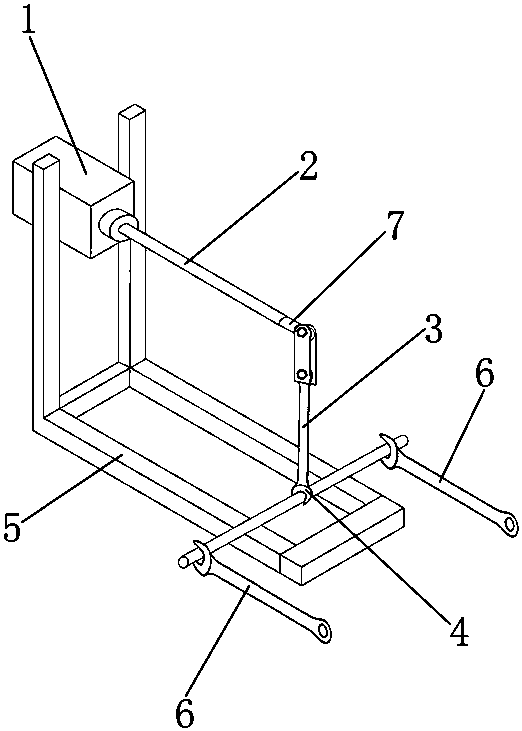

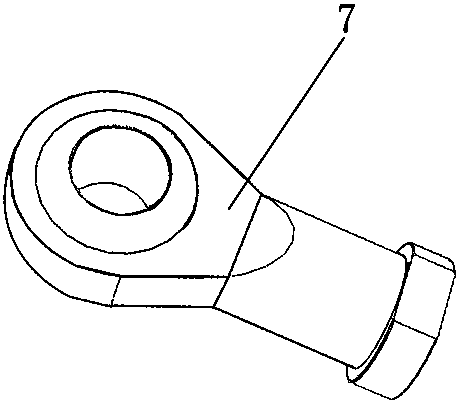

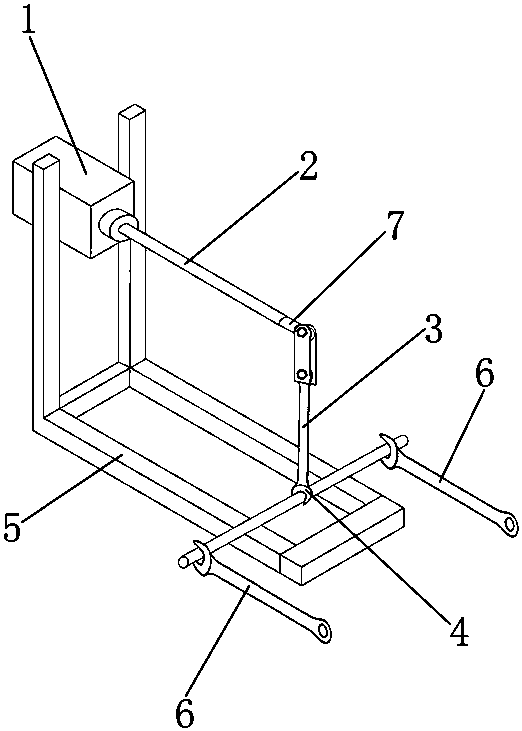

[0022] The straight thread sleeve connection device of the present invention, such as figure 1 As shown, it includes a reciprocating device and a steel bar socket wrench 3; a piston rod 2 that can move horizontally back and forth is arranged in the reciprocating device; the lower end of the steel bar socket wrench 3 is provided with a socket clamp 4; the piston The front end of bar 2 is flexibly connected with the upper end of steel bar wrench. Also includes a base 5; the longitudinal section of the base 5 is L-shaped; the base 5 includes a vertical section and a horizontal section perpendicular to each other; the aforementioned reciprocating device is fixedly connected to the upper end of the vertical section; the reciprocating device is fixedly arranged on On the base 5, the vertical distance between the piston rod 2 and the horizontal section of the base 5 is equal to the height of the steel bar socket wrench 3; Ensure that the torque of the piston rod 2 transmitted to the...

Embodiment 2

[0026] On the basis of Embodiment 1, the straight thread sleeve connection method of the straight thread sleeve connection device of the present invention includes the following steps: Socketing the end of the steel bar to be connected with the straight thread sleeve;

[0027] The steel bar is fixed by the fixing fixture 6;

[0028] Connect the socket clip 4 of the steel bar socket wrench 3 onto the aforementioned straight threaded socket;

[0029] Start the reciprocating device, the piston rod 2 reciprocates back and forth along the horizontal direction, drives the upper end of the steel socket wrench 3 to move back and forth through the movable connection, and the socket clamp 4 located at the lower end of the steel socket wrench 3 reciprocates to realize the alignment of the straight thread sleeve connect. In the specific implementation process, the speed of the cylinder 1 can be adjusted by the control valve to achieve the purpose of controlling the reciprocating speed of...

Embodiment 3

[0032] On the basis of Embodiment 1 and Embodiment 2, this embodiment takes a certain avenue station project as an example. The diameter of the stressed steel bars of the main structural plate of a certain avenue station is greater than or equal to 20mm, and the station is nearly 600 meters long, and the mechanical connection joints of the steel bars exceed 50,000 pieces, the project volume is large, and the efficiency of manual connection is relatively low. Using straight thread sleeve connection device instead of part of manual connection will greatly shorten the installation time of steel bars, which can effectively shorten the construction period and effectively save costs.

[0033] According to the actual observation and analysis on site, the average number of fastening sleeves per two people per working day is about 60-70, and the whole station requires about 1,550 workers. Calculated at 260 yuan per person per day, the total is 403,000 yuan.

[0034] Using the straight t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com